Patents

Literature

32results about How to "Easily applied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

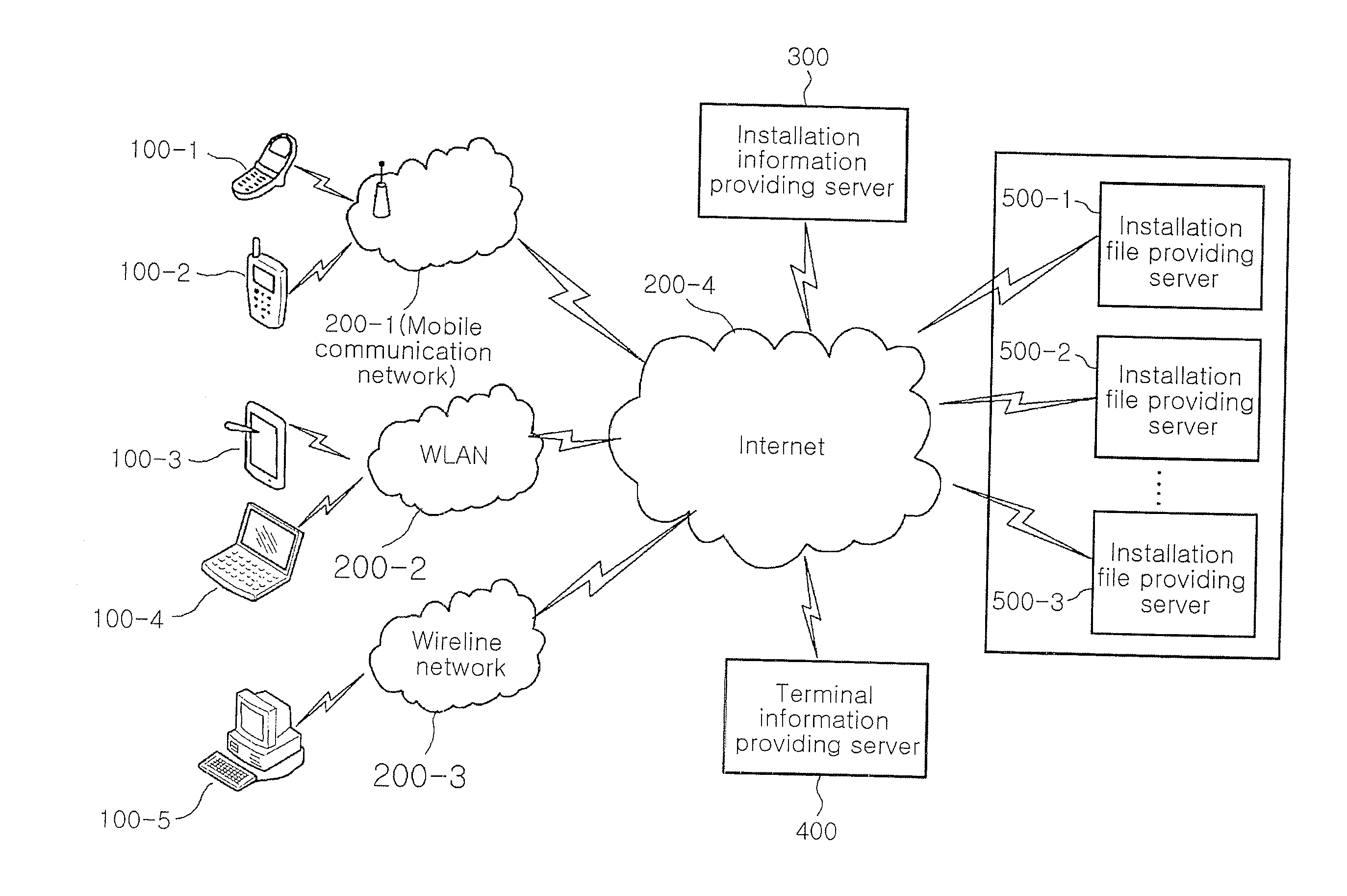

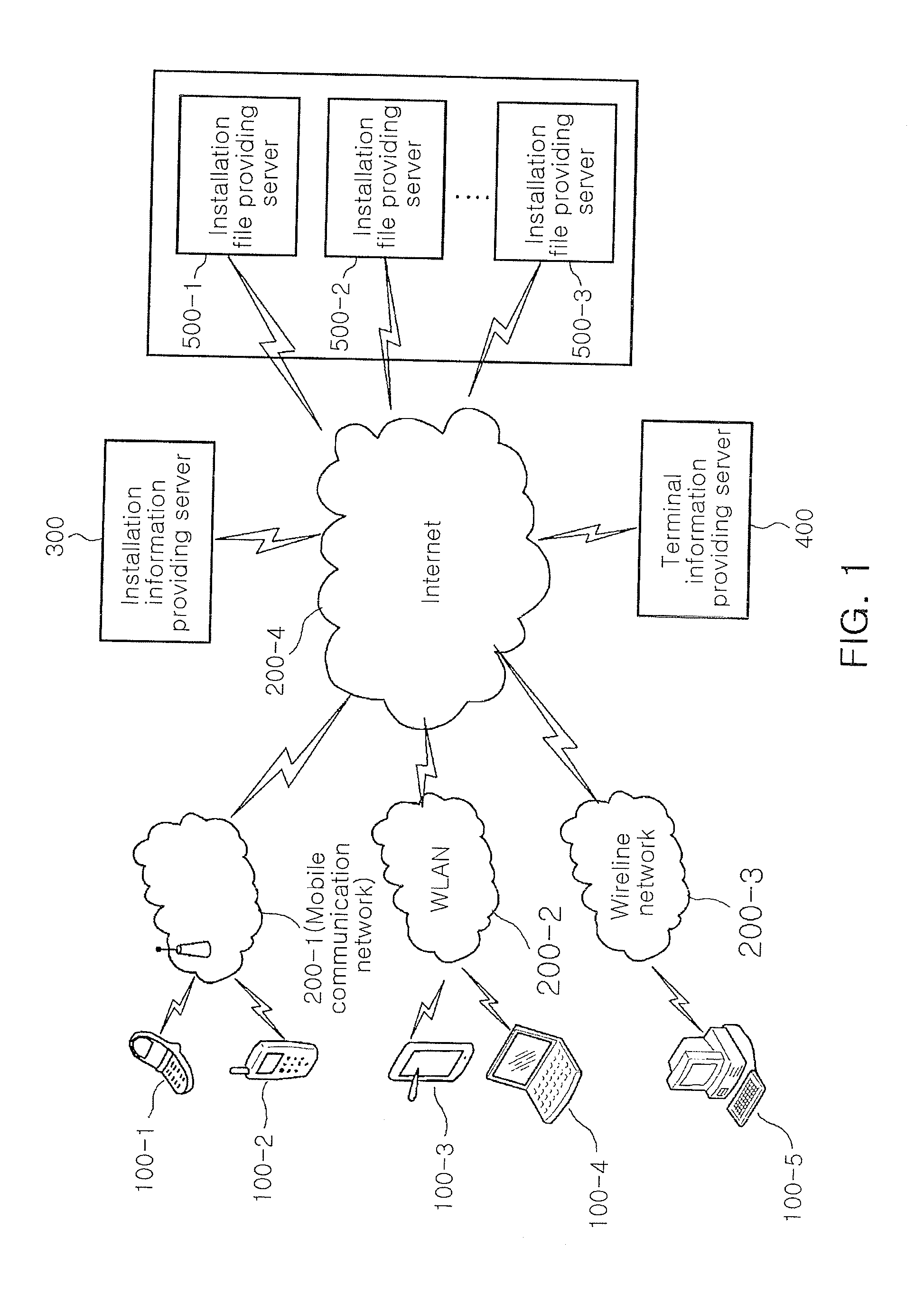

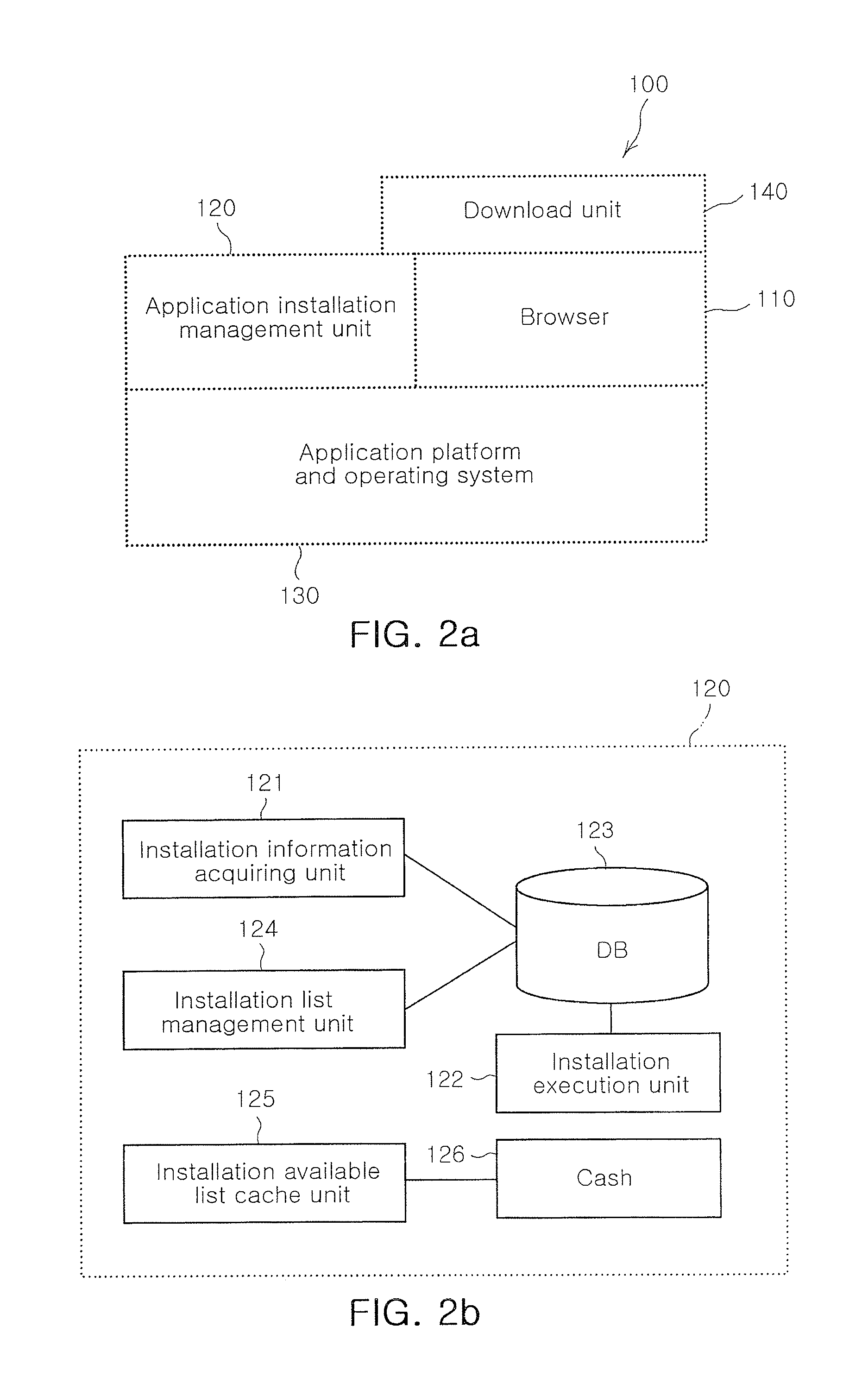

Method and apparatus for installing application using application identifier

InactiveUS20110010704A1Easily appliedEfficient use ofMultiple digital computer combinationsProgram loading/initiatingApplication softwareApplication Identifier

An application installation method and apparatus using an application identifier (AI) are disclosed. The application installation method includes: transmitting, by a terminal, an AI inputted by a user and terminal information to an installation information providing server; acquiring, by the installation information providing server, installation information corresponding to the AI and the terminal information, and transmitting the acquired installation information; and connecting, by the terminal, to an installation file providing server according to the installation information, downloading an installation file corresponding to the AI, and installing an application corresponding to the AI.

