Patents

Literature

145results about How to "Simplify manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

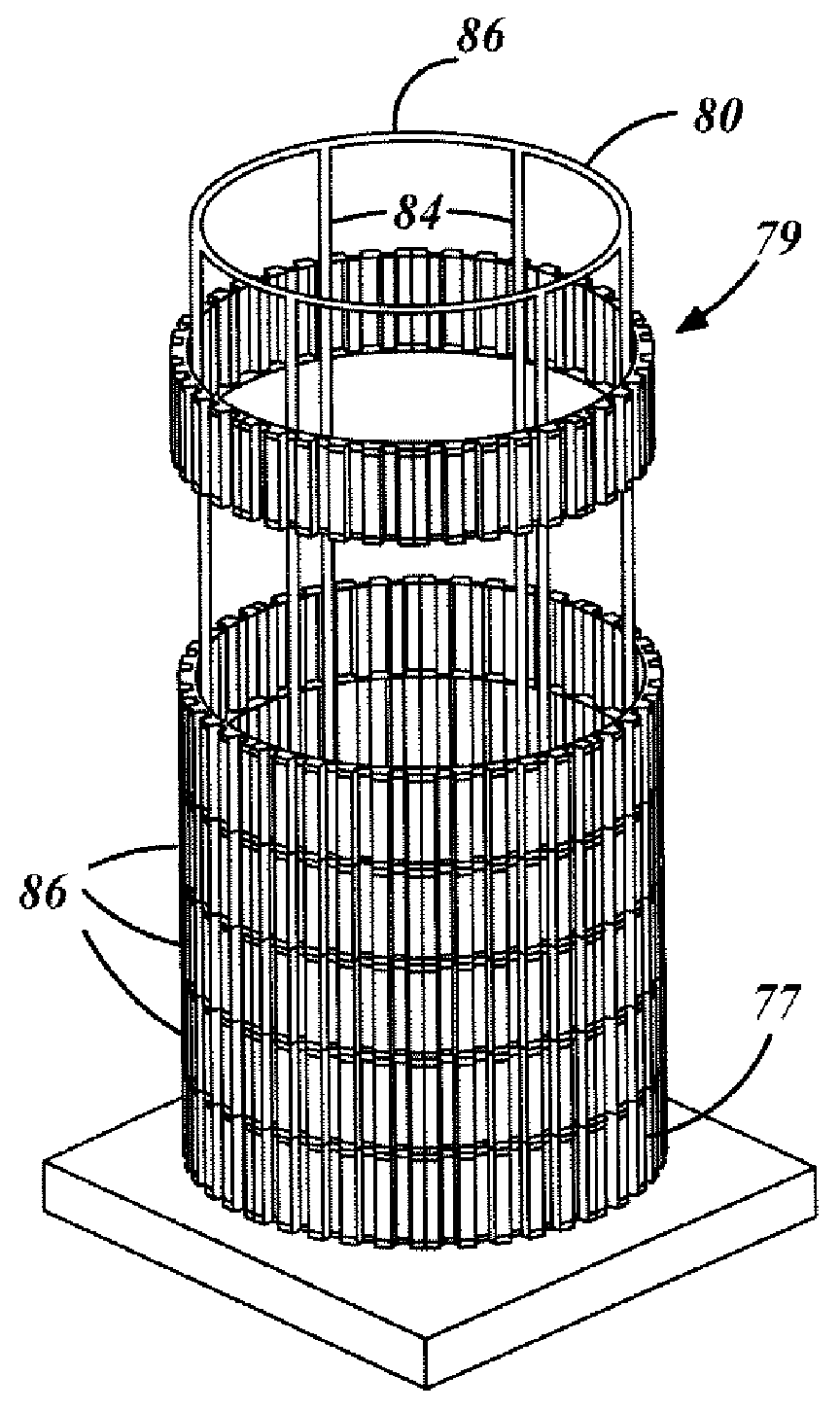

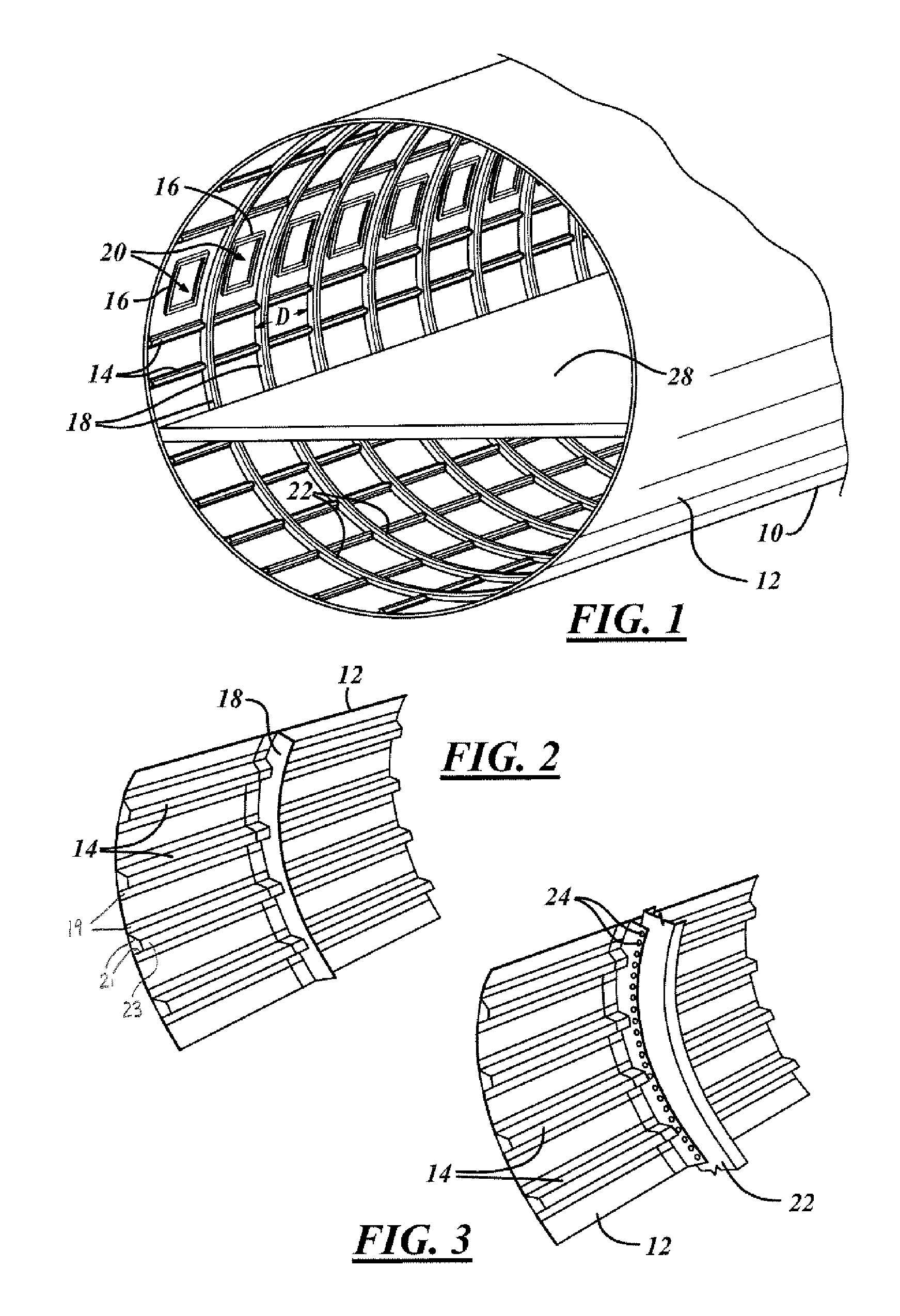

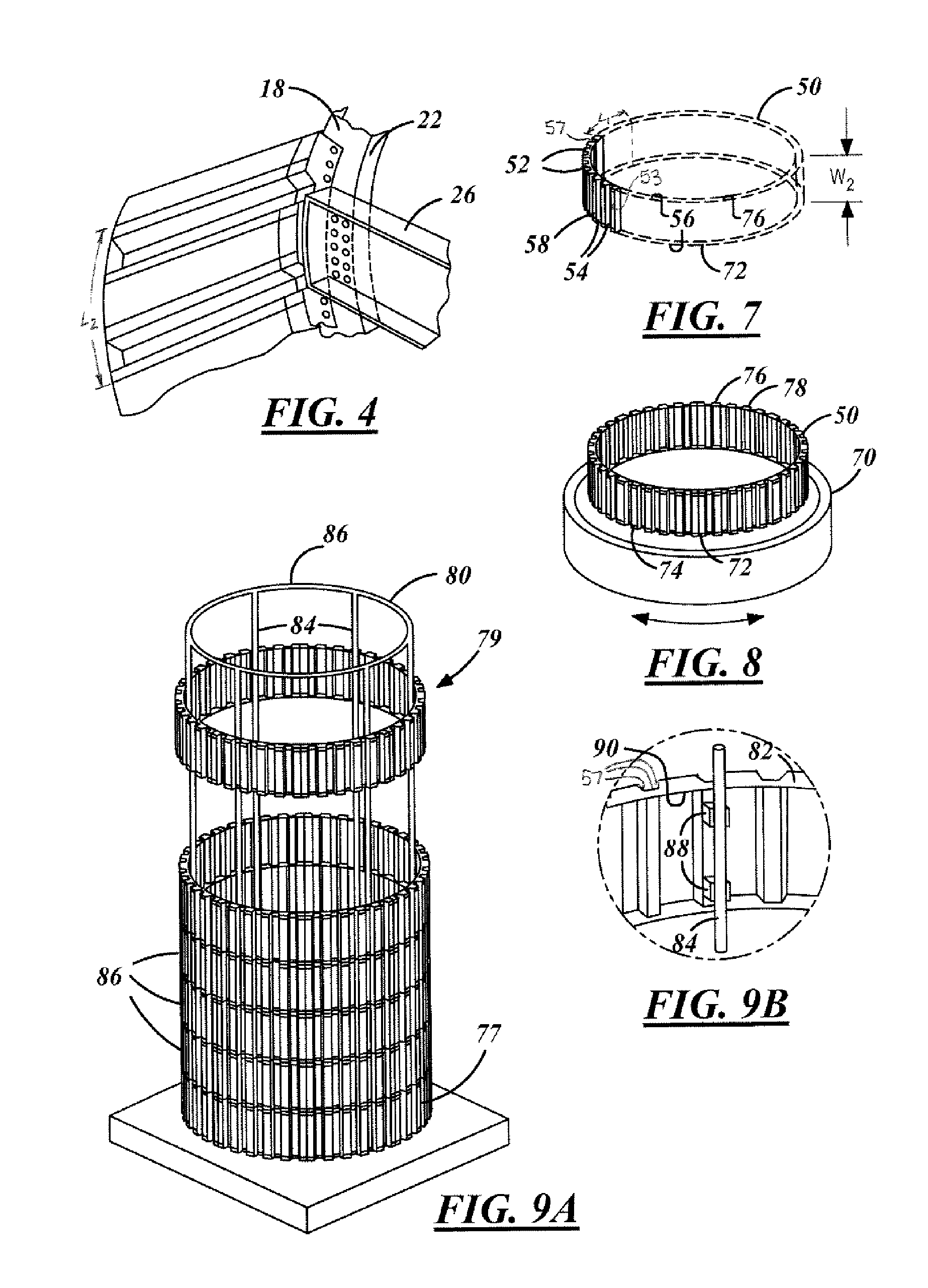

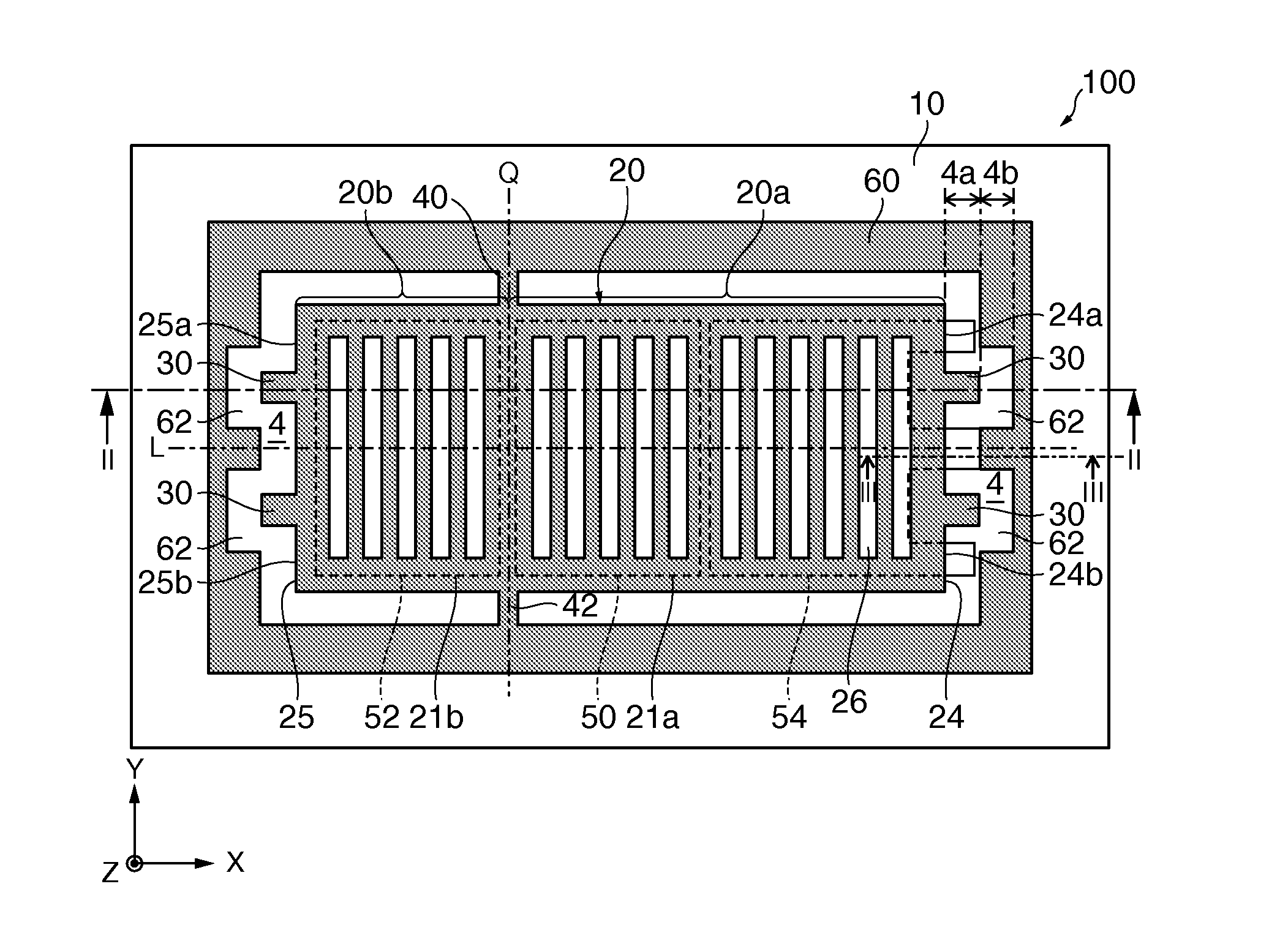

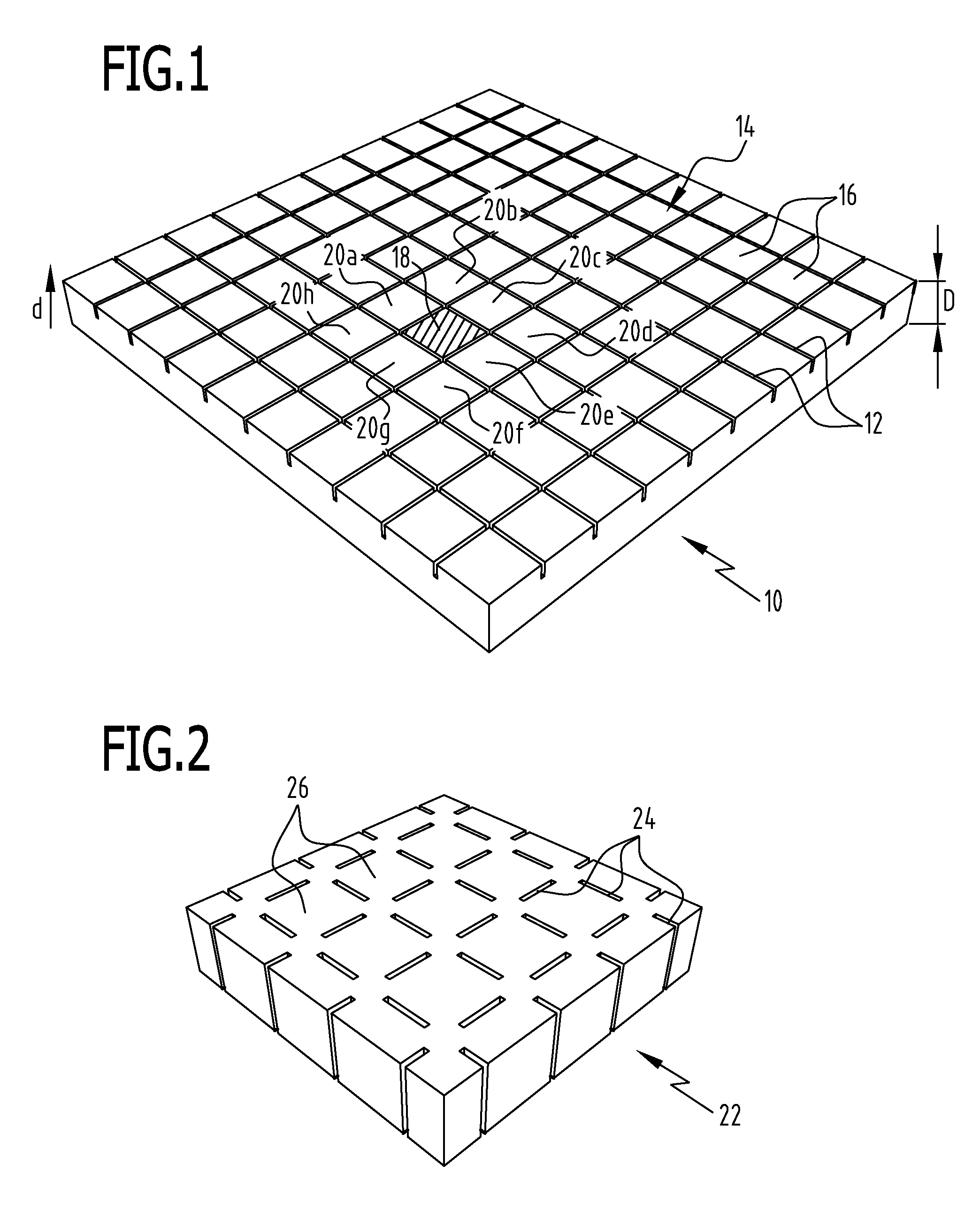

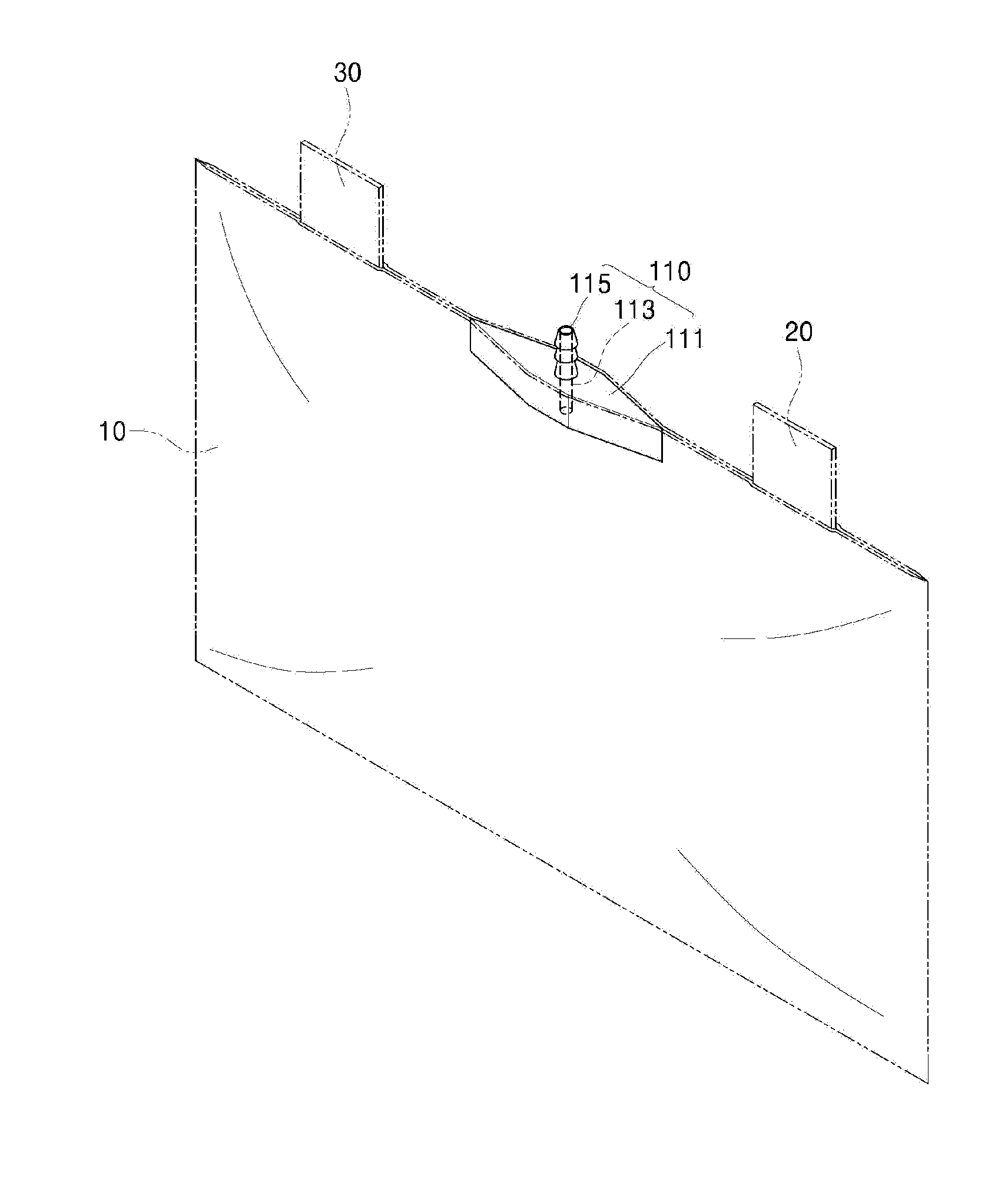

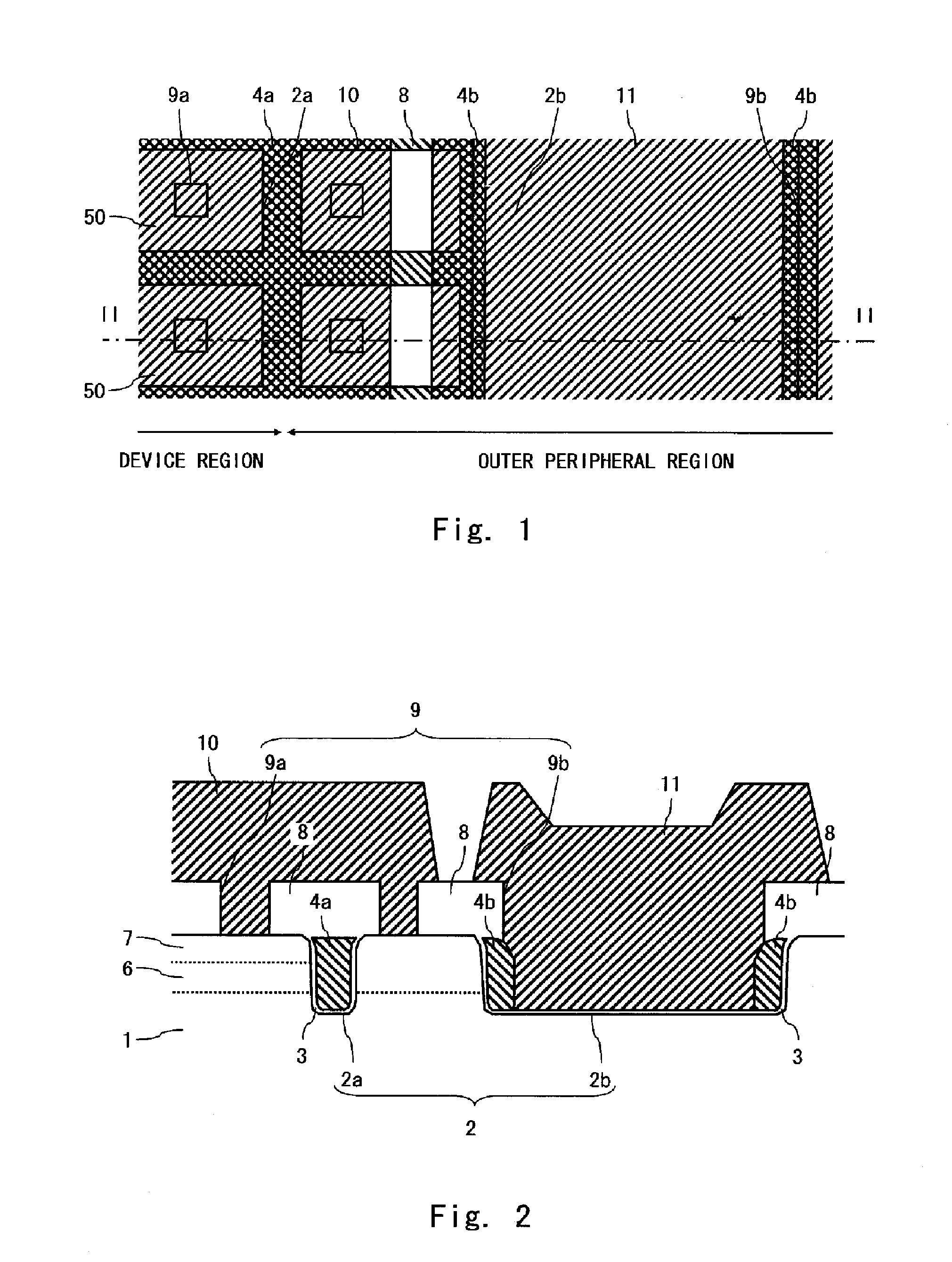

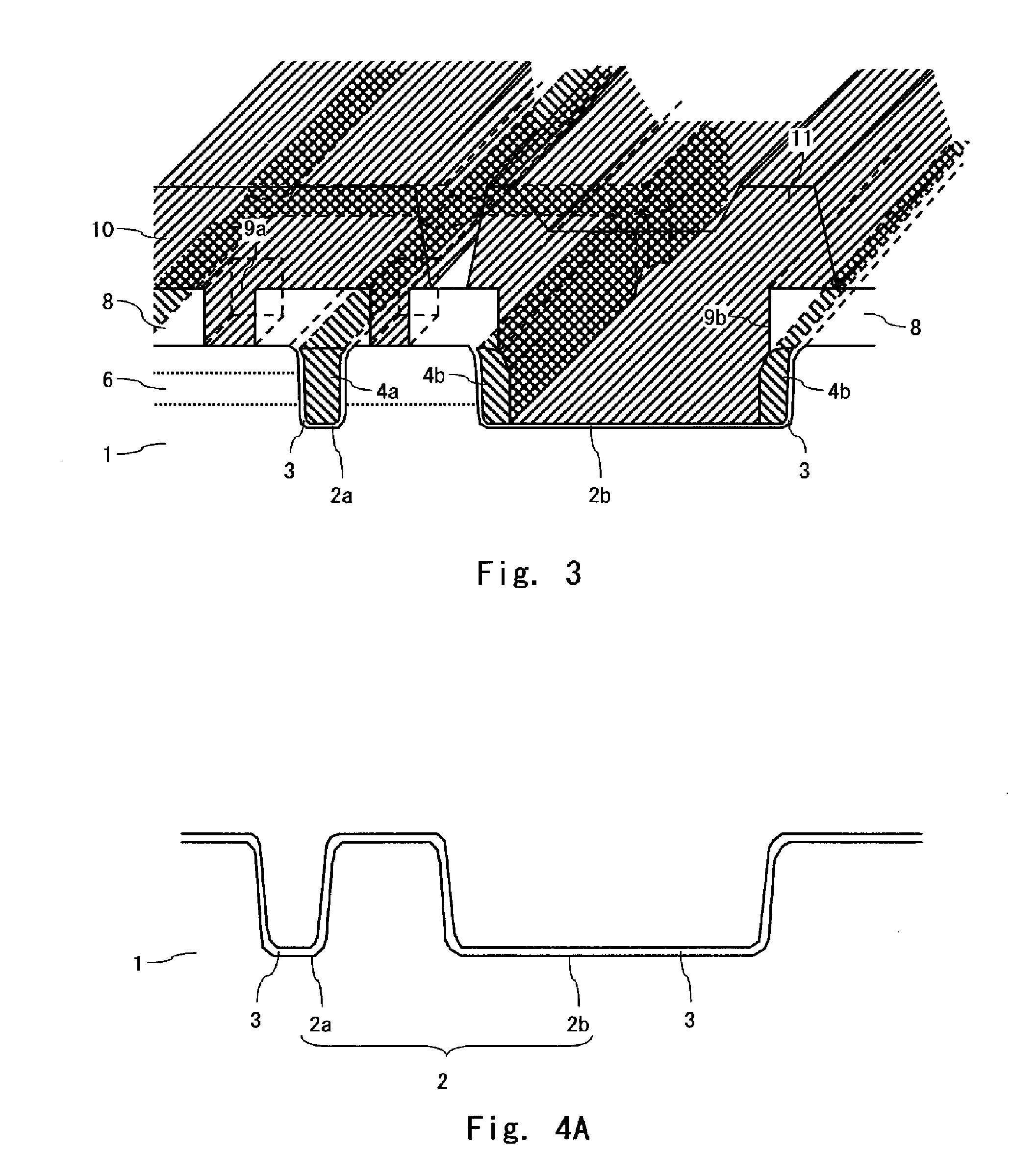

Multi-ring system for fuselage barrel formation

InactiveUS20060231682A1Simplify manufacturing processReduce countConfectioneryFuselage bulkheadsPlanetary ringAirplane

An aircraft fuselage barrel (10) includes a skin (12) and a shear tie (18). The shear tie (18) resides within and is integrally formed with the skin (12). The shear tie (18) is separate from and configured for frame attachment thereon. A multi-ring system (79) for fuselage barrel formation includes a mold (68) with a ring (50). The ring (50) has width (W2) approximately equal to a separation distance (D) between two adjacent fuselage frames (22) and includes a module (52) that has a circumferential length (L1) that is greater than a circumferential distance between two fuselage longerons (14). A support structure (80) is coupled to and supports the mold (68). A method of forming the aircraft fuselage barrel (10) includes constructing the support structure (80). Rings (86) of the mold (68) are attached to and over the support structure (80). The mold (68) is constructed. Material is laid-up onto the mold (68) to integrally form the one-piece fuselage barrel (10) including a Hat-configured longeron (14).

Owner:THE BOEING CO

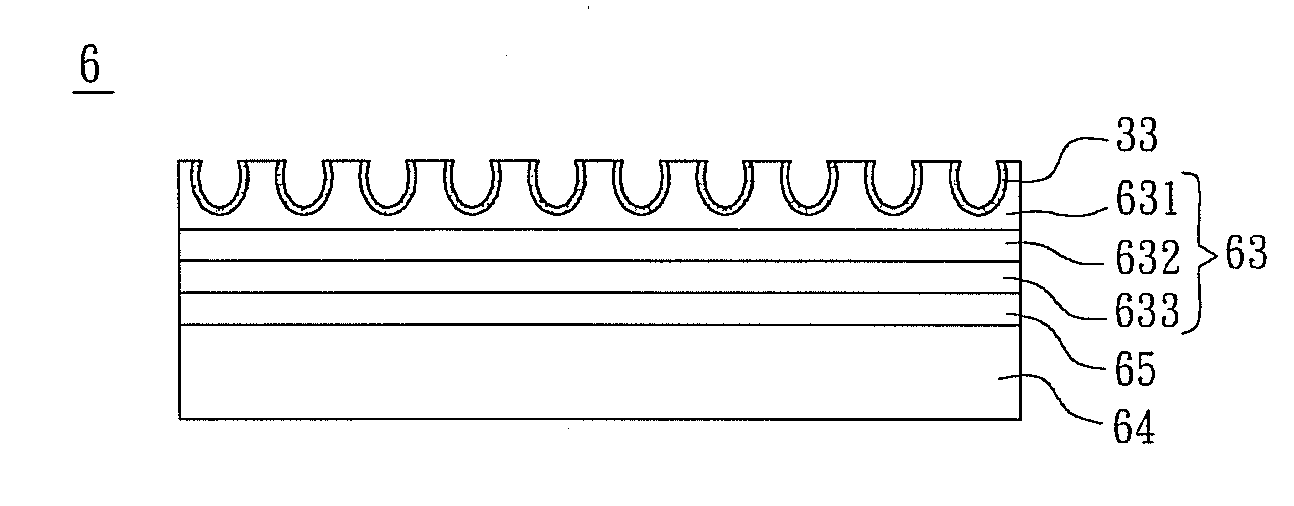

Organic el display panel and manufacturing method thereof

ActiveUS20090284135A1Simplify manufacturing processImprove characteristicDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringPolymer

An organic EL display panel having a polymer organic EL layer with a uniform thickness is provided. The organic EL display panel includes a substrate, anode electrodes set on the substrate; a hole transport layer provided on the substrate on which the anode electrodes are set; banks provided in lines on the hole transport layer to define line-state pixel regions; an interlayer set in a line in the pixel region; a polymer organic EL layer set in a line on the interlayer in the pixel region; and a cathode electrode provided on the polymer organic EL layer.

Owner:JOLED INC

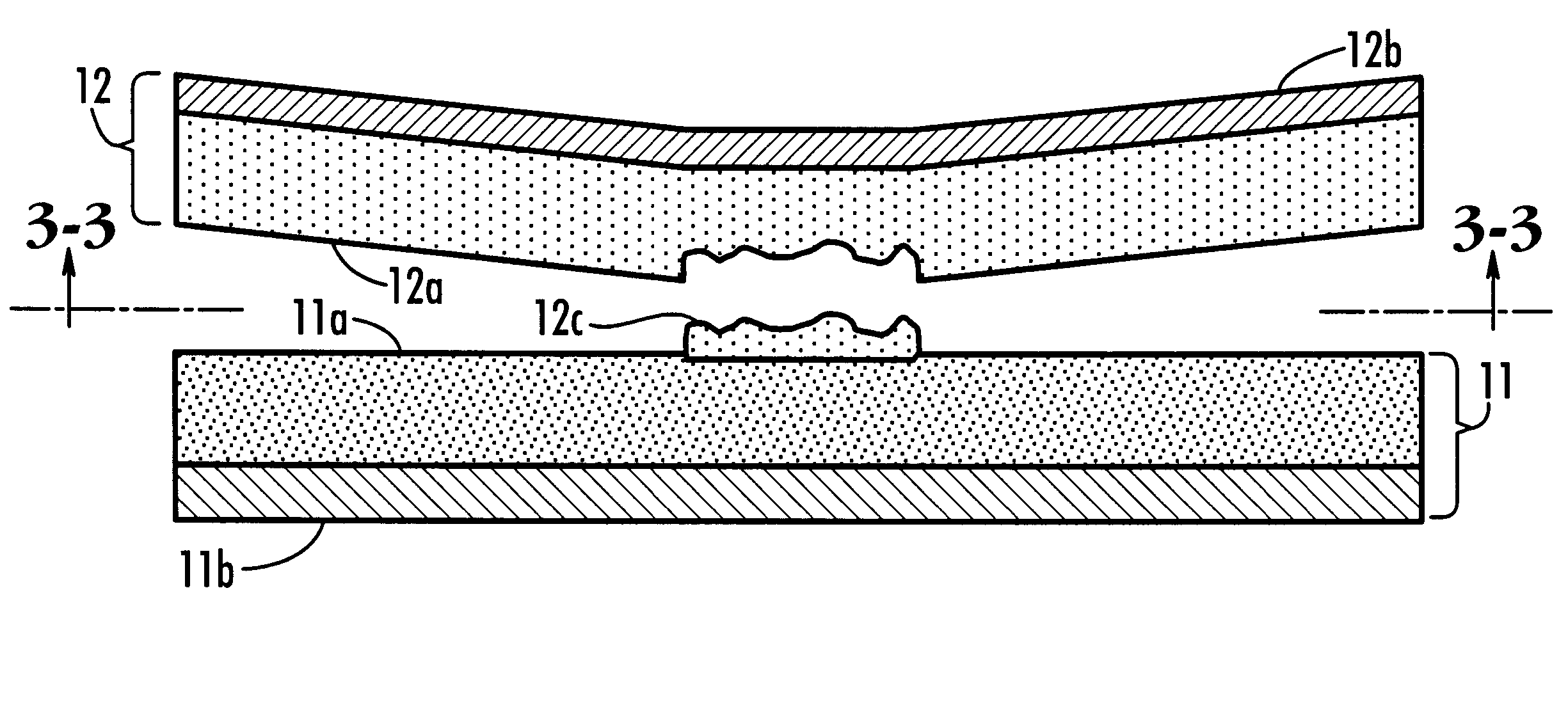

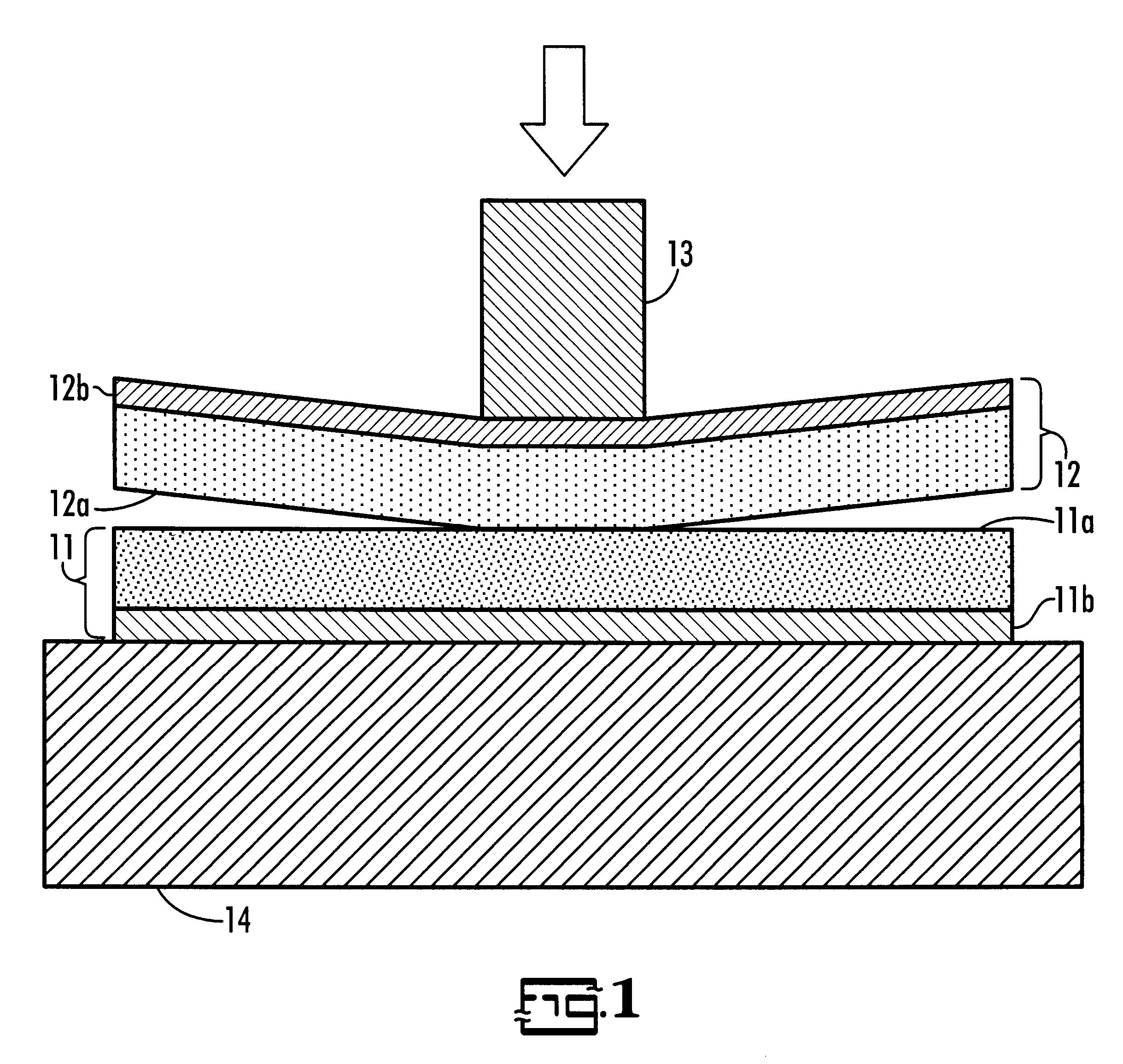

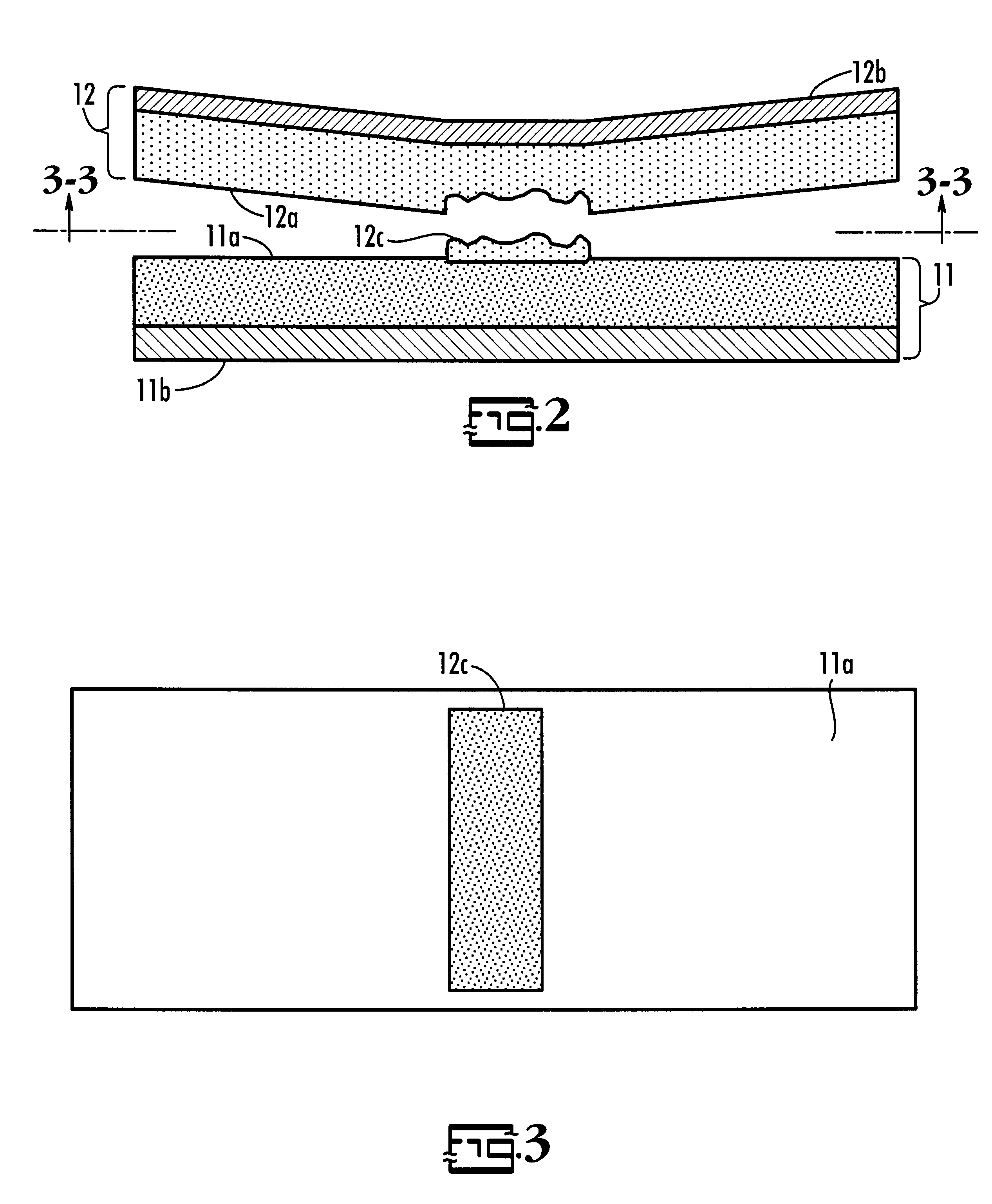

Method of producing zone specific peelable heat seals for flexible packaging applications

InactiveUS6245176B1High degree of reliabilitySimplify manufacturing processFlexible coversWrappersMechanical engineeringPolymer

A method for creating peelable or frangible seals comprising the steps of: 1) selecting a first planar film with a polyethylene based resin disposed on its surface; 2) defining a frangible sealing zone on a surface of the first planar film; 3) heat sealing a second planar film to the frangible zone where the second planar film has a seal surface comprising a plurality of polymers; and 4) cooling the first and second planar films and frangible zone. A seal is created whereby peeling away the second planar film causes a rupture in the polymers disposed on the second planar film's surface.

