A kind of scr nano membrane denitration catalyst and its preparation method and application

A denitration catalyst and nano-membrane technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of difficult catalyst treatment, high catalyst manufacturing cost, and increased volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

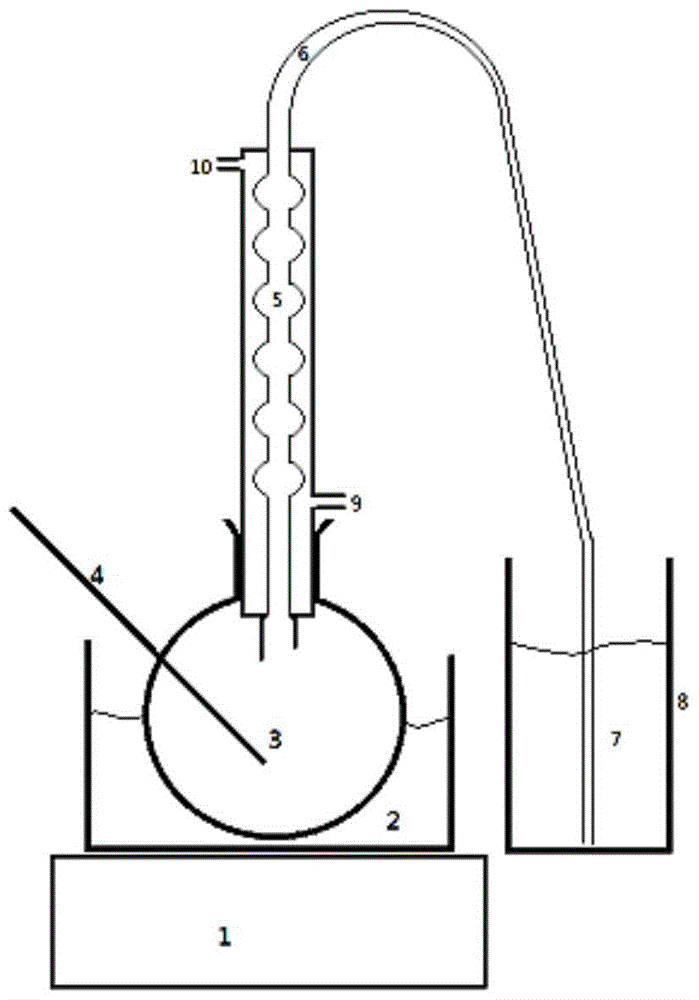

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: prepare nano-membrane catalyst I, compare the denitrification effect of catalyst I and traditional honeycomb catalyst:

