High-performance acrylic resin type photosensitive circuit board ink and preparation method thereof

A technology of acrylic resin and circuit board, which is applied in the field of ink and can solve problems such as thermal stability and poor electrical signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

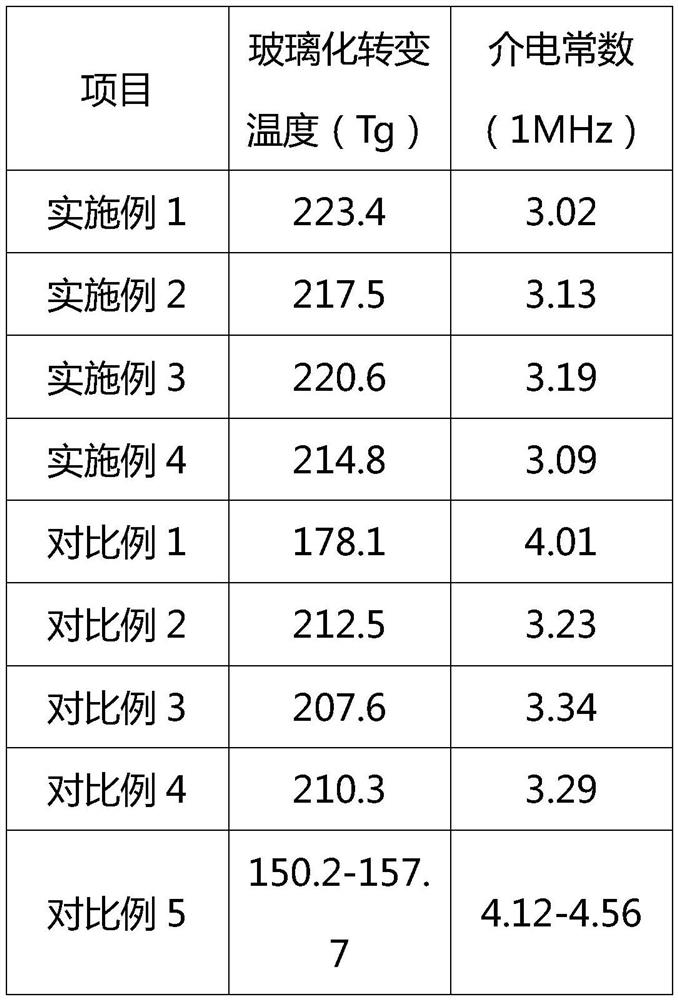

Examples

preparation example Construction

[0026] The preparation method of described high-performance acrylic resin type photosensitive circuit board ink comprises the following steps:

[0027] S1: Mix epoxy acrylate resin, cyanate prepolymer, and N-phenylmaleimide, add epoxy resin curing agent, heat up to 70-78°C, stir for 25-35min, then add maleic anhydride , styrene, acrylic acid, slowly heated up to 90°C, reacted for 1-2h, and then distilled under reduced pressure to remove the organic solvent, to obtain a weak base water-soluble photosensitive epoxy acrylate prepolymer;

[0028] S2: Mix the weak base water-soluble photosensitive epoxy acrylate prepolymer, photosensitive monomer and water-based photoinitiator, pigment, filler, wetting agent, dispersant, defoamer, drier, thixotropic agent, water according to Proportionally mixed, fully stirred and emulsified by a high-speed disperser for 2-3 hours, and then ground by a three-roll mill to a fineness of ≤5 μm to obtain the ink.

[0029] Preferably, in the step S1, t...

Embodiment 1

[0032]A high-performance acrylic resin type photosensitive circuit board ink, in parts by weight, includes the following components: 140 parts of the epoxy acrylate resin, 35 parts of cyanate ester prepolymer, N-phenylmaleimide 25 parts of amine, 1.8 parts of maleic anhydride, 3 parts of styrene, 10 parts of acrylic acid, 3 parts of epoxy resin curing agent, 6 parts of photosensitive monomer, 0.6 part of wetting agent, 0.4 part of dispersant, 1.5 parts of defoamer, 3 parts of drier, 0.4 parts of thixotropic agent, 11 parts of water-based photoinitiator, 0.5 parts of pigment, 30 parts of filler, 4 parts of water.

[0033] The preparation method of above-mentioned high-performance acrylic resin type photosensitive circuit board ink, comprises the following steps:

[0034] S1: Mix epoxy acrylate resin, cyanate prepolymer and N-phenylmaleimide, add epoxy resin curing agent, heat up to 75°C, stir for 30min, then add maleic anhydride, styrene, Acrylic acid, slowly heated up to 90°C...

Embodiment 2

[0037] A high-performance acrylic resin photosensitive circuit board ink, in parts by weight, comprising the following components: 130 parts of epoxy acrylate resin, 31 parts of cyanate ester prepolymer, 22 parts of N-phenylmaleimide 2.4 parts of maleic anhydride, 4 parts of styrene, 8 parts of acrylic acid, 1 part of epoxy resin curing agent, 5 parts of photosensitive monomer, 0.6 parts of wetting agent, 0.3 parts of dispersant, 1.2 parts of defoamer, drying 2.5 parts of agent, 0.5 parts of thixotropic agent, 12 parts of water-based photoinitiator, 0.5 parts of pigment, 38 parts of filler, and 2 parts of water.

[0038] The preparation method of above-mentioned high-performance acrylic resin type photosensitive circuit board ink, comprises the following steps:

[0039] S1: Mix epoxy acrylate resin, cyanate prepolymer, and N-phenylmaleimide, add epoxy resin curing agent, heat up to 78°C, stir for 25 minutes, then add maleic anhydride, styrene, For acrylic acid, slowly raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com