Owner:GREENLAND STEVEN J

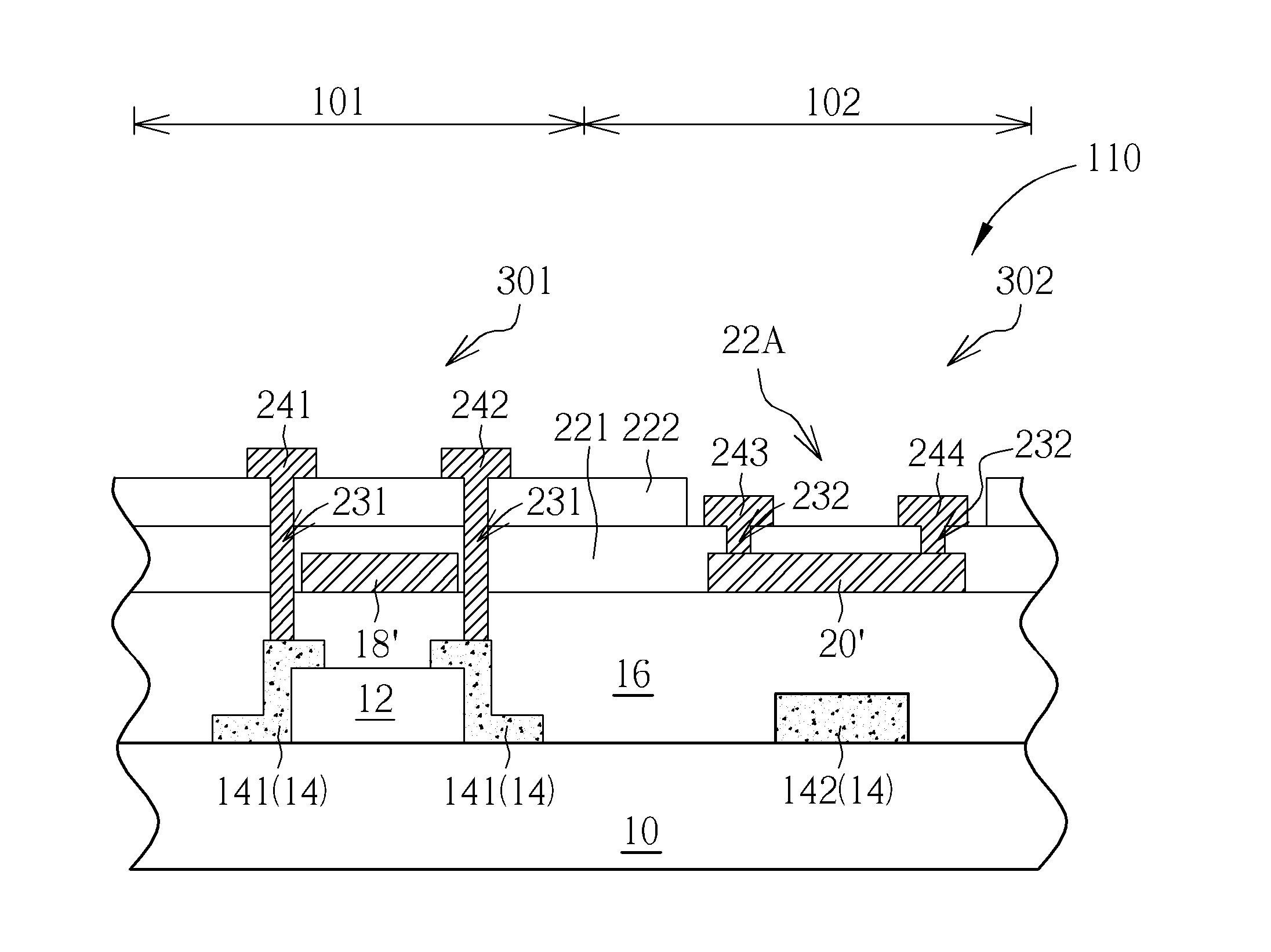

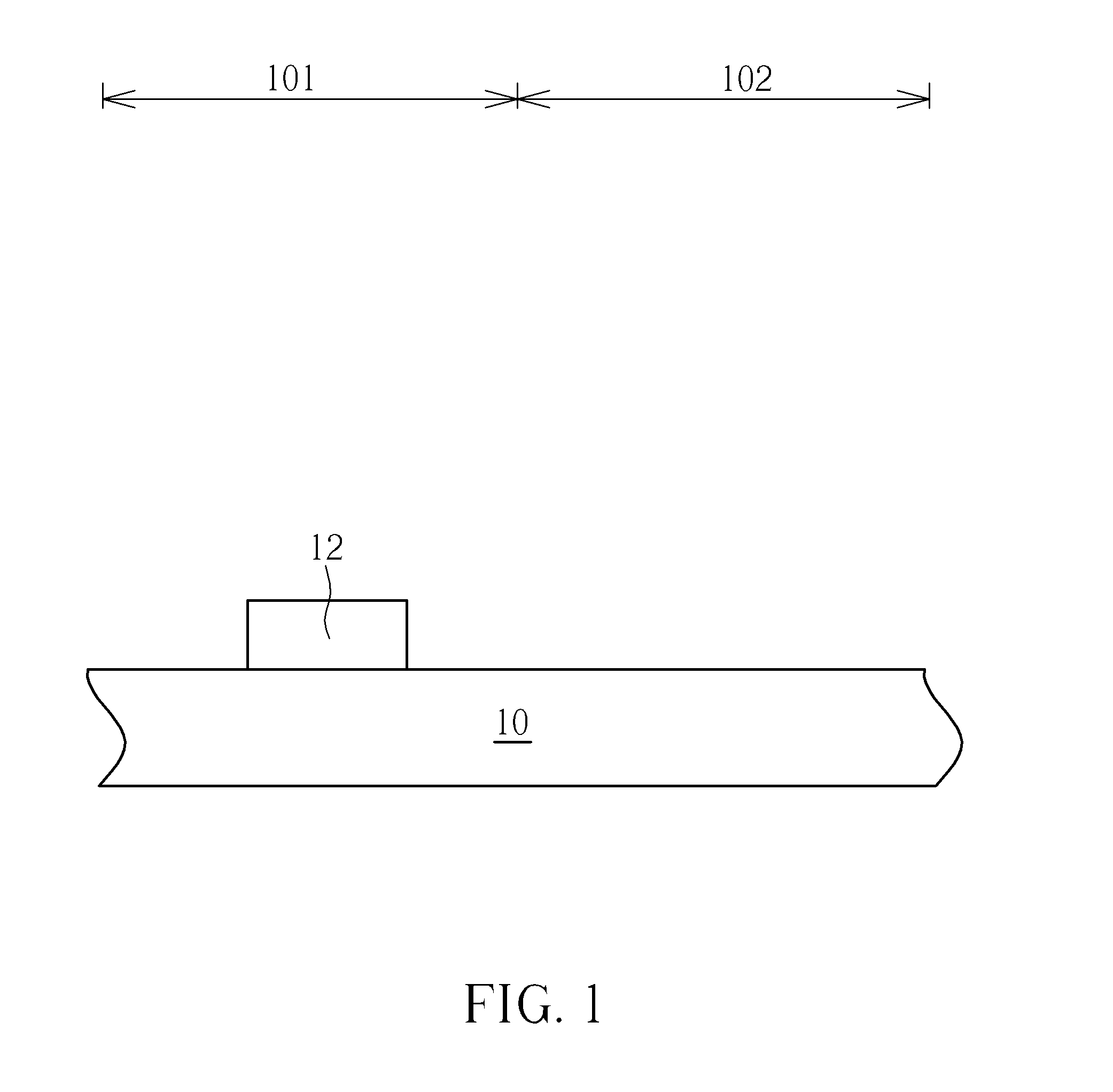

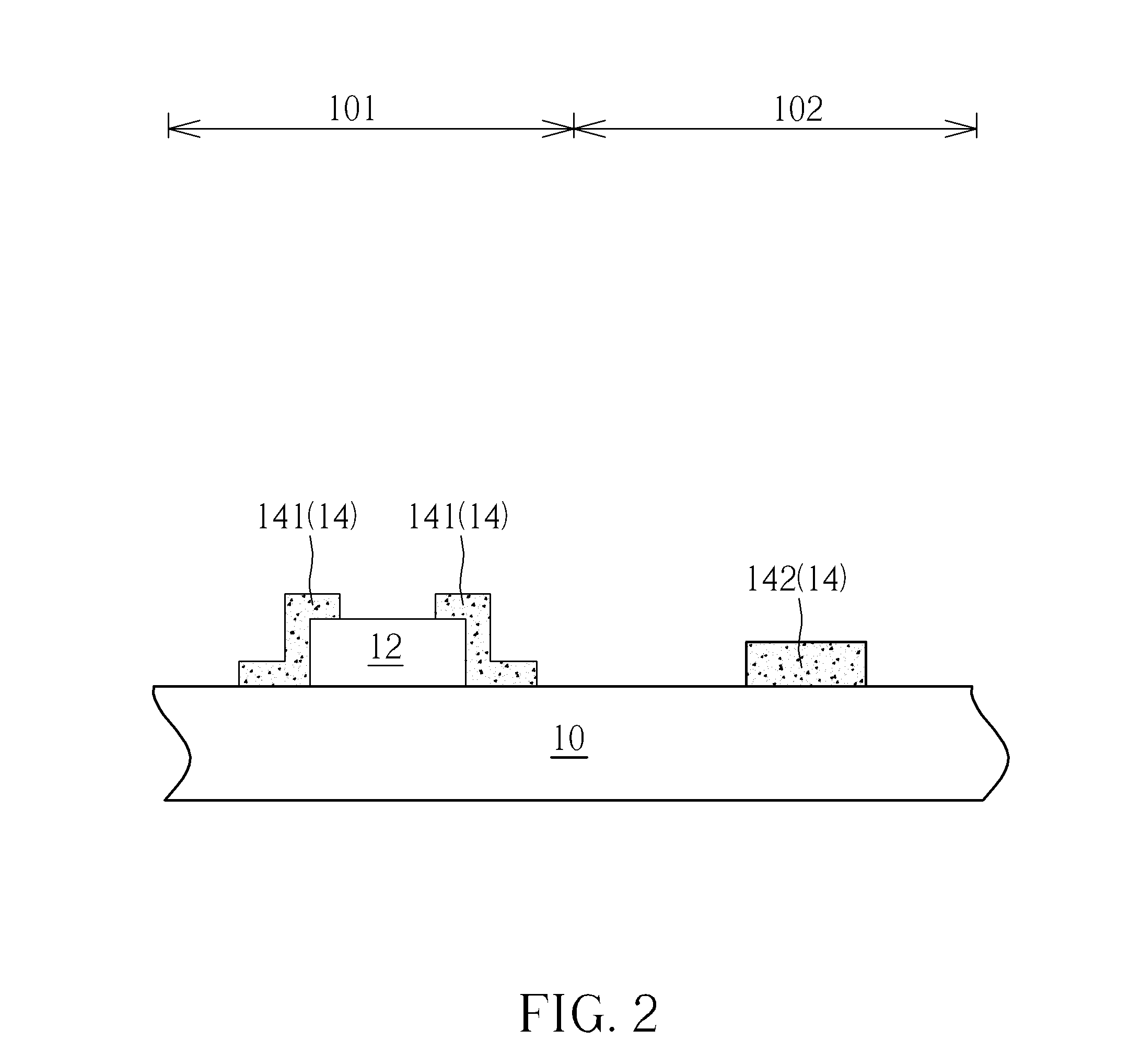

Semiconductor device and electroluminescent device and method of making the same

ActiveUS20130015448A1Simplify manufacturing processReduce resistanceTransistorSolid-state devicesPower semiconductor deviceSemiconductor device modeling

A semiconductor device, disposed on a substrate, includes a first channel layer, a patterned doped layer, a gate insulating layer, a conducting gate electrode, a second channel layer, a first electrode and a second electrode, and a third electrode and a fourth electrode. The first channel layer is disposed on the substrate and in a first region. The patterned doped layer includes a doped gate electrode disposed in a second region, and two contact electrodes electrically connected to two sides of the first channel layer, respectively. The conducting gate electrode is disposed on the gate insulating layer in the first region. The second channel layer is disposed on the gate insulating layer in the second region. The first electrode and the second electrode are electrically connected to the contact electrodes, respectively. The third electrode and the fourth electrode are electrically connected to two sides of the second channel layer, respectively.

Owner:AU OPTRONICS CORP

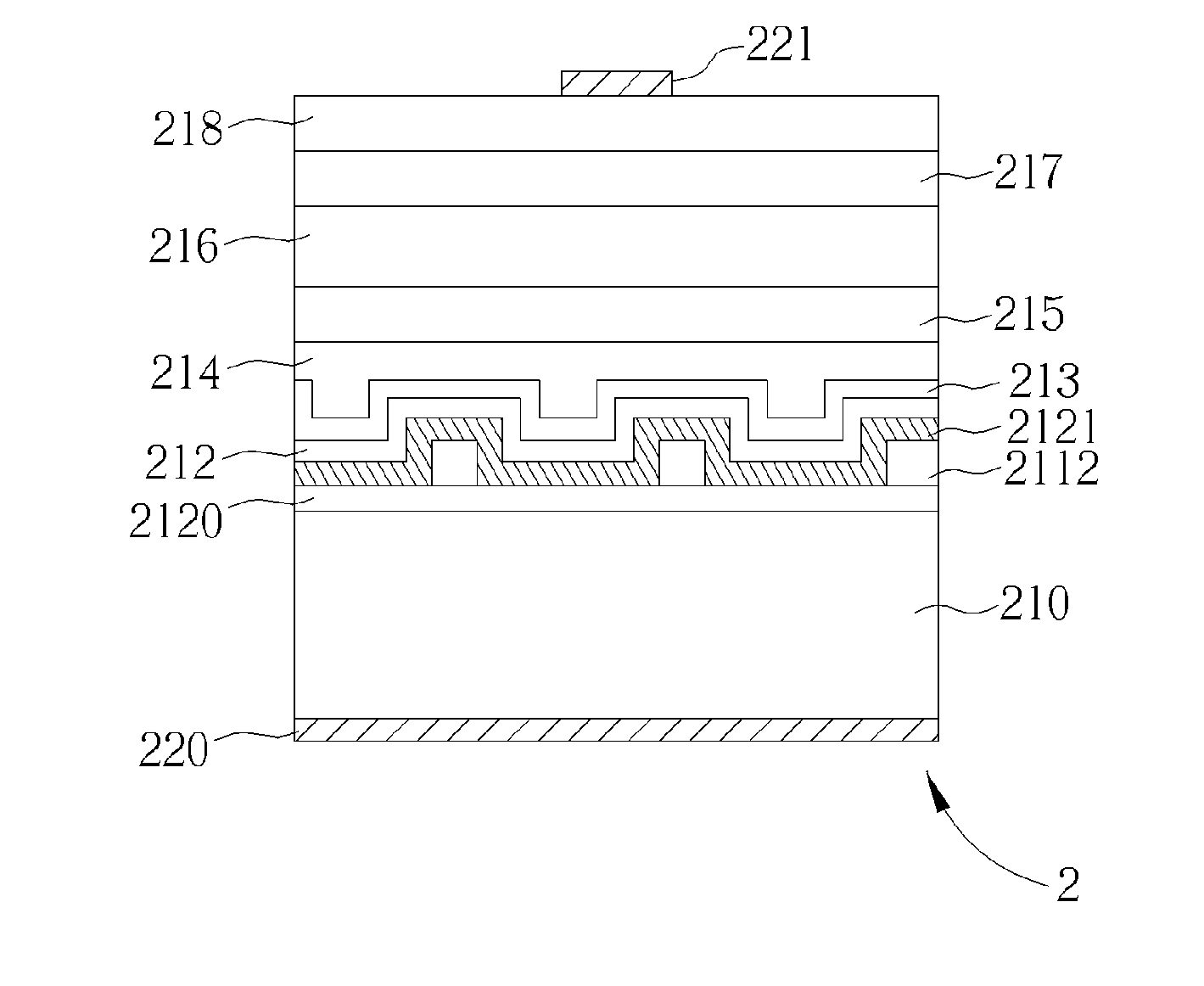

Thin film resistor structure

ActiveUS20130234292A1Simplify manufacturing processProcess be complicateSemiconductor/solid-state device detailsSolid-state devicesSheet resistanceEngineering

A thin film resistor structure includes a substrate, a flat bottom ILD (inter layer dielectric) disposed on the substrate, a plurality of first contacts disposed in the bottom ILD, and each top surface of the first contacts is on the same level as a top surface of the bottom ILD; a flat top ILD disposed on the bottom ILD, a plurality of second contacts disposed in the top ILD, and each top surface of the second contacts is on the same level as a top surface of the top ILD, and a thin film resistor disposed between the bottom ILD and the top ILD.

Owner:UNITED MICROELECTRONICS CORP

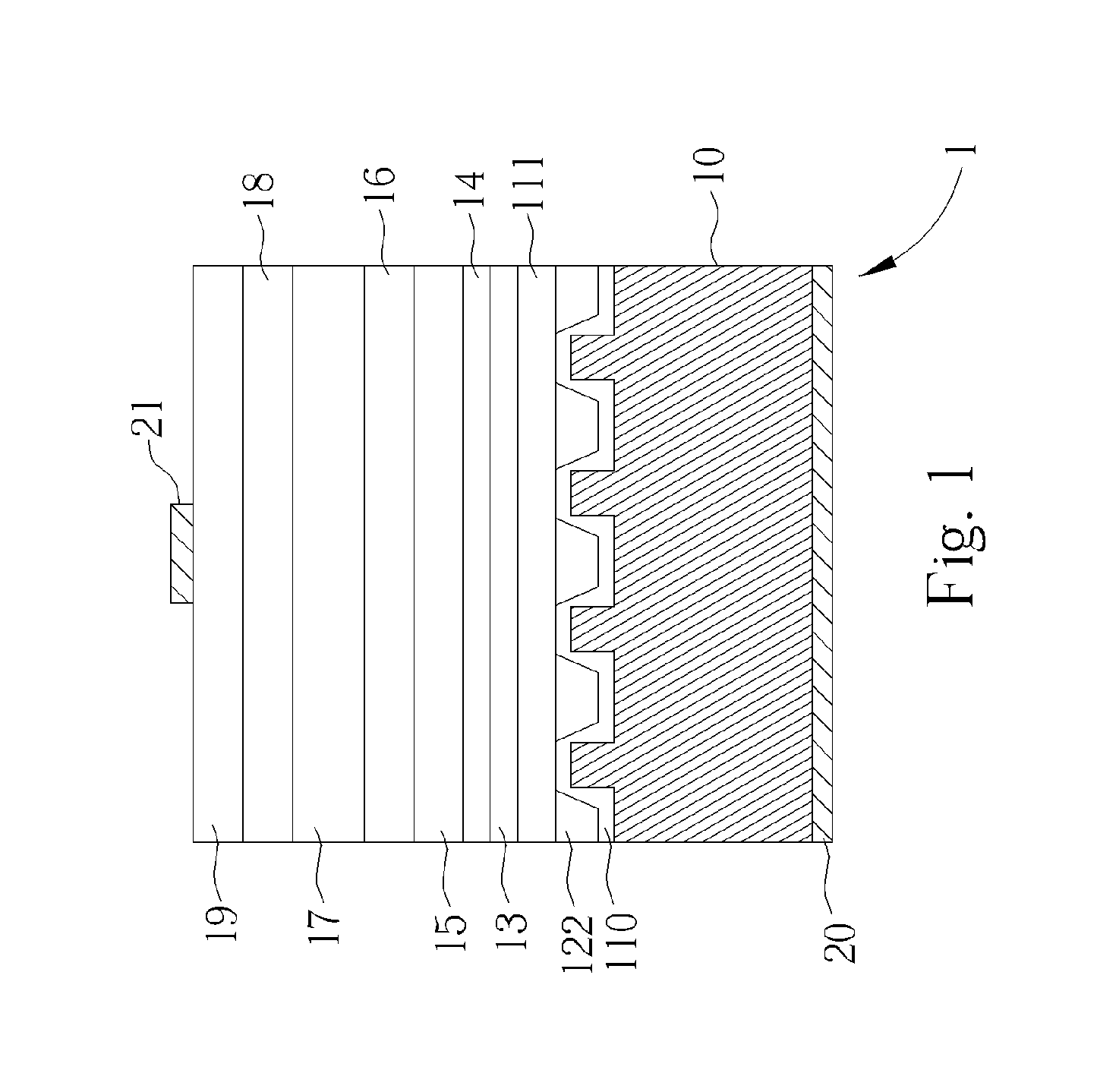

Organic adhesive light-emitting device with a vertical structure

ActiveUS20050184297A1Simplify manufacturing processCost reductionSemiconductor/solid-state device detailsElectroluminescent light sourcesChemistryOhmic contact

An organic adhesive light-emitting device with a vertical structure is provided. The organic adhesive light-emitting device comprises a conductive substrate with a concavo-convex upper surface; a first metal layer formed on the concavo-convex upper surface of the conductive substrate; an organic adhesive material formed over the first metal layer; a second metal layer formed over the organic adhesive material, wherein all or part of the first metal layer over the concavo-convex upper surface is in ohmic contact with the second metal layer through the organic adhesive material; a reflective layer formed over the second metal layer; and a light-emitting stack layer formed over the second metal layer. The process for manufacturing the present invention organic adhesive light-emitting device is less complex than that for manufacturing prior art diodes.

Owner:EPISTAR CORP

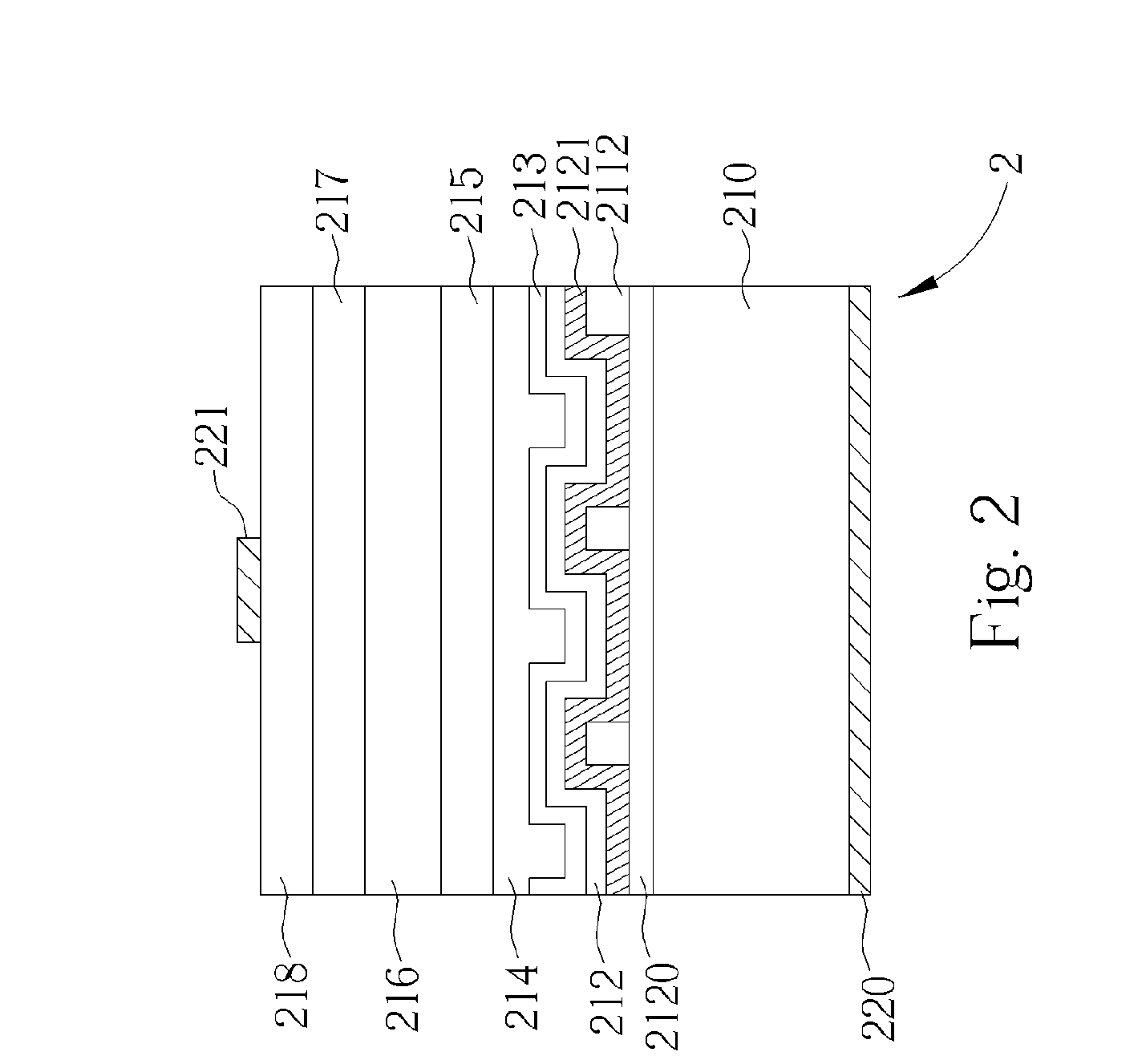

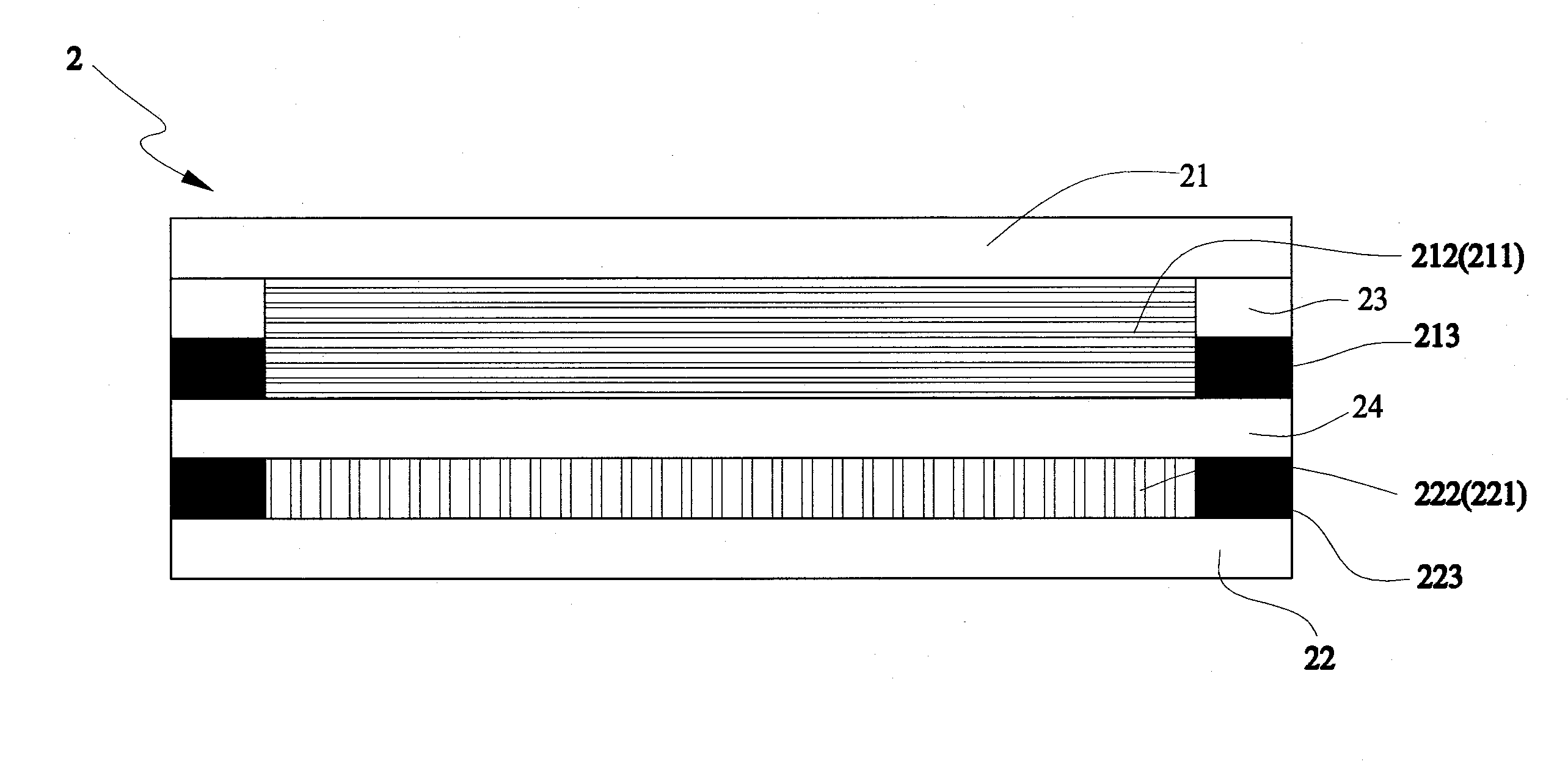

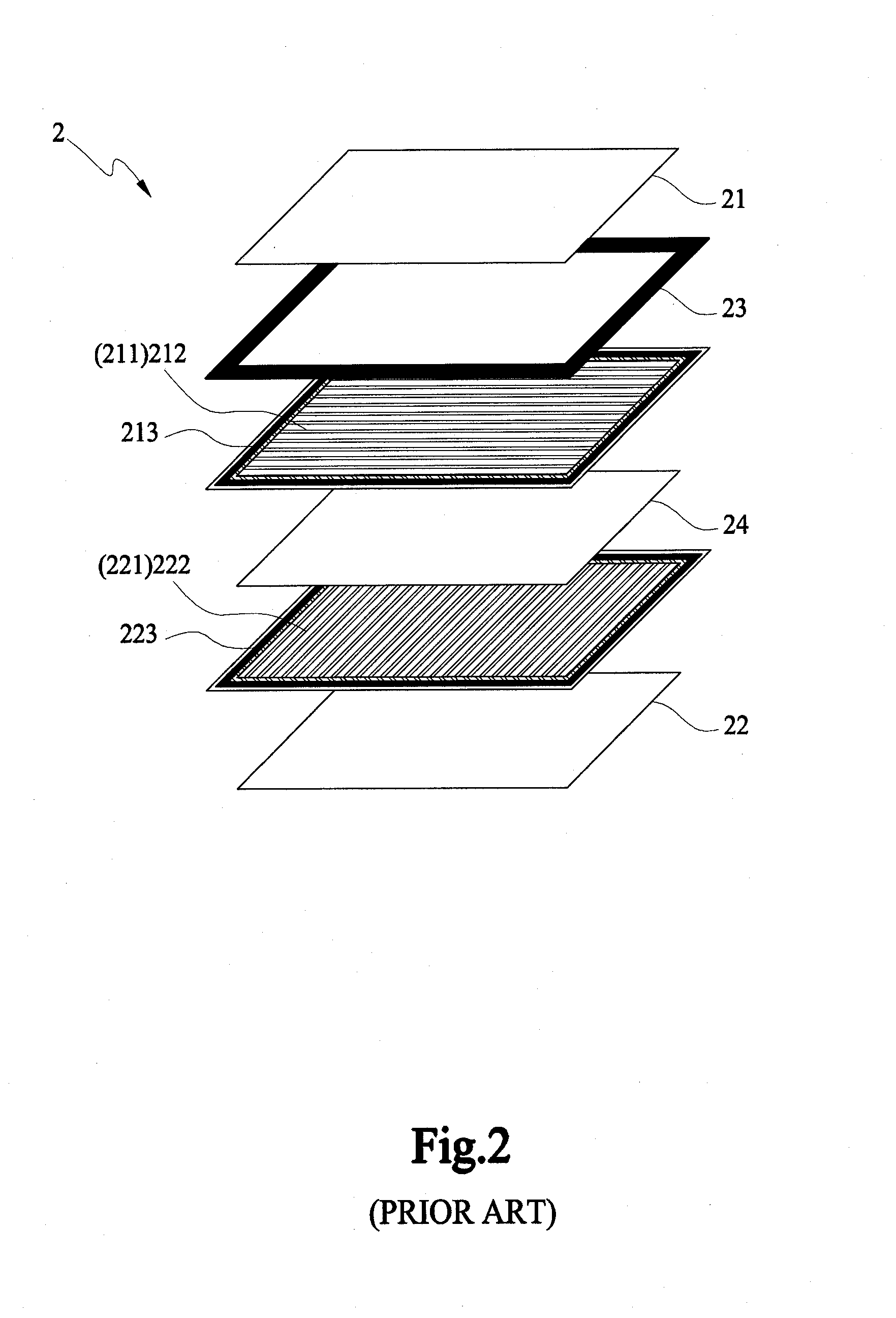

Capacitive touch device structure

InactiveUS20110132670A1Reduce thicknessSimplify manufacturing processTransmission systemsDetails for portable computersElectrically conductiveTransmittance

A capacitive touch device structure includes a first transparent substrate, a second transparent substrate, a picture layer at the periphery of a lower surface of the first transparent substrate, first and second transparent conductive thin films formed on corresponding surfaces of the two transparent substrates respectively, a plurality of first and second circuits, and an adhesive layer for laminating the first and second transparent substrates. After the corresponding surfaces of the capacitive touch device are attached, the first or second transparent conductive thin film and the first or second circuit are considered to be in the same plane, so as to achieve the effects of reducing the thickness of the capacitive touch device, improving the light transmittance effectively, minimizing the number of layers of the first or second transparent conductive thin film and the first or second circuit, simplifying the manufacturing process and improving the yield rate.

