High-heat-resistance permanent antistatic material and preparation method thereof

An antistatic, high heat-resistant technology, applied in the field of high heat-resistant permanent antistatic materials and their preparation, high heat-resistant permanent antistatic materials, can solve the problems of not having antistatic and conductive effects, electrostatic safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

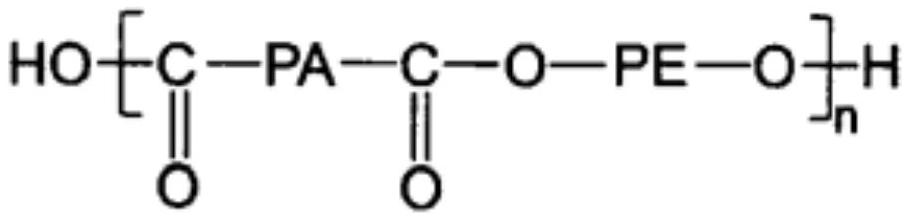

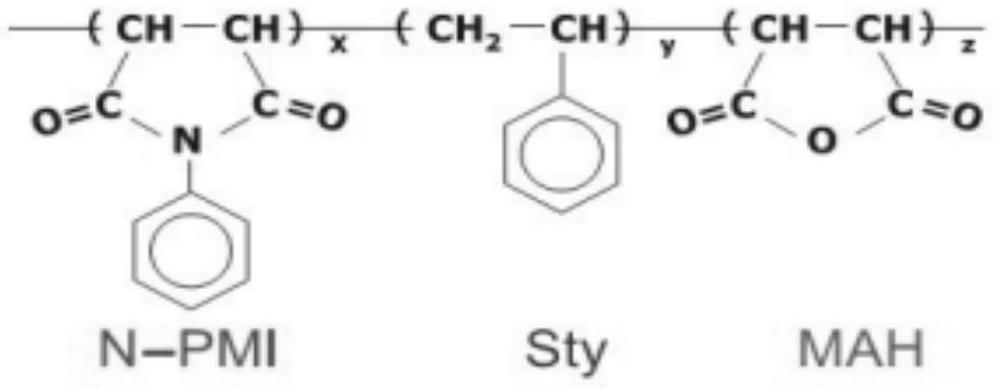

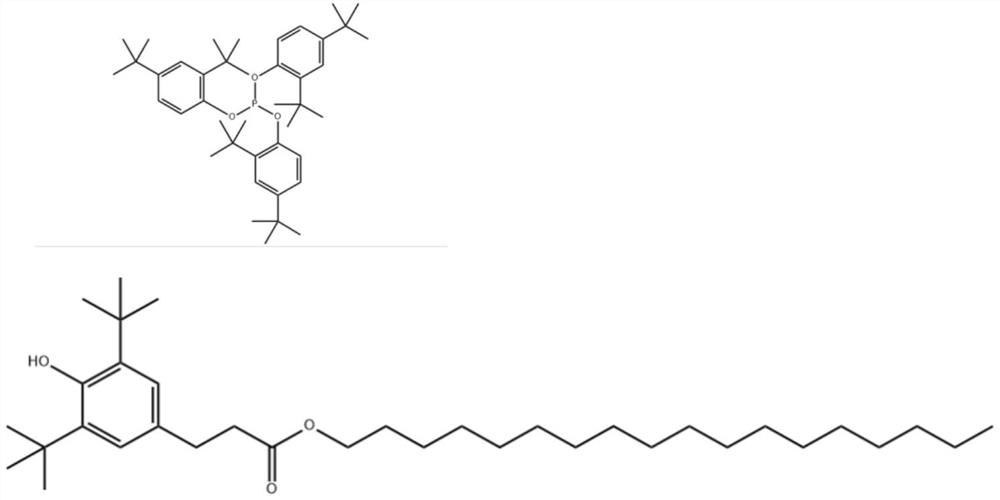

[0050]The high heat-resistant permanent antistatic material proposed by the present invention comprises the following components according to parts by weight: 89 parts of ABS, 5 parts of heat-resistant agent, 5 parts of antistatic agent, 0.5 part of antioxidant and 0.5 part of lubricant; The electrostatic agent is nylon elastomer of polyamide and polyether; the heat-resistant agent is a resin heat-resistant modifier containing N-phenylmaleimide structure.

[0051] The preparation method of the high heat-resistant permanent antistatic material proposed by the present invention, the specific operation steps are as follows: take by weight 89 parts of ABS, 5 parts of heat-resistant agent, 5 parts of antistatic agent, 0.5 part of antioxidant and 0.5 part of lubricant .

[0052] S1. Dry ABS, antioxidant, lubricant and heat-resistant agent;

[0053] S2. Pre-blending ABS with antioxidant, lubricant and heat-resistant agent to obtain a blend;

[0054] S3. The blend obtained in step S...

Embodiment 2

[0058] The high heat-resistant permanent antistatic material proposed by the present invention comprises the following components according to parts by weight: 84 parts of ABS, 5 parts of heat-resistant agent, 10 parts of antistatic agent, 0.3 part of antioxidant and 0.7 part of lubricant; The electrostatic agent is nylon elastomer of polyamide and polyether; the heat-resistant agent is a resin heat-resistant modifier containing N-phenylmaleimide structure.

[0059] The preparation method of the high heat-resistant permanent antistatic material proposed by the present invention, the specific operation steps are as follows: take by weight 89 parts of ABS, 5 parts of heat-resistant agent, 10 parts of antistatic agent, 0.3 part of antioxidant and 0.7 part of lubricant share.

[0060] S1. Dry ABS, antioxidant, lubricant and heat-resistant agent;

[0061] S2. Pre-blending ABS with antioxidant, lubricant and heat-resistant agent to obtain a blend;

[0062] S3. The blend obtained i...

Embodiment 3

[0066] The high heat-resistant permanent antistatic material proposed by the present invention comprises the following components according to parts by weight: 79 parts of ABS, 5 parts of heat-resistant agent, 15 parts of antistatic agent, 0.4 part of antioxidant and 0.6 part of lubricant; The electrostatic agent is nylon elastomer of polyamide and polyether; the heat-resistant agent is a resin heat-resistant modifier containing N-phenylmaleimide structure.

[0067] The preparation method of the high heat-resistant permanent antistatic material proposed by the present invention, the specific operation steps are as follows: take by weight 79 parts of ABS, 5 parts of heat-resistant agent, 15 parts of antistatic agent, 0.4 part of antioxidant and 0.6 part of lubricant share.

[0068] S1. Dry ABS, antioxidant, lubricant and heat-resistant agent;

[0069] S2. Pre-blending ABS with antioxidant, lubricant and heat-resistant agent to obtain a blend;

[0070] S3. The blend obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com