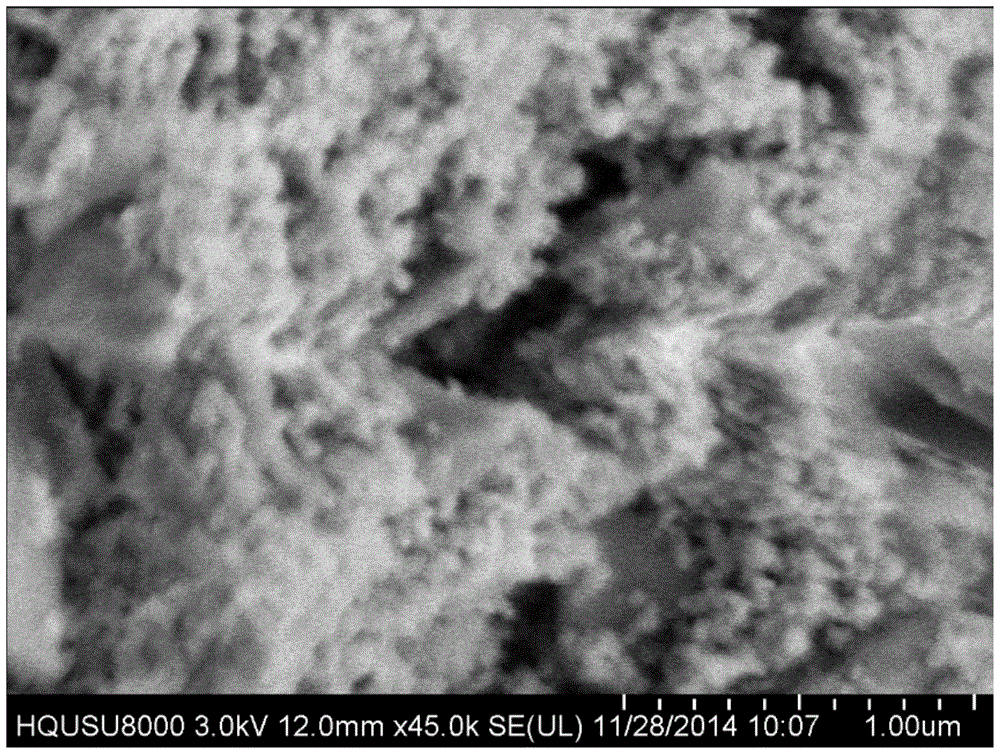

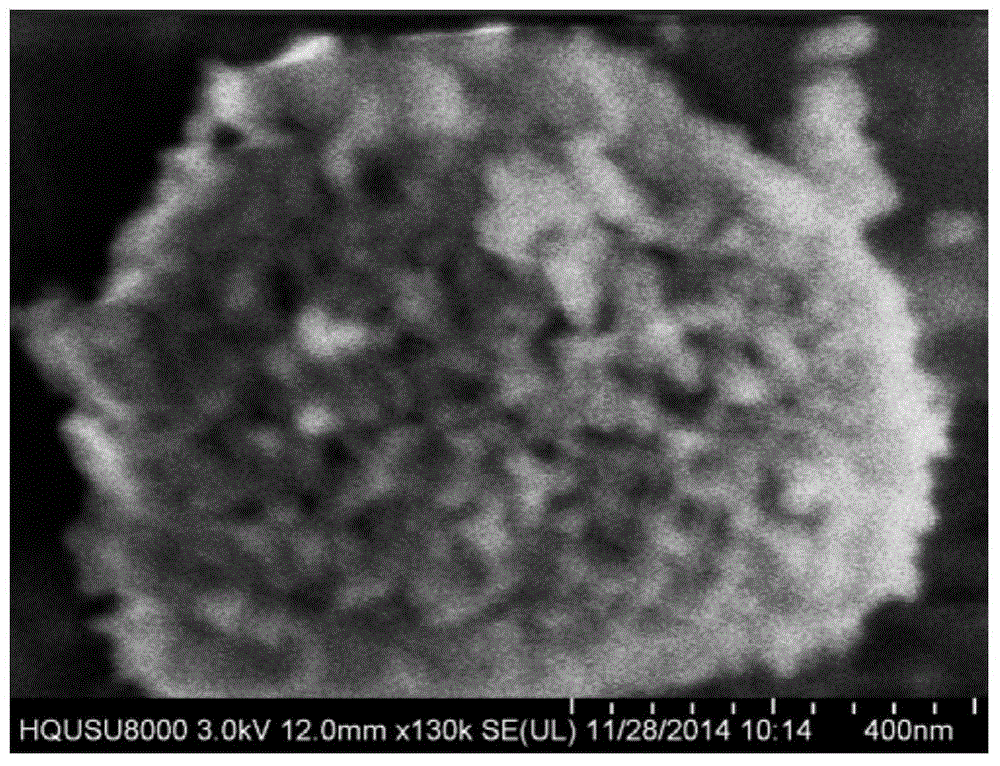

[0069] A preparation method of SCR denitrification nano-membrane catalyst, using ceramic Pall ring (φ15×15) as carrier, with 25nm TiO 2 Nanoparticles are auxiliary carriers, based on the mass of the catalyst carrier, V 2 o 5 The loading mass fraction is 3.7%, MnO 2 The loading mass fraction of PdO is 2.8%, the loading mass fraction of PdO is 2.2%, WO 3 The loading mass fraction is 4.1%, CeO 2 The loading mass fraction is 0.3%, TiO 2 The loading mass fraction of nanoparticles is 86.9%; including the following steps:

[0070](1), carrier cleaning, drying: the carrier is washed 3 times with tap water to remove dust; then after cleaning 1 time with 40% hydrofluoric acid with a mass fraction, neutralize the residual acid on the carrier surface with 3% sodium hydroxide, and use Wash 3 times with tap water to remove residual alkali; wash ...

Embodiment 2

[0080] Embodiment 2: preparation catalyst II

[0081] A preparation method of SCR denitrification nano-membrane catalyst, using ceramic Pall ring (φ15×15) as carrier, with 25nm TiO 2 Nanoparticles and 100nm Fe 3 o 4 Nanoparticles are auxiliary carriers, based on the mass of the catalyst carrier, V 2 o 5 The loading mass fraction of PdO is 8%, the loading mass fraction of PdO is 2.5%, CeO 2 The loading mass fraction is 0.85%, WO 3 The loading mass fraction is 1.2%, TiO 2 The loading mass fraction of nanoparticles is 75%, Fe 3 o 4 The loading mass fraction of nanoparticles is 22.45%; including the following steps:

[0082] (1), carrier cleaning and drying: the carrier is washed with tap water to remove dust; then it is washed once with oleum, and the residual acid on the surface of the carrier is neutralized with 1% sodium hydroxide solution; it is washed 3 times with tap water, Remove residual lye; wash with distilled water for 3 times, then wash with deionized water f...

Embodiment 3

[0089] Embodiment 3: preparation catalyst III

[0090] A preparation method of SCR denitrification nano-membrane catalyst, using ceramic Pall ring (φ15×15) as carrier, with 25nm TiO 2 Nanoparticles are auxiliary carriers, based on the mass of the catalyst carrier, V 2 o 5 The loading mass fraction is 5%, MnO 2 The loading mass fraction is 2.8%, CeO 2 The loading mass fraction is 0.25%, WO 3 The loading mass fraction is 2.2%, TiO 2 The loading mass fraction of nanoparticles is 89.75%; including the following steps:

[0091] (1), carrier cleaning, drying: the carrier is washed with tap water to remove dust; then it is washed once with 40% hydrofluoric acid with a mass fraction; neutralize the residual hydrofluoric acid with 1% sodium hydroxide solution; Wash 3 times with tap water to remove residual lye on the surface; wash 3 times with distilled water, then wash 3 times with deionized water; vacuum dry at 150°C and 10Pa for 5 hours;

[0092] (2) Carrier surface modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com