Owner:ELECTRONICS & TELECOMM RES INST

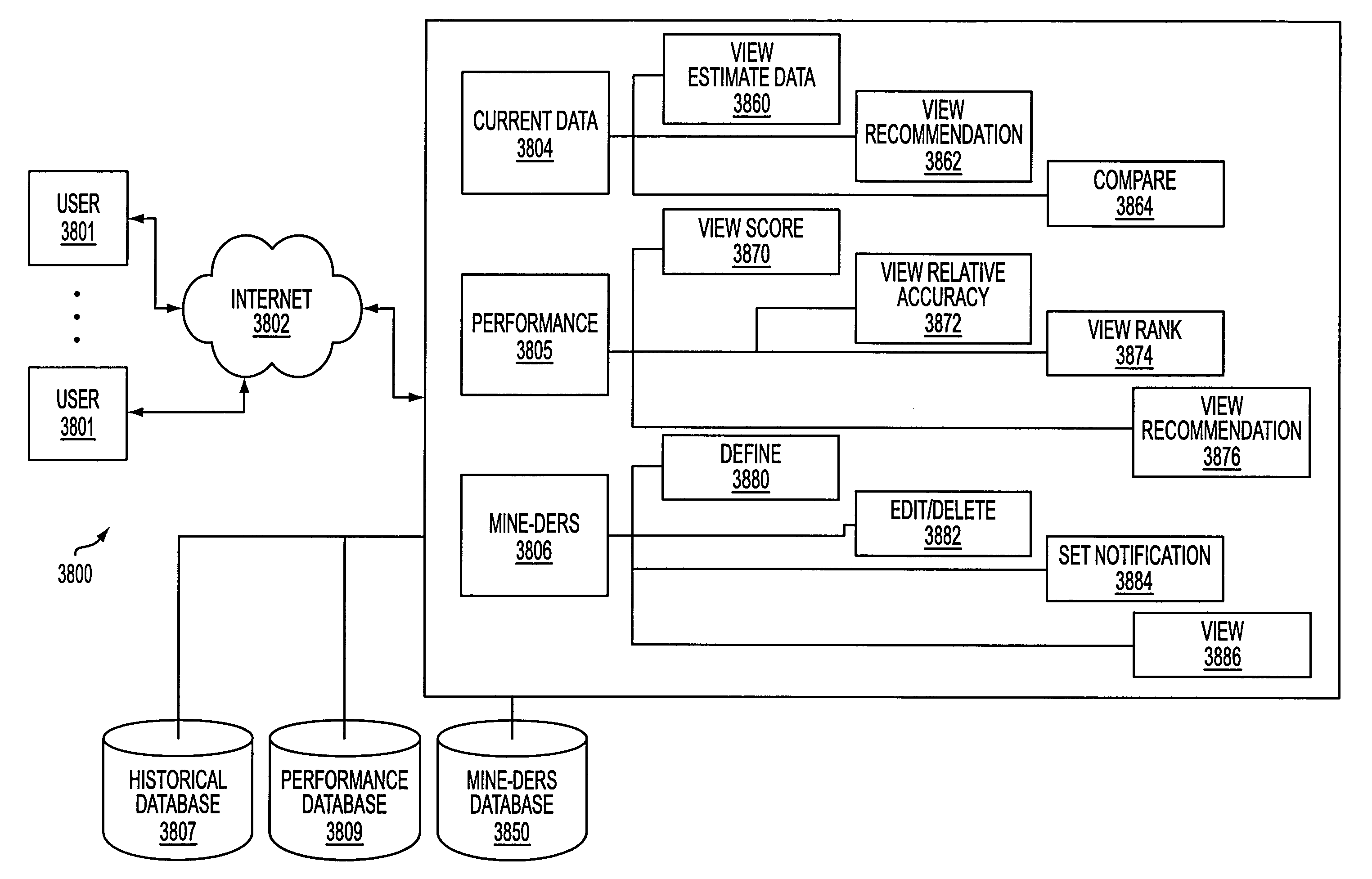

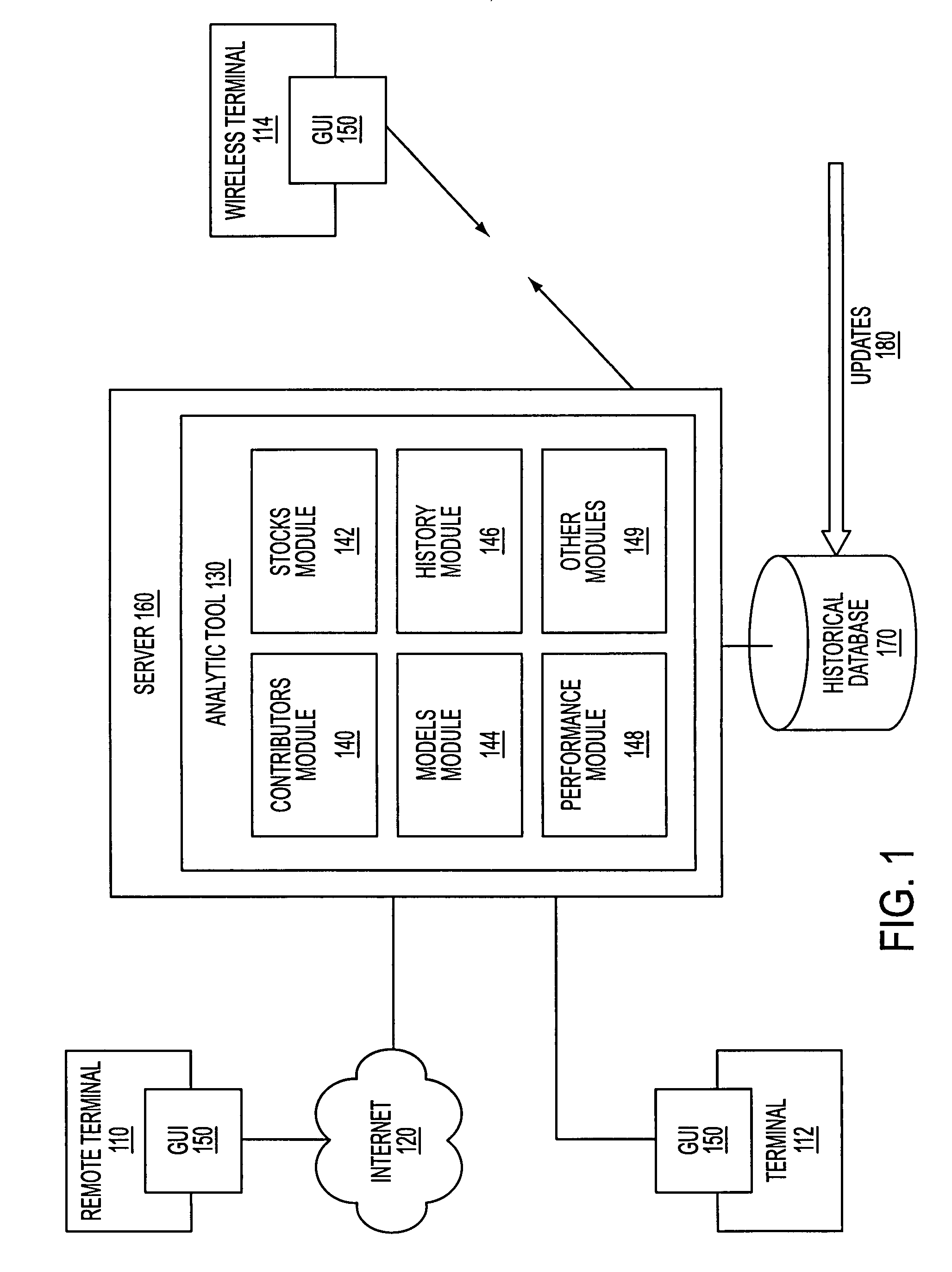

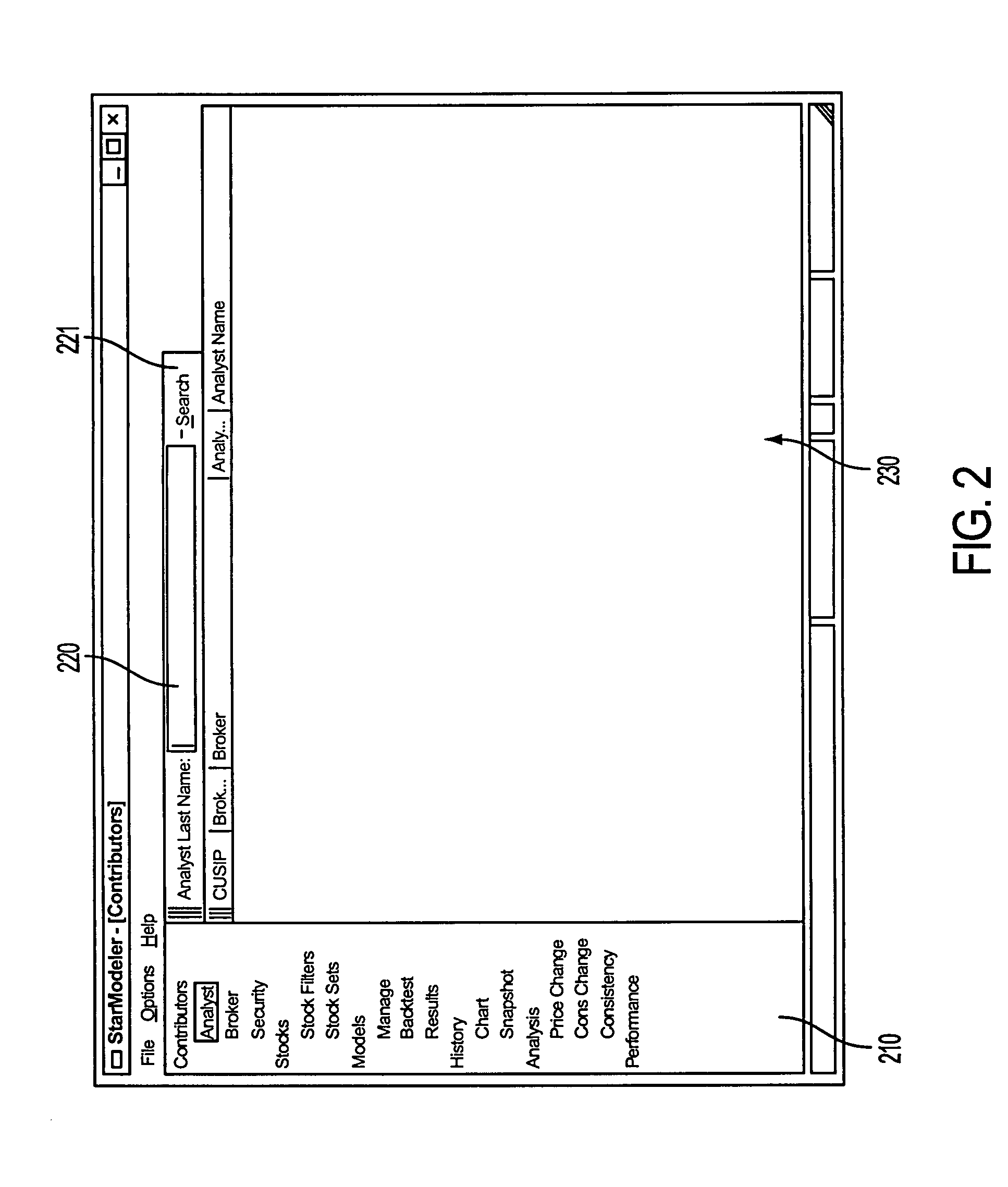

Security analyst estimates performance viewing system and method

A system and method for measuring, analyzing, and tracking the past performance of security analysts' earnings estimates and recommendations. The present invention provides a database of historical data relating to security analyst earnings estimate predictions wherein a historical model enables users to view the historical data as a time series of earnings estimates for each analyst selected, for a selected period of time, for a predetermined earnings event. Users may define a model to automatically create enhanced composite estimates wherein an improved prediction of the quantity being estimated, such as company earnings, revenue or cash flow is obtained. Users may view performance screens and historical performance data for a particular contributor or various contributors for a given security. Other views may be available.

Owner:REFINITIV US ORG LLC

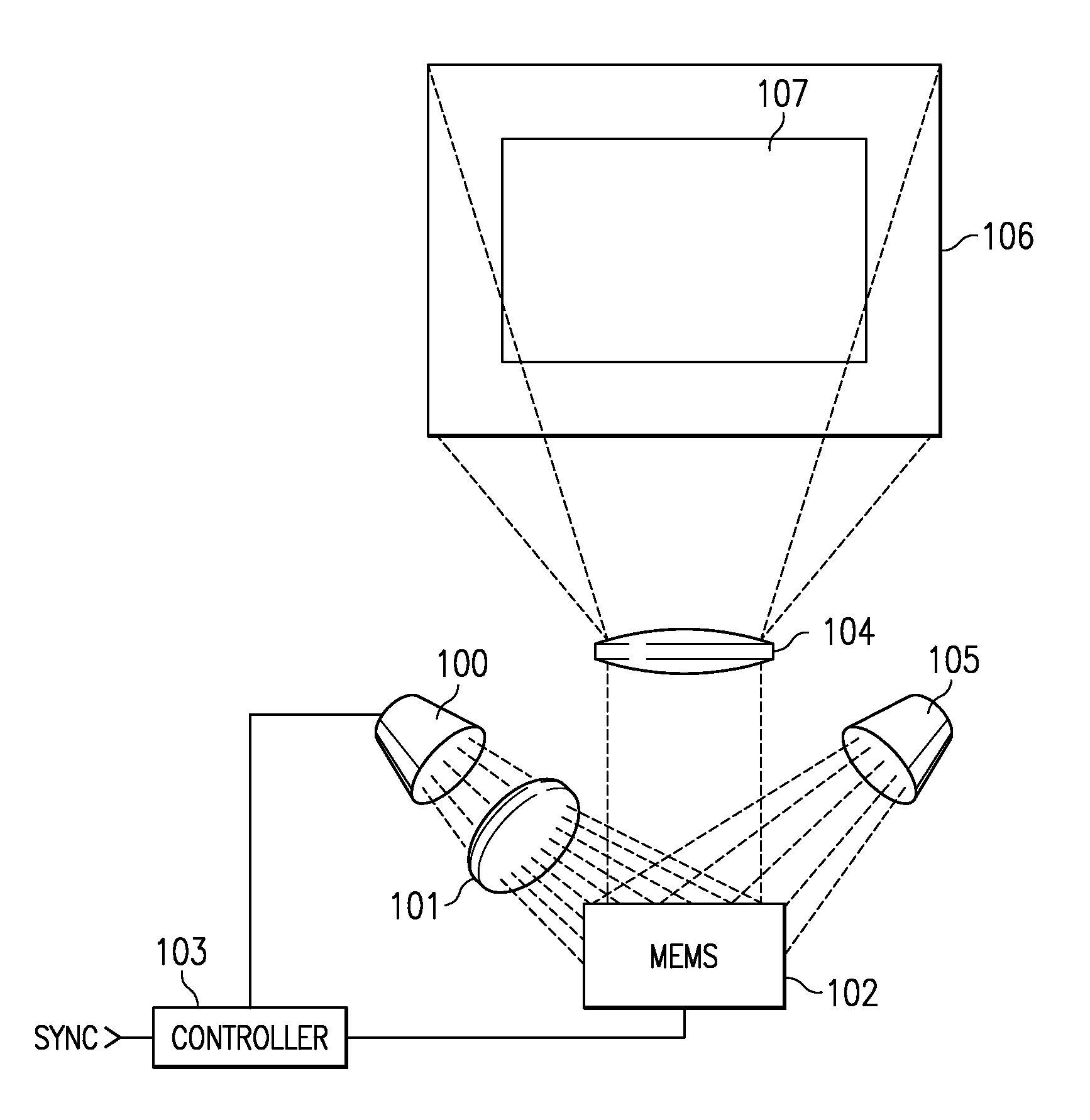

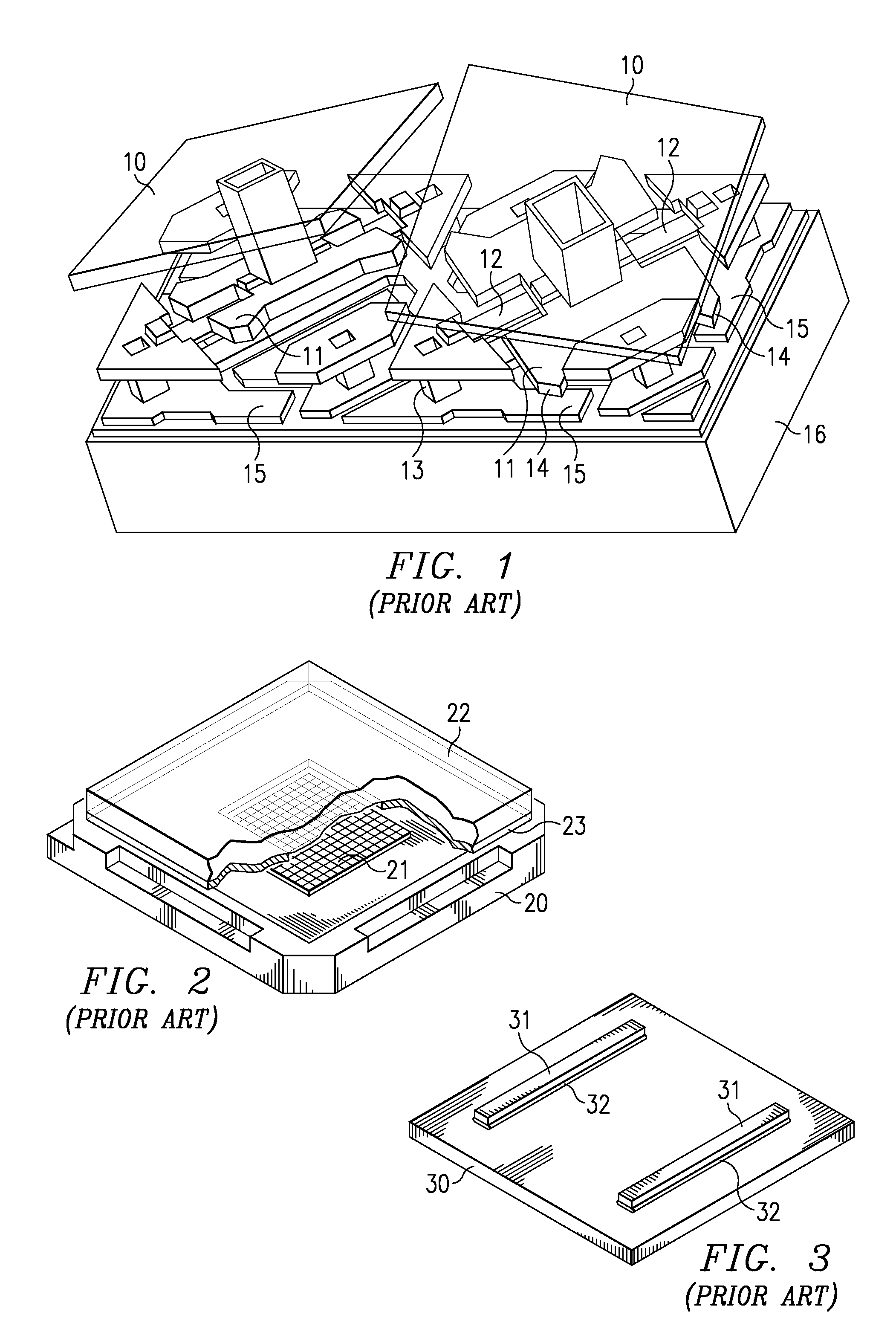

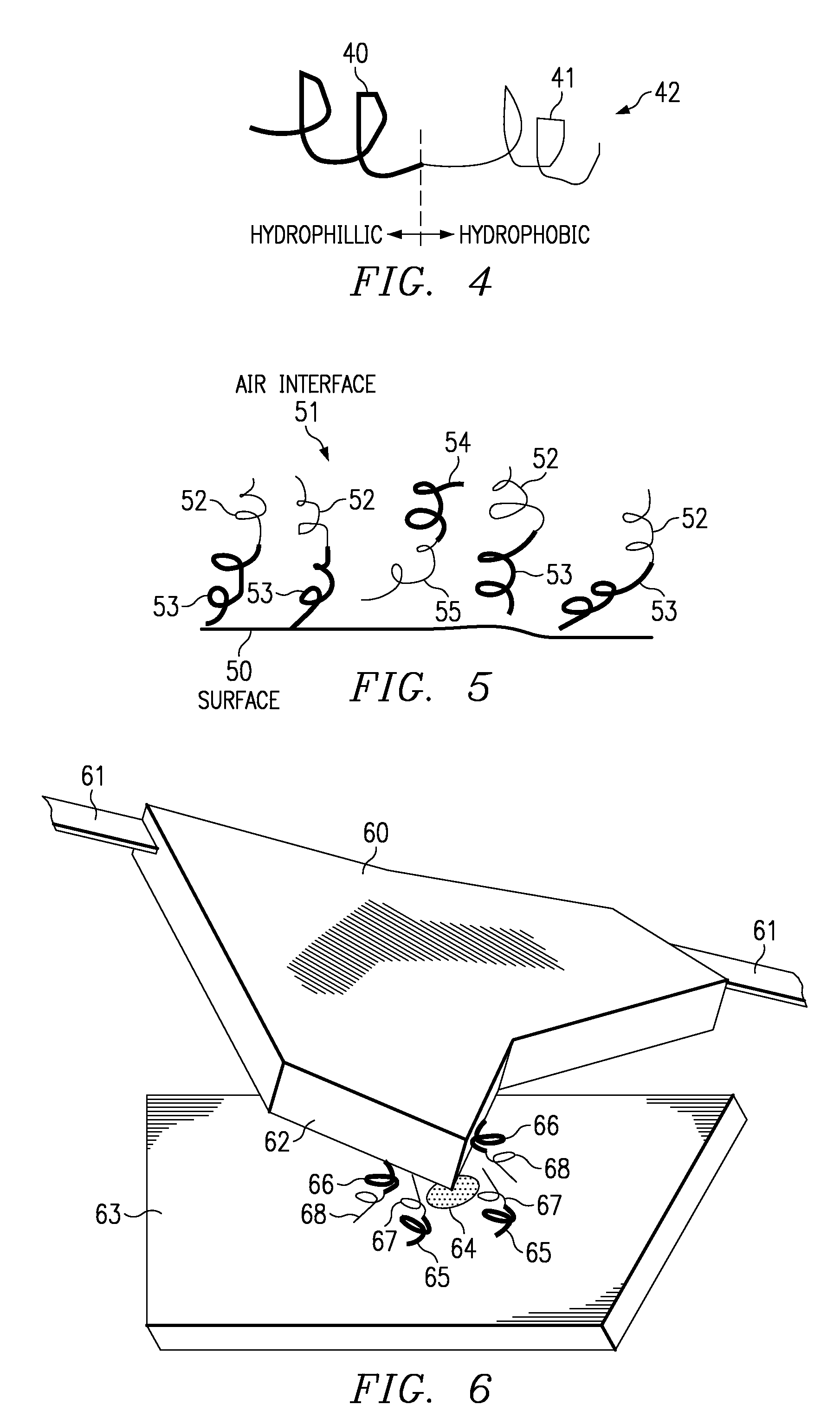

Lubricating micro-machined devices using fluorosurfactants

ActiveUS7291363B2Easily appliedPrevent onsetProjectorsSemiconductor/solid-state device manufacturingLubricationInorganic fluorine compounds

A method of lubricating MEMS devices using fluorosurfactants 42. Micro-machined devices, such as a digital micro-mirror device (DMD™) 940, which make repeated contact between moving parts, require lubrication in order to prevent the onset of stiction (static friction) forces significant enough to cause the parts to stick irreversibly together, causing defects. These robust and non-corrosive fluorosurfactants 42, which consists of a hydrophilic chain 40 attached to a hydrophobic fluorocarbon tail 41, are applied by nebulization and replace the more complex lubricating systems, including highly reactive PFDA lubricants stored in polymer getters, to keep the parts from sticking. This lubrication process, which does not require the use of getters, is easily applied and has been shown to provide long-life, lower-cost, operable MEMS devices.

