Patents

Literature

72results about How to "High degree of reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

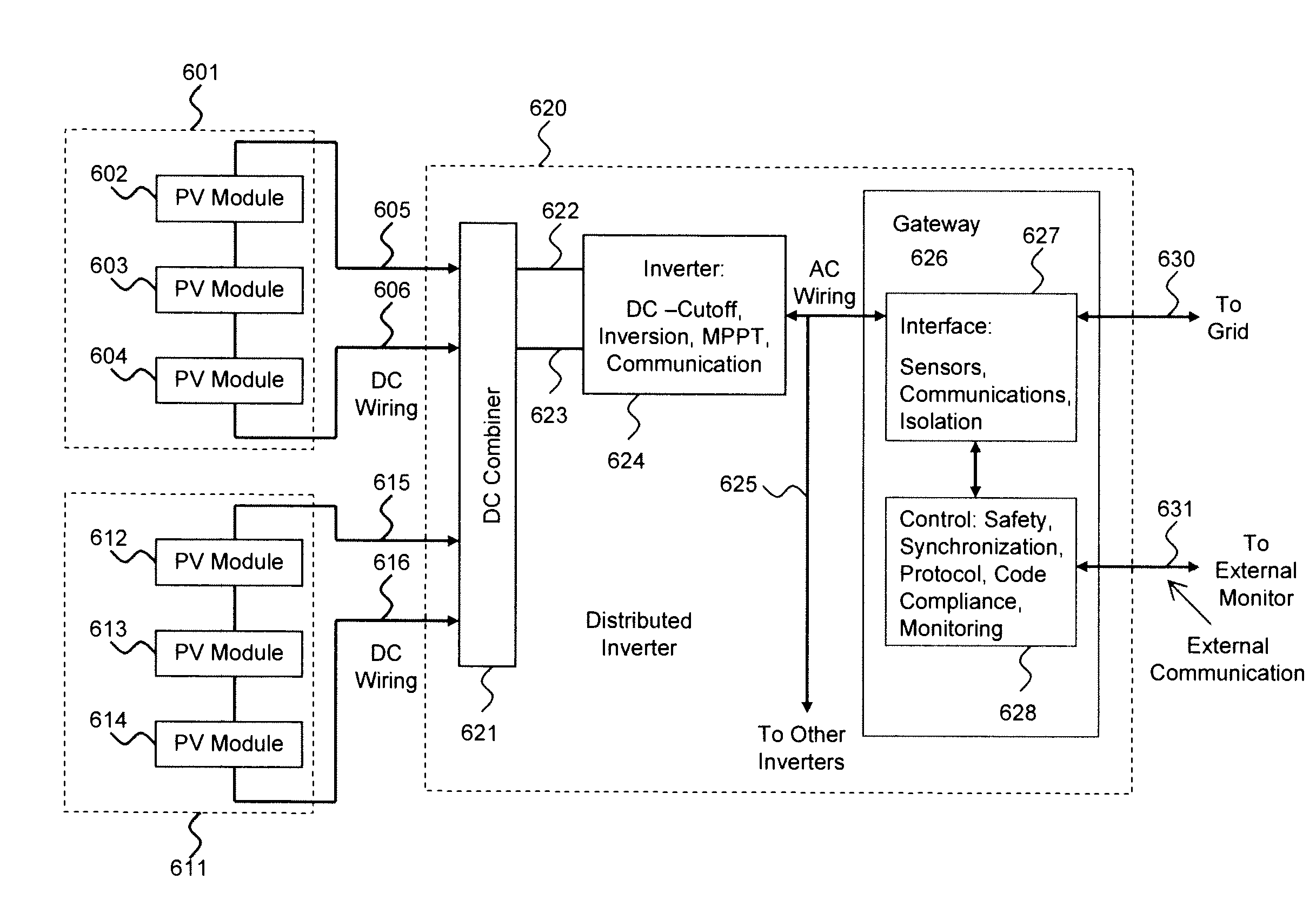

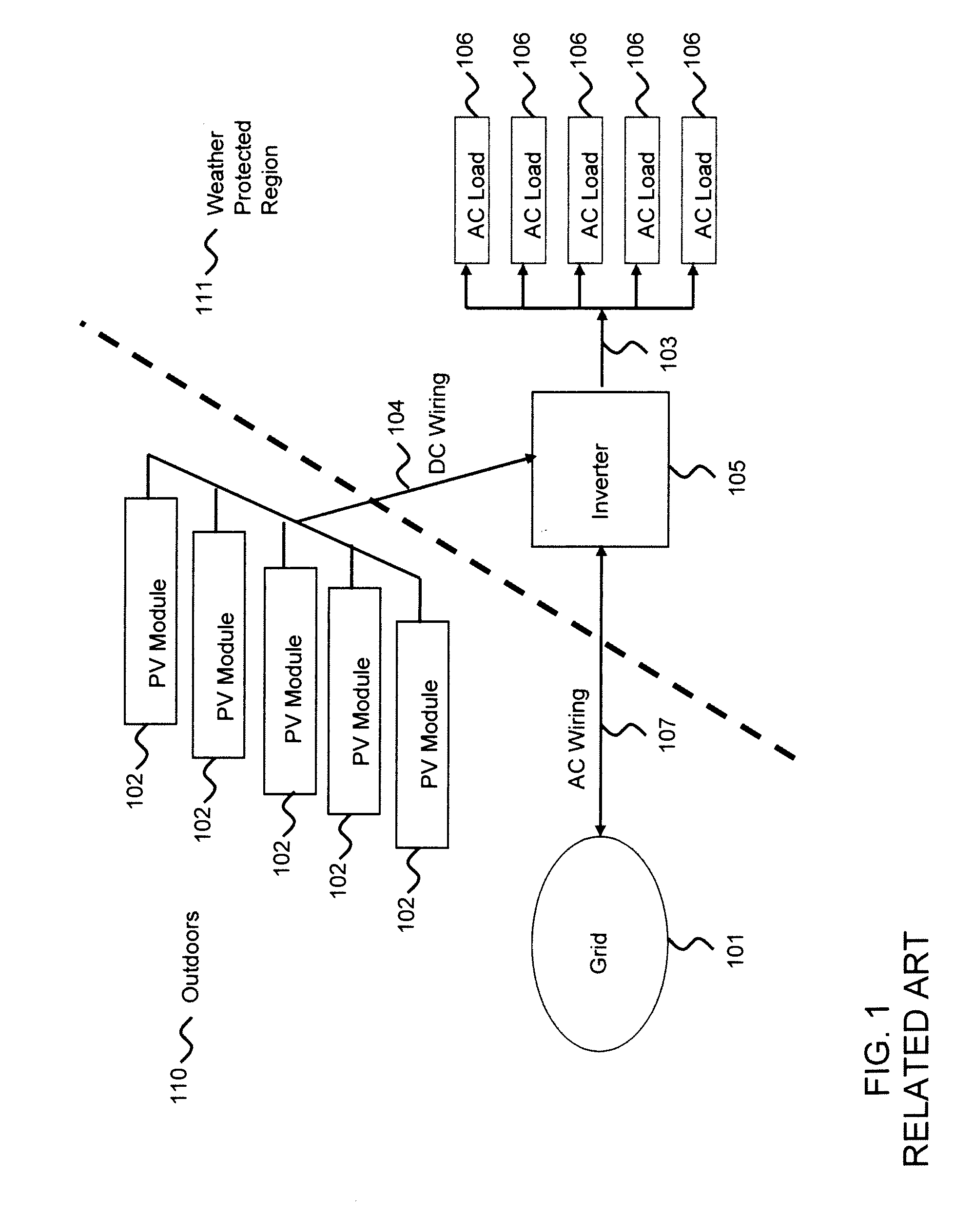

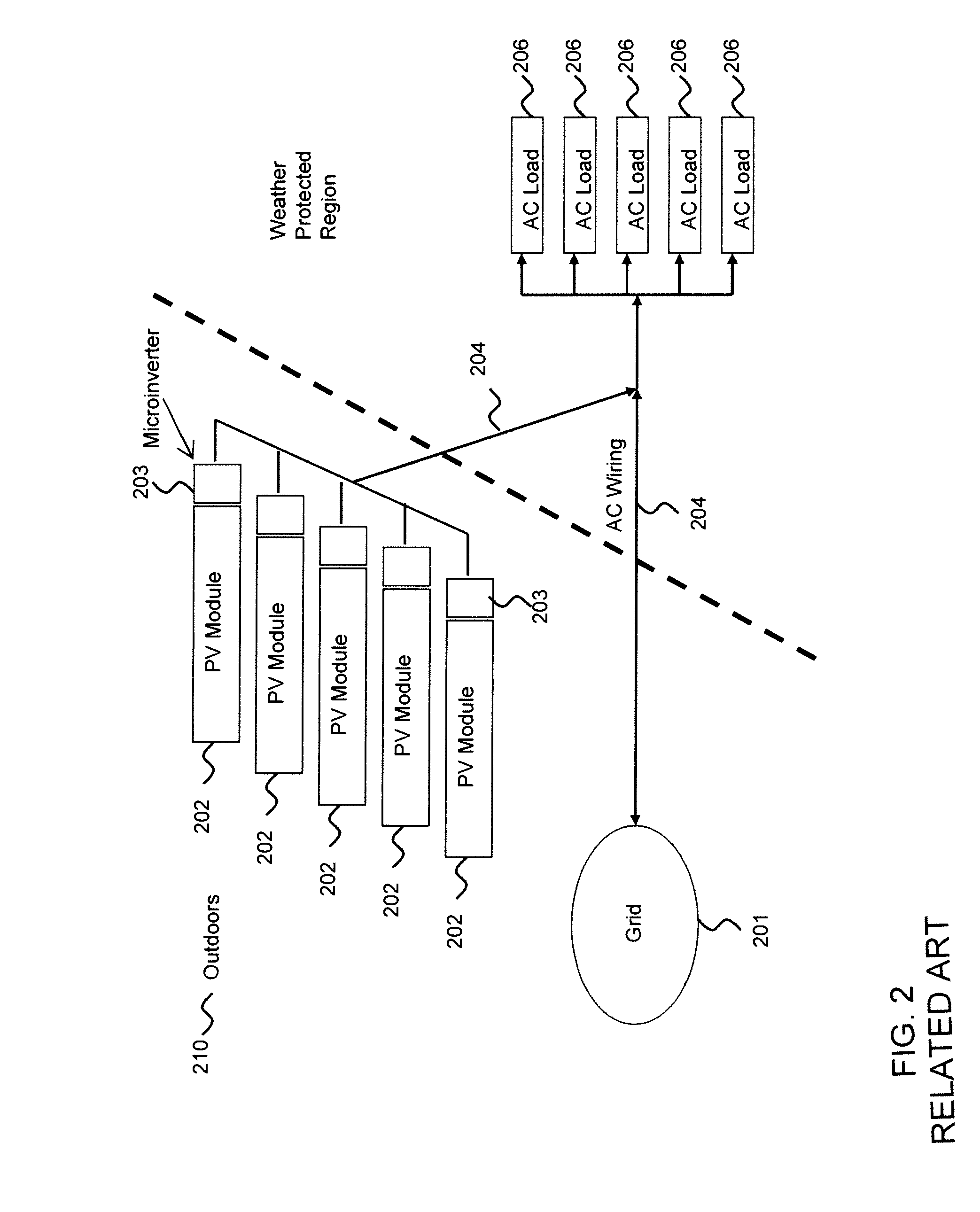

Distributed inverter and intelligent gateway

InactiveUS20090000654A1Simple and safeHigh degree of reliabilityDc network circuit arrangementsPV power plantsAC powerEngineering

A system and method for converting DC from one or more sources to AC power utilizing a novel partitioning scheme are disclosed. This partitioning scheme is particularly well suited for photovoltaic (PV) microinverter applications. The primary goals are to make installation, operation and maintenance of the system safe and simple. Secondary goals are to improve reliability and lifetime of the converter in a cost effective manner. In one embodiment, the microinverters are placed in one-to-one proximity with the photovoltaic modules, each proximate microinverter incorporating a reduced number of functions and components. Remaining common functions and controls are implemented separately.

Owner:ENPHASE ENERGY

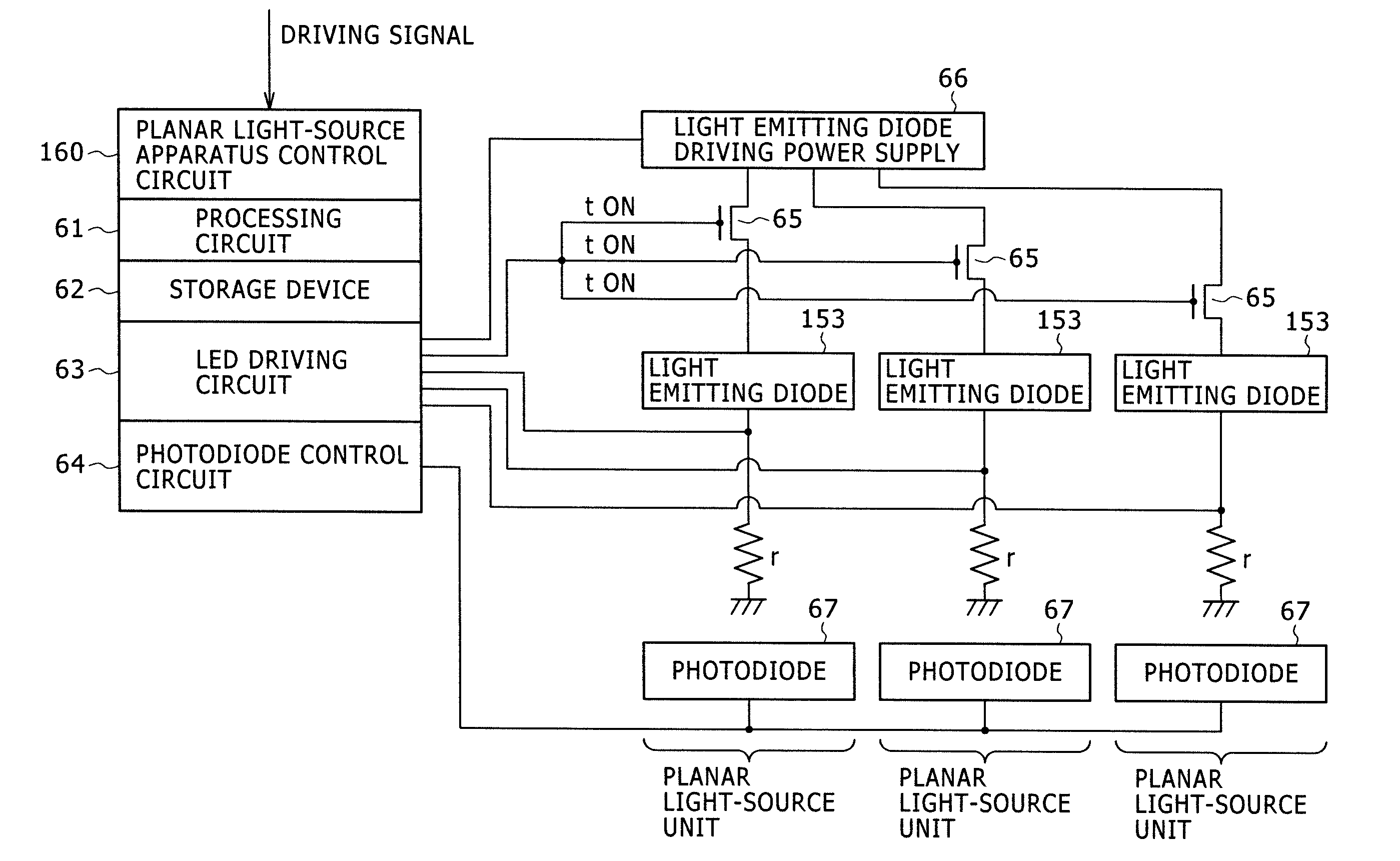

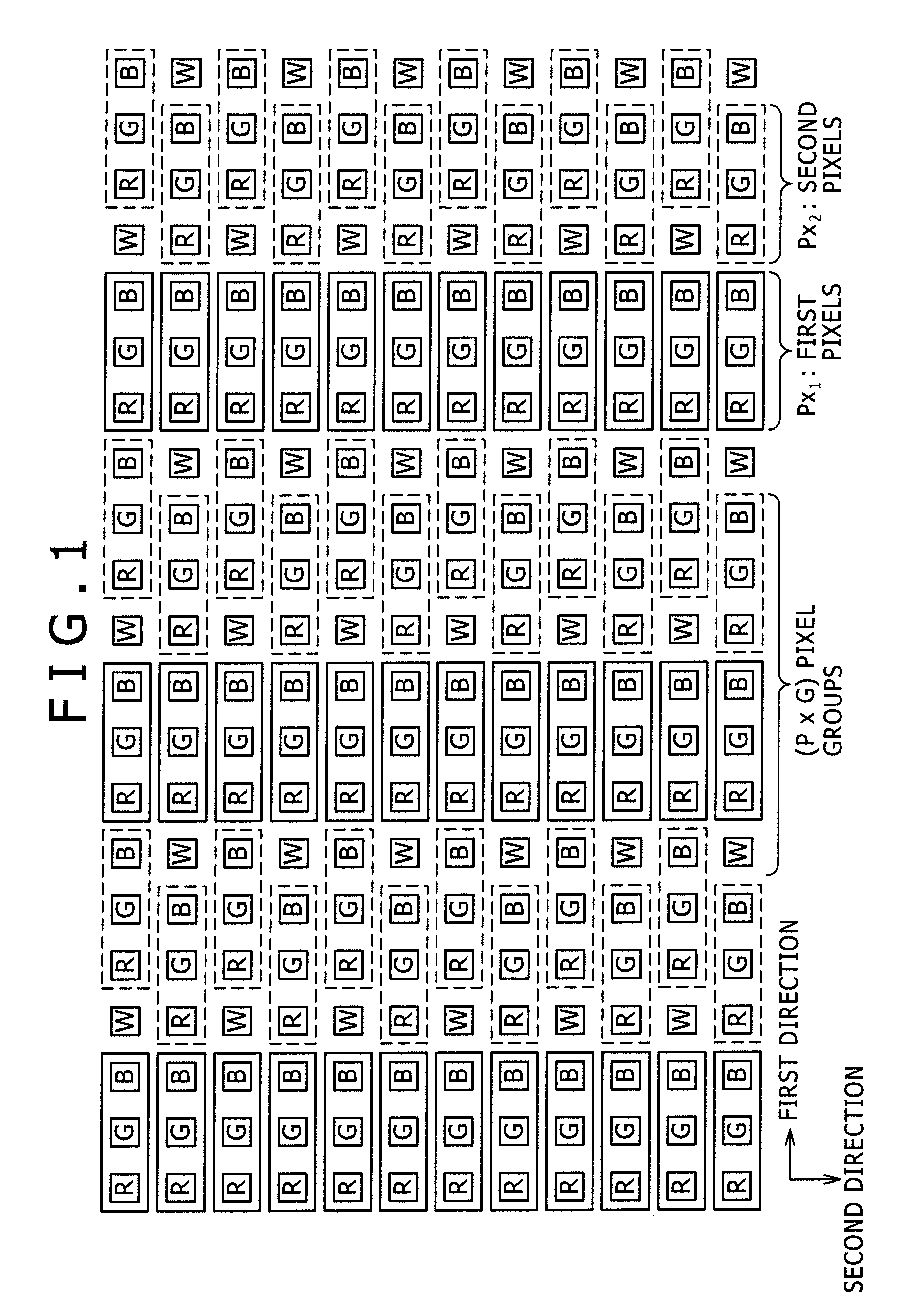

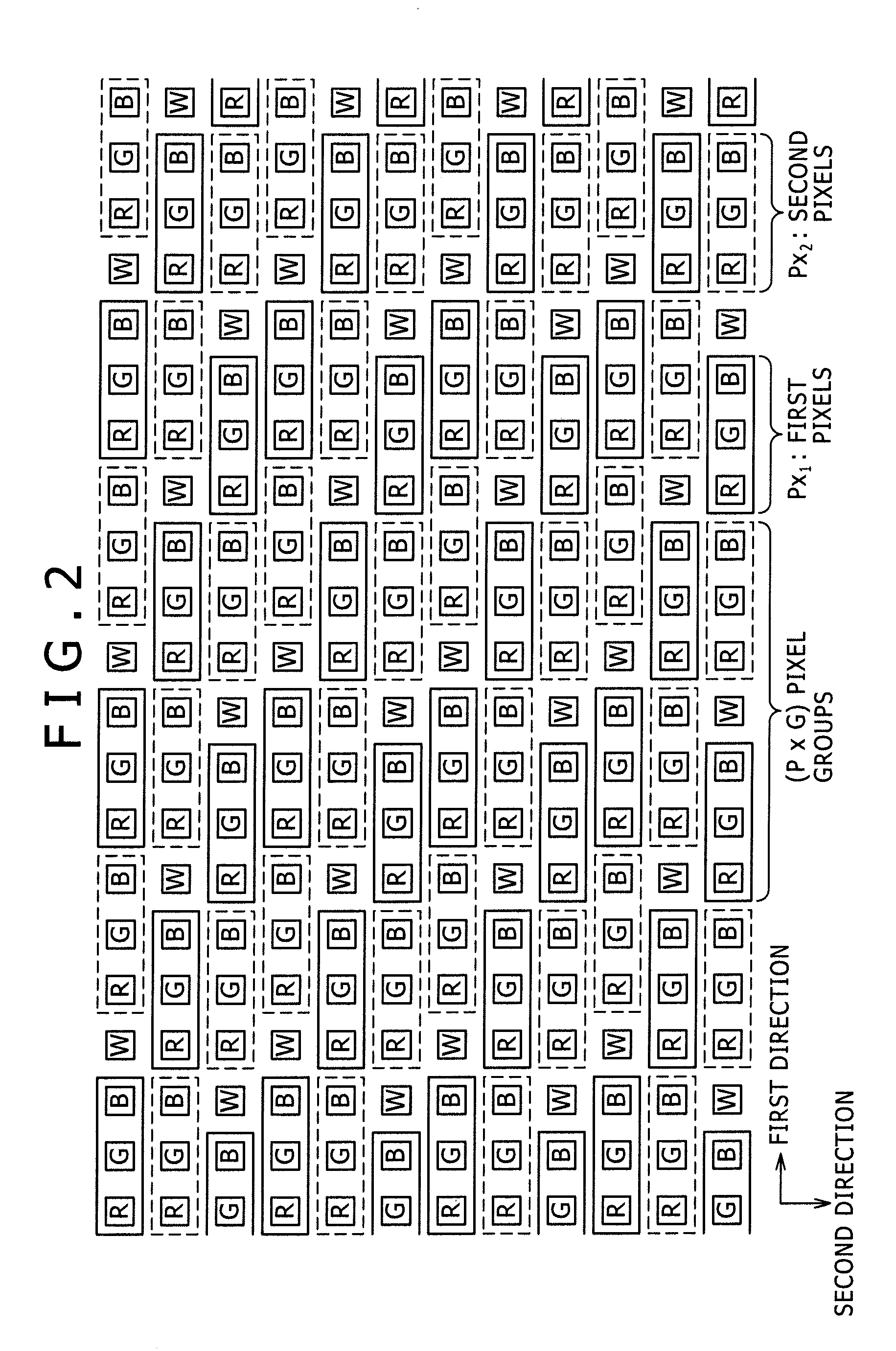

Image display panel, image display apparatus driving method, image display apparatus assembly, and driving method of the same

ActiveUS20090322802A1Increase luminanceHigh degree of reliabilityCathode-ray tube indicatorsInput/output processes for data processingSignal processingImage display

Disclosed herein is a method for driving an image display apparatus including: an image display panel whereon pixels each having first to third sub-pixels are laid out in first and second directions to form a 2-dimensional matrix, at least each specific pixel and an adjacent pixel adjacent to the specific pixel in the first direction are used as first and second pixels respectively to create one of pixel groups, and a fourth sub-pixel is placed between the first and second pixels in each of the pixel groups; and a signal processing section configured to generate first to third sub-pixel output signals for the first pixel on the basis of respectively first to third sub-pixel input signals and to generate first to third sub-pixel output signals for the second pixel on the basis of respectively first to third sub-pixel input signals.

Owner:JAPAN DISPLAY WEST

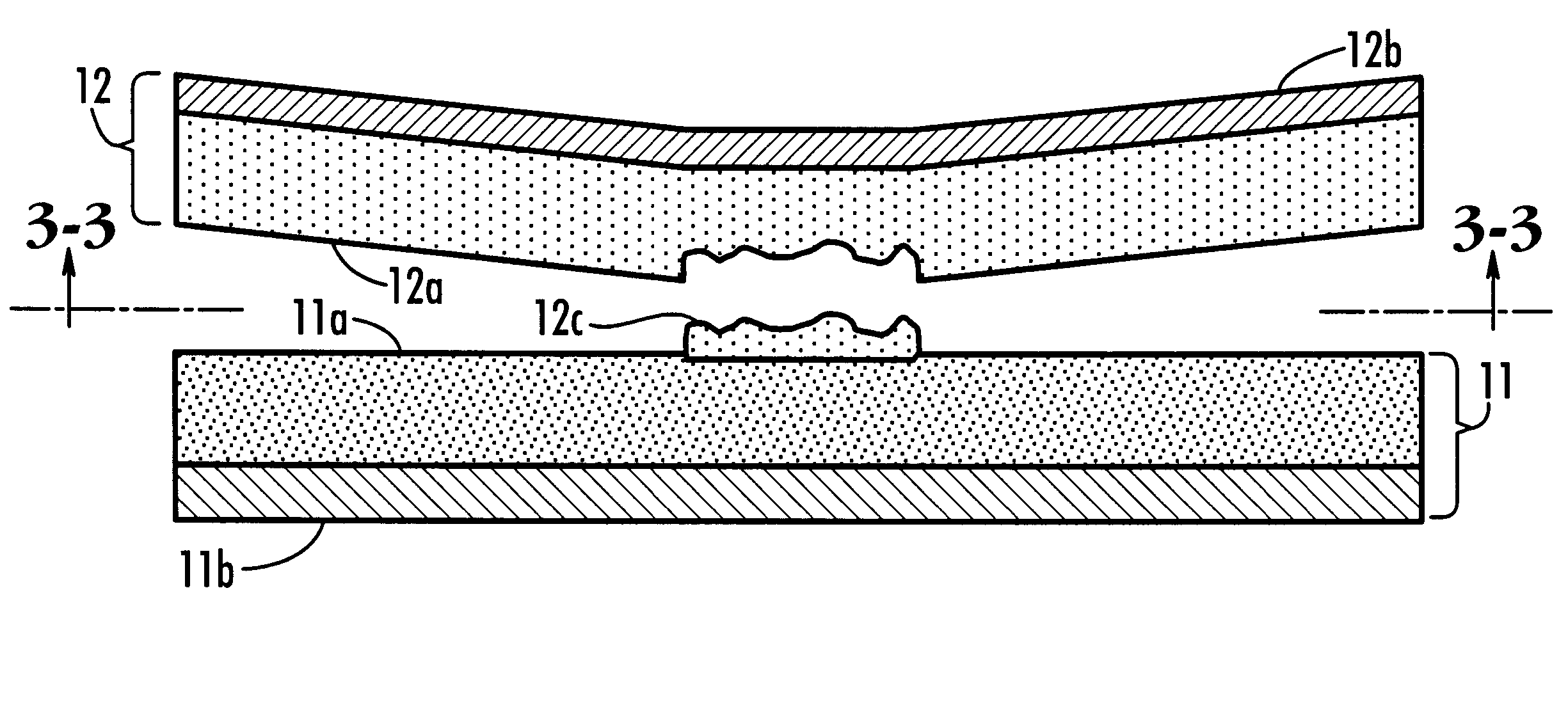

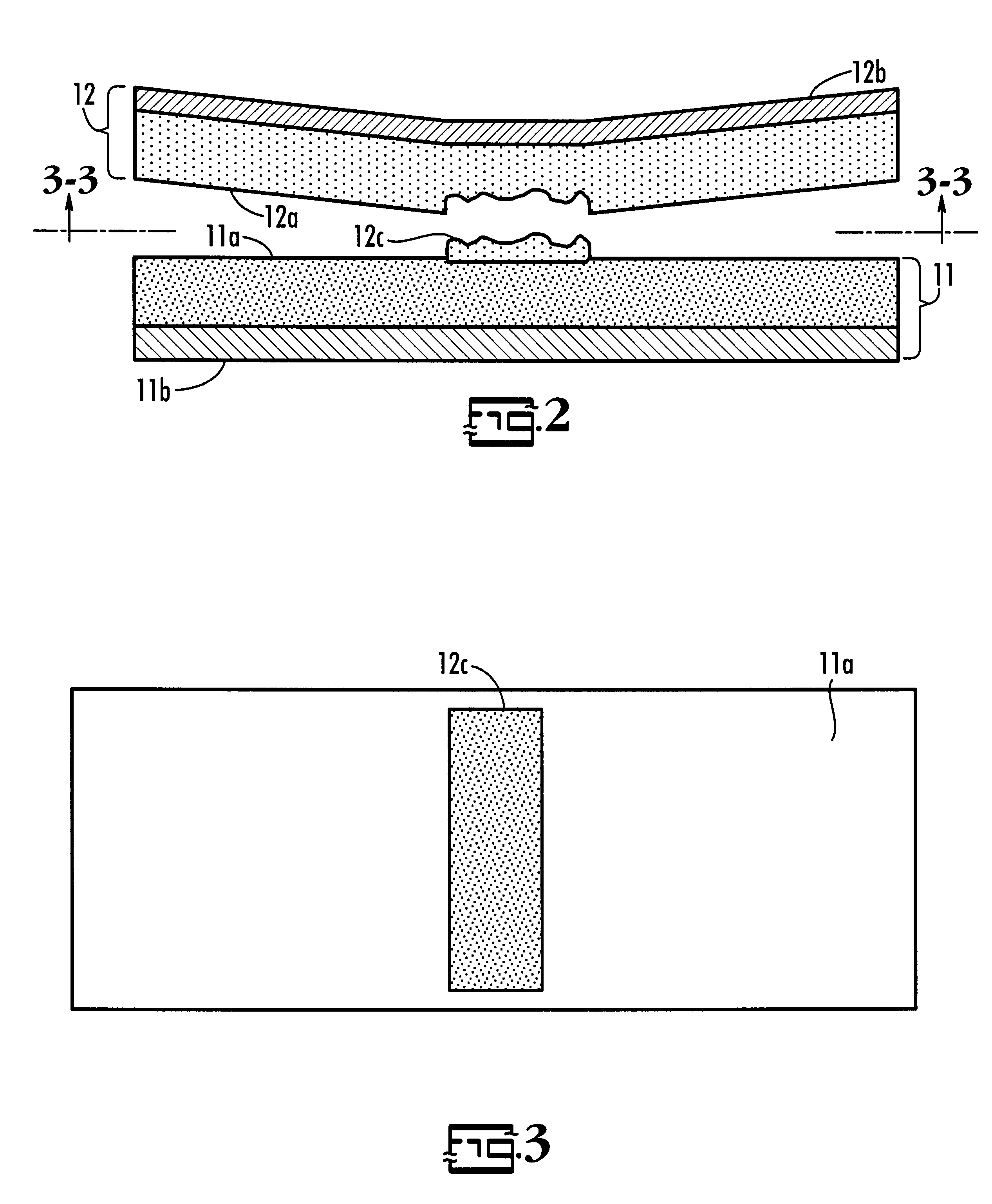

Method of producing zone specific peelable heat seals for flexible packaging applications

InactiveUS6245176B1High degree of reliabilitySimplify manufacturing processFlexible coversWrappersMechanical engineeringPolymer

A method for creating peelable or frangible seals comprising the steps of: 1) selecting a first planar film with a polyethylene based resin disposed on its surface; 2) defining a frangible sealing zone on a surface of the first planar film; 3) heat sealing a second planar film to the frangible zone where the second planar film has a seal surface comprising a plurality of polymers; and 4) cooling the first and second planar films and frangible zone. A seal is created whereby peeling away the second planar film causes a rupture in the polymers disposed on the second planar film's surface.

Owner:GREENLAND STEVEN J

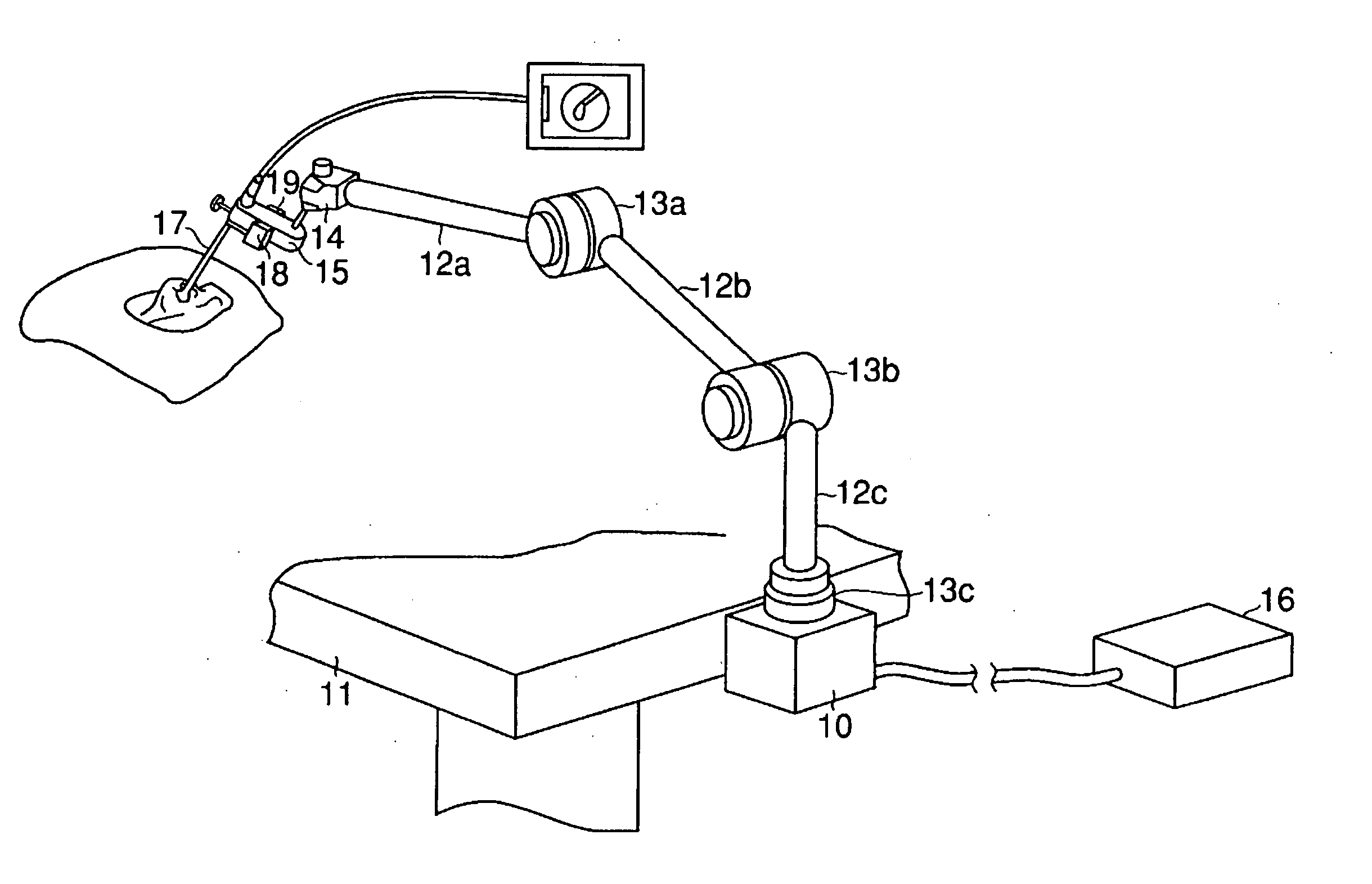

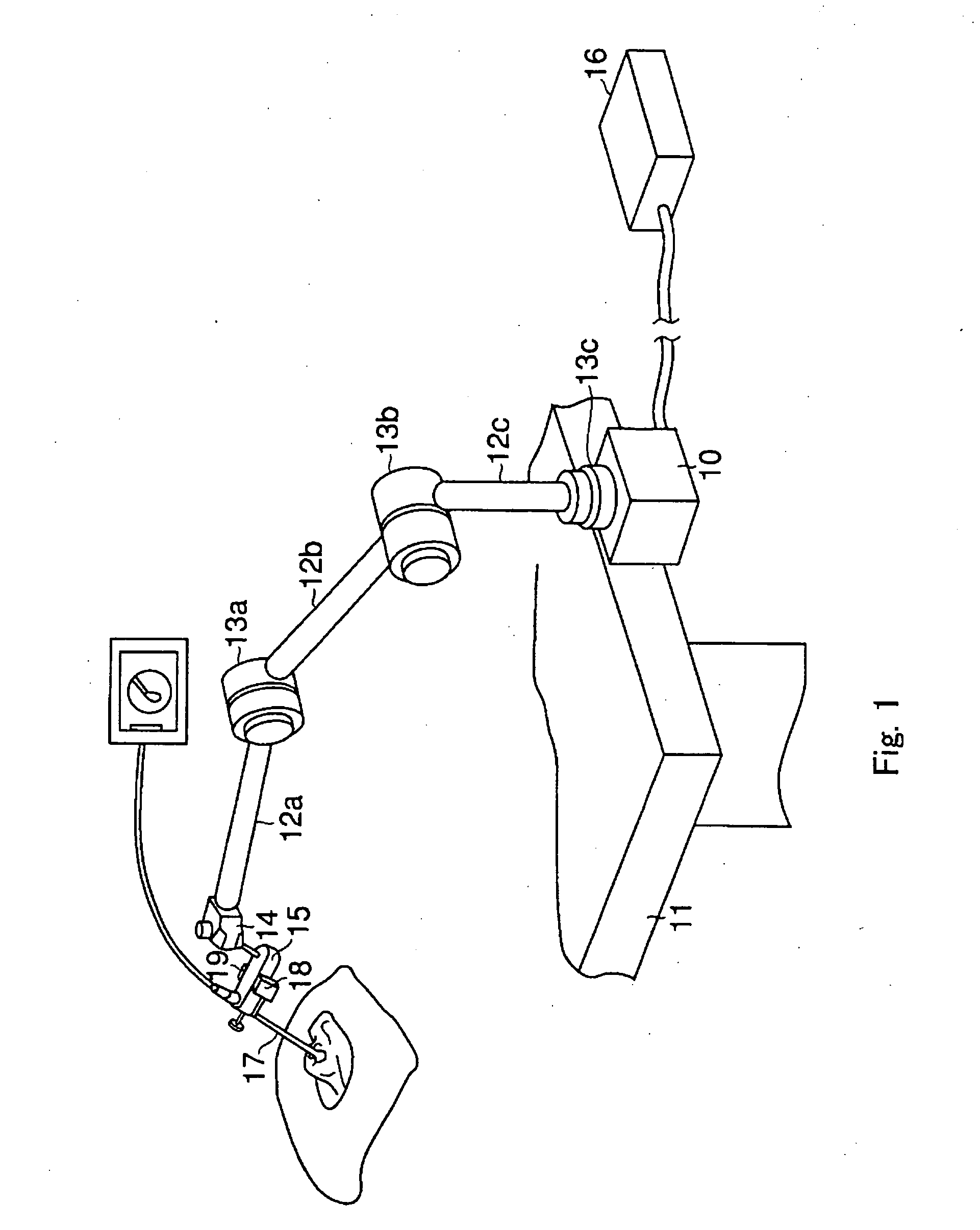

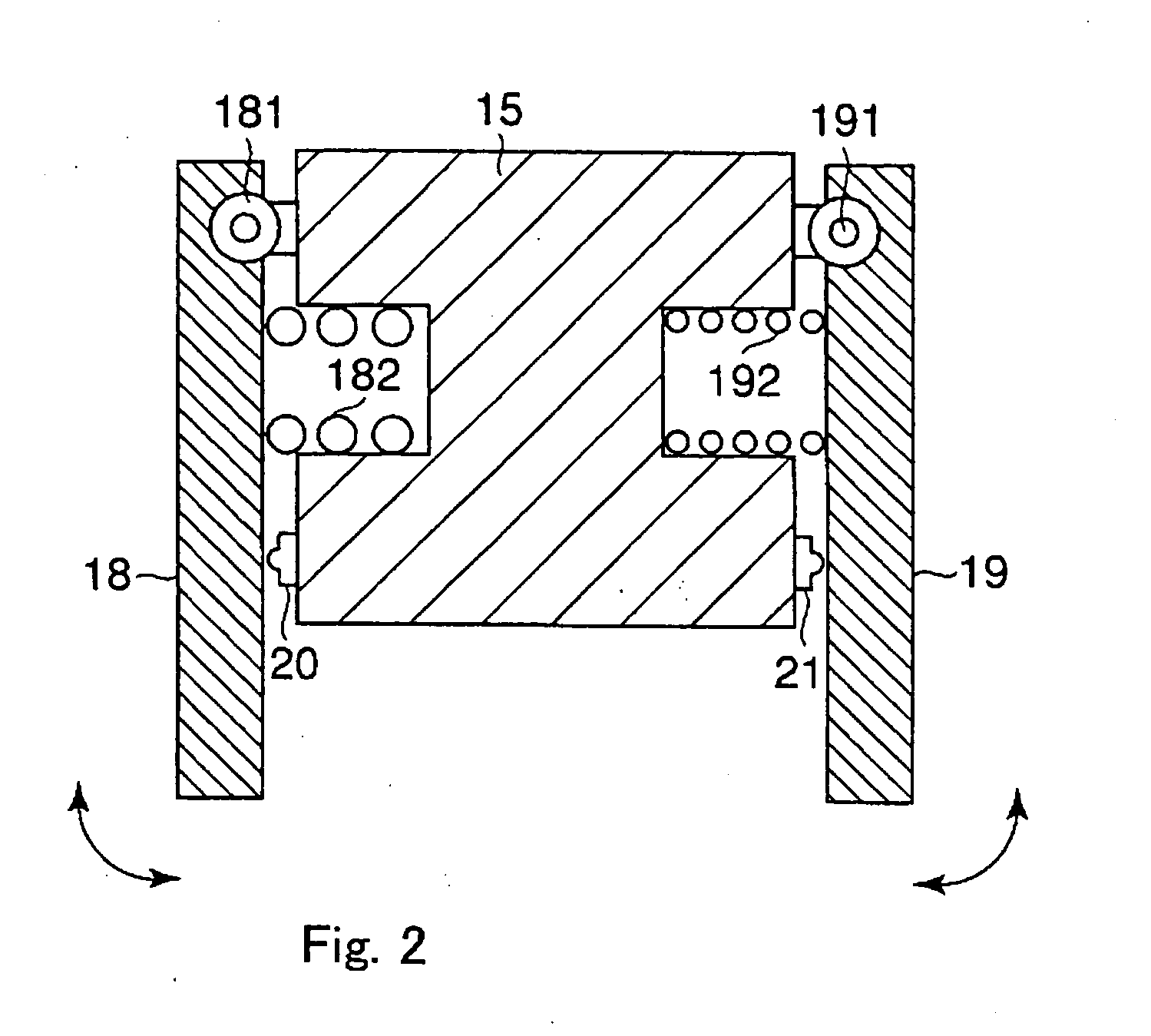

Medical device supporting apparatus

InactiveUS20050075536A1High degree of reliabilityHigh degree of accuracyEndoscopesSurgical instrument detailsThree-dimensional spaceEngineering

A medical device supporting apparatus for supporting a medical device in a three-dimensional space, in which a holding device for holding the medical device is supported by a supporting mechanism three-dimensionally, and the state of the supporting unit is switched between the movable state and the locked state by operating a plurality of final control elements. Operation is stabilized by differentiating the amount of operating force of the plurality of final control elements.

