Special foaming agent for hard PVC (polyvinyl chloride) low-foaming material and preparation method thereof

A foaming agent and low-foaming technology, which is used in the preparation of special foaming agents for rigid PVC low-foaming materials, can solve the problems of large cells, resin aging and unevenness of foam products, and achieve fine cells. Structure, foaming process control, easy effect of foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

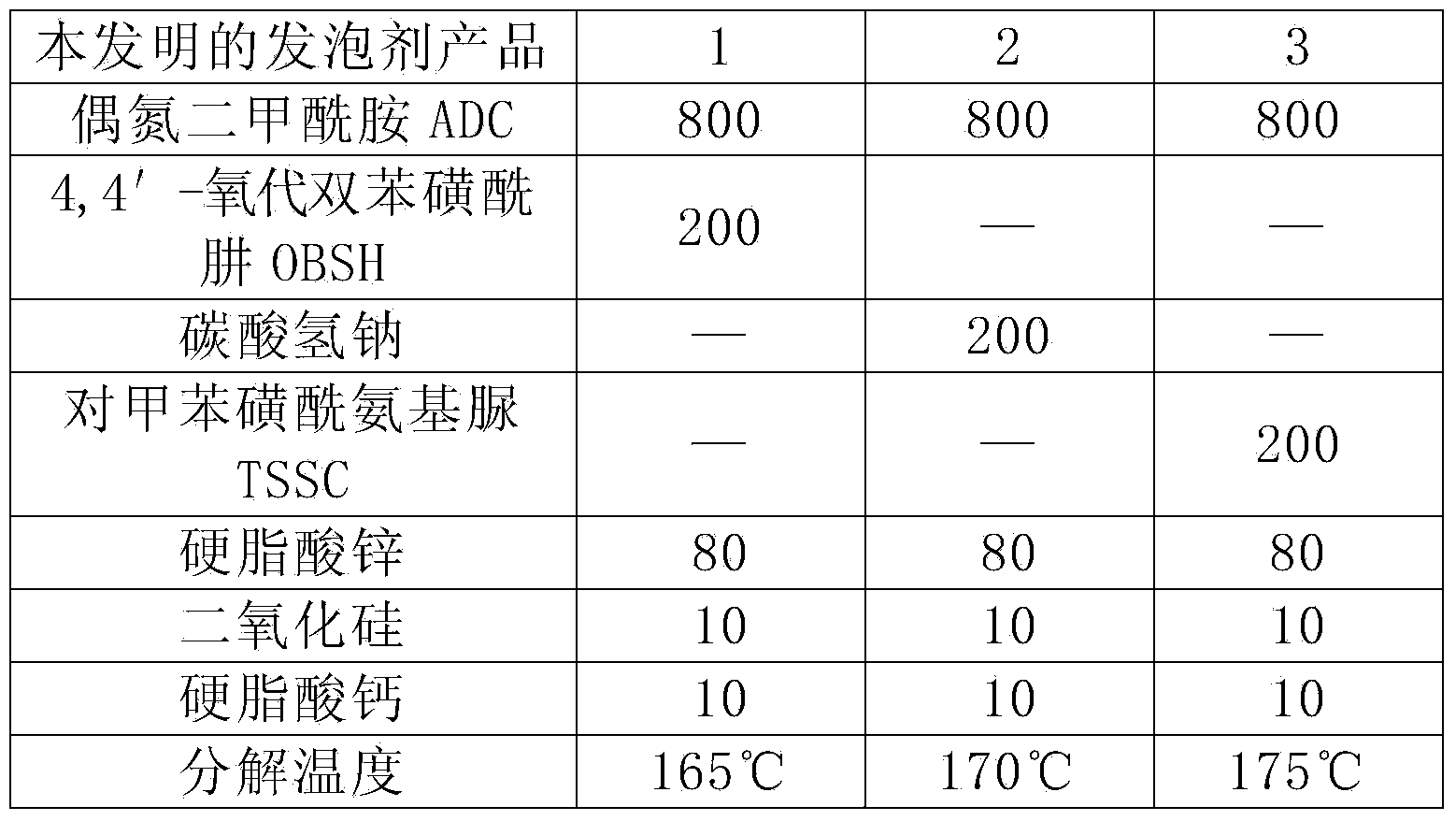

[0019] Adopt 800g azodicarbonamide ADC, 80g zinc stearate, 10g silicon dioxide, 10g calcium stearate, produce foaming agent of the present invention respectively with different auxiliary blowing agent 200g, each raw material is as shown in table-1 Show. First add silicon dioxide and calcium stearate into the mixer and mix for 3 minutes, then add azodicarbonamide, 4,4'-oxobisbenzenesulfonyl hydrazide OBSH or sodium bicarbonate or p-toluenesulfonamide Urea TSSC and zinc stearate were placed in a mixer and mixed for 10 minutes to obtain each foaming agent of the present invention.