Owner:TEXAS INSTR INC

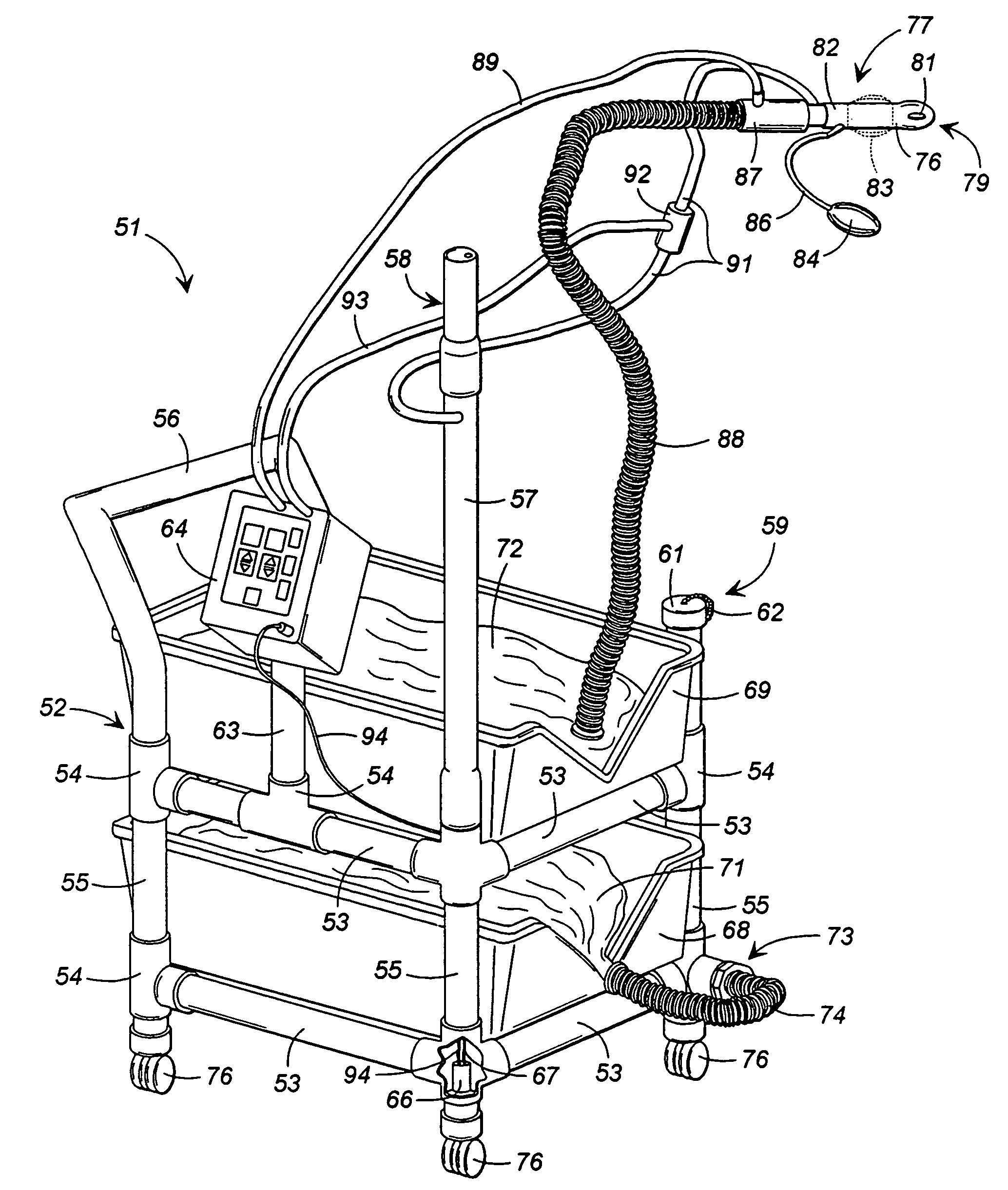

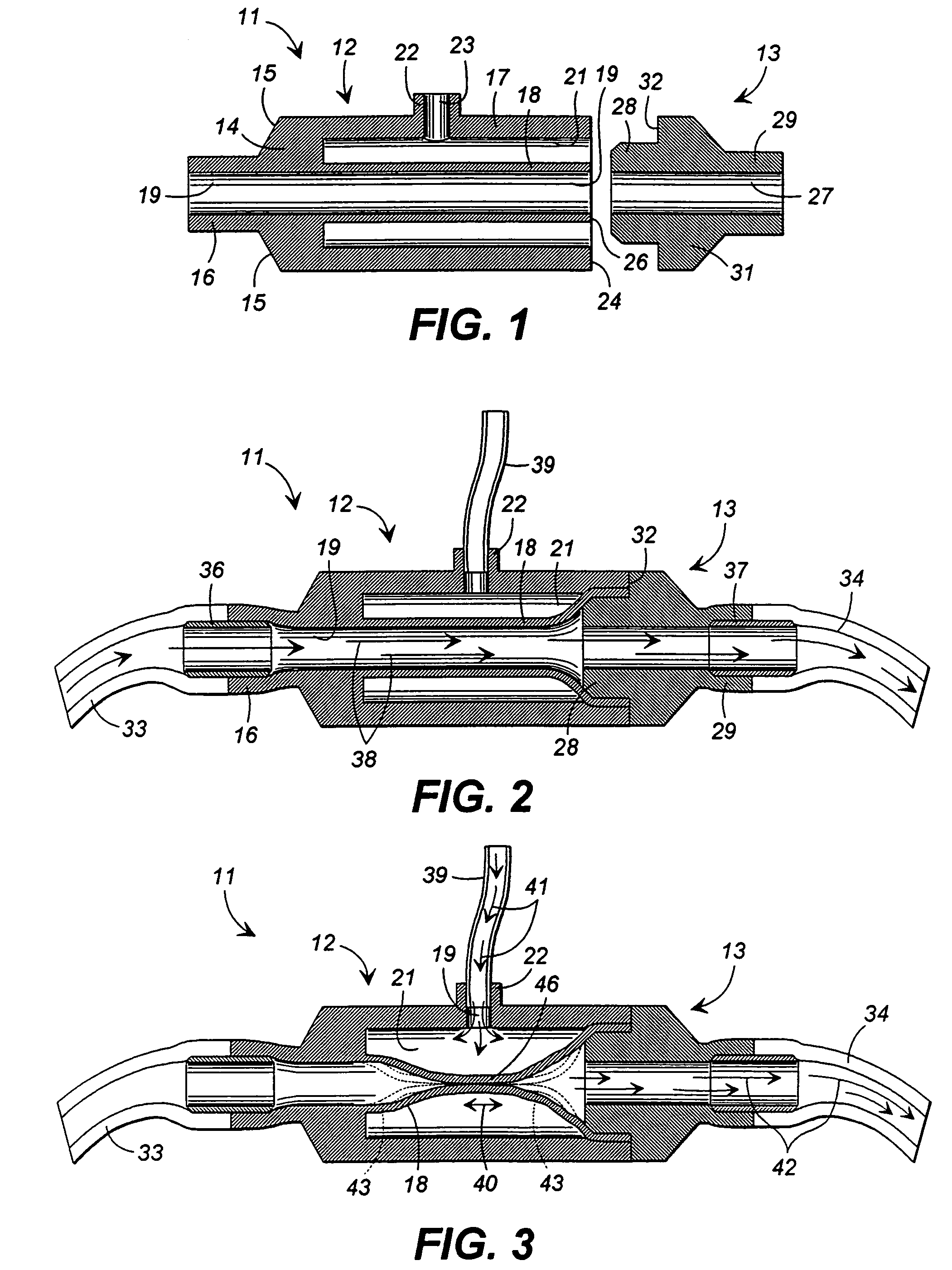

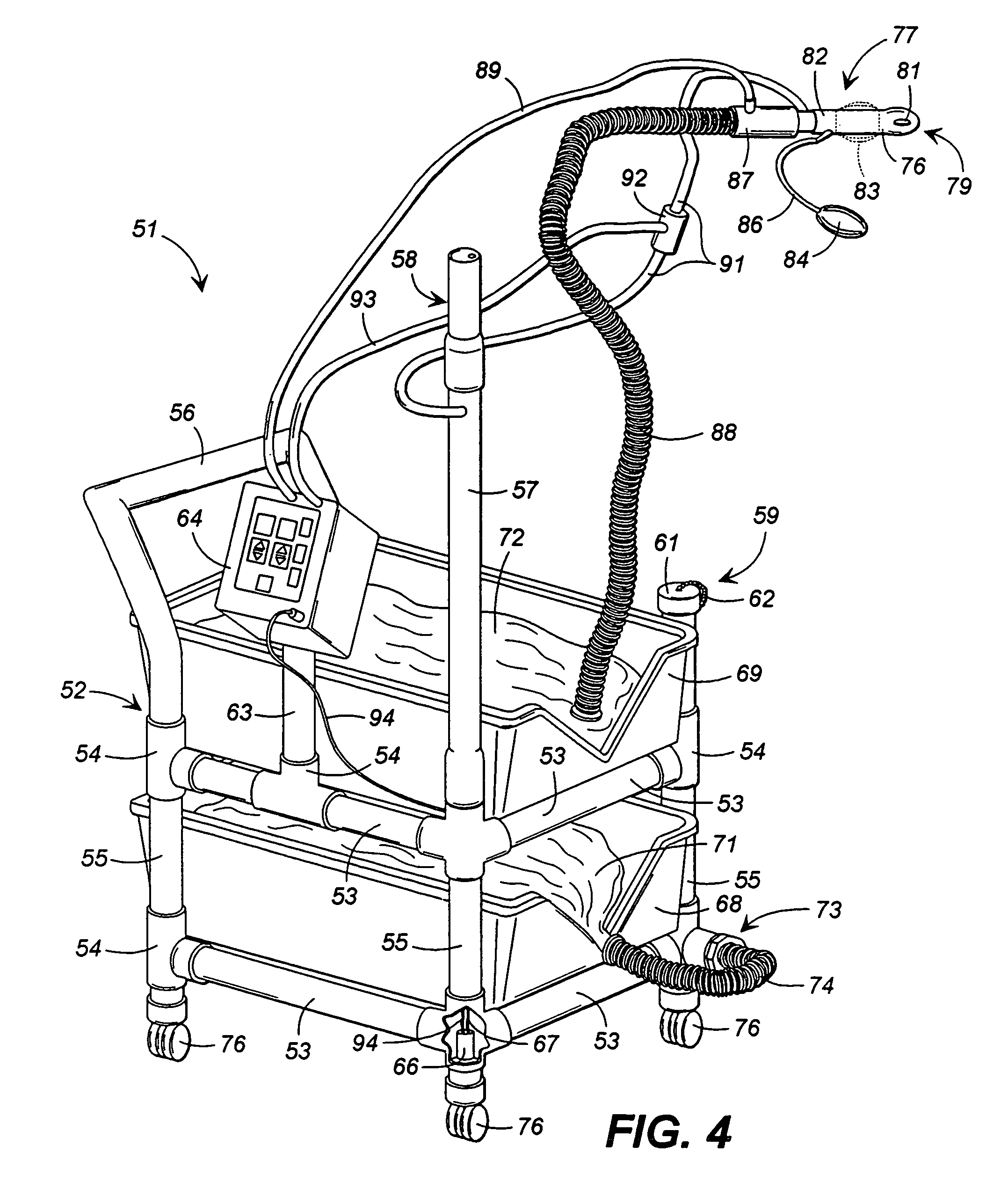

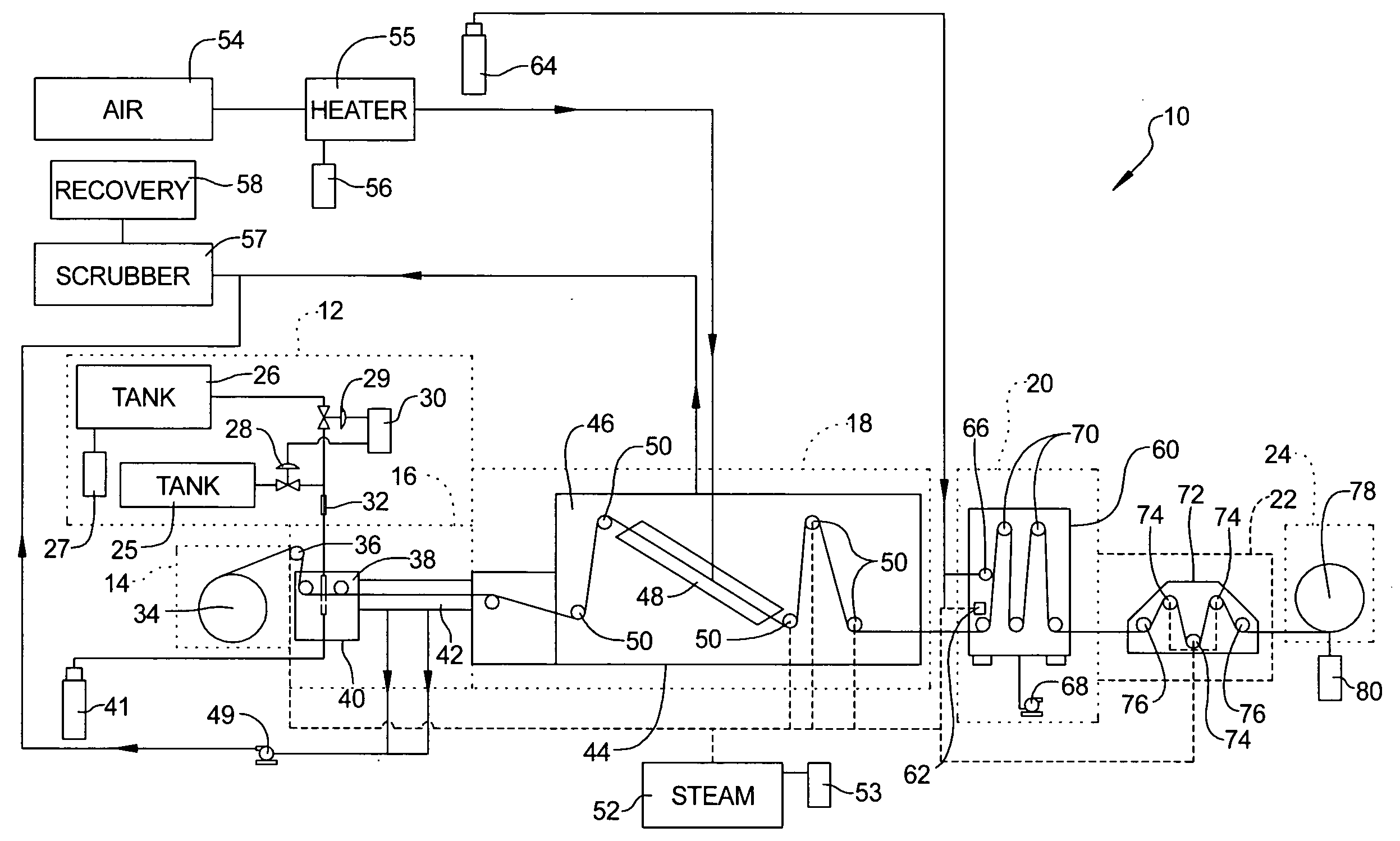

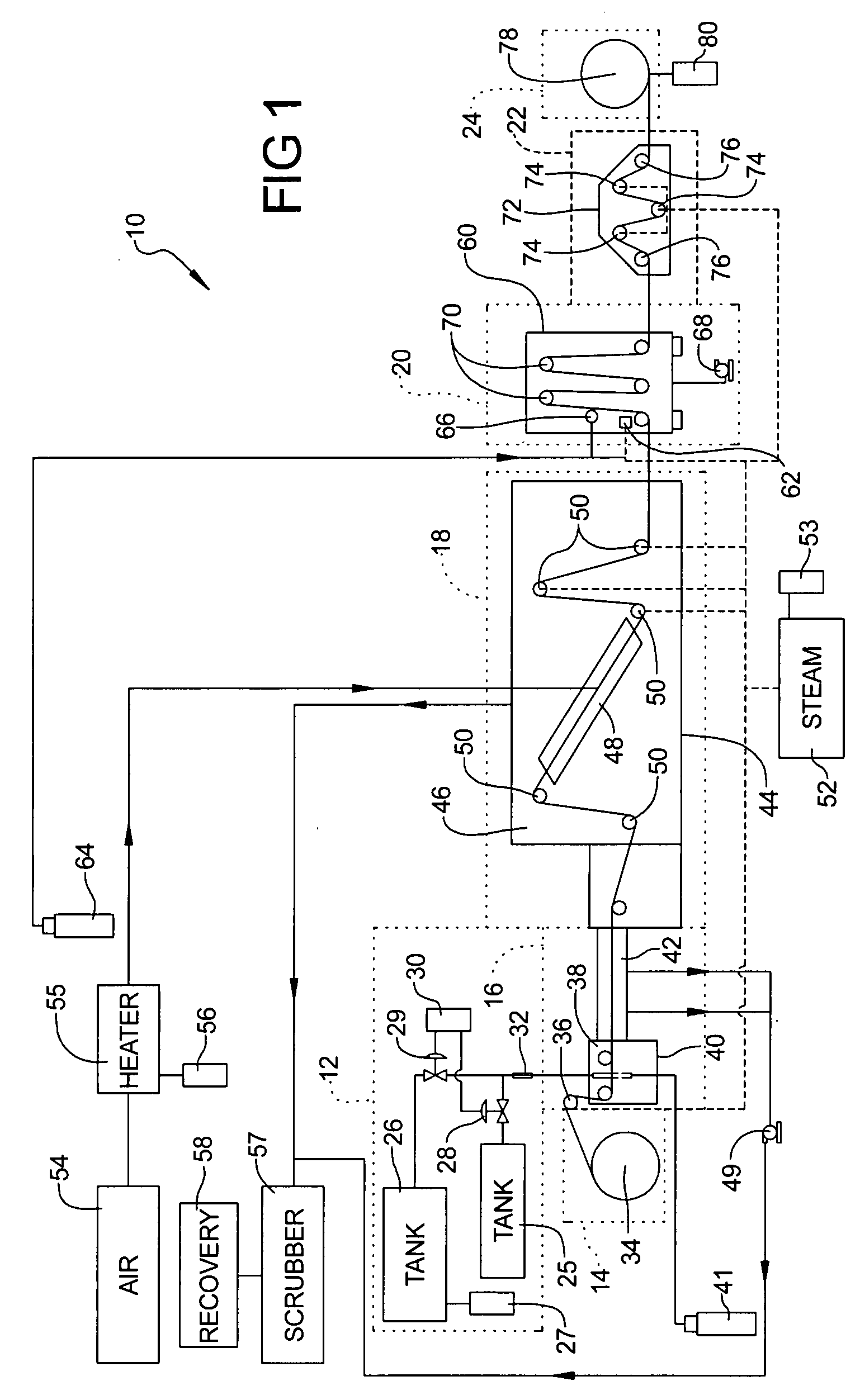

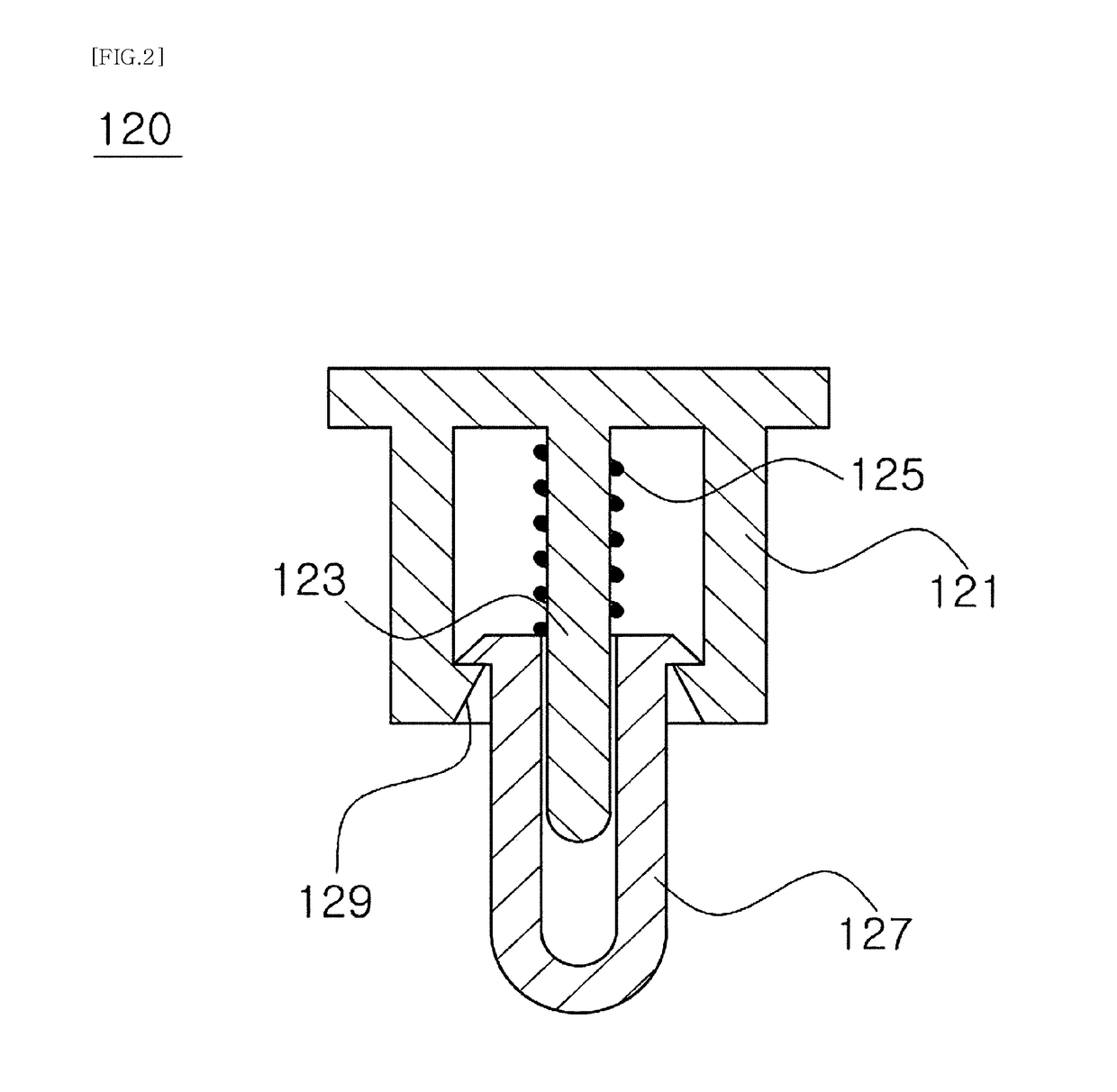

Method and apparatus for delivering a colonic lavage

InactiveUS6984226B1Easy to useEasily appliedDiaphragm valvesEngine diaphragmsLavage fluidEngineering

A method of providing a colonic lavage includes the steps of delivering a predetermined volume of lavage liquid to the colon to fill the colon with lavage liquid to a predetermined level, substantially maintaining the predetermined level of lavage liquid within the colon for a predetermined time in a hold cycle to hydrate impacted material within the colon, inducing a pulsed motion of the lavage liquid within the colon during the hold cycle to enhance hydration and break up of impacted material within the colon and to induce peristaltic activity of the colon, and draining lavage liquid from the colon. The step of inducing pulsed motion of the lavage liquid within the colon may be accomplished through an inverse pulsed technique or a pulsed hold technique.