Owner:J TOUCH CORPORATION

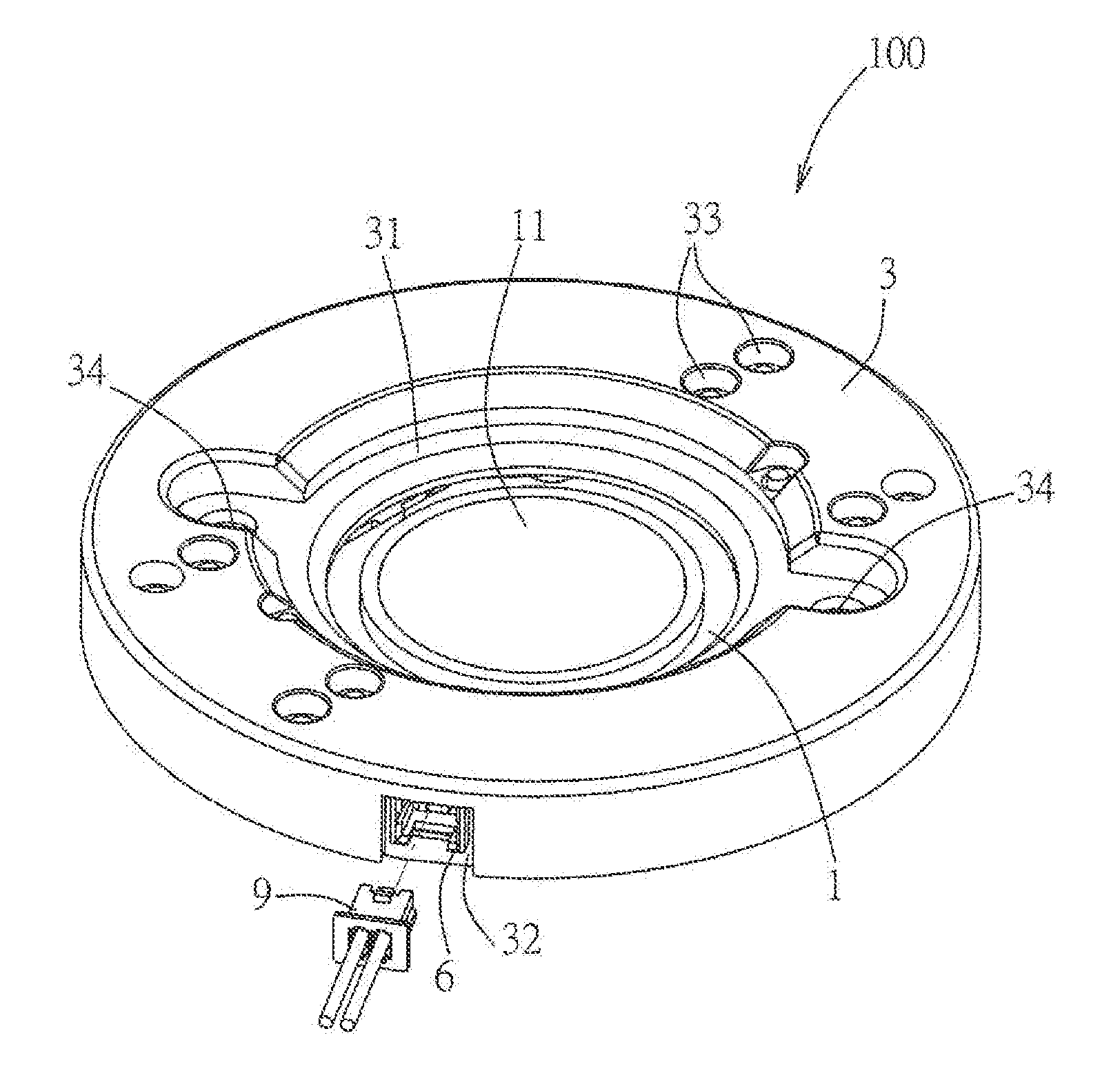

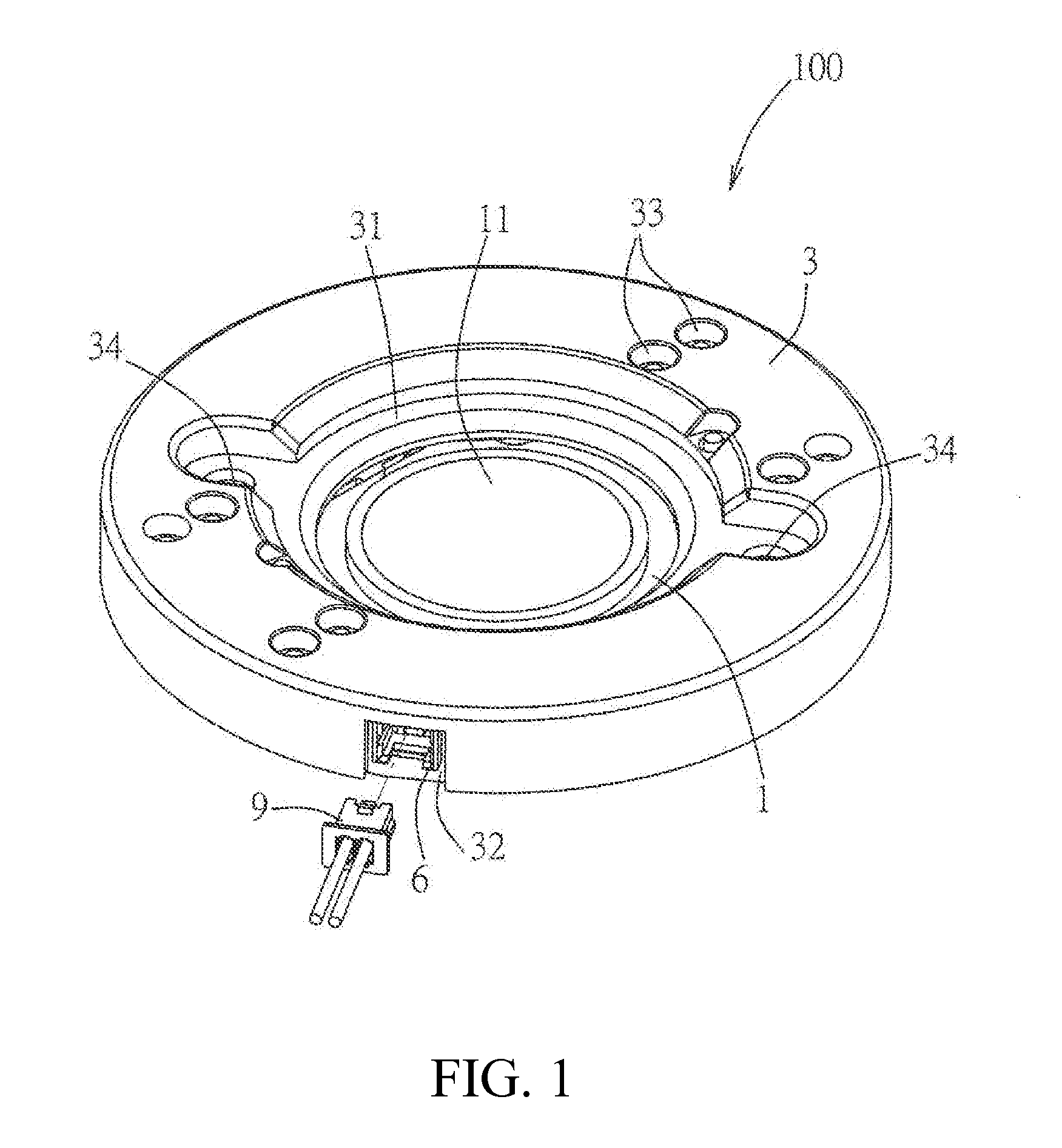

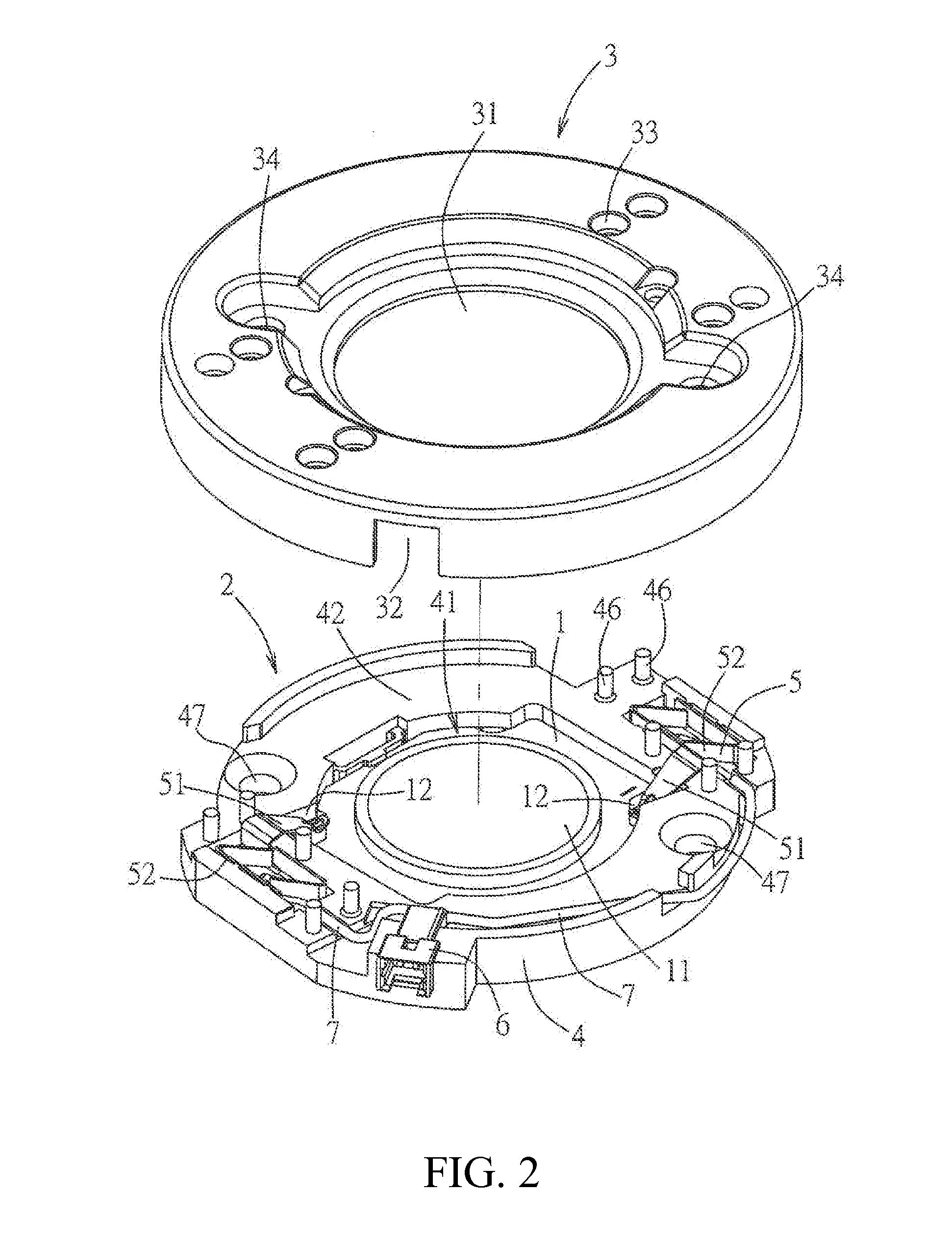

LED holder

ActiveUS20150131301A1Simplify manufacturing processCost savingPlanar light sourcesPoint-like light sourceContact padElectrical wiring

A holder comprises a base body, at least two terminals, a connector and at least two wires. The base body defines a receiving hole for receiving the light emitting module. The terminals are provided to the base body and each have a pressing contact portion and a wire insertion structure, the pressing contact portions extend into the receiving hole and respectively press against the contact pads of the light emitting module. The connector is provided to the base body so as to externally connect a mating connector. The wires respectively correspond to the terminals to allow one end of each wire to be detachably connected to the wire insertion structure of the corresponding terminal and the other end of the each wire to be connected to the connector so that the terminals and the connector are electrically connected.

Owner:MOLEX INC

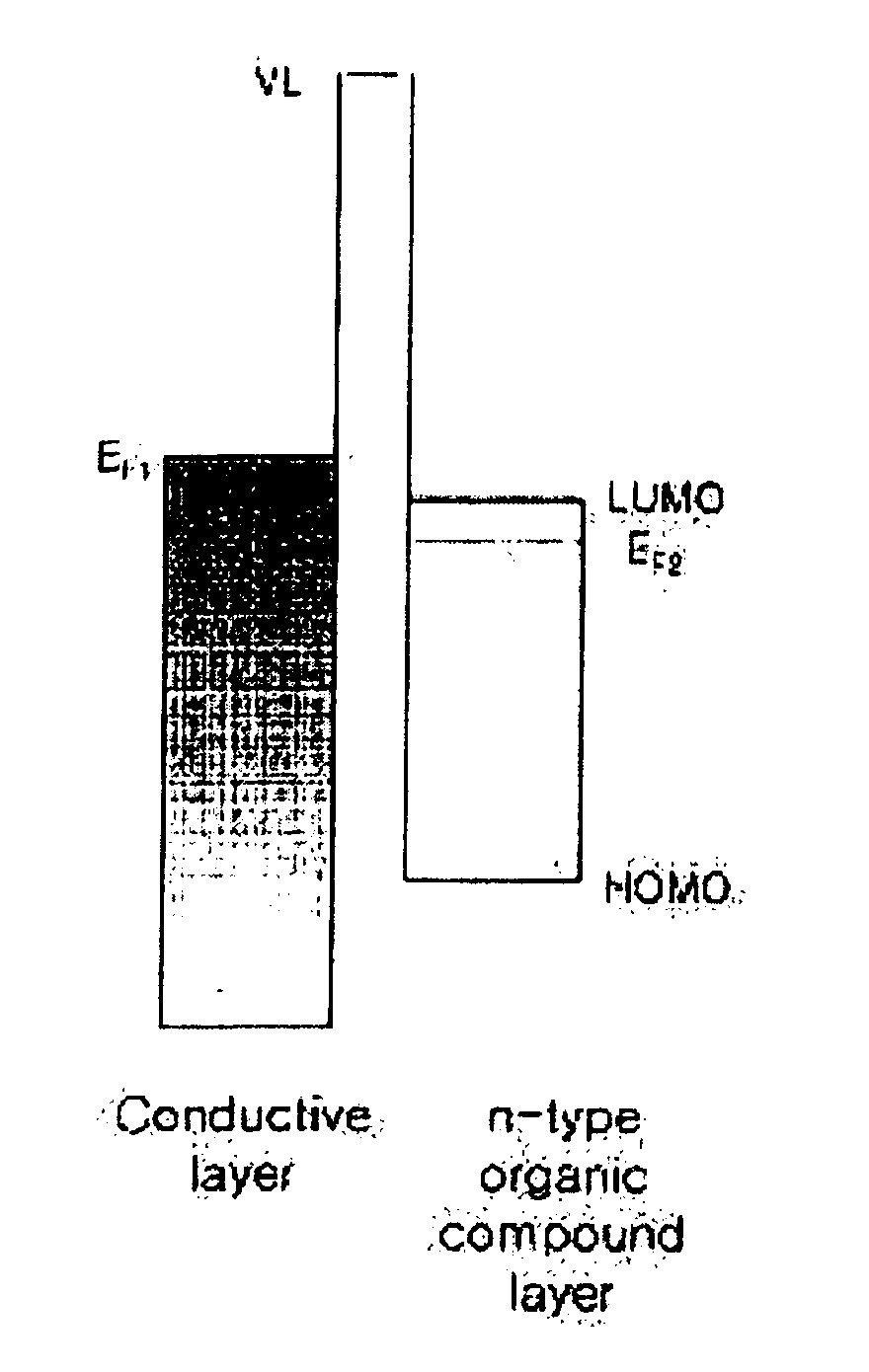

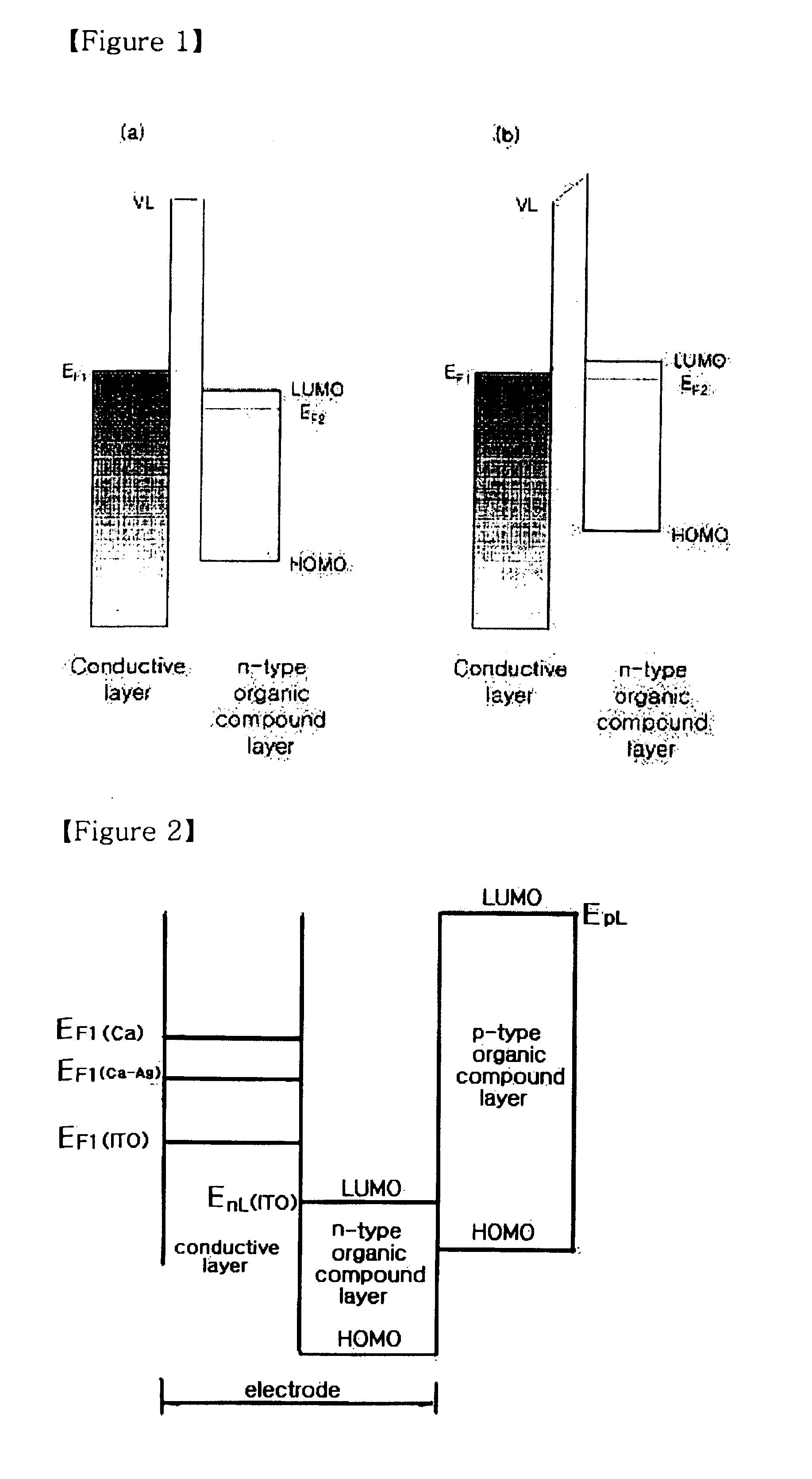

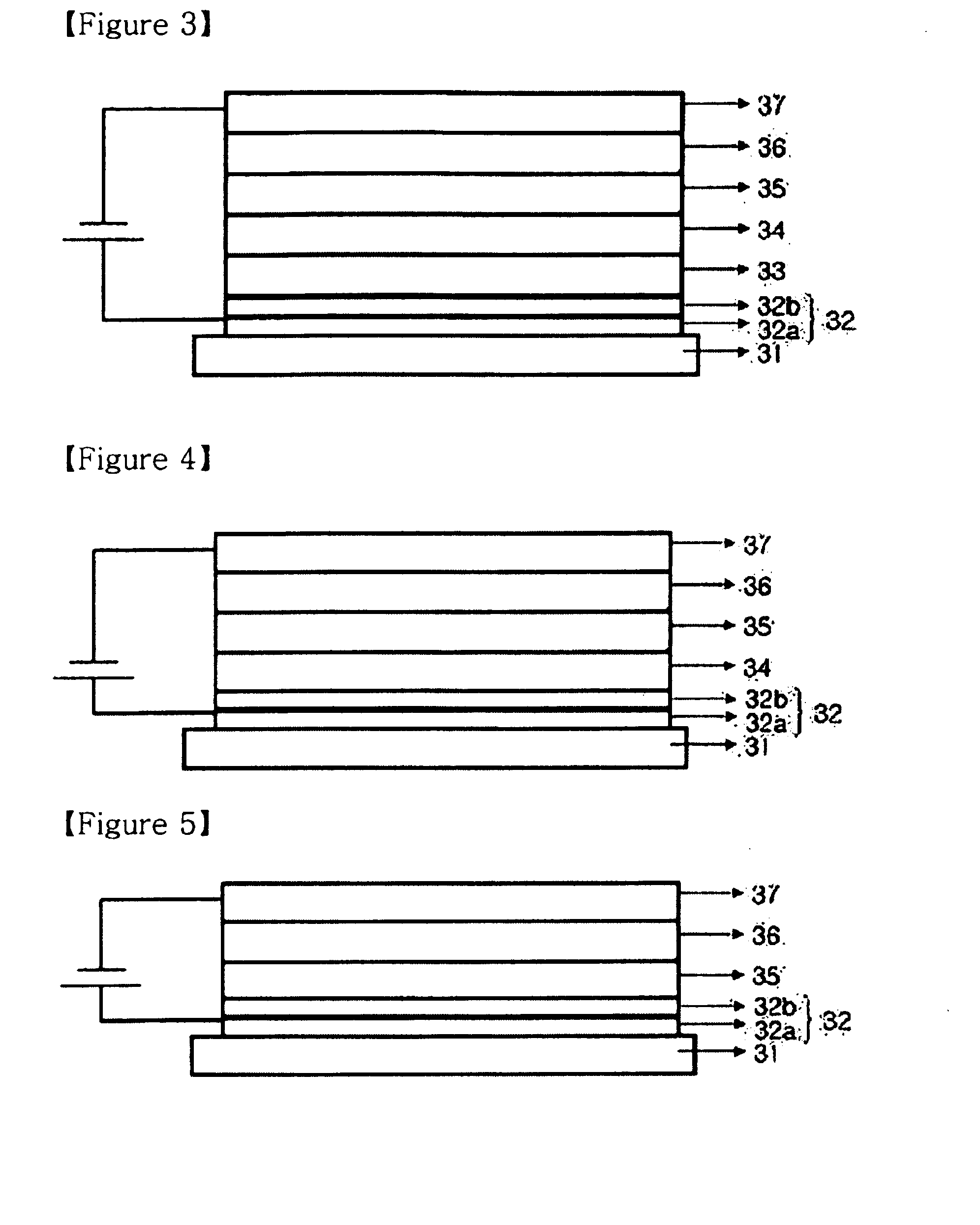

Organic electronic device

ActiveUS20070102698A1Simplify manufacturing processHigh efficiencyFinal product manufactureSolid-state devicesFermi energyOptoelectronics

Disclosed is an electronic device including an n-type organic compound layer as a portion of an electrode for hole injection or hole extraction. The electronic device includes a first electrode including a conductive layer and an n-type organic compound layer disposed on the conductive layer; a second electrode; and a p-type organic compound layer that is interposed between the n-type organic compound layer of the first electrode and the second electrode and forms an NP junction together with the n-type organic compound layer of the first electrode and energy levels of the layers satisfy the following Expressions (1) and (2): 2 eV<EnL−EF1≦4 eV (1) EpH−EnL≦1 eV (2) where EF1 is a Fermi energy level of the conductive layer of the first electrode, EnL is an LUMO energy level of the n-type organic compound layer of the first electrode, and EpH is an HOMO energy level of the p-type organic compound layer forming the NP junction together with the n-type organic compound layer of the first electrode.

Owner:LG CHEM LTD

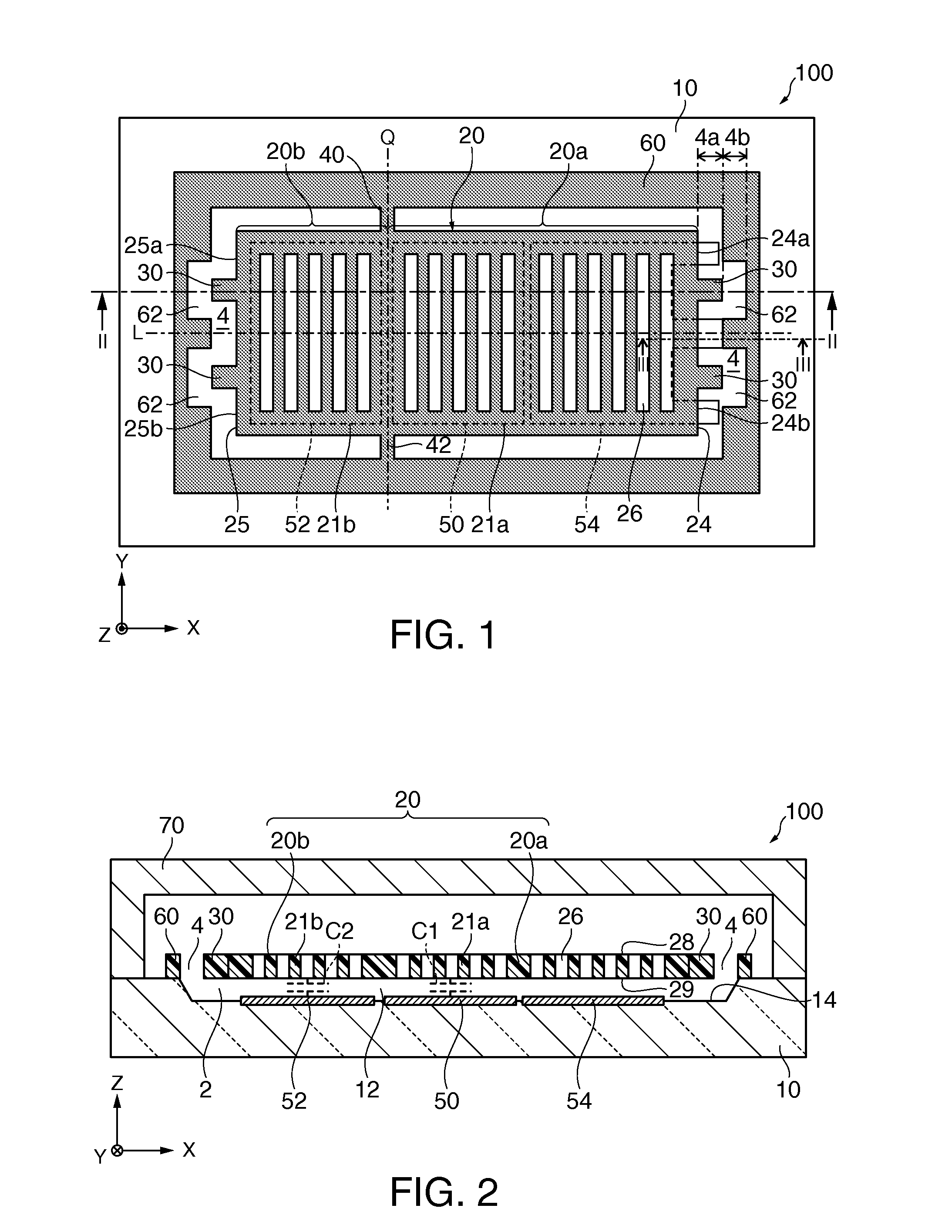

Physical quantity sensor and electronic apparatus

ActiveUS20130192370A1Simplify manufacturing processHigh reliabilityAcceleration measurement using interia forcesPhysicsElectric equipment

A physical quantity sensor includes a substrate, an oscillating member that is disposed over the substrate, support portions that support the oscillating member and that are disposed along a first axis, and detection electrodes that are disposed on the substrate so as to oppose the oscillating member. The oscillating member has a pair of side faces intersecting a second axis perpendicular to the first axis in a plane, and a protrusion is formed on at least one of the pair of side faces.

Owner:SEIKO EPSON CORP

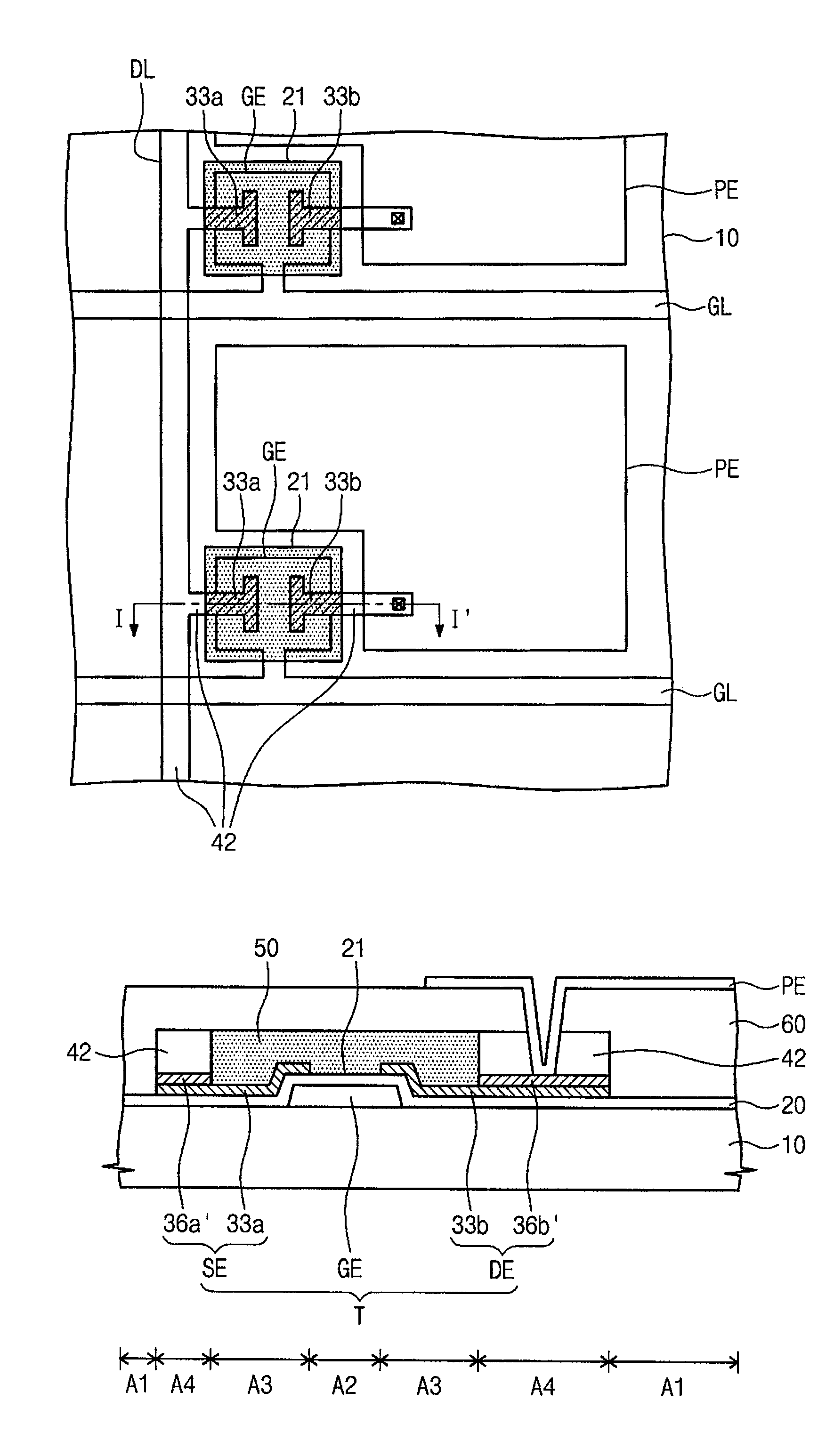

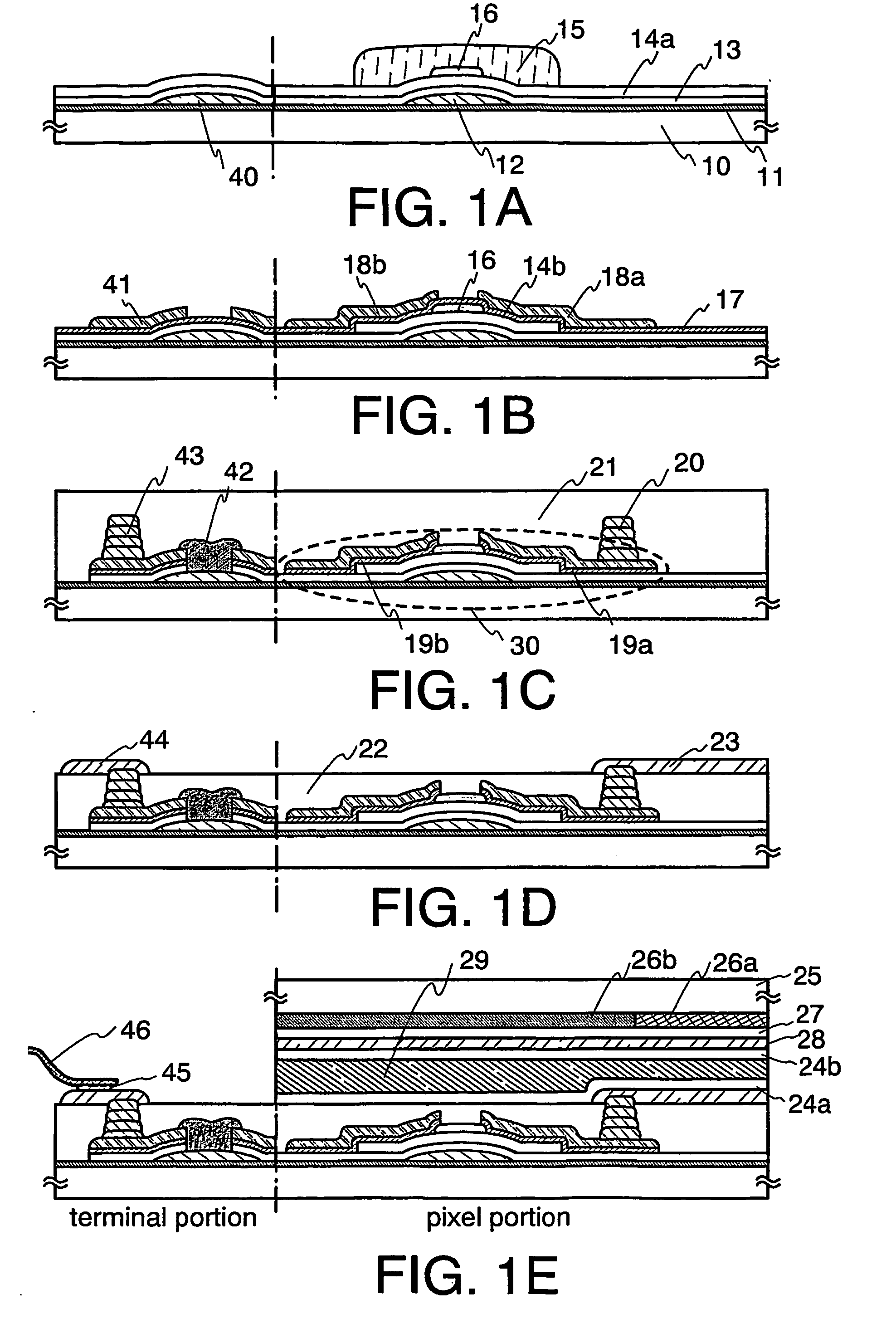

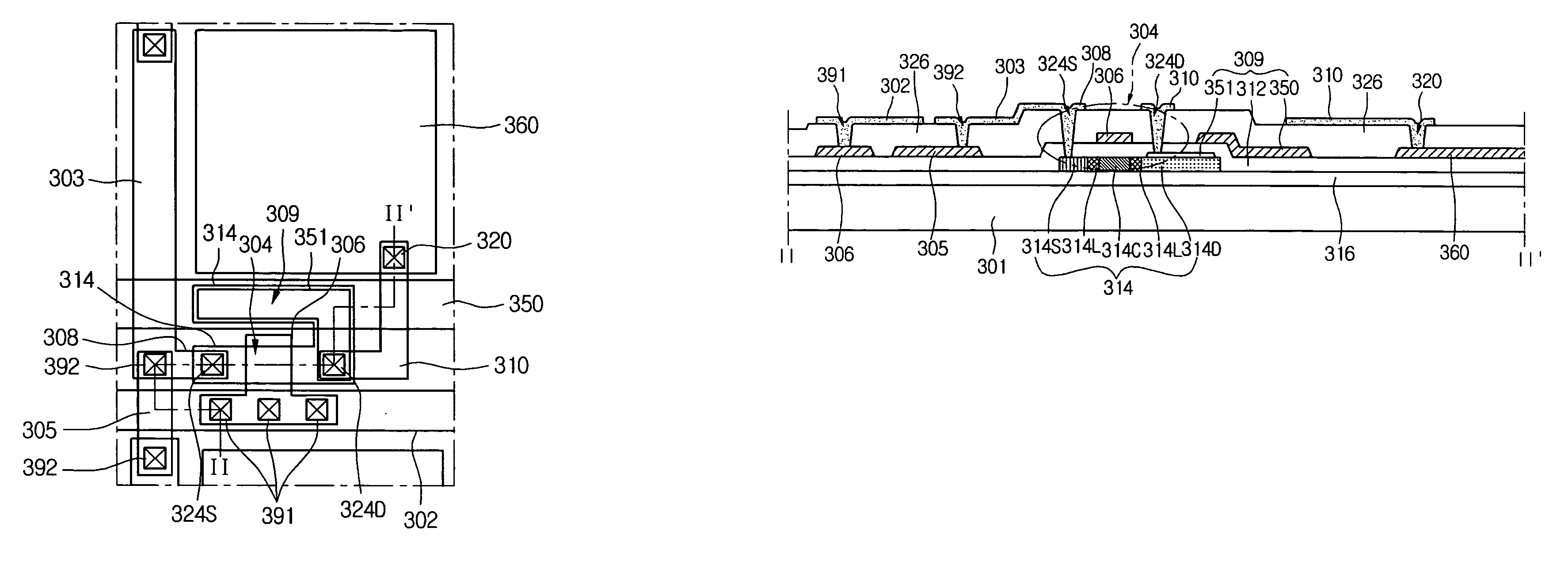

Display substrate and method of manufacturing the same

ActiveUS20090146137A1Simplify manufacturing processManufacturing cost be reduceSolid-state devicesSemiconductor/solid-state device manufacturingResistPhotolithography

In a manufacturing method of a display substrate according to one or more embodiments, a plurality of thin films are patterned by using a photoresist film pattern having different thicknesses in each area on a substrate as etch masks. The photoresist film pattern may be etch-backed at least twice during the manufacturing process of the display substrate and may be used as the etch mask for patterns having shapes different from each other. Accordingly, the number of processes for manufacturing the mask patterns, which may be formed by a photolithography method in order to pattern the thin films formed on the substrate, may be reduced.

Owner:SAMSUNG DISPLAY CO LTD

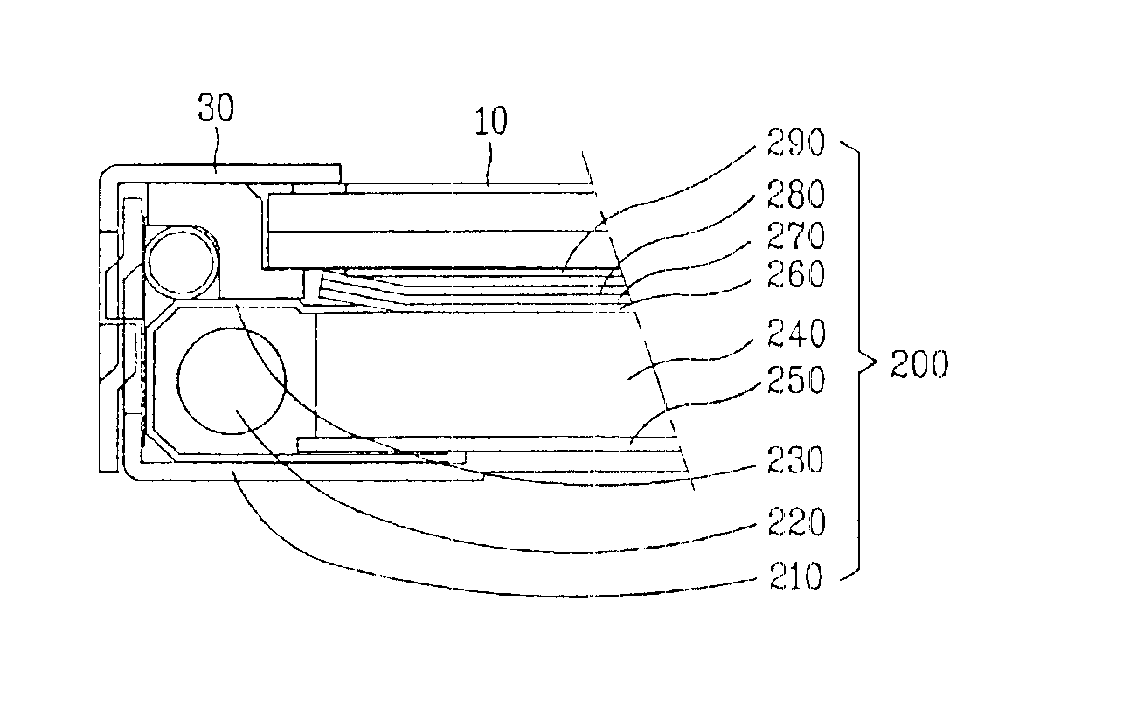

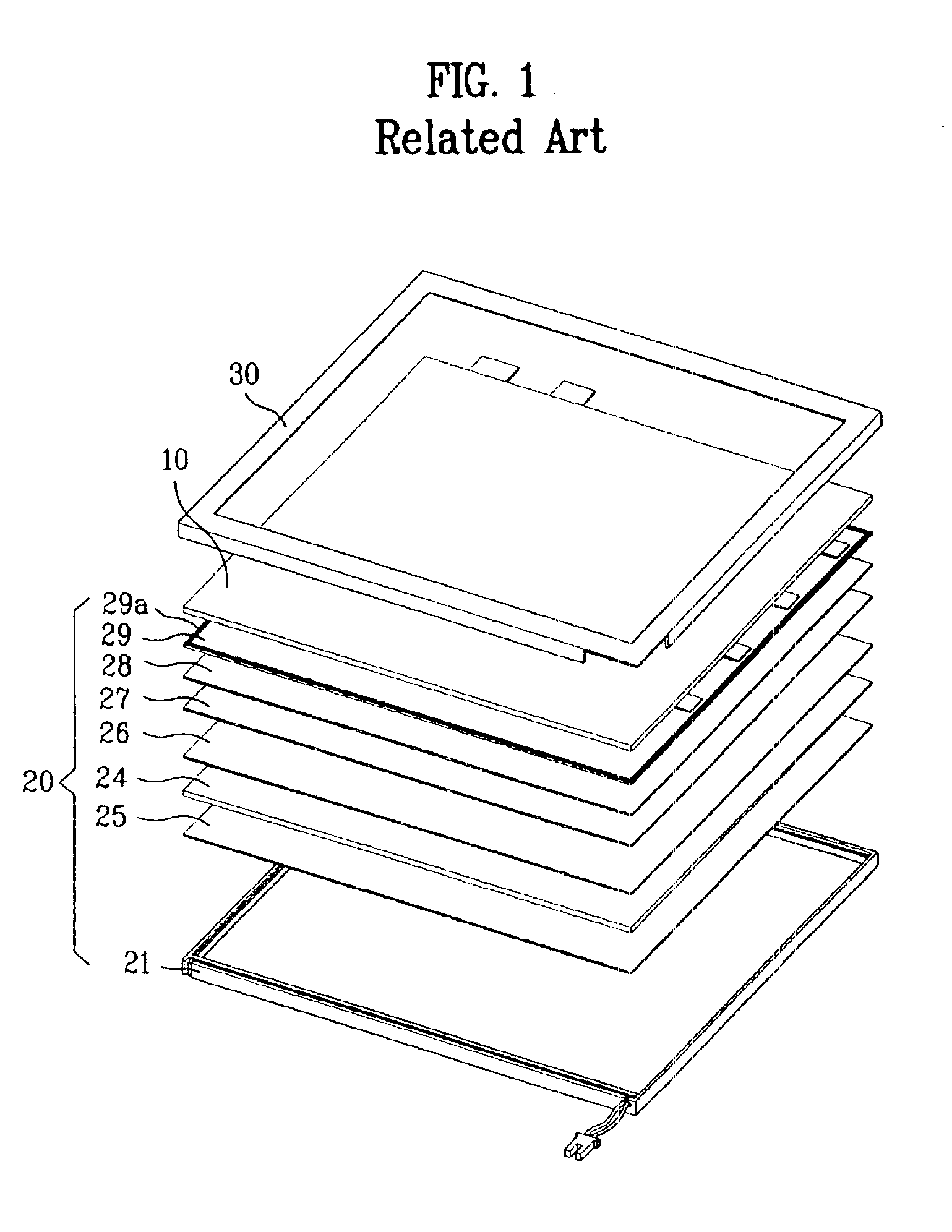

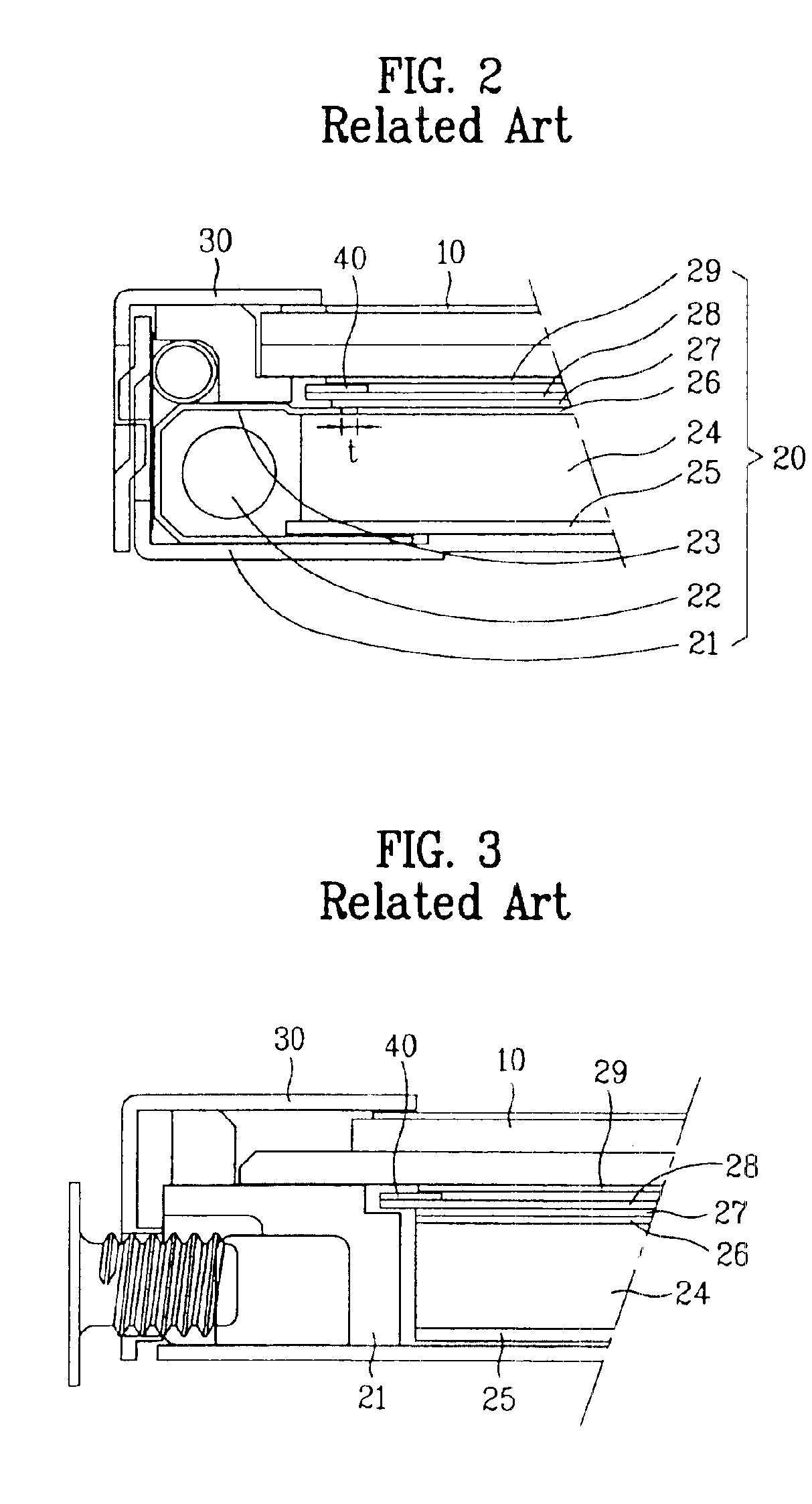

Backlight assembly of liquid crystal display device

InactiveUS6891580B2Simplify manufacturing processPrevent light leakageShow cabinetsMechanical apparatusLiquid-crystal displayLiquid crystal

A backlight assembly of a liquid crystal display (LCD) device is disclosed, in which each edge of the diffusion and prism sheets is extended to upper surfaces of the metal reflecting plate and the mold frame, so that it is possible to prevent light emitted from a lamp from leaking into a liquid crystal panel without passing through one of the diffusion and prism sheet.