Owner:OLYMPUS CORP

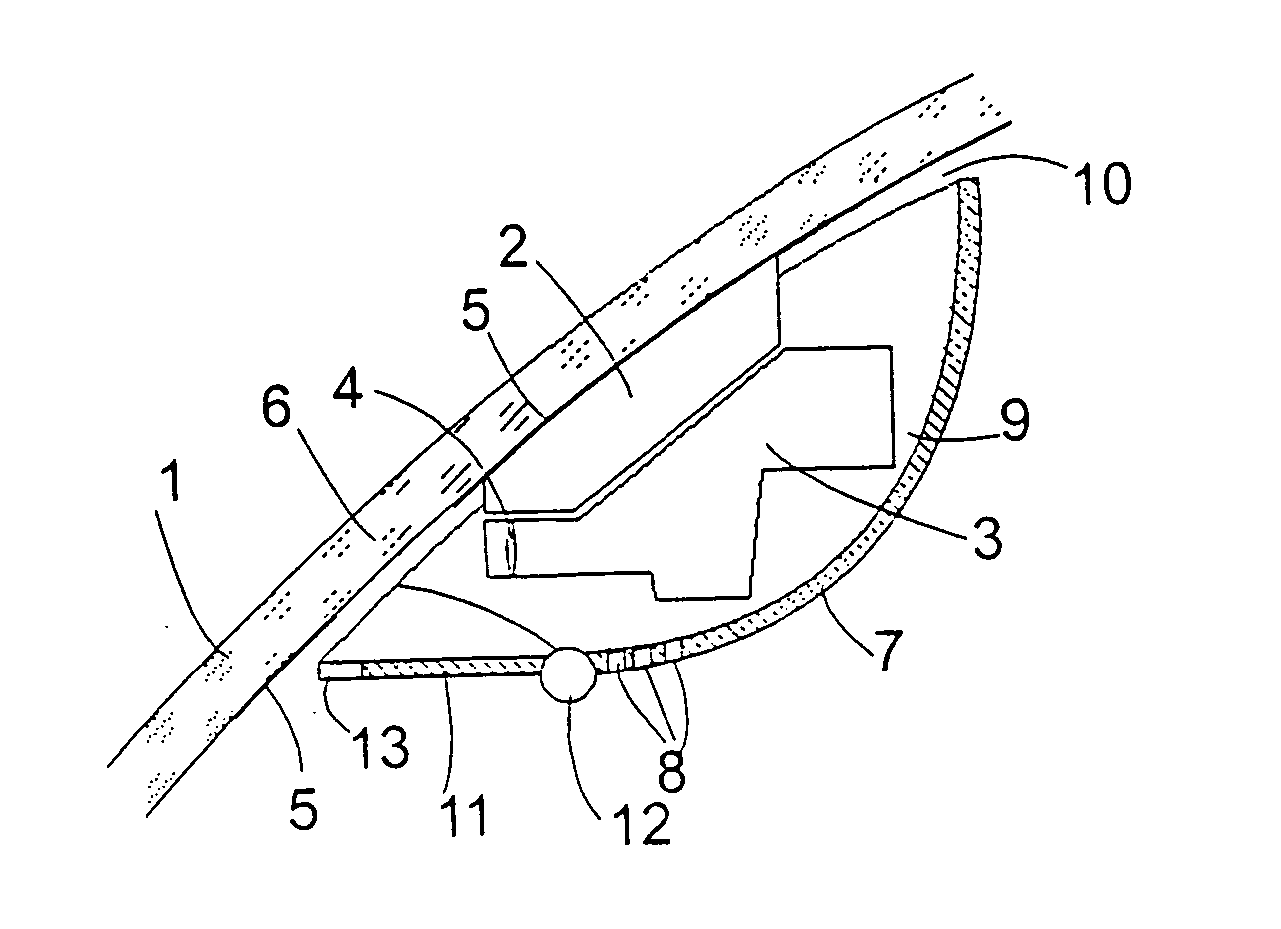

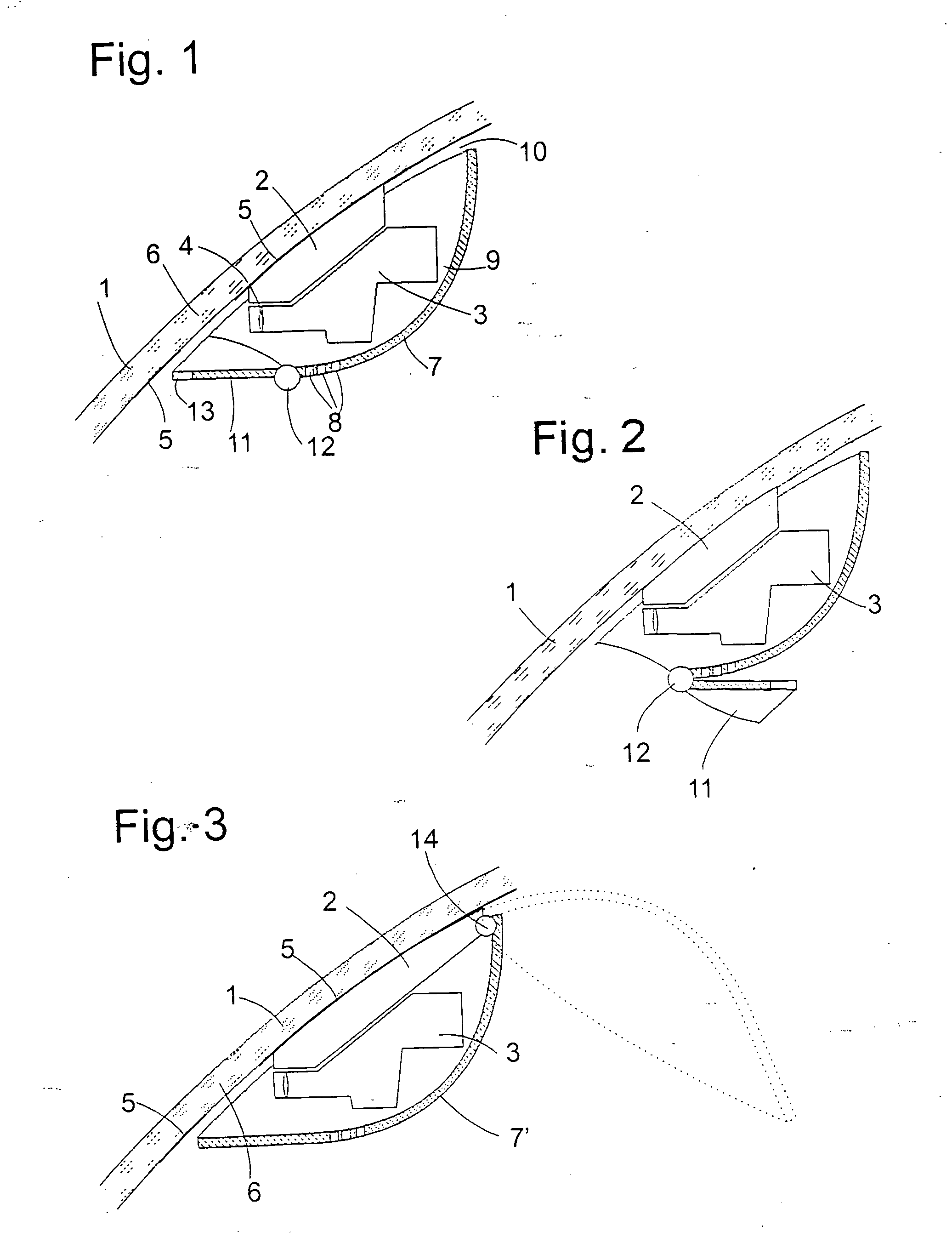

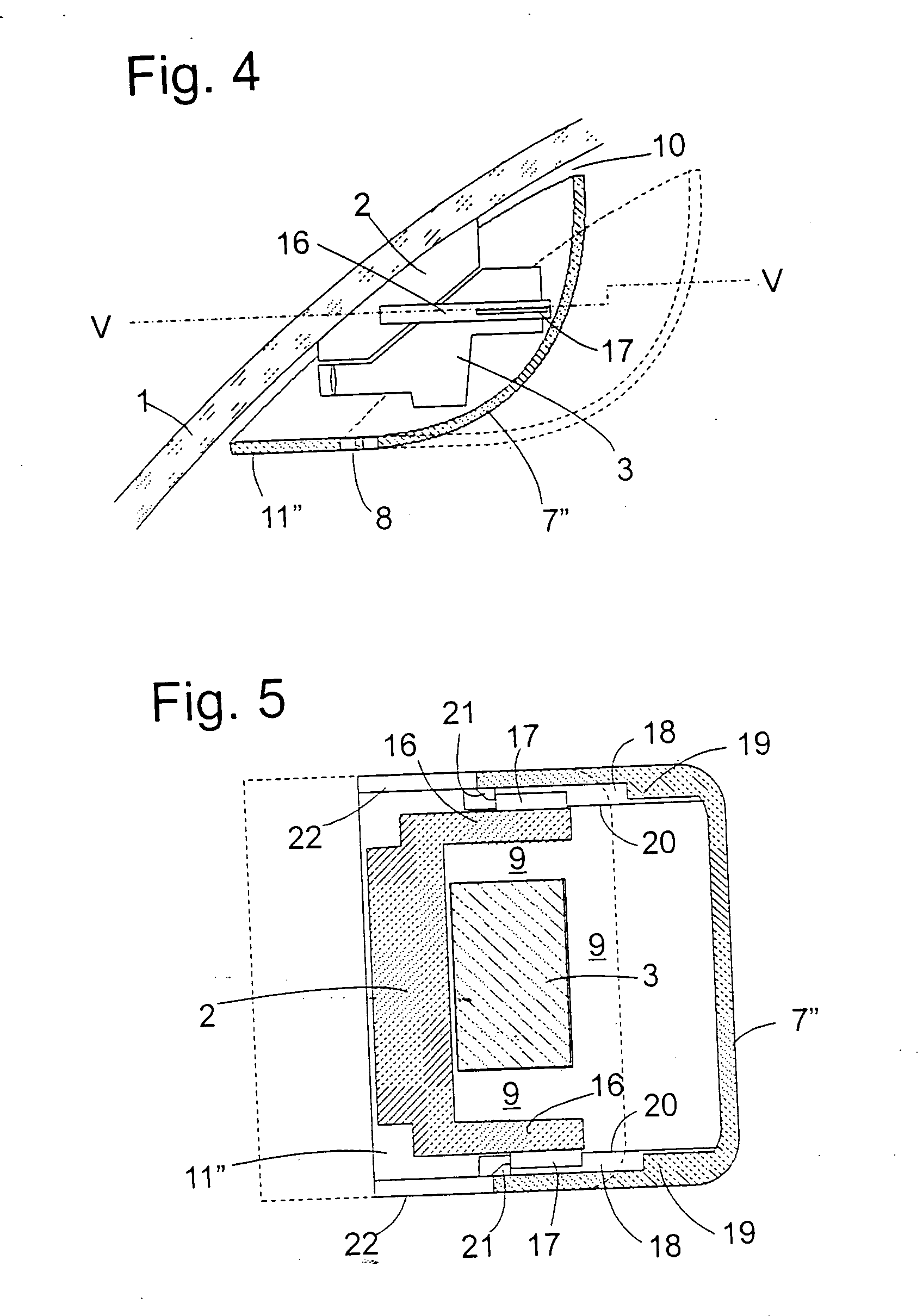

Camera system for a motor vehicle

InactiveUS20050001901A1Easy to checkHigh degree of reliabilityColor television detailsClosed circuit television systemsEngineeringMotorized vehicle

In a camera system to be installed in a passenger compartment of motor vehicle, a camera (3) is surrounded by a housing (7) and is oriented towards the windshield (1) of the passenger compartment. Between the camera (3) and the windshield (1) a shield (11) is provided, which is moveable between a closed position in which the camera (3) is shielded against scatter light from the passenger compartment and an open position in which access may be had to the front lens (4) of the camera (3) and the area (6) of the windshield lying in the field of view of the camera (3).

Owner:DAIMLER AG

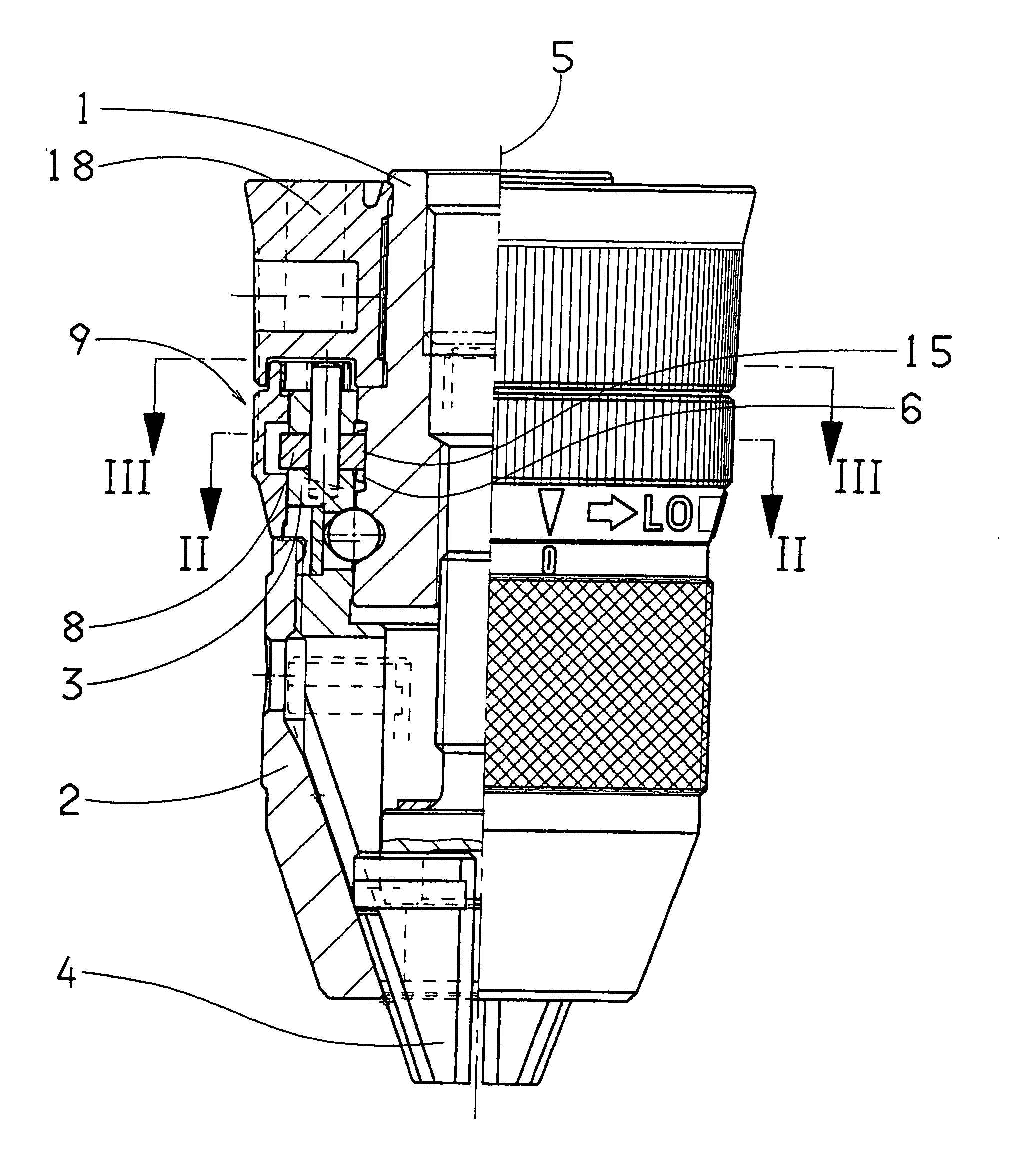

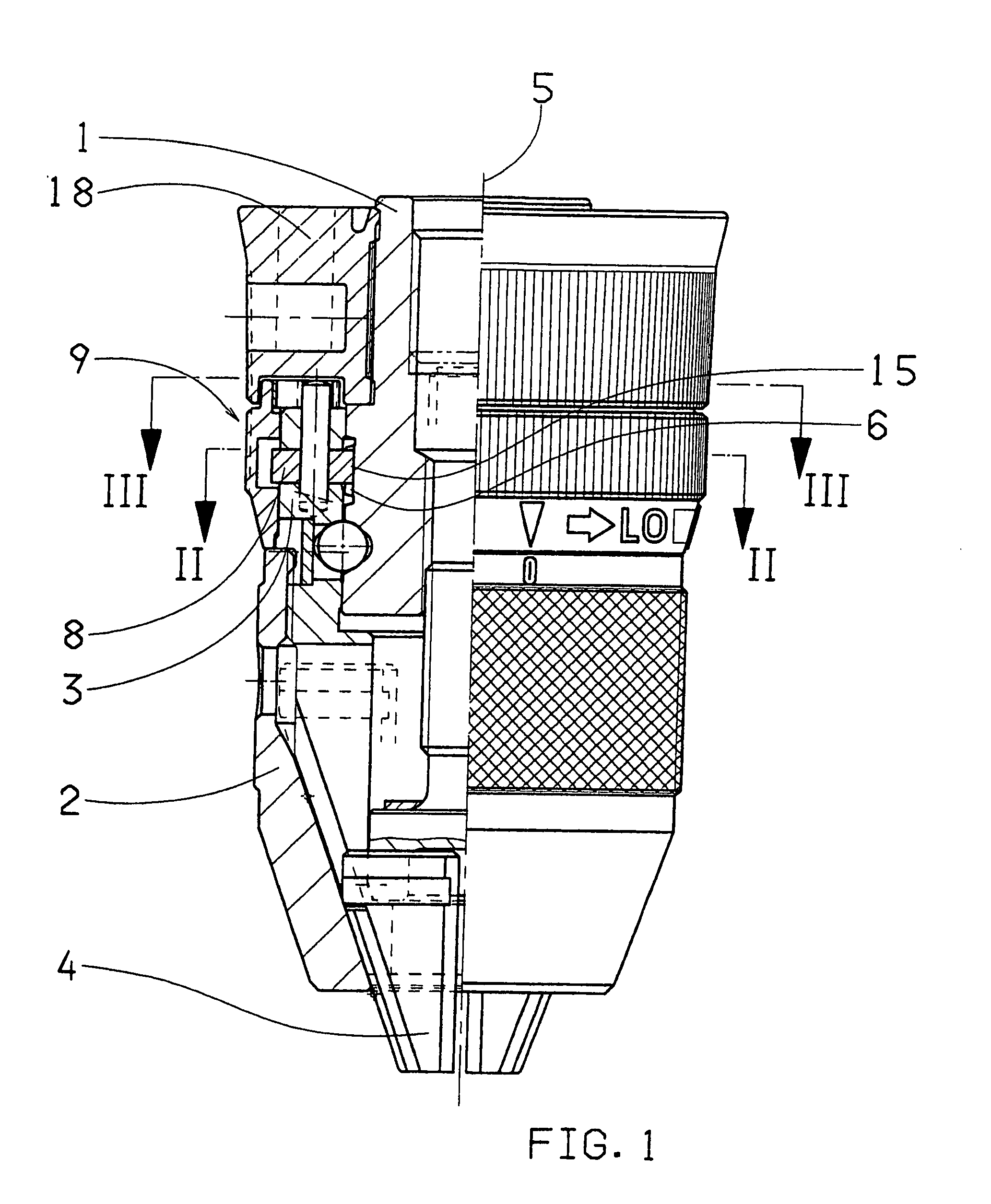

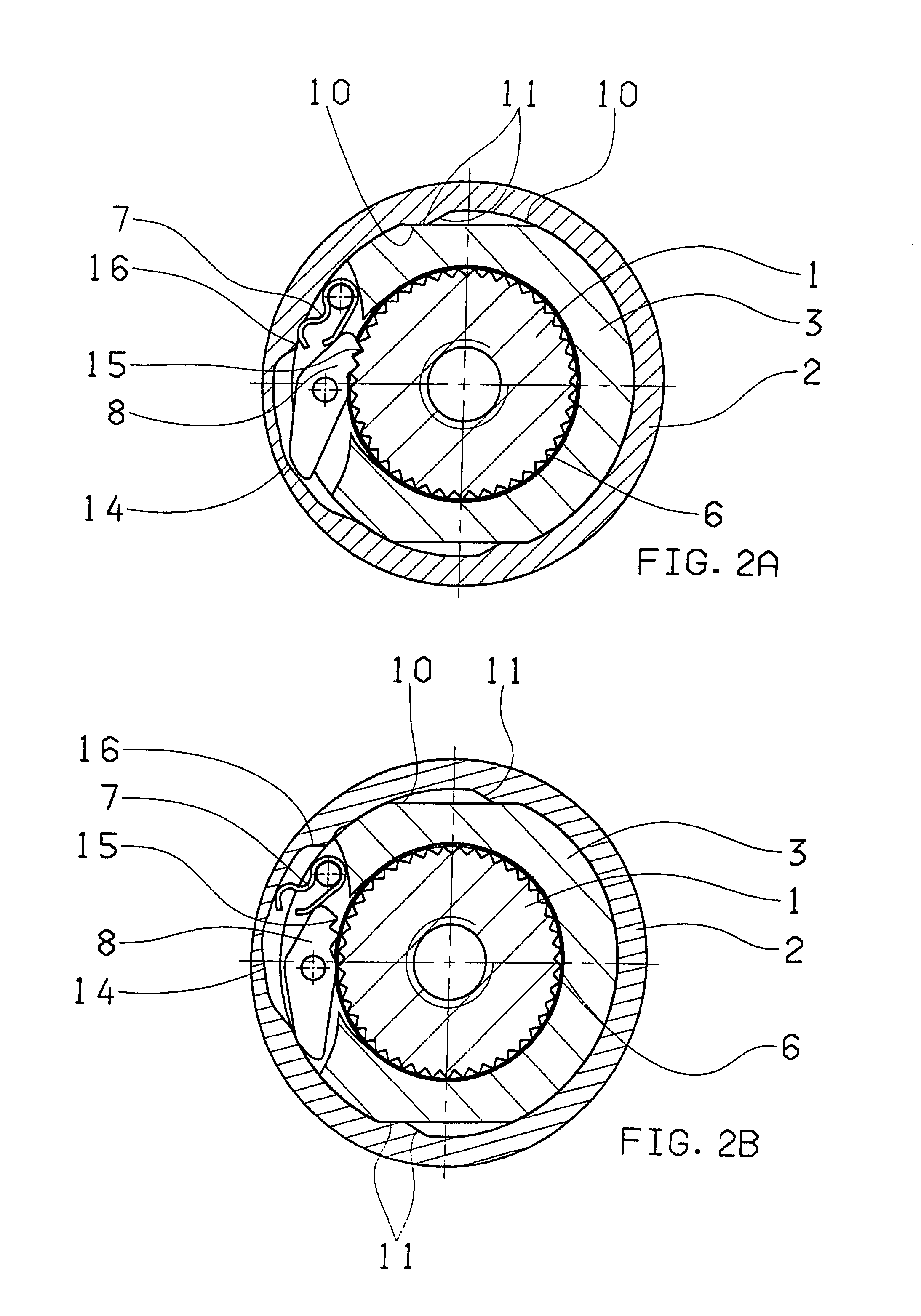

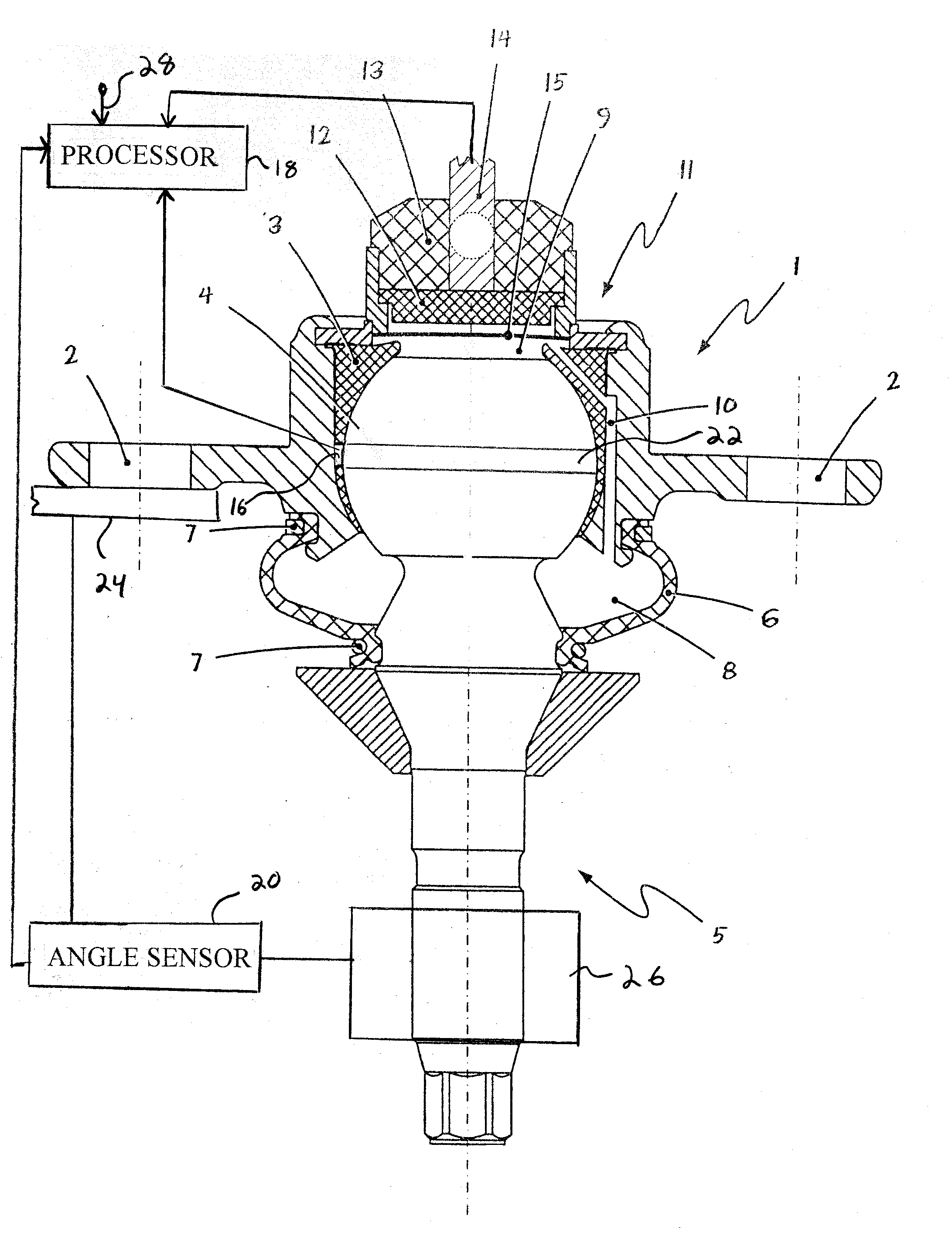

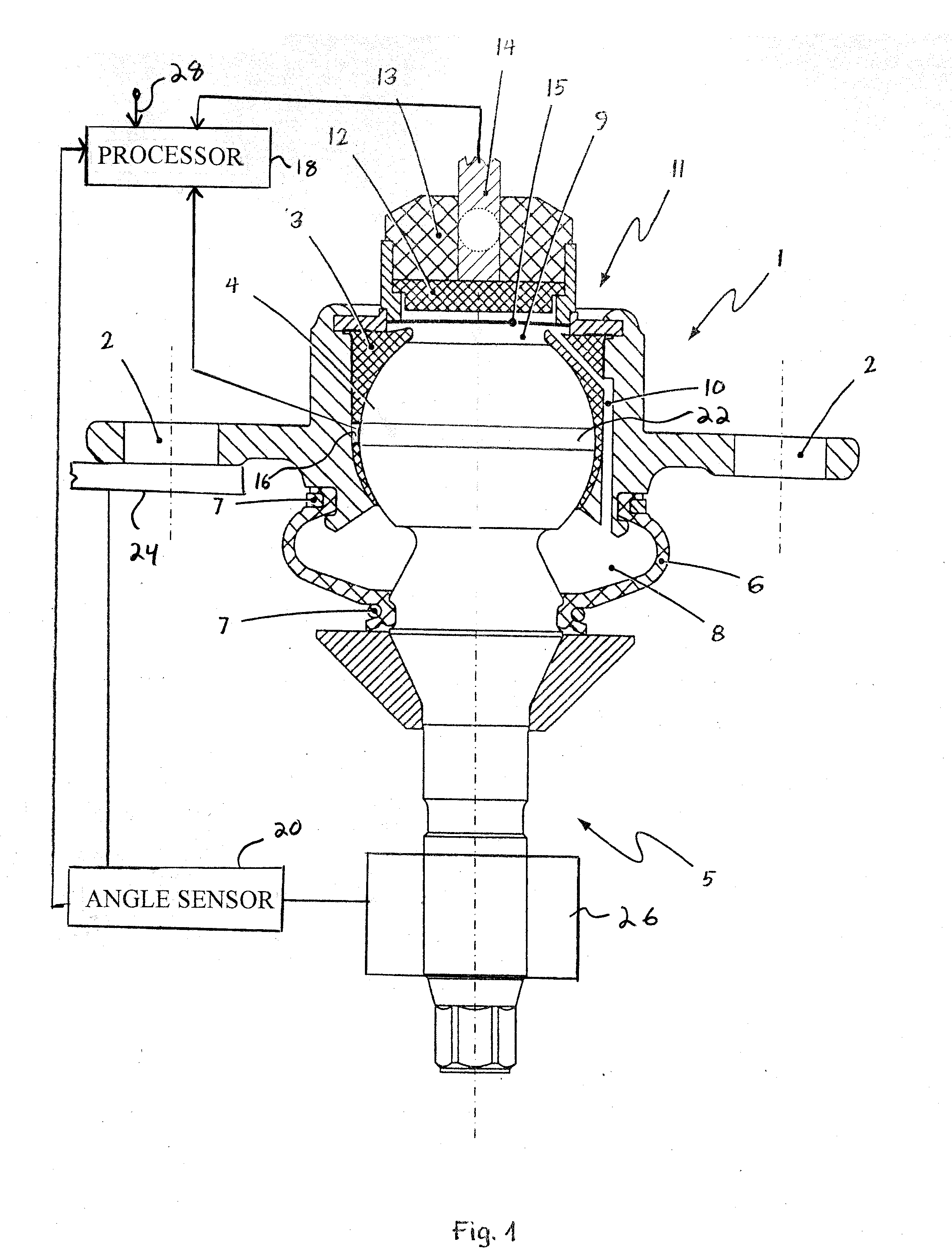

Drill chuck

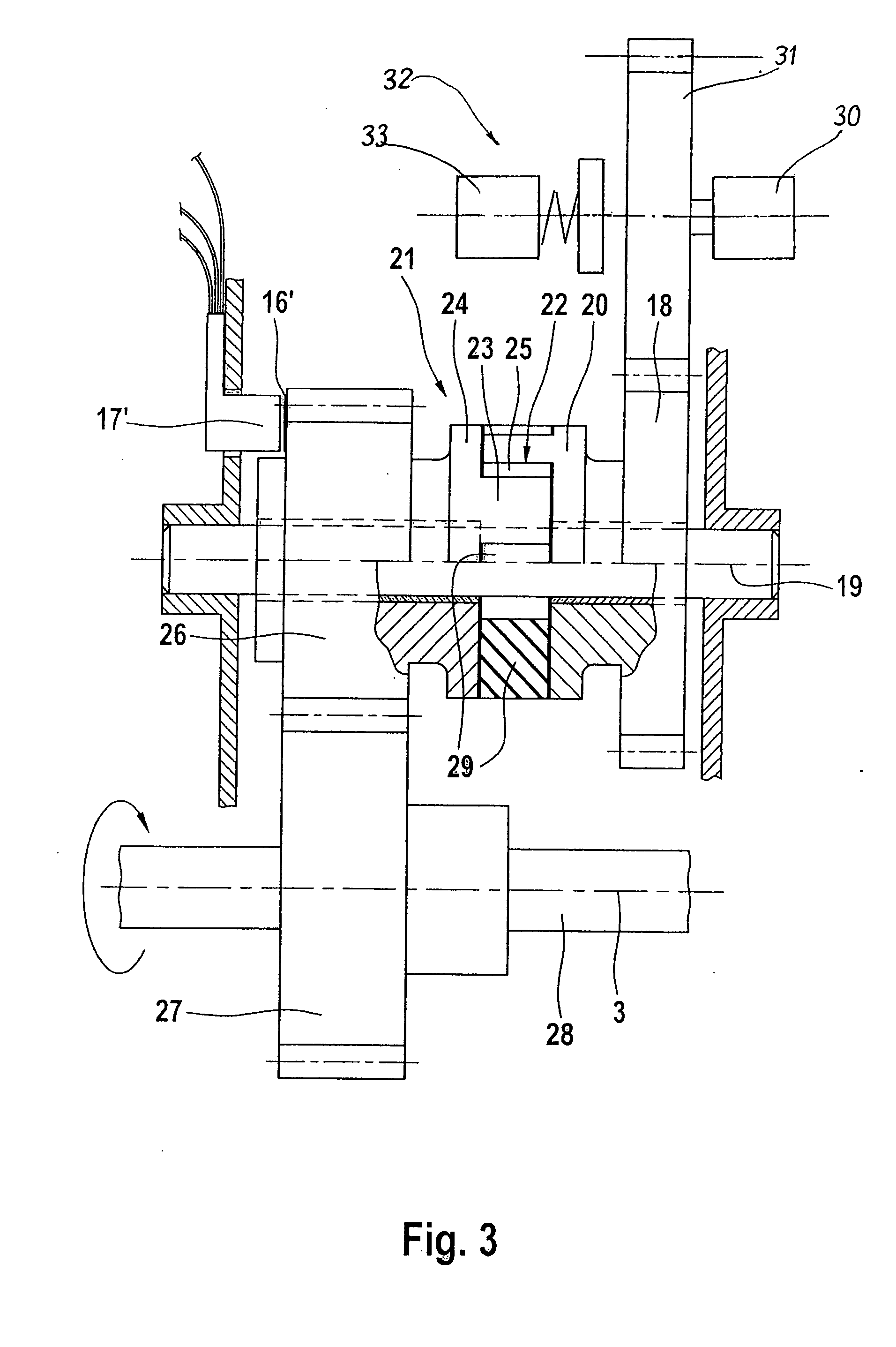

ActiveUS8070168B2High degree of reliabilityImprove torsion resistanceSleeve/socket jointsChucksEngineeringDrill

The invention relates to a clamping drill chuck including a chuck body (1), a clamping cone (2) that can be rotated coaxially in relation to the chuck body (1) and is axially supported on a jaw holder (3) mounted on the chuck body (1) and in which clamping jaws (4) are guided in guiding slits, said clamping jaws being adjustable, by means of the jaw holder (3), for the clamping and releasing action by a relative rotation between the chuck body (1) and the clamping cone (2). The drill chuck also includes a locking device (9) provided with a toothed ring (6) which is coaxial to the chick axle (5), in addition to a latch mechanism (8) which is mounted on the jaw holder (3) and engages in the toothed ring (6) when subjected to the force of a spring (7).