Owner:JANE S ABELL TRUSTEE U A DATED 09 17 2014 +1

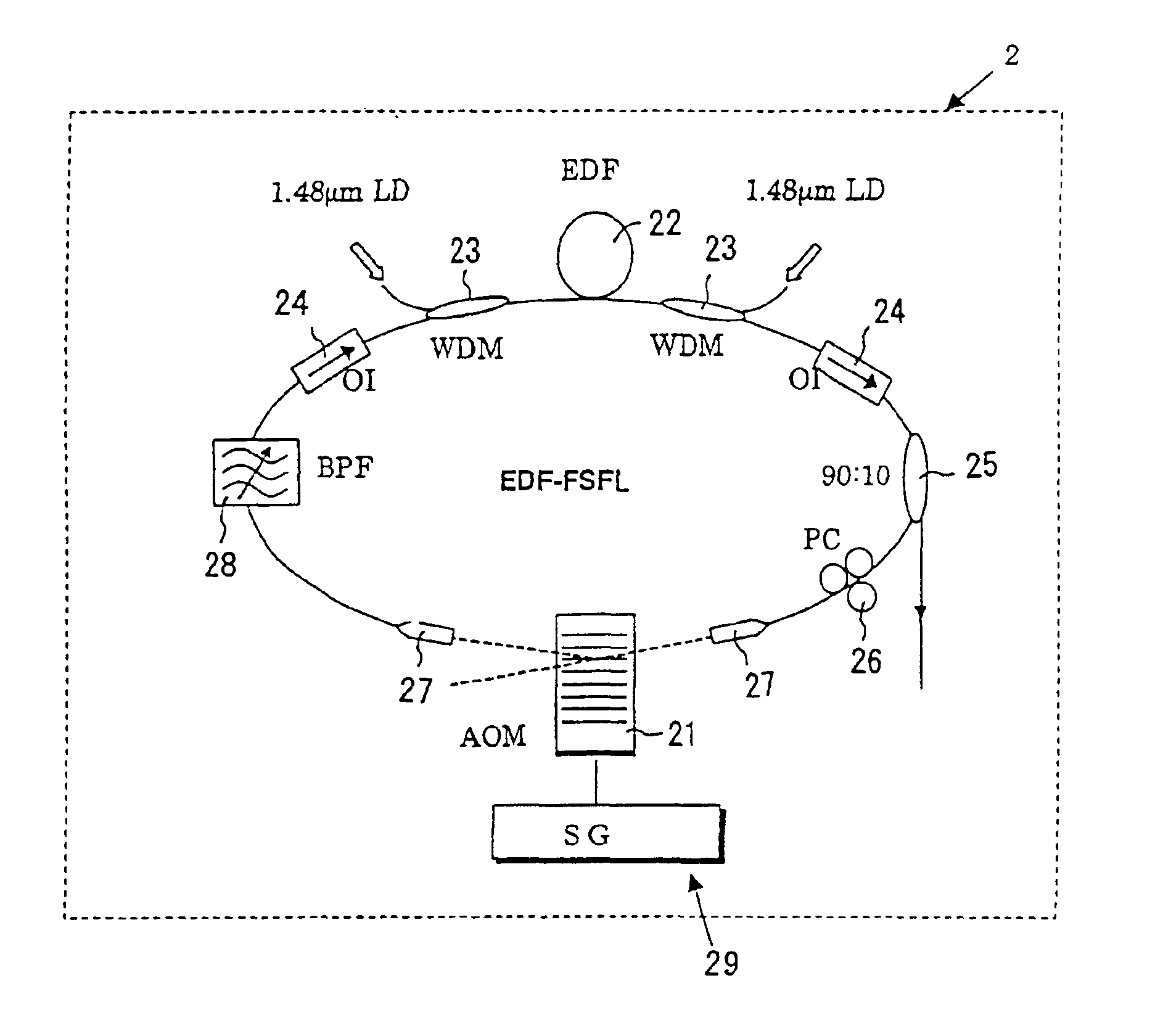

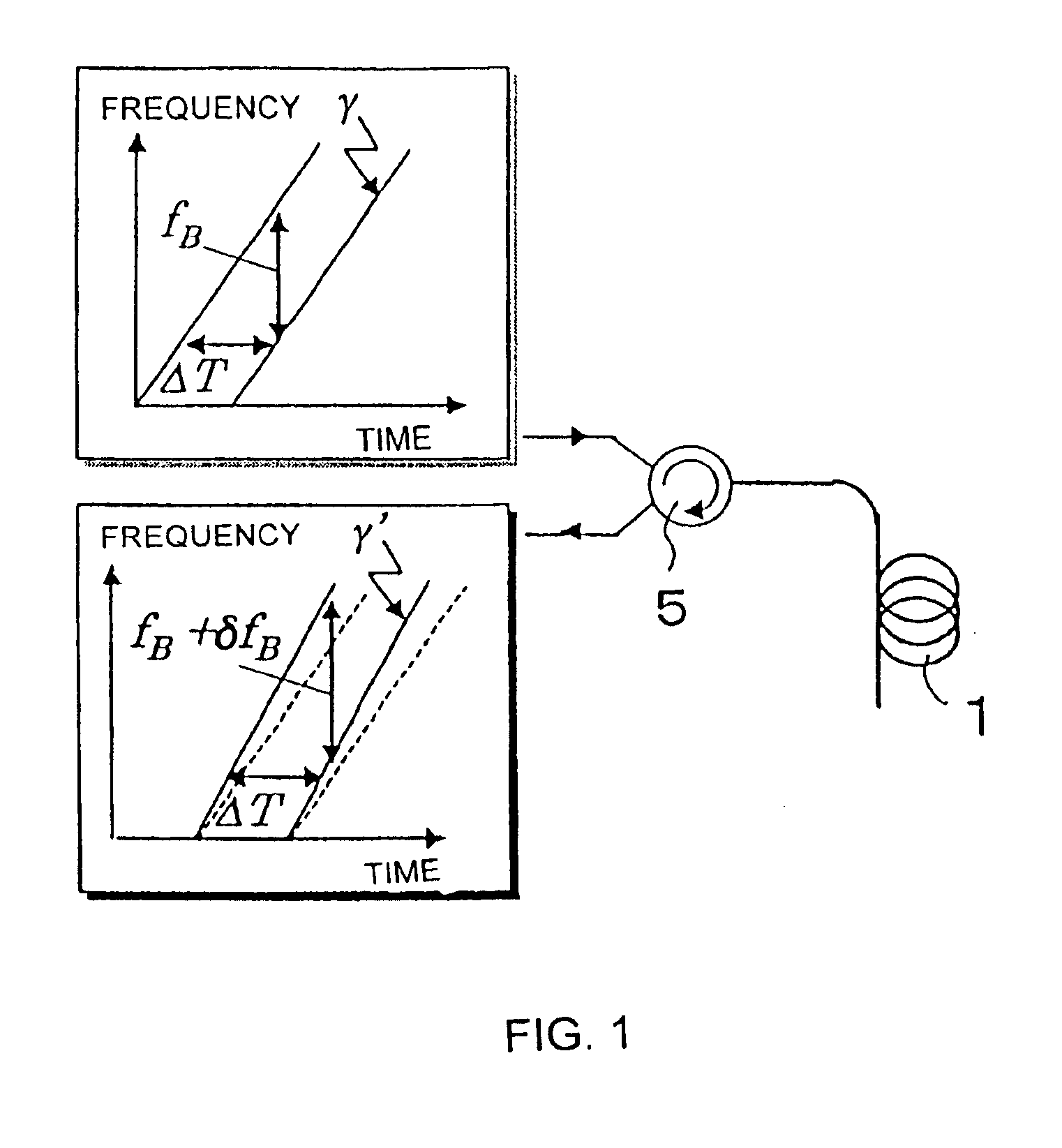

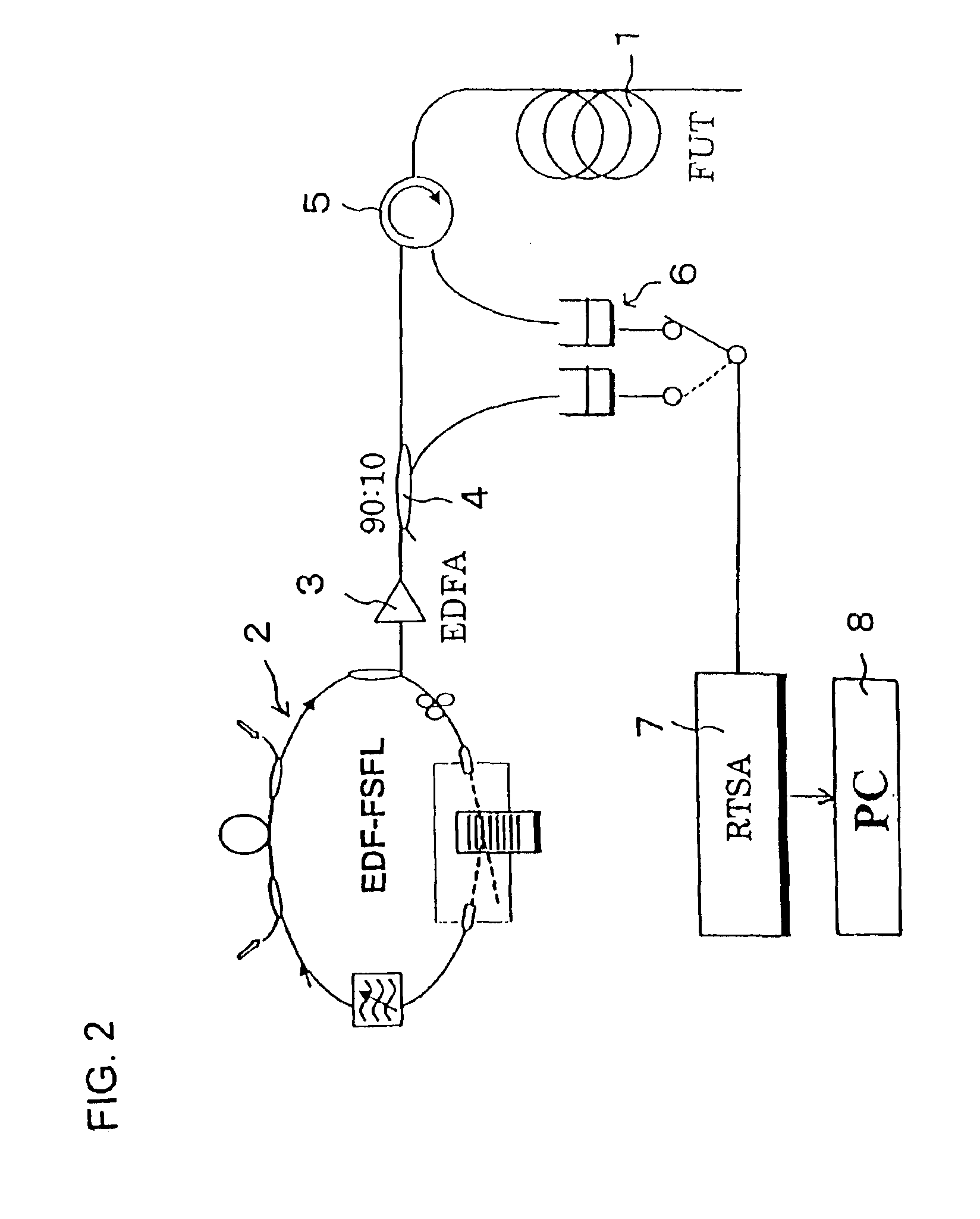

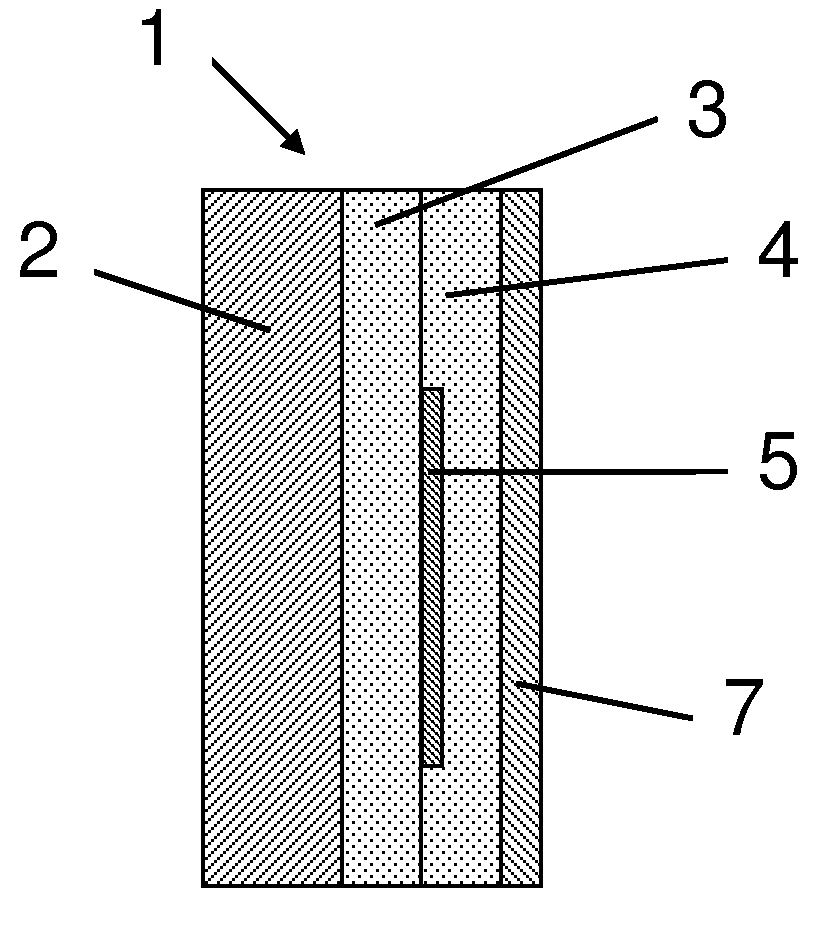

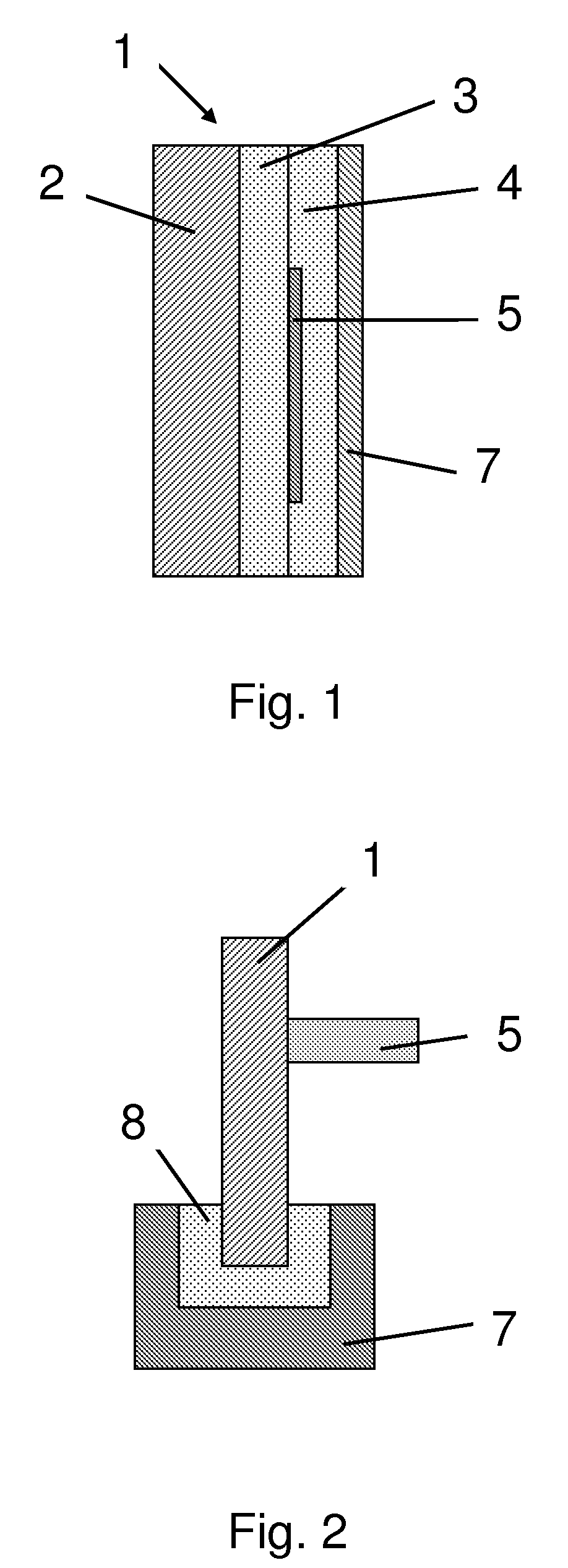

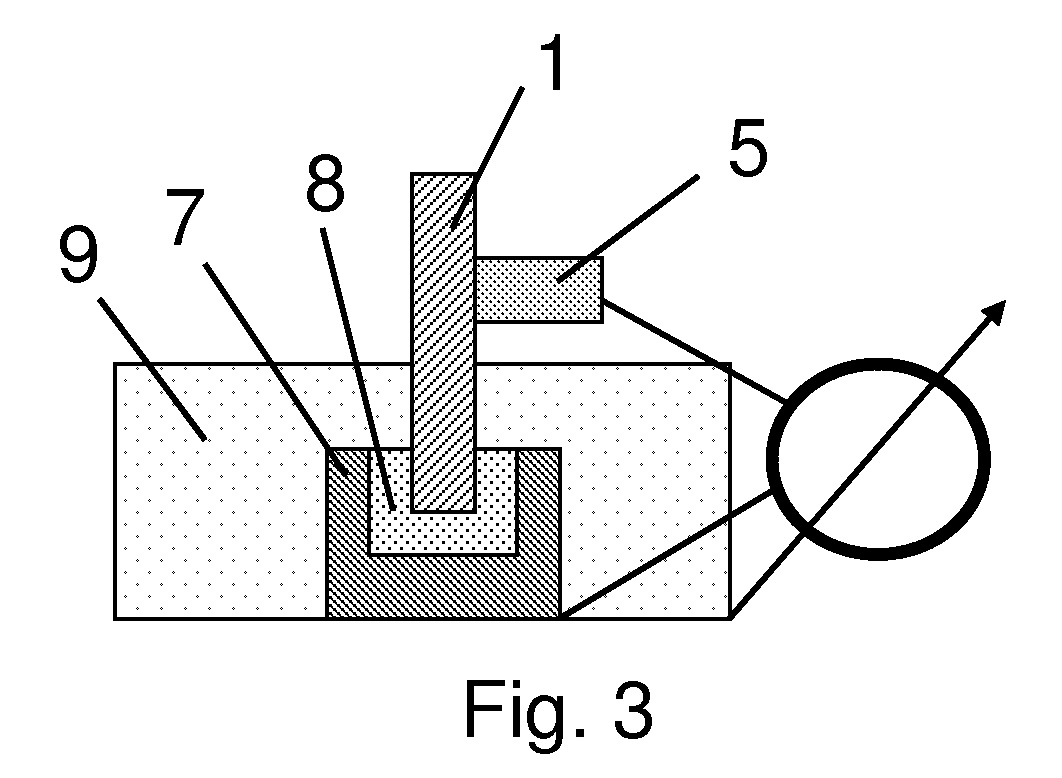

Group velocity dispersion measuring device and group velocity dispersion measuring method

InactiveUS6856723B1Easily appliedQuick measurementCoupling light guidesTesting optical propertiesOptical couplerPhotodetector

A group velocity dispersion measuring device capable of measuring group velocity dispersion (GVD) with a simple configuration and in a short time, comprising an FSF laser (FSFL) (2) for generating frequency chirp light, an optical amplifier (AMP) (3) for amplifying the frequency chirp light, an optical coupler (4), a circulator (5) for branch-controlling optical signals, a photodetector (6) for receiving a ray of light before and after its propagation through an optical fiber (1) to be measured, and an RF spectrum analyzer (RFSA) (7) for observing an optical spectrum waveform. Beat signals generated between chirp lights before and after the propagation, through the optical fiber (1) to be measured, of frequency chirp light emitted from the FSF laser (2) are alternately observed to calculate a GVD value from frequency differences between these beat signals.

Owner:JAPAN SCI & TECH CORP

Apparatus and method for treating materials with compositions

InactiveUS20080276970A1Increase completeness of reactionEasily appliedCoatingsCleaning using liquidsHydrocarbon solventsSilanes

An apparatus and method for treating subject materials with compositions includes a material treatment section for treating a subject material with a composition of a silane-containing material and a hydrocarbon solvent to form a treated material, and a neutralizing section for neutralizing the treated material such that the treated material has a pH in a range of approximately 7 to approximately 8.