Owner:LG DISPLAY CO LTD

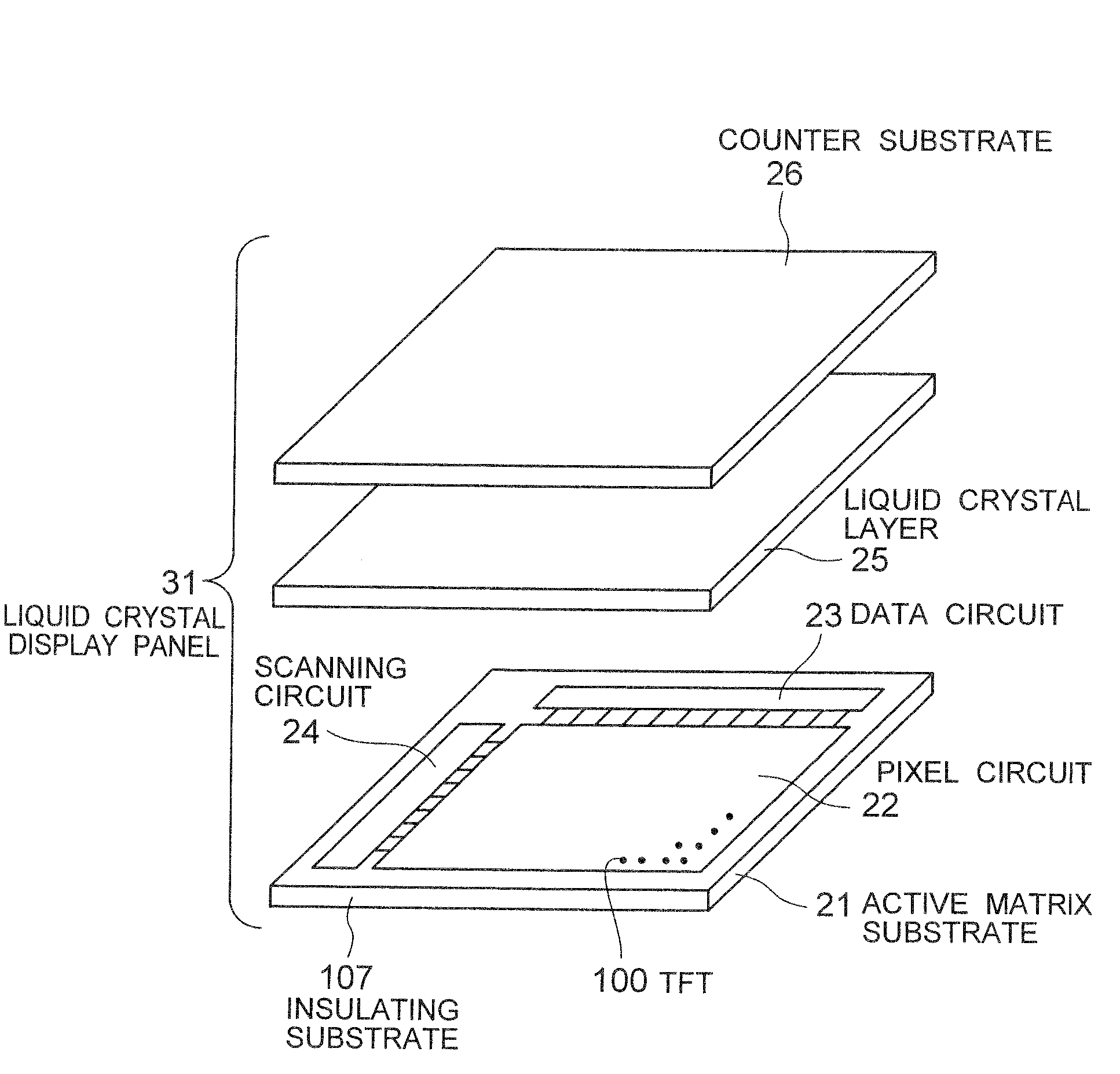

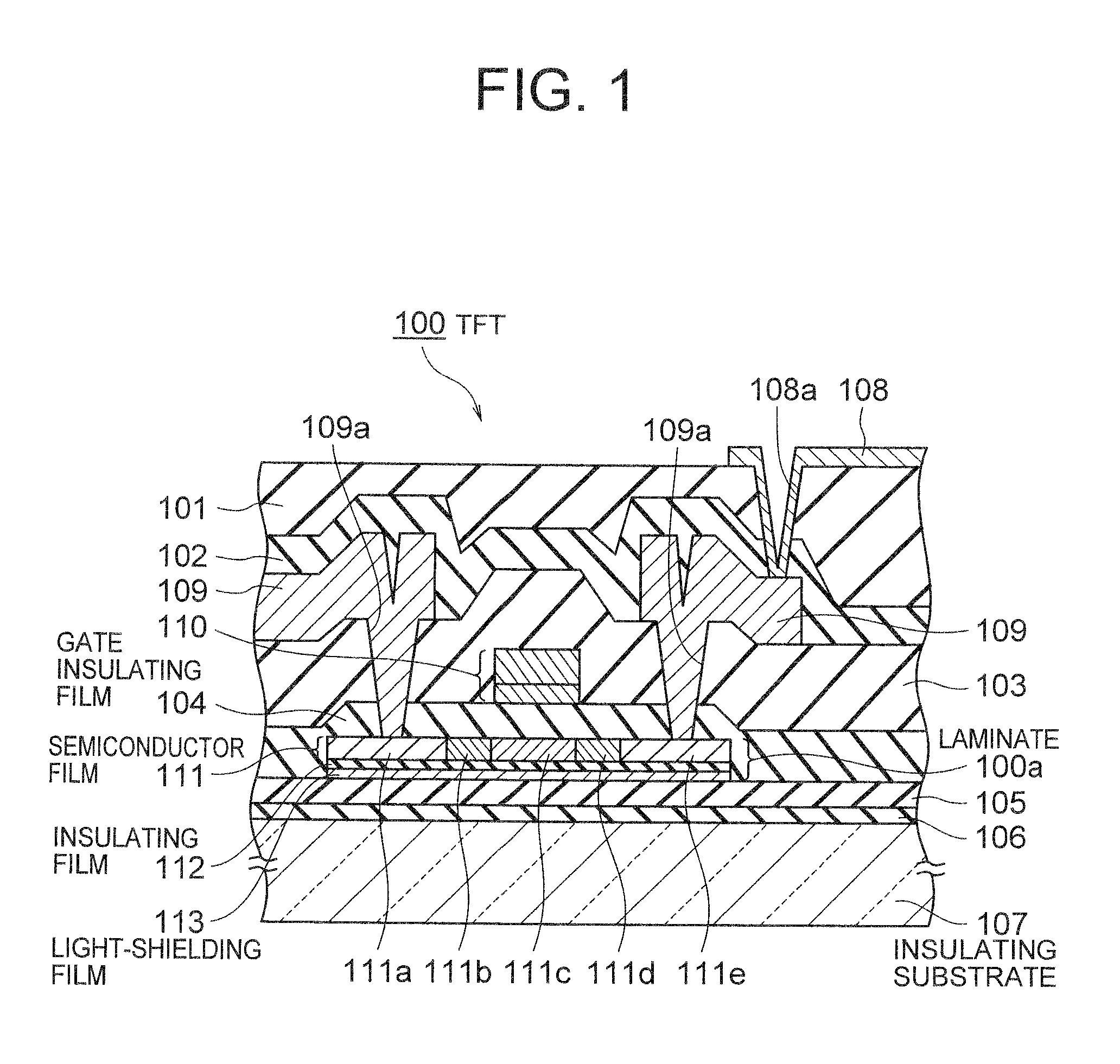

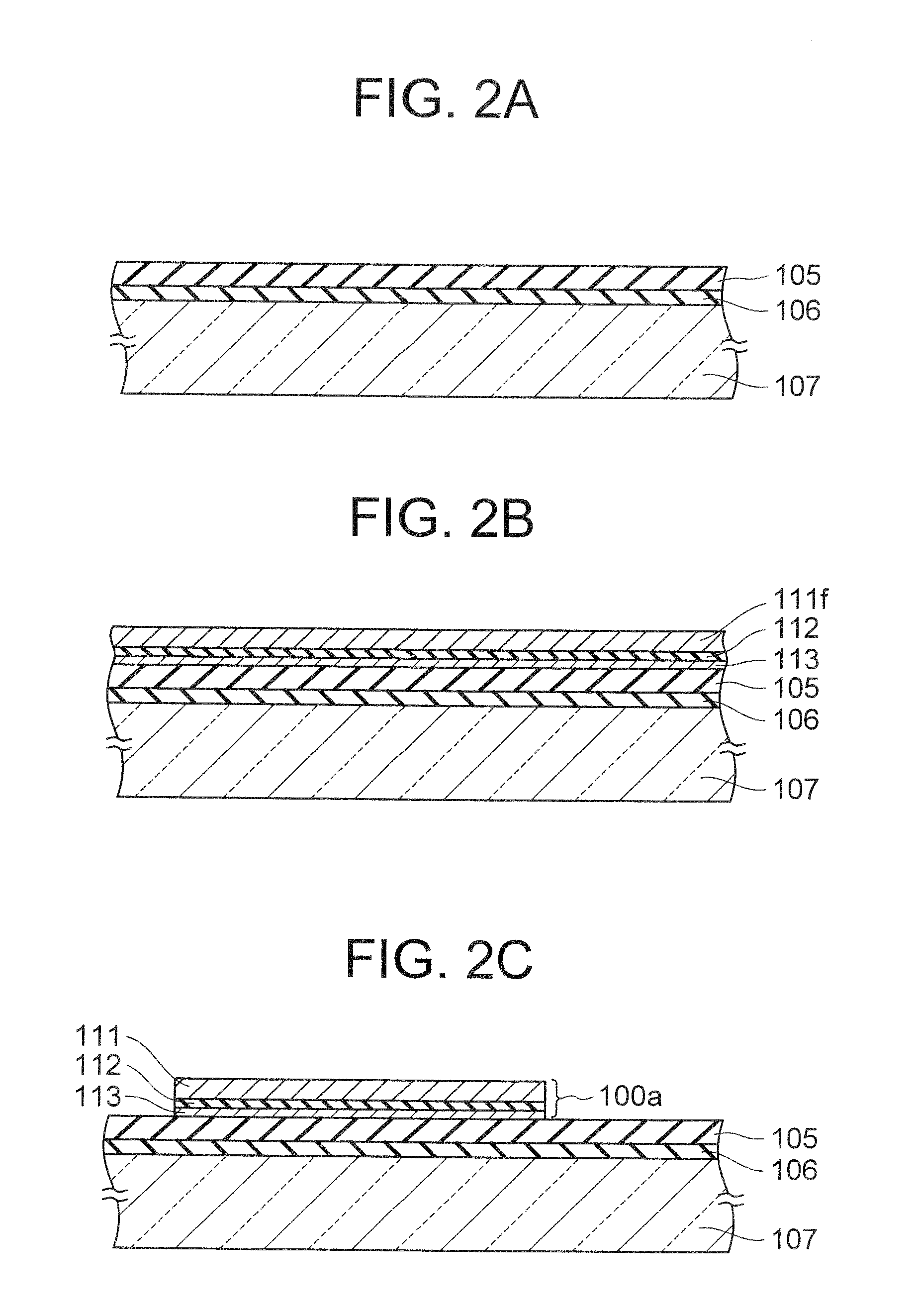

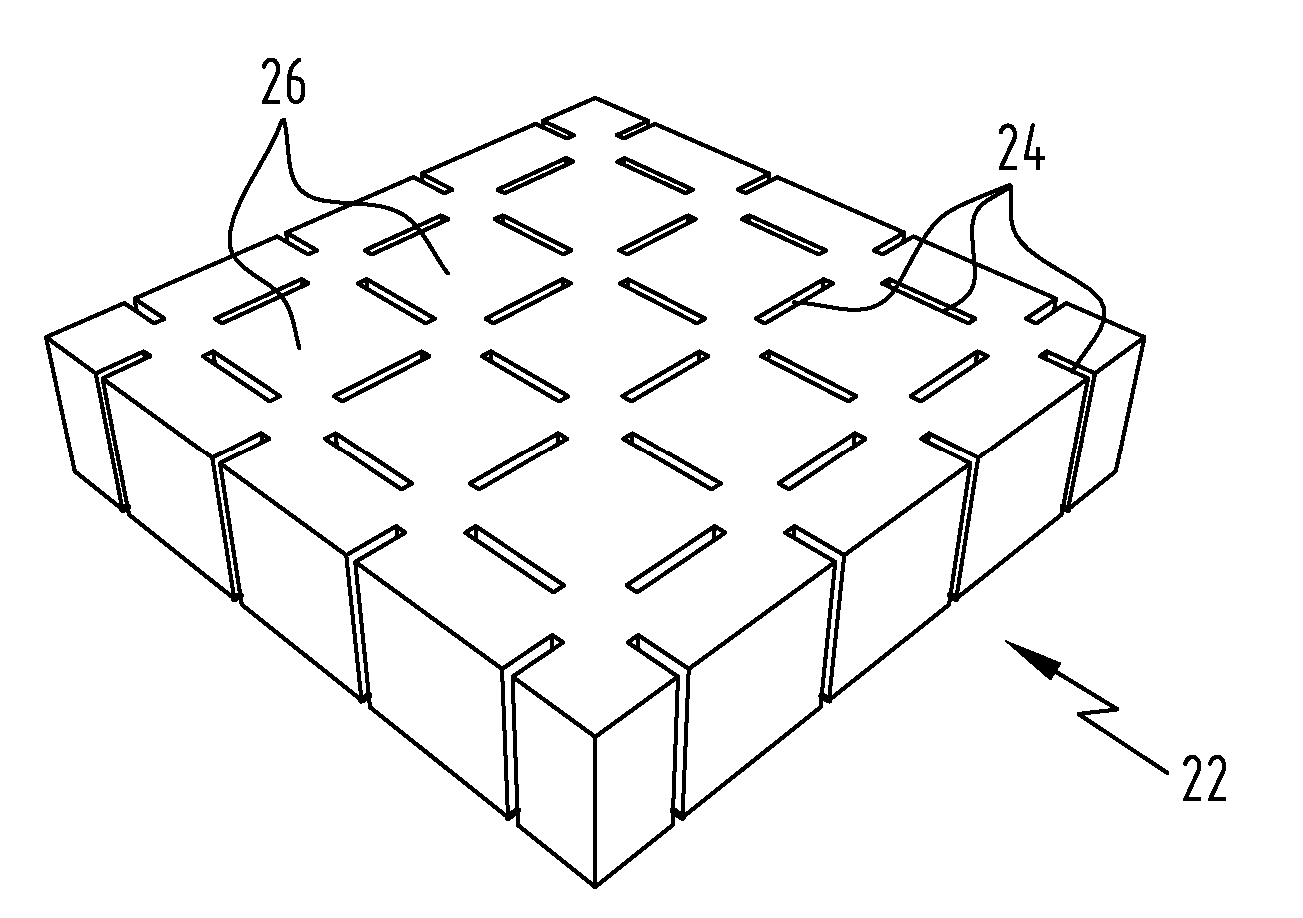

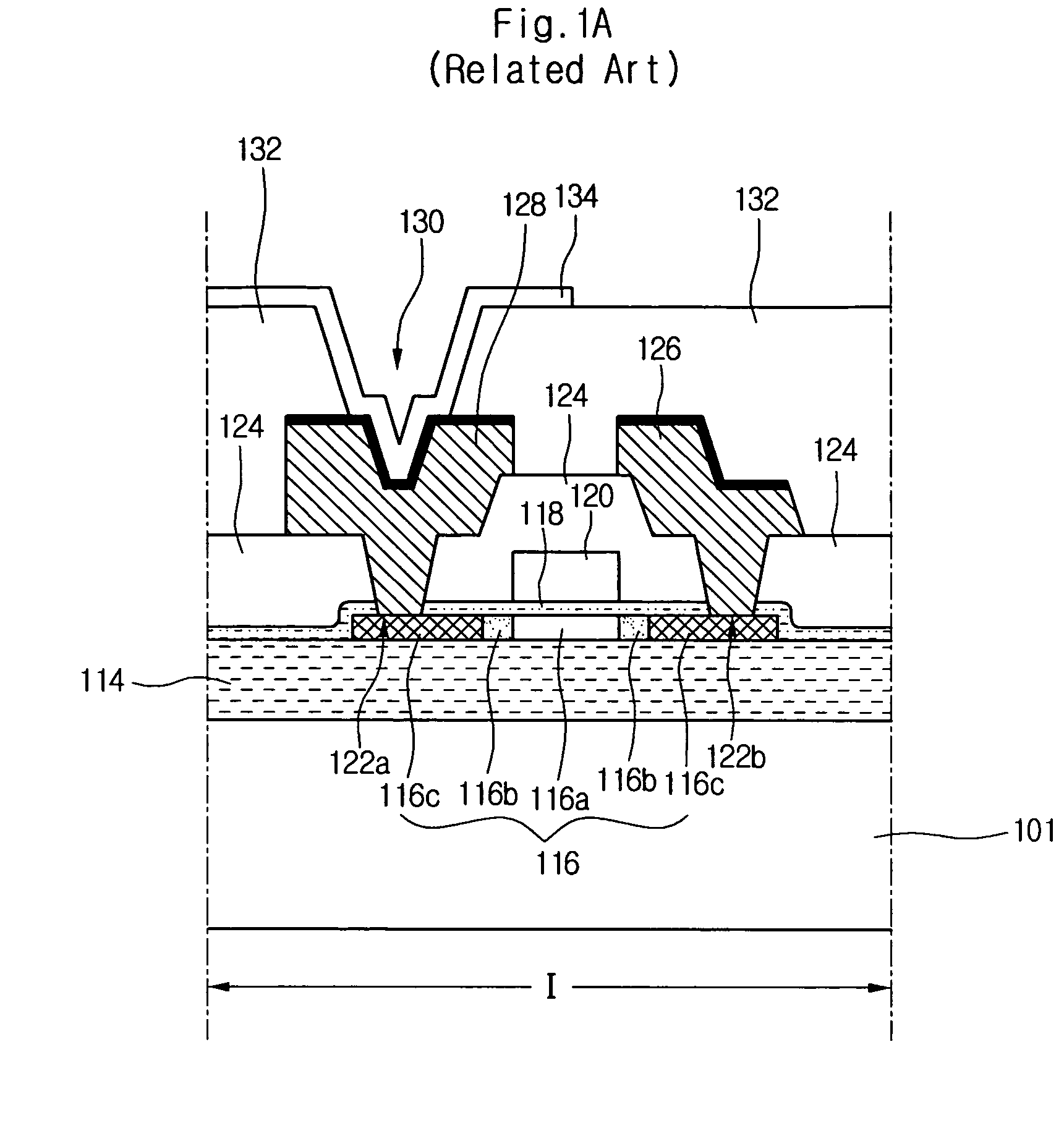

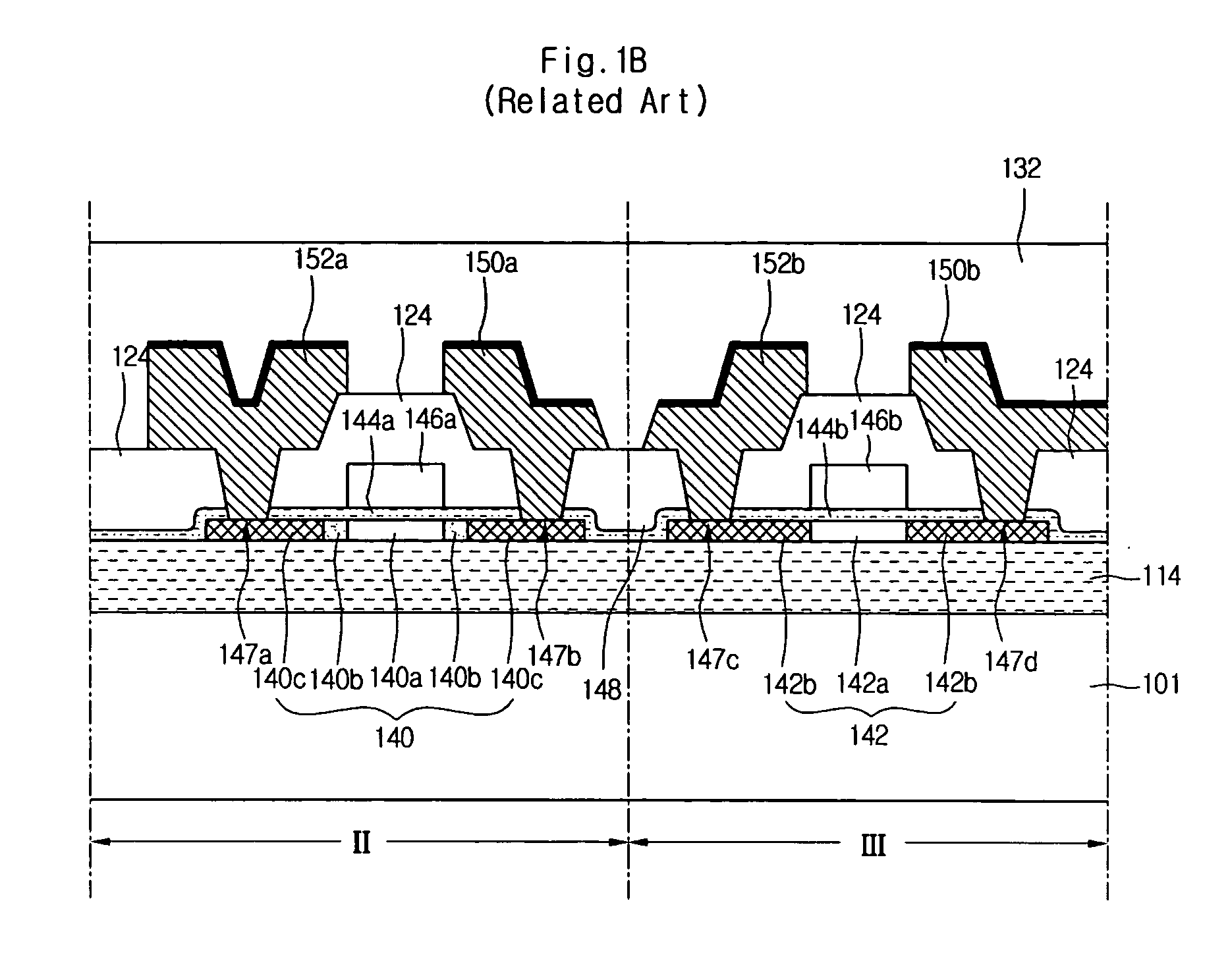

Thin film transistor and manufacturing method of the same

ActiveUS20090014721A1Low costSimplify manufacturing processTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

To achieve TFT having a high light-resistance characteristic with a suppressed light leak current at low cost by simplifying the manufacturing processes. The TFT basically includes a light-shielding film formed on a glass substrate that serves as an insulating substrate; an insulating film formed on the light-shielding film; a semiconductor film formed on the insulating film; and a gate insulating film formed on the semiconductor film. Each layer of a laminate that is configured with three layers of the light-shielding film, the insulating film, and the semiconductor film is patterned simultaneously. Further, each layer of the laminate is configured with silicon or a material containing silicon.

Owner:NEC LCD TECH CORP

Ceramic Armor Plate, an Armor System, and a Method of Manufacturing a Ceramic Armor Plate

A ceramic armor plate is proposed which is formed in one piece and which comprises a plurality of connected segments that are functionally separated by crack stoppers, whereby the crack stoppers serve to prevent the propagation of cracks from one segment to a neighboring segment.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