Owner:ROHM GMBH & CO KG

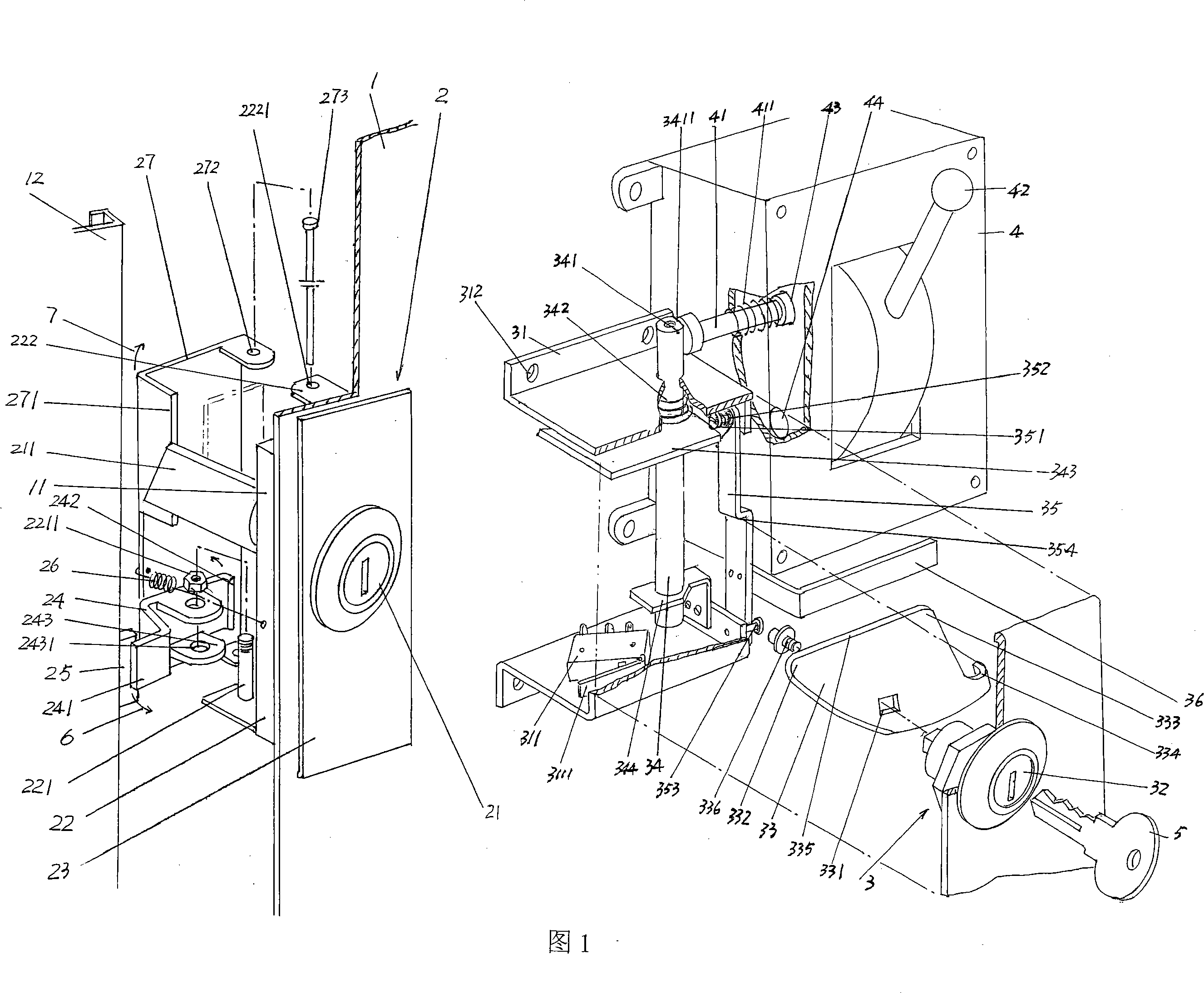

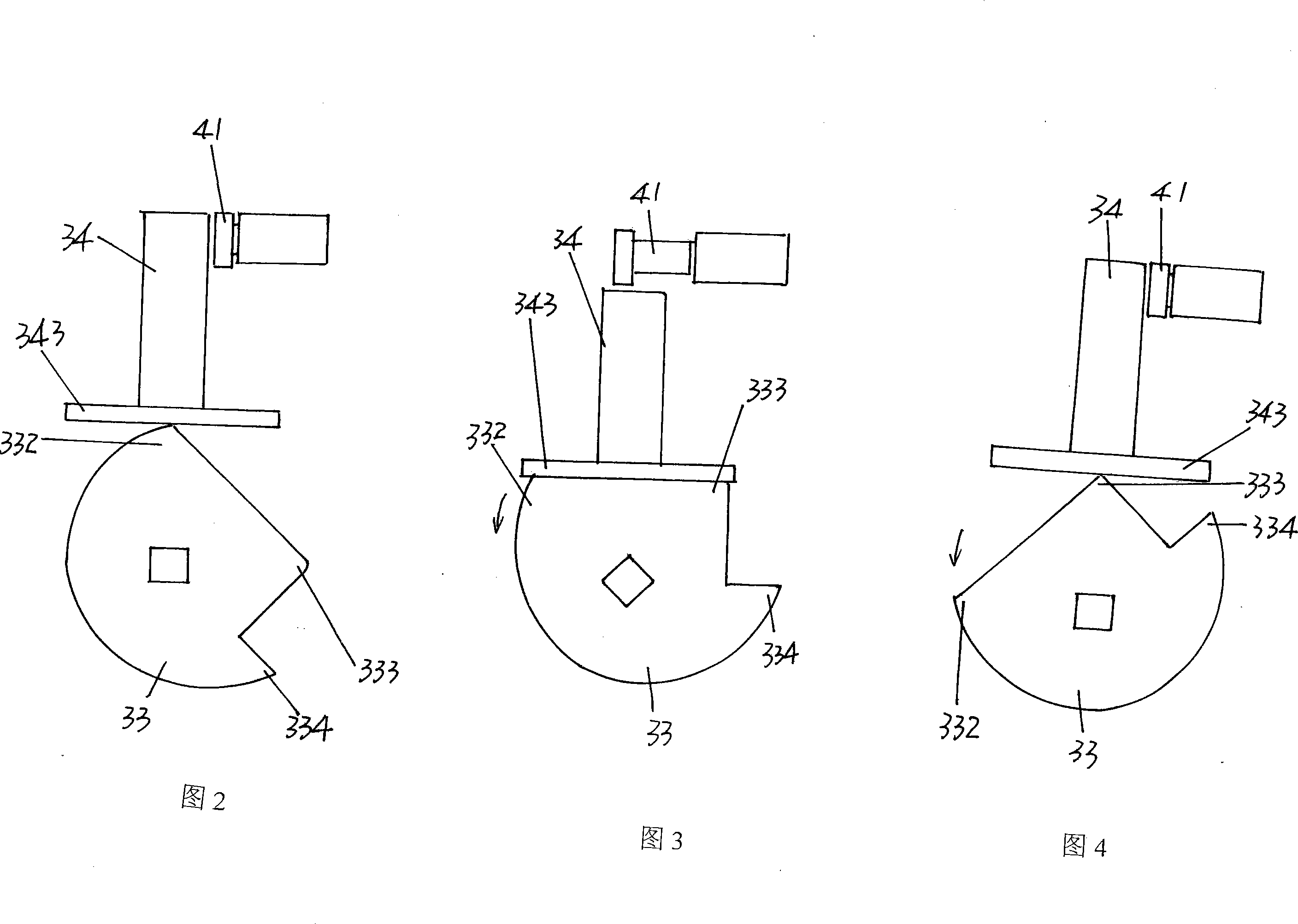

Mechanical interlock mechanism of high-voltage segregate switch with vacuum contactor and high-pressure chamber cabinet door

InactiveCN101162655AImprove economySimple structureSubstation/switching arrangement detailsElectric switchesEngineeringHigh pressure

The invention discloses a mechanical interlock mechanism for a high-voltage isolating switch, a vacuum contactor and a hyperbaric cabinet door, belonging to the high-voltage whole-set electrical device safety protective device technical field. The invention comprises a first mechanical lockup device arranged on the inner wall of the door of the hyperbaric cabinet, a second mechanical lockup device arranged on the outer wall of the door of the hyperbaric cabinet, and a key for locking or unlocking the first mechanical lockup device and the second mechanical lockup device; the first mechanical lockup device is arranged at the edge of the door of the hyperbaric cabinet. The invention has the advantages of simple structure, high reliability; and only a mounting hole for the bolt of the first mechanical lockup device is arranged on the door, so the invention is of convenient installation; the cost of the first mechanical lockup device and the second mechanical lockup device is just one-tenth of the prior device, so the invention is of good economy; the first lockup device and the second mechanical lockup device are both controlled by the same key, that is, the first lockup device and the second lockup device use a common key, so the invention is of safety and reliability.

Owner:常熟市森源电气科技有限公司

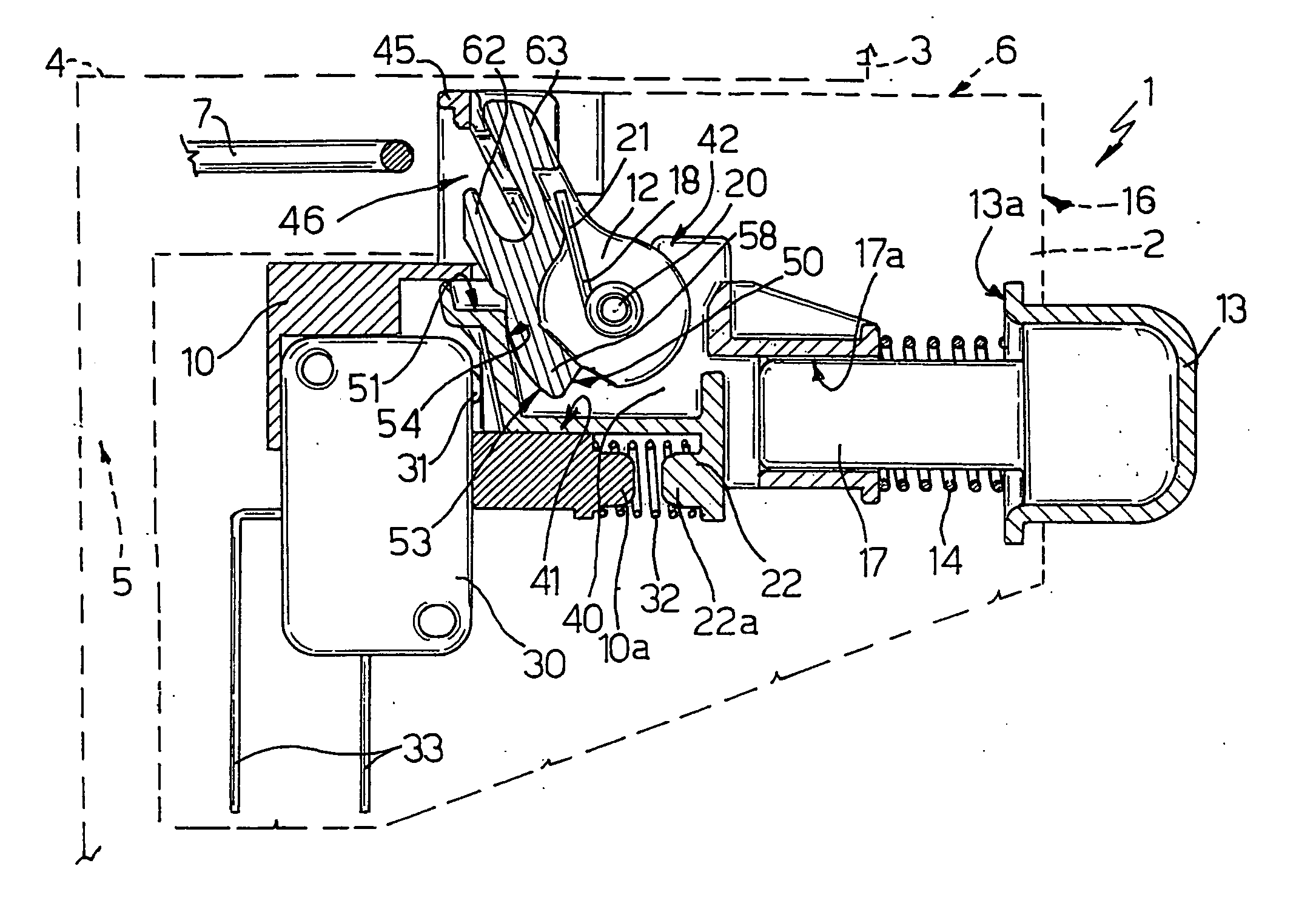

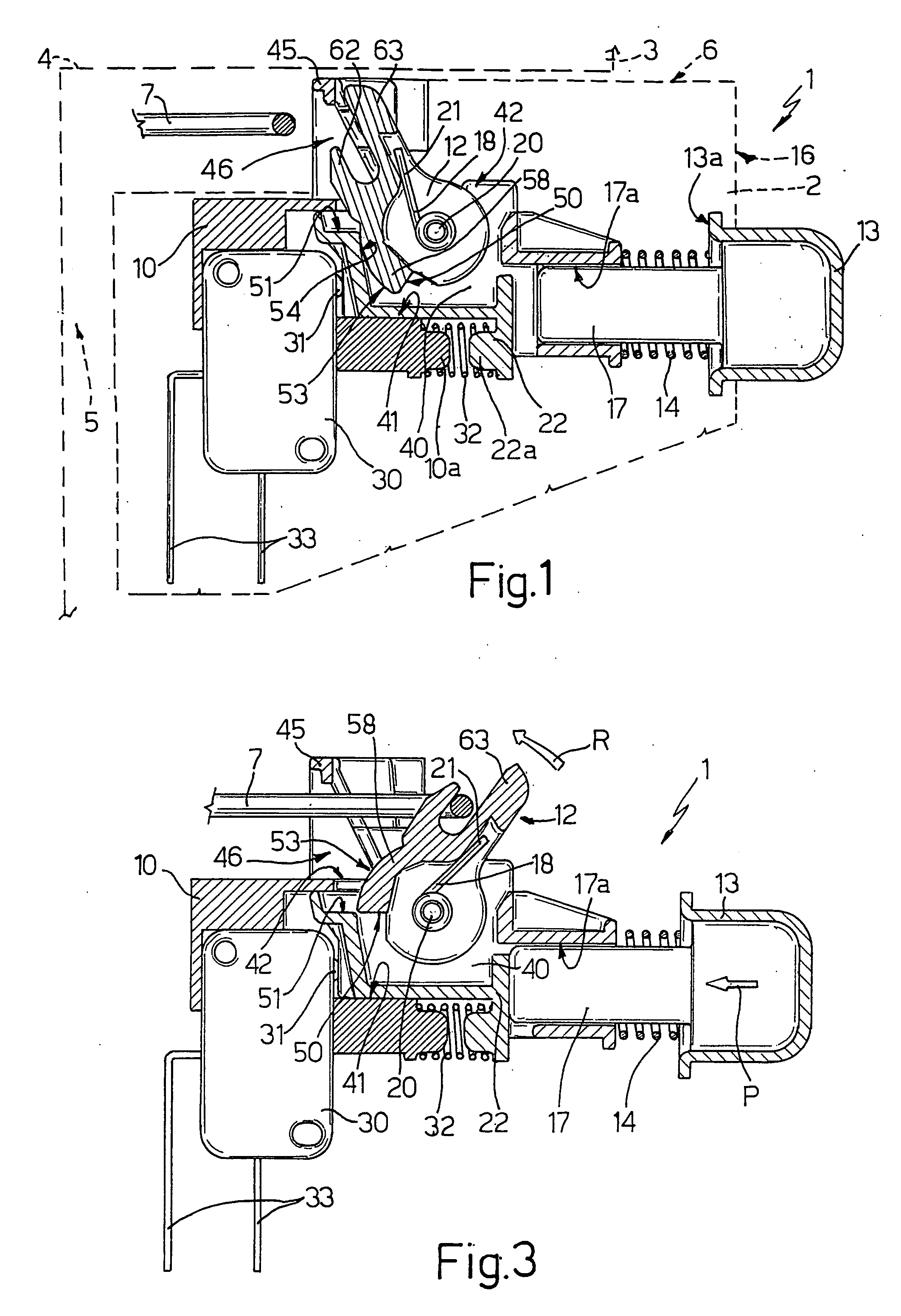

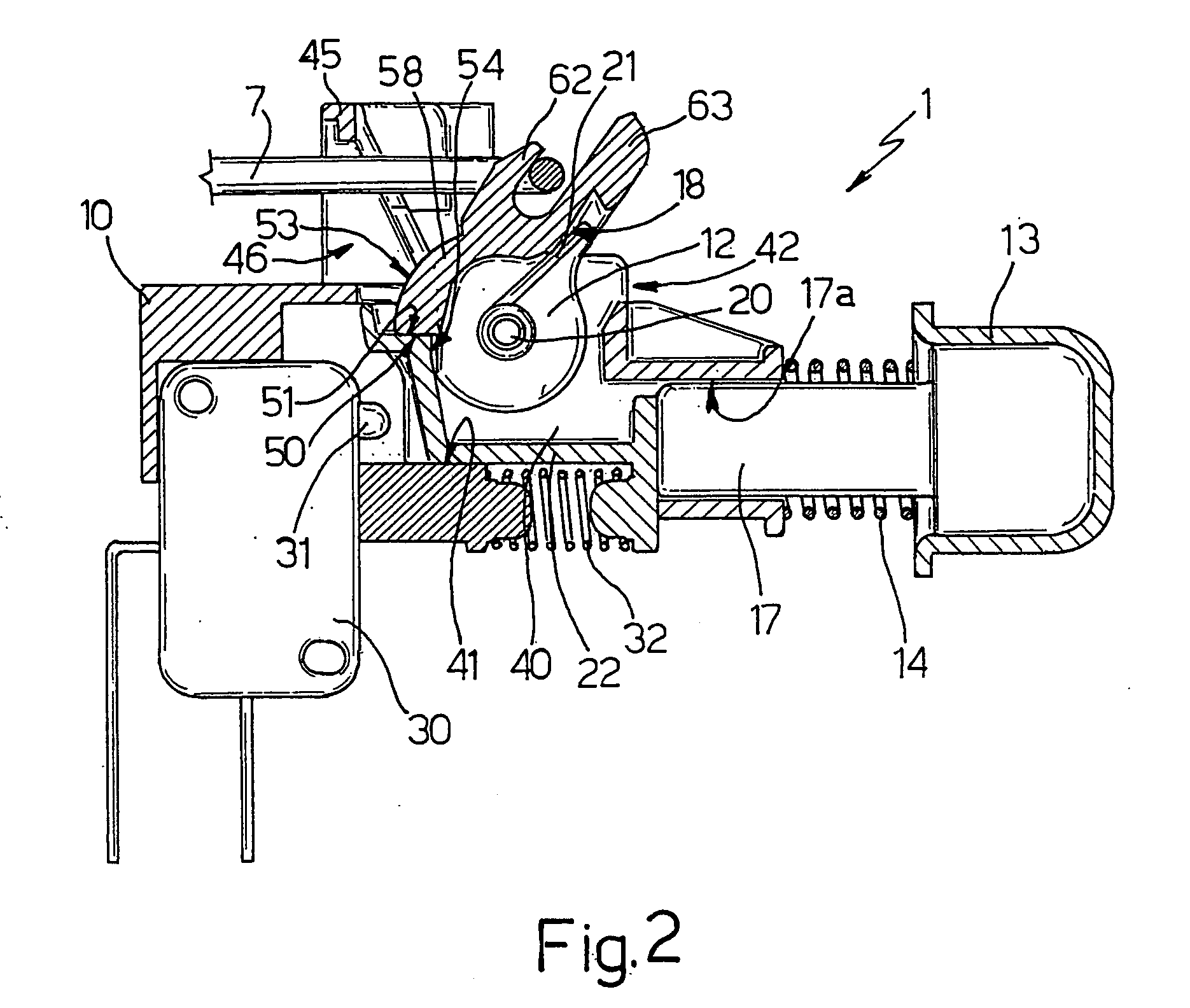

Latch device for a door of an electric household appliance in particular a dishwashing machine

ActiveUS20060033346A1Low-cost manufacture and assemblyHigh degree of reliabilityWing handlesConstruction fastening devicesEngineeringMechanical engineering

Owner:ITW IND COMPONENTS SRL

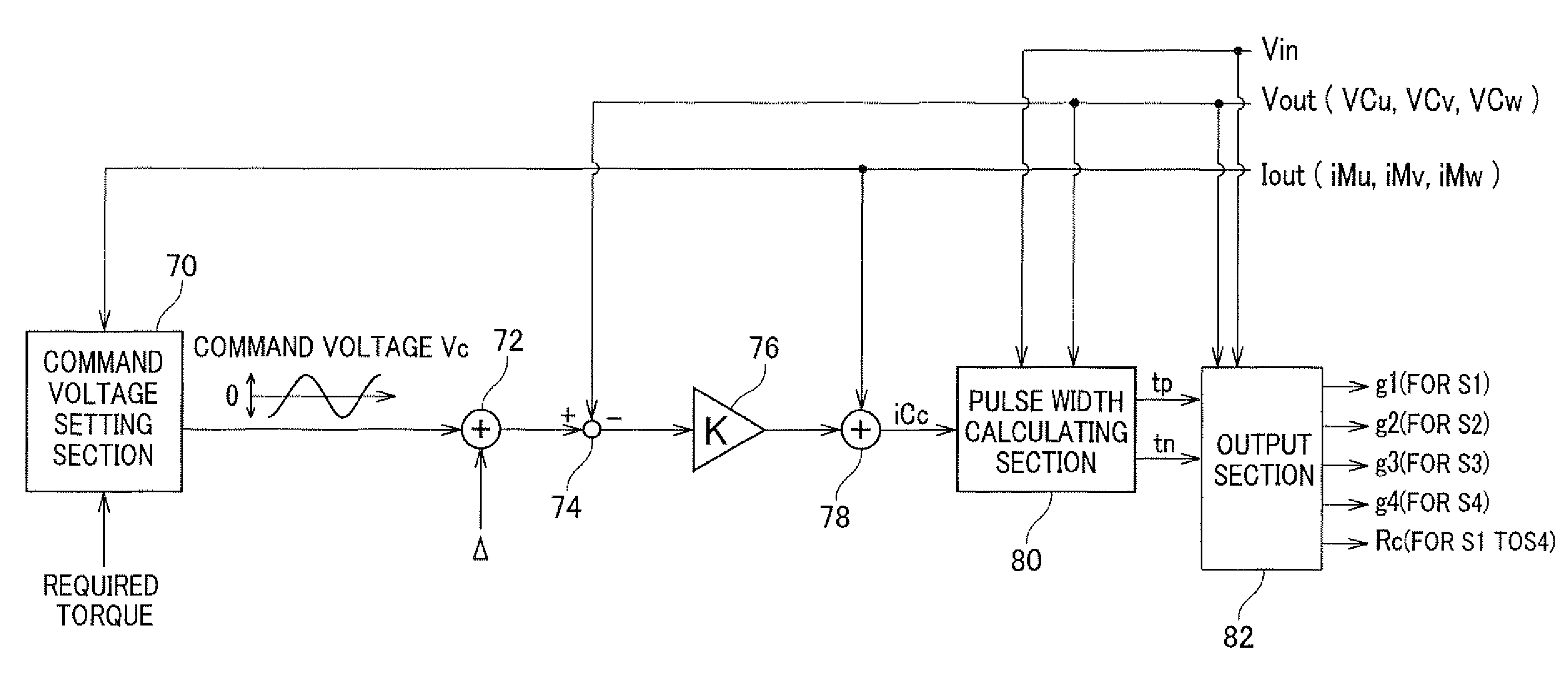

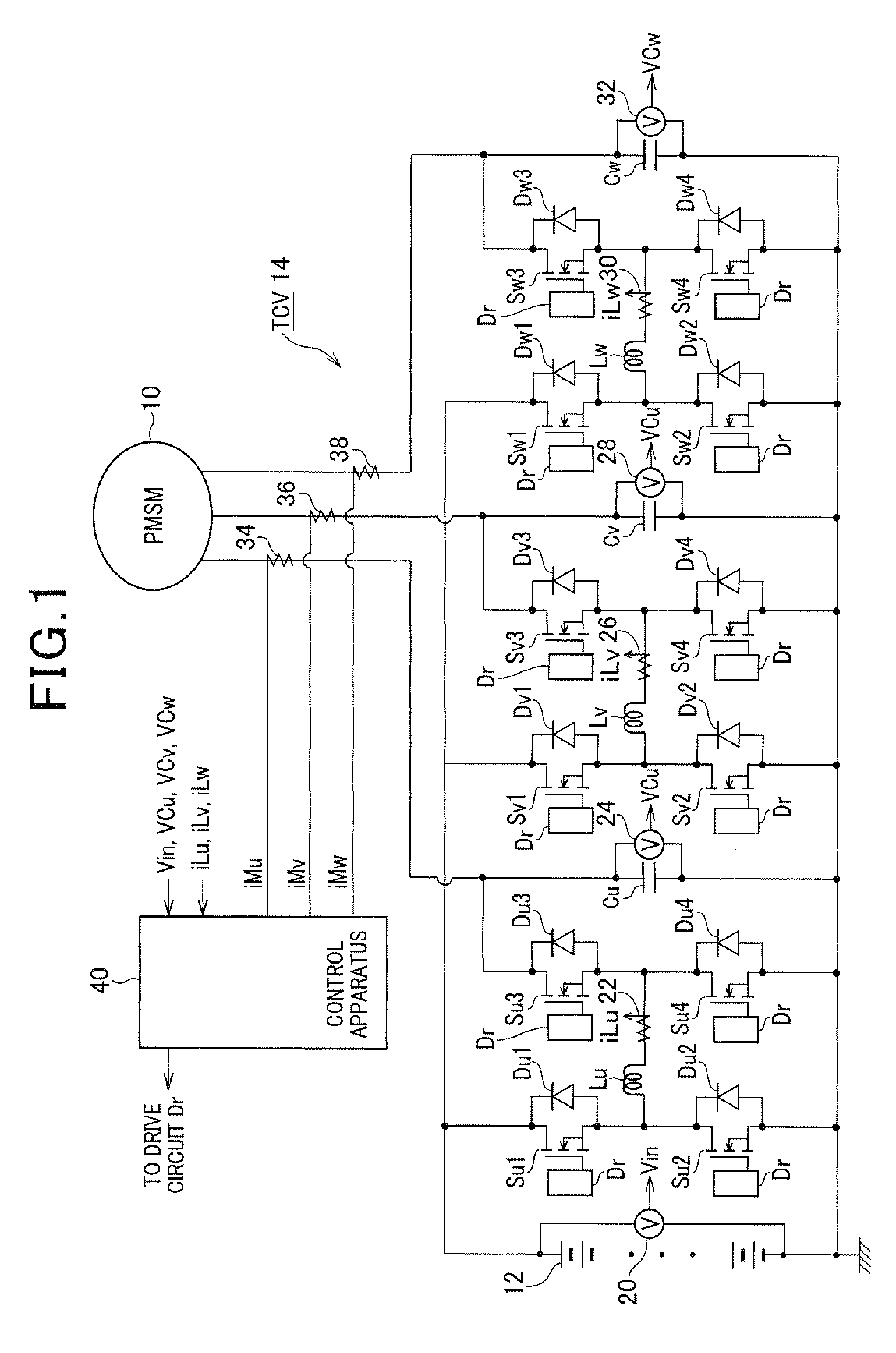

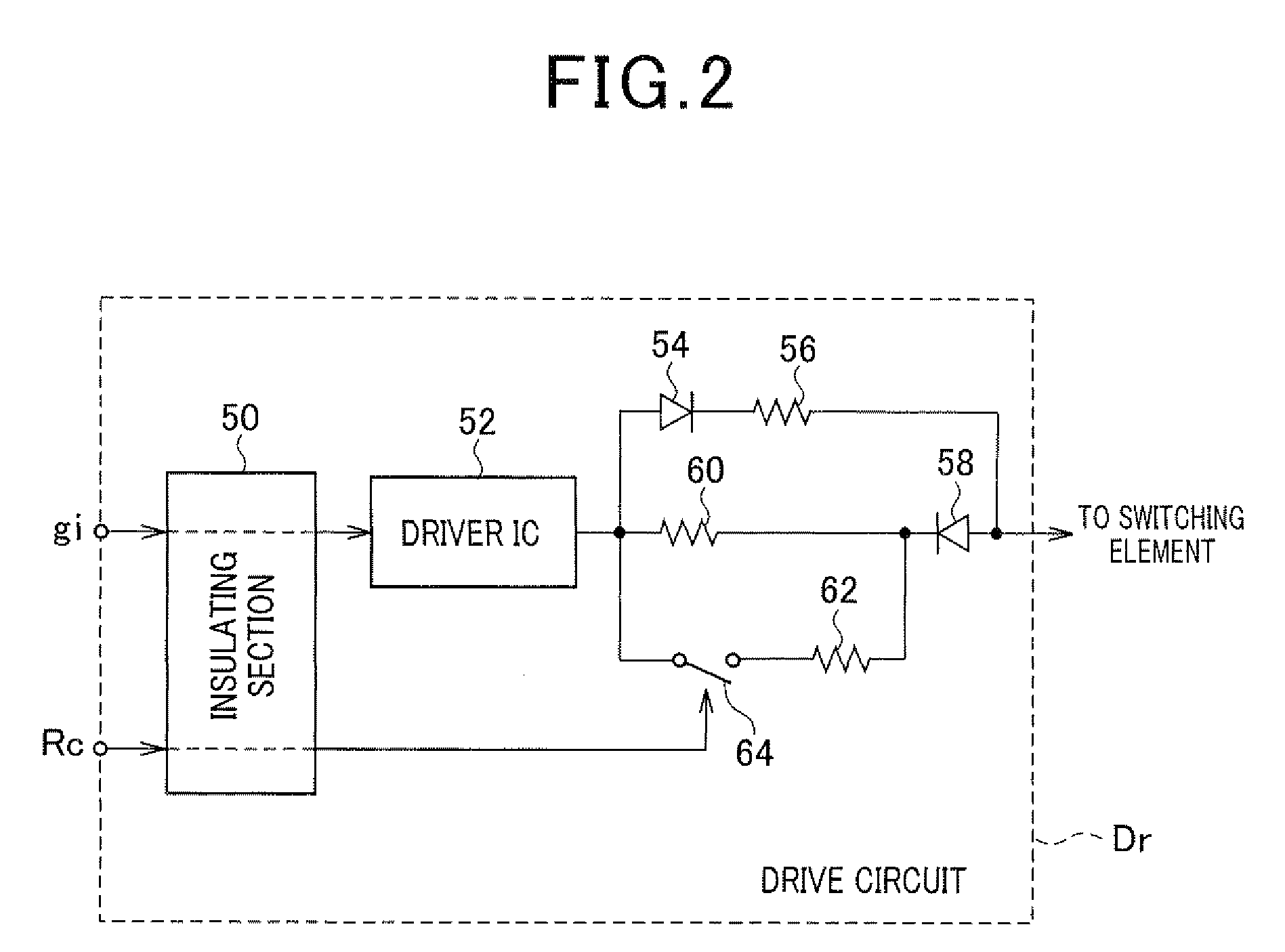

Control apparatus for controlling power conversion apparatus

InactiveUS20090237052A1Improve accuracyHigh degree of reliabilitySpeed controllerAC motor controlDriver circuitControl power

The control apparatus is for controlling a power conversion apparatus with a chopper circuit including at least one voltage-controlled type switching element provided with a drive circuit, and a coil to generate back electromotive force. The control apparatus includes a function of outputting an operation command signal to the drive circuit to control an output voltage of the power conversion apparatus, a second function of setting, on the basis a current flowing through the switching element, a switching speed of the switching element to such a value that noise exceeding a withstand voltage between a conduction control terminal and an output terminal of the switching element can be prevented from occurring when the switching element is switched, and a third function of adjusting the drive circuit to drive the switching element such that the switching element is switched at the switching speed set by the second function.