[0020] According to the industry standard of azodicarbonamide ADC, the decomposition temperature of the blowing agent of the present invention was tested, and the results are shown in Table-1.

[0021] Table-1 (unit g)

[0022]

Embodiment 2

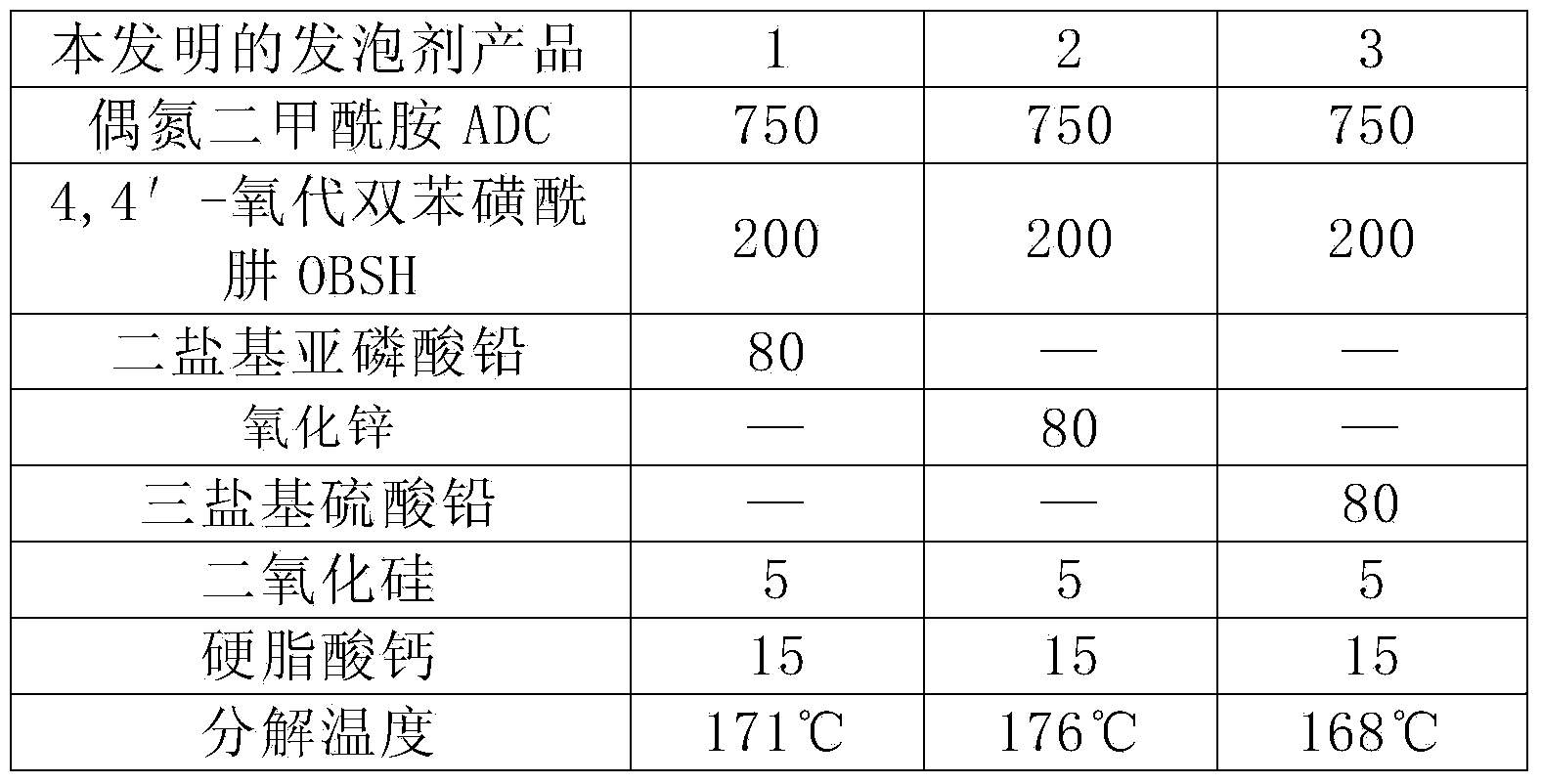

[0024] 750g of azodicarbonamide ADC, 200g of 4,4'-oxobisbenzenesulfonyl hydrazide OBSH, 5g of silicon dioxide, 15g of calcium stearate, and 80g of different types of activators are used to produce the blowing agent of the present invention respectively, The raw materials are shown in Table-2. First, add silicon dioxide and calcium stearate into the mixer and mix for 3 minutes, then add azodicarbonamide, 4,4'-oxobisbenzenesulfonyl hydrazide OBSH, Dibasic lead phosphite or zinc oxide or tribasic lead sulfate are placed in a mixer and mixed for 15 minutes to obtain the blowing agent of the present invention.