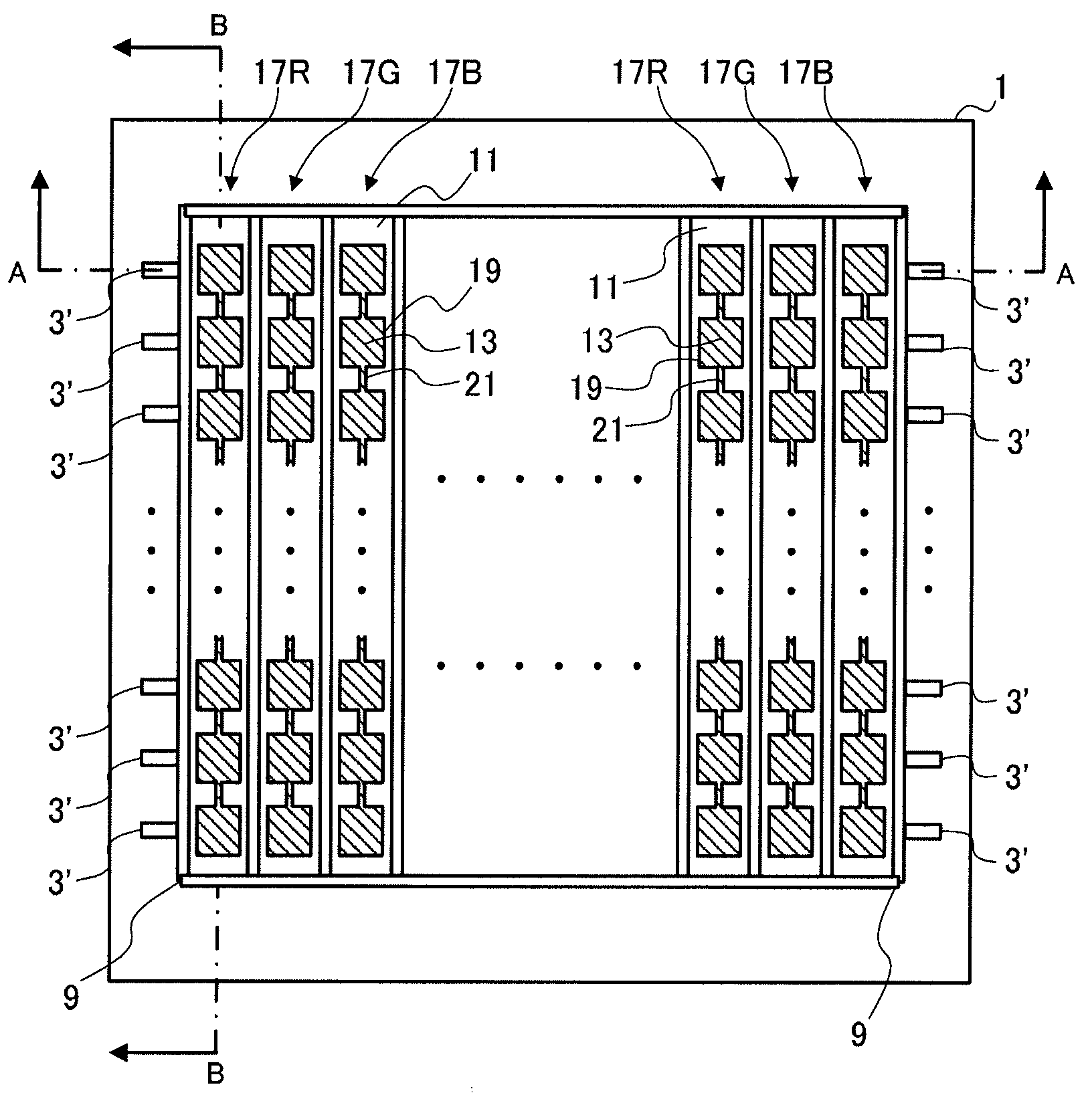

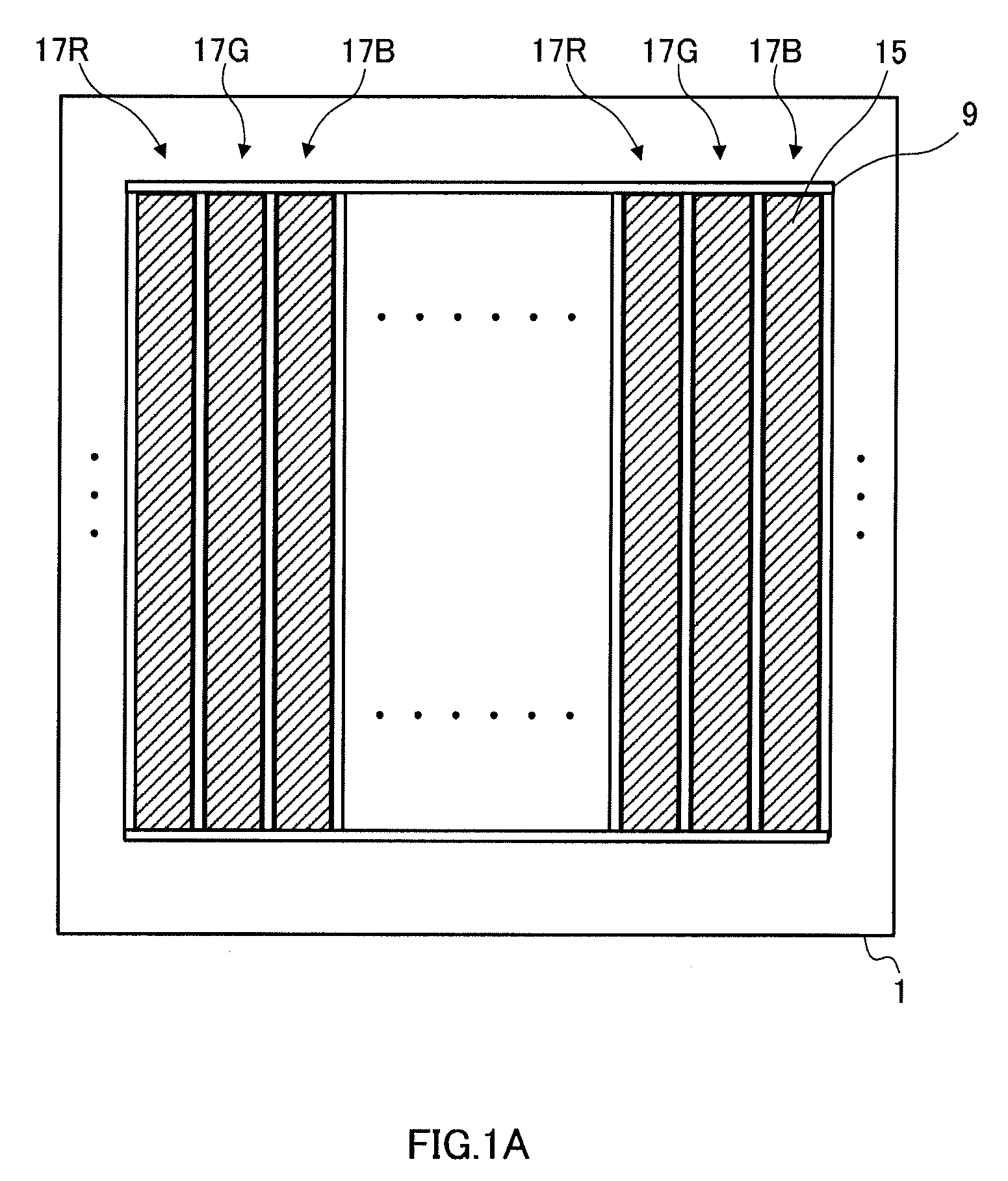

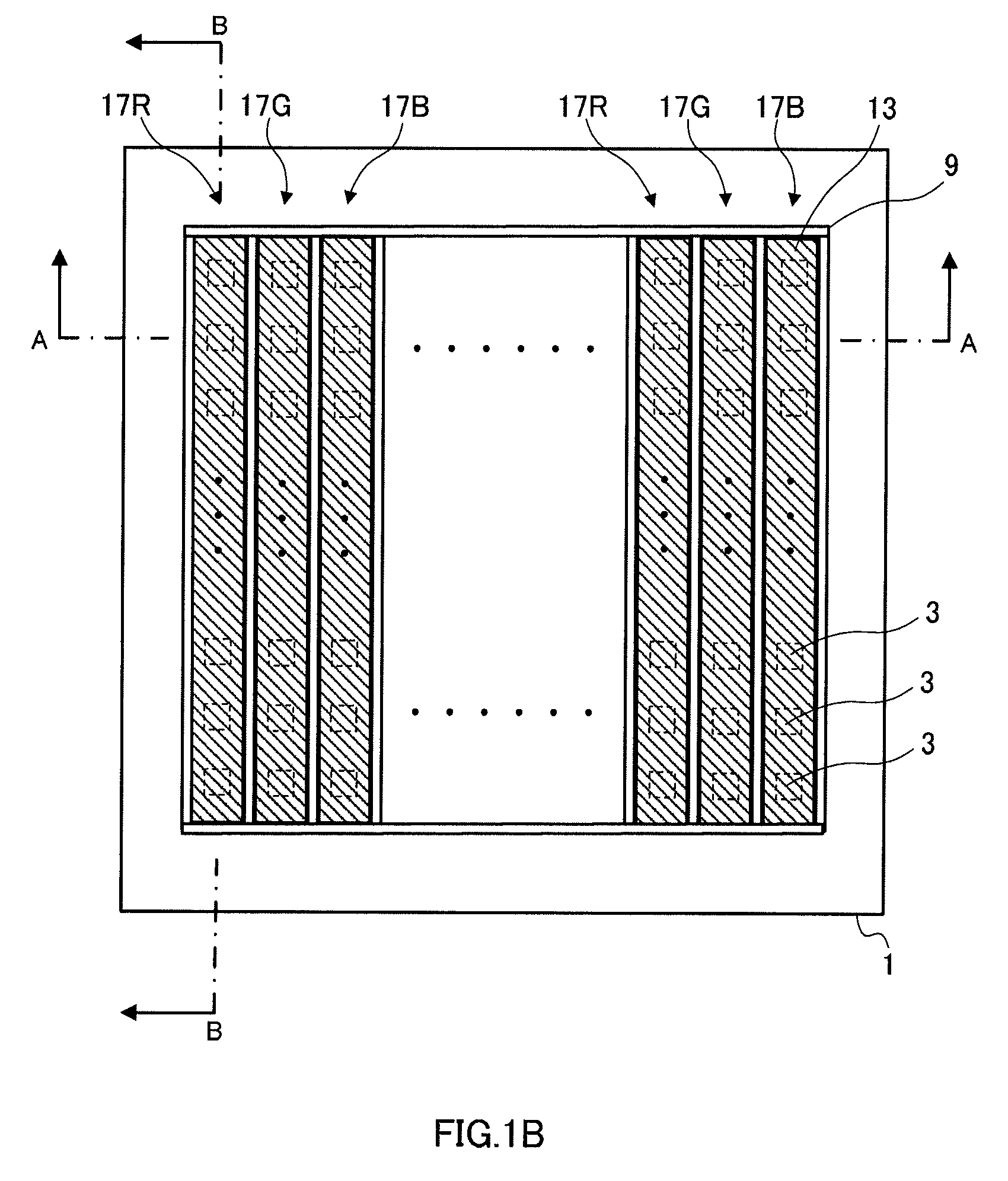

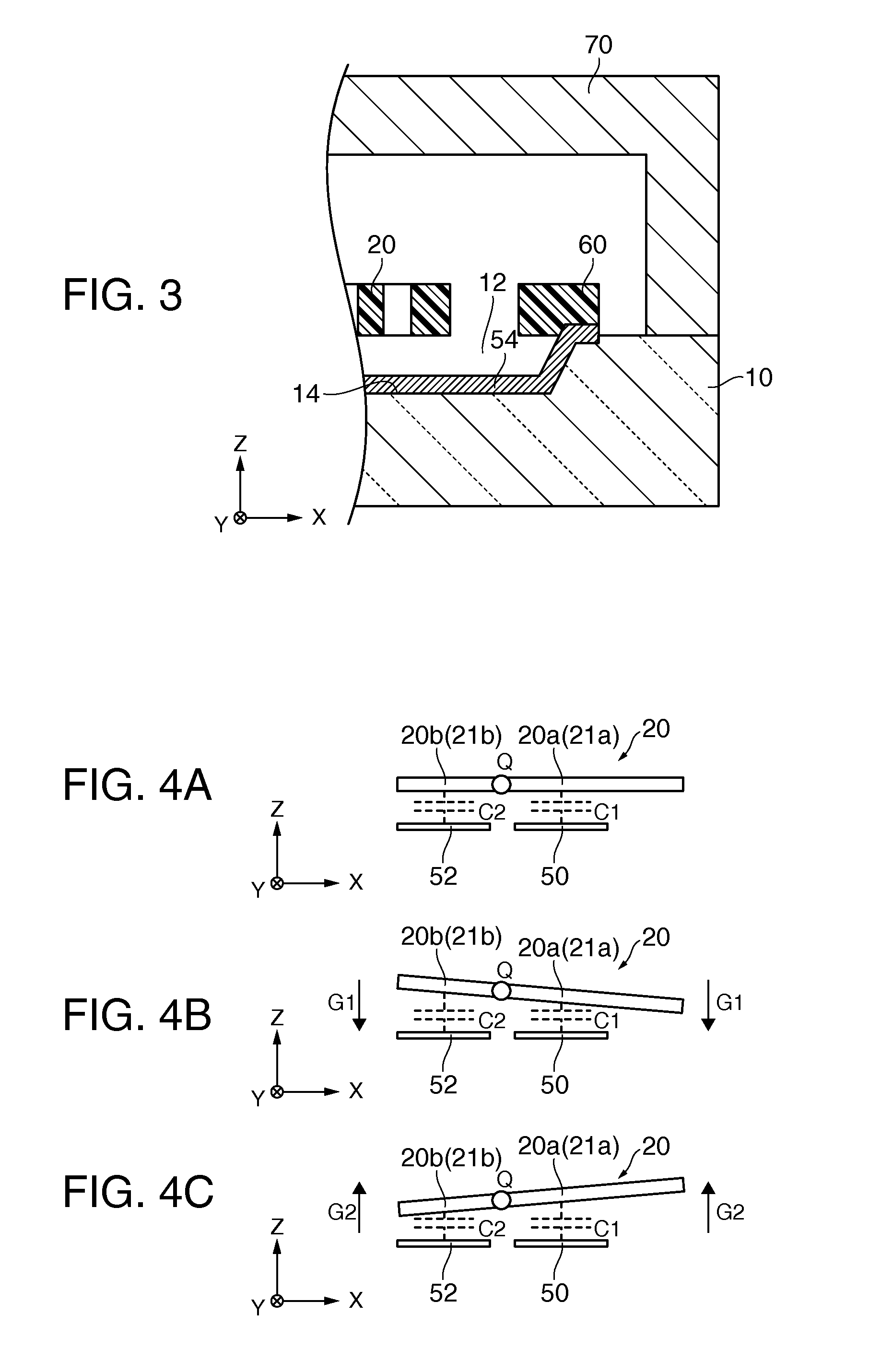

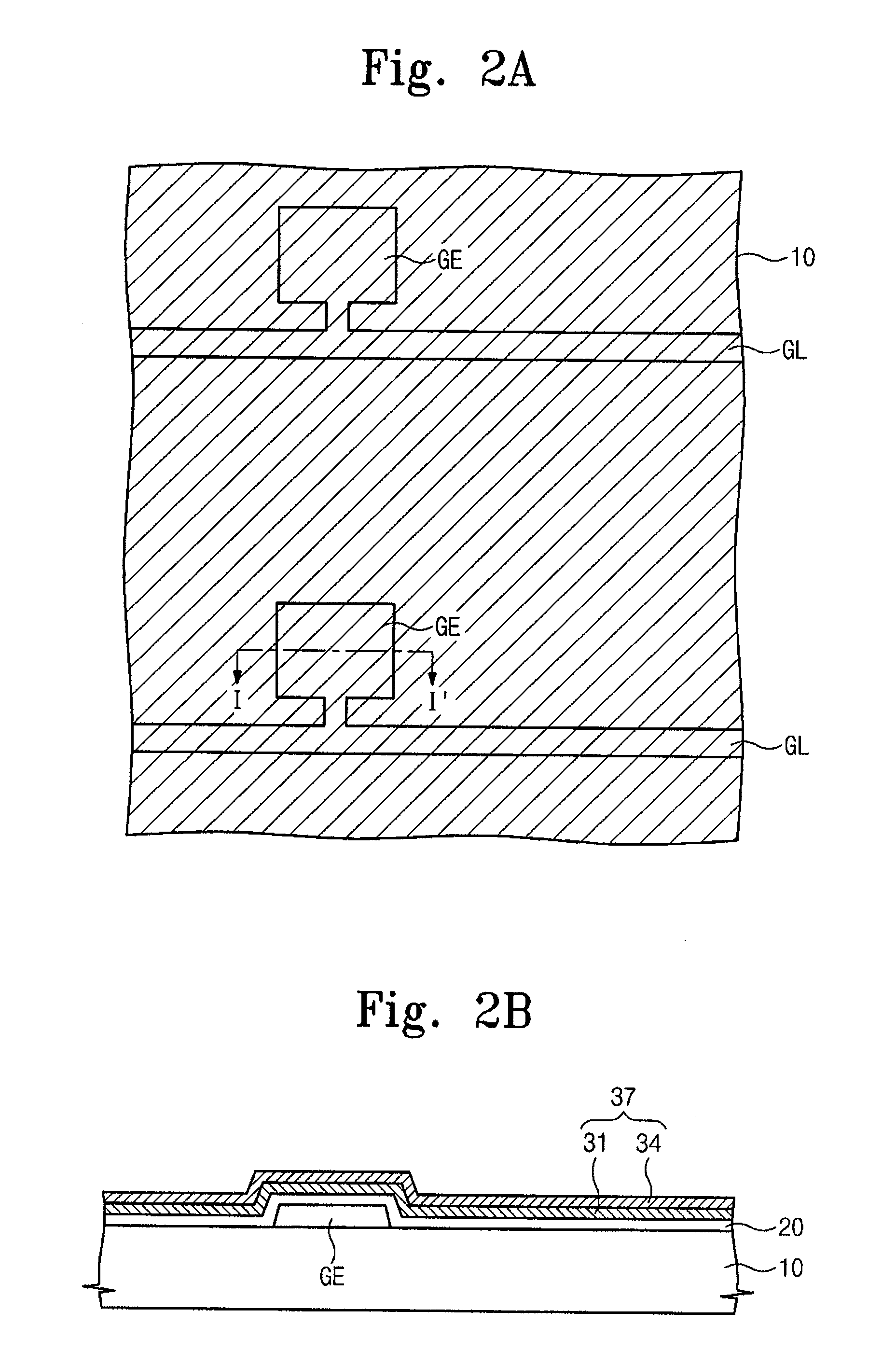

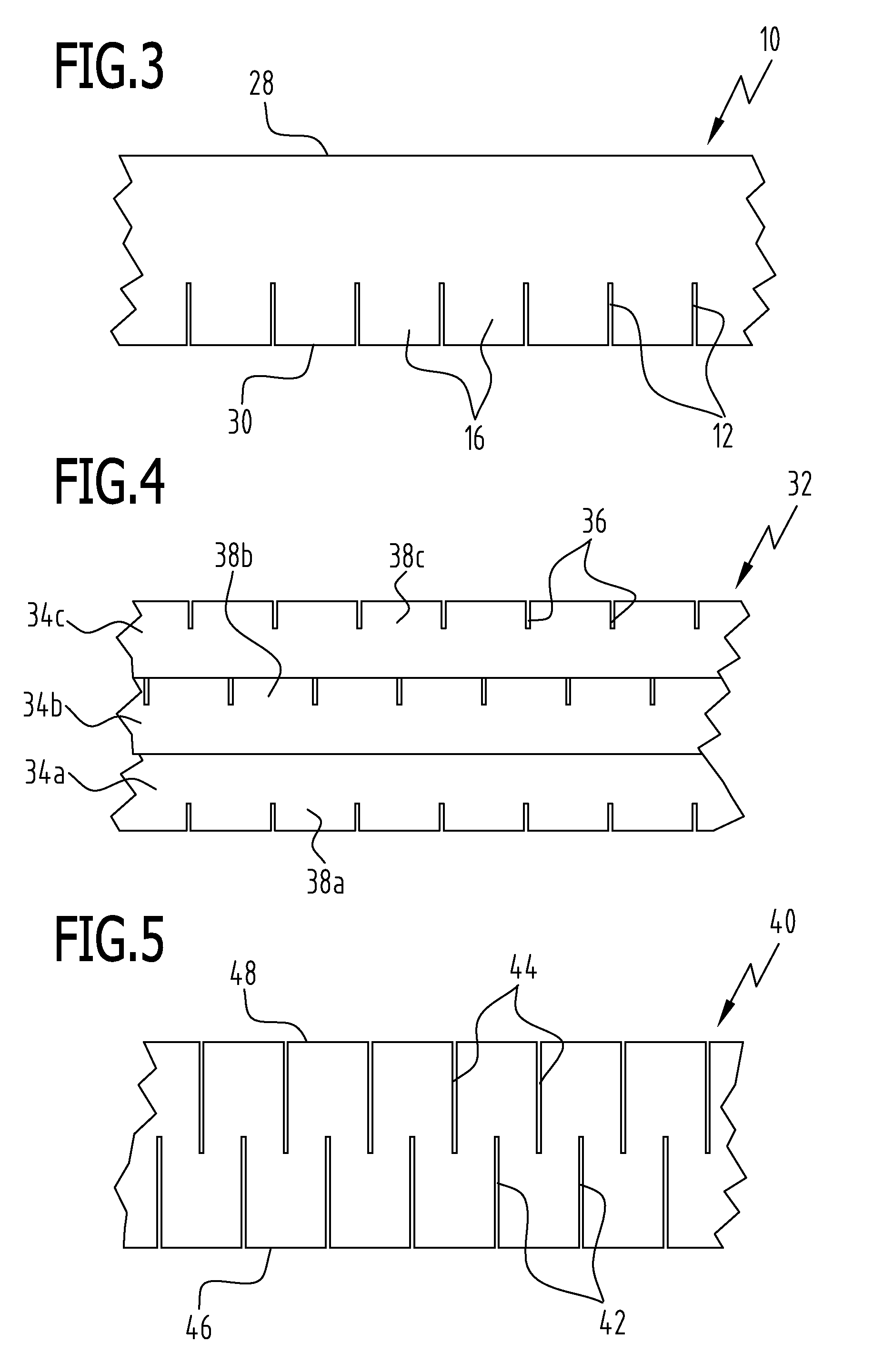

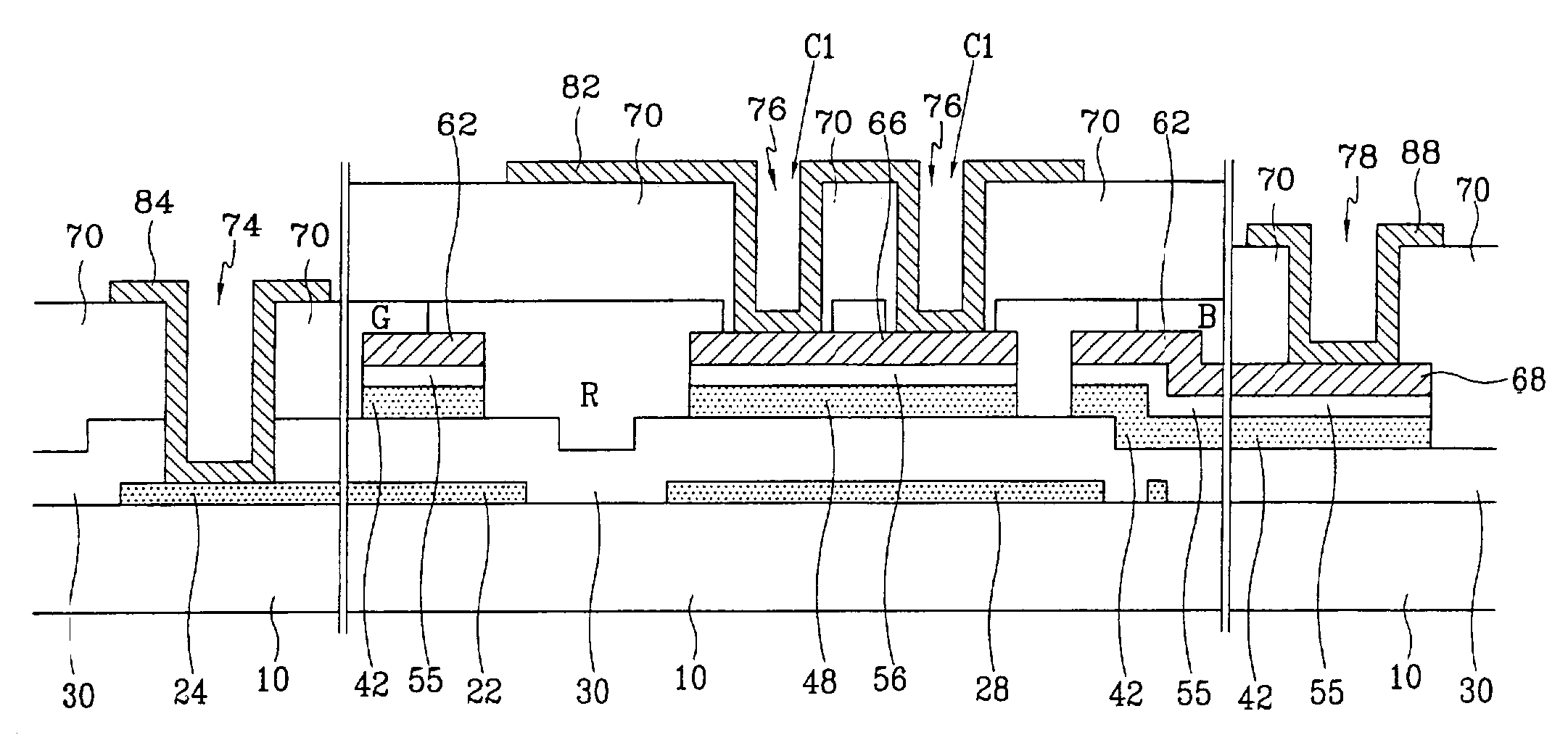

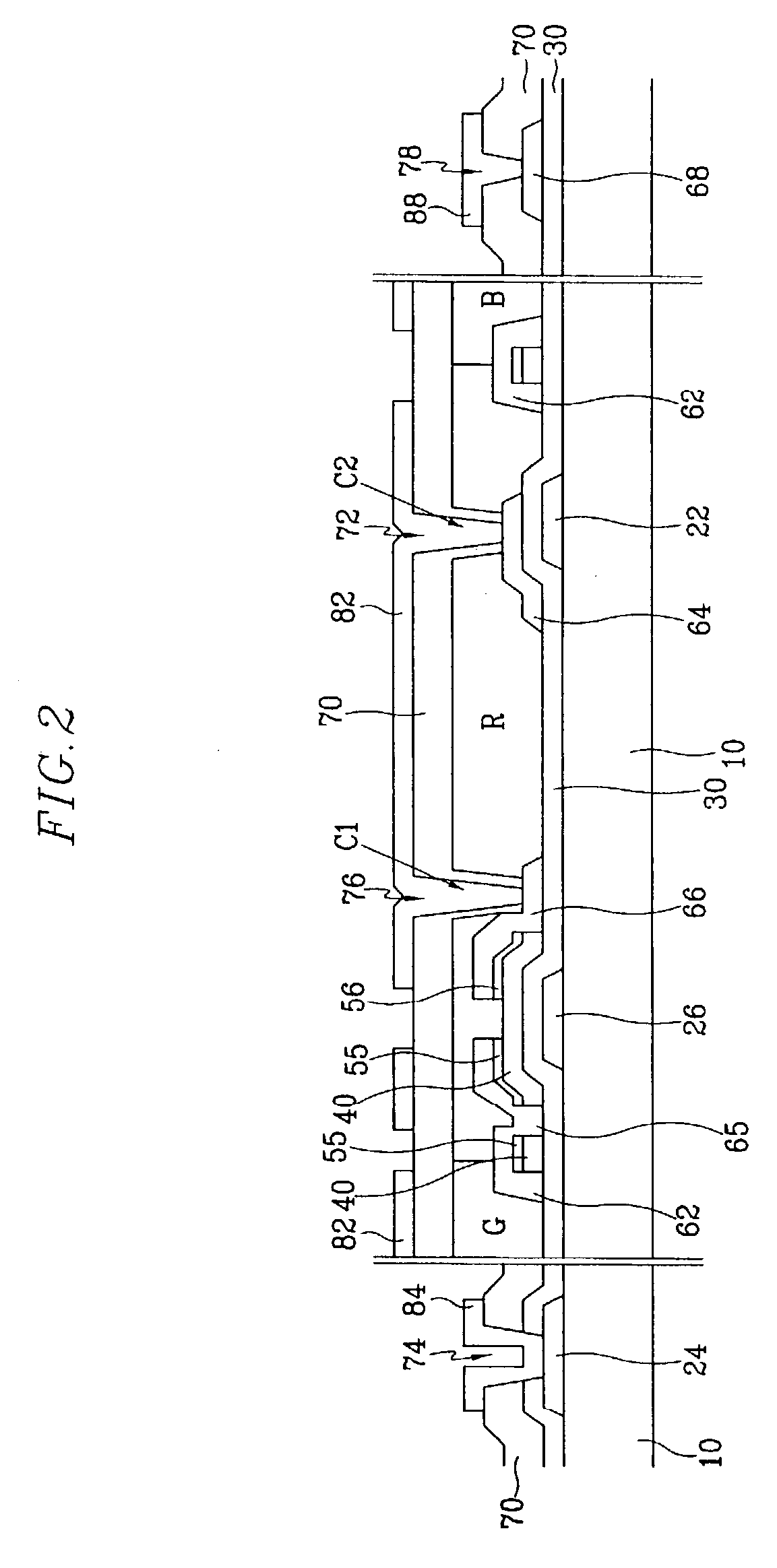

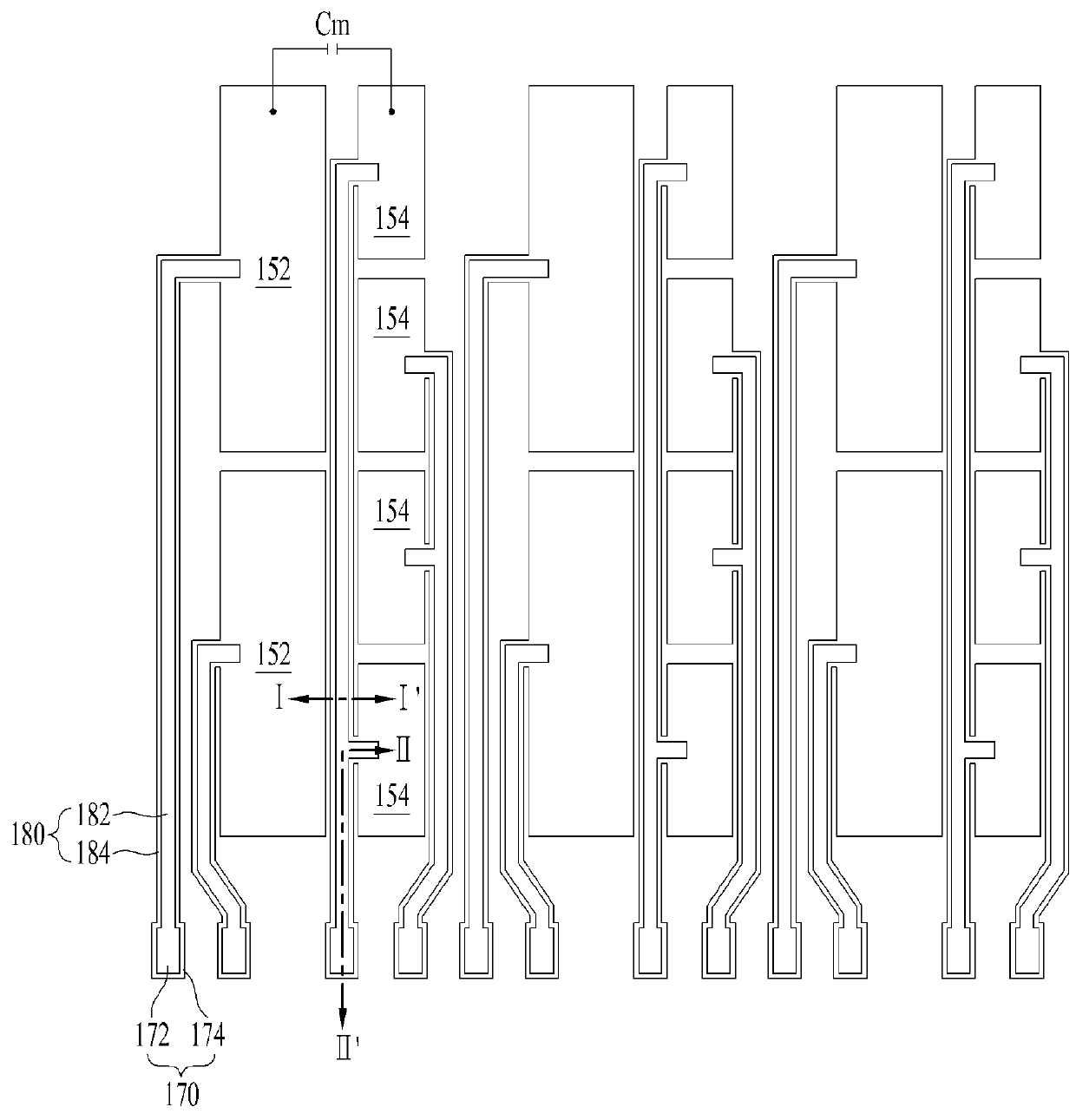

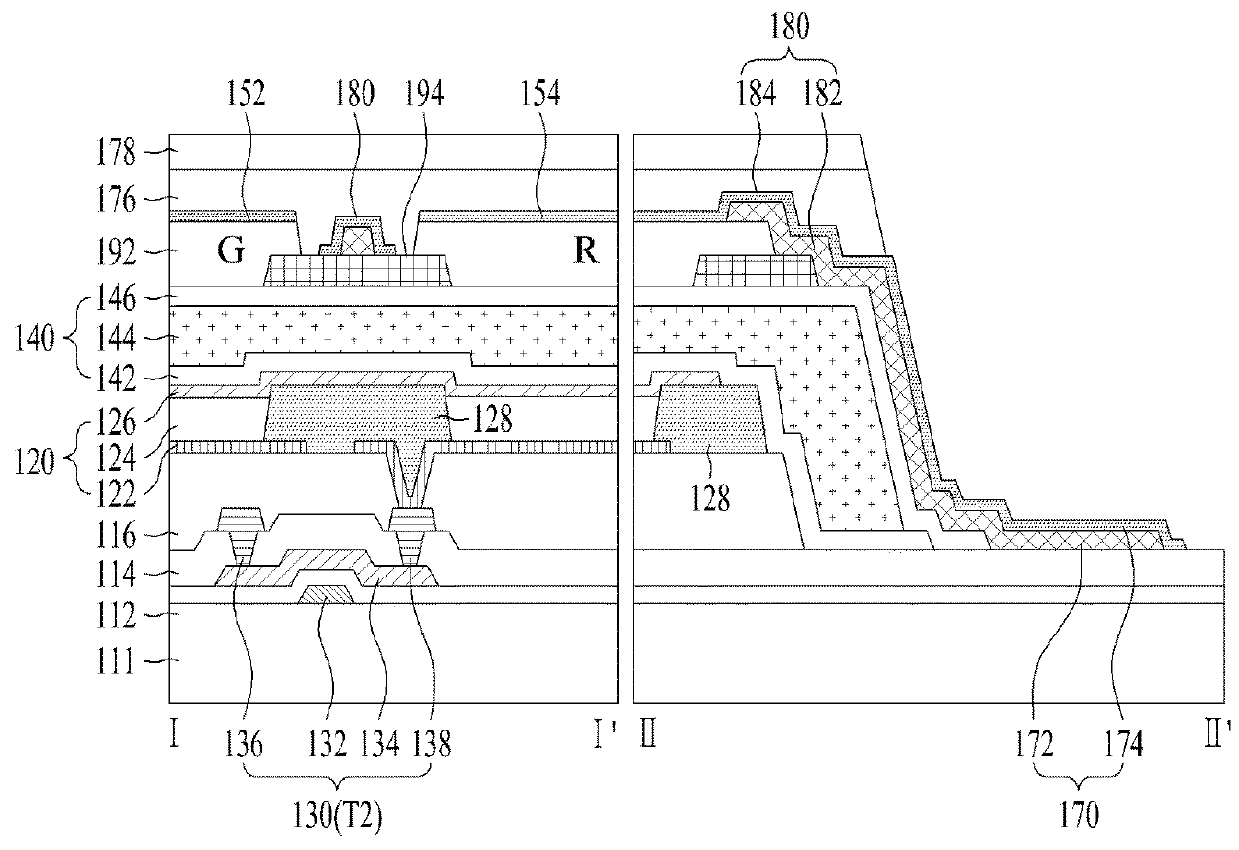

Thin film transistor array panel for display and manufacturing method thereof

InactiveUS7102168B2Simplify manufacturing processSimple manufacturing processTransistorSolid-state devicesResistOhmic contact

A gate wire including a gate line, a gate pad and a gate electrode is formed on a substrate. A gate insulating layer, a semiconductor layer, a doped amorphous silicon layer and a conductive layer are deposited in sequence, and then a photoresist film pattern is formed thereon. The photoresist film pattern includes a first portion positioned between a source electrode and a drain electrode, a second portion thicker than the first portion, and the third portion with no photoresist. A data wire including a data line, a data pad, a source electrode, a drain electrode and a conductor pattern for storage capacitor, an ohmic contact layer pattern and a semiconductor pattern are formed by etching the conductive layer, the doped amorphous silicon layer and the semiconductor layer using the photoresist film pattern. A plurality of color filters of red, green and blue having apertures exposing part of the drain electrode are formed thereon. A passivation layer made of acryl-based organic material having excellent planarization characteristic is formed thereon. A pixel electrode, an auxiliary gate pad and an auxiliary data pad connected to the drain electrode, the gate pad and the data pad via contact holes, respectively, are formed on the passivation layer. The contact hole exposing the drain electrode is located within the aperture.

Owner:SAMSUNG DISPLAY CO LTD

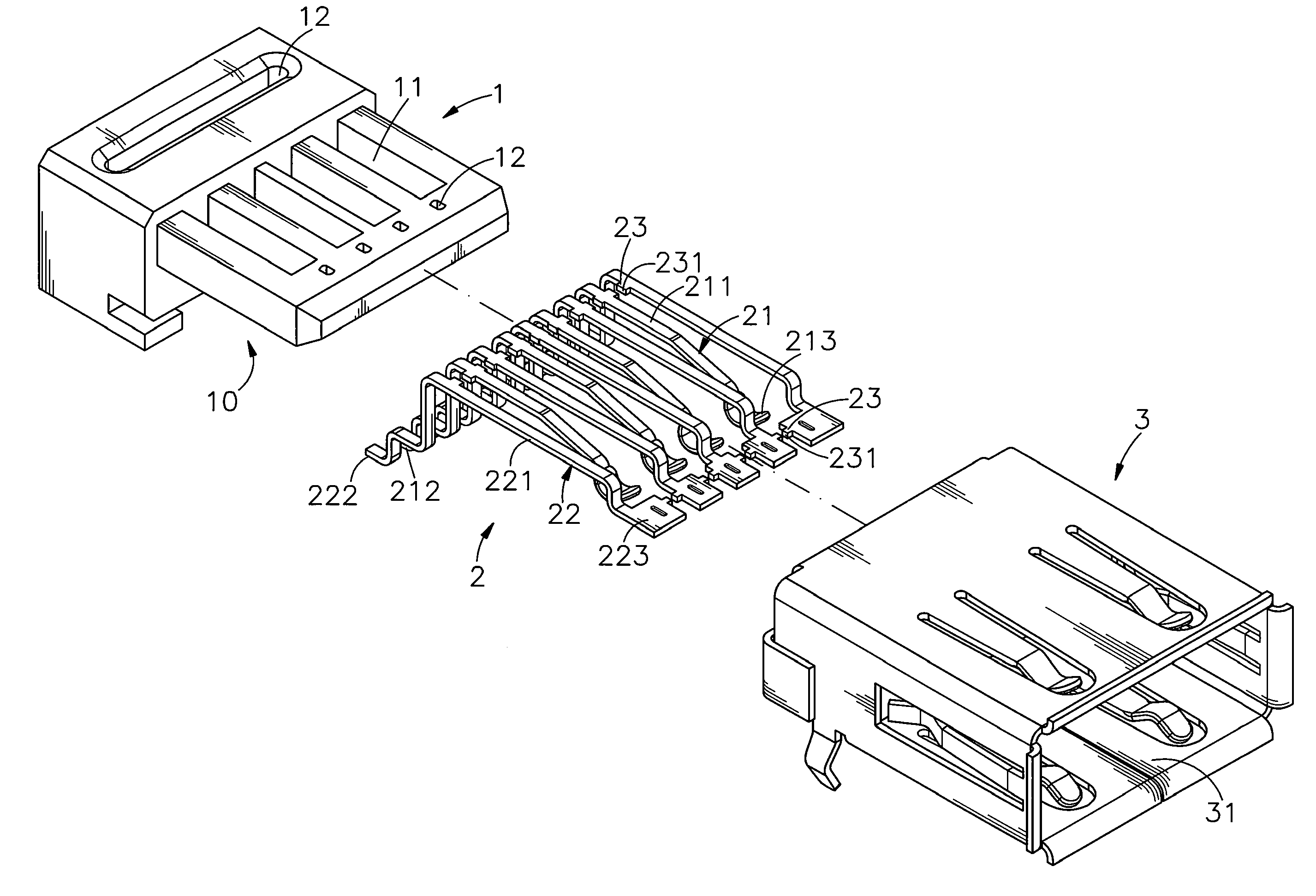

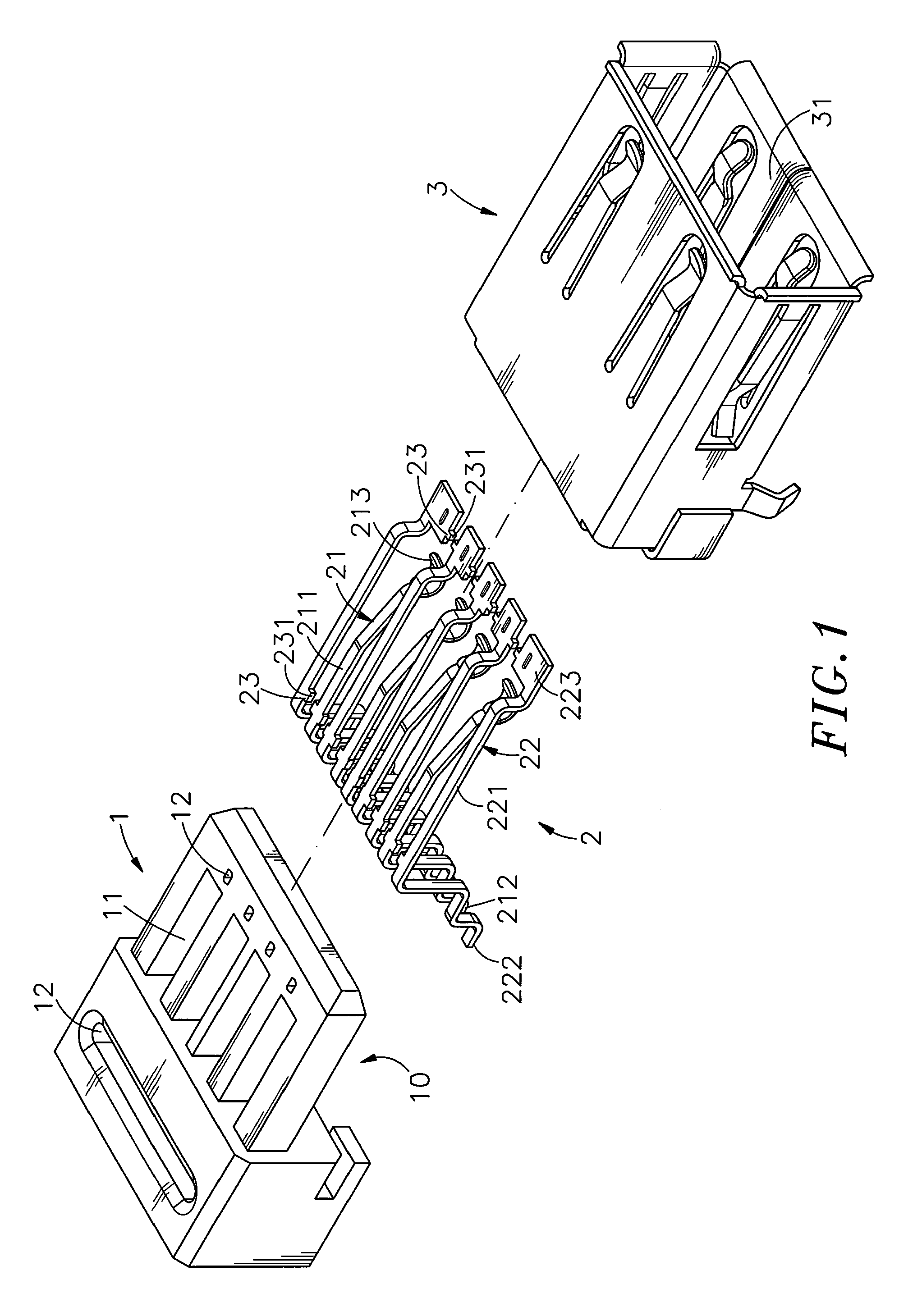

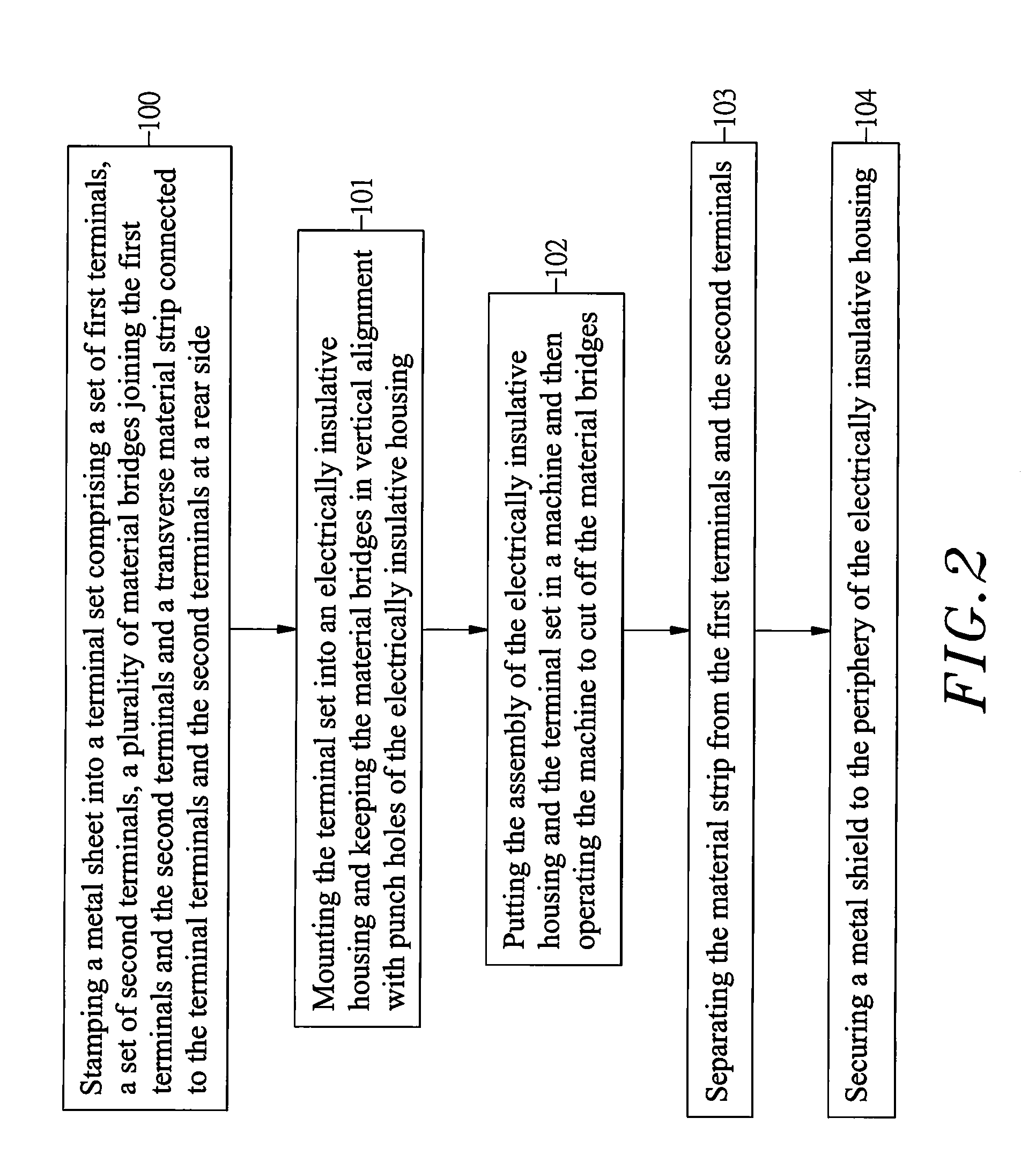

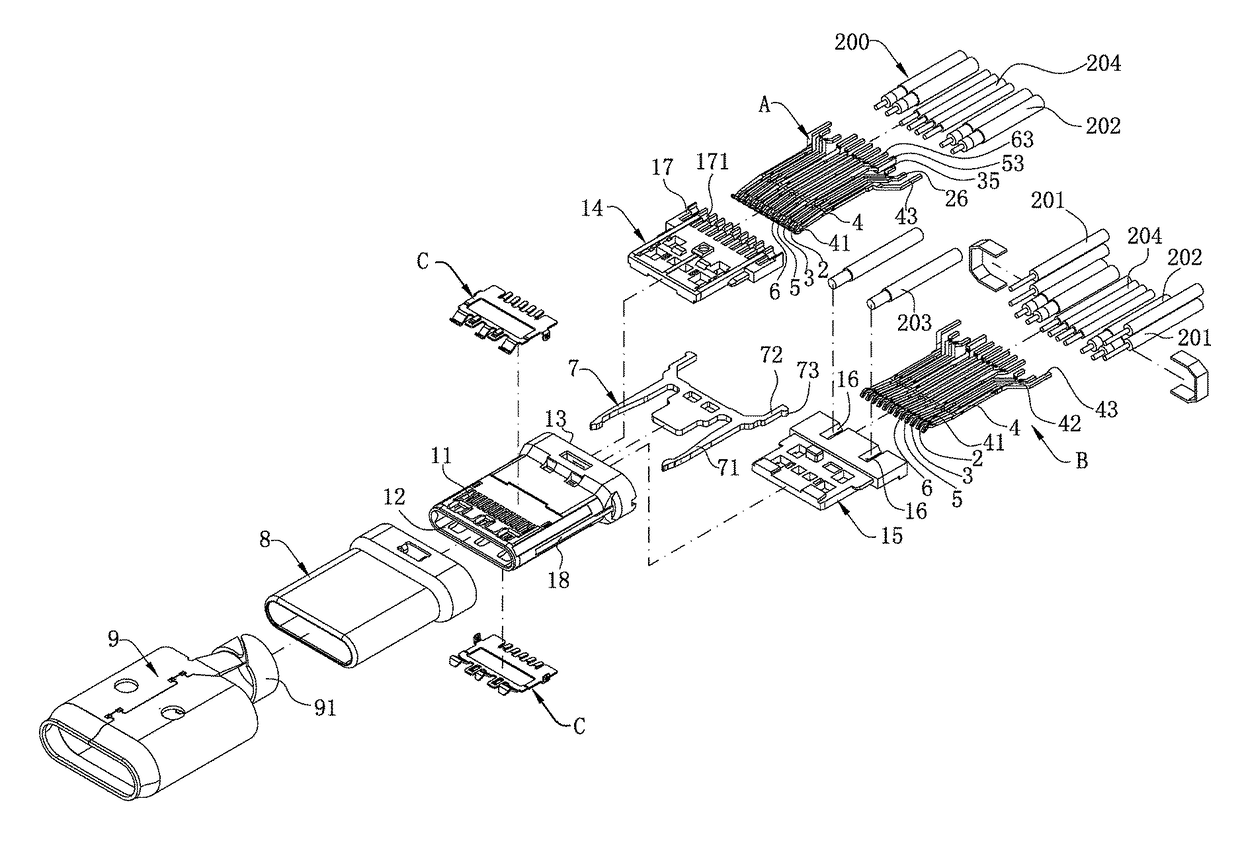

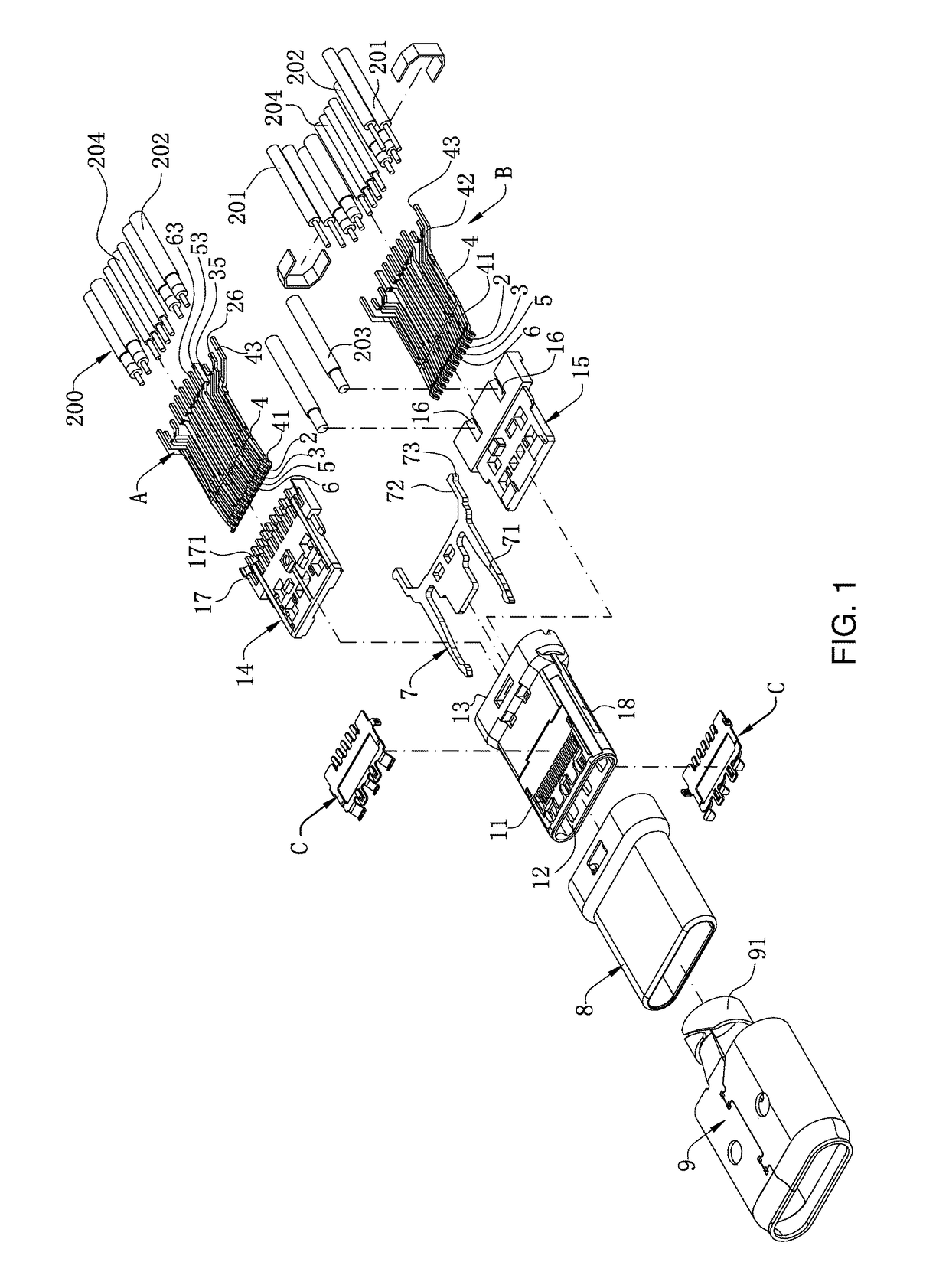

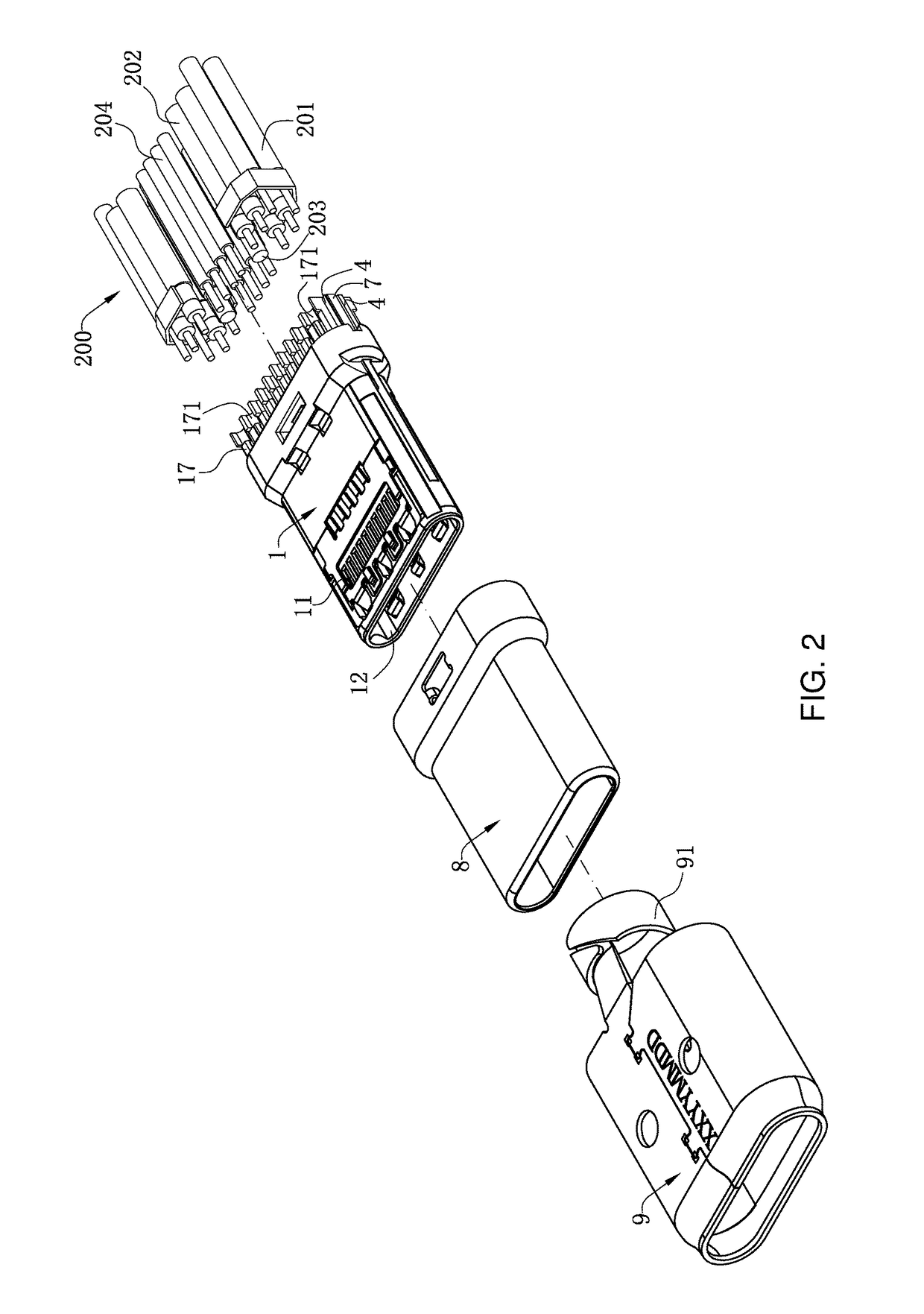

USB connector and its fabrication method

ActiveUS20100112862A1Simplify manufacturing processSimple manufacturing processContact member manufacturingElectrically conductive connectionsEngineeringUSB

A USB connector fabrication method includes the steps of (a) stamping a metal sheet into a terminal set having a set of first terminals, a set of second terminals and material bridges joining the first terminals and the second terminals, (b) preparing an electrically insulative housing having punch holes and then mounting the terminal set in the electrically insulative housing to keep the material bridges in vertical alignment with the punch holes, (c) using a machine to cut off the material bridges and (d) securing a metal shield around the periphery of the electrically insulative housing.