Owner:DENSO CORP

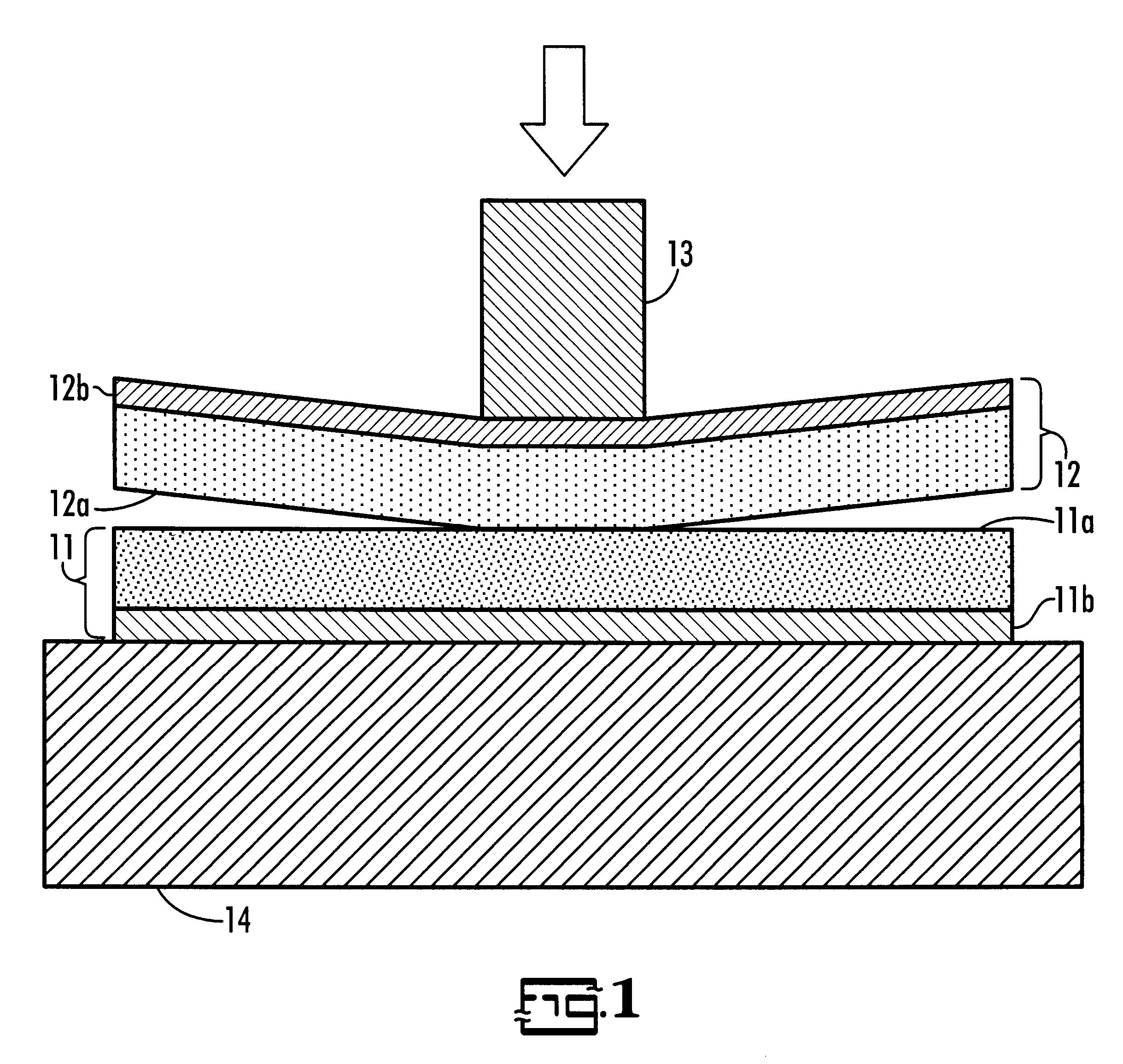

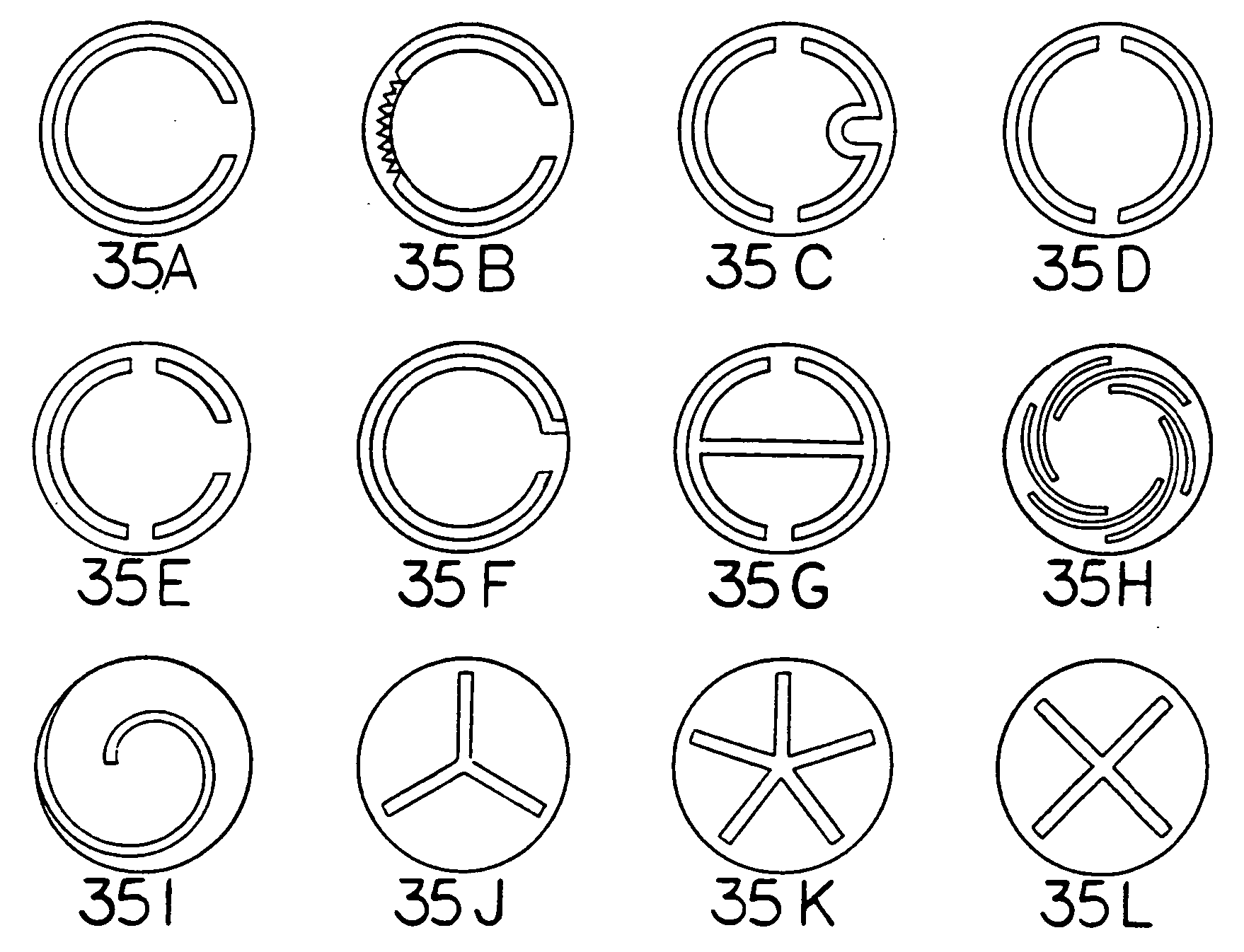

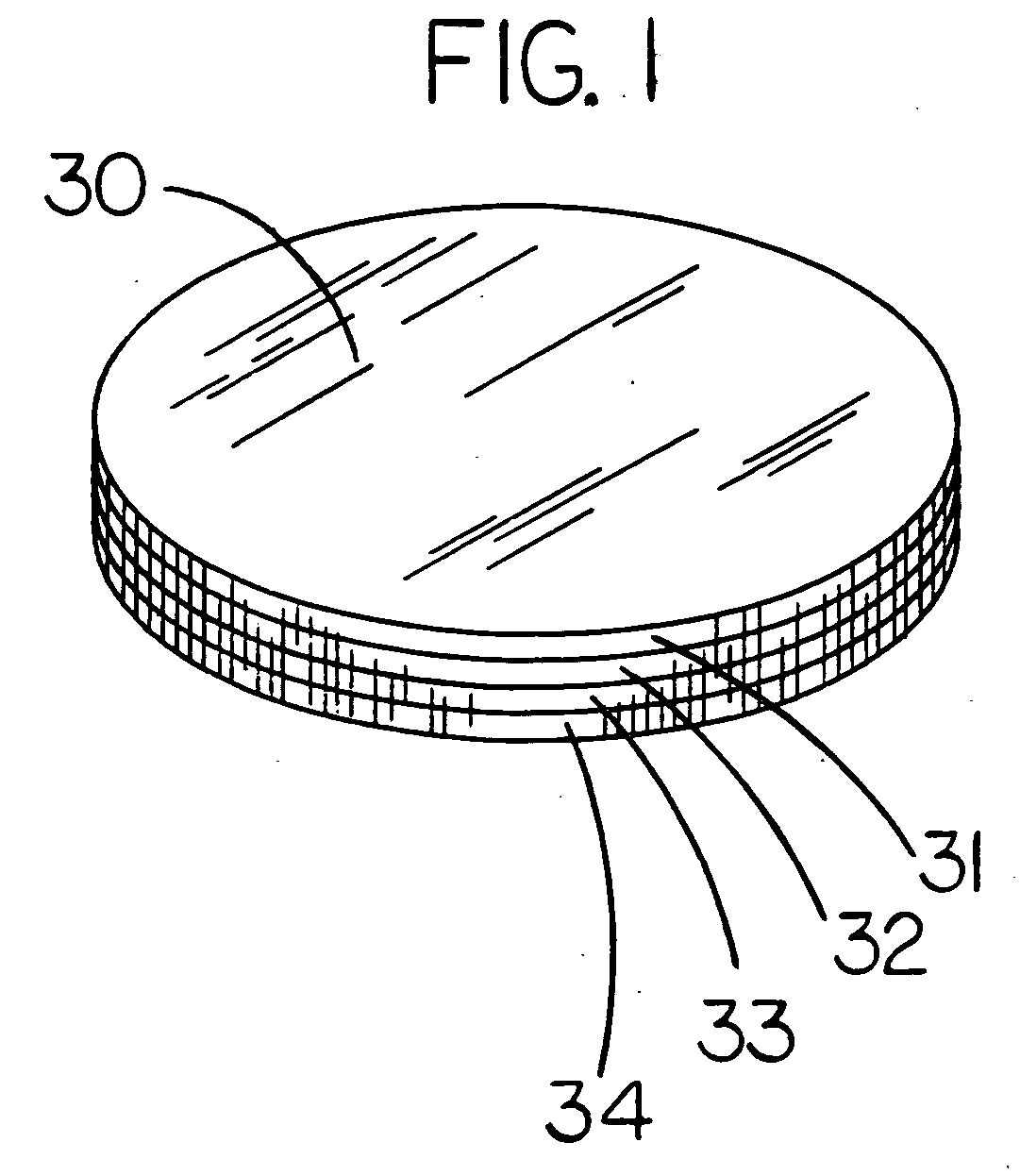

Pressure activated self opening container and seal

InactiveUS20050155991A1Easily appliedHigh degree of reliabilityCapsClosure using stoppersBurst pressureEngineering

An improved multi layered frangible seal is bonded over the pour spout opening of flexible plastic bottle containers of the type used for storing and dispensing pourable products such as motor oil or transmission fluid and the like. The seal provides a leak proof closure that is only strong enough to remain intact when subjected to the pressure created by the weight of the liquid contents when the filled uncapped container is held in an inverted position. At the same time the seal is also weak enough to break open and dispense the contents when a set amount of additional pressure is brought to bear against the seal by a consumer squeezing the inverted container. The seal allows the pour spout of the inverted container to be inserted into the fill opening while remaining intact which prevents any spilling of the contents. The seal is then broken open by the consumer squeezing the flexible bottle which dispenses the contents into the fill opening thereby eliminating the need for a fill funnel. The seal invention is constructed of a first layer of leak proof frangible material that is bonded to an additional layer of material. The additional layer of material contains one or more cut through and / or cut out void configurations forming a breaking pattern that turns the additional layer into a break and tear template layer. Bonding the template layer to the frangible layer strengthens the surface area of the frangible layer every where except in the area of the breaking pattern by leaving only the first frangible layer covering over the cut through and / or cut out void configuration forming the breaking pattern. This leaves a weakness in the multi layered seal only in the area of the breaking pattern which forces the seal to break open and tear only in the weaker single layered area of the breaking pattern configuration when sufficient pressure is brought to bear against the seal by a consumer squeezing the inverted container. The use of a separate layer of material to form the frangible area of the seal provides the ability to accurately control the thickness of the seal material that must break open, thus allowing the burst pressure of the seal to be precisely set. An uncut area of the breaking pattern forms a connector that keeps the broken open portion of the seal attached to the annular portion of the seal remaining bonded to the pour spout rim thus preventing any contamination of the dispensed contents when the seal breaks open.

Owner:JACKMAN BRIAN FRANCIS

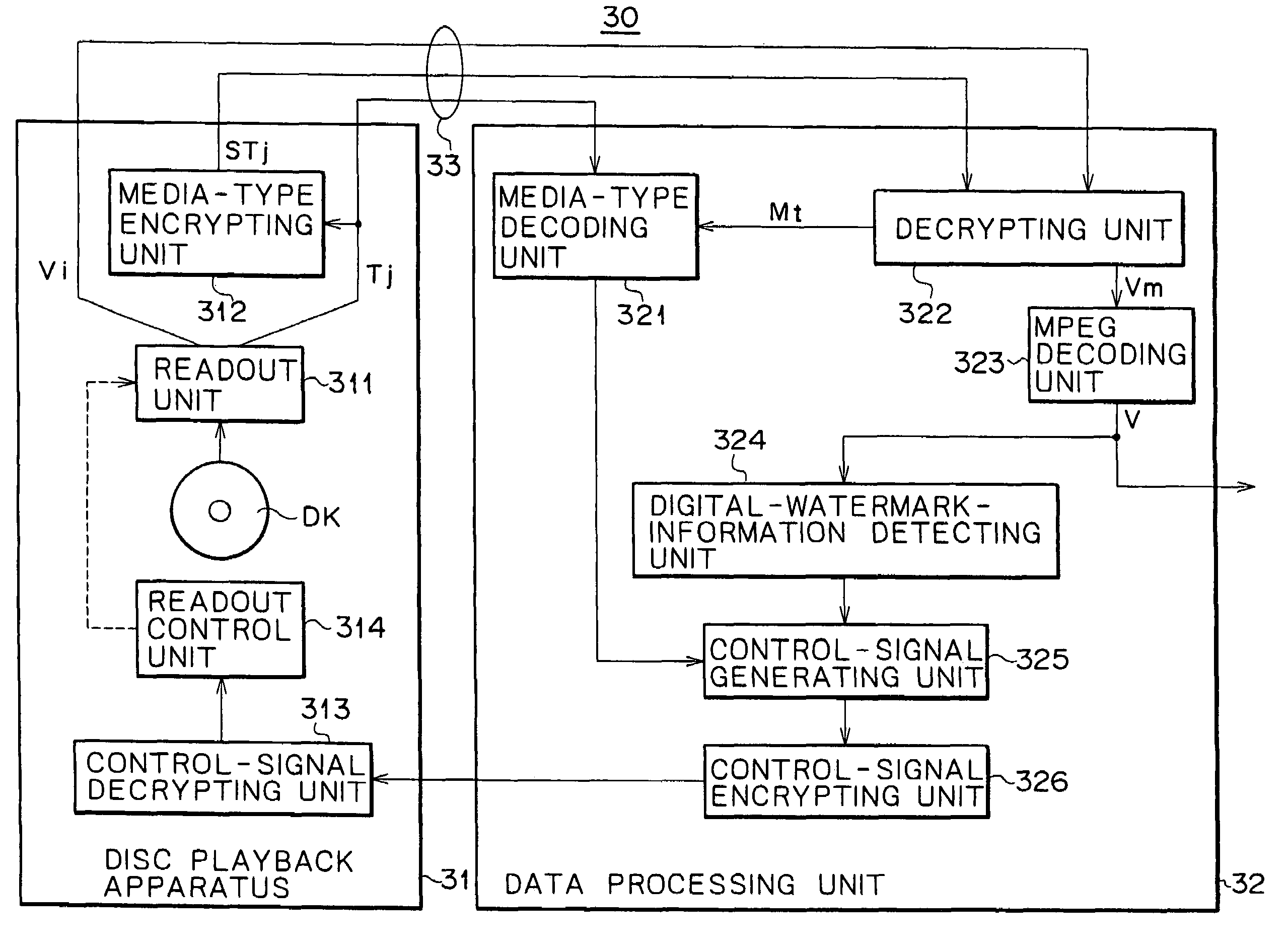

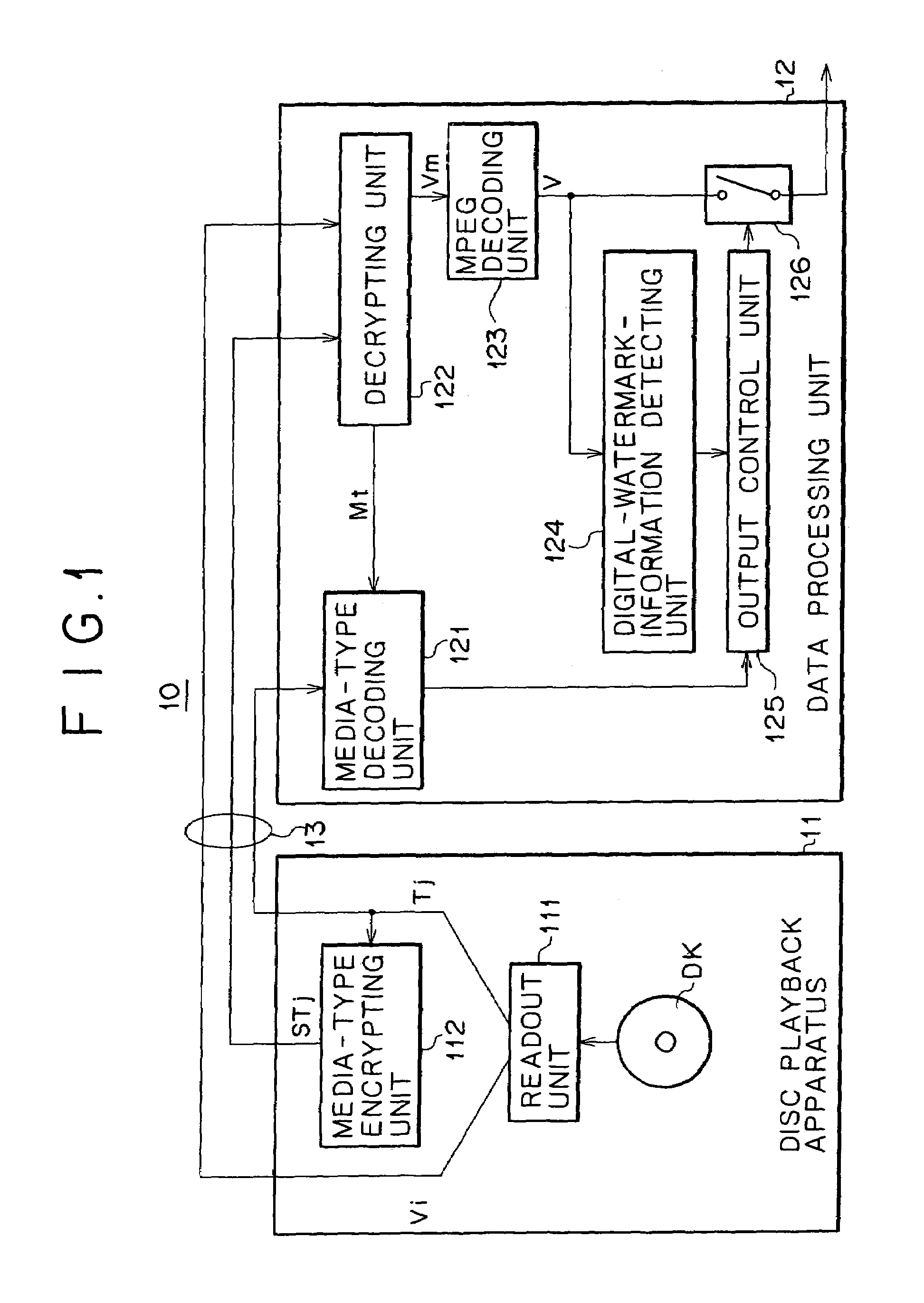

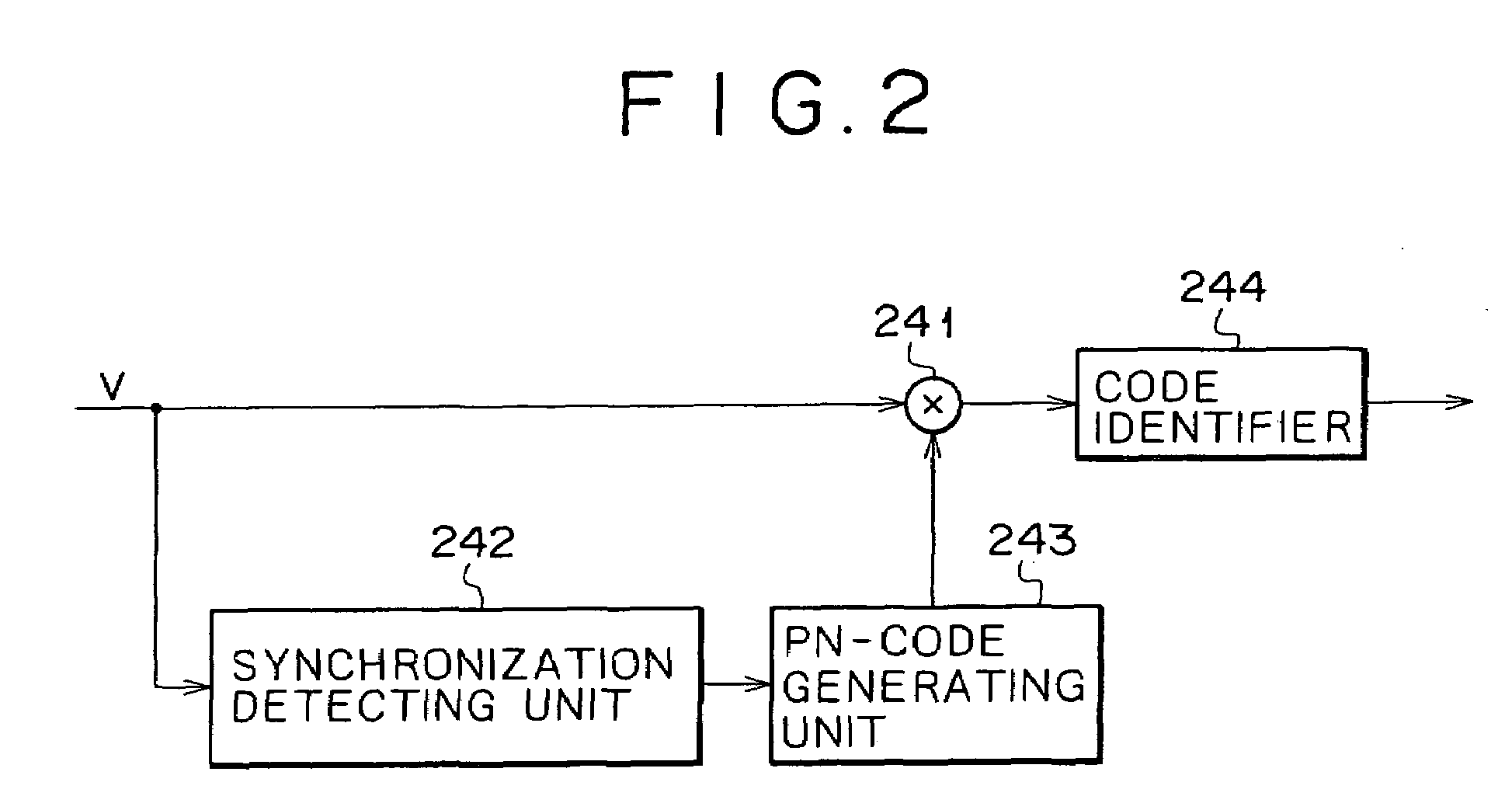

Information-signal playback system, information-signal reading apparatus, information-signal processing apparatus, information-signal playback method, information-signal reading method and information-signal processing apparatus

InactiveUS7548887B1High degree of reliabilityControlled reproductionTelevision system detailsUnauthorized memory use protectionDigital videoThrough transmission

The present invention relates to an apparatus and a method for protecting the copyright of an information signal recorded on a recording medium such as a DVD (Digital Video Disc) for presenting the signal to the user or an information signal transmitted through transmission media such as the Internet and for preventing an illegal copy of such an information signal. To put it in detail, information on copyright protection which is read out from the recording medium and information on copyright protection which is encrypted to make the information difficult to alter is used. If both of the information do not match each other, the information on copyright protection is judged to have been altered in an attempt to play back the information signal which is obtained as a result of an illegal copy operation in which case, the operation to play back the information signal is disabled.

Owner:SONY CORP

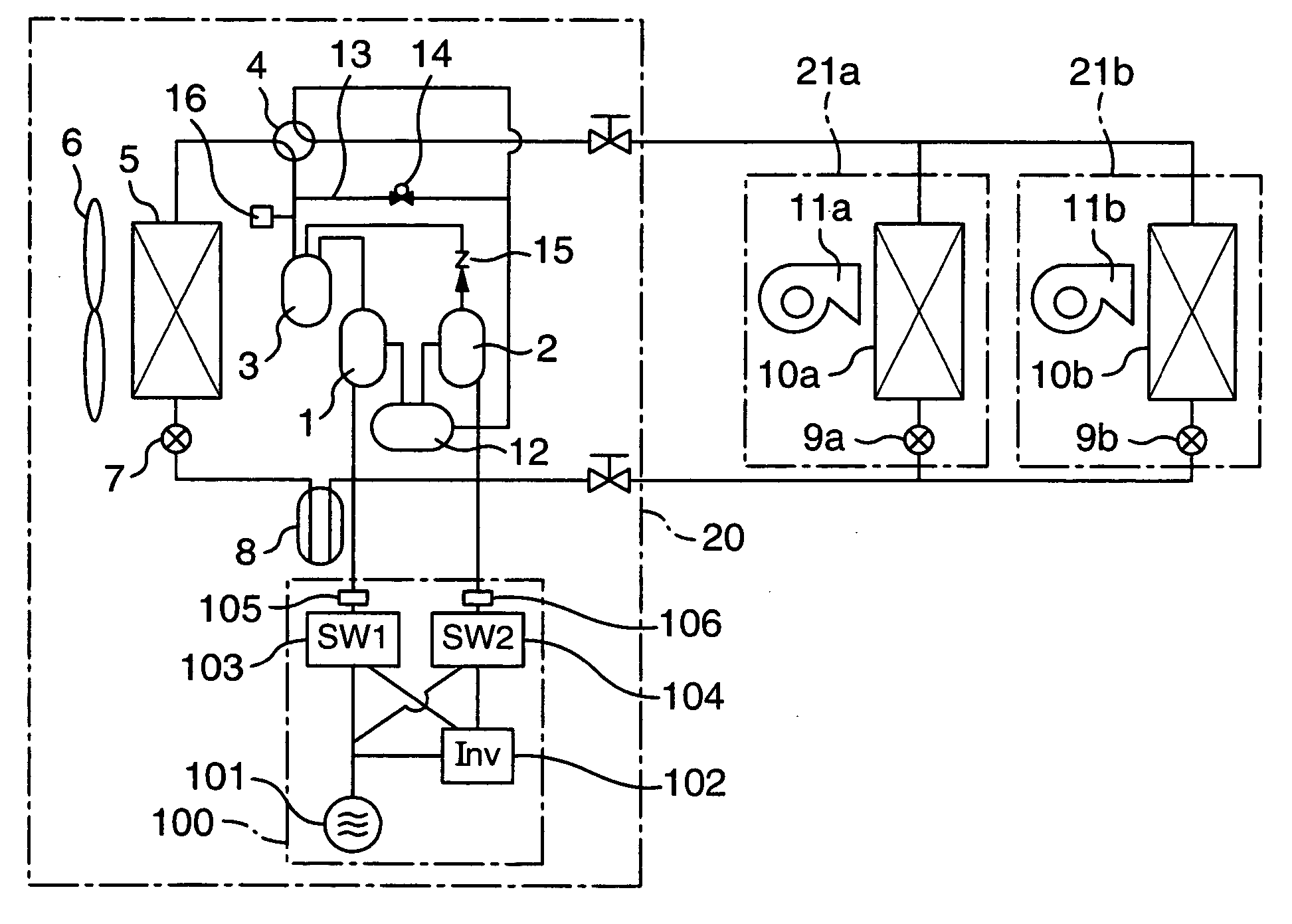

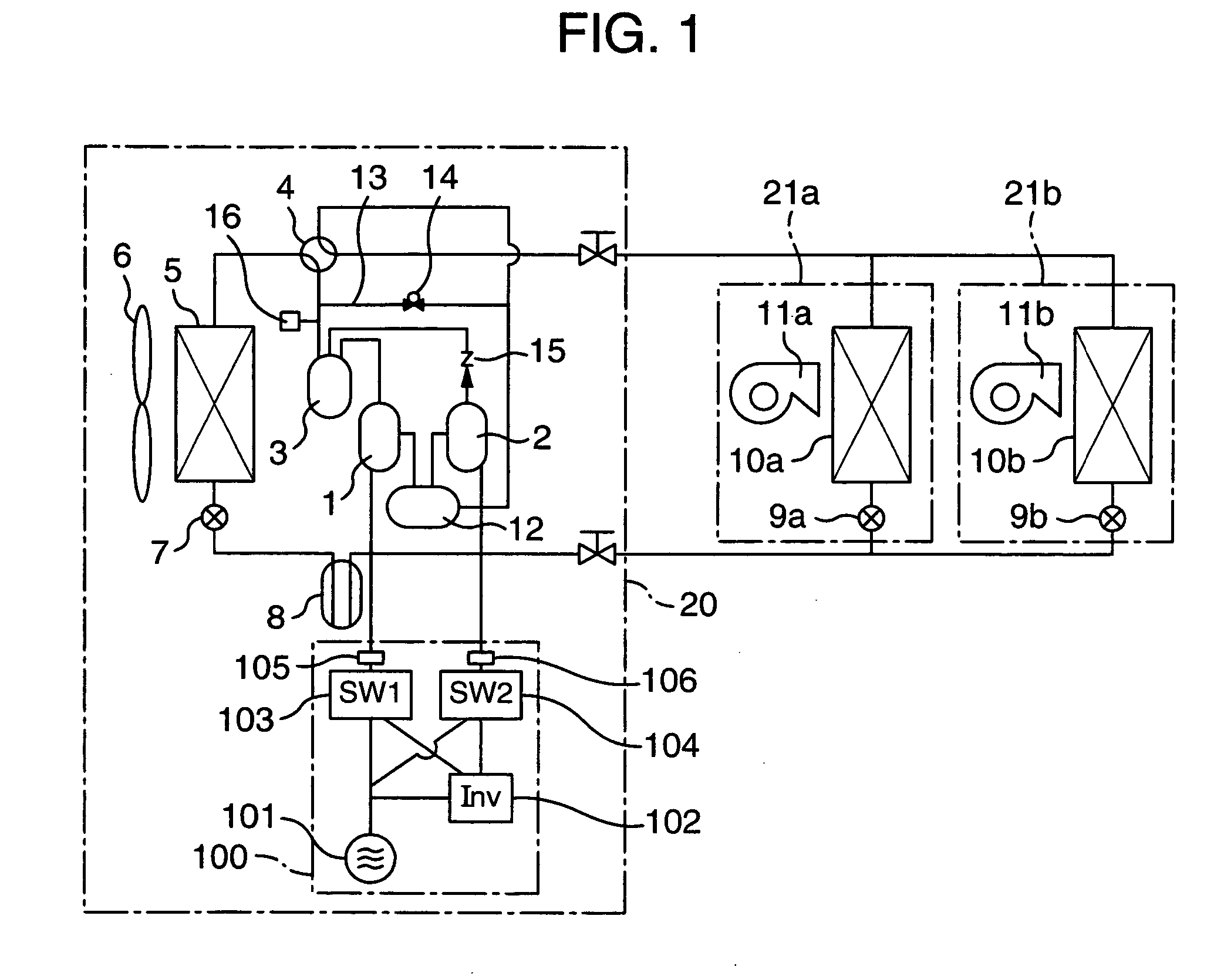

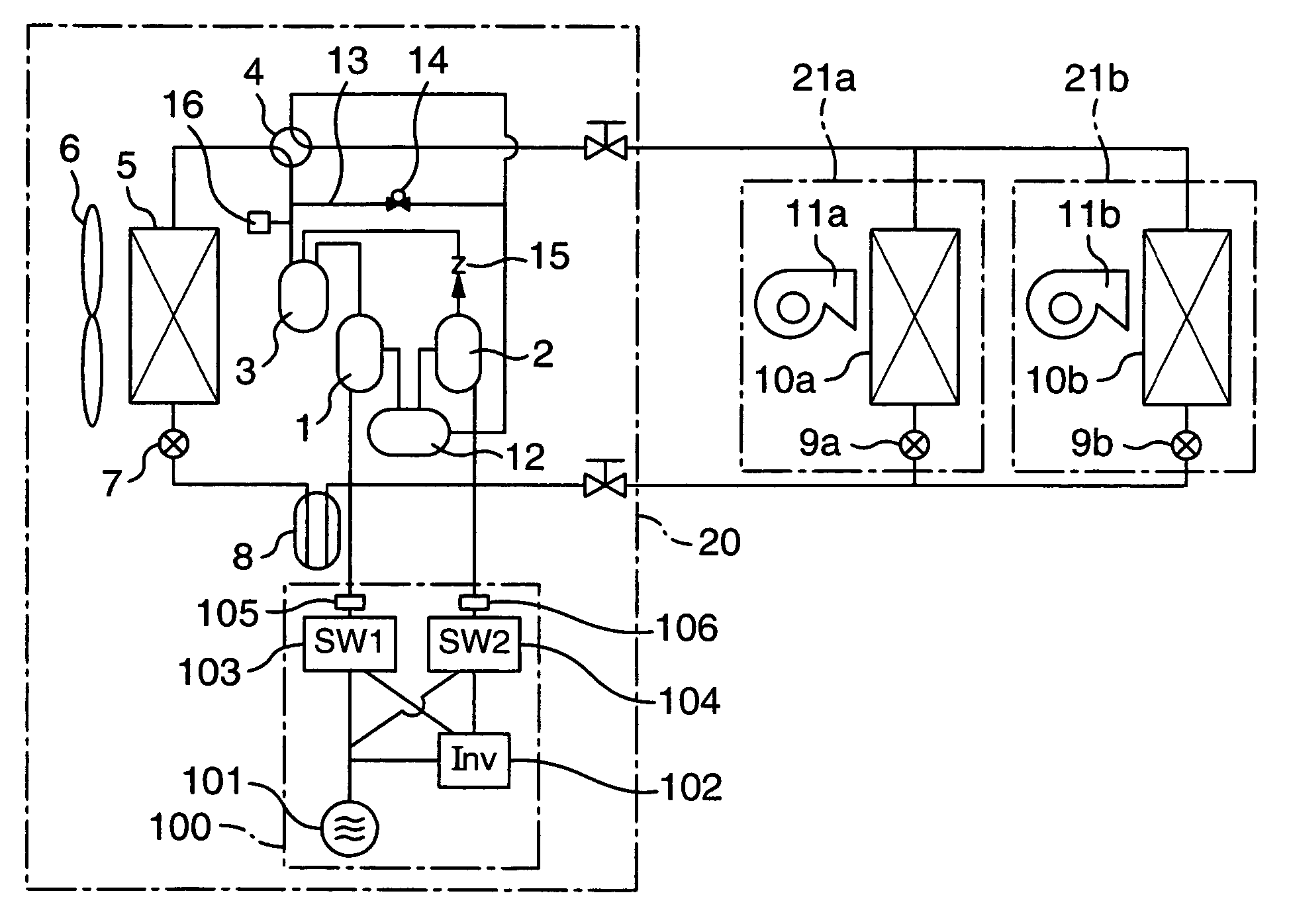

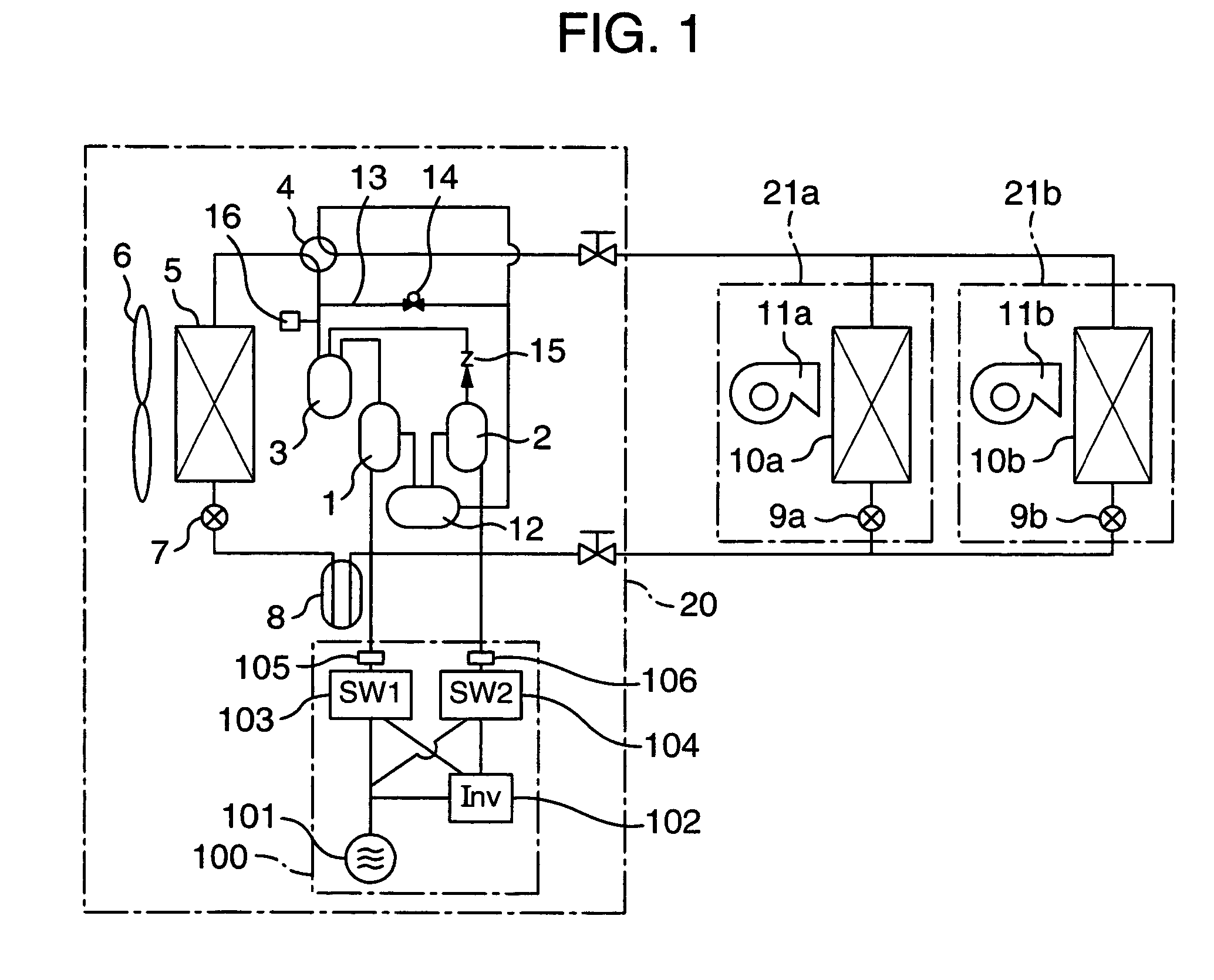

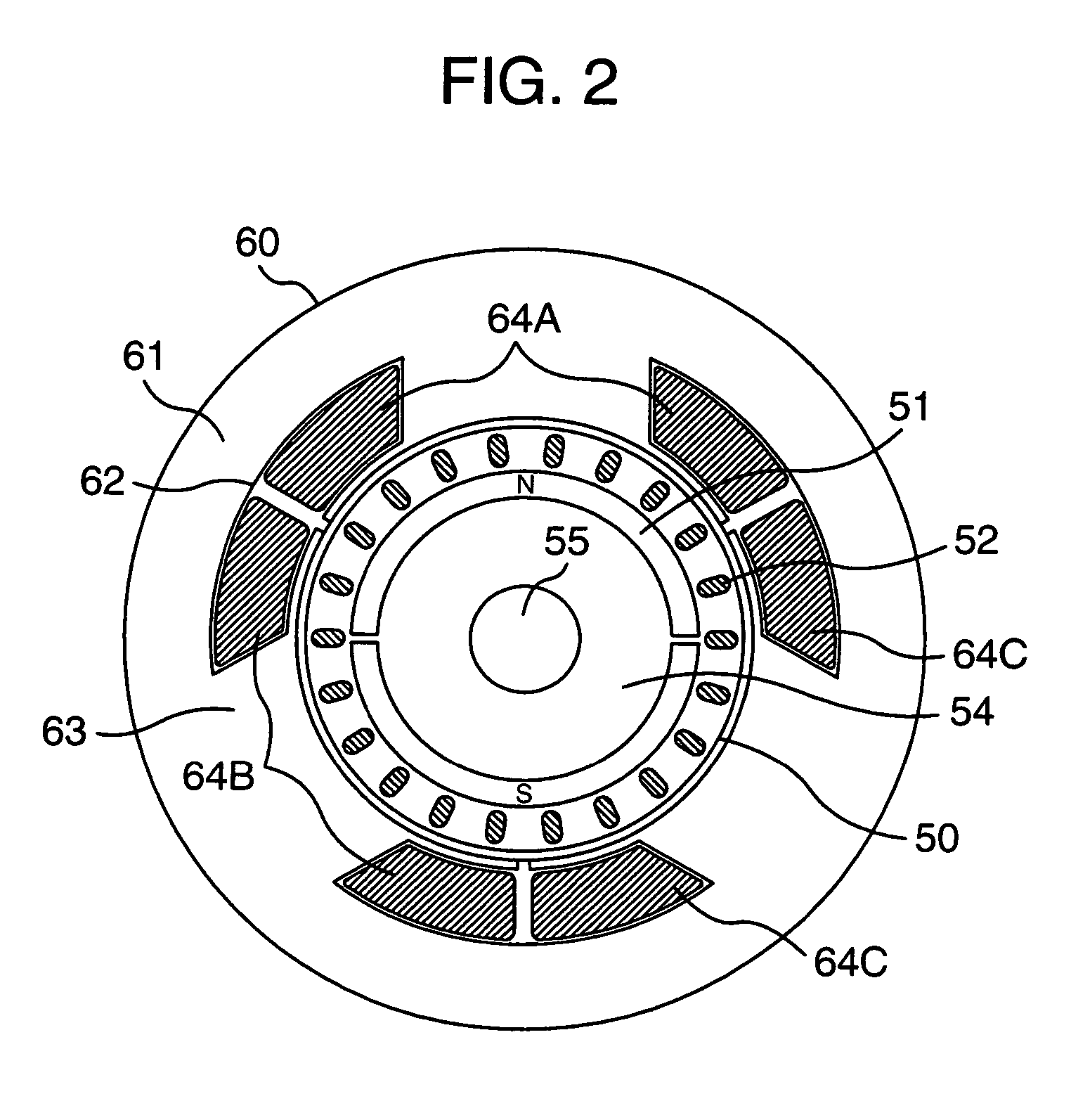

Refrigerating machine

InactiveUS20050086960A1Improve efficiencyHigh degree of reliabilityRotary/oscillating piston combinations for elastic fluidsPump componentsDriving currentSynchronous motor

A refrigerating machine having a compressor driven by a motor. The motor incorporates an armature with an iron core having a cage type conductor and a permanent magnet which is magnetized so as to enable the motor to operate as a synchronous motor. A bypass passage is provided between a discharge side of the compressor and a suction side of the compressor, a shut-off valve is provided for opening and closing the bypass passage, a pressure detecting device is provided for detecting a discharge pressure from the compressor and a current detector is provided for detecting a value of drive current for the compressor. The shut-off valve is opened and closed in accordance with the discharge pressure and the value of the drive current.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

