High-heat-resistance bio-based degradable polylactic acid modified material and preparation method thereof

A modified material, polylactic acid technology, applied in the field of high heat-resistant bio-based degradable polylactic acid modified material and its preparation, can solve the problems of tableware with poor heat resistance, unstable strength, and easy breakage , to achieve the effect of increasing heat distortion temperature, improving heat resistance and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

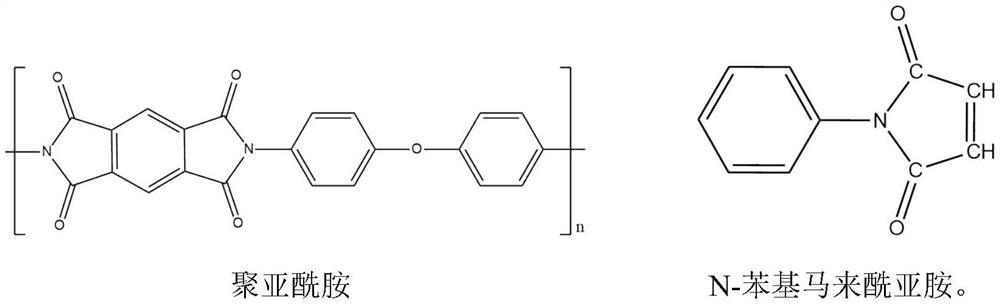

[0028] (1) PLA-LX175 and N-phenylmaleimide were dried at 60° C. for 6 hours and set aside for use;

[0029] (2) after drying, take PLA-LX175 (95 parts by weight) and N-phenylmaleimide (5 parts by weight), then take by weighing nucleating agent: aromatic sulfonate ( LAK-300) (0.2 parts by weight), chain extender: ADR-4300 (1.5 parts by weight), stabilizer: di-tert-butyl peroxide (0.5 parts by weight), lubricant: Ethylene-vinyl acetate copolymer (2 parts by weight), antioxidant: antioxidant 1010 (0.2 part by weight) was added to the high-speed mixer successively and stirred for 5 to 8 minutes, and discharged for use;

[0030] (3) adding the mixed material of step (2) into the twin-screw extruder to carry out melt blending extrusion, cooling, and pelletizing to obtain this product; wherein, the rotating speed of the described high-speed mixer is 1200 rev / min; The temperature range of the twin-screw extruder is 150°C-190°C.

[0031] The heat distortion temperature of the obtaine...

Embodiment 2

[0033] (1) PLA-LX175 and N-phenylmaleimide were dried at 60° C. for 6 hours and set aside for use;

[0034] (2) after drying, take PLA-LX175 (95 parts by weight) and N-phenylmaleimide (8 parts by weight), then take by weighing nucleating agent: aromatic sulfonate ( LAK-300) (0.4 parts by weight), chain extender: ADR-4300 (1.8 parts by weight) stabilizer: di-tert-butyl peroxide (0.8 parts by weight), lubricant: ethylene -vinyl acetate copolymer (3 parts by weight), antioxidant: antioxidant 1010 (0.5 part by weight) was added to the high-speed mixer successively and stirred for 5 to 8 minutes, and the material was discharged for use;

[0035] (3) adding the mixed material of step (2) into the twin-screw extruder to carry out melt blending extrusion, cooling, and pelletizing to obtain this product; wherein, the rotating speed of the described high-speed mixer is 1200 rev / min; The temperature range of the twin-screw extruder is 150°C-190°C.

[0036] The heat distortion temperatu...

Embodiment 3

[0038] (1) Dry PLA-LX175 and polyimide at 60°C for 6 hours and set aside for use;

[0039] (2) After drying, take PLA-LX175 (95 parts by weight) and polyimide (10 parts by weight), then take by weighing the nucleating agent: talcum powder (0.4 parts by weight), expanding Chain agent: ADR-4385 (2 parts by weight), stabilizer: di-tert-butyl peroxide (0.8 parts by weight), lubricant: ethylene-vinyl acetate copolymer (3 parts by weight) ), antioxidant: antioxidant 1010 (1 part by weight) was added to the high-speed mixer successively and stirred for 5 to 8 minutes, and the material was discharged for use;

[0040] (3) adding the mixed material of step (2) into the twin-screw extruder to carry out melt blending extrusion, cooling, and pelletizing to obtain this product; wherein, the rotating speed of the described high-speed mixer is 1200 rev / min; The temperature range of the twin-screw extruder is 150°C-190°C.

[0041] The heat distortion temperature of the obtained high heat-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com