Owner:CHANT SINCERE

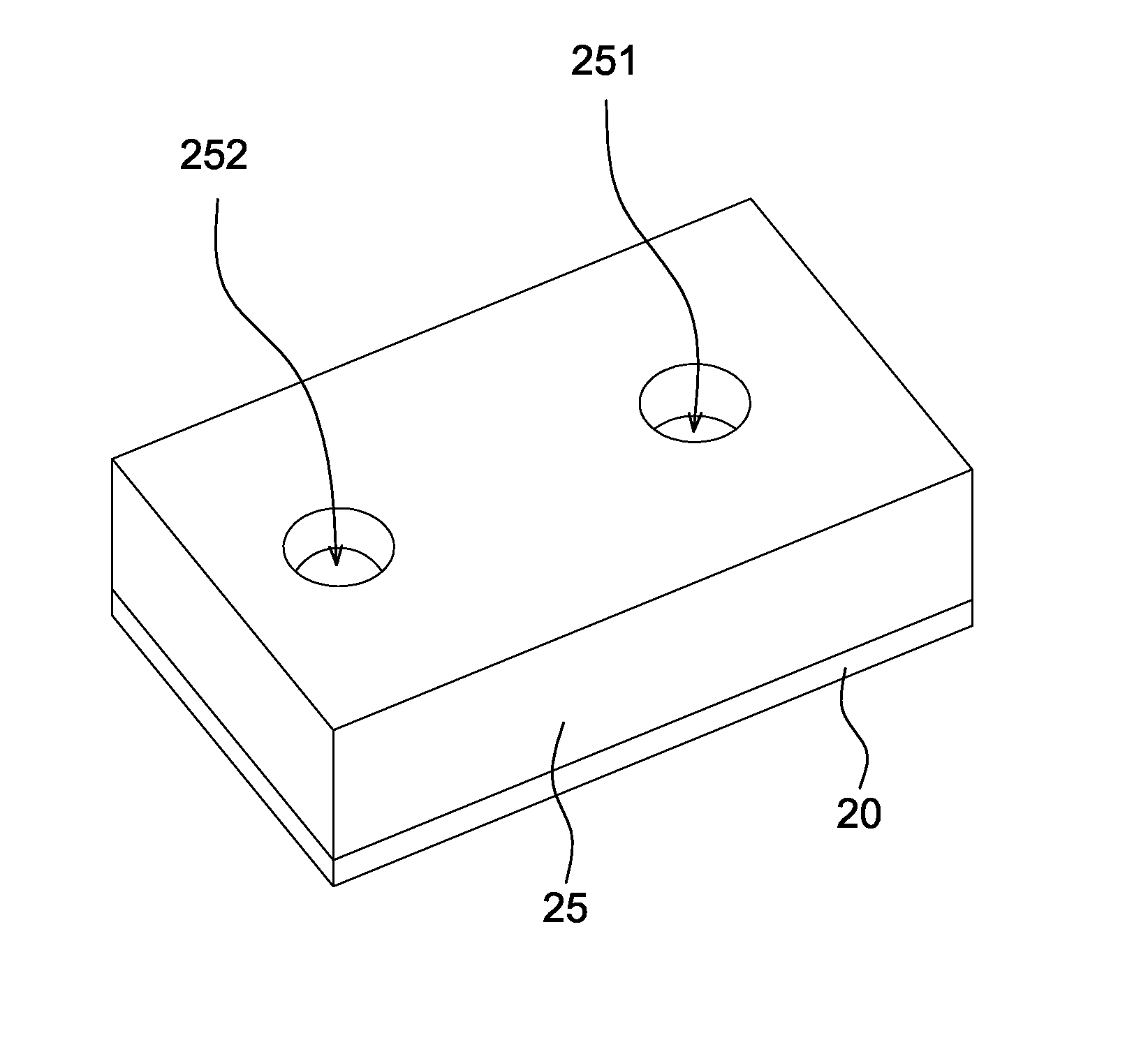

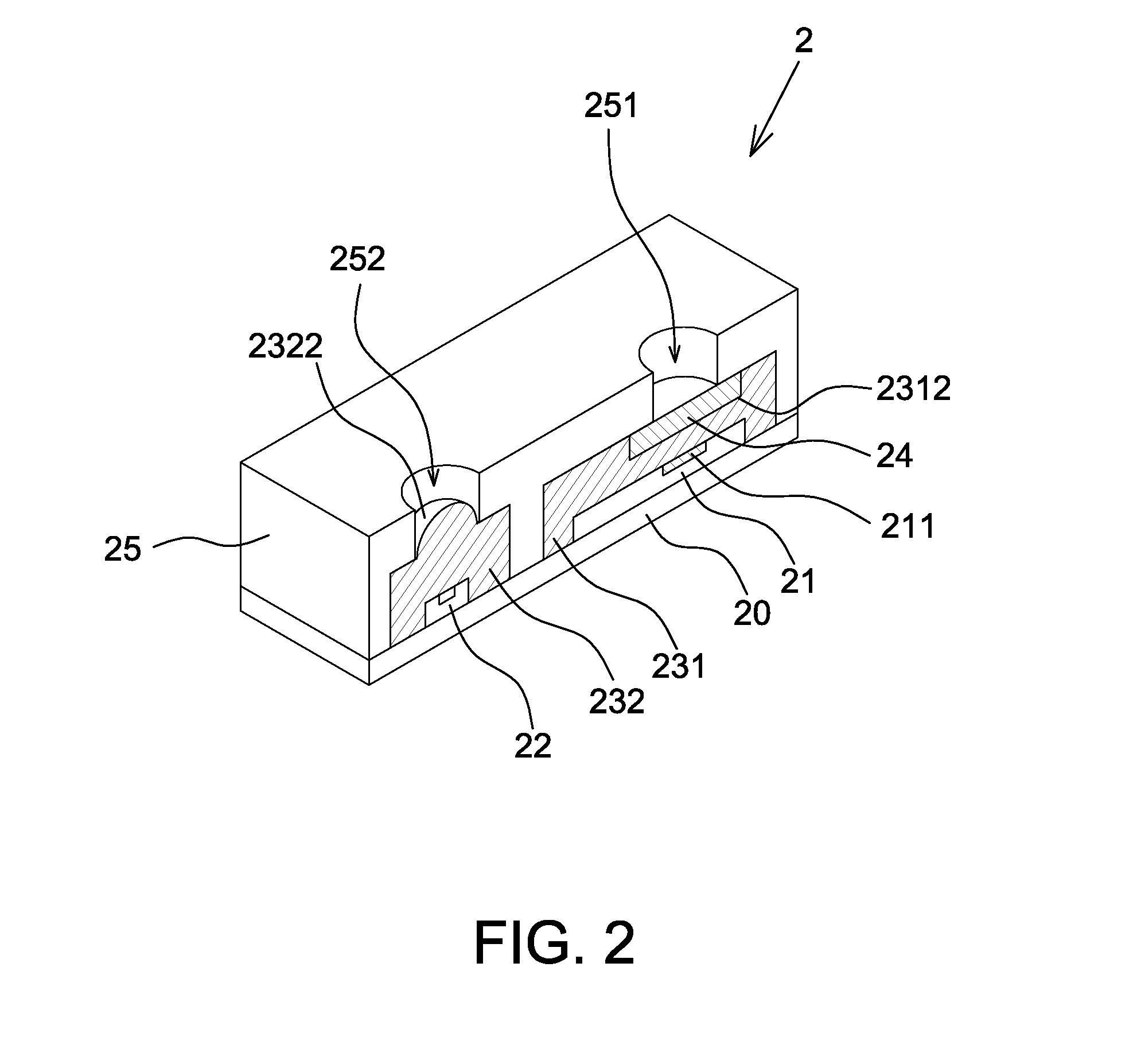

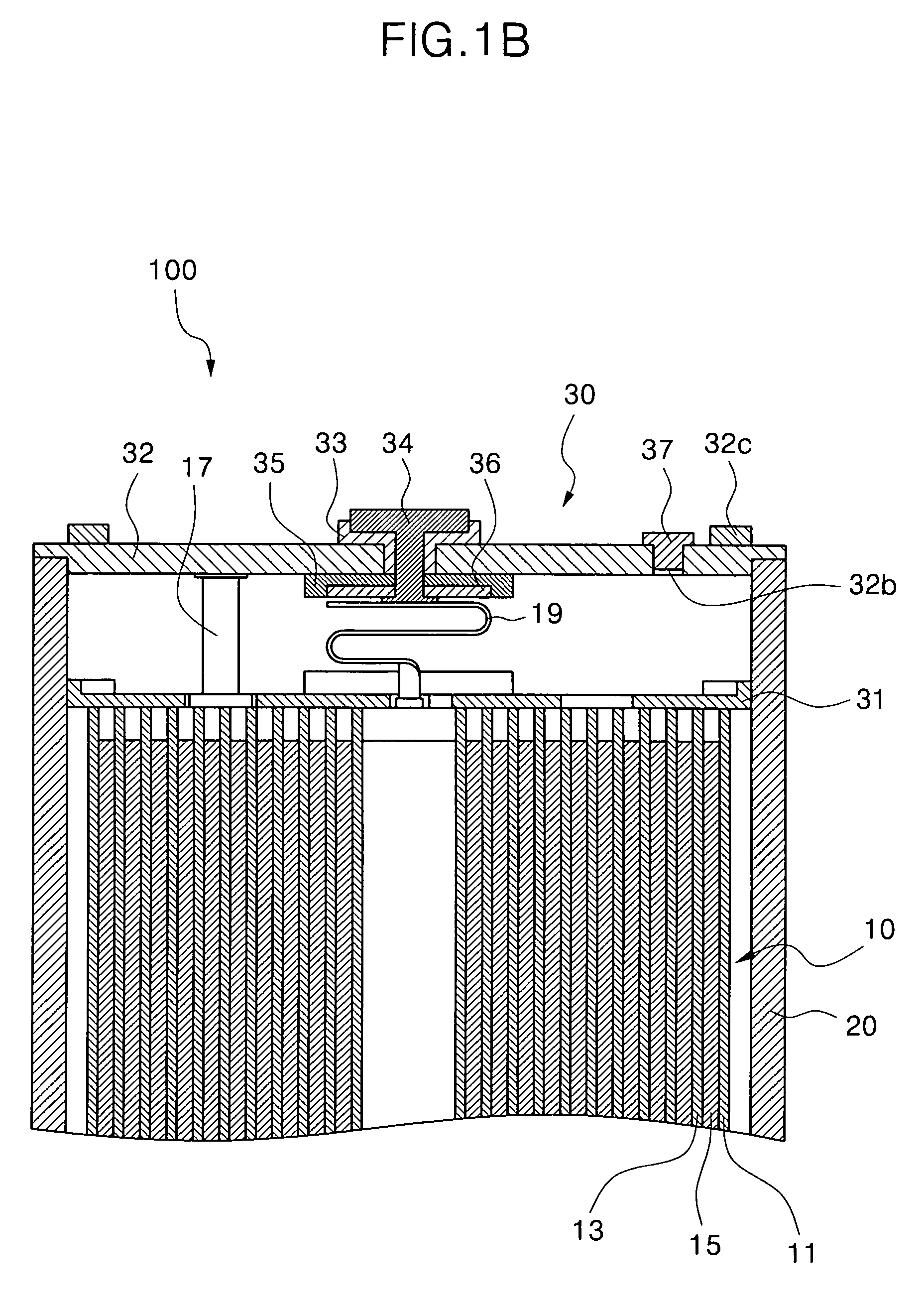

Image module package and manufacturing method thereof

ActiveUS20160041029A1Simplify manufacturing processEliminate mechanical damage to sense surfacePhotometrySolid-state devicesEngineeringComputer module

There is provided an image module package including a substrate, a photo sensor chip, a molded transparent layer and a glass filter. The substrate has an upper surface. The photo sensor chip is attached to the upper surface of the substrate and electrically connected to the substrate. The molded transparent layer covers the photo sensor chip and a part of the upper surface of the substrate, wherein a top surface of the molded transparent layer is formed with a receptacle opposite to the photo sensor chip. The glass filter is accommodated in the receptacle.

Owner:PIXART IMAGING INC

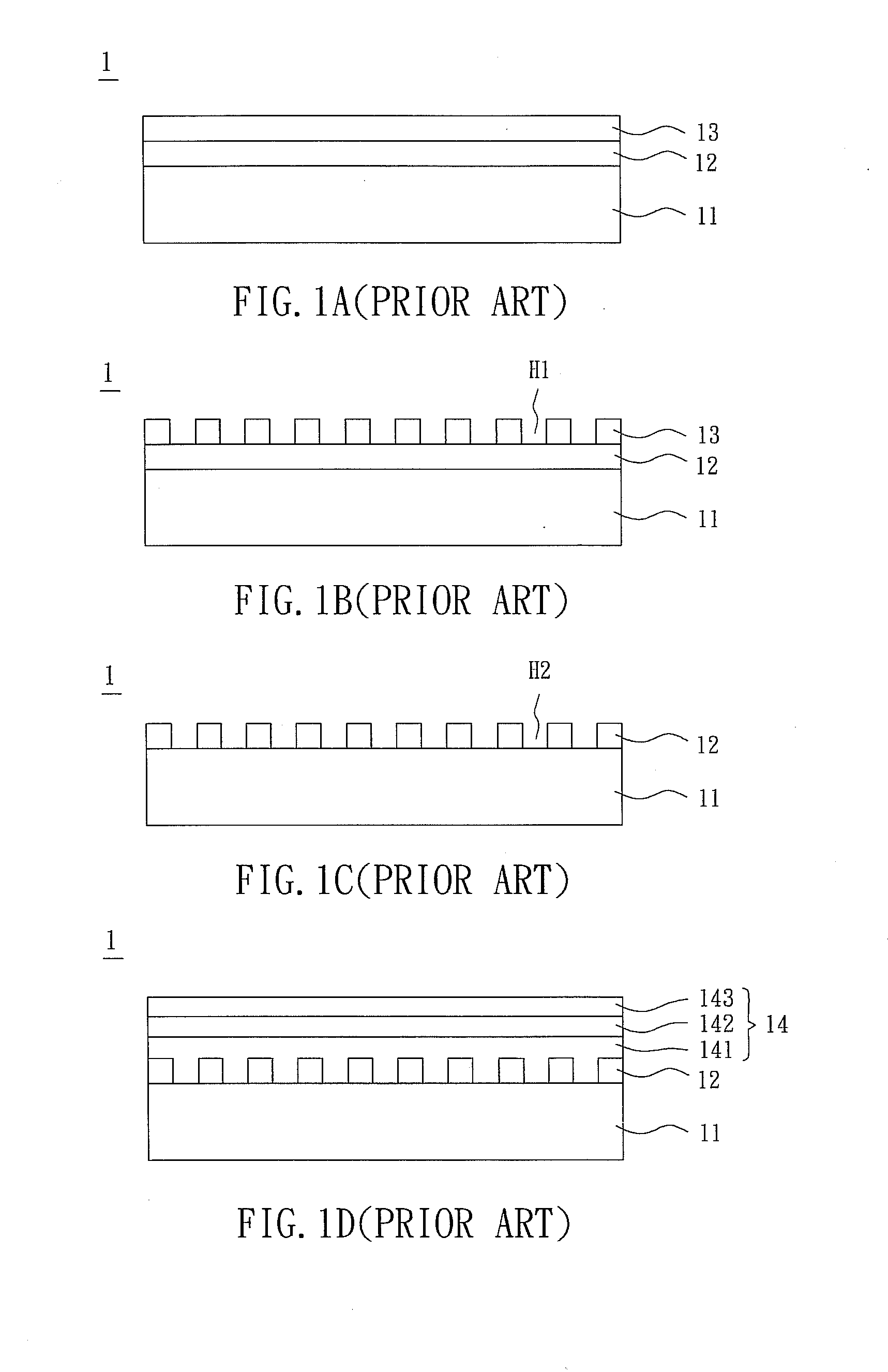

Epitaxial substrate and manufacturing method thereof and manufacturing method of light emitting diode apparatus

InactiveUS20090090930A1Simplify manufacturing processEnhance production yieldSemiconductor/solid-state device manufacturingNanoopticsNanometreNanoparticle

A manufacturing method of an epitaxial substrate includes the steps of: forming a sacrificial layer, which has a first micro / nano structure, on a substrate; and forming a buffer layer on the sacrificial layer. The sacrificial layer comprises a plurality of micro / nano particles, and the first micro / nano structure is formed after the plurality of micro / nano particles are removed. An epitaxial substrate and a manufacturing method of a light emitting diode (LED) apparatus are also disclosed.

Owner:DELTA ELECTRONICS INC +1

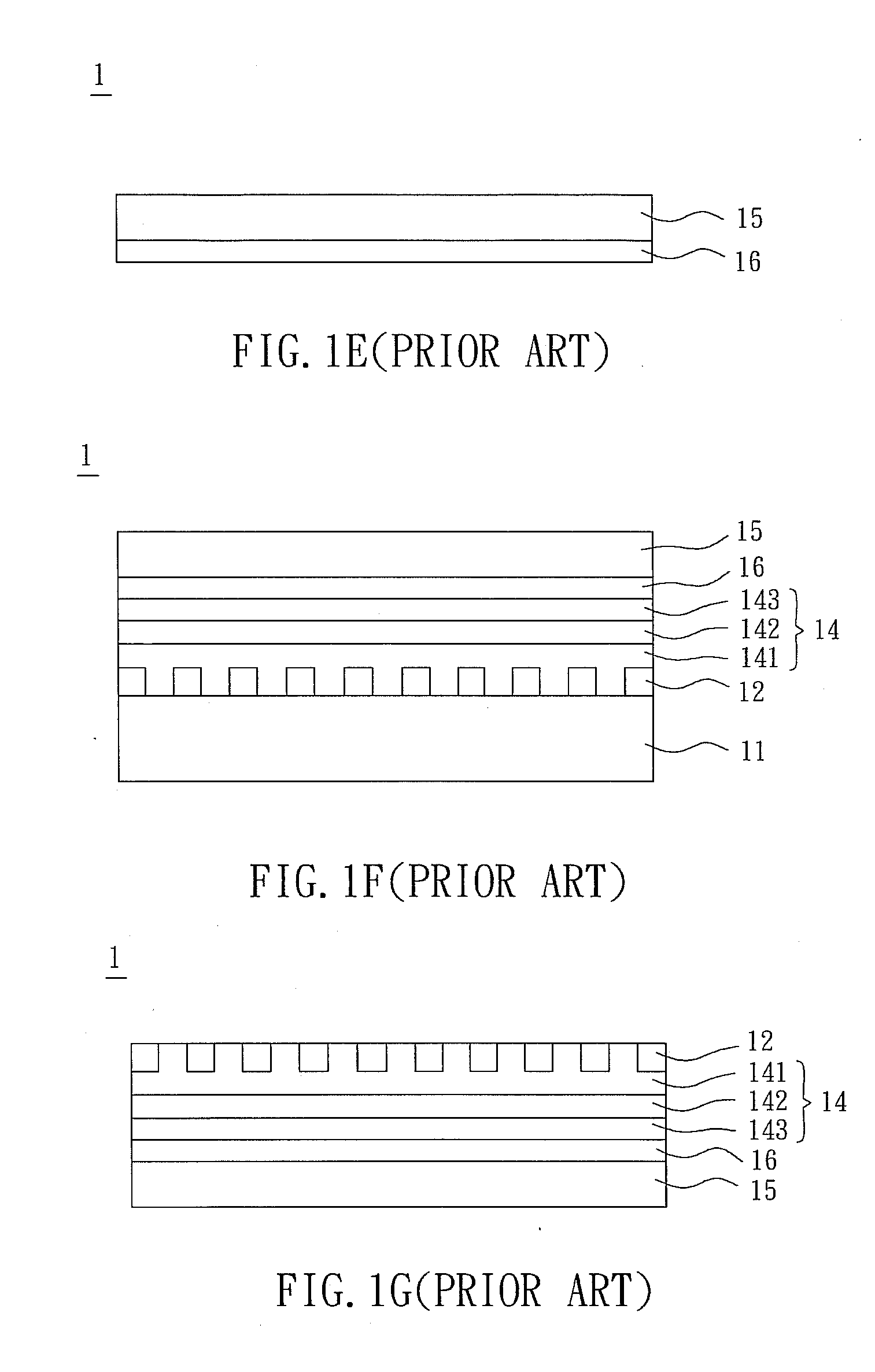

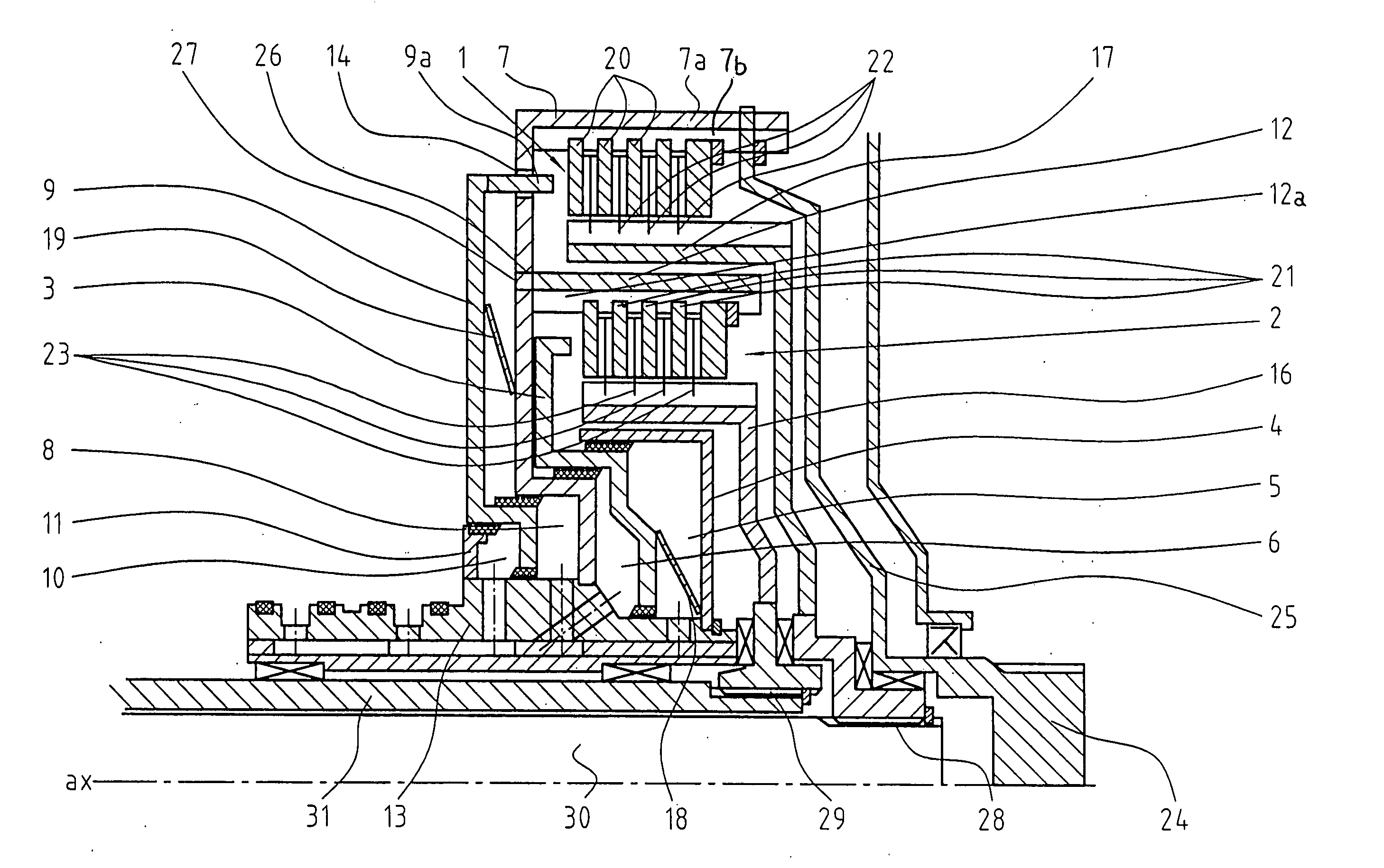

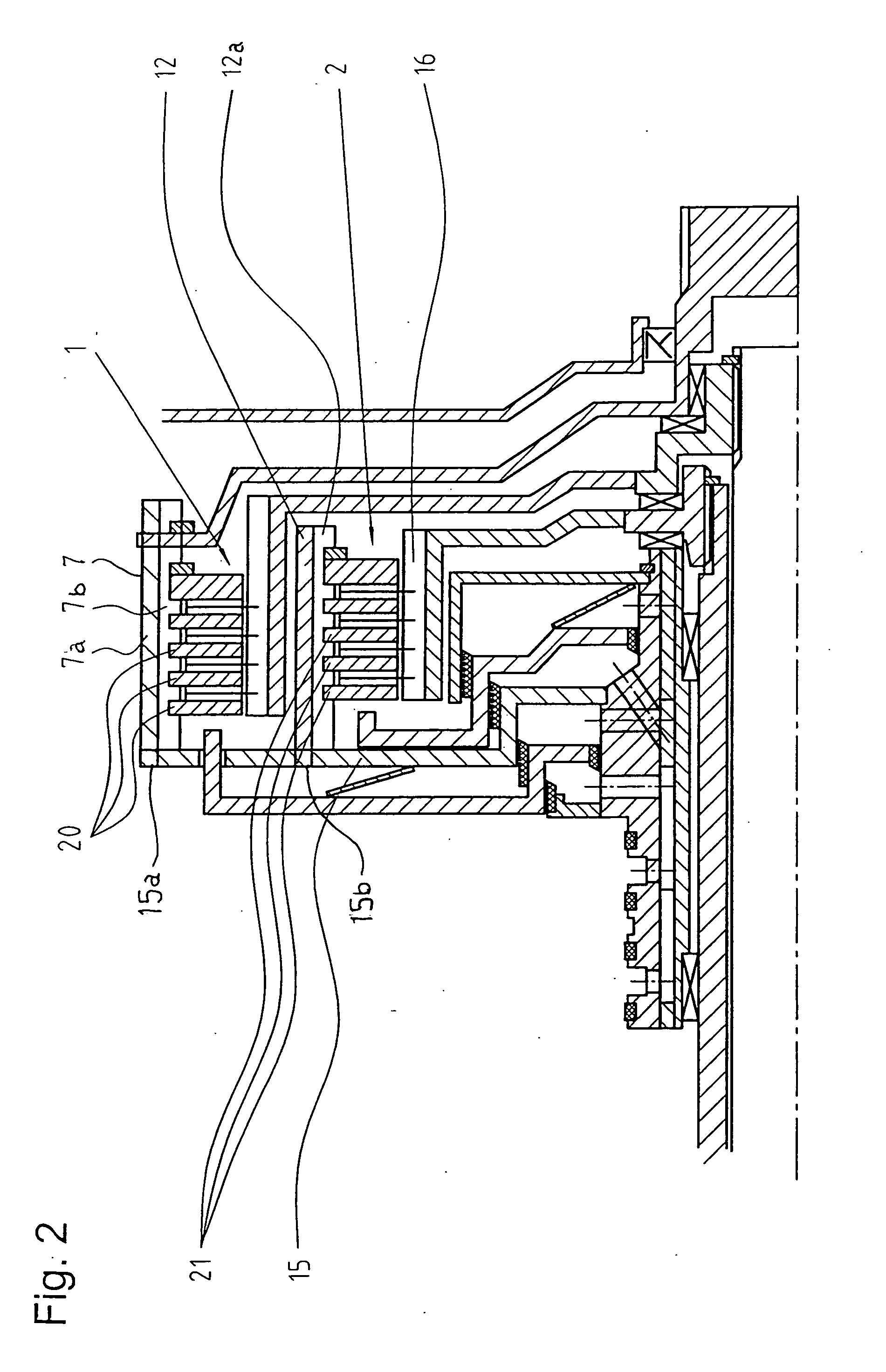

Dual clutch transmission with radially nested clutches having a common disk carrier

ActiveUS20050284725A1Reduce weight and space requirementSimplify manufacturing processMechanical actuated clutchesFluid actuated clutchesClutchVariator

A dual clutch transmission having radially nested clutches includes an outer clutch having a plurality of first outer clutch disks, a plurality of first inner clutch disks, and a first inner support carrier, with the first inner clutch disks operatively mounted to the first inner carrier. The transmission further includes an inner clutch having a plurality of second outer clutch disks, a plurality of second inner clutch disks, and a second inner support carrier is included. The second inner clutch disks are operatively mounted to the second inner carrier. A common disk carrier having a first outer clutch disk carrier operatively supports the first outer clutch disks of the outer clutch and a second outer clutch disk carrier that operatively supports the second outer clutch disks of the inner clutch.

Owner:BORG WARNER INC

Electrical connector

ActiveUS9768568B1Production cost be reduceSimplify manufacturing processElectrically conductive connectionsTwo-part coupling devicesSolderingElectrical and Electronics engineering

An electrical connector for connecting a cable, includes an insulating body and a first terminal group received in the insulating body. The first terminal group includes a ground terminal, a power terminal, and first and second high-speed signal terminals. The first high-speed signal terminal has a first contacting portion, a first bending portion and a first soldering portion from front to rear. The extending direction of the first bending portion is different from that of the first contacting portion. The second high-speed signal terminal has a second contacting portion, a second bending portion, a reverse bending portion and a second soldering portion from front to rear. The second bending portion extends in a bending direction toward the first bending portion. The reverse bending portion reversely bends from the second bending portion. The spacing between the first and second soldering portions and the space for accommodating the cable are enlarged.

Owner:LOTES

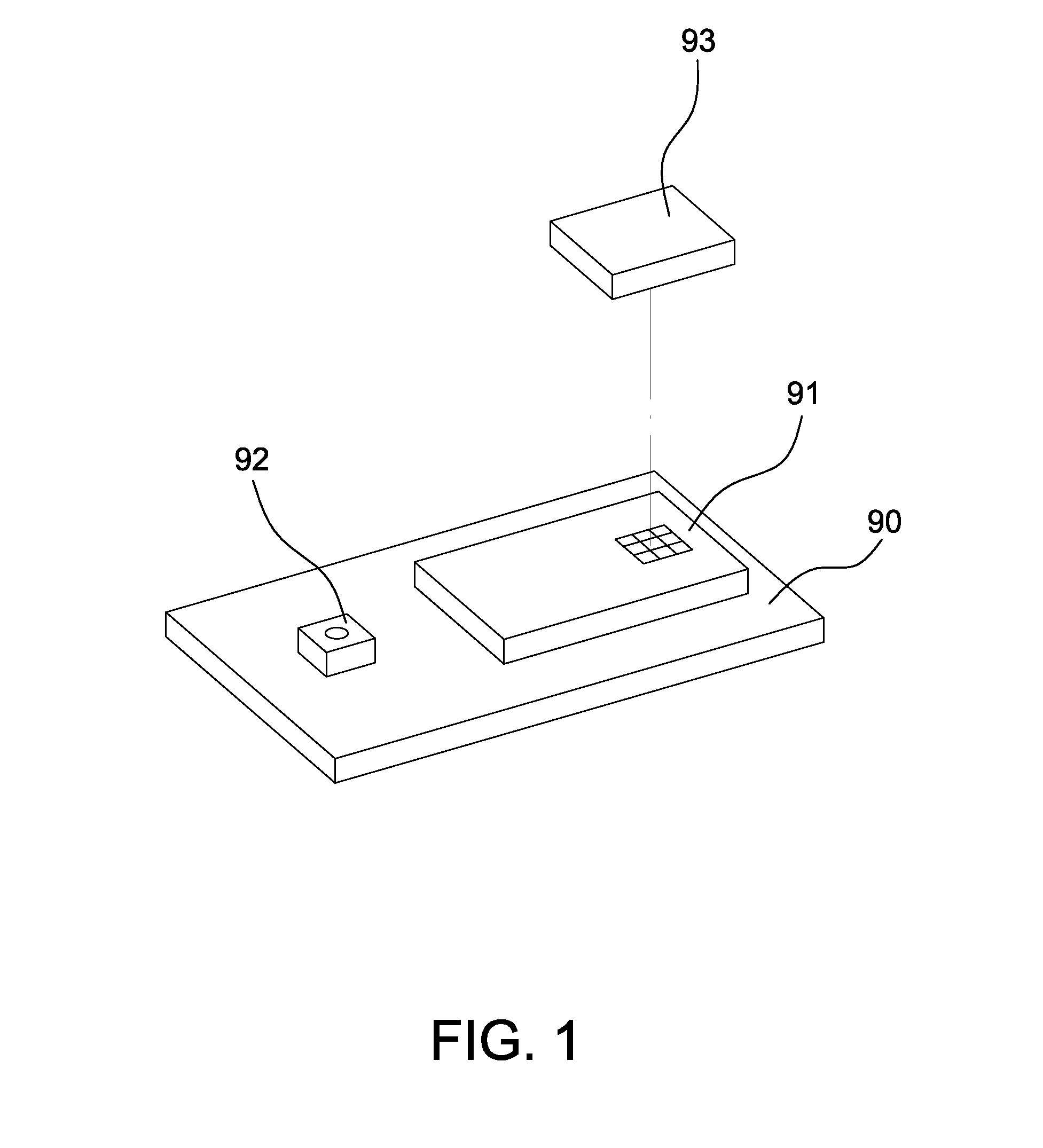

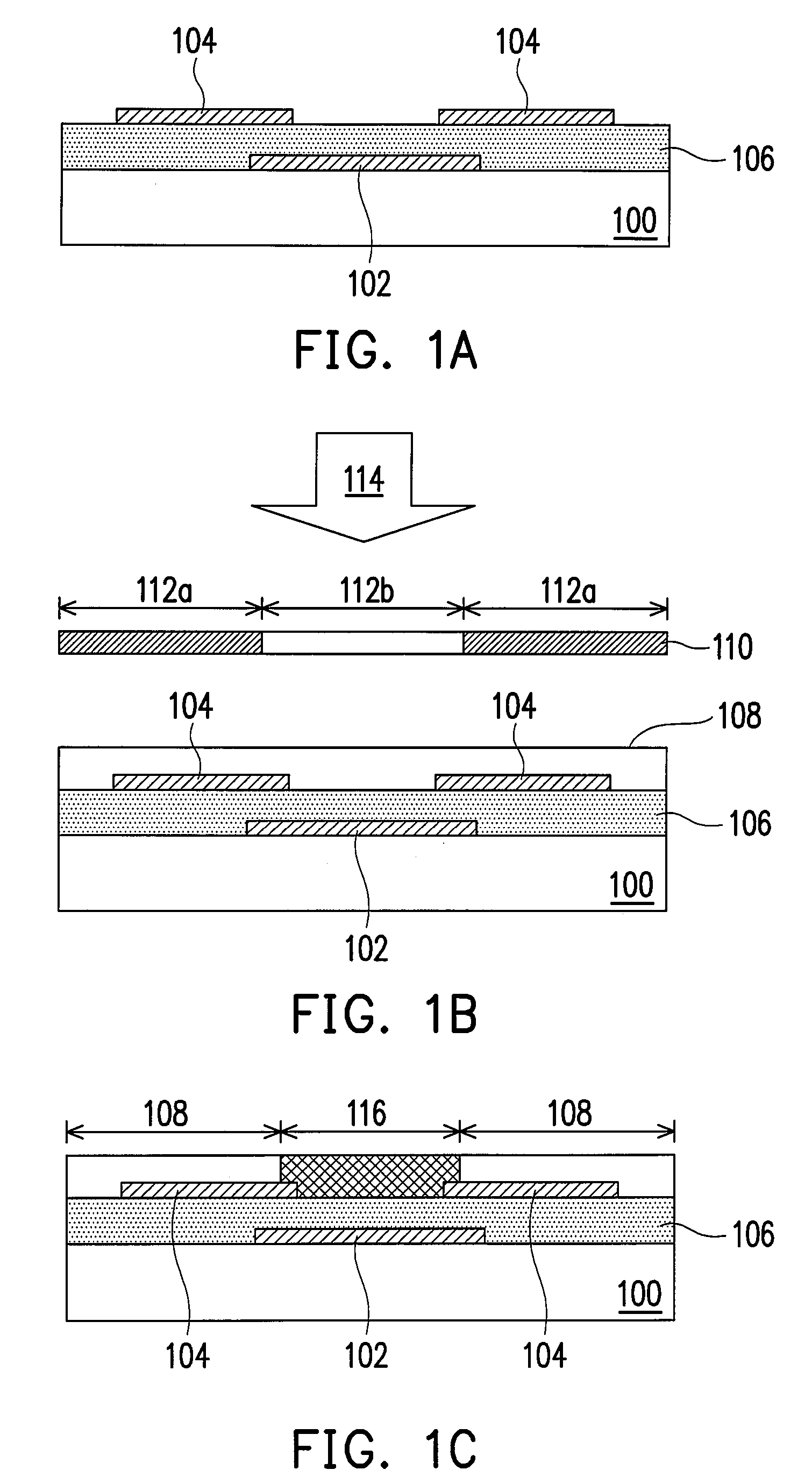

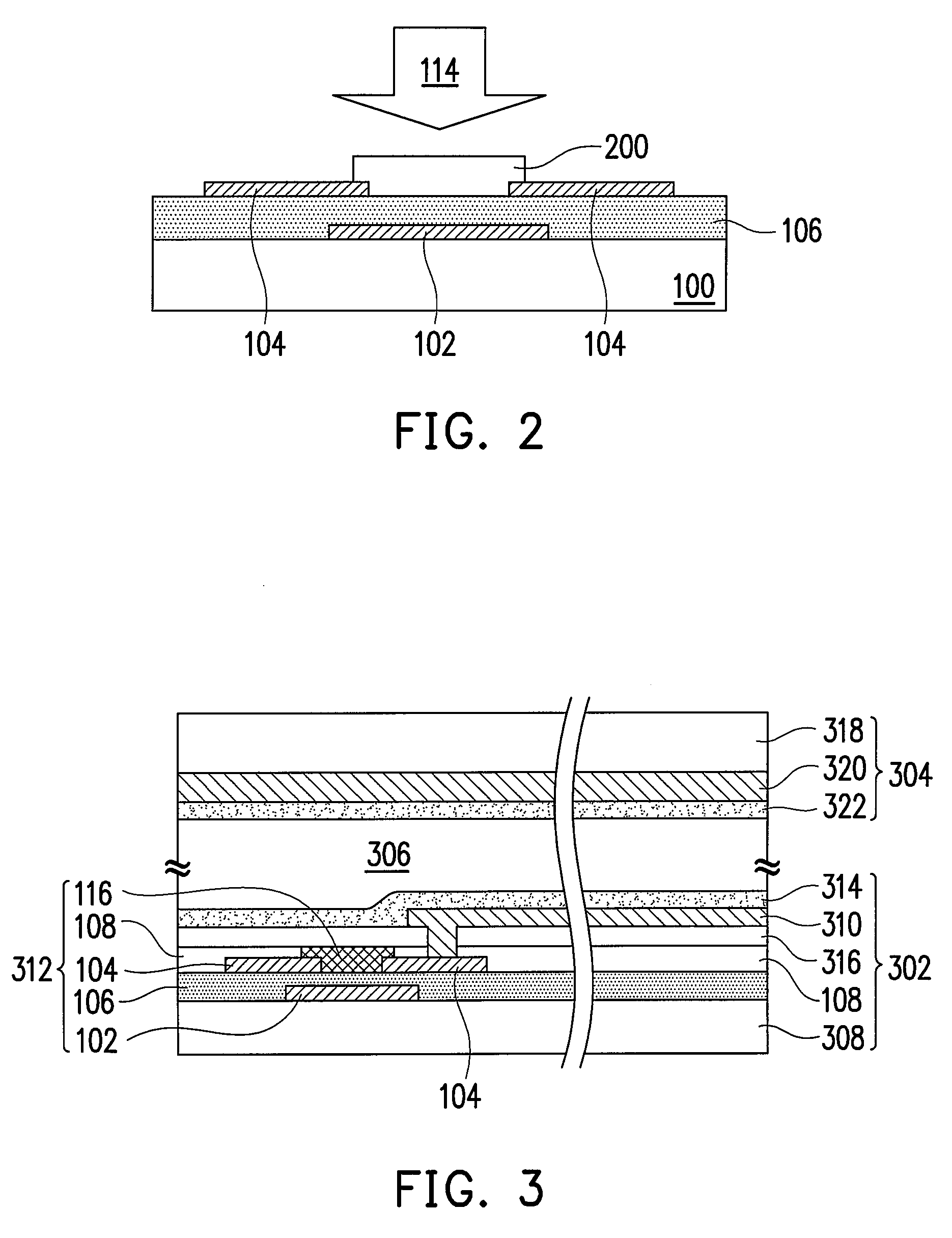

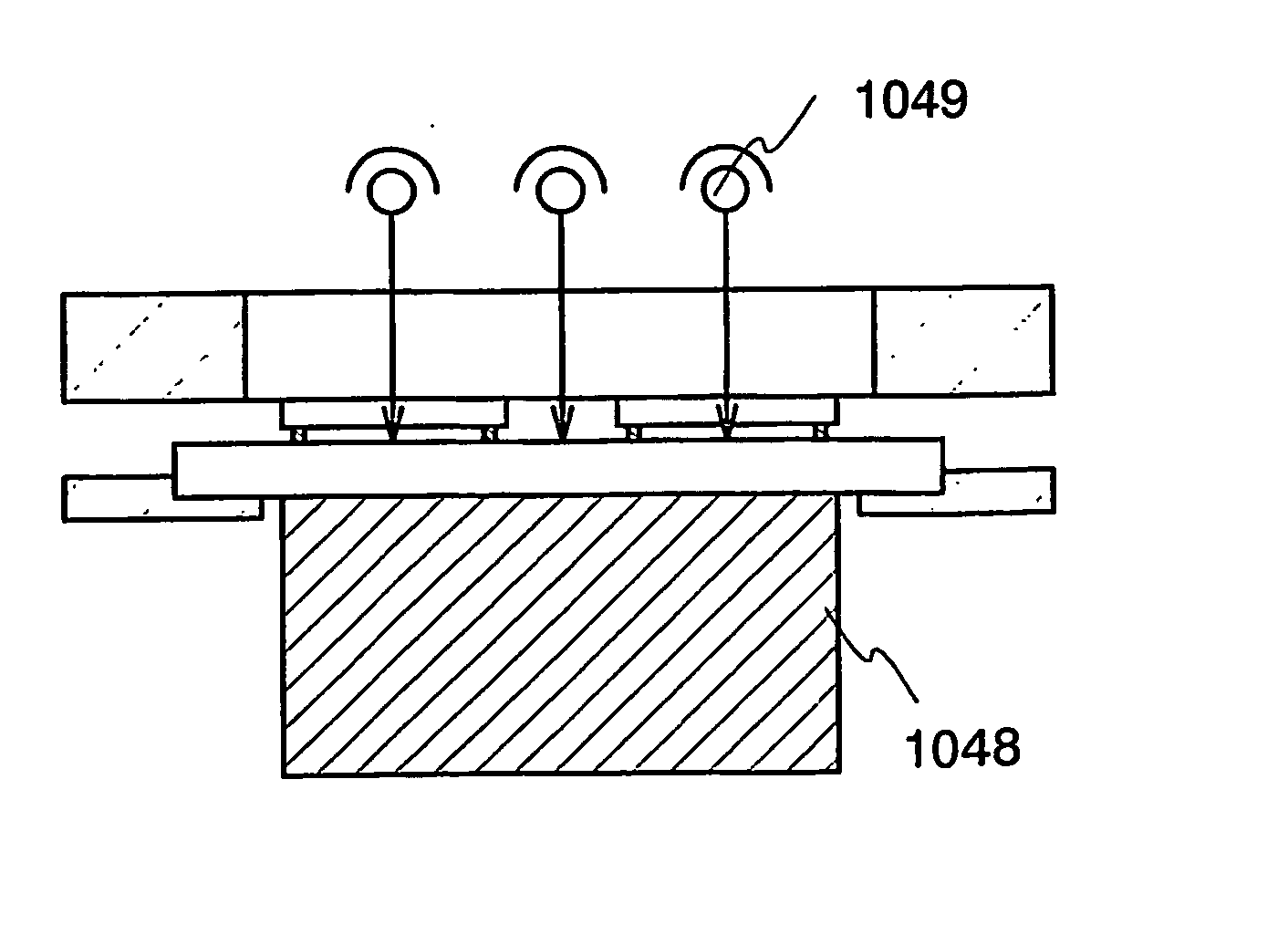

Drop discharge apparatus, method for forming pattern and method for manufacturing semiconductor device