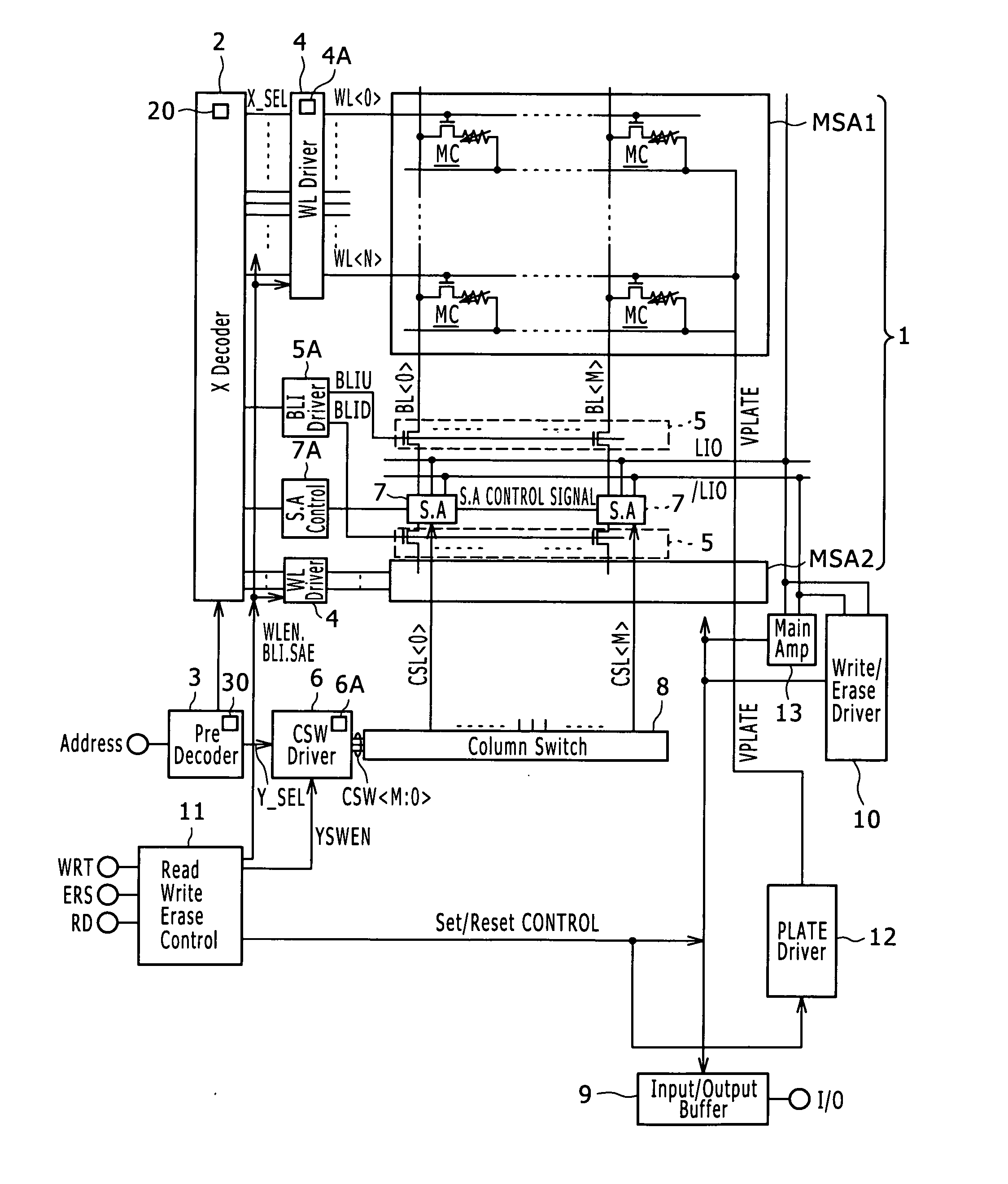

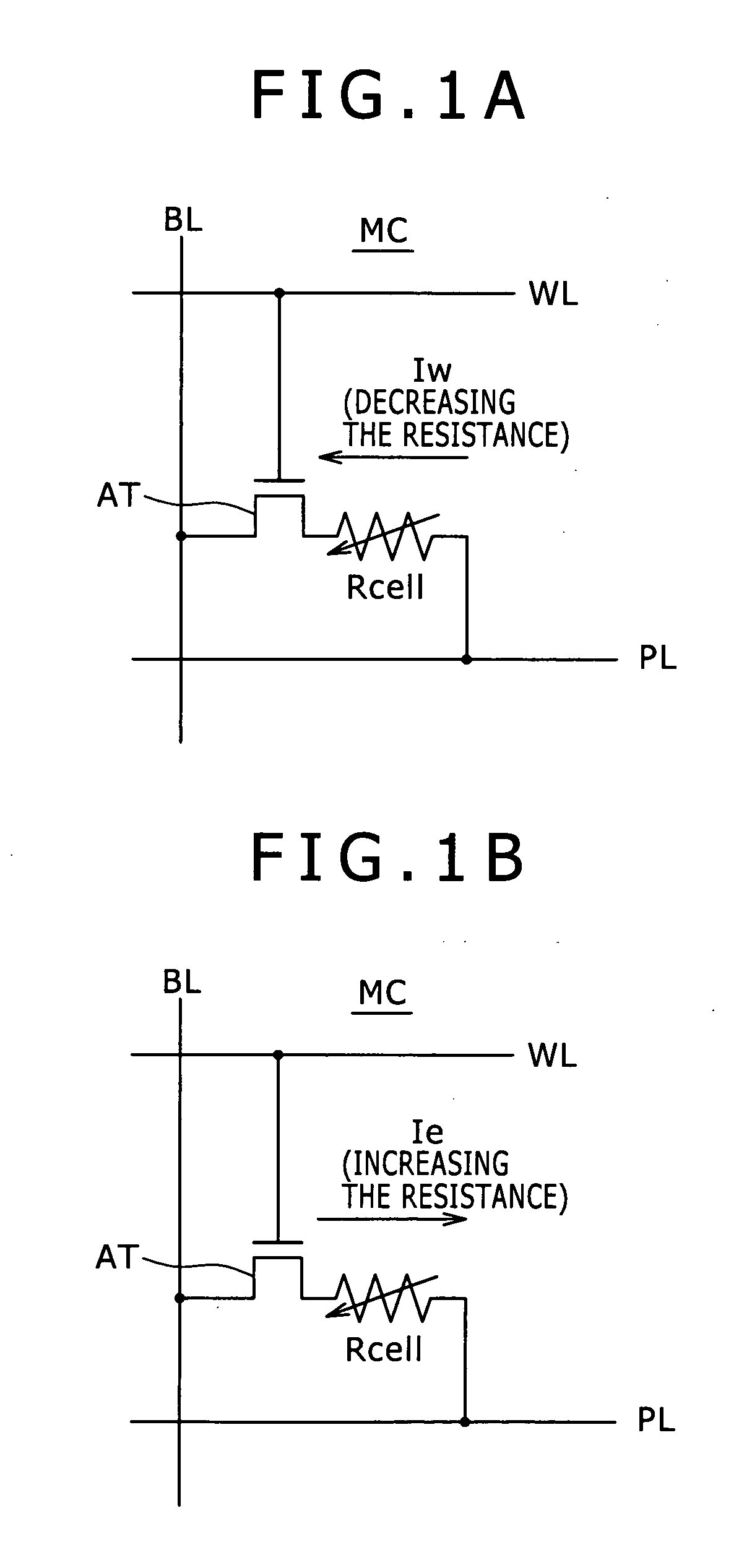

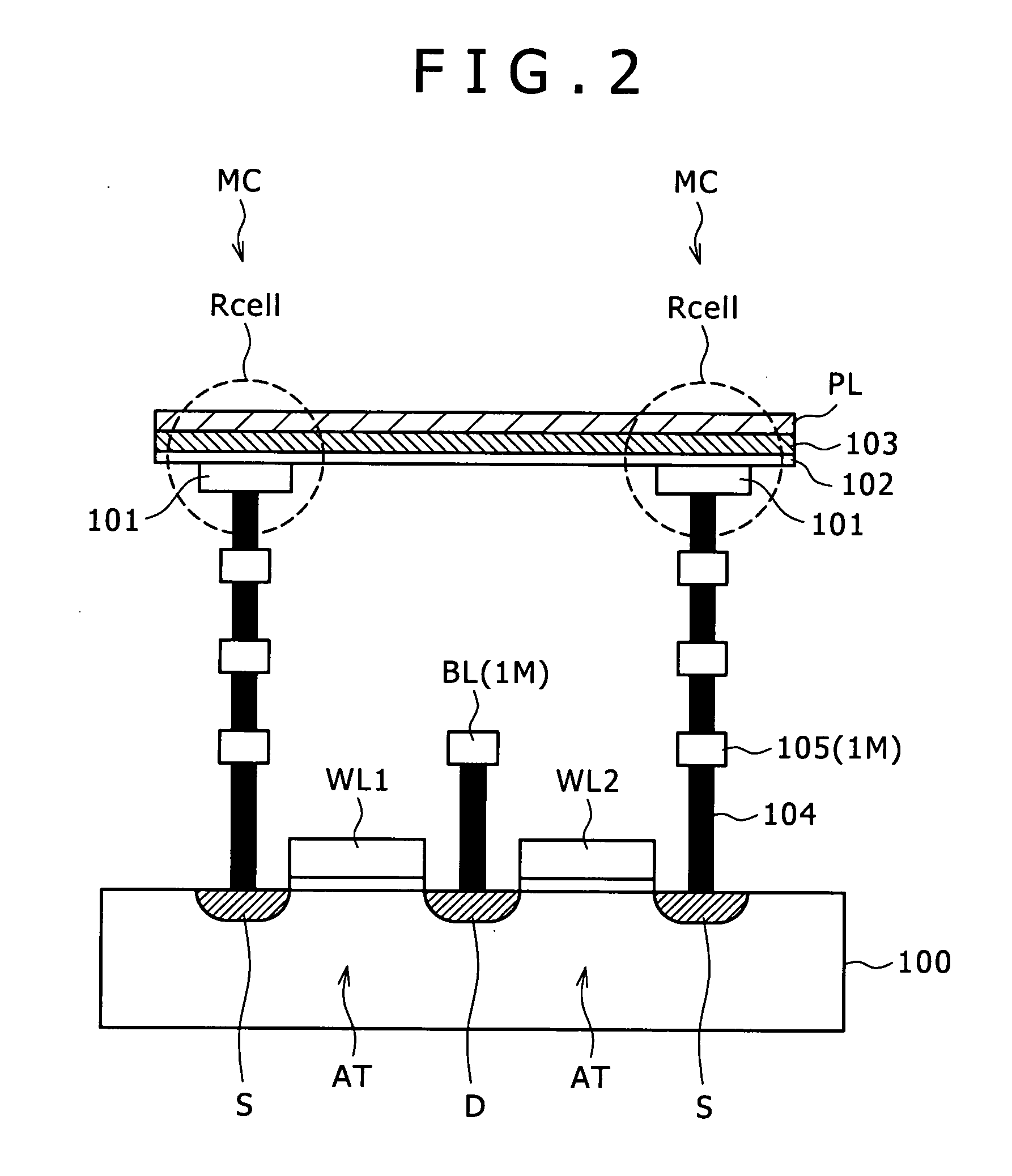

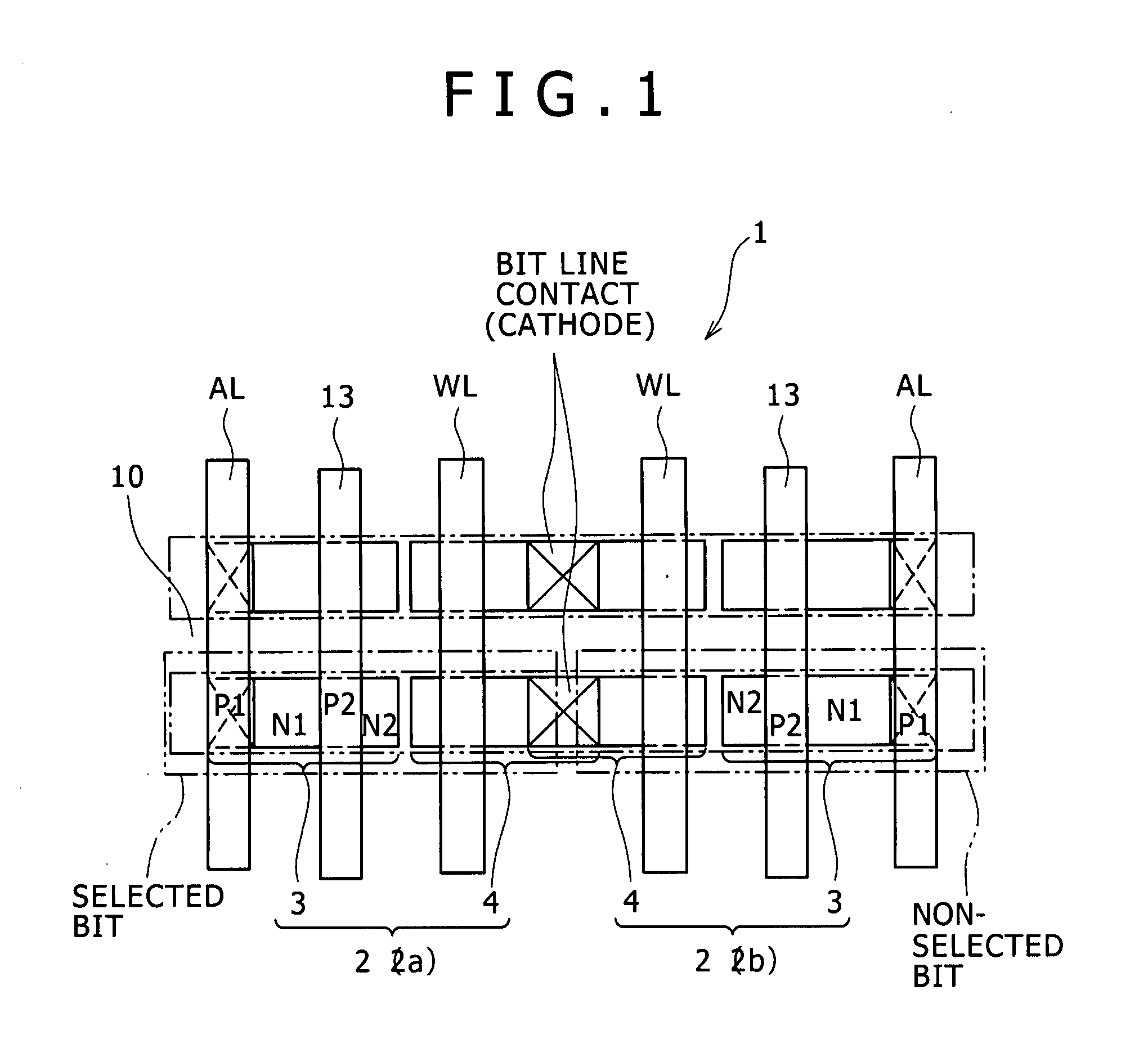

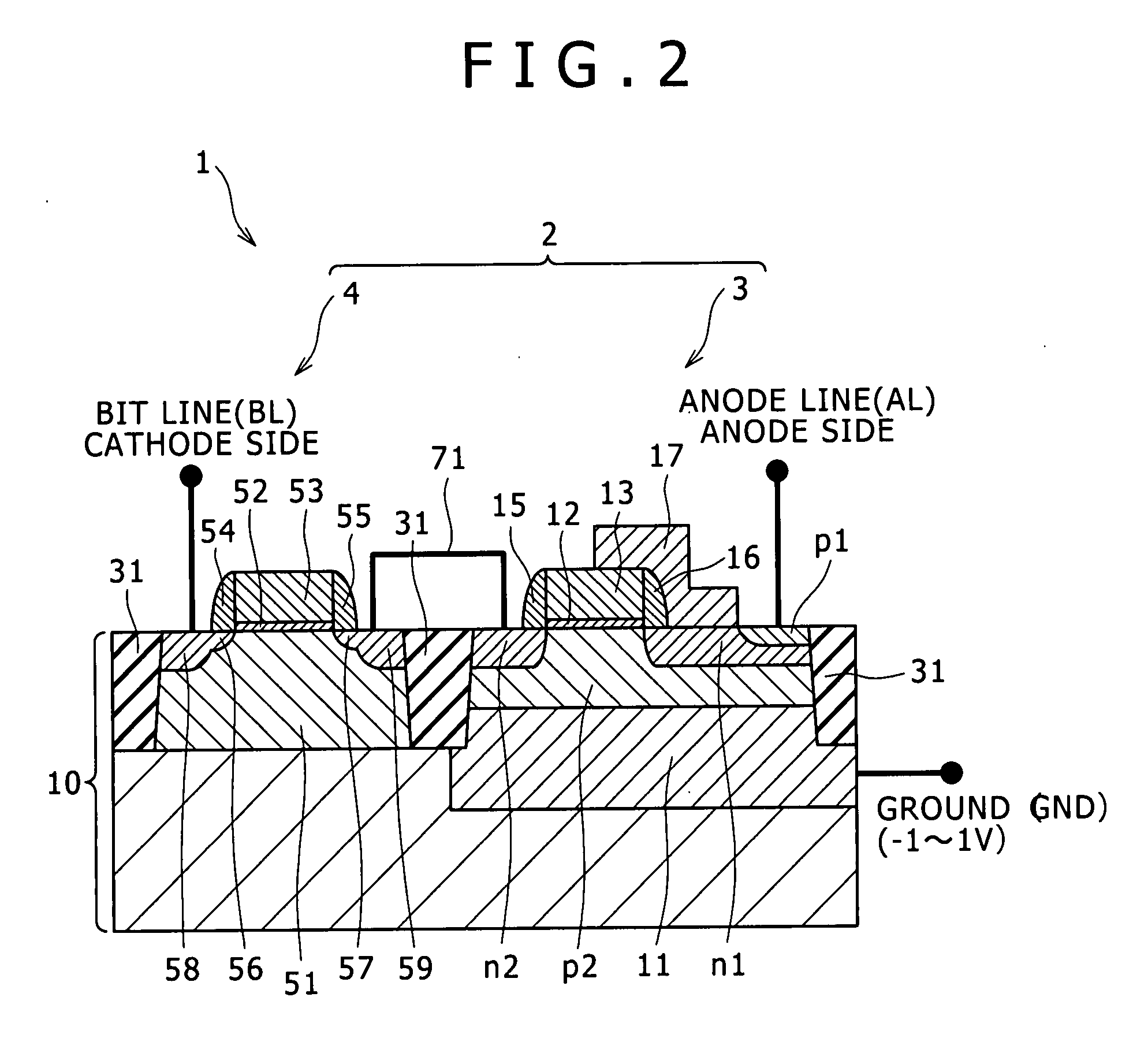

Memory device and operation method of the same

ActiveUS20100214818A1High degree of reliabilityHigh speedDigital storageSense amplifierData storage system

Disclosed herein is a memory device including: first and second wires; memory cells including a variable-resistance storage element having a data storage state making a transition by a change of a voltage applied and an access transistor connected in series between the first and second wires; driving control sections controlling a direct verify sub-operation by applying a write / erase pulse between the first and second wires in a data write / erase operation respectively for causing a cell current to flow between the first and second wires through the memory cell for a transition of the data storage state; sense amplifiers sensing an electric-potential change occurring on the first wire in accordance with control on the direct verify sub-operation; and inhibit control sections determining whether or not to inhibit a sense node of the sense amplifier from electrically changing at the next sensing time on the basis of an electric potential appearing at the sense node at the present sensing time.

Owner:SONY SEMICON SOLUTIONS CORP

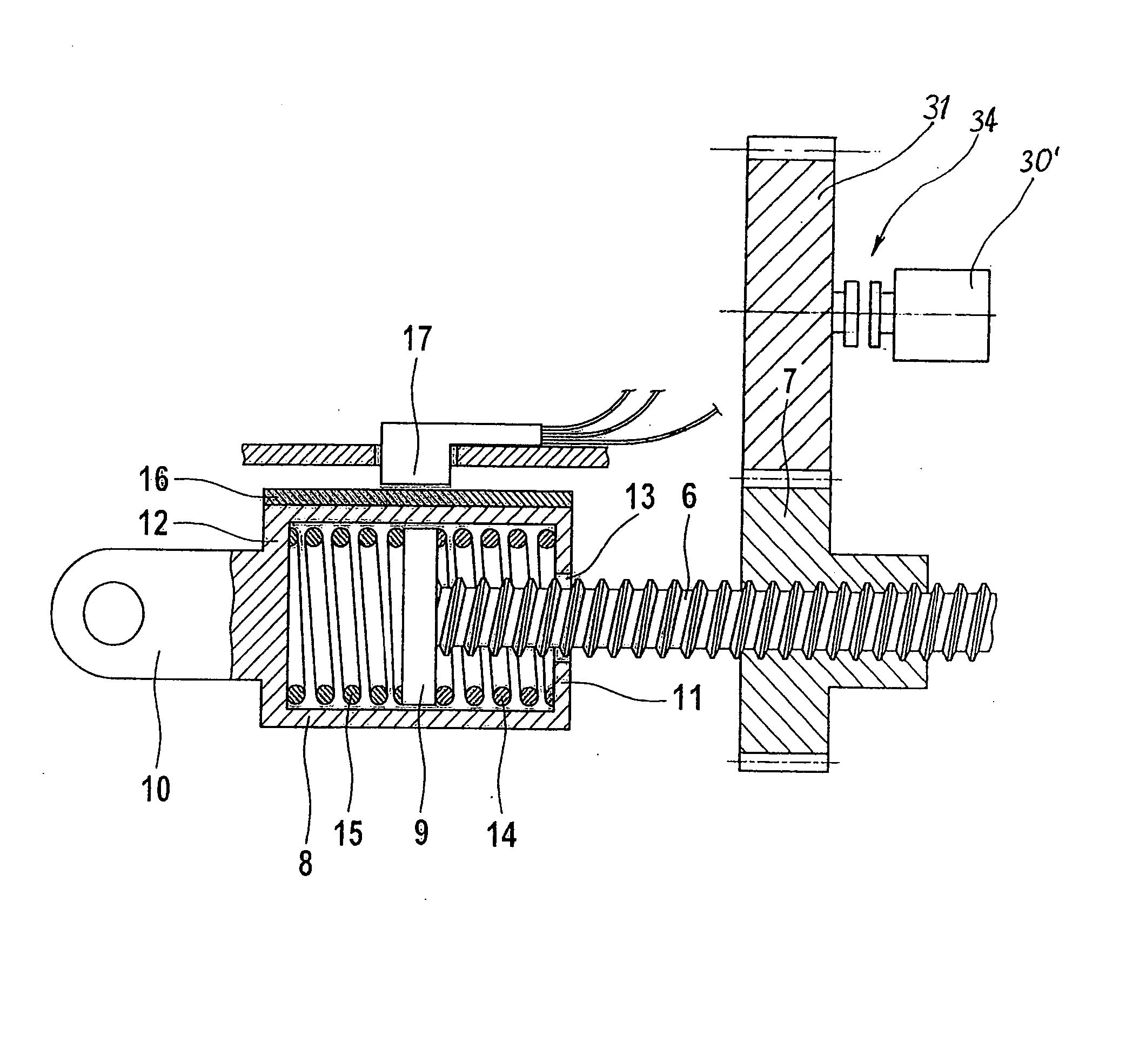

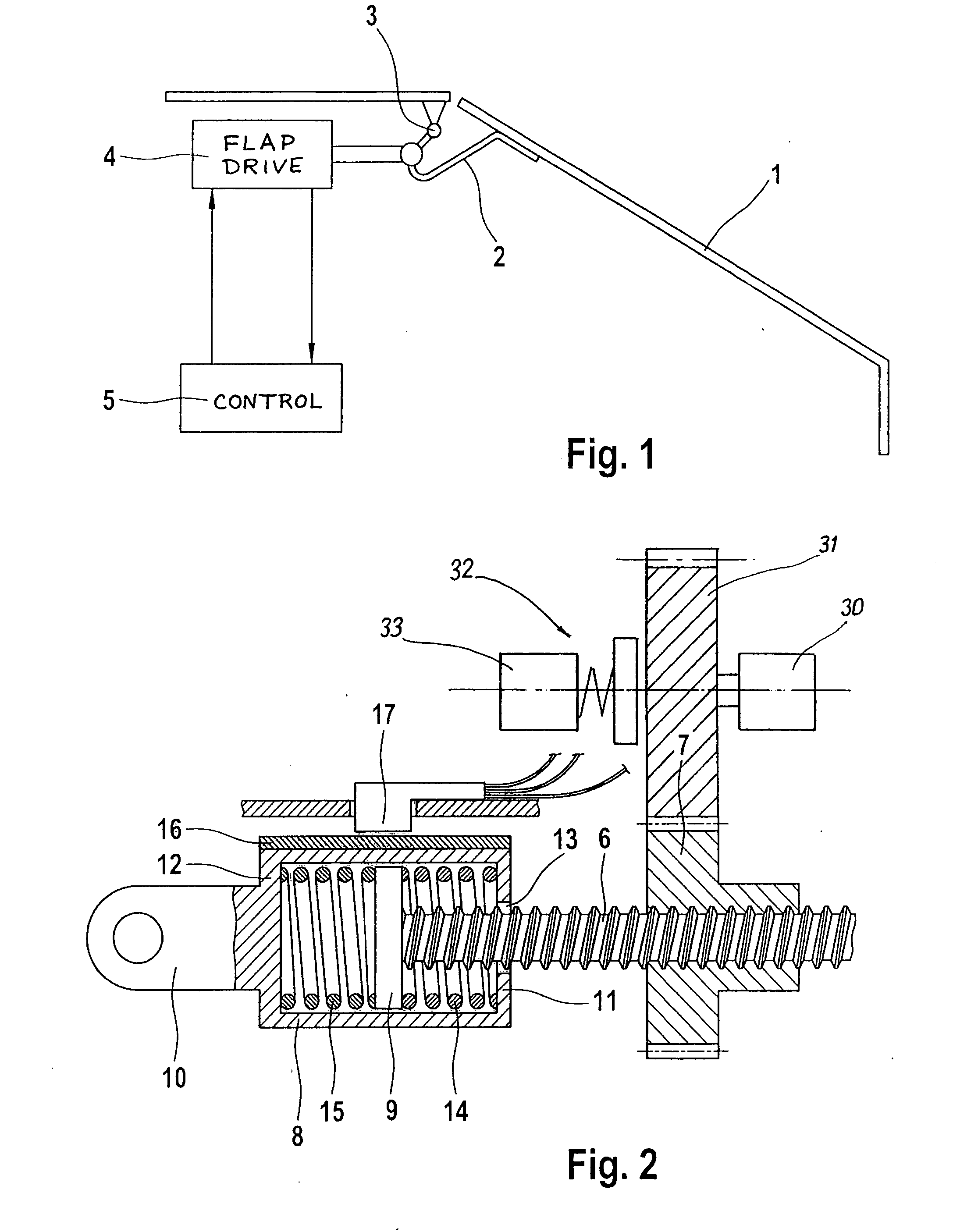

Flap drive

ActiveUS20070289397A1Simple constructionHigh degree of reliabilityBuilding braking devicesMan-operated mechanismDrive motorEngineering

A drive train for a pivotable flap of a motor vehicle includes a holding device which can hold the flap in at least one open position, a first element which can be driven by a drive motor, and a second element connected to the pivotable flap to pivot the flap in response to movement of the first element. When the second element is moved along a path of motion relative to the first element counter to a specific spring force, a sensor generates a signal indicating relative motion of the elements, and a control device releases the holding device in response to the signal, whereby the flap can be moved manually by applying a force counter to the spring force.

Owner:STABILUS

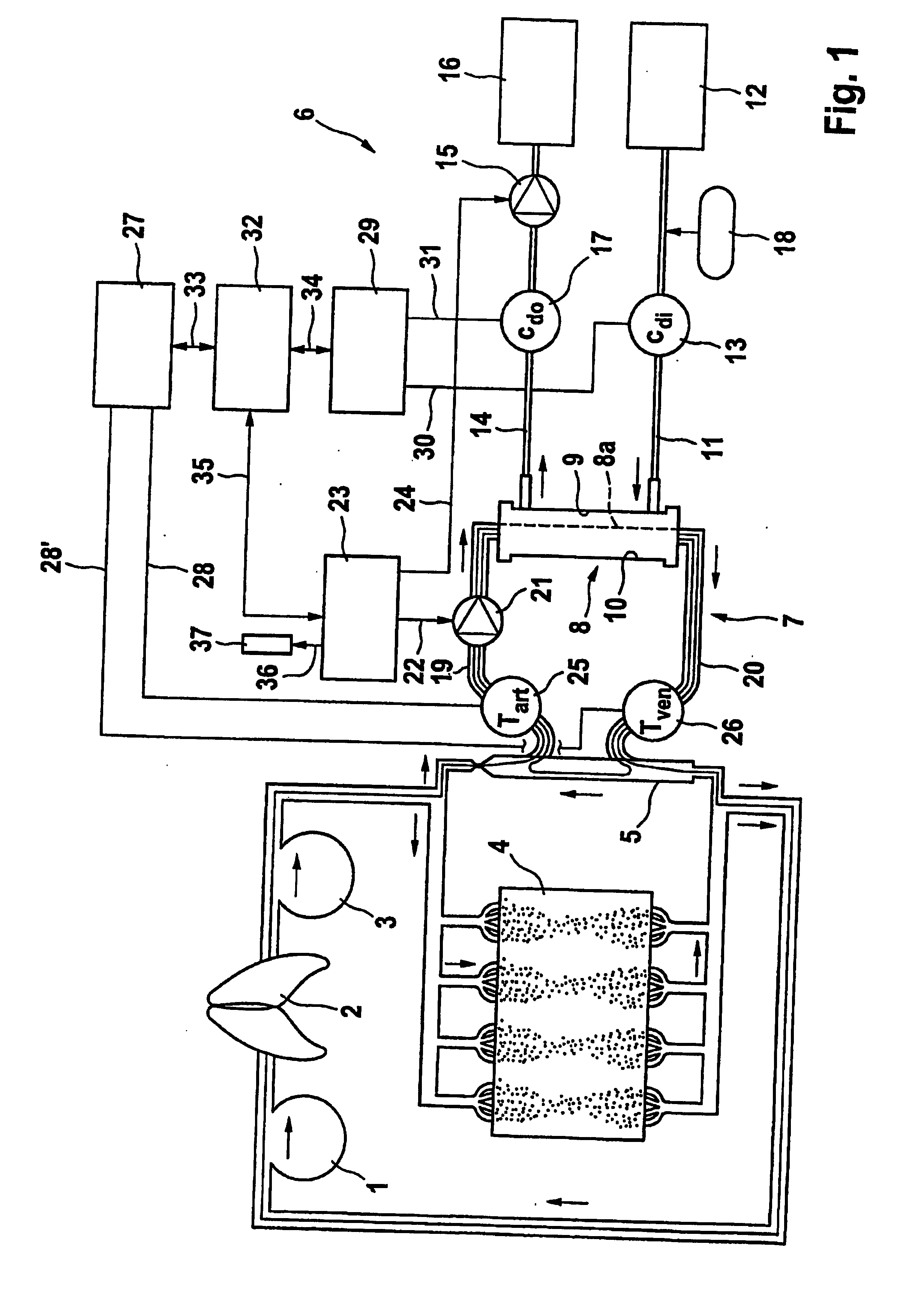

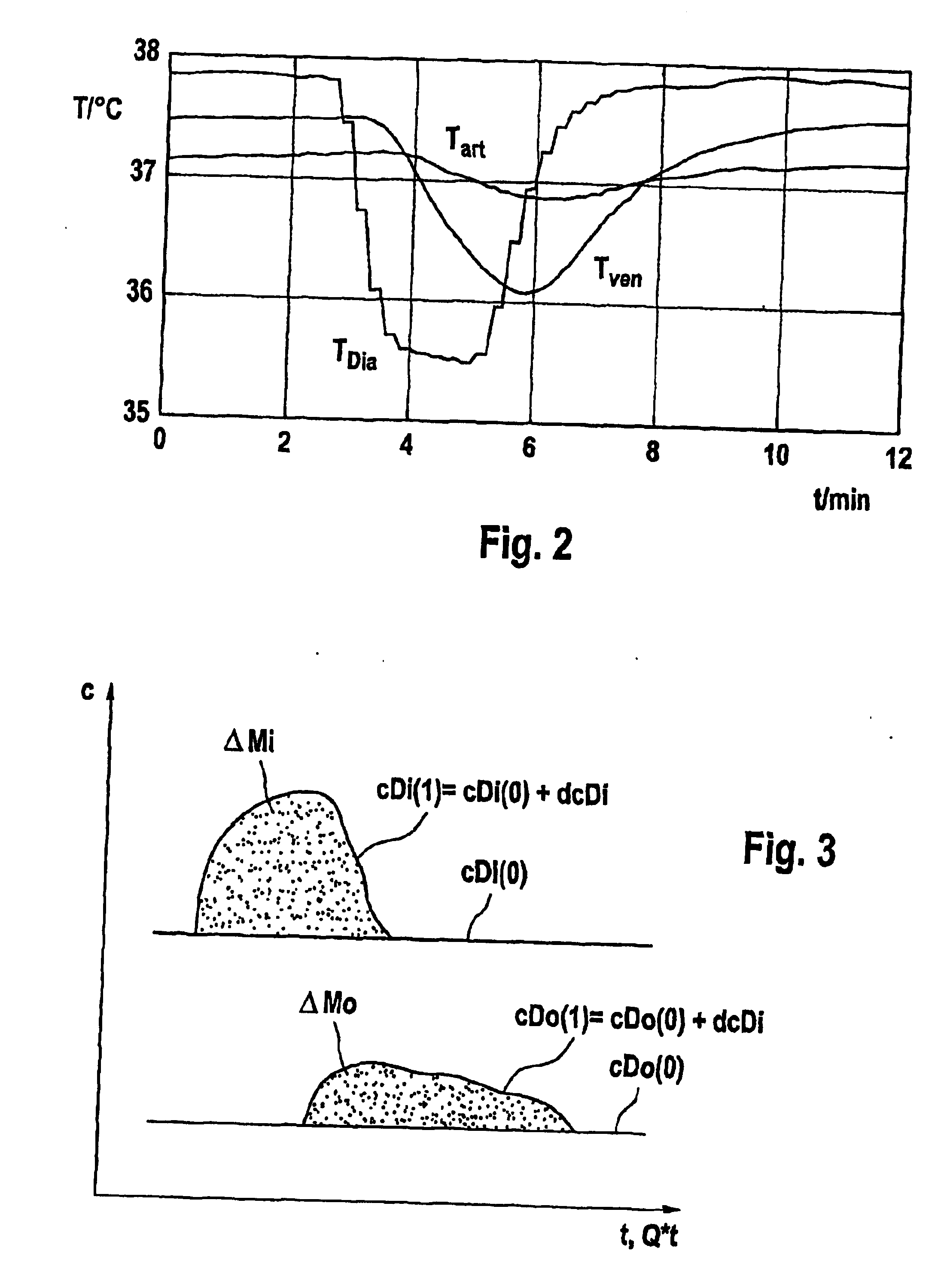

Device and Method for Detecting Complications During an Extracorporeal Blood Treatment

ActiveUS20080097272A1High degree of reliabilityImprove reliabilitySemi-permeable membranesSolvent extractionDialysis fluidIntensive care medicine

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

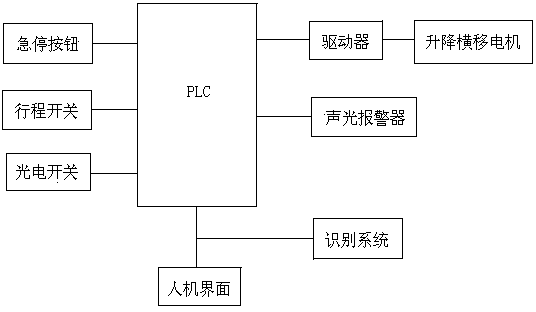

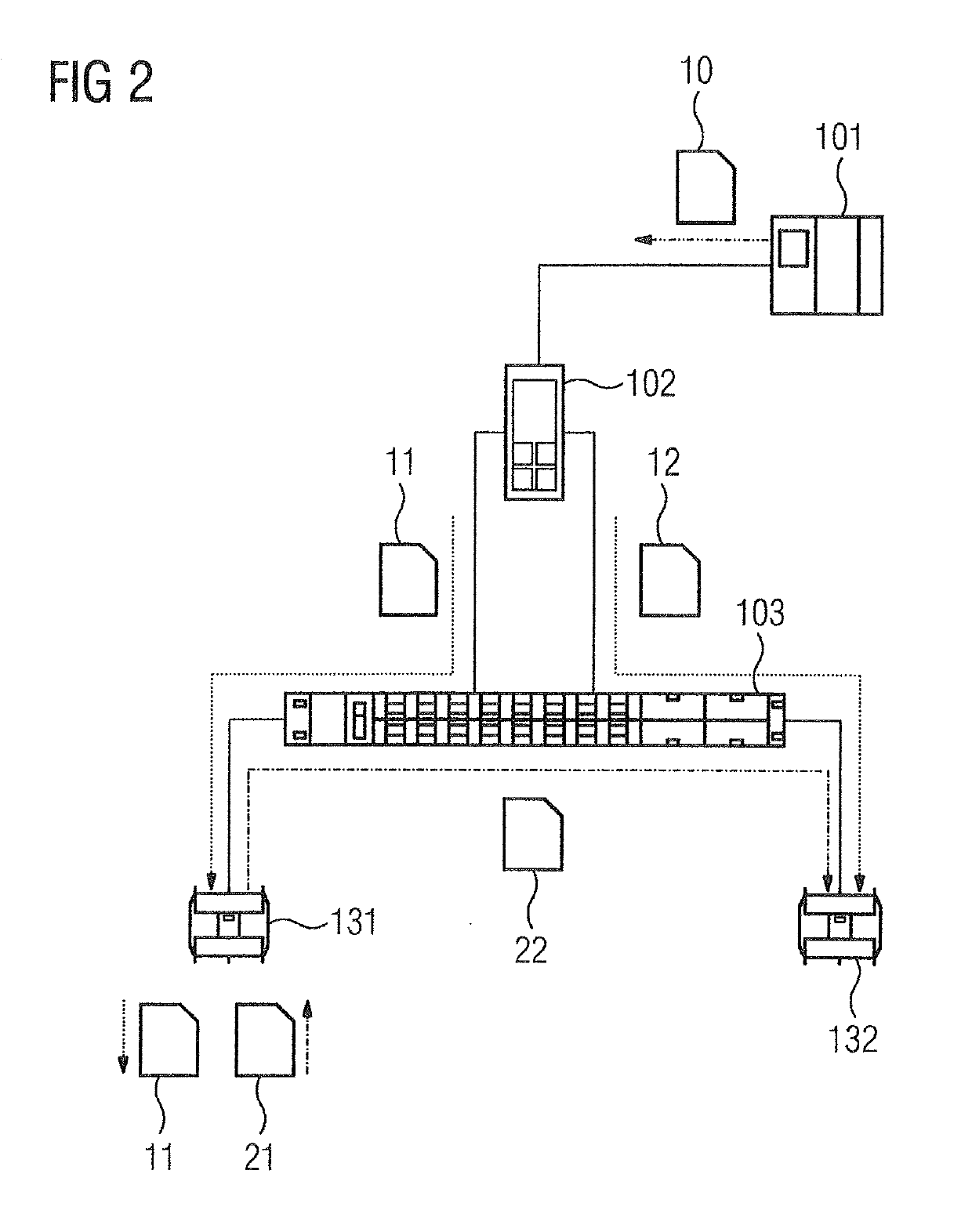

Control system for three-dimensional parking garage

InactiveCN104179379AStable jobHigh degree of reliabilityProgramme control in sequence/logic controllersParkingsAutomotive engineeringScram

The invention discloses a control system for a three-dimensional parking garage. The control system comprises a PLC, wherein the input end of the PLC is connected with a scram button, a travel switch and an optoelectronic switch; the output end of the PLC is connected with a driver and an audible and visual alarm; a lifting and traverse moving motor is further connected with the driver, and mounted on each parking space; the PLC is further connected with a human-computer interface which is connected with a recognition system. The control system provided by the invention is stable in operation and high in reliability, and adopts a remote control technology and an automatic recognition system; when a car is parked safely, the parking garage can park the car at an appropriate position automatically, and unmanned operation can be realized; the management of the whole parking garage can be brought into a building automatic system, and network is accessed, so that a comprehensive computer management grid information system is formed, and unmanned management of the three-dimensional parking garage can be realized.

