Polymer/graphene aerogel composite foam material and preparation method thereof

A graphene airgel and composite foam technology, applied in the direction of graphene, nano-carbon, etc., can solve problems such as difficult to effectively control graphene graphene network, achieve high mechanical strength, avoid agglomeration, and avoid uneven dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

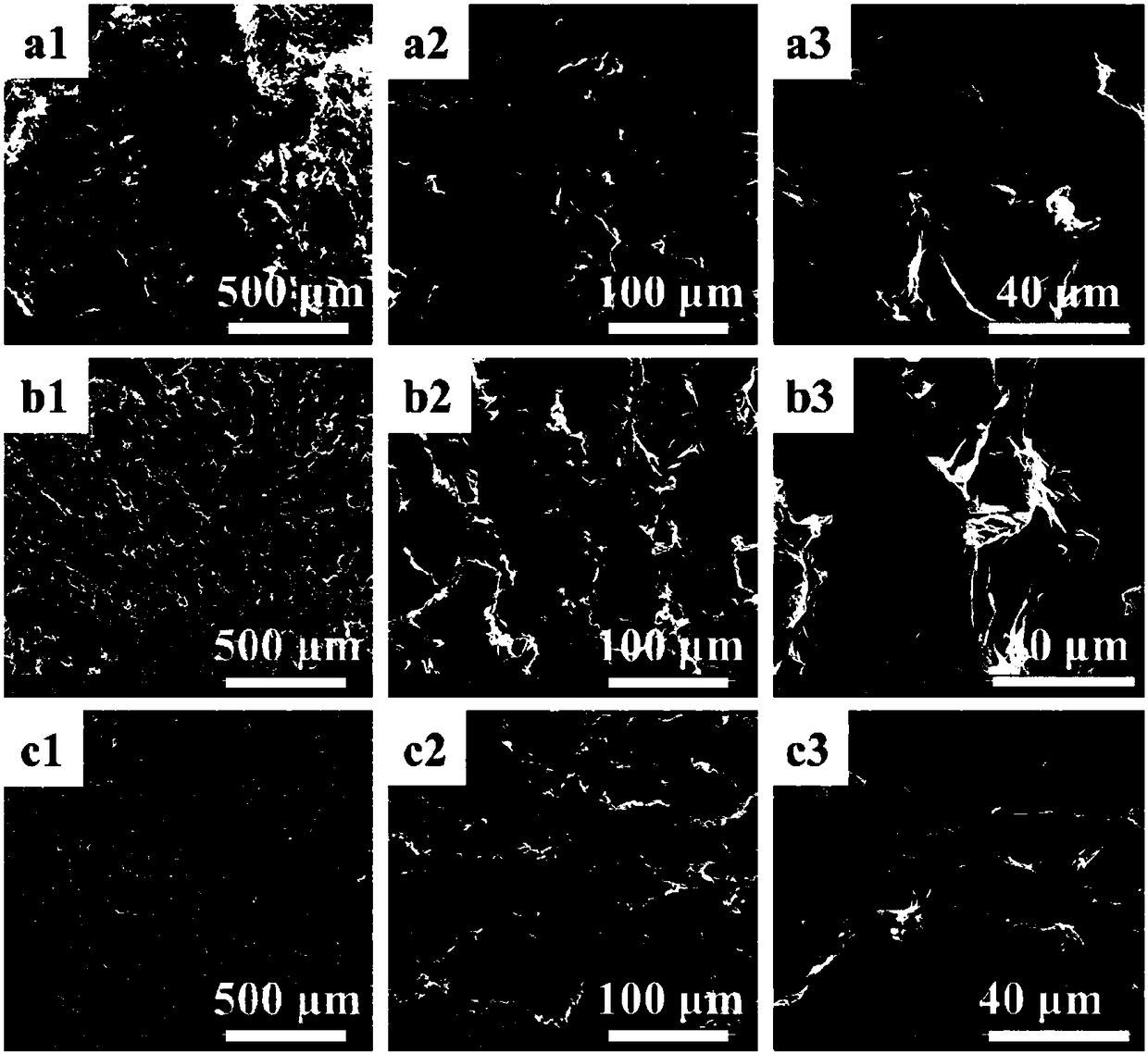

Image

Examples

Embodiment 1

[0039] (1) Preparation of graphite oxide

[0040] Using expandable graphite with a sheet size of about 200 μm as raw material, react at 900°C for 5 minutes to obtain expanded graphite, and prepare graphite oxide by modifying the Hummers method: mix expanded graphite, sodium nitrate, and concentrated sulfuric acid at a ratio of 1g:0.5g:100mL in Stir in an ice bath for 10 minutes, slowly add potassium permanganate according to the ratio of 8g potassium permanganate per 1g of expanded graphite, after adding potassium permanganate, react at 35°C for 2.5h, and then add 8g of potassium permanganate per 1g of expanded graphite The proportion of 200mL water was diluted with deionized water, and 120mL of 5wt% H 2 o 2 The solution terminates the reaction, and then centrifuges after repeated washing with hydrochloric acid and deionized water. When the supernatant obtained by centrifugation is neutral, freeze-dry for 48 hours to obtain graphite oxide. Measure the carbon-oxygen molar rati...

Embodiment 2

[0049] In this implementation, the preparation of thermoplastic polyurethane / graphene airgel composite foam material, the steps are as follows:

[0050] (1) Preparation of graphite oxide

[0051] Using expandable graphite with a sheet size of about 300 μm as raw material, graphite oxide was prepared according to the method in step (1) of Example 1.

[0052] (2) Preparation of graphene airgel

[0053] Disperse graphite oxide in water, and mechanically stir at 200 r / m for 1 h to obtain a 5 mg / mL graphene oxide solution. The sheet size of graphene oxide is 20-30 μm. Add 100mg of ascorbic acid to 10mL, 5mg / mL graphene oxide solution, stir mechanically at a speed of 200r / m for 15min and mix well, and then place it in an oil bath at 90°C under airtight conditions for heating and reduction for 3h to obtain partially reduced oxidized Graphene hydrogel, soak the obtained hydrogel in deionized water for 7 days, replace it with new deionized water every 24 hours, then freeze it at -10°...

Embodiment 3

[0059] In this implementation, the polystyrene / graphene airgel composite foam material is prepared, and the steps are as follows:

[0060] (1) Preparation of graphite oxide

[0061] Graphite oxide was prepared according to the method in Example 1 step (1).

[0062] (2) Preparation of graphene airgel

[0063]Disperse graphite oxide in water, and ultrasonically stir at a speed of 200 r / m for 0.5 h to obtain a 3 mg / mL graphene oxide solution. The sheet size of graphene oxide is 10-25 μm. Add 120mg of ethylenediamine to 10mL, 3mg / mL graphene oxide solution, stir mechanically at a speed of 200r / m for 15min to mix evenly, then place it in an oven under airtight conditions and heat reduction at 80°C for 1h to obtain partially reduced Graphene oxide hydrogel, soaking the obtained hydrogel with ethanol-water solution with ethanol volume percentage of 20% for 2 days, during which a new ethanol water solution was replaced every 12 hours, and then placed under the condition of -20°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com