InactiveUS7585783B2Pattern accuracy be improveSimplify manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingPhotolithographyEngineering

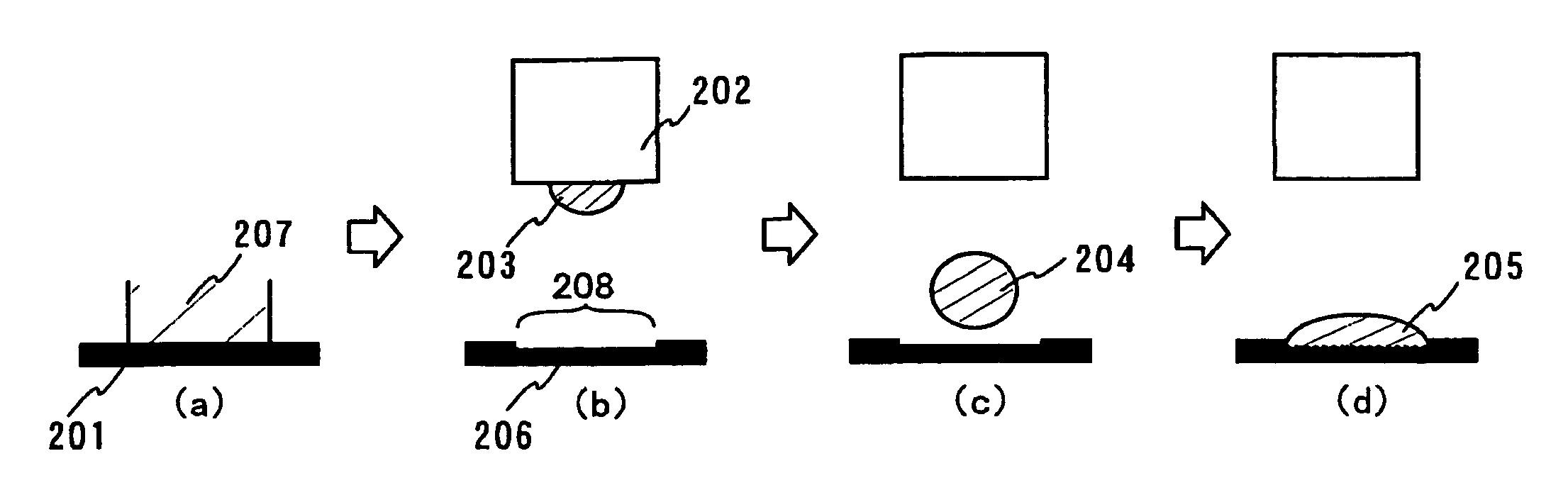

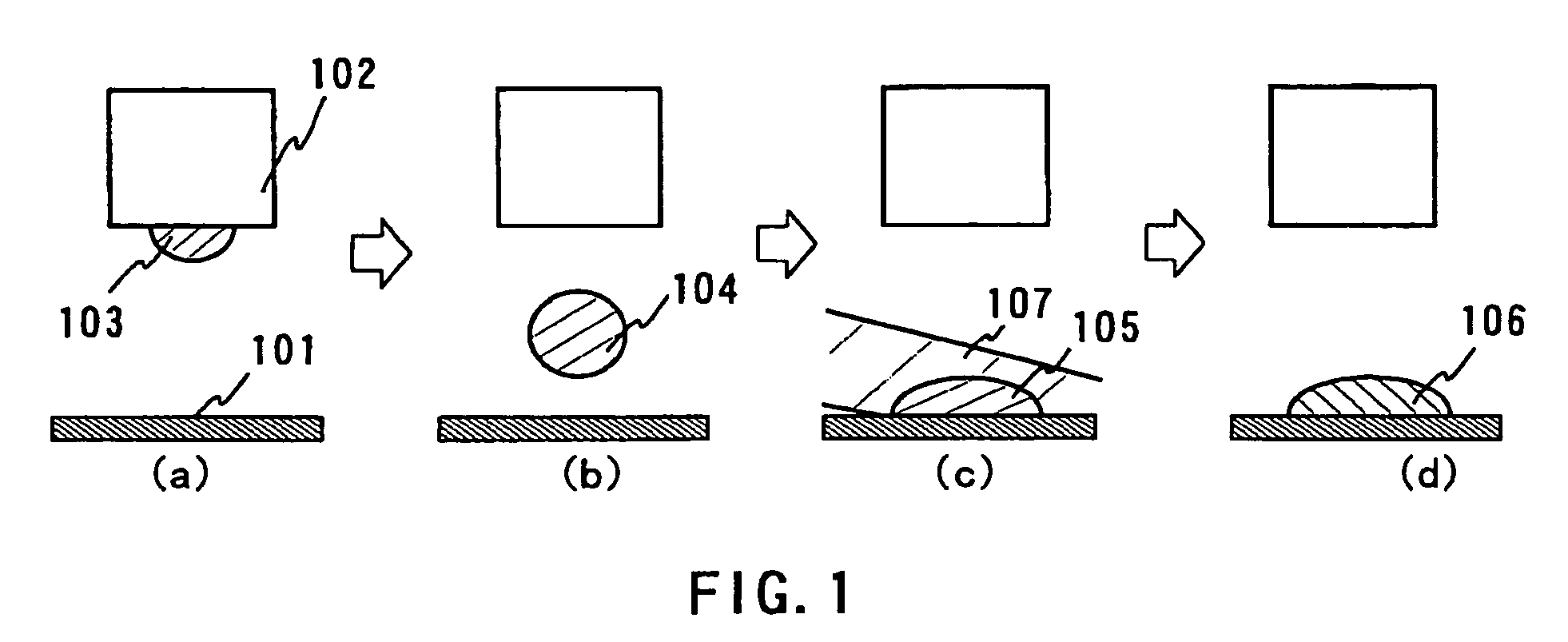

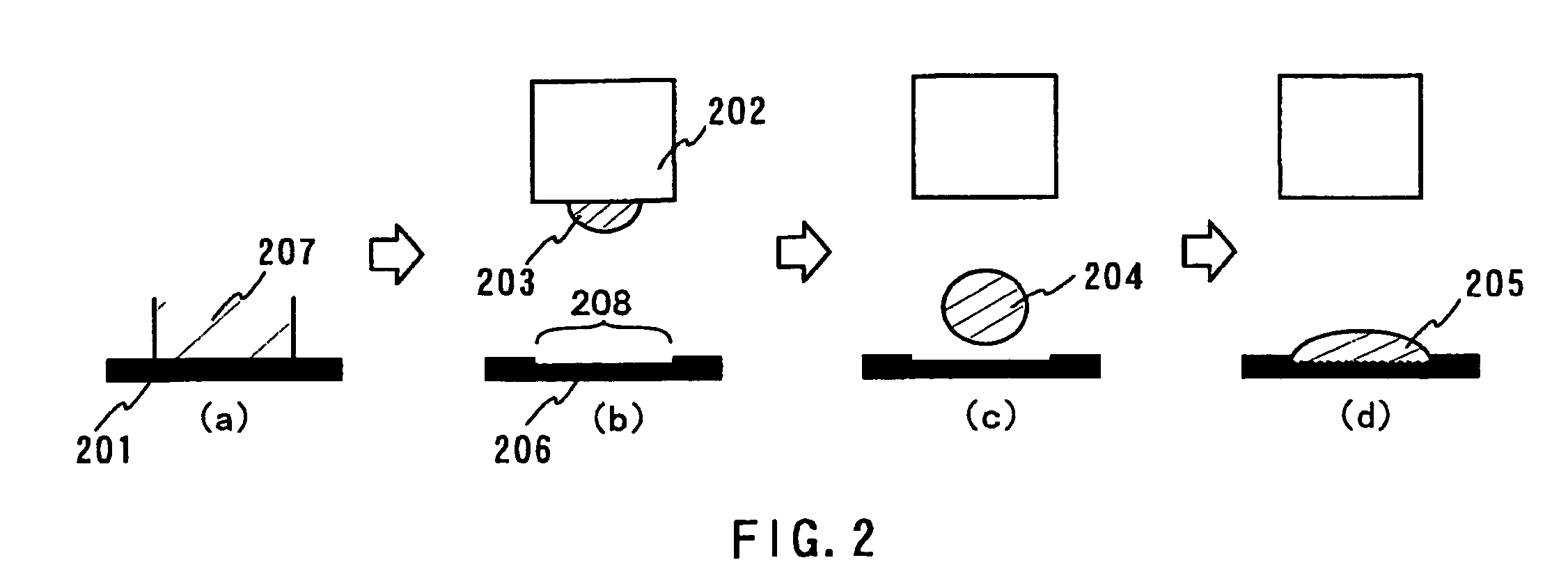

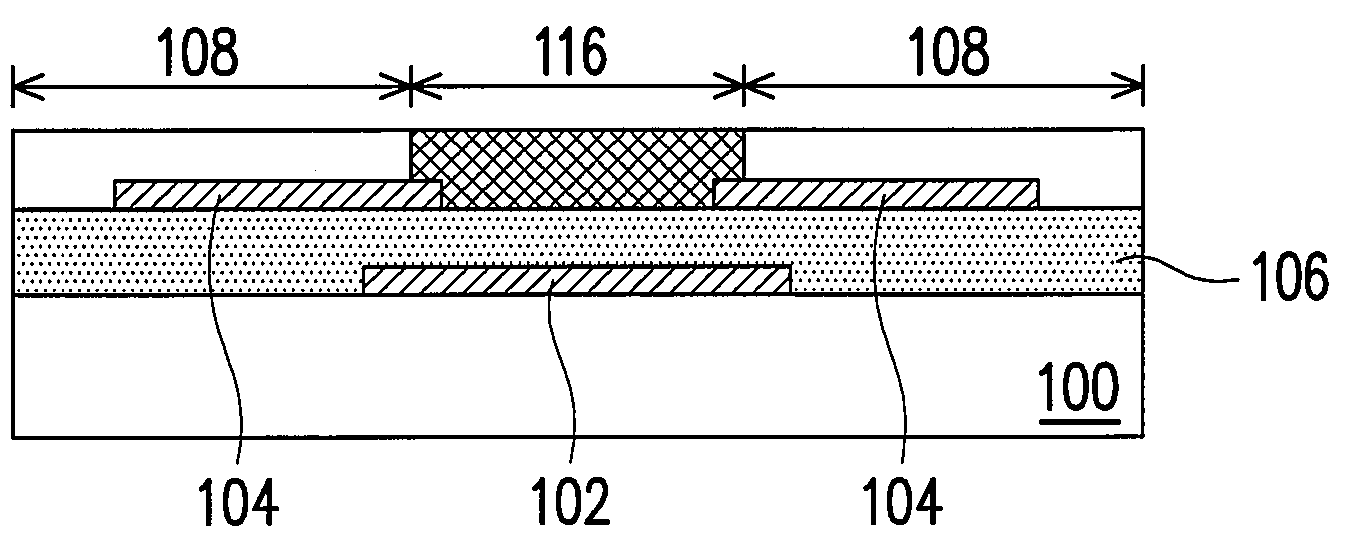

In this invention, it provides a method for forming a pattern, which is capable of improving position control after a drop, which was discharged from a drop discharge apparatus, was landed on a substrate. In addition, it provides a drop discharge apparatus which is capable of improving drop position accuracy after it was landed. Further, it provides a method for manufacturing a semiconductor device which uses the drop discharge apparatus of this invention.This invention is characterized in that a drop which was discharged from a discharge part, or a substrate on which a drop is landed, is irradiated with a laser beam, and a landing position of a drop is controlled. By this invention, it is possible to form a pattern, without using a photolithography process.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor, method of fabricating active layer thereof, and liquid crystal display

InactiveUS20080057631A1Manufacturing cost be reduceSimplify manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor propertiesLiquid-crystal display

A manufacturing method of an active layer of a thin film transistor is provided. The method includes following steps. First a substrate is provided, and a semiconductor precursor solution is then prepared through a liquid process. Thereafter, the semiconductor precursor solution is provided on the substrate to form a semiconductor precursor thin film. After that, a light source is used to irradiate the semiconductor precursor thin film to remove residual solvent and allow the semiconductor precursor thin film to produce semiconductor property, so as to form a semiconductor active layer.

Owner:TAIWAN TFT LCD ASSOC +6

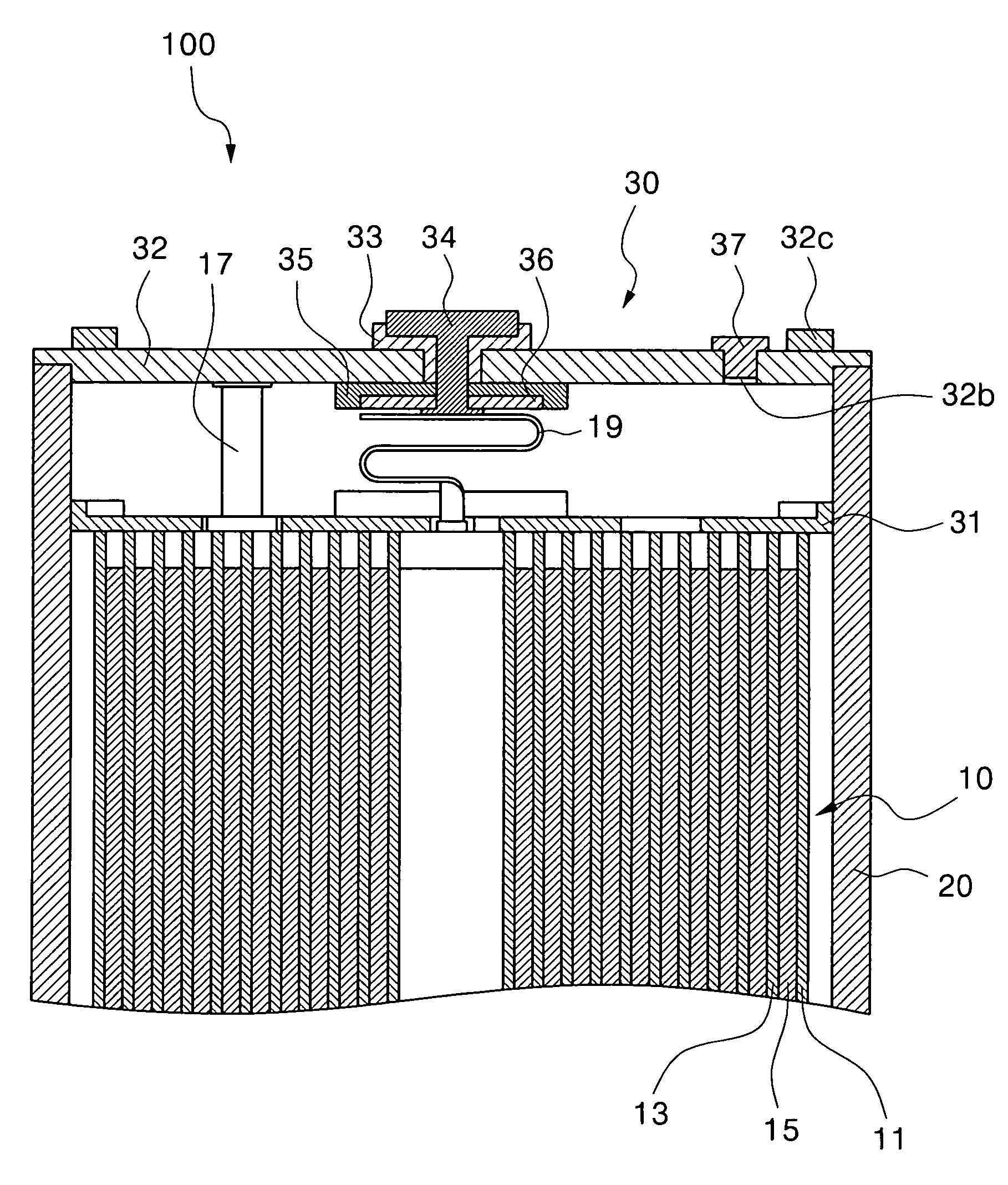

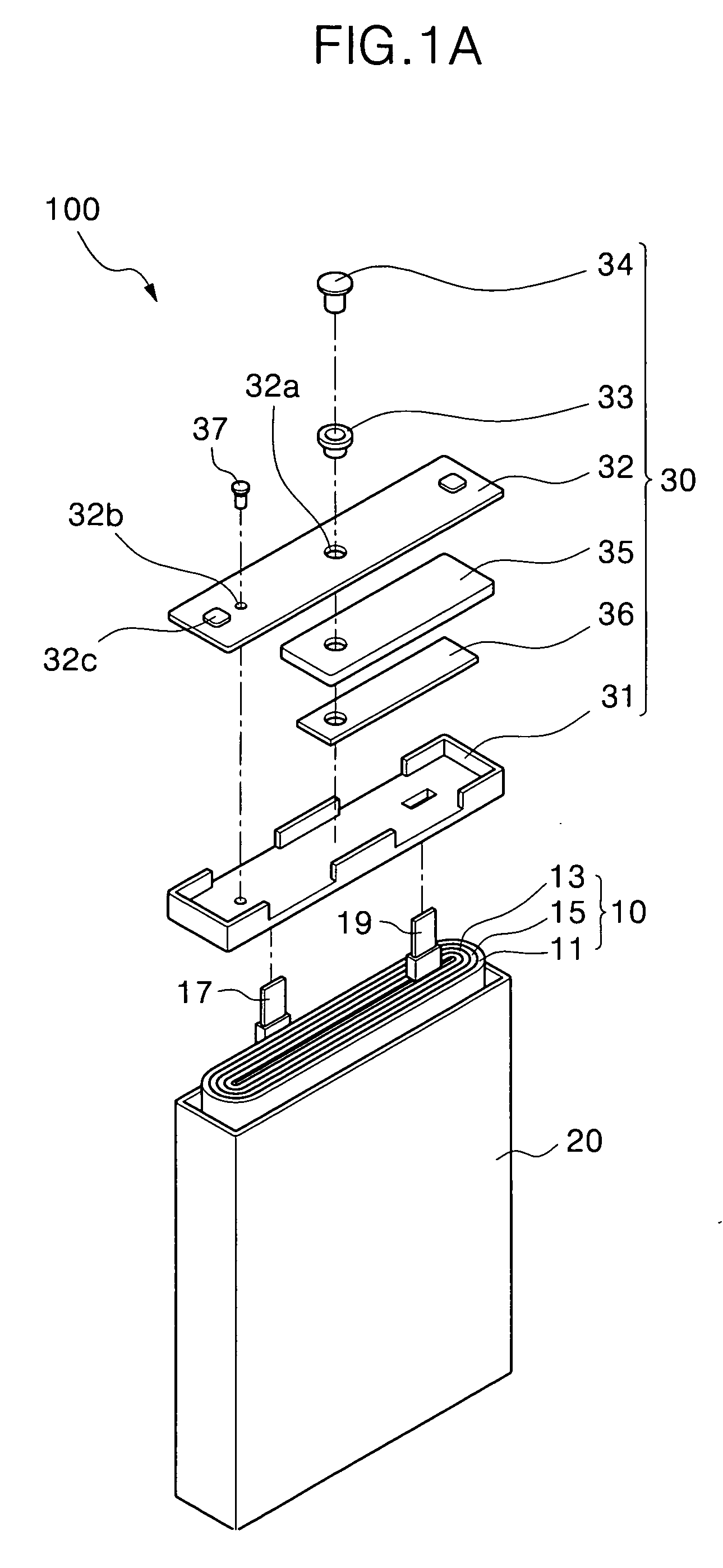

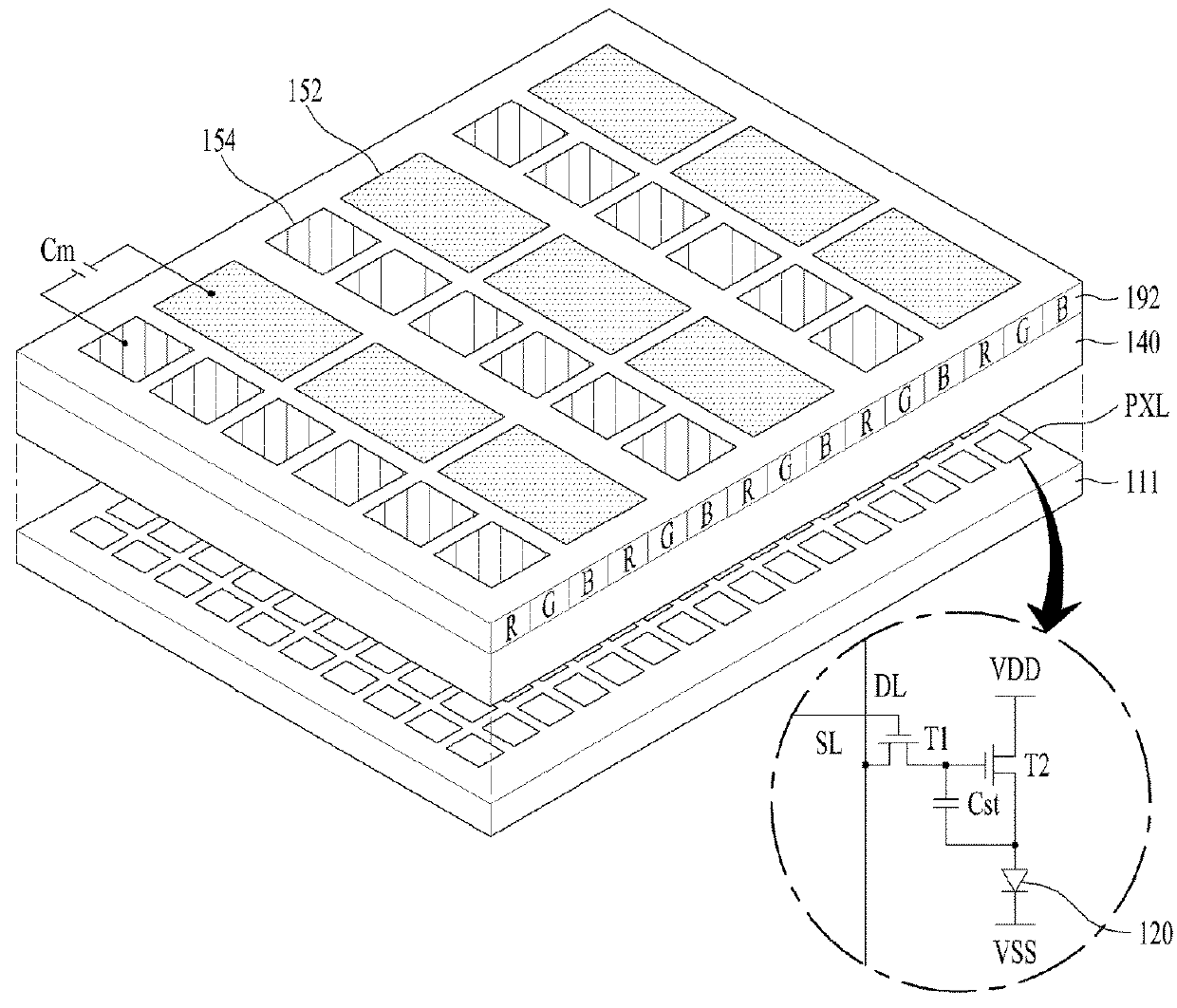

Protection circuit assembly and battery pack having the same

InactiveUS20090155632A1Simplify manufacturing processIncrease productivityCells structural combinationLi-accumulatorsProduction rateLead plate

A protection circuit assembly and a battery pack including the same, which can simplify a manufacturing process and increase productivity. The protection circuit assembly includes a protection circuit board including a connection terminal, and a first lead plate connected to the connection terminal and having a coupling hole. The battery pack includes a bare cell having a protrusion, and a protection circuit assembly electrically connected with the bare cell and including a first lead plate having a coupling hole. Accordingly, the battery pack includes a protection circuit assembly including a lead plate having a coupling hole, and a bare cell including a structure inserted into the coupling hole, and thus it is possible to simplify a manufacturing process and increase productivity.

Owner:SAMSUNG SDI CO LTD

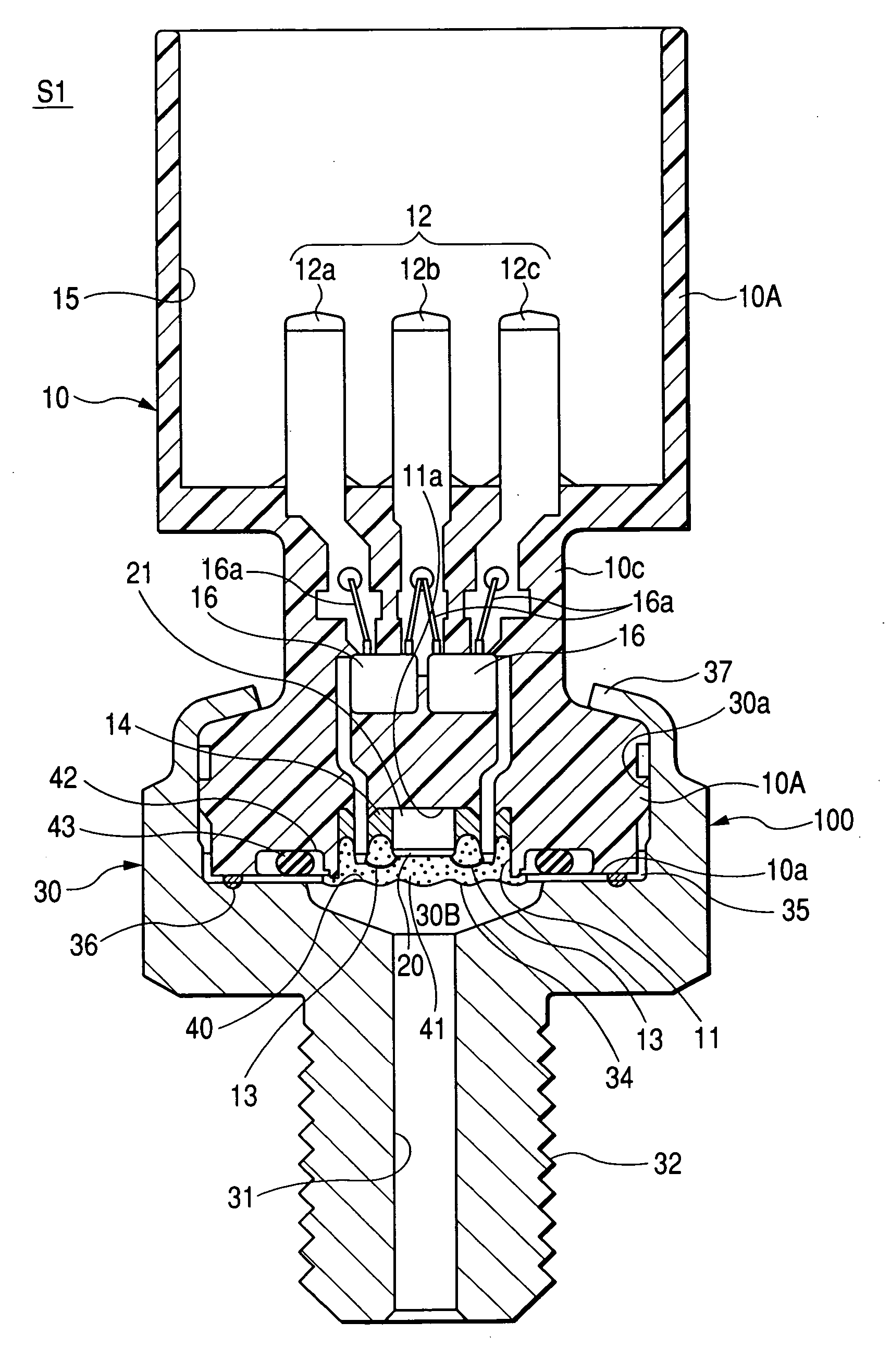

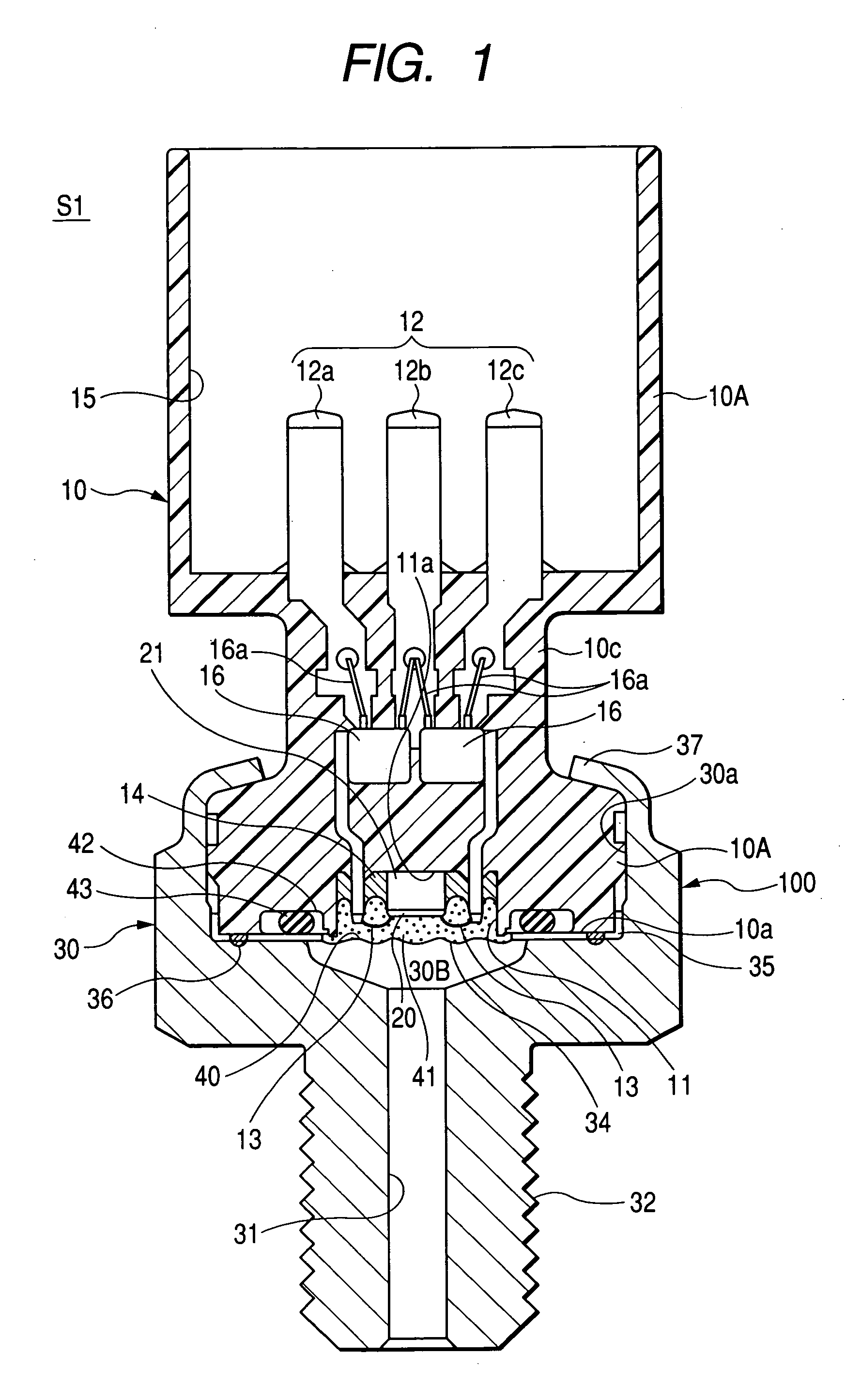

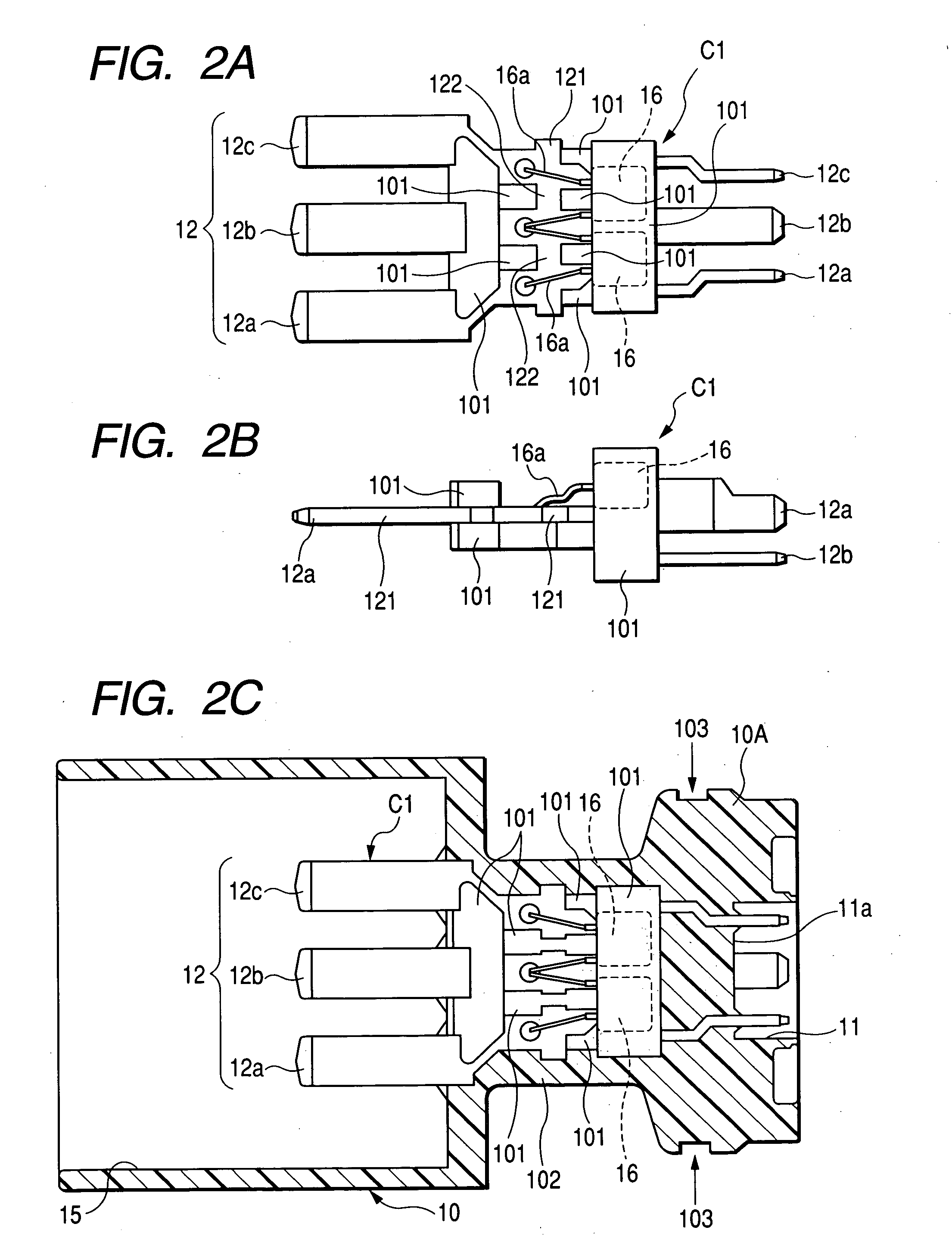

Pressure sensor and related method

ActiveUS20050204823A1Simplify manufacturing processCost reductionSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringPressure sensor

A pressure sensor and related manufacturing method are disclosed wherein a connector case 10 is coupled to a housing 30 in a unitary structure. The connector case 10 includes a primary resin section 101 that enfolds and seals a terminal 12 while fixedly supporting a capacitor 16 on the terminal 12. The primary resin section 101 is encompassed by a secondary resin section 102 so as to enfold and seal the primary resin section 101 such that both ends of the terminal 12 are exposed to an outside. In one aspect, the primary resin section 101 enfolds and seals the capacitor and the terminal. In another aspect, the primary resin section 101 enfolds and seals the terminal and is formed with fixing portions 101a, 10ab, 101c by which the capacitor is fixedly supported on the terminal.

Owner:DENSO CORP

Liquid crystal display device and method for manufacturing the same

InactiveUS20070069210A1Material efficiency be improveSimplify manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingEtchingMaterial efficiency

As a substrate gets larger, time of manufacture is increased due to the repetition of film formations and etchings; waste disposal costs of etchant and the like are increased; and material efficiency is significantly reduced. A base film for improving adhesion between a substrate and a material layer formed by a droplet discharge method is formed in the invention. Further, a manufacturing method of a liquid crystal display device according to the invention includes at least one step for forming the following patterns required for manufacturing a liquid crystal display device without using a photomask: a pattern of a material layer typified by a wiring (or an electrode) pattern, an insulating layer pattern; or a mask pattern for forming another pattern.