Owner:JIANGSU MONTMERY ELEVATOR

Refrigerating machine

InactiveUS6966194B2Improve efficiencyHigh degree of reliabilityRotary/oscillating piston combinations for elastic fluidsPump componentsDriving currentSynchronous motor

A refrigerating machine having a compressor driven by a motor. The motor incorporates an armature with an iron core having a cage type conductor and a permanent magnet which is magnetized so as to enable the motor to operate as a synchronous motor. A bypass passage is provided between a discharge side of the compressor and a suction side of the compressor, a shut-off valve is provided for opening and closing the bypass passage, a pressure detecting device is provided for detecting a discharge pressure from the compressor and a current detector is provided for detecting a value of drive current for the compressor. The shut-off valve is opened and closed in accordance with the discharge pressure and the value of the drive current.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

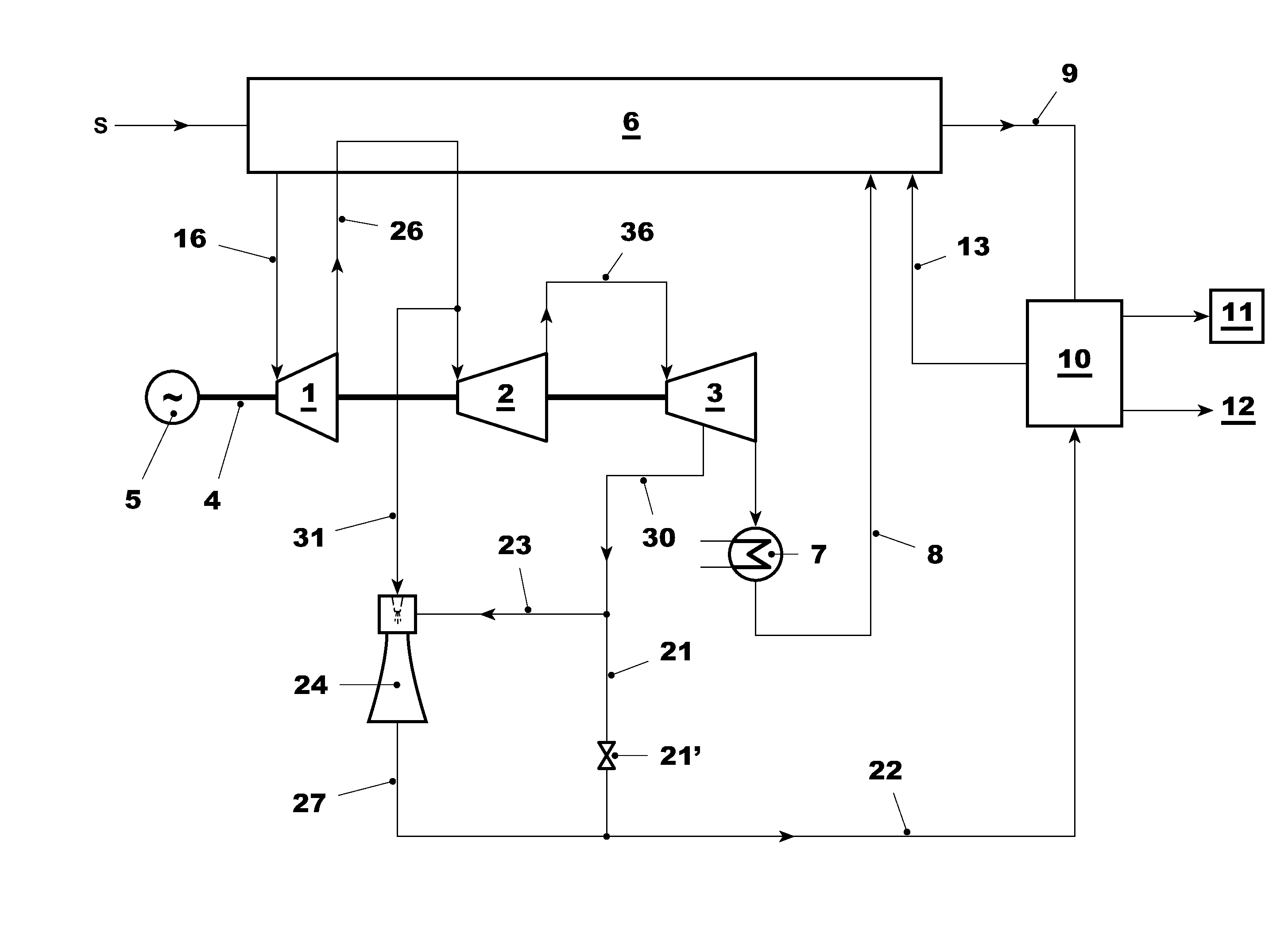

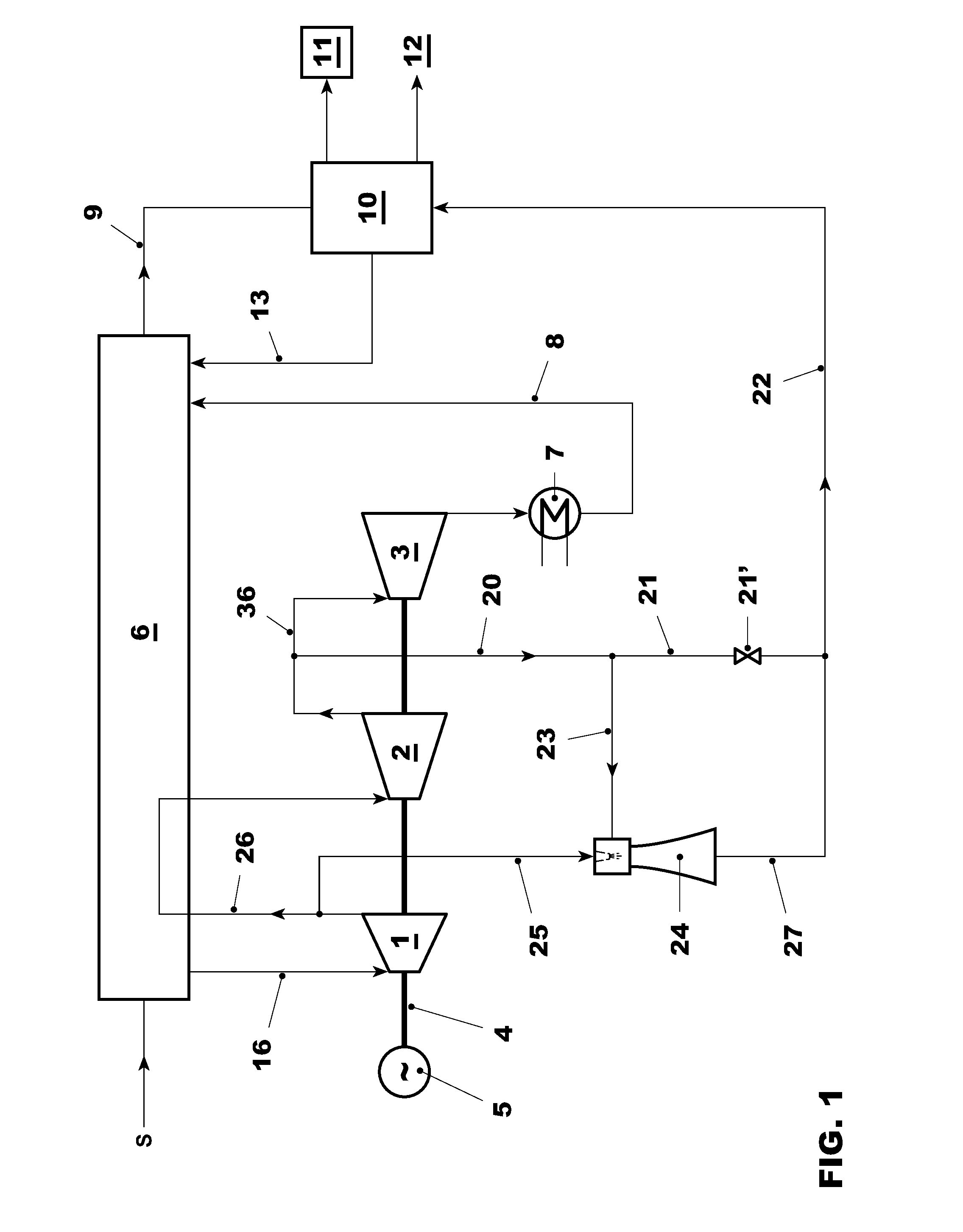

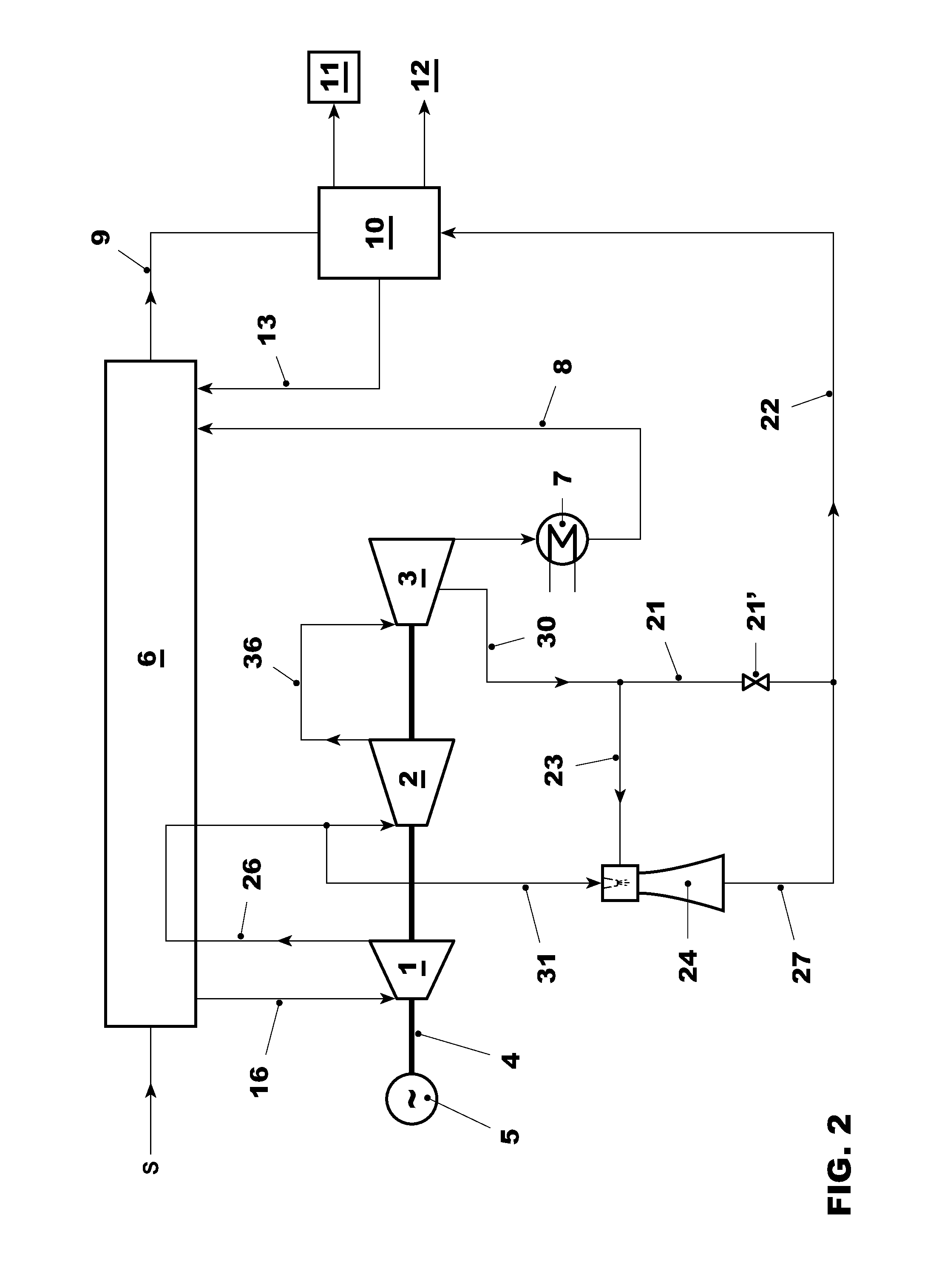

Power plant with co2 capture and method to operate such power plant

ActiveUS20130133326A1Improve efficiencyImprove reliabilitySteam useDirect carbon-dioxide mitigationNuclear engineeringElectric power

A fossil fuel fired power plant for the generation of electrical energy comprises a water steam cycle and a plant (10) for the capture of CO2 from exhaust gases emitted by the power plant and a steam jet ejector (24) configured and arranged to receive an input steam flow from a low- or intermediate pressure extraction point in the power plant and to increase its pressure. It is further arranged to receive motive steam (25) from a further extraction point in the power plant. A steam line (27, 22) directs the steam of increased pressure from the steam jet ejector (24) to the CO2 capture plant (10). The power plant according to this invention allows the use of low-pressure steam for the operation of the CO2 capture plant, where the extraction of such steam affects the overall efficiency of the power plant to a lesser degree than in power plant of the state of the art.

Owner:GENERAL ELECTRIC TECH GMBH

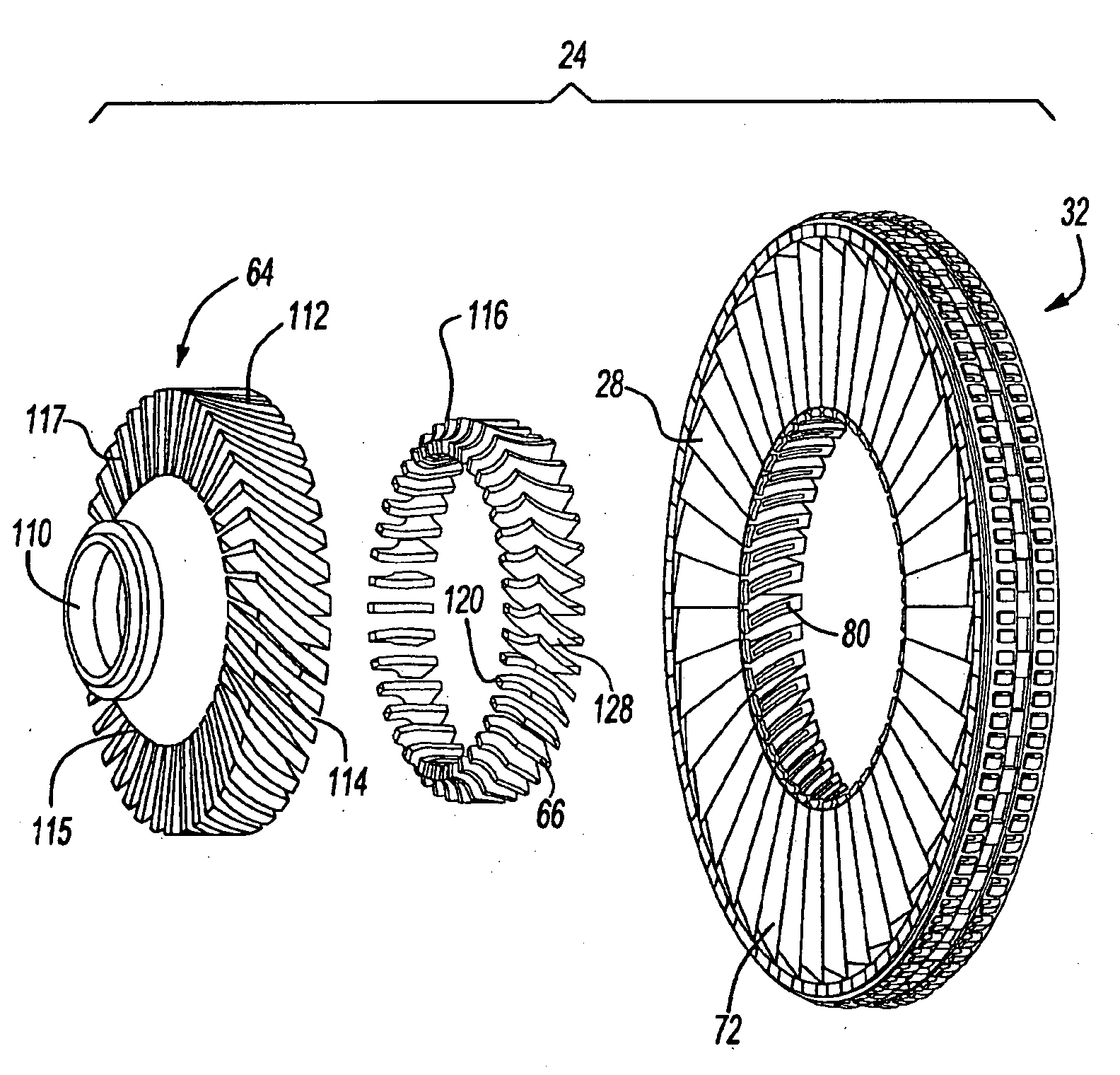

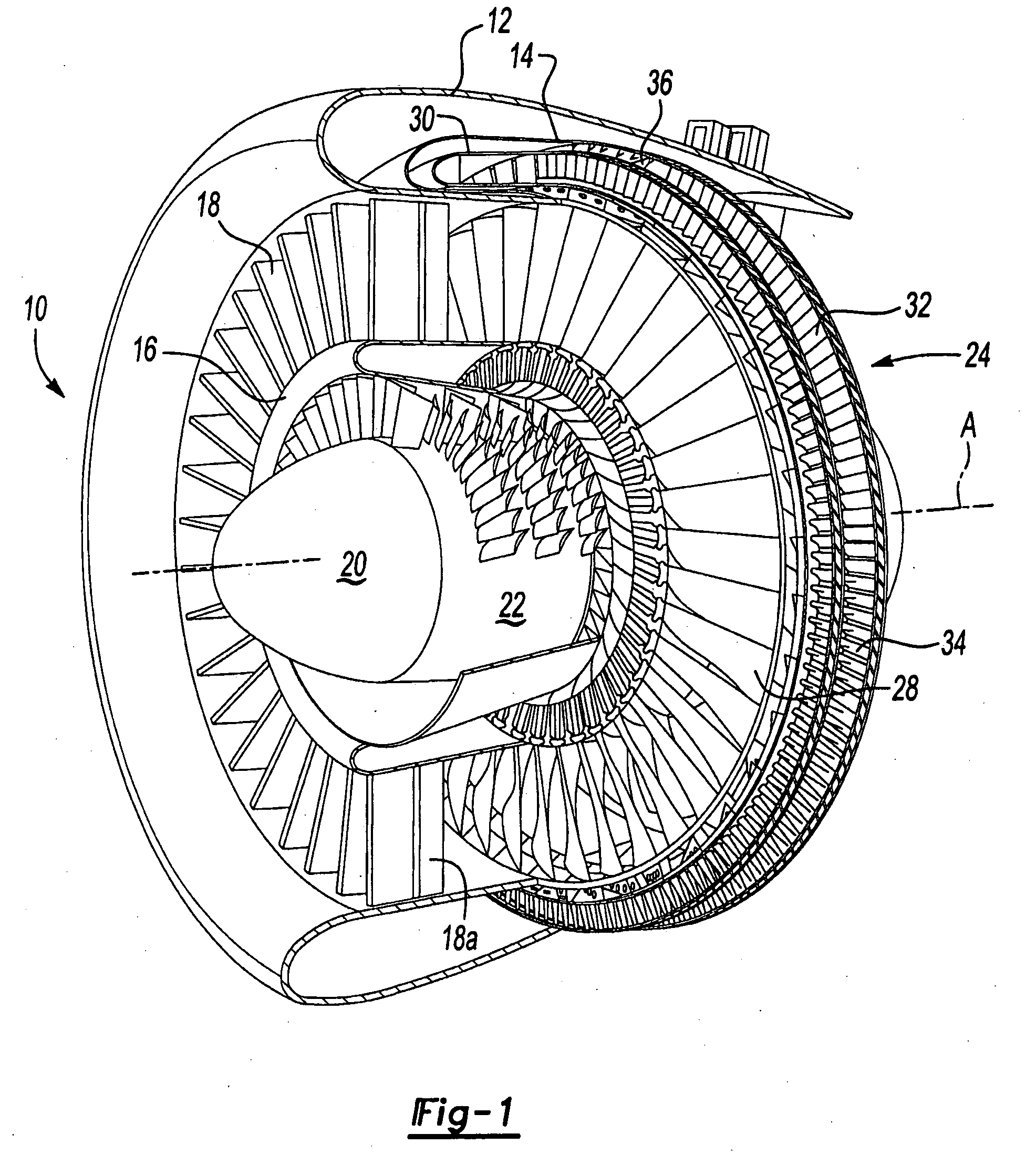

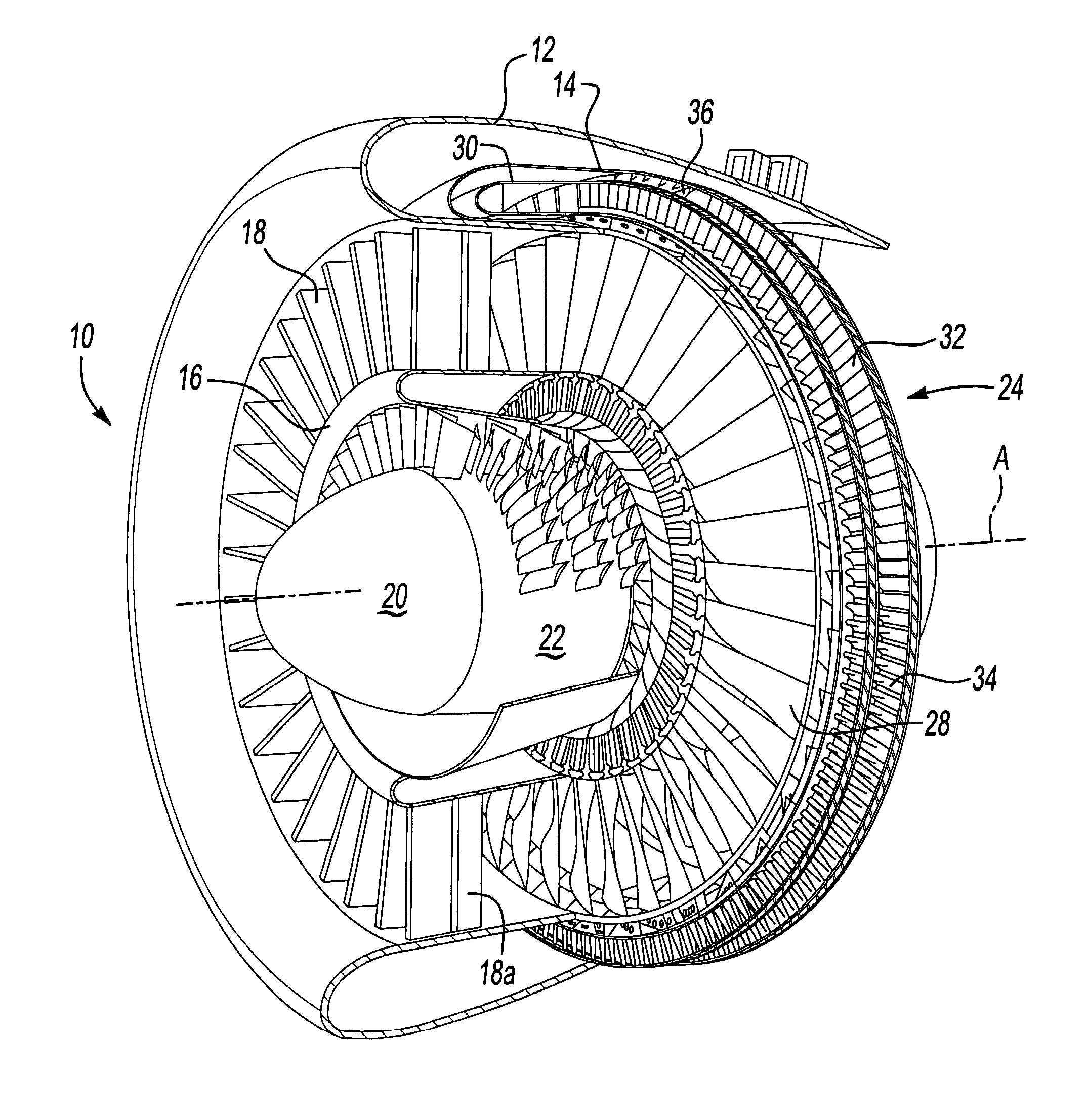

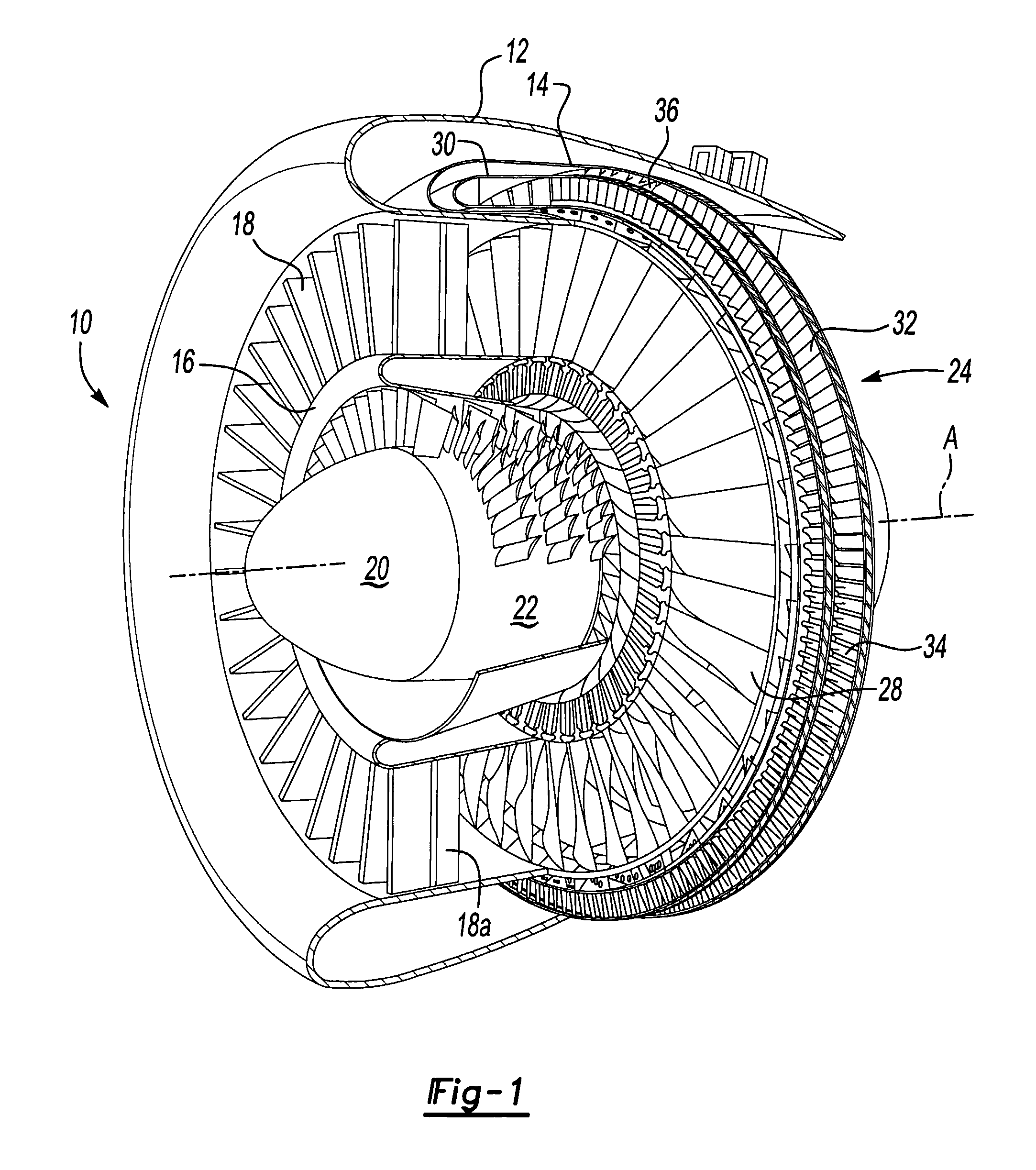

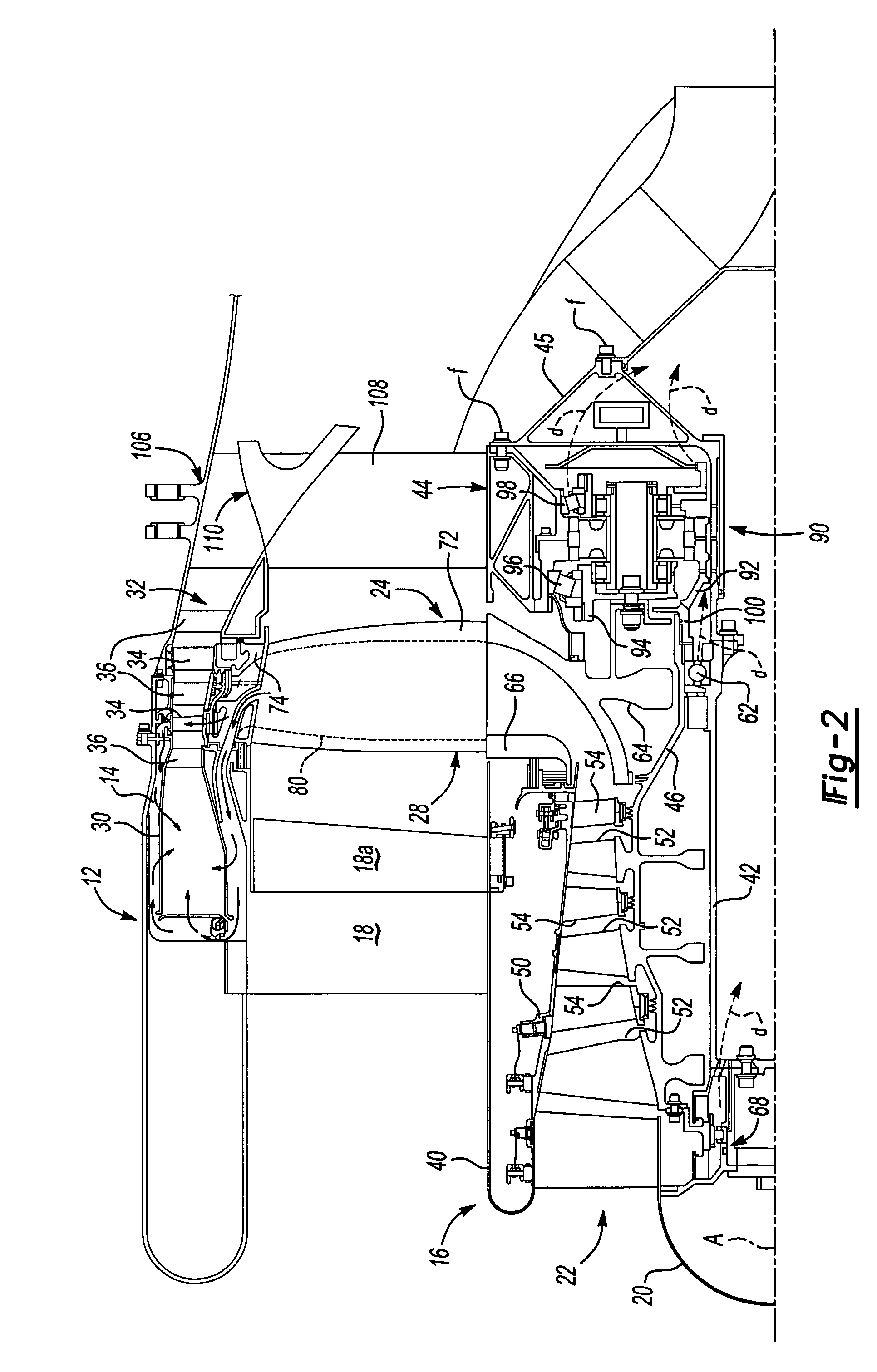

Fan-turbine rotor assembly for a tip turbine engine

ActiveUS20090148297A1High degree of reliabilityInexpensive to manufacturePropellersGas turbine plantsAirflowInducer

A fan-turbine rotor assembly (24) for a tip turbine engine (10) includes a fan hub (64) with an outer periphery (112) scalloped by a multitude of elongated openings (114) which extend into a fan hub web (115). Each elongated opening defines an inducer receipt section (117) to receive an inducer section (66) and a hollow fan blade section (72). An inducer exhaust from each inducer section is located adjacent a core airflow passage (80) within each fan blade section to provide communication therebetween.

Owner:RAYTHEON TECH CORP

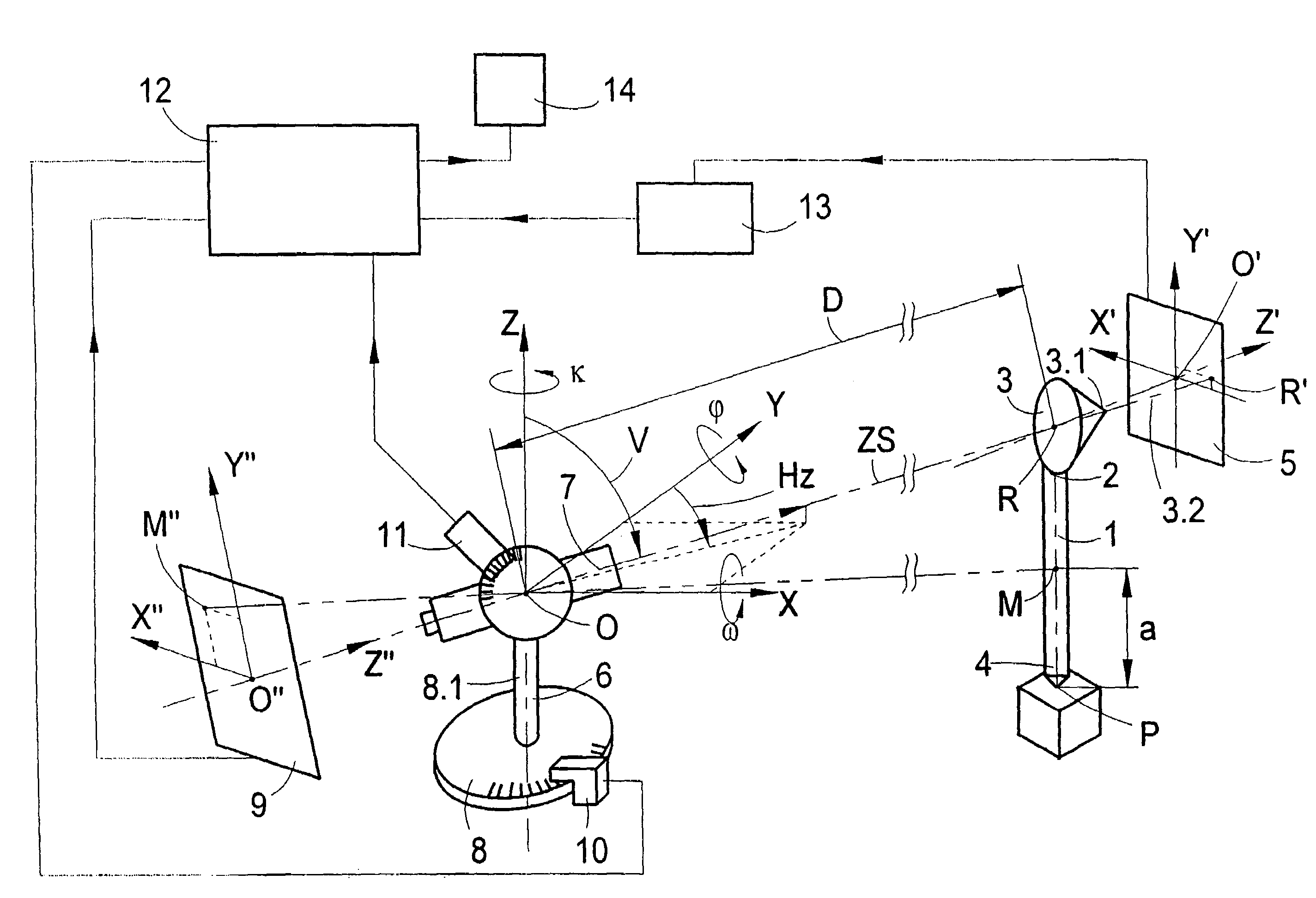

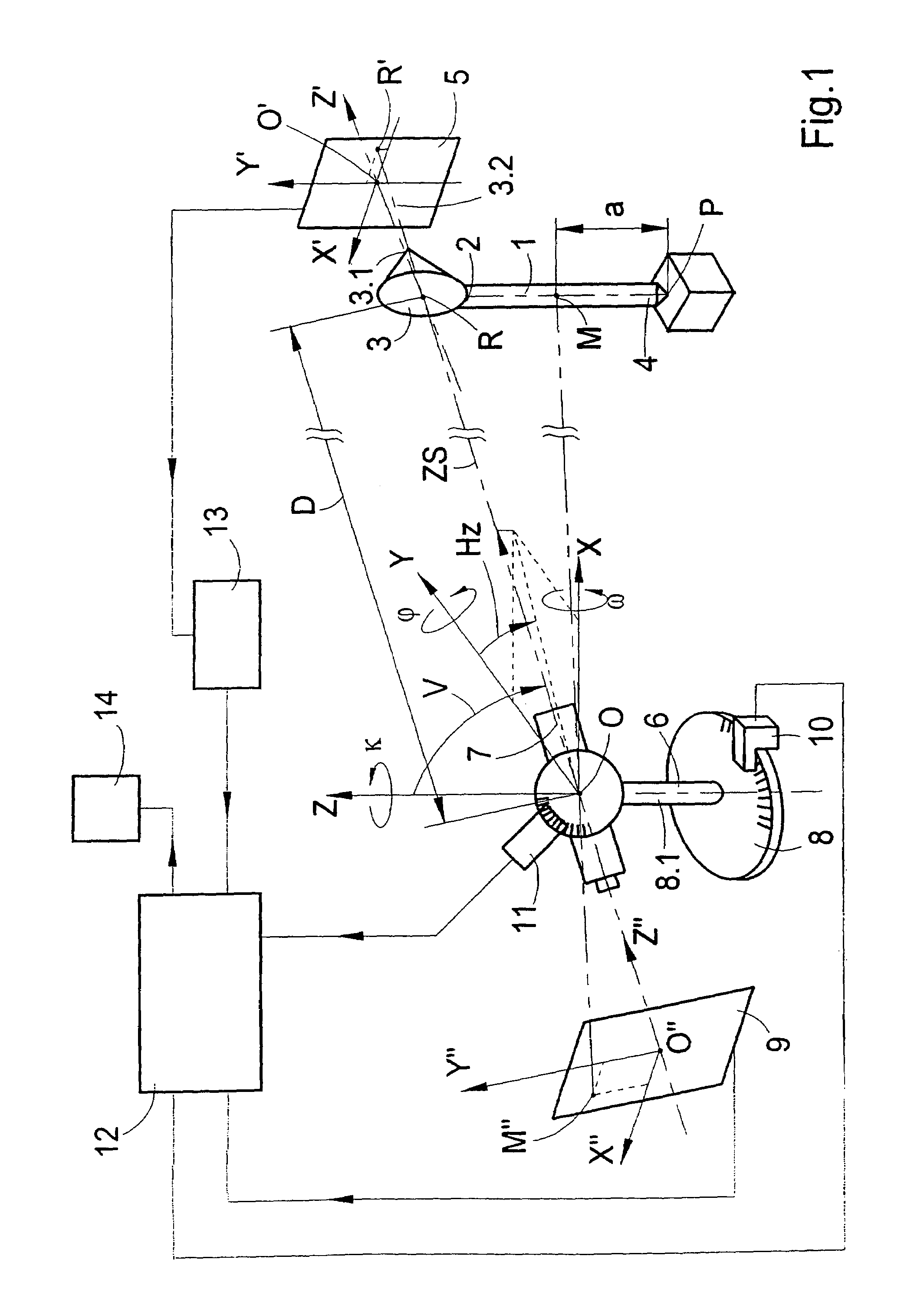

Method for determining the spatial location and position of a reflector rod in relation to a marked ground point

ActiveUS7079234B2Improve accuracyHigh degree of reliabilityAngle measurementActive open surveying meansSpatial OrientationsLight beam

A method for determining the position of a reflector rod provided with a reflector, using a sighting beam emitted from a base station is disclosed. The reflector and a first position sensor define a first coordinate system. The direction of the sighting beam to the reflector is measured from the base station in a second coordinate system, using horizontal and vertical angles. A second position sensor arranged in the direction of the sighting axis of the base station determines the location and orientation of the reflector rod. Measurement data in the first coordinate system is generated to determine the spatial orientation of the reflector relative to the light beam. Imaging optics are used to image the reflector on the second position sensor. The position of the reflector in the second coordinate system and the distance from the base station to the reflector are determined.