Owner:PETRA INT HLDG

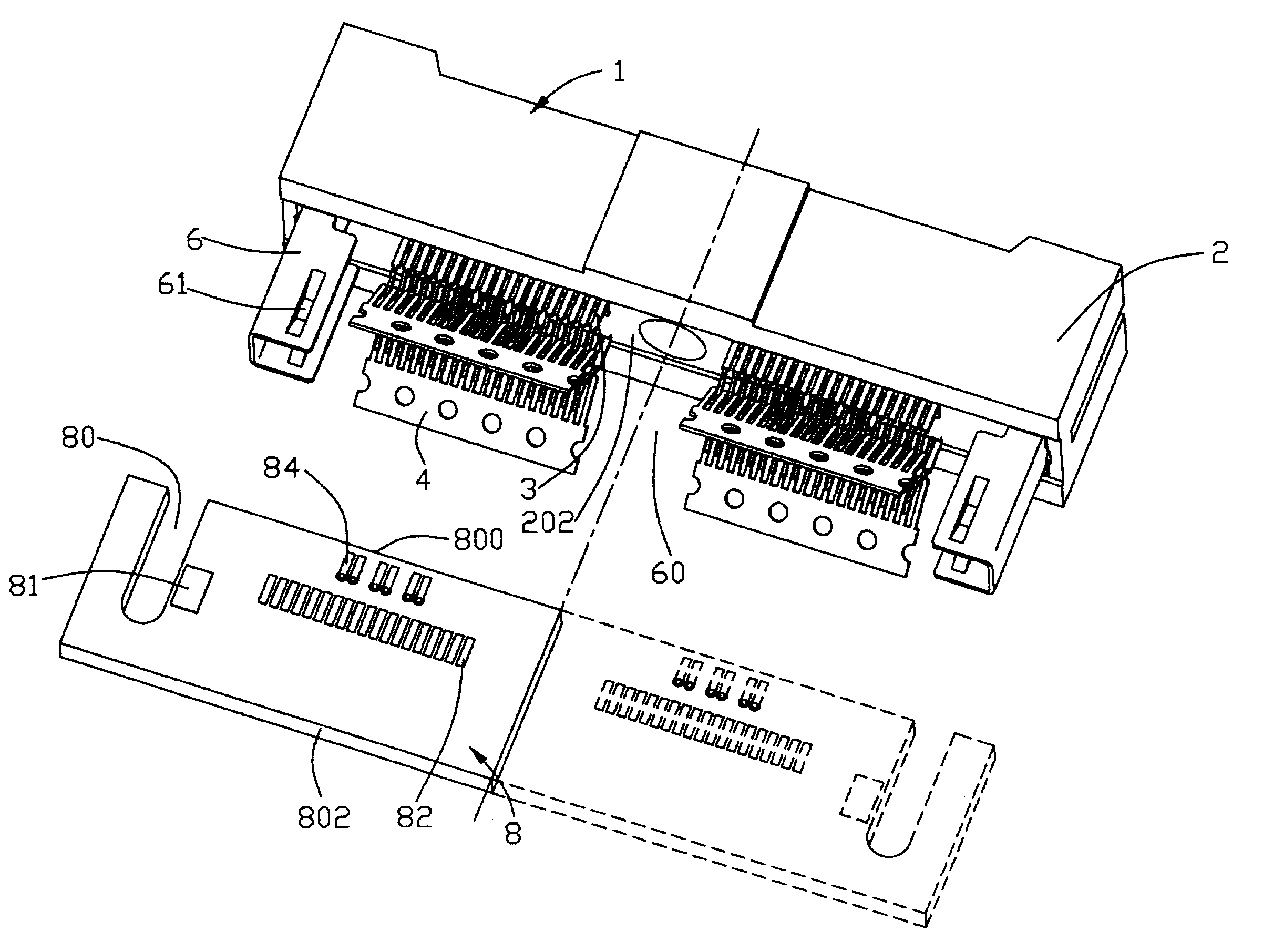

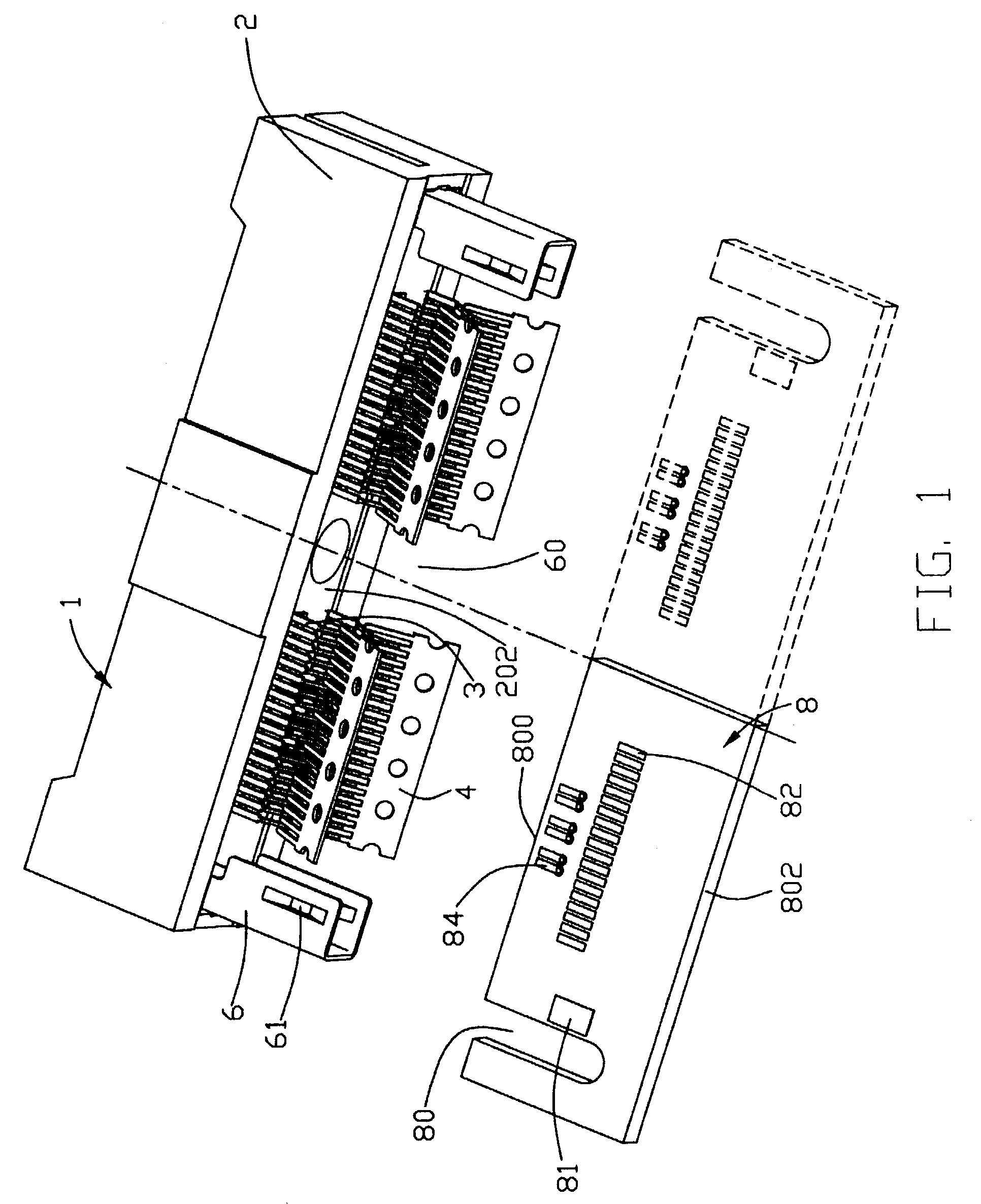

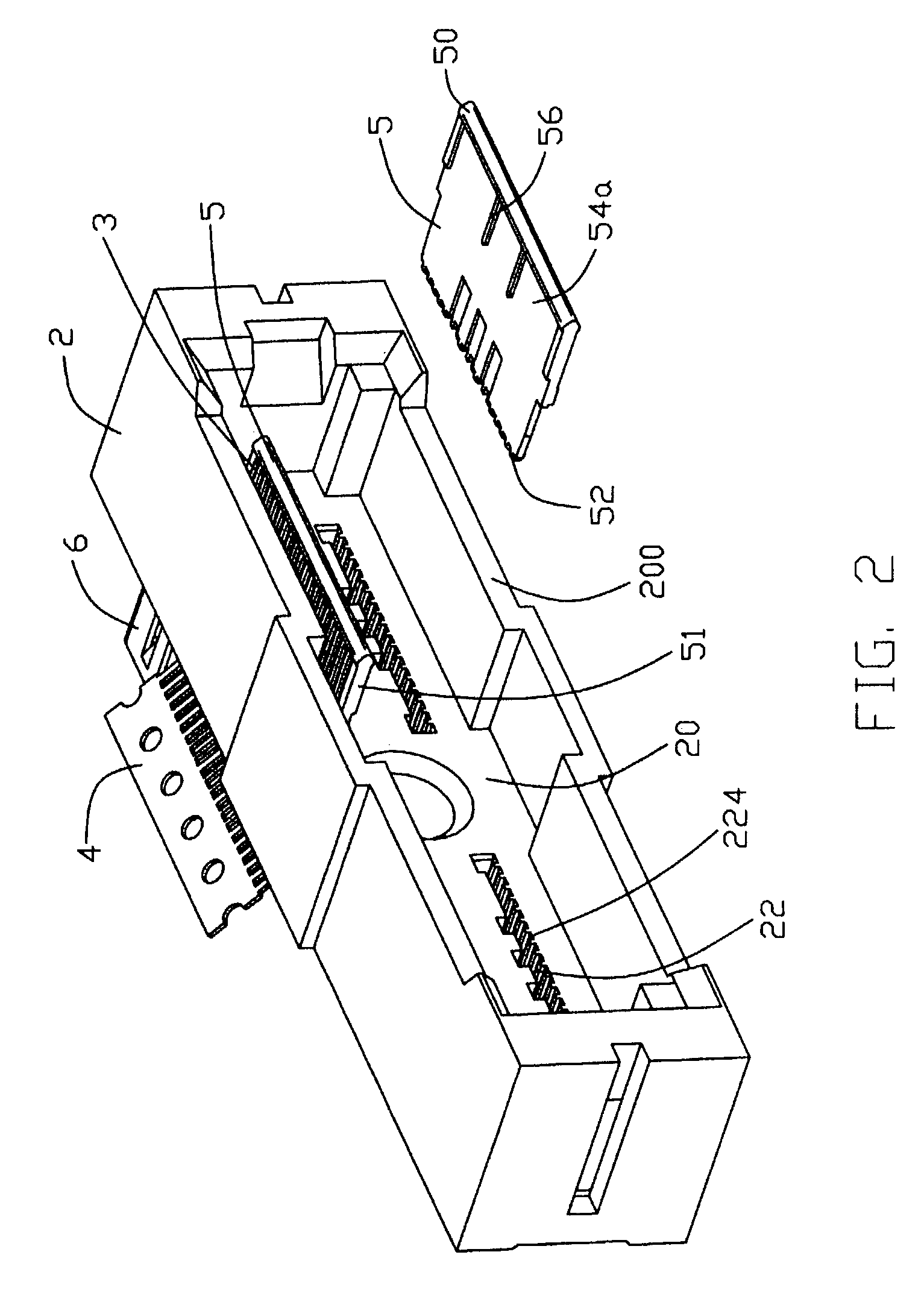

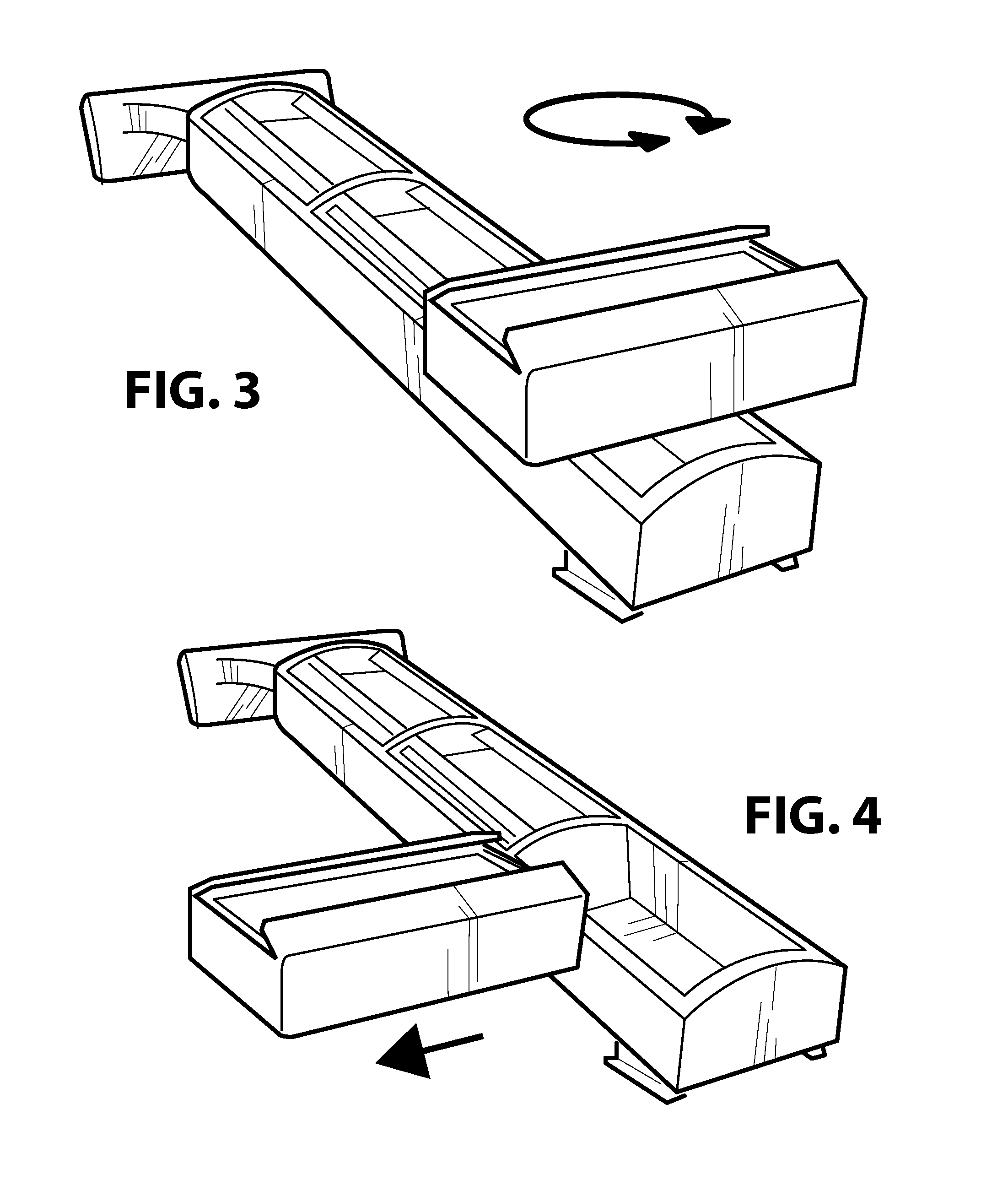

Method of making a straddle mount connector

InactiveUS7188408B2Easily appliedAccurately alignedContact member manufacturingContact member assembly/disassemblyEngineeringElectrical and Electronics engineering

A method of making an electrical connector includes the steps of: providing a connector body (2) having an insert (5) defining a recessed area (54a) at one side and a number of channels (54b) at an opposite side; assembling a ground bus (4) to the recessed area of the insert, the ground bus including a carrier strip (46) with a number of fingers (460) extending therefrom; assembling a number of signal contacts (3) to the channels of the insert, each signal contact including a board mounting portion (32); and displacing the carrier strip such that each finger extends into space (320) between the mounting portions of two adjacent signal contacts.