[0025] According to the azodicarbonamide ADC industry standard, the decomposition temperature of the foaming agent of the present invention was tested, and the results are shown in Table-2.

[0026] Table-2 (unit g)

[0027]

Embodiment 3

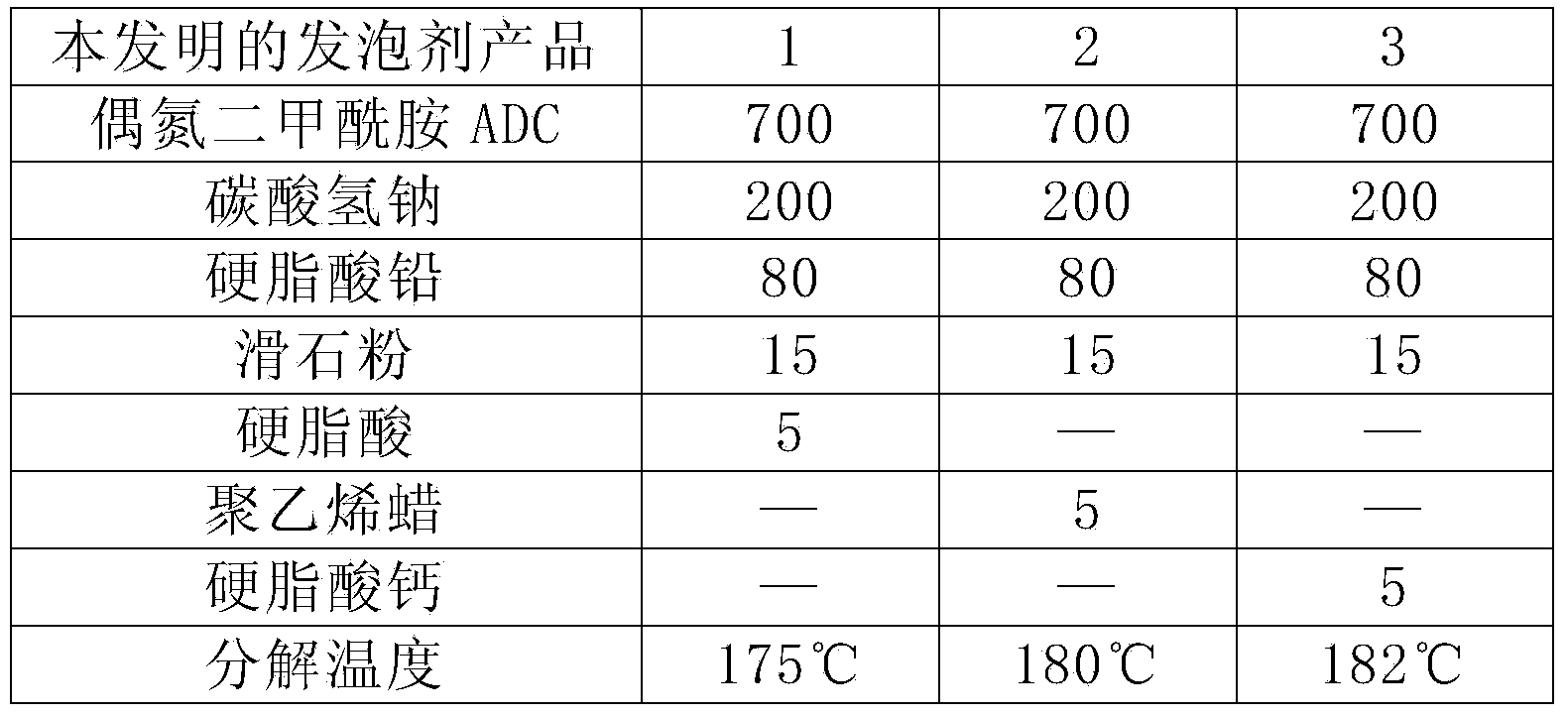

[0029] Mix 700g of azodicarbonamide ADC, 200g of sodium bicarbonate, 80g of lead stearate, and 15g of talcum powder. Produce whipping agent of the present invention respectively with different kinds of processing aid 5g, each raw material is as shown in table-3, at first talcum powder, stearic acid or polyethylene wax or calcium stearate are added in mixer and mix 7 minutes, Azodicarbonamide, sodium bicarbonate, and lead stearate were placed in a mixer in turn, and mixed for 20 minutes to obtain the blowing agent of the present invention.

[0030] According to the azodicarbonamide ADC industry standard, the decomposition temperature of the blowing agent of the present invention was tested, and the results are shown in Table-3.

[0031] Table-3 (unit g)

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com