Owner:TRIMBLE JENA

Ball and Socket Joint with a Sensor Means and Process for Detecting Tightness

InactiveUS20080193207A1Increase reliabilityHigh degree of reliabilityMeasurement of fluid loss/gain rateCouplings for rigid shaftsInterior spaceEngineering

A ball and socket joint, for example, for an axle system of a motor vehicle. The ball and socket joint has an essentially ring-shaped or pot-shaped joint housing (1), in the essentially cylindrical interior space of which a ball shell (3) is arranged. The ball (4) of a ball pivot is accommodated in the ball shell (3) in a slidingly movable manner. The ball and socket joint has, furthermore, a sealing bellows (6) as well as a sensor means for monitoring the tightness of the ball and socket joint.

Owner:ZF FRIEDRICHSHAFEN AG

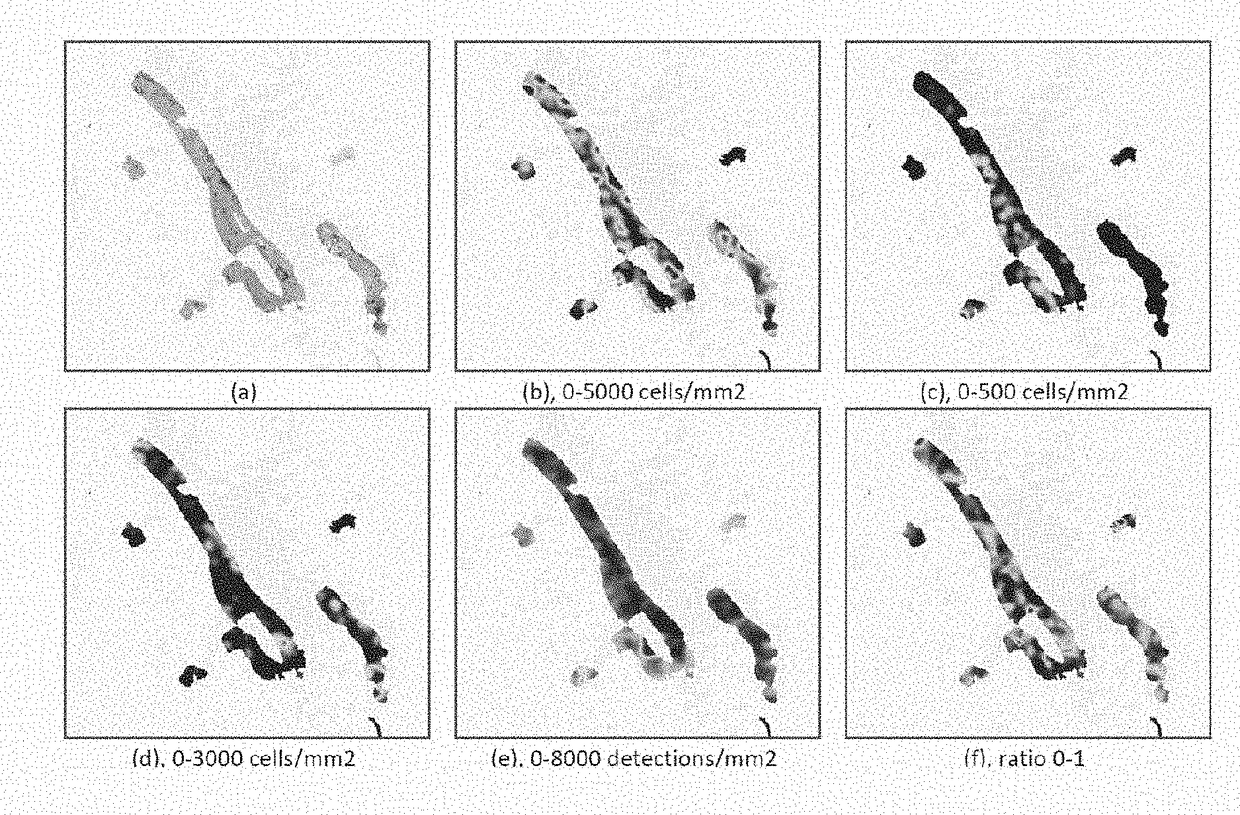

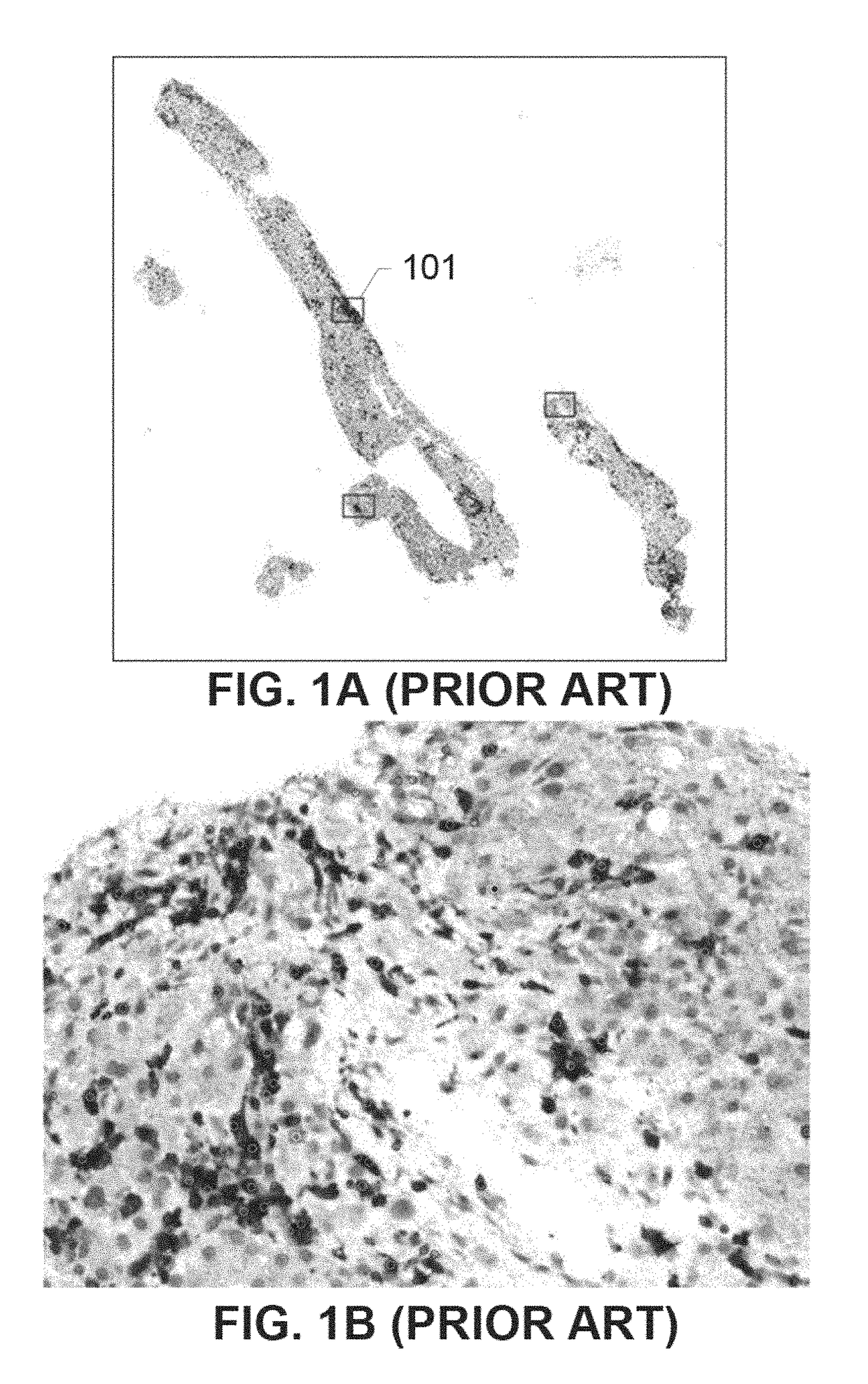

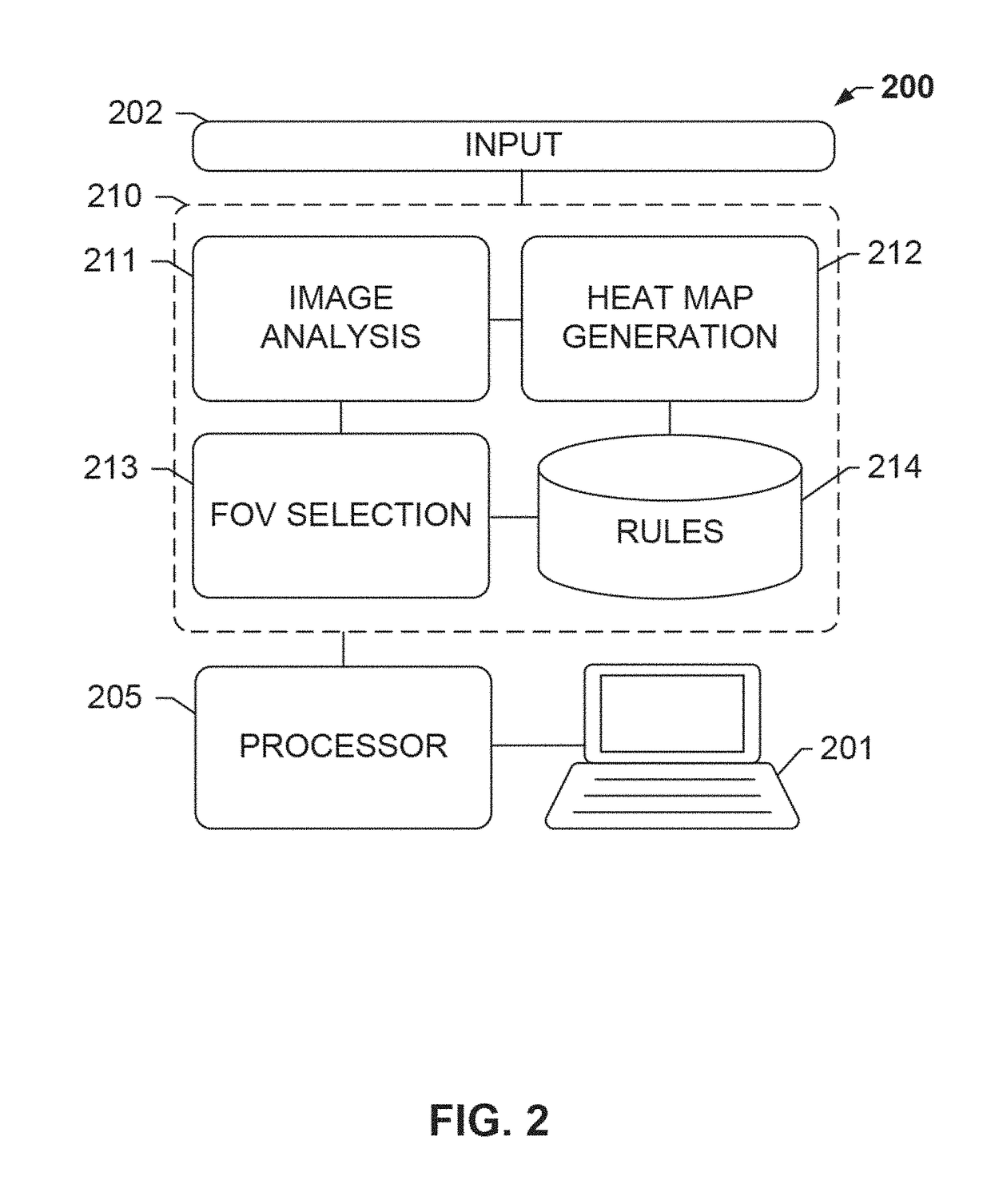

Quality Control of Automated Whole-slide Analyses

ActiveUS20180012360A1High degree of reliabilityImprove reliabilityImage enhancementImage analysisSubject specificWhole slide image

The subject disclosure presents systems and methods for automatically selecting meaningful regions on a whole-slide image and performing quality control on the resulting collection of FOVs. Density maps may be generated quantifying the local density of detection results. The heat maps as well as combinations of maps (such as a local sum, ratio, etc.) may be provided as input into an automated FOV selection operation. The selection operation may select regions of each heat map that represent extreme and average representative regions, based on one or more rules. One or more rules may be defined in order to generate the list of candidate FOVs. The rules may generally be formulated such that FOVs chosen for quality control are the ones that require the most scrutiny and will benefit the most from an assessment by an expert observer.

Owner:F HOFFMANN LA ROCHE & CO AG +1

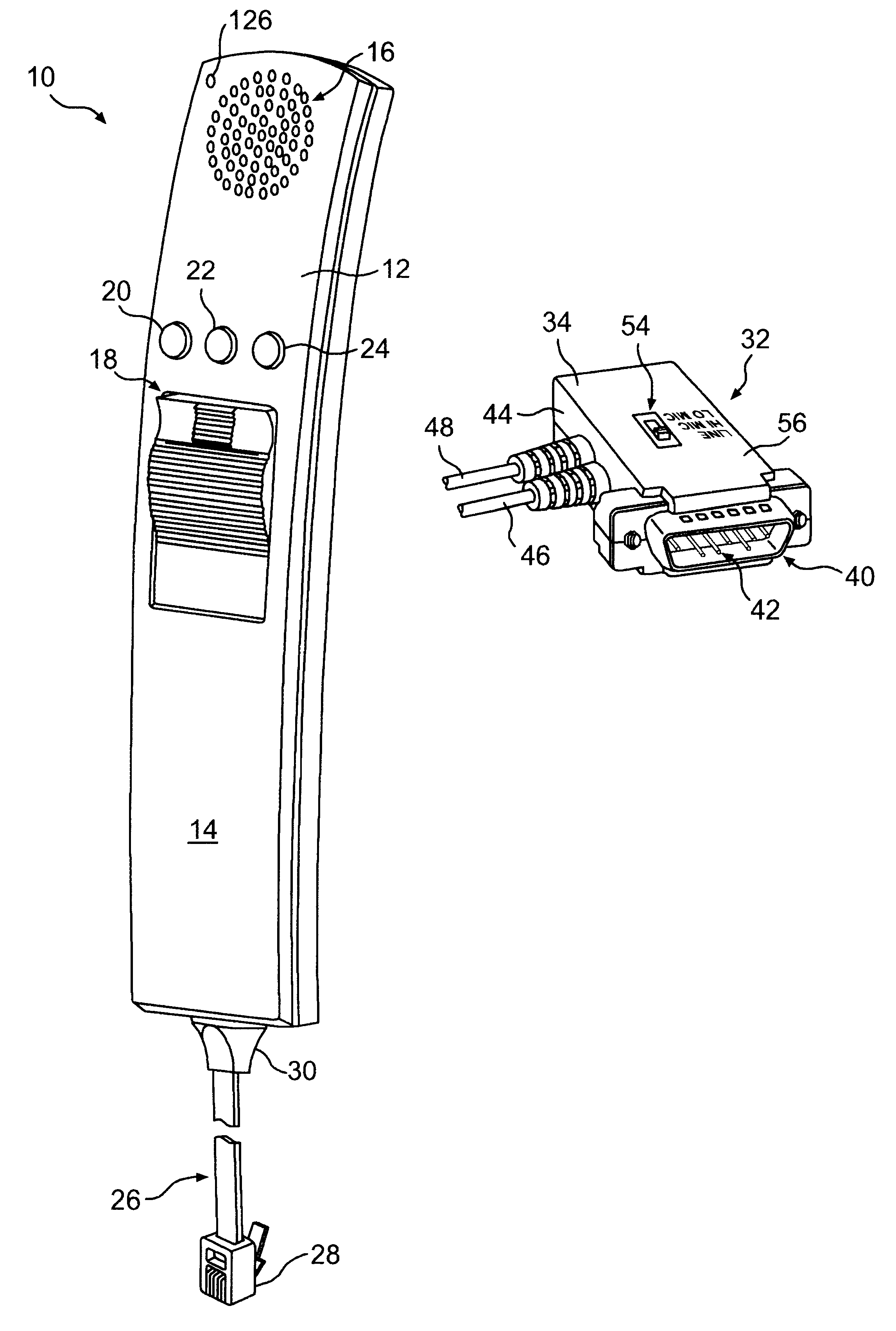

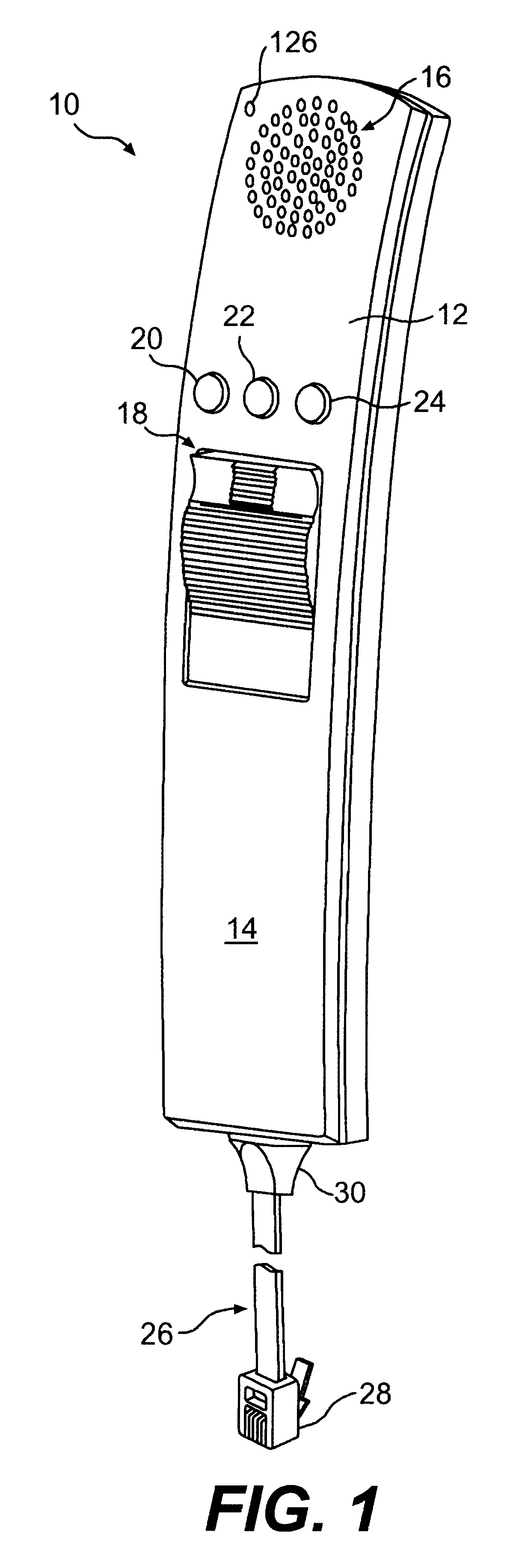

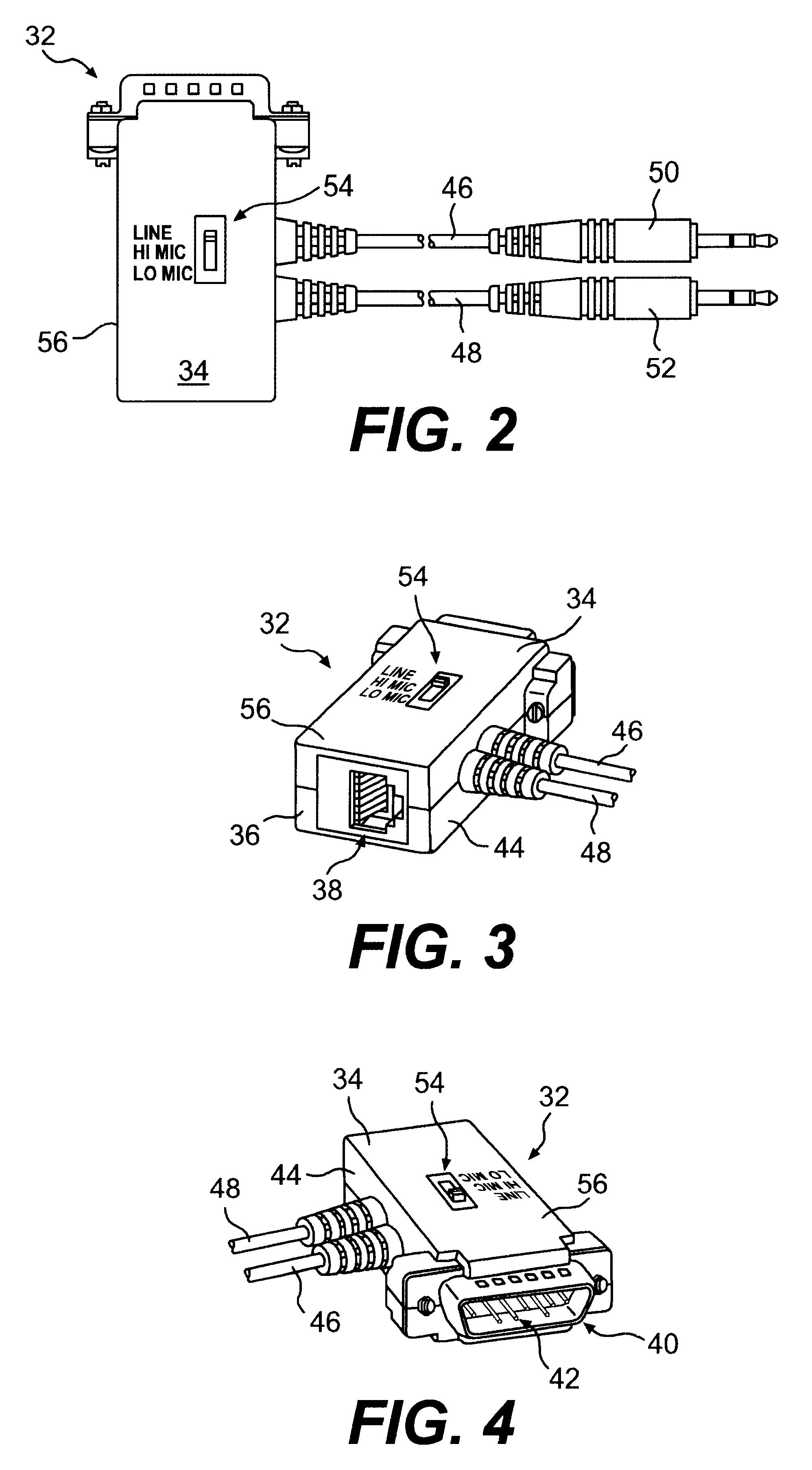

Hand microphone interfaced to game controller port of personal computer

InactiveUS6529450B1High degree of reliabilityReduce manufacturing costTelephonic communicationRecord information storageGame portControl signal

A hand microphone and an adaptor module form an assembly which is a peripheral device for a personal computer. The hand microphone is used to control dictation functions to be carried out by the PC. Two separate analog control signal channels are output from the hand microphone and applied, respectively, as X- and Y-axis inputs for the game port on the PC. Control signals carried in the two signal channels are generated by actuating control switches mounted on the hand microphone.

Owner:GMAC COMMERICAL FINANCE LLC AS AGENT +1

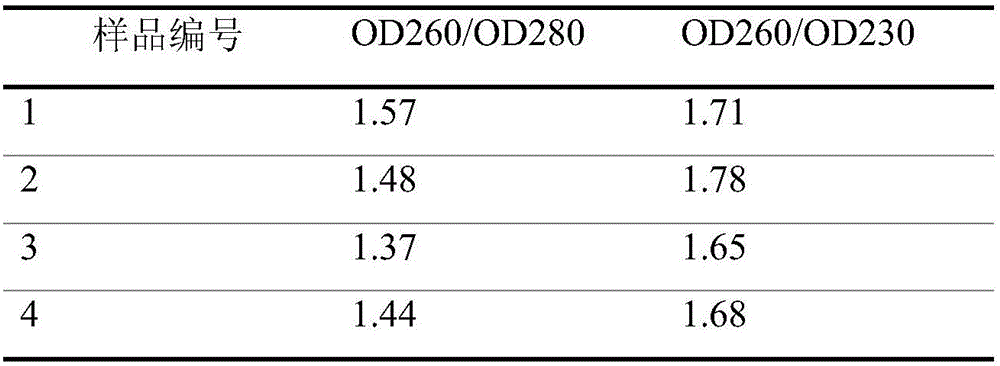

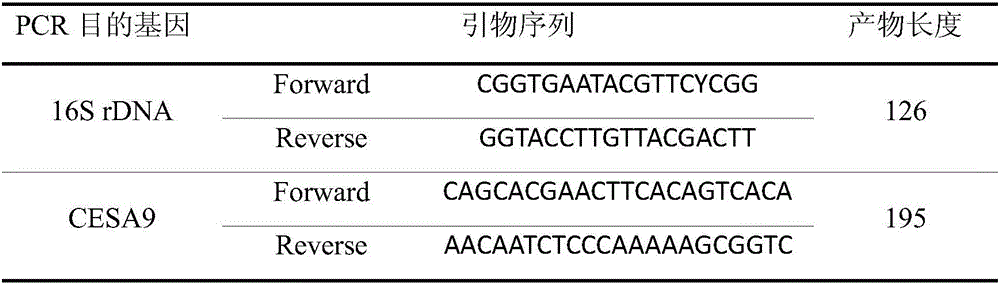

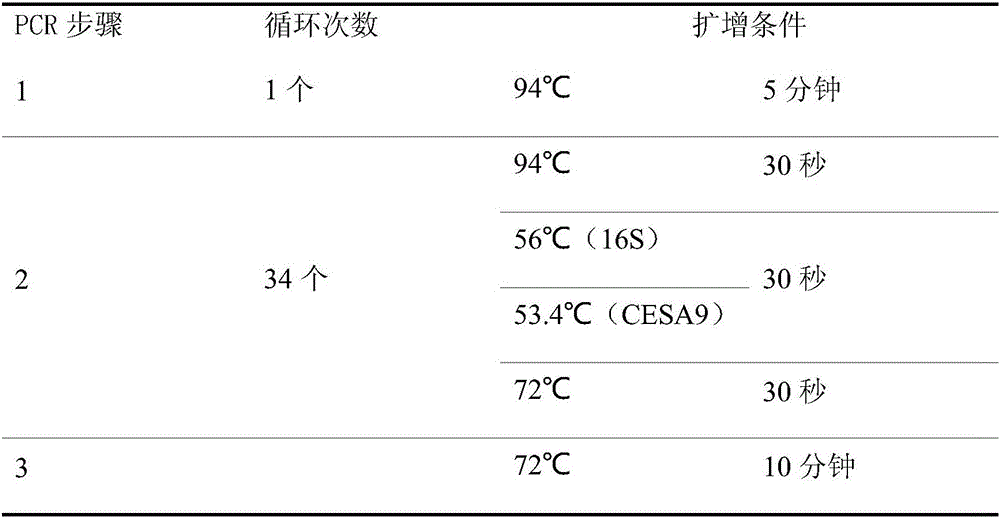

Method for high-efficiency extraction of extracellular DNA in sediments

InactiveCN106480015APracticalHigh degree of reliabilityMicrobiological testing/measurementDNA preparationInternal standardExtracellular dna

Provided is a method for high-efficiency extraction of extracellular DNA in sediments. The method includes construction of an extracellular DNA internal standard gene (CESA9), extraction of sediment sample extracellular DNA, and quantification of the internal standard gene. The internal standard gene CESA9 used for calculating the DNA extraction efficiency in the method is a section of a cellulose synthase gene in arabidopsis thaliana and cannot be detected in to-be-extracted DNA environmental samples. The method can separate and purify the extracellular DNA in the environmental samples. Through measurement by an ultraviolet spectrophotometer, the OD260 / OD280 of the extracted DNA can reach 1.57, the OD260 / OD230 can reach 1.78, subsequent molecular operation can be carried out, and the practicability is relatively high. Through analysis of the extraction efficiency of the DNA, the extraction rate of the extracellular DNA in the sediments by the method can reach 57%, and the method is indicated to have relatively high reliability degree.

Owner:TIANJIN UNIV

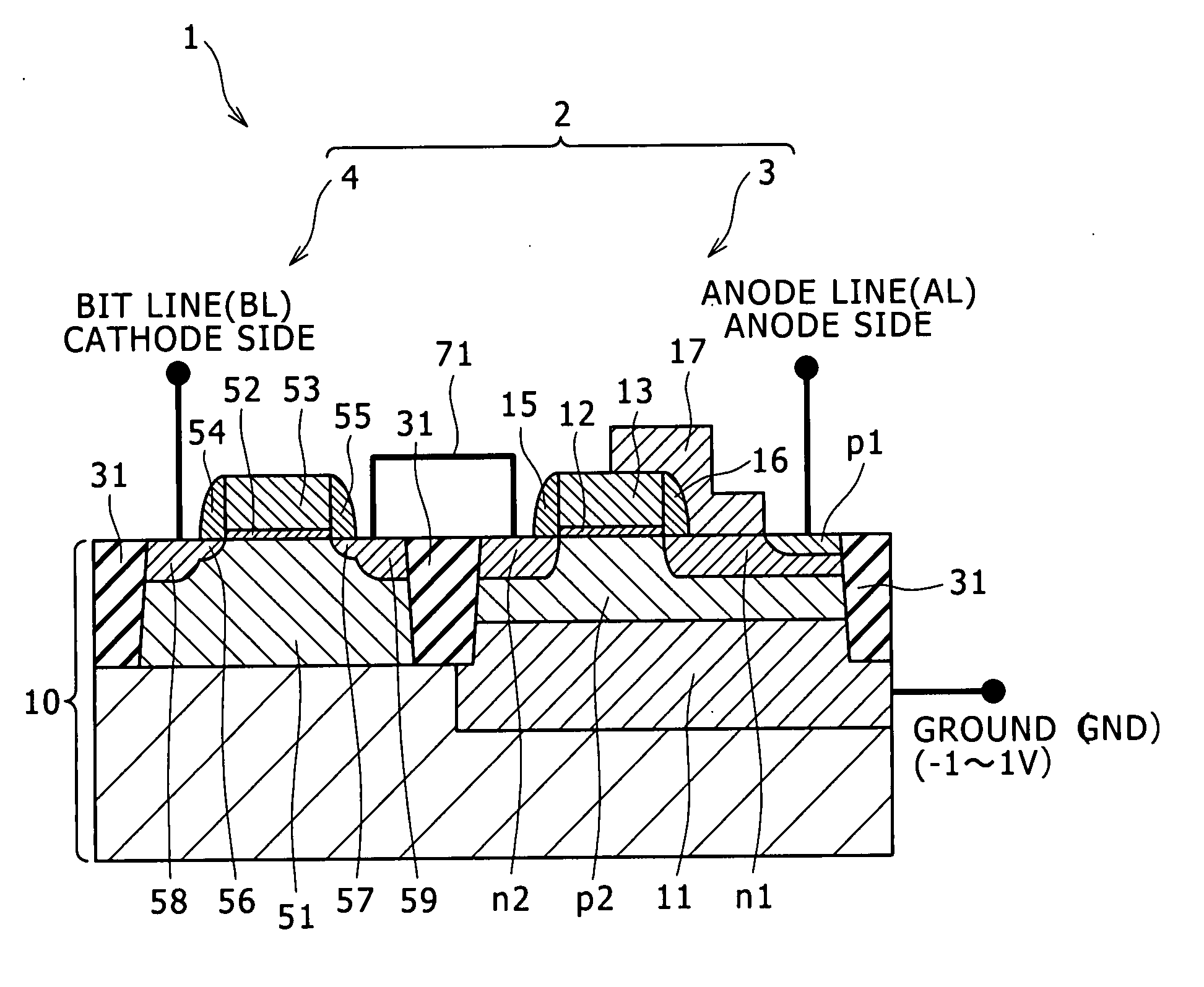

Semiconductor device and driving method therefor

InactiveUS20080002463A1Excessive carryHigh degree of reliabilityThyristorSolid-state devicesThyratronEngineering

A semiconductor device includes a bulk semiconductor substrate, a plurality of storage elements, a bit line, a first voltage being applied to the first region side of the thyristor, and a voltage lower than the first voltage being applied to a word line. The plurality of storage elements formed on the bulk semiconductor substrate and each including a thyristor formed on the bulk semiconductor substrate and including a first region of a first conductor type, a second region of a second conduction type opposite to the first conduction type, a third region of the first conduction type and a fourth region of the second conduction type jointed together in order, a gate electrode formed on the third region, and a field effect transistor formed on the semiconductor substrate on which the thyristor is formed and connected to the fourth region of the thyristor.

