Polyurethane foam stabilizer with low density and low thermal conductivity factor and preparation method thereof

A low thermal conductivity, polyurethane foam technology, applied in the field of polyurethane foam stabilizer and its preparation, can solve the problem that the surface activity, emulsifying performance and comprehensive balance performance of the foam stabilizer need to be improved, and the reduction of the density of the foam core and the reduction of the thermal conductivity are not considered. and other problems, to achieve the effect of excellent emulsification, strong nucleation ability and good nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

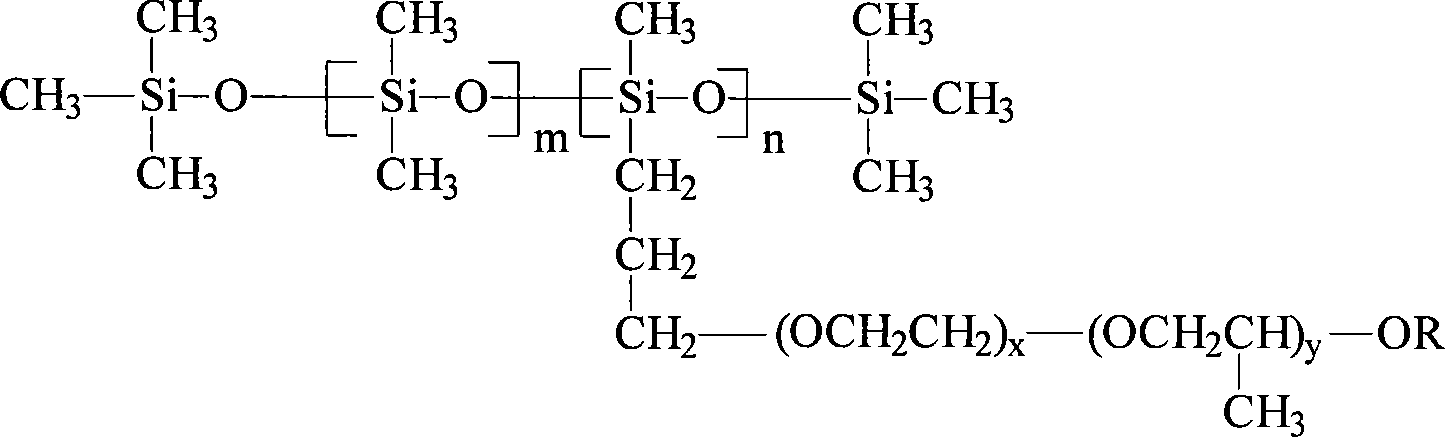

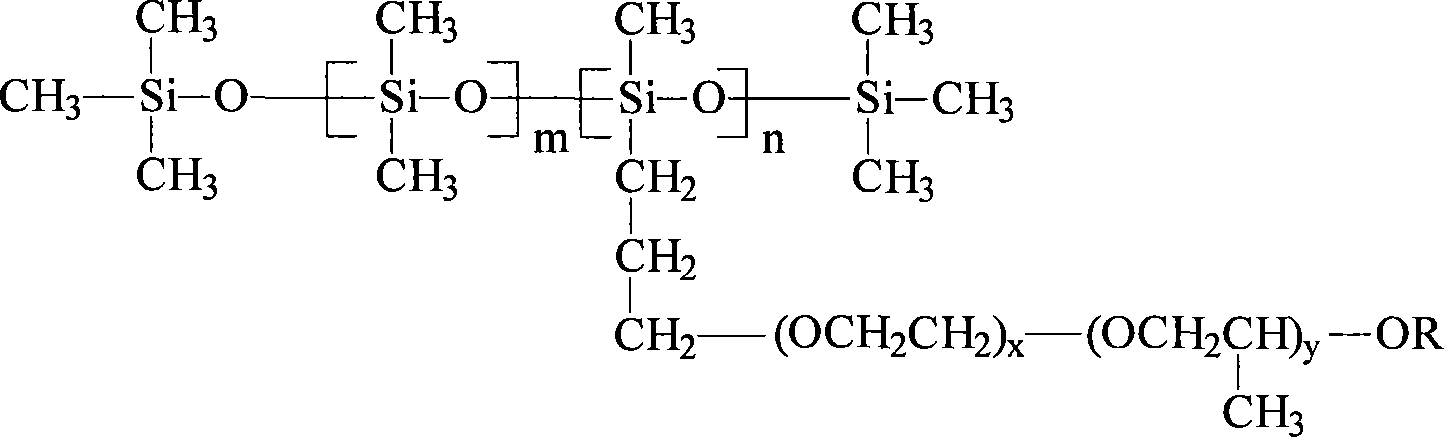

Method used

Image

Examples

Embodiment 1

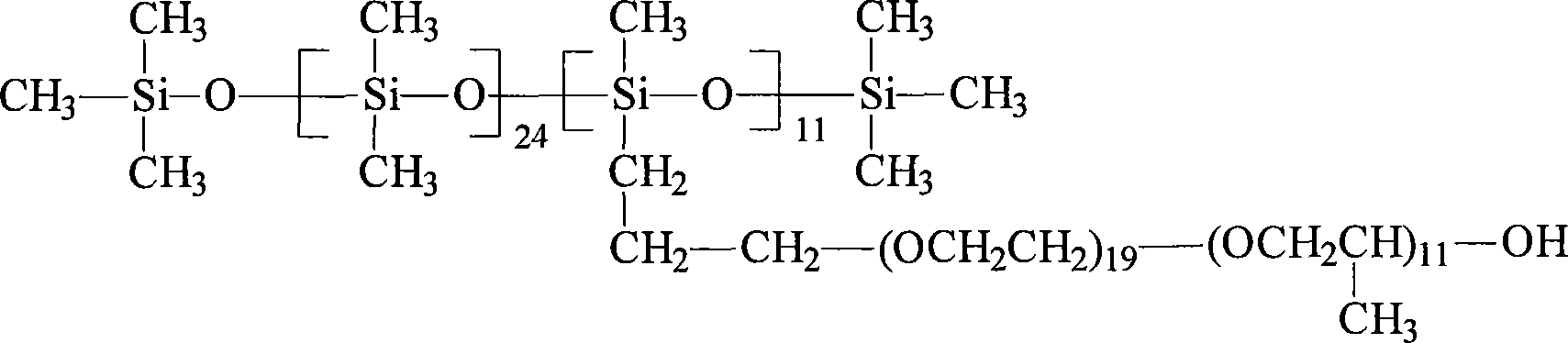

[0020] A) Add 5.8g of allyl alcohol, 120g of ethylene oxide and 100g of propylene oxide into the reactor, and react for 5 hours under the conditions of 1.1g of catalyst KOH, pressure ≤ 0.4Mpa, and reaction temperature of 110°C to obtain terminal Propylene polyether;

[0021] B) react octamethylcyclotetrasiloxane, hydrogen-containing silicone oil, and hexamethyldisiloxane under the action of sulfuric acid at a reaction temperature of 80°C for 5 hours to obtain polysiloxane (II), wherein The molar ratio between octamethylcyclotetrasiloxane, hydrogen-containing silicone oil and hexamethyldisiloxane is 10:1:1.5;

[0022] C) 150 g of modified polyether (I) obtained by the above two-step reaction and 80 g of polysiloxane (II) are heated under normal pressure to 115 ° C under the action of 30 ppm Pt catalyst and 120 g of toluene, and while heating Open the water in and out of the reflux condenser, let the toluene reflux in the kettle through the condenser; then keep warm for 4 hours...

Embodiment 2