Owner:HON HAI PRECISION IND CO LTD

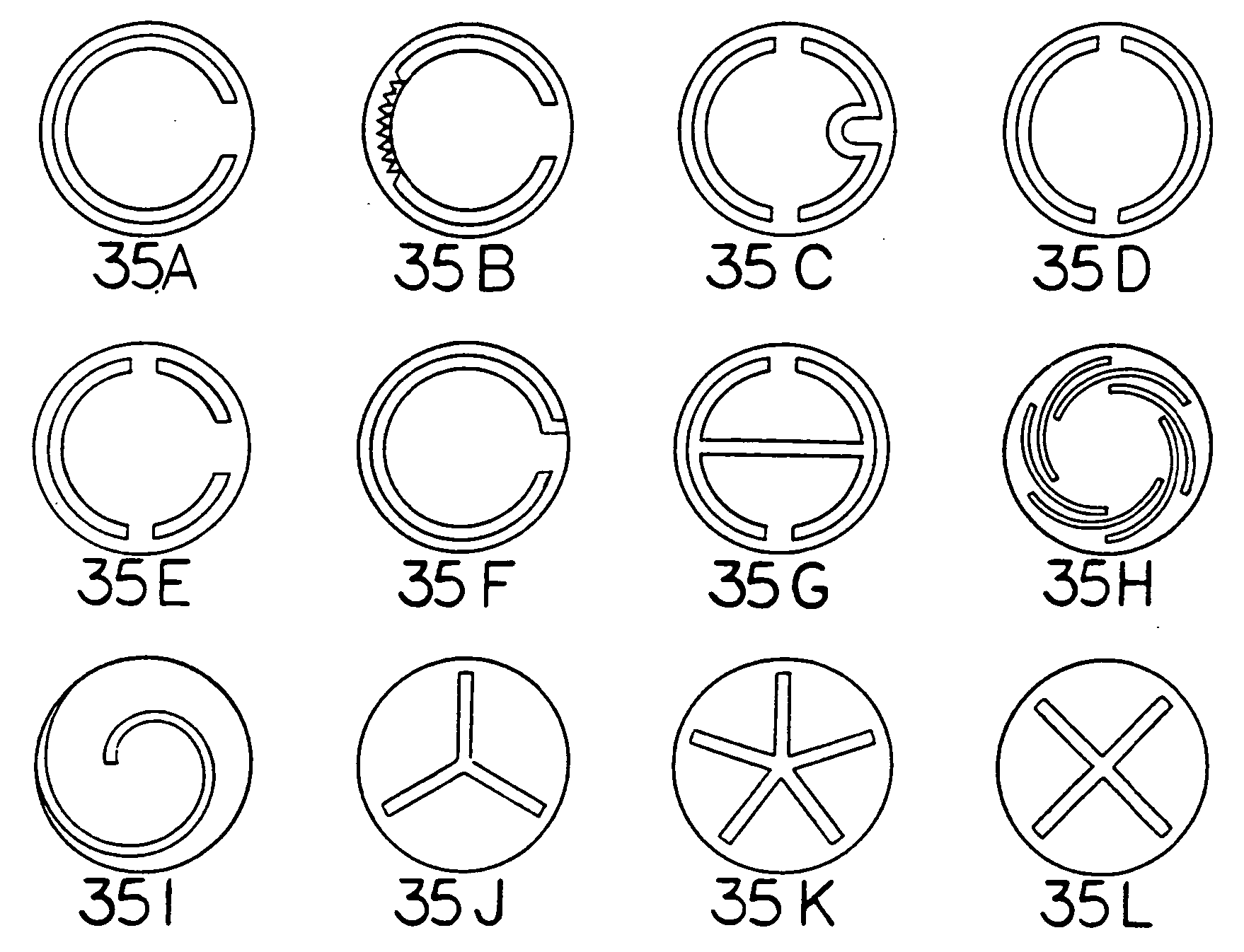

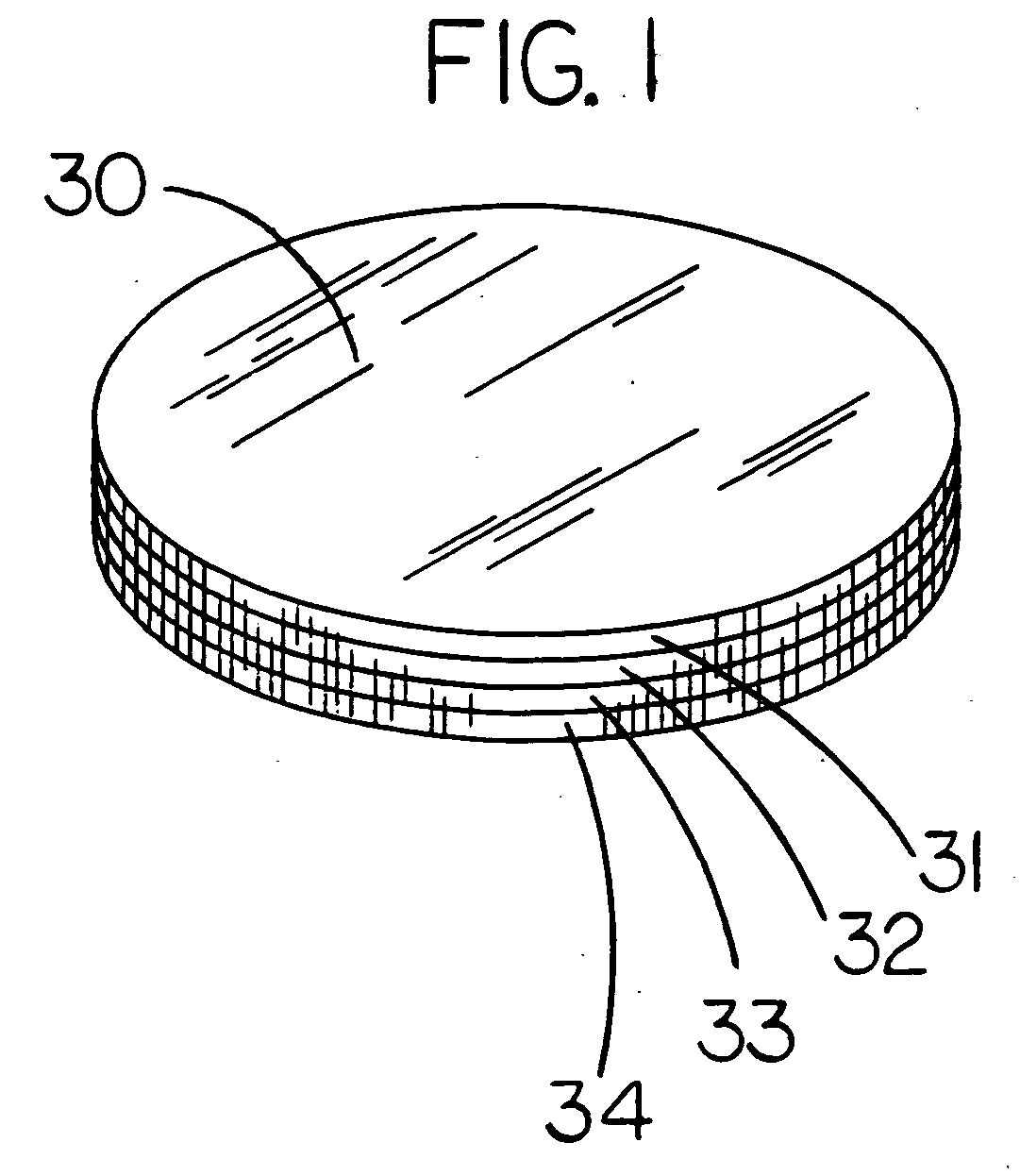

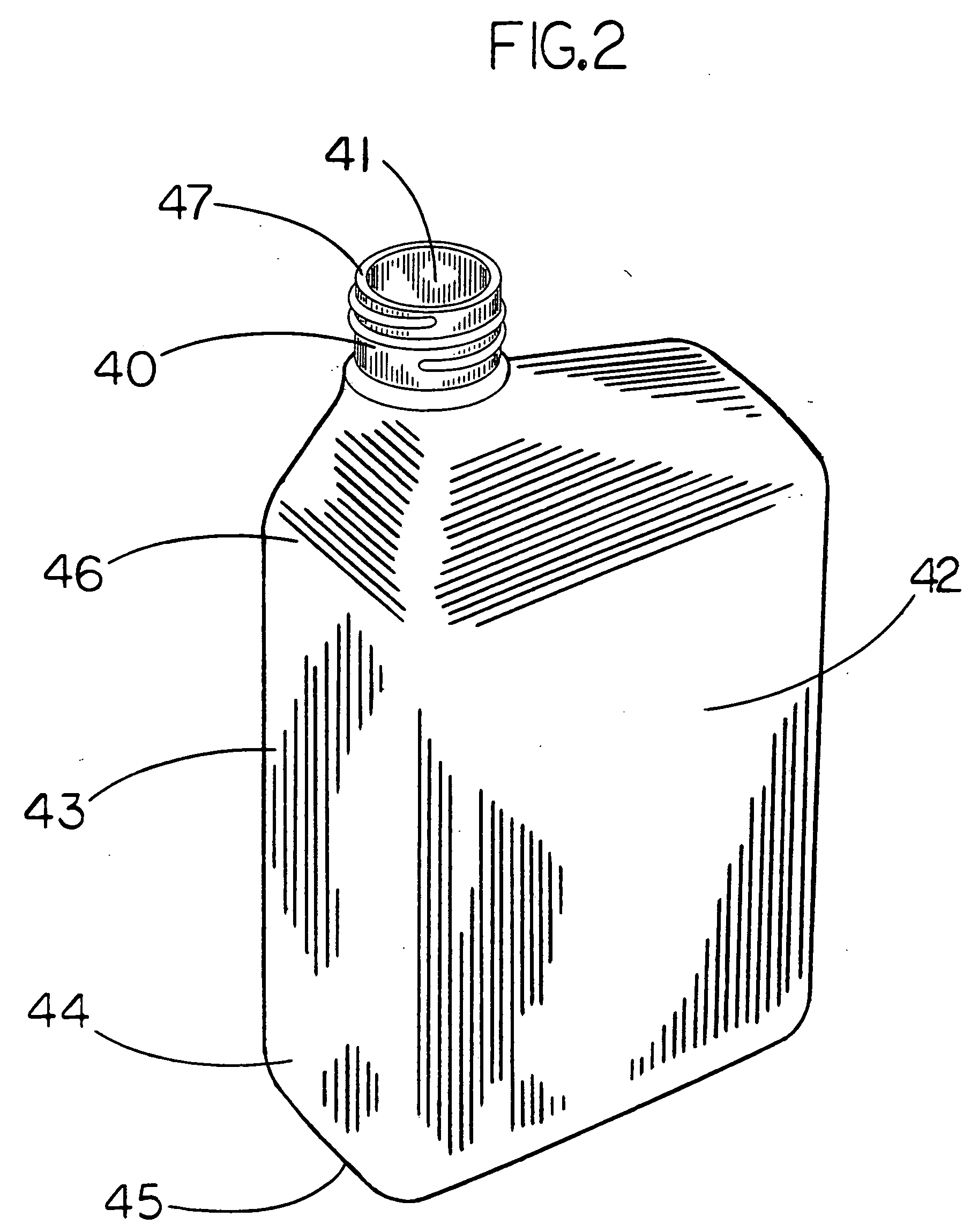

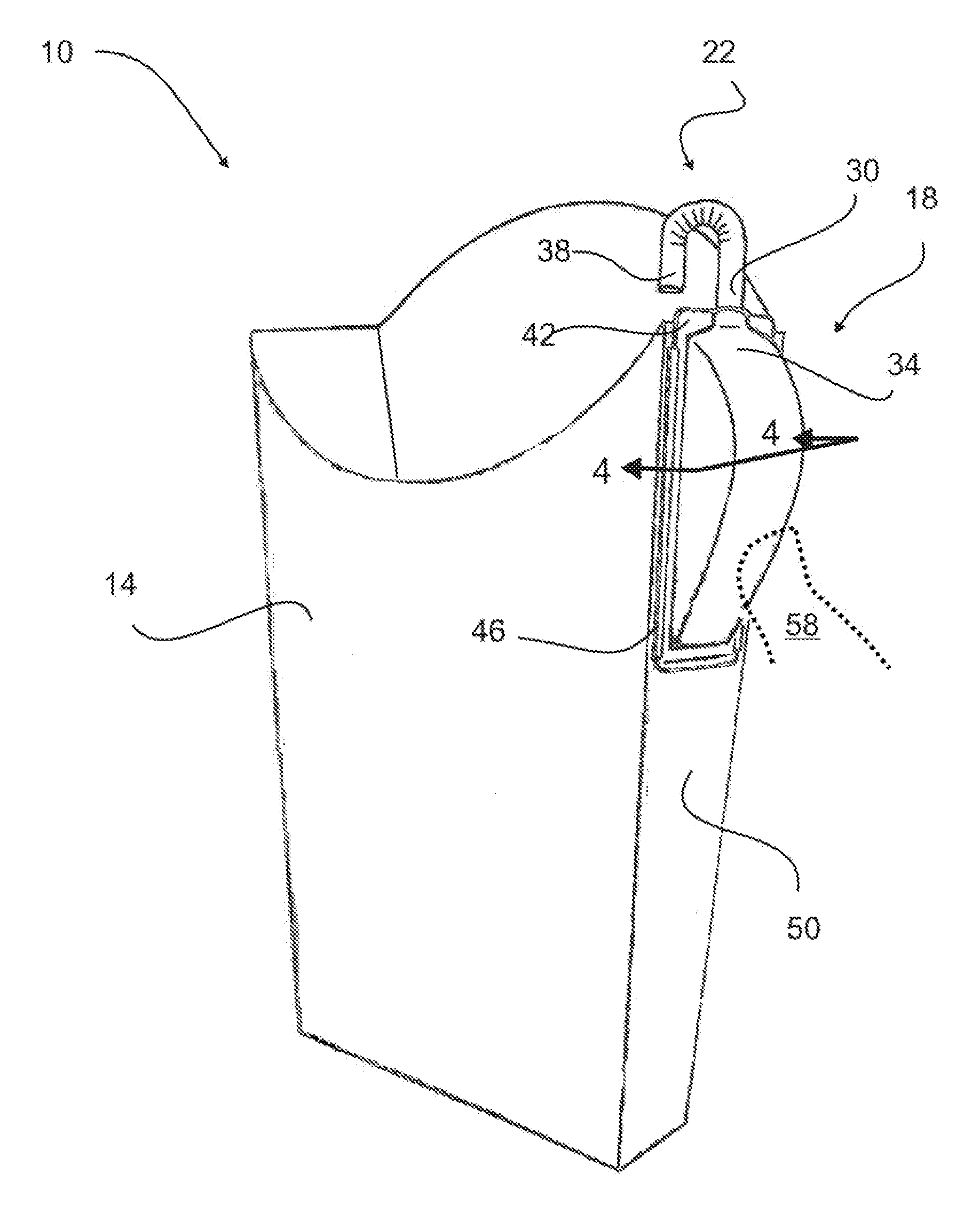

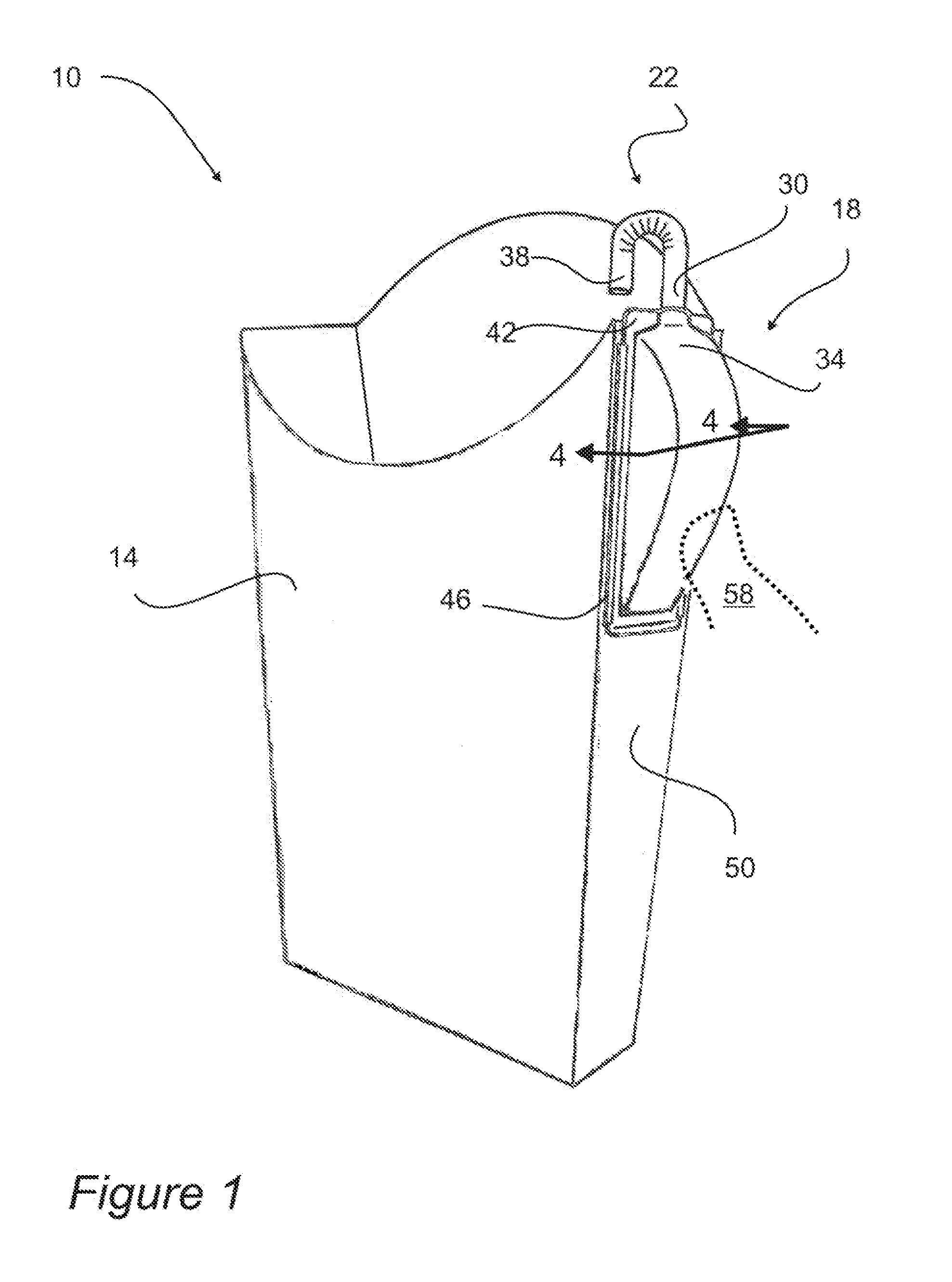

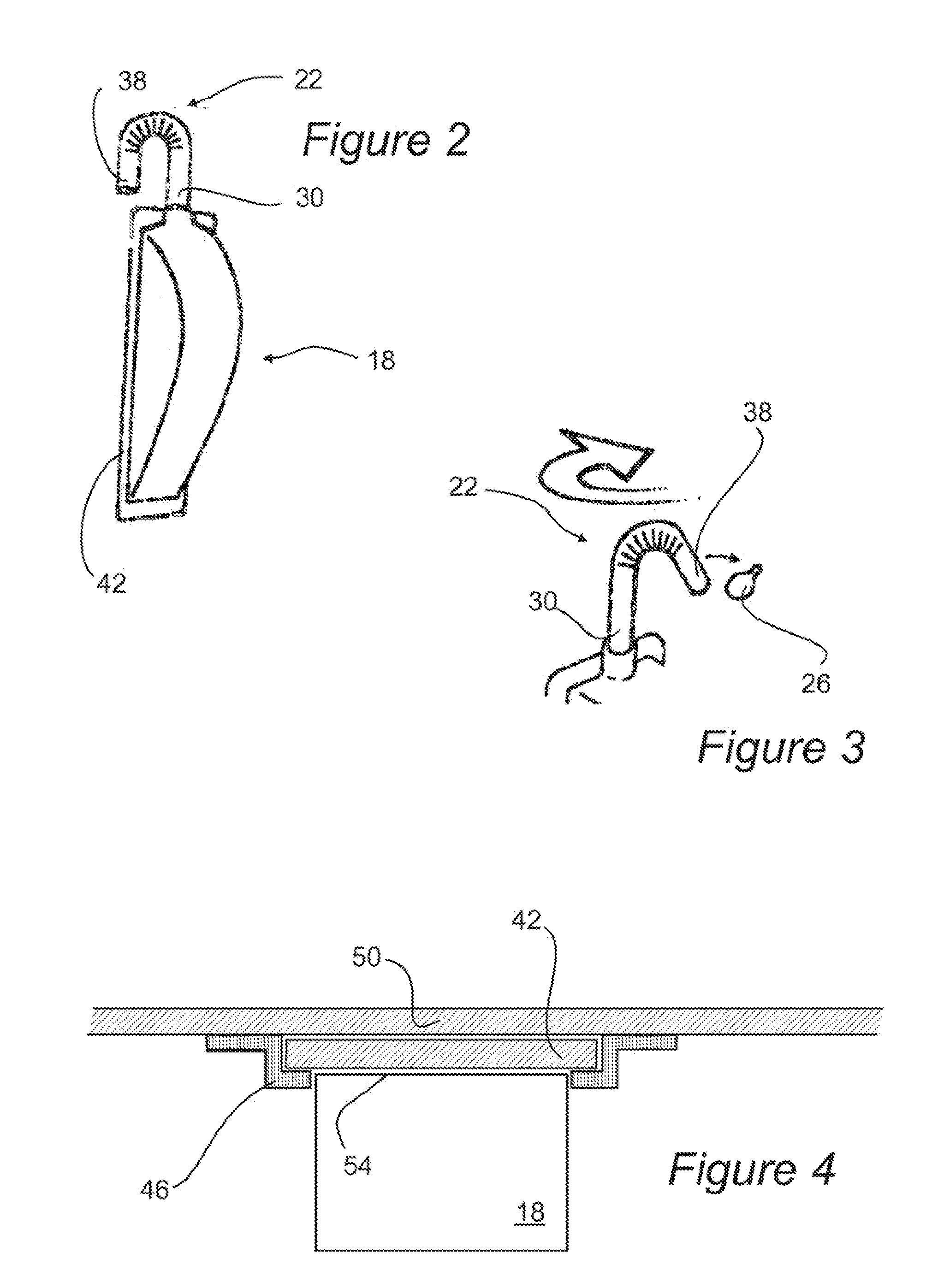

Pressure activated self opening container and seal

InactiveUS20050155991A1Easily appliedHigh degree of reliabilityCapsClosure using stoppersBurst pressureEngineering

An improved multi layered frangible seal is bonded over the pour spout opening of flexible plastic bottle containers of the type used for storing and dispensing pourable products such as motor oil or transmission fluid and the like. The seal provides a leak proof closure that is only strong enough to remain intact when subjected to the pressure created by the weight of the liquid contents when the filled uncapped container is held in an inverted position. At the same time the seal is also weak enough to break open and dispense the contents when a set amount of additional pressure is brought to bear against the seal by a consumer squeezing the inverted container. The seal allows the pour spout of the inverted container to be inserted into the fill opening while remaining intact which prevents any spilling of the contents. The seal is then broken open by the consumer squeezing the flexible bottle which dispenses the contents into the fill opening thereby eliminating the need for a fill funnel. The seal invention is constructed of a first layer of leak proof frangible material that is bonded to an additional layer of material. The additional layer of material contains one or more cut through and / or cut out void configurations forming a breaking pattern that turns the additional layer into a break and tear template layer. Bonding the template layer to the frangible layer strengthens the surface area of the frangible layer every where except in the area of the breaking pattern by leaving only the first frangible layer covering over the cut through and / or cut out void configuration forming the breaking pattern. This leaves a weakness in the multi layered seal only in the area of the breaking pattern which forces the seal to break open and tear only in the weaker single layered area of the breaking pattern configuration when sufficient pressure is brought to bear against the seal by a consumer squeezing the inverted container. The use of a separate layer of material to form the frangible area of the seal provides the ability to accurately control the thickness of the seal material that must break open, thus allowing the burst pressure of the seal to be precisely set. An uncut area of the breaking pattern forms a connector that keeps the broken open portion of the seal attached to the annular portion of the seal remaining bonded to the pour spout rim thus preventing any contamination of the dispensed contents when the seal breaks open.

Owner:JACKMAN BRIAN FRANCIS

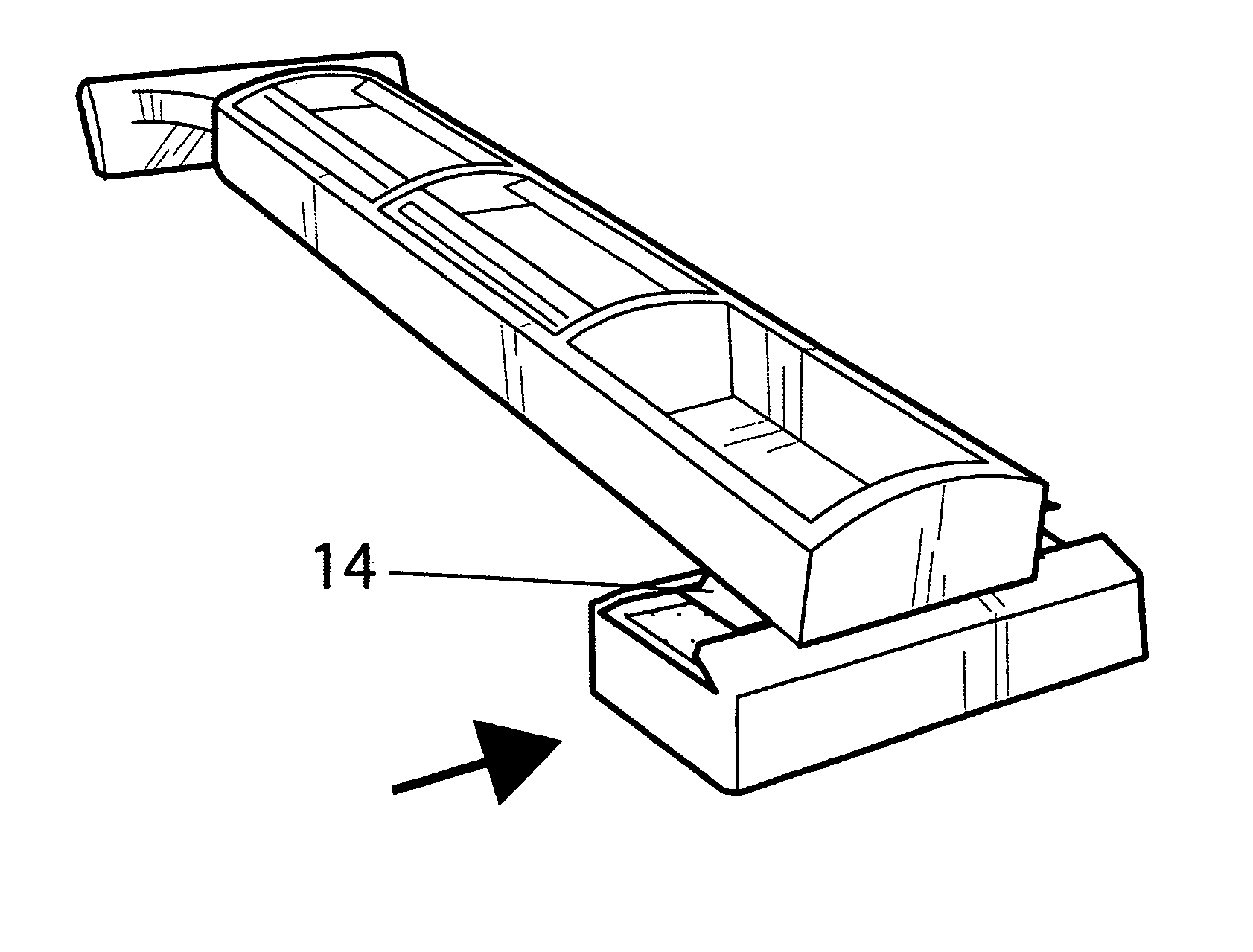

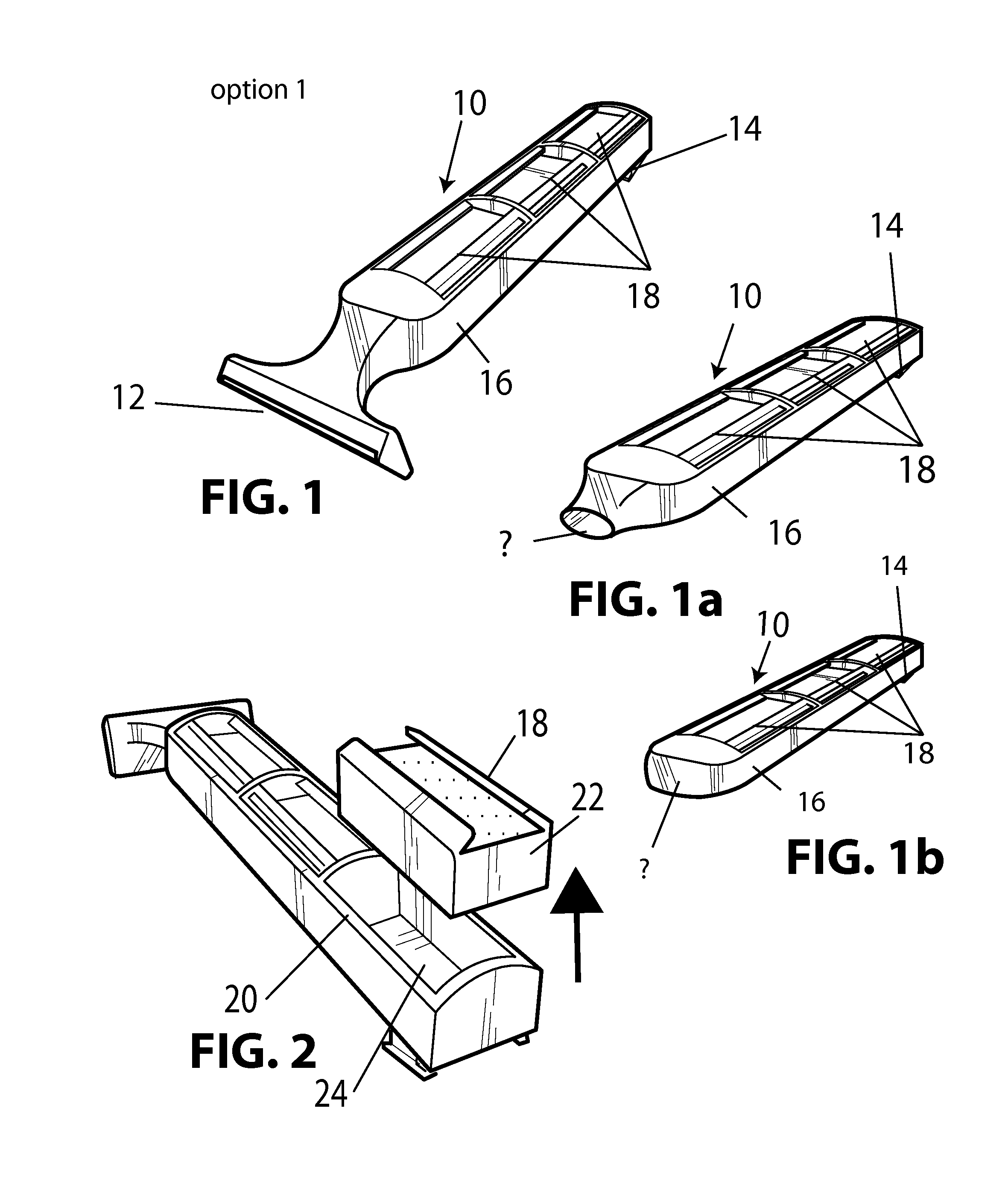

Skin Care And Shaving Cartridge System

InactiveUS20140033537A1Easily appliedEfficient use ofBrushesMetal working apparatusLarge porePre and post

A skin care and shaving system is provided comprising disposable razor cartridge with one or more blades, skin engaging applicator member made of sponge like material and a handle for holding. The sponge like material includes small and large pore sponge and also foam pad which helps in applying all kinds of skin shaving enhancer such as shaving cream, lotion, gel, moisturizer during pre and post shave. Further, in another aspect of the present invention, it is provided a skin enhancer cartridge comprising a handle and a skin engaging applicator member without and razor blades attached to the system. The product of the present invention is a disposable one wherein the whole shaving system is disposable or in some cases the handle of the cartridge can be reused.

Owner:KUMAR SELVA

Anti-blocking coating for pressure sensitive adhesives using cellulose acetate butyrate

InactiveUS6083630AEasily appliedAvoid blockageSynthetic resin layered productsCellulosic plastic layered productsPressure sensitiveHot-melt adhesive

A composition comprising a hot melt adhesive; and a coating for the adhesive comprising cellulose acetate butyrate, wherein the cellulose acetate butyrate is coated on the hot melt adhesive, and a method to prevent blocking of hot melt adhesives comprising coating cellulose acetate butyrate on at least a portion of the surface of a hot melt adhesive.

Owner:EASTMAN CHEM CO

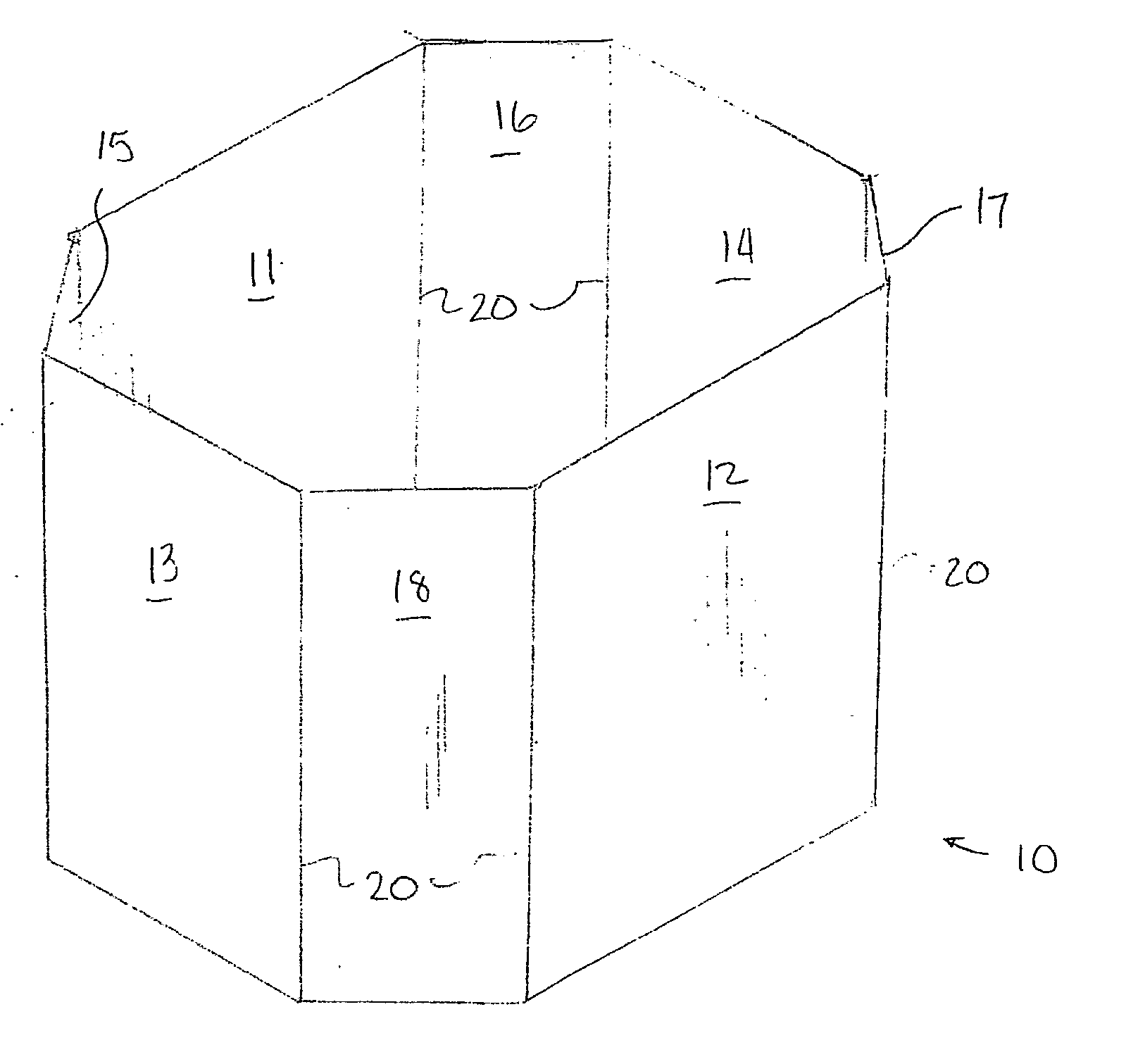

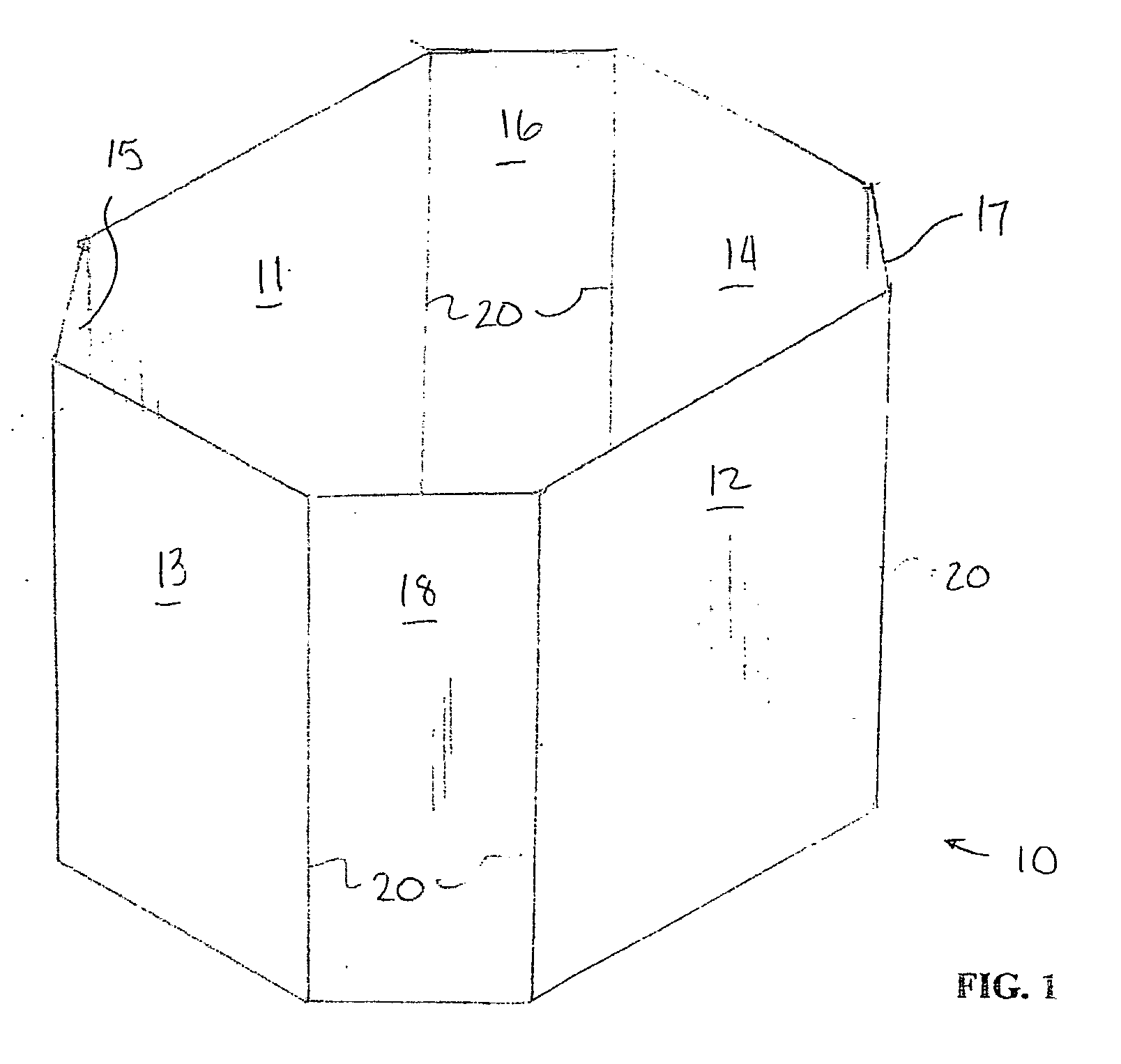

Octagonal bulk bin with self-locking gusset-fold bottom flaps

ActiveUS20070051783A1Reduce widthEasily appliedPaper/cardboardOther accessoriesEngineeringSelf locking

An octagonal bulk bin has sidewalls, end walls and diagonal corner panels interposed between adjacent sidewalls and end walls. Bottom flaps are foldably joined to a bottom edge of the sidewalls, end walls, and diagonal corner panels, and gusset panels connect adjacent side edges of the bottom flaps, facilitating set up of the bulk bin and spacing flap cuts from the corners of the bin to minimize or eliminate initiation of tears in the vertical corners of the bin. A plastic pallet tray has an upstanding lip around its periphery, shaped and sized to closely receive the bottom end of the octagonal bin to reinforce the bottom end and facilitate handling of the bin.

Owner:INT PAPER CO

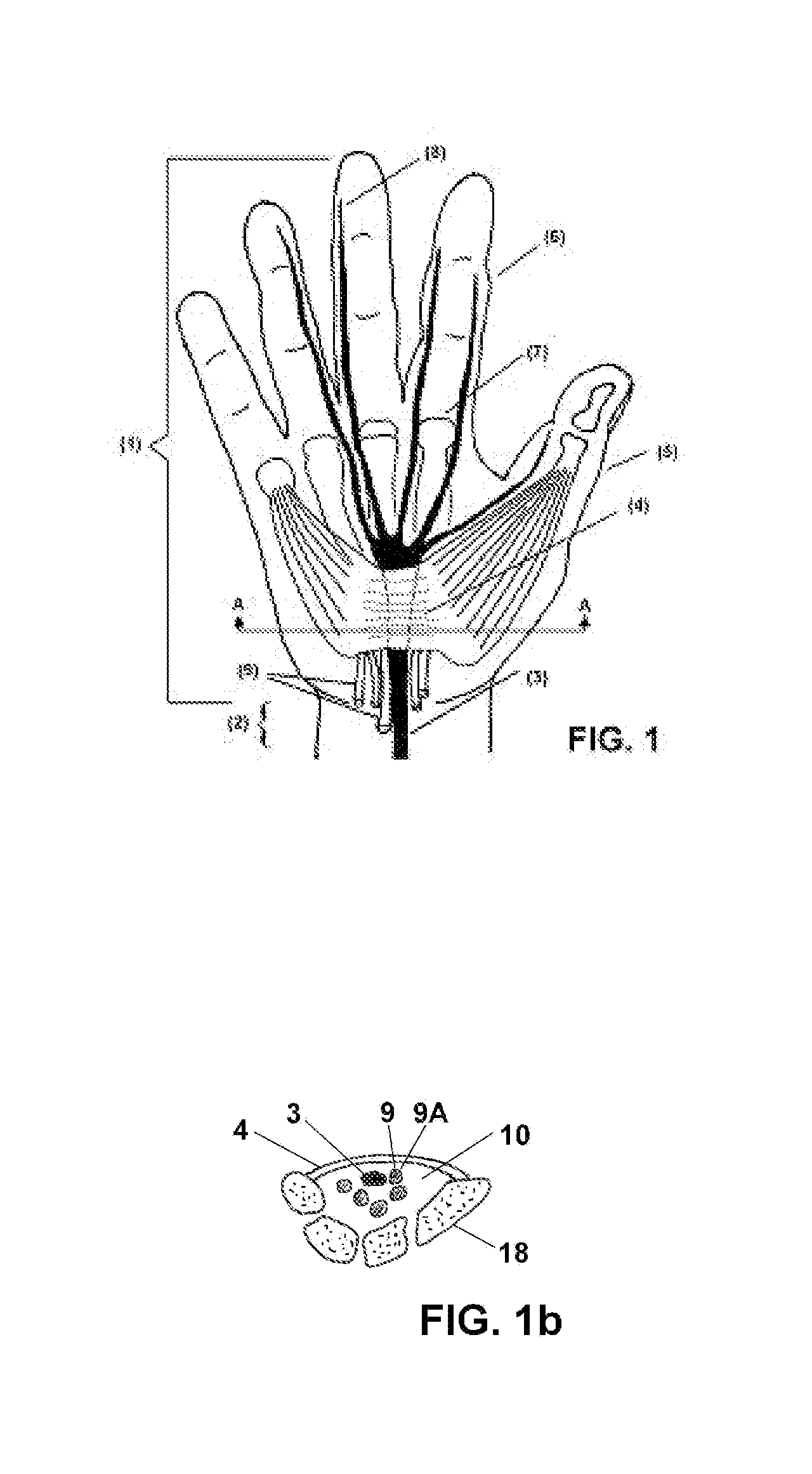

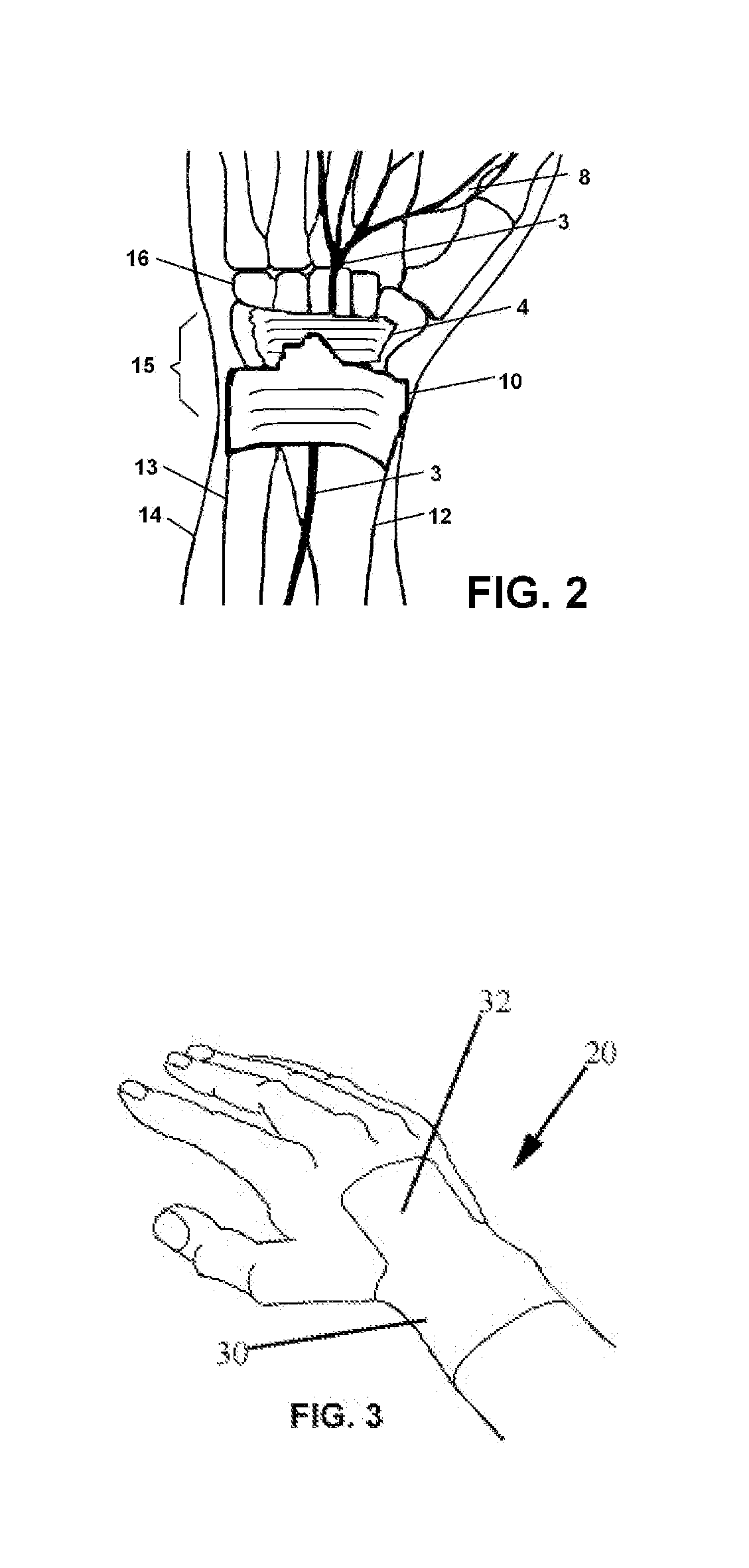

Adhesive Wrist Support System

InactiveUS20130218060A1Light weightEasily appliedNon-surgical orthopedic devicesRange of motionMedian nerve

A support system for treatment of repetitive stress injuries. The support system uses a support layer formed from a thin, flexible, stretch resistant material. An adhesive is used that has a high shear strength to prevent the support layer from slipping when applied to the patient. The adhesive loses considerable adhesion as temperatures approach 125 degrees Fahrenheit. This allows the support system to be easily removed at temperatures within the comfort range of the user by soaking in hot water or use of a hair dryer. The system is applied to a wrist or other injury by securing around the wrist. A second portion of the support layer extends up to a portion of the back of the wrist. The user is able to move and flex the wrist through the full range of motion, however with a dampening effect which promotes neutral wrist postures and minimizes accumulative irridation to the median nerve.

Owner:BUSHBY DONALD P

Flame resistant matelasse fabrics

InactiveUS20070077839A1Easily appliedReduce level of flammabilityWarp knittingMulti-ply fabricsWoven fabricCushion

The invention relates to the use of a flame resistant three-layer double-knit or woven fabric, also know as a matelasse fabric. The top layer is of standard non-flame resistant face yarn, the middle layer is of flame resistant filler yarn and the bottom layer is of flame resistant core wrap spun yarn. This flame resistant matelasse fabric can be used to protect a mattress, foundation, mattress pad, pillow, comforter, upholstery cushion, pillow, office panel, transportation seat or any other article requiring flame resistant protection. In this invention, a matelasse fabric is formed by circular double knitting or weaving a flame resistant core spun yarn into the bottom portion of the fabric, utilizing a heavy cotton count flame resistant filler yarns for the middle layer and using conventional non-flame resistant yarns for the top layer. The invention has particular applicability in the formation of flame resistant mattresses and foundations that require passage of large open flame tests such as CPSC's 16 CFR part 1633, California's Test Bulletin 603 and Test Bulletin 129 and in the formation of flame resistant upholstered furniture that requires passage of California's Test Bulletin 133 or British Standard 5852 using the crib 5 ignition source or higher.

Owner:MCKINNON LAND