Owner:SEMICON ENERGY LAB CO LTD

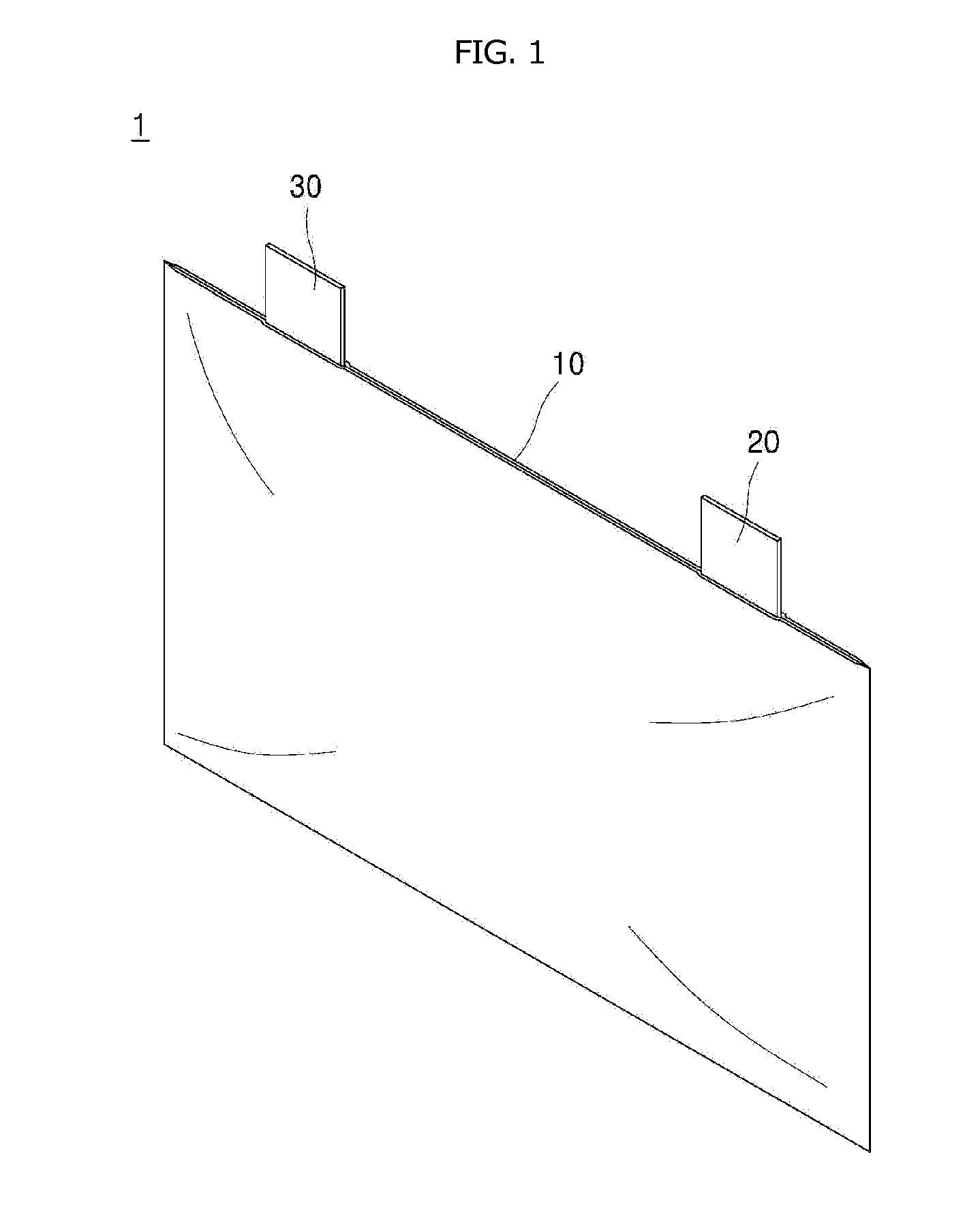

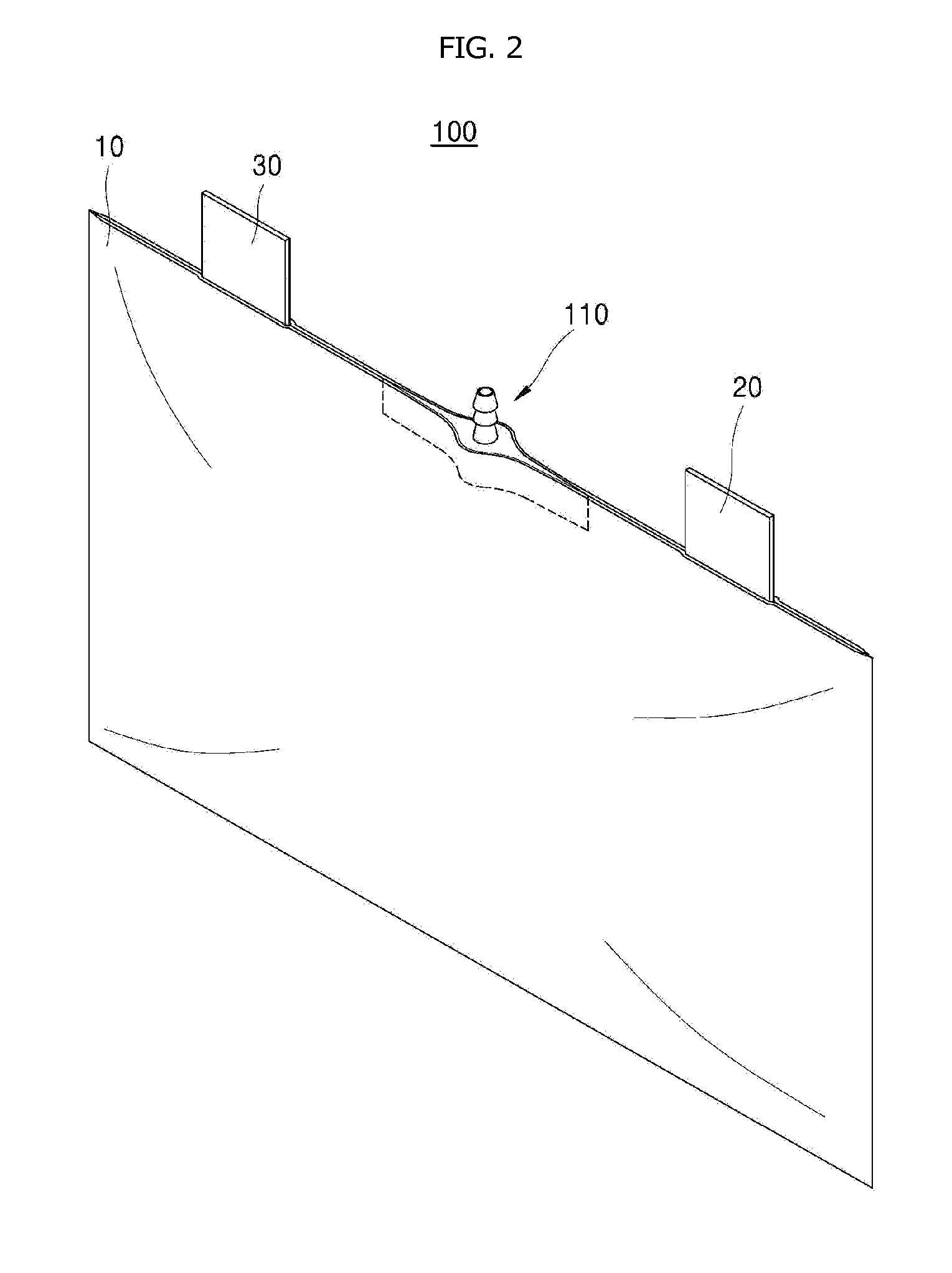

Pouch type lithium secondary battery having tubular passage structure

ActiveUS20160020452A1Simplify manufacturing processImprove performanceFinal product manufactureVent arrangementsUrologyElectrolyte

Provided is a pouch type lithium secondary battery having a tubular passage structure. The pouch type lithium secondary battery having a tubular passage structure includes: a tubular passage structure having a passage of injecting an electrolyte from an outer portion of a pouch and discharging gas from an inner portion of the pouch by communicating the inner portion of the pouch with the outer portion of the pouch.

Owner:SK ON CO LTD

Display Device with Touch Sensor

ActiveUS20180095567A1Simplify manufacturing processCost reductionSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsAdhesion process

Disclosed are an organic light emitting display device and a method of manufacturing the same to reduce thickness and weight. The organic light emitting display device with a touch sensor removes the necessity of an additional adhesion process by directly forming a touch sensing electrode and a touch driving electrode arranged in parallel and a color filter on an encapsulation layer covering a light emitting device, thereby simplifying a manufacturing process and reducing manufacturing costs.

Owner:LG DISPLAY CO LTD

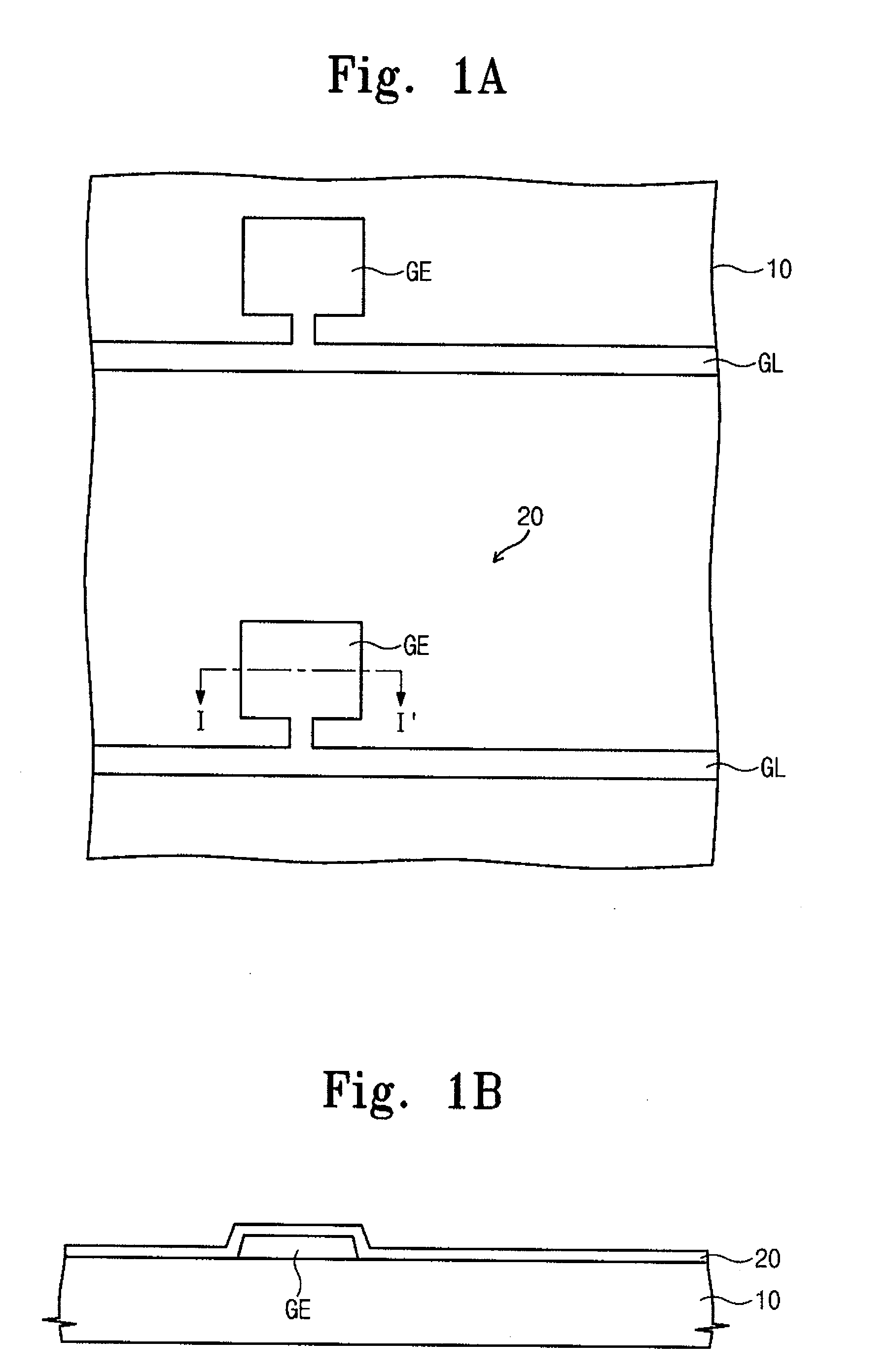

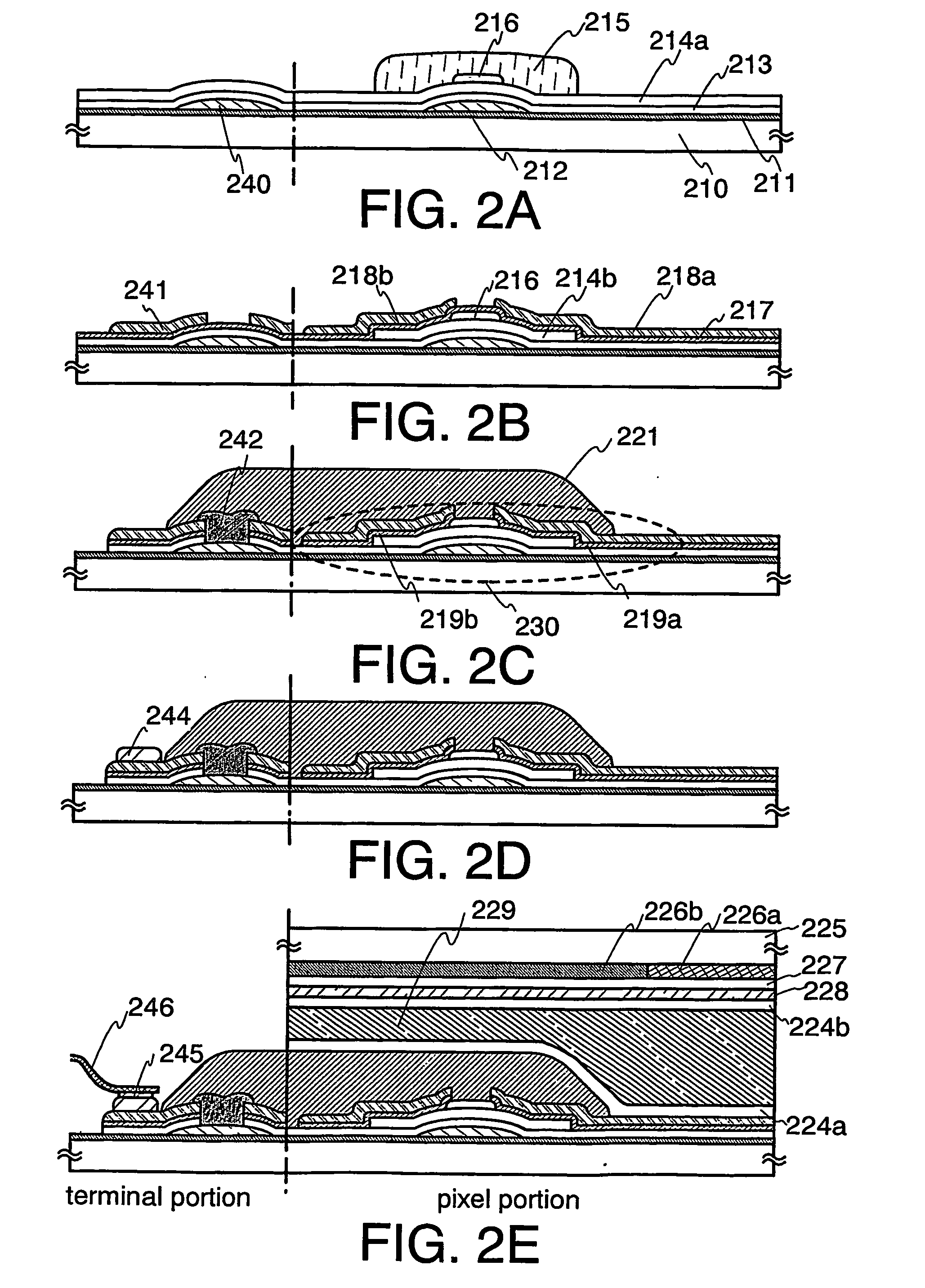

Liquid crystal display device and method of manufacturing the same

ActiveUS20060097261A1Simplify manufacturing processManufacturing cost be reduceSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A liquid crystal display device including first and second active layers over a substrate, a storage line over the second active layer, a first insulating layer over the storage line, a gate electrode on the first insulating layer and corresponding to the first active layer, a second insulating layer over the gate electrode, source and drain electrodes connected to the first active layer through the first and second insulating layers, a gate line connected to the gate electrode through the second insulating layer, a data line substantially perpendicularly arrange with respect to the gate line to define a pixel region, a pixel electrode connected to the drain electrode through the second insulating layer, and a connection line connected to one of the gate line and the data line through the second insulating layer.

Owner:LG DISPLAY CO LTD

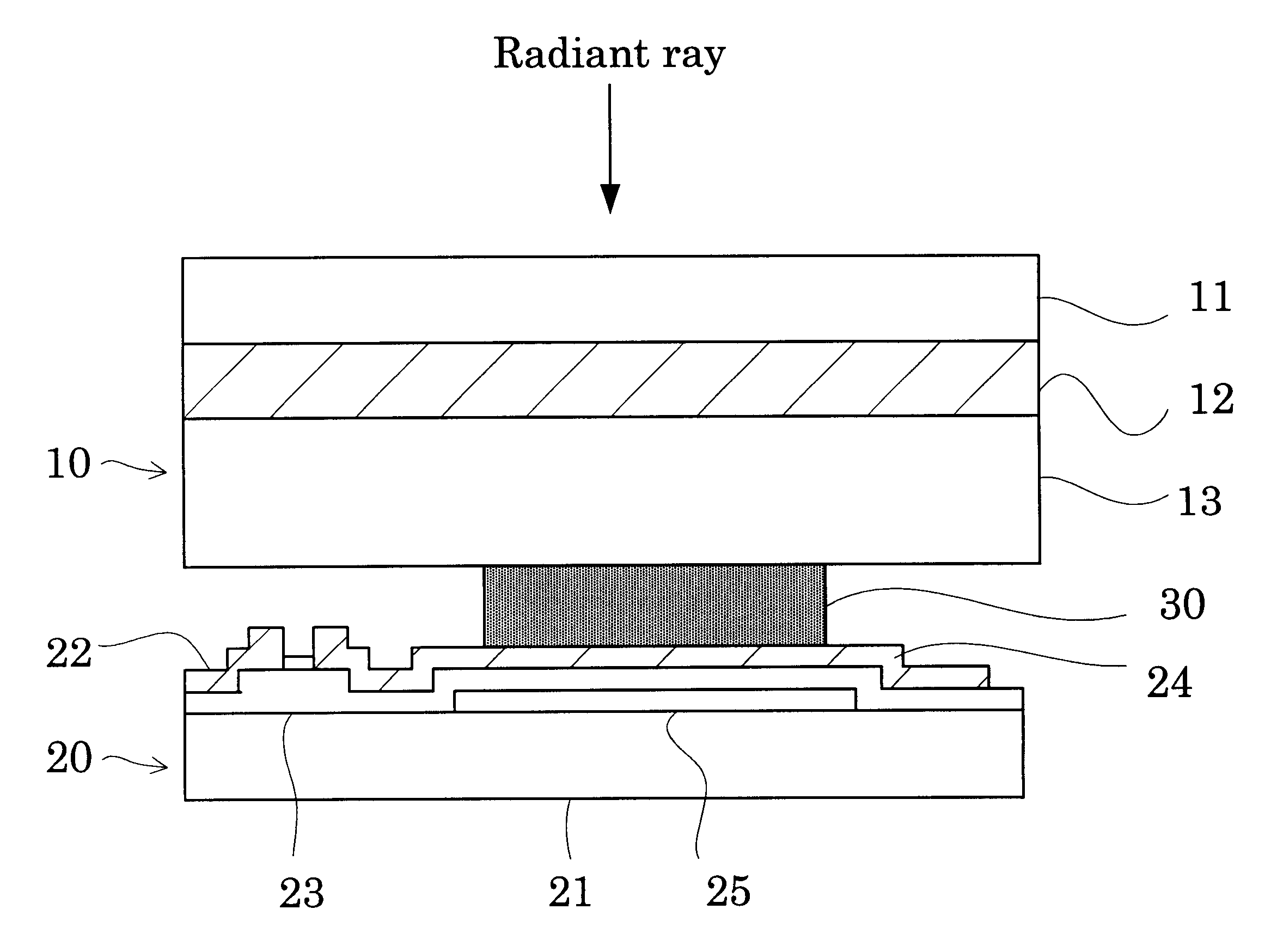

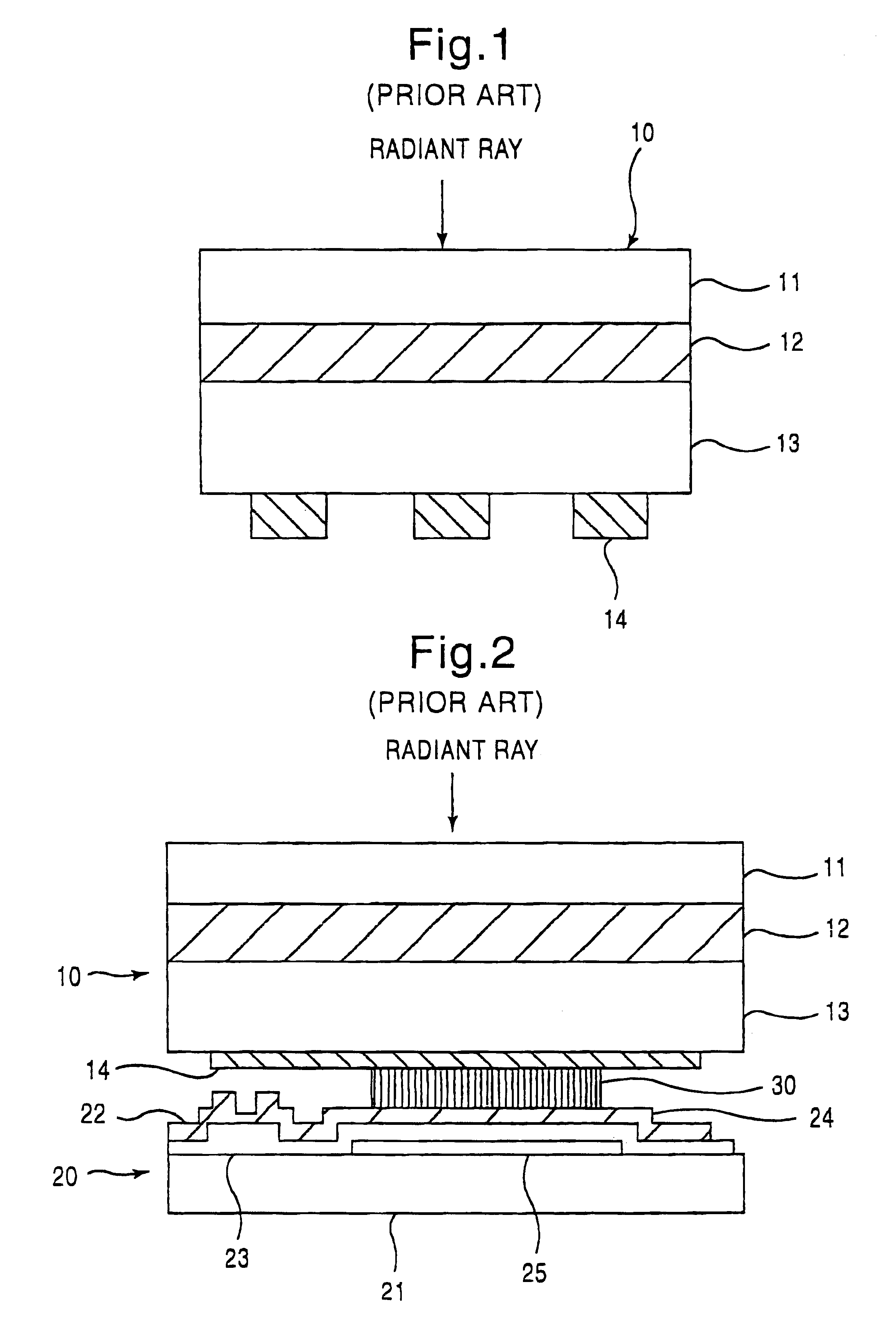

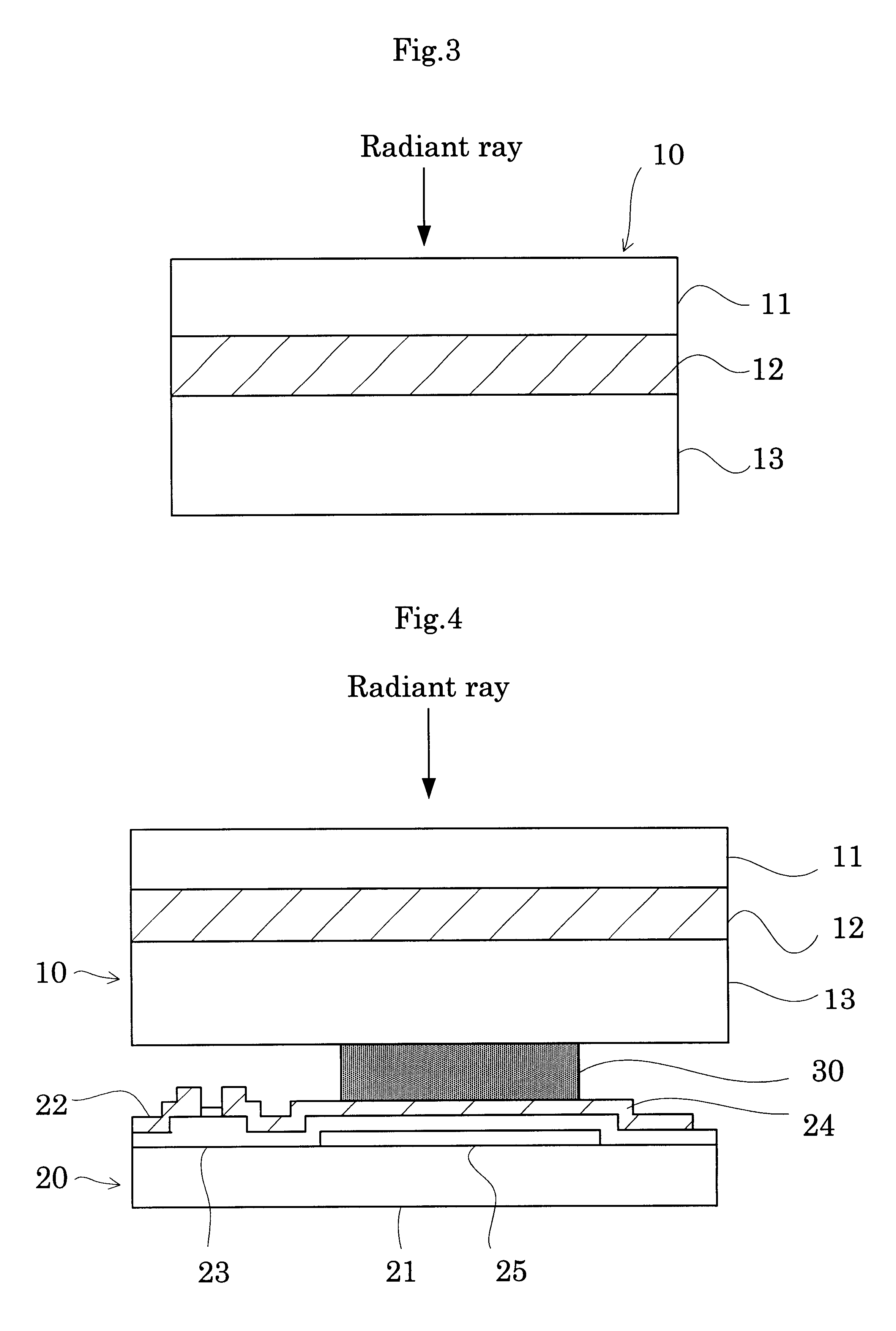

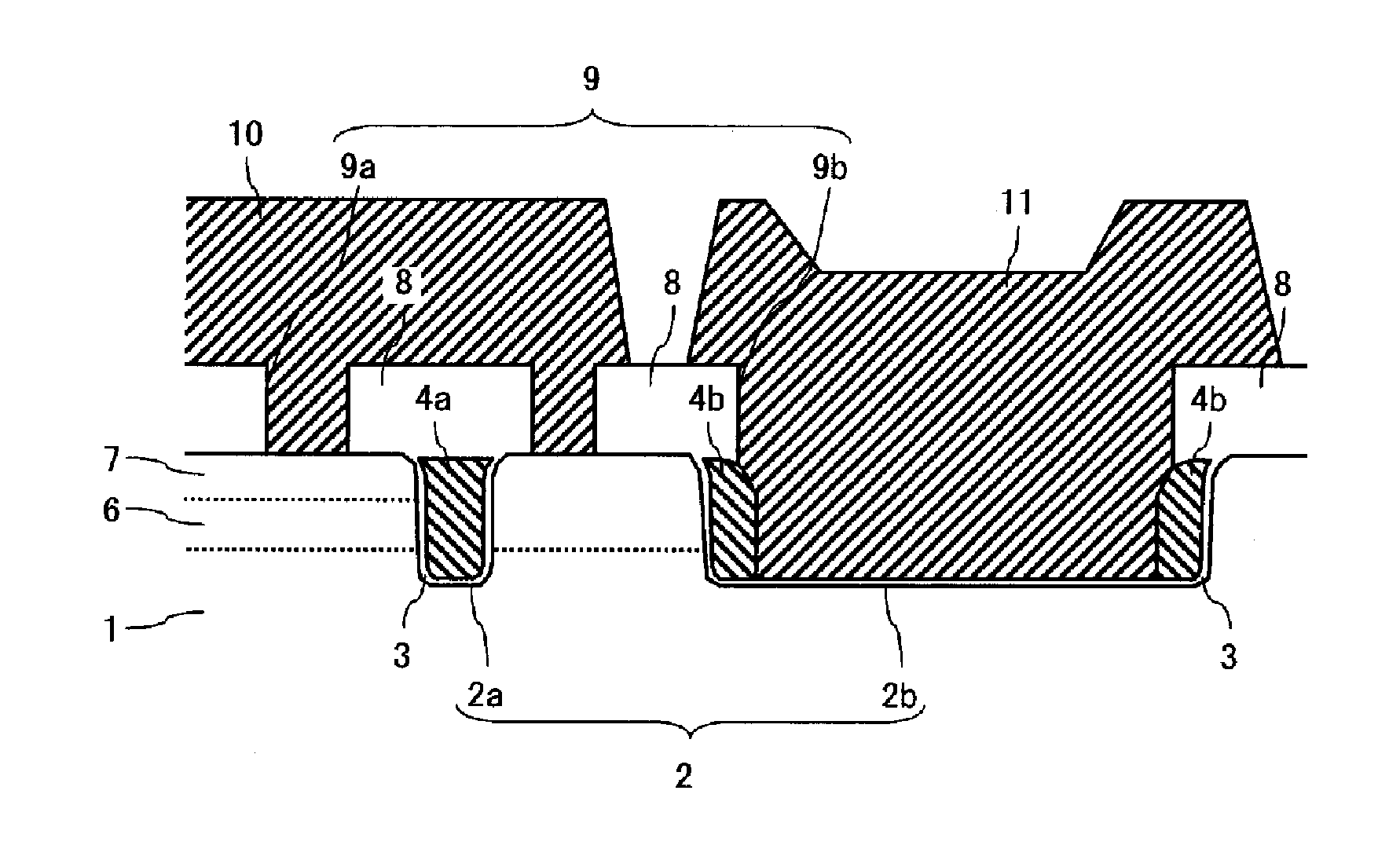

Electromagnetic imaging apparatus and manufacturing method therefor

ActiveUS6949749B2Simplify structureSimplify manufacturing processTelevision system detailsSolid-state devicesPhysicsSurface plate

A detector panel having a bias application electrode and a converter layer formed on a supporting substrate, and a readout panel (active matrix panel), are bonded to each other directly through a single layer of electroconductive resin. That is, a pattern of photosensitive resin is formed before-hand on reading electrodes of the readout panel, and this readout panel and the converter layer are bonded together directly. Since the converter layer has no pixel electrodes formed thereon, the converter layer need not be smoothed, and the two panels need not be positionally adjusted to each other with high precision.

Owner:SHIMADZU CORP +1

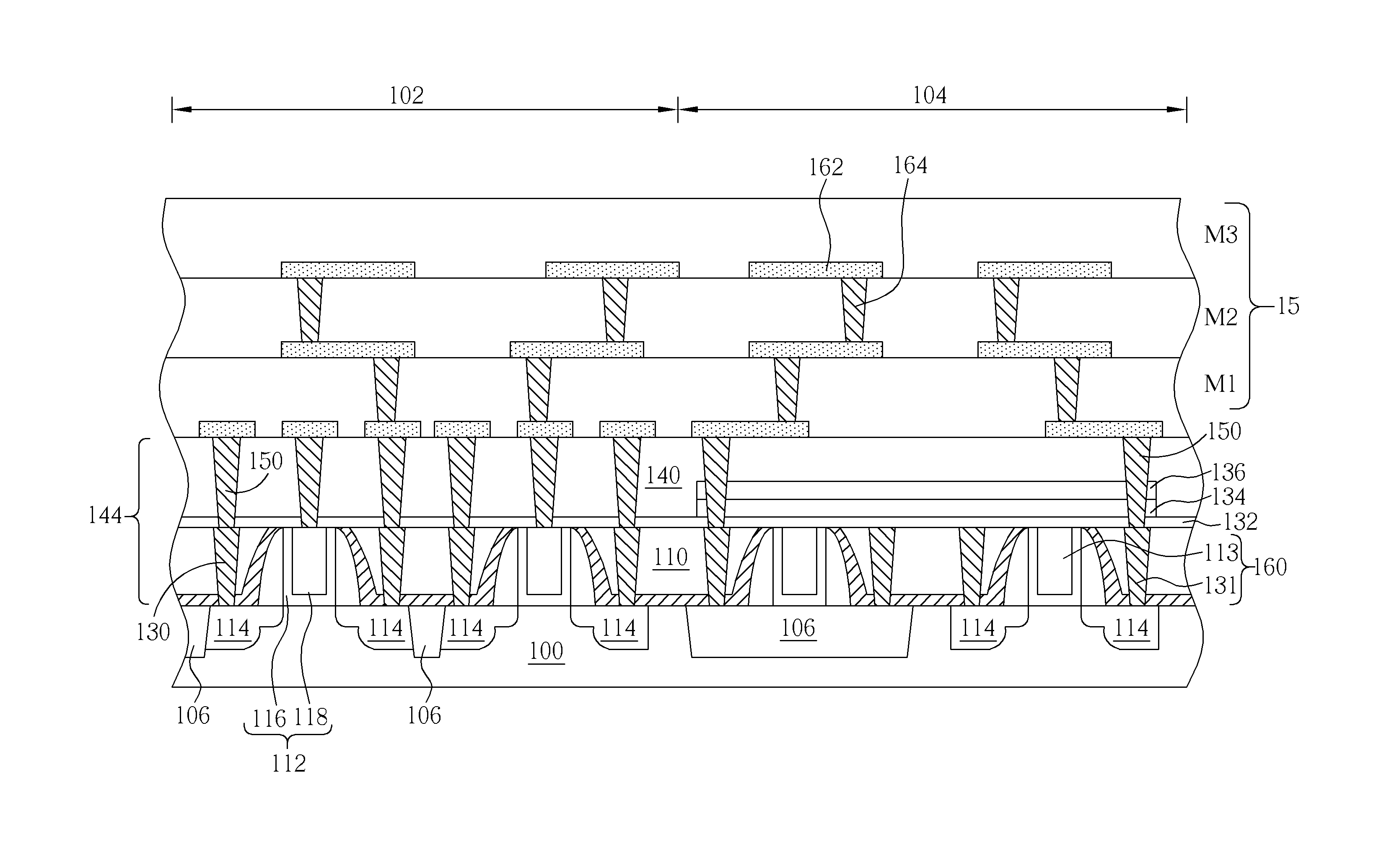

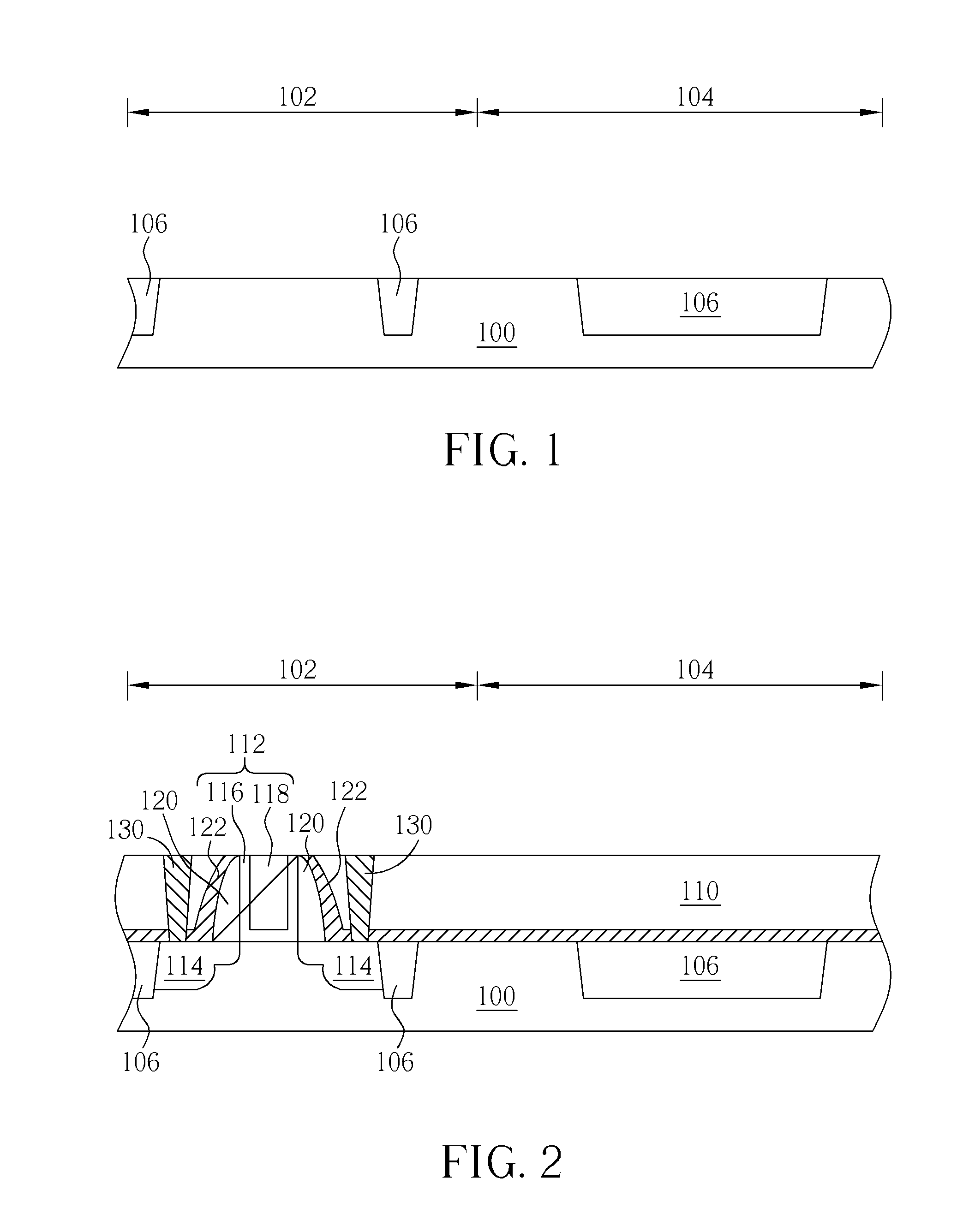

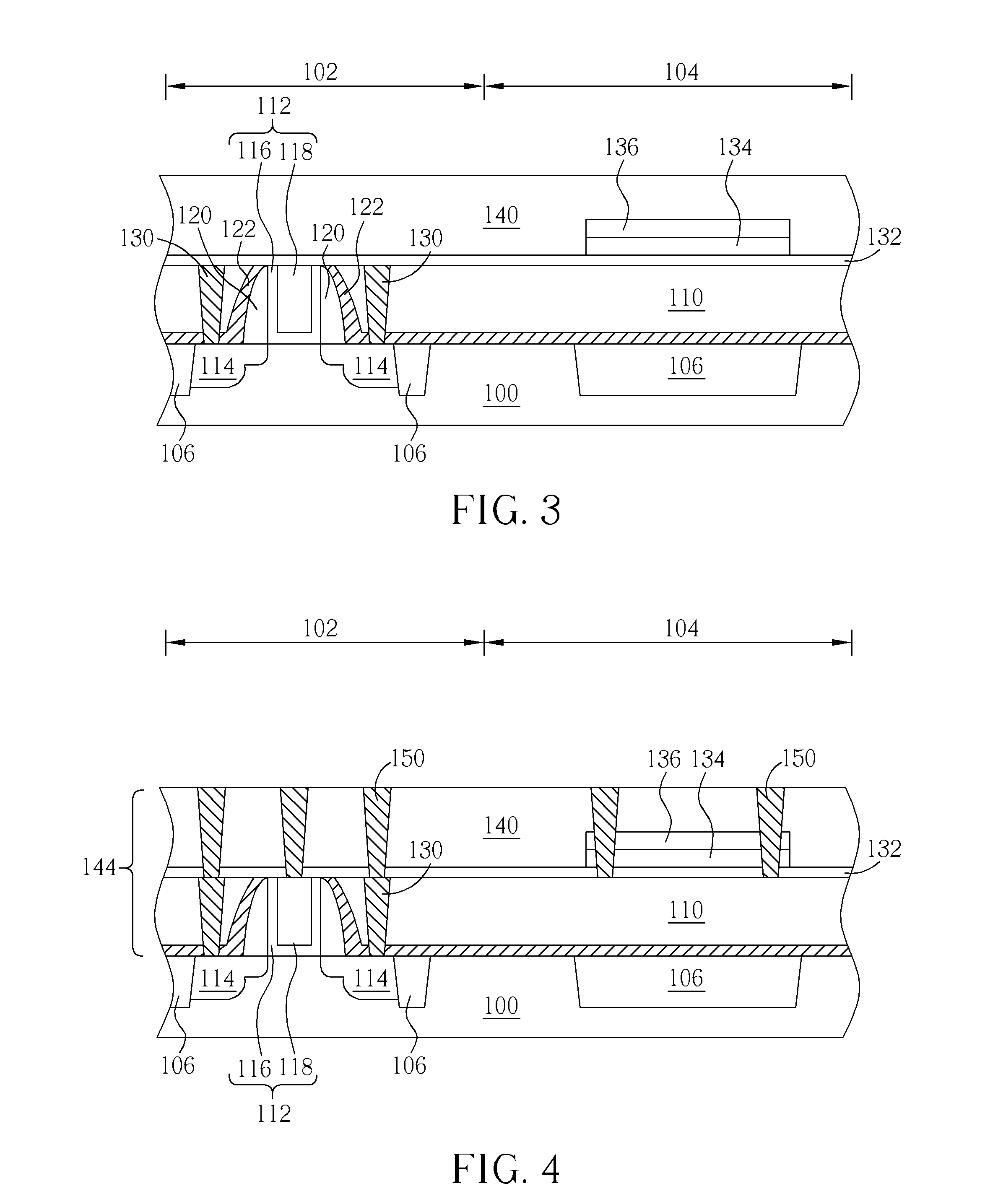

Semiconductor device and method of manufacturing the same

InactiveUS20100258863A1Cost reductionSimplify manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETSemiconductor

A semiconductor device according to the present invention having a vertical MOSFET that includes a first trench that is formed in a semiconductor substrate and includes a gate electrode of the vertical MOSFET embedded therein with a gate insulating film interposed therebetween, a second trench that is connected with the first trench and has a trench width wider than the first trench, a gate pad that is connected with the gate electrode and formed to a sidewall of the second trench with the gate insulating film interposed therebetween, and a gate line that is connected with a sidewall of the gate pad and electrically connects with the gate electrode via the gate pad.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com