[0026] A) Add 5.8g of allyl alcohol, 160g of ethylene oxide and 100g of propylene oxide into the reactor, and react for 6 hours under the conditions of 1.06g of catalyst KOH, pressure ≤ 0.4Mpa, and reaction temperature of 100°C to obtain terminal Propylene polyether;

[0027] B) react octamethylcyclotetrasiloxane, hydrogen-containing silicone oil, and hexamethyldisiloxane under the action of sulfuric acid at a reaction temperature of 80°C for 5 hours to obtain polysiloxane (II), wherein The molar ratio between octamethylcyclotetrasiloxane, hydrogen-containing silicone oil and hexamethyldisiloxane is 15:1:1.5;

[0028] C) 200g of modified polyether (I) obtained by the above two-step reaction and 80g of polysiloxane (II) are heated up to 115°C under normal pressure under the action of 50ppm Pt catalyst and in the presence of 180g xylene, and heated Open the water in and out of the reflux condenser at the same time, so that the xylene is refluxed in the kettle through the conden...

Embodiment 3

[0032] A) Add 5.8g of allyl alcohol, 120g of ethylene oxide and 100g of propylene oxide into the reactor, and react for 4 hours in the presence of 1.0g of catalyst KOH, pressure ≤ 0.4Mpa, and reaction temperature of 130°C to obtain terminal Propylene polyether;

[0033] B) react octamethylcyclotetrasiloxane, hydrogen-containing silicone oil, and hexamethyldisiloxane under the action of sulfuric acid at a reaction temperature of 80°C for 5 hours to obtain polysiloxane (II), wherein The molar ratio between octamethylcyclotetrasiloxane, hydrogen-containing silicone oil and hexamethyldisiloxane is 20:2.5:2;

[0034] C) 150 g of modified polyether (I) obtained by the above two-step reaction and 75 g of polysiloxane (II) are heated to 115° C. under normal pressure under the action of 10 ppm Pt catalyst and in the presence of 110 g of toluene. At the same time, open the water in and out of the reflux condenser, so that the solvent refluxes in the kettle through the condenser; then k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com