Owner:SONY CORP

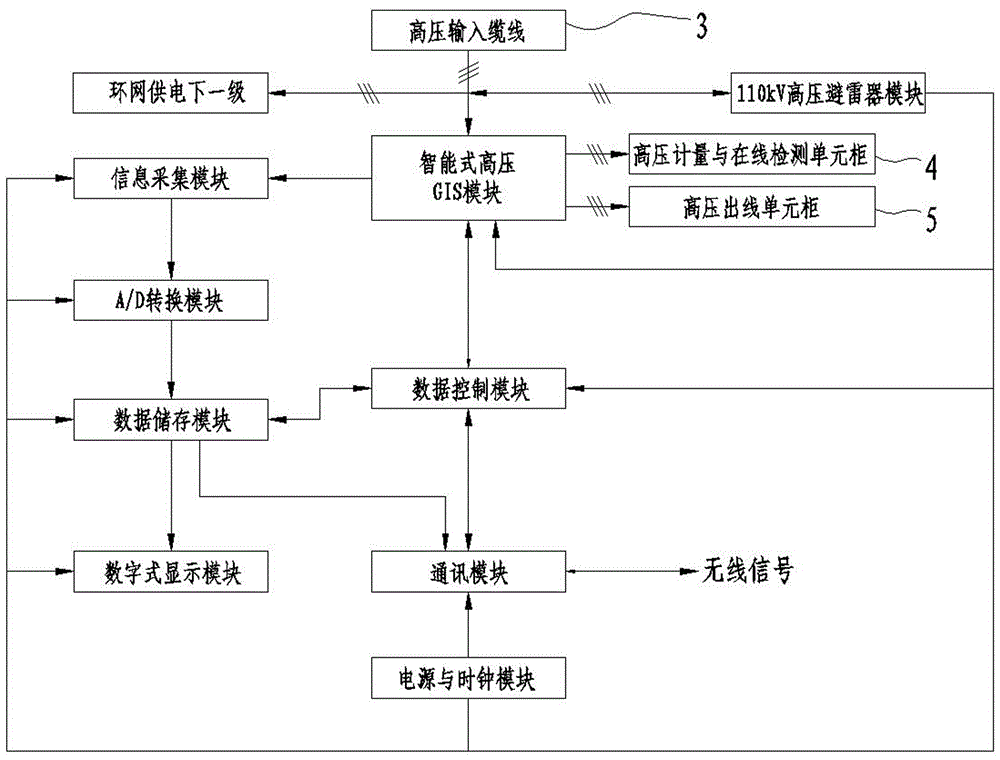

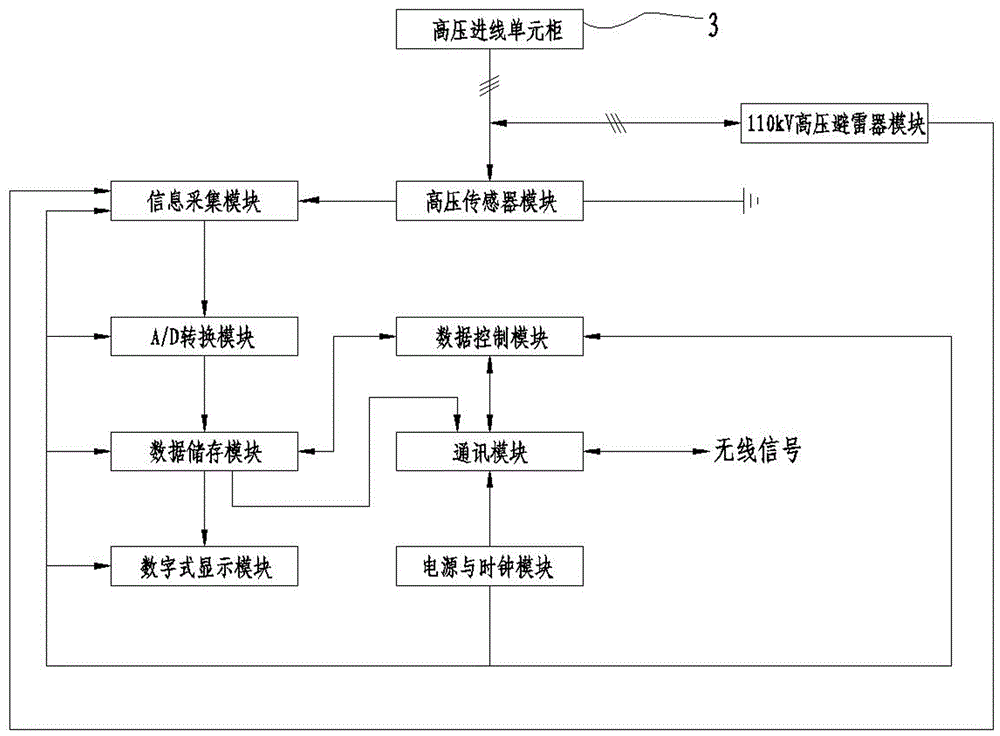

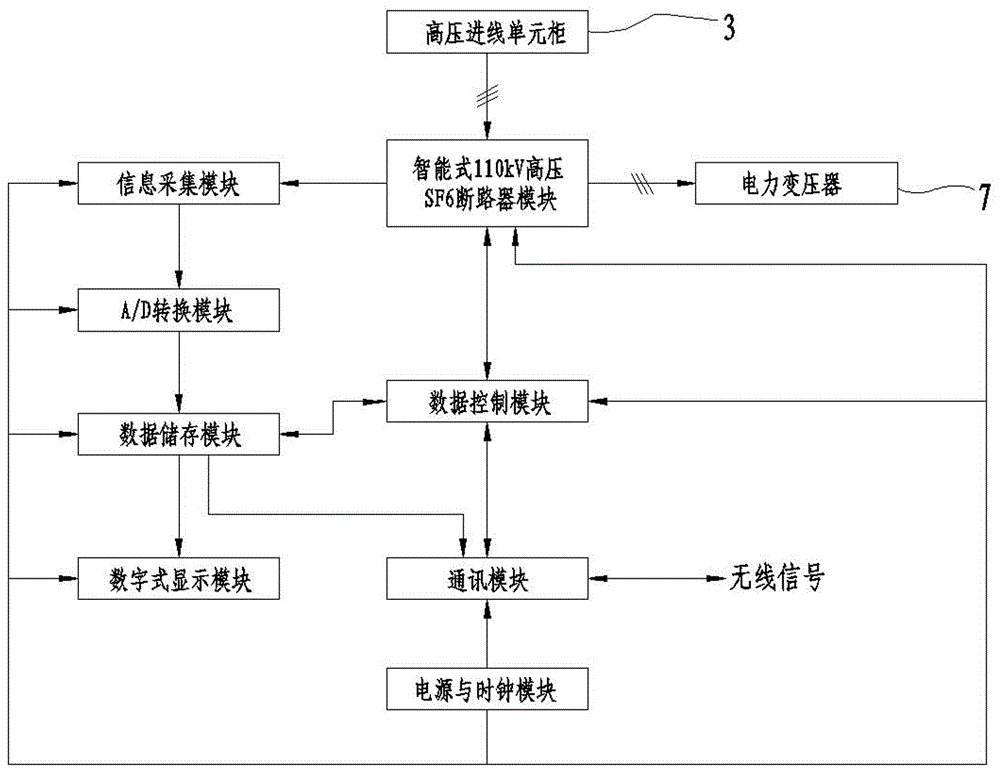

110kV/10kV and 110kV/35kV two pre-installed integrated intelligent substations

ActiveCN105958354ANo electromagnetic radiationReduce noiseBoards/switchyards circuit arrangementsTransformers/inductances coils/windings/connectionsAutomatic controlTransformer

The invention provides 110kV / 10kV and 110kV / 35kV two pre-installed integrated intelligent substations. Transformers are 110kV / 10kV and 110kV / 35kV two three-phase power transformers and are of a five-stem core structure; three phases of 110kV high-voltage windings of the transformers are in YN connection; each phase of 10kV and 35kV low-voltage windings and 10kV and 35kV fuses are connected in series to form a low-voltage phase arm; and three phases of low-voltage phase arms form d connection, and the connection group is labeled as YN, d11, and has a ''three-phase noninterference'' function. Various accessories in the substations are installed in a high-strength steel structure box body in an integrated manner, so that the characteristic of high ''integration'' is highlighted. By the substations, modern high-new technologies of a digital technology, an automatic control technology, an information collection and transmission technology and the like are combined, so that the characteristic of high ''intelligentization'' is highlighted. Production assembly and debugging of various components in the substations are completed once in a factory, so that the characteristic of high ''pre-installation'' is highlighted; the size and the floor area of the 110kV / 10kV and 110kV / 35kV two pre-installed integrated intelligent substations are greatly reduced; and the power supply safety and reliability are ensured.

Owner:SHANXI JIDA VOLTAGE TRANSFORMER CO LTD

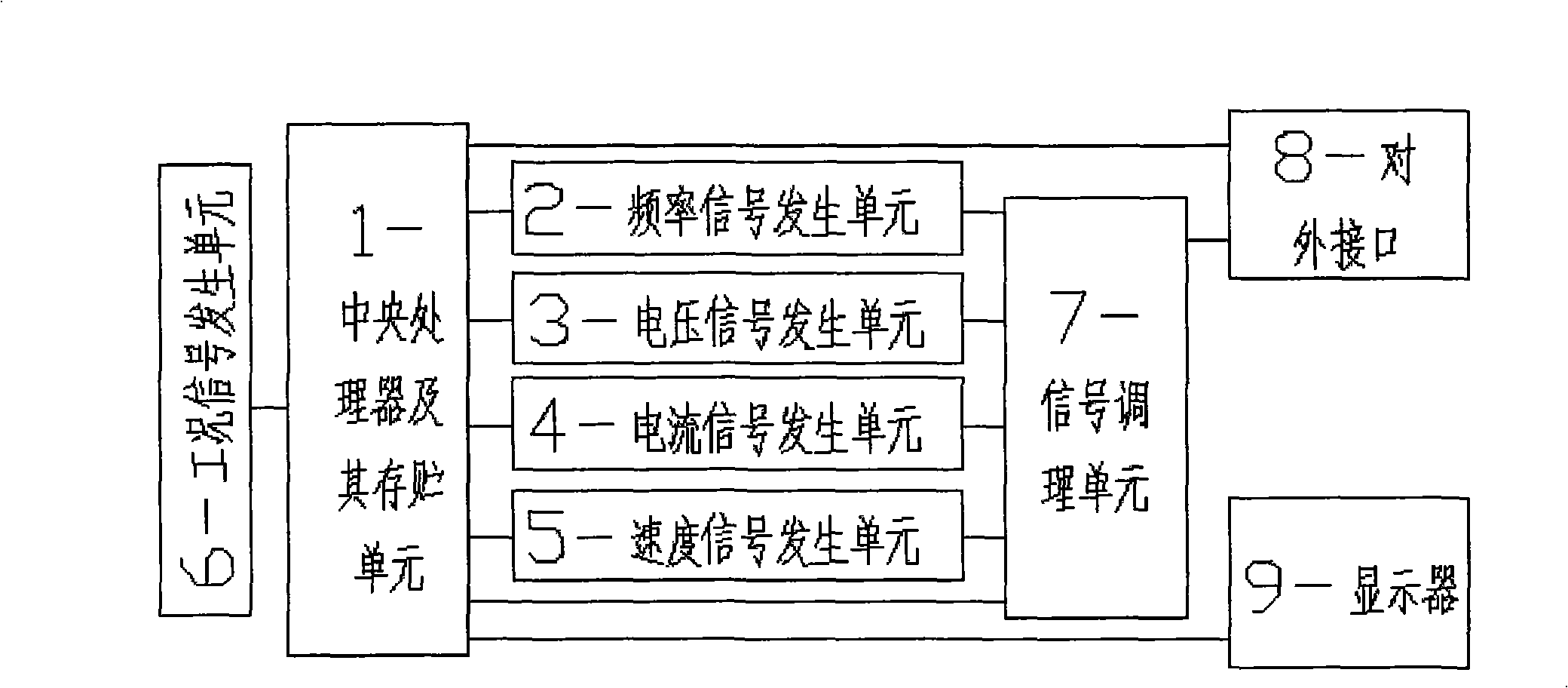

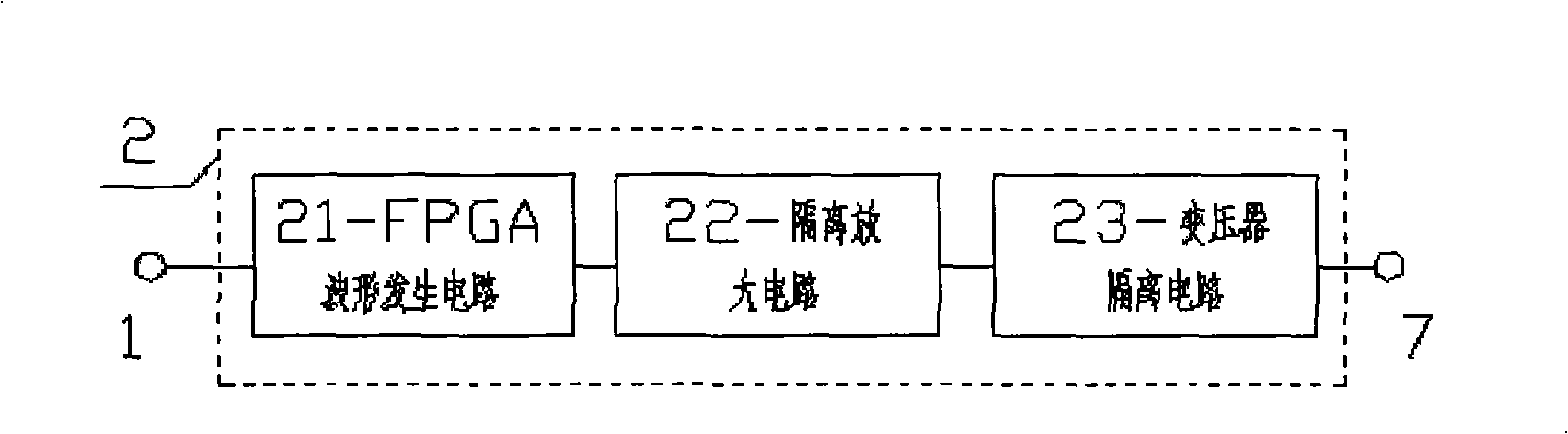

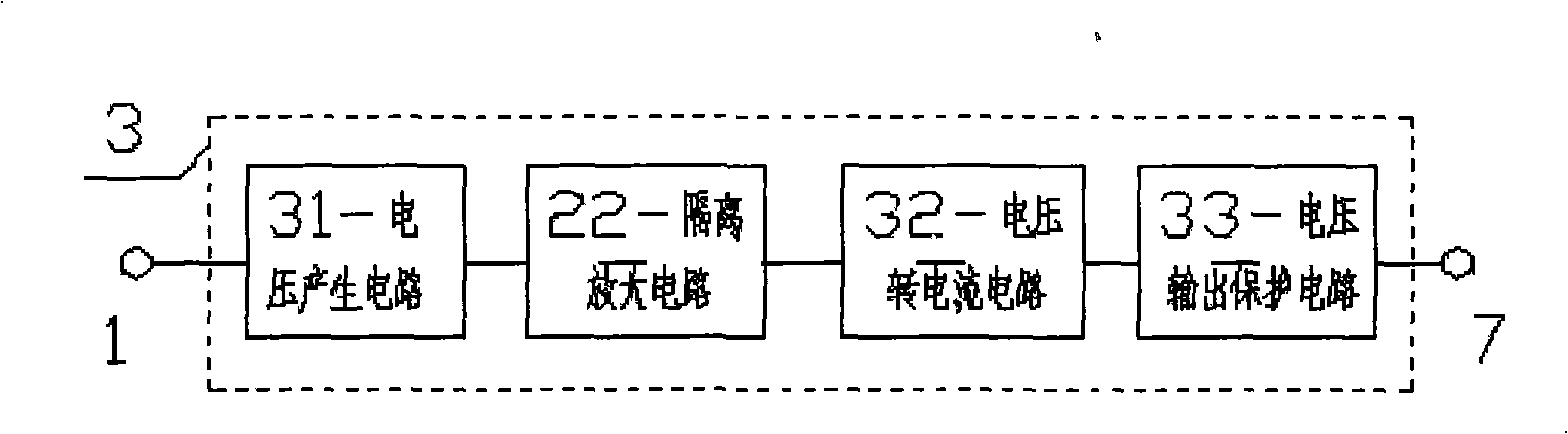

Analog signal generator

InactiveCN101349615AHigh degree of integrationHigh degree of reliabilityRailway vehicle testingElectricitySignal conditioning

The invention discloses an analog signal generator, which comprises a central processing unit, a storage unit (1) of the central processing unit and a work information generating unit (6), wherein the central processing unit and the storage unit (1) thereof are electrically connected with a frequency signal generating unit (2), a voltage signal generating unit (3), a current signal generating unit (4), a speed signal generating unit (5), the work information generating unit (6), a signal conditioning unit (7), an external interface (8) and a display (9), wherein the signal conditioning unit (7) is further electrically connected with the frequency signal generating unit (2), the voltage signal generating unit (3), the current signal generating unit (4), the speed signal generating unit (5) and the external interface (8). The invention has the advantages of high integration degree, convenient installation, simple operation and high reliability degree. The analog signal generator is suitable for manufacturing enterprises and scientific research units of various large-scale transport equipments.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

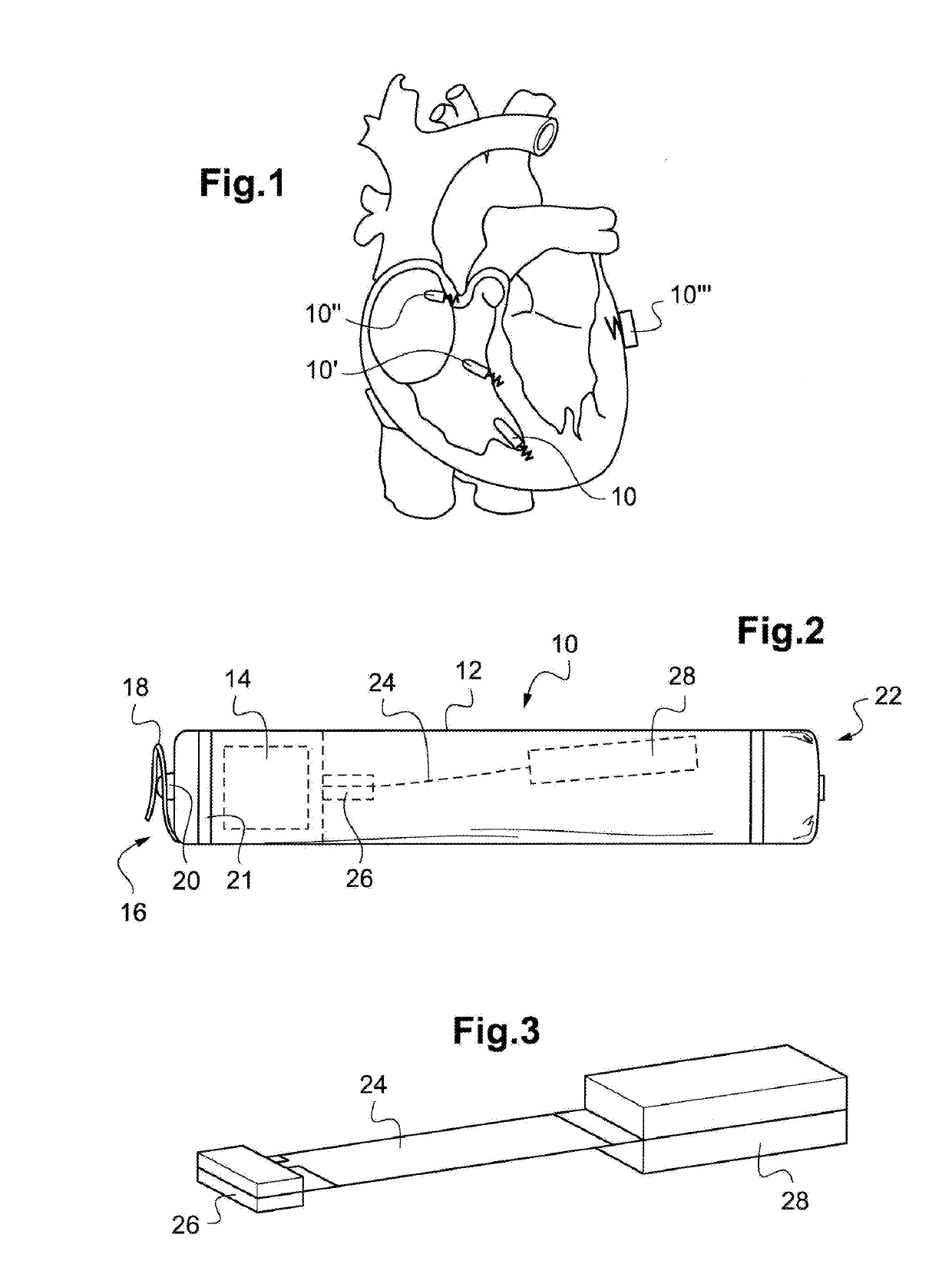

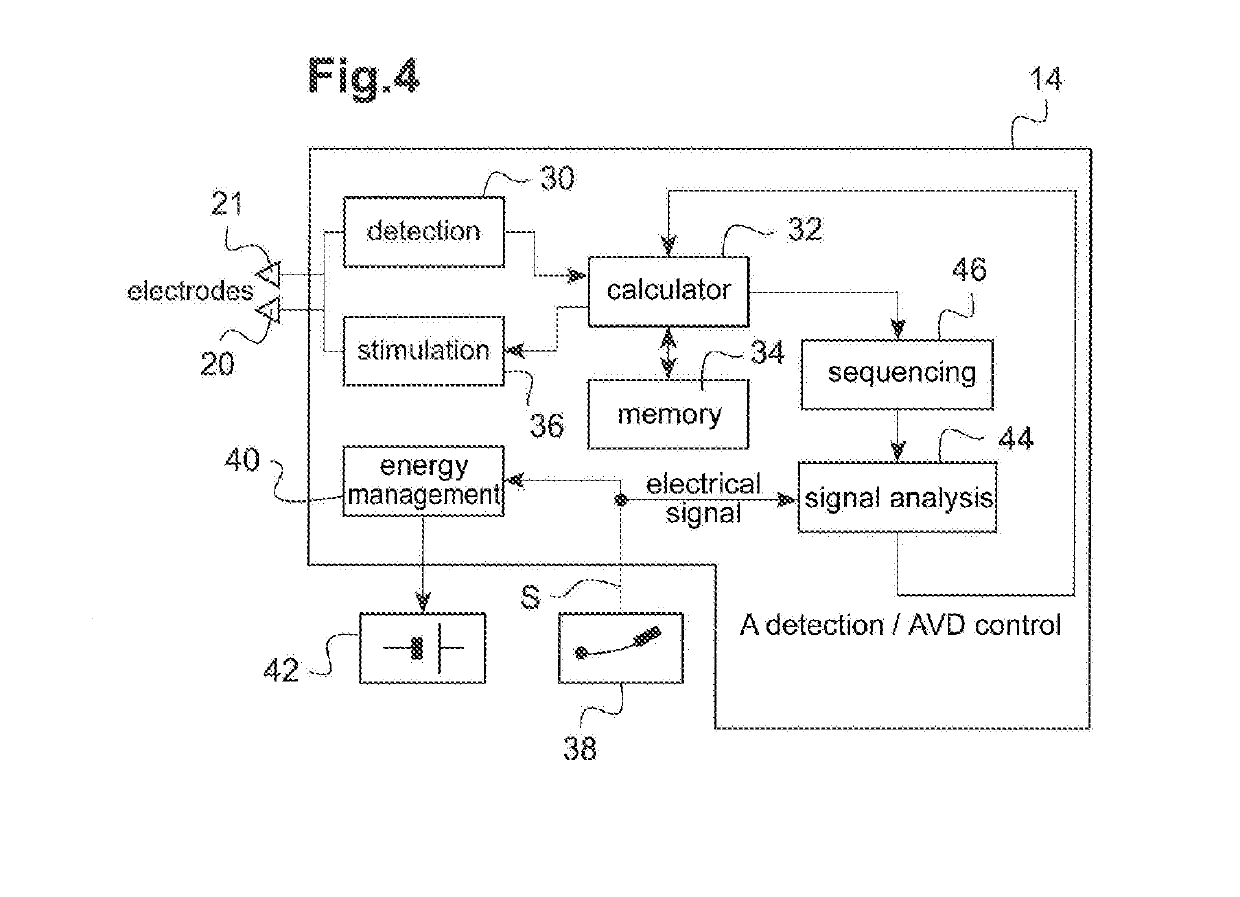

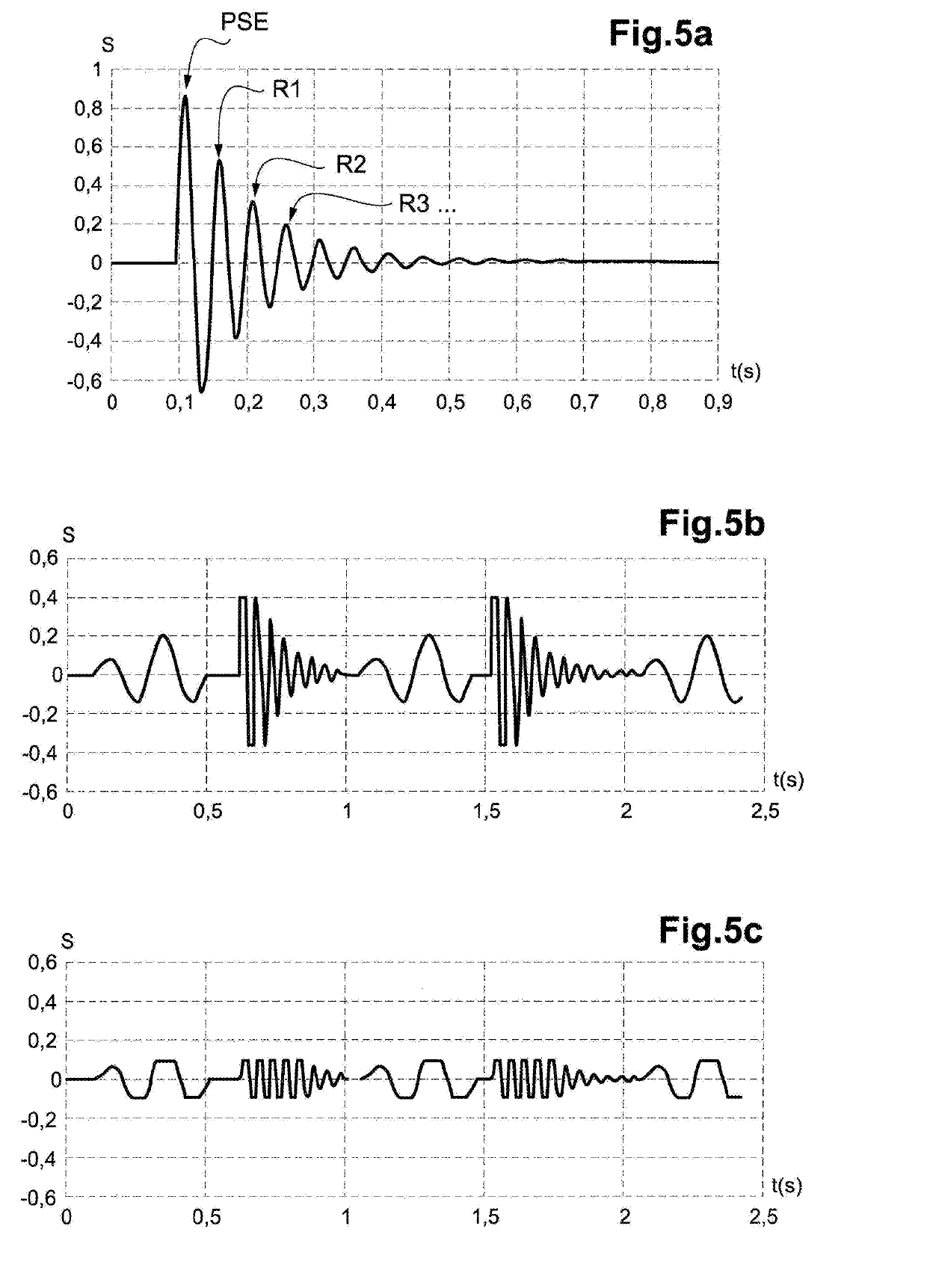

Autonomous cardiac implant of the "leadless capsule" type, with detection of atrial activity by analysis of the charging electric signal delivered by an energy harvesting module

ActiveUS20190151666A1Increase complexityHigh degree of reliabilityPiezoelectric/electrostriction/magnetostriction machinesHeart stimulatorsElectric energyEnergy harvester

An energy harvester converts into electrical energy the external stresses applied to the implant at the heartbeat rhythm. This harvester includes an inertial unit and a transducer delivering an oscillating electrical signal that is rectified and regulated for powering the implant and charging an energy storage component. The instantaneous variations of this electrical signal are analyzed in a detection window following or preceding a ventricular contraction, to obtain atrial activity information representative of the atrium contribution to the electric signal, in particular information about the presence / absence of a spontaneous atrial contraction, and / or parameters making it possible to determine an atrioventricular delay to be applied if the ventricle has to be stimulated.

Owner:CAIRDAC

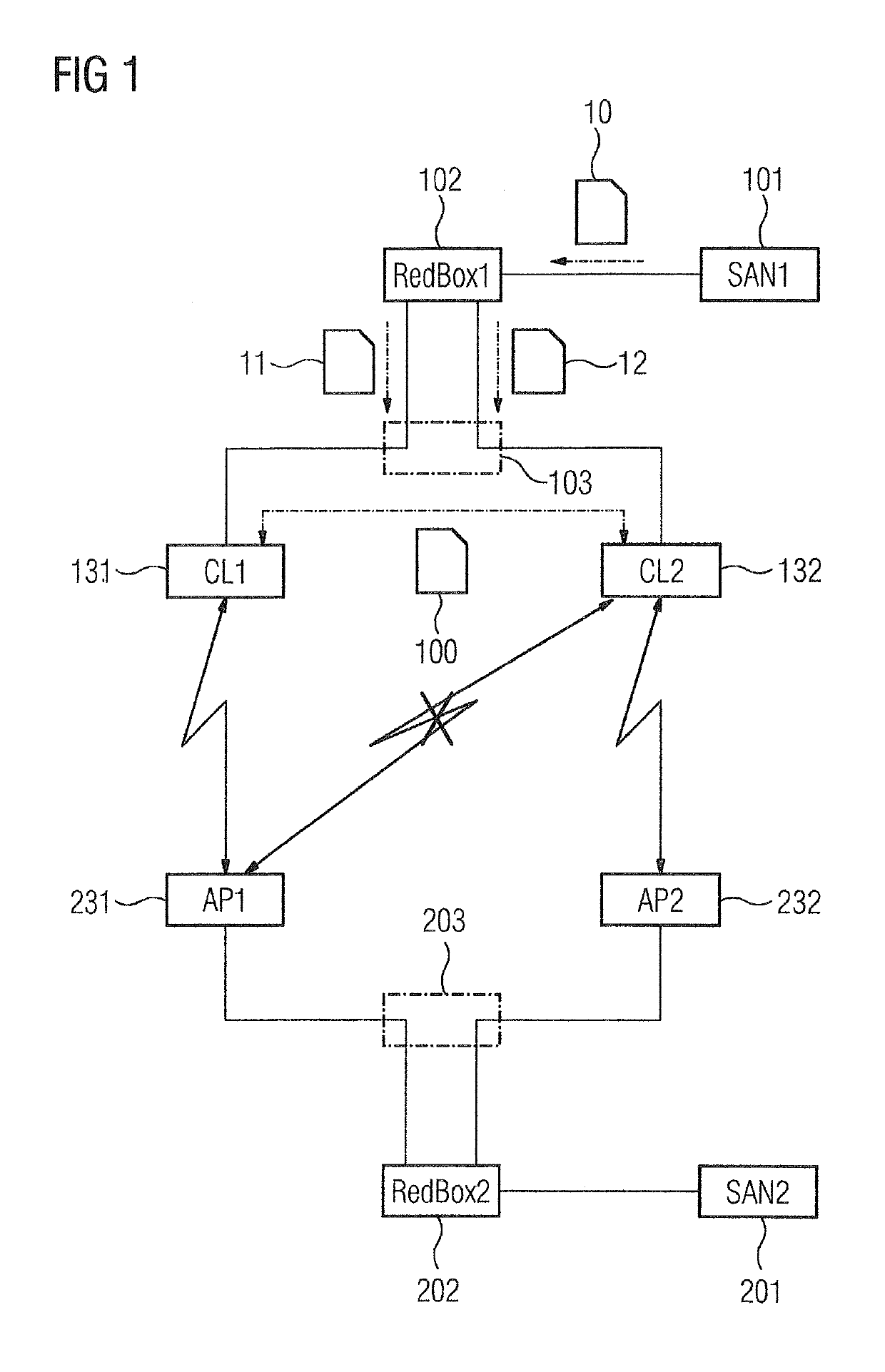

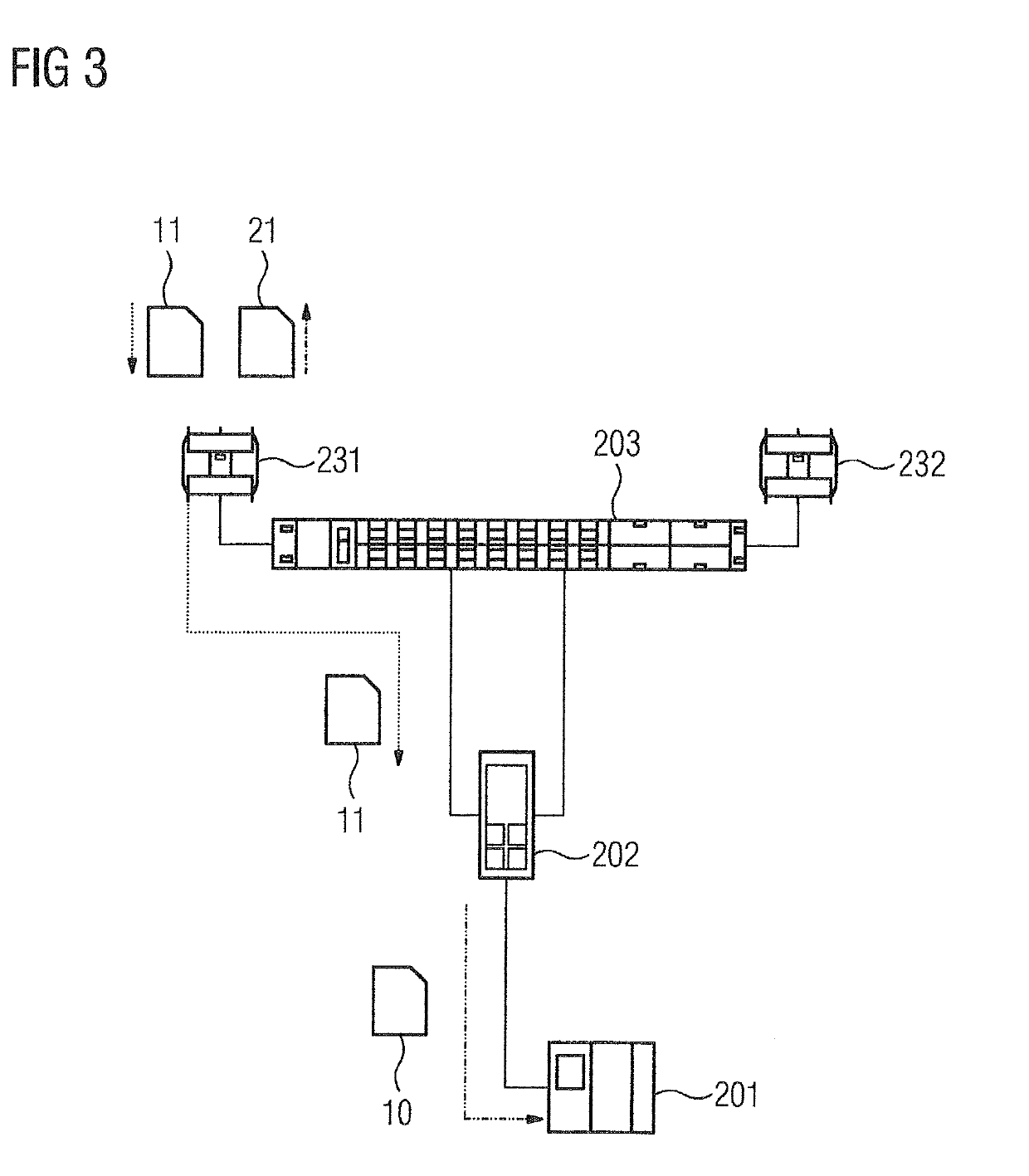

Redundantly Operable Industrial Communication System, Method for Operation Thereof and Radio subscriber Station

ActiveUS20190159032A1High degree of reliabilityEfficient useNetworks interconnectionSecurity arrangementIndustrial communicationAuthorization

A radio communication system for an industrial automation system in which at least a first and a second communication device are redundantly linked to an industrial communication network, wherein the first and second communication devices are each connected indirectly or directly to a particular first radio subscriber station or radio base station and to a particular second radio subscriber station or radio base station via the first communication network connection and via the second communication network connection of the communication devices, where the radio subscriber stations interchange messages about available radio base stations among one another and use the messages to coordinate which of the radio subscriber stations has exclusive authorization for a radio link to a selected radio base station at present or within a definable period.

Owner:SIEMENS AG

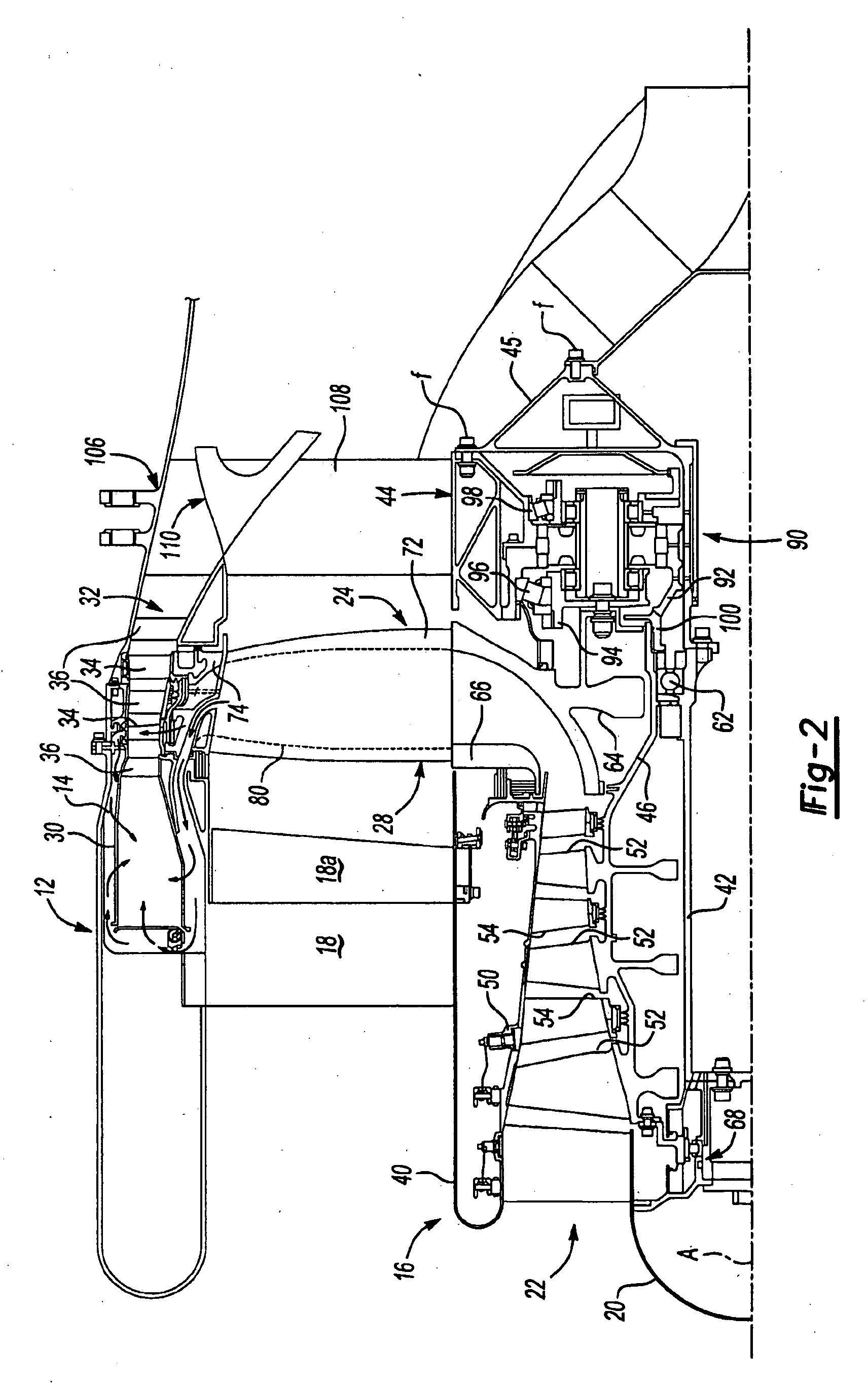

Tip Turbine Engine Comprising A Nonrotable Compartment

InactiveUS20080044281A1Low part-countHigh degree of reliabilityPump componentsEngine fuctionsFluid systemTurbine

A non-rotating compartment along an engine centerline of a tip turbine engine is defined between an inner support housing, an outer support housing and an aft housing. The non-rotating compartment provides a space that may be utilized for a multitude of engine accessories and components including an engine lubricating fluid system.

Owner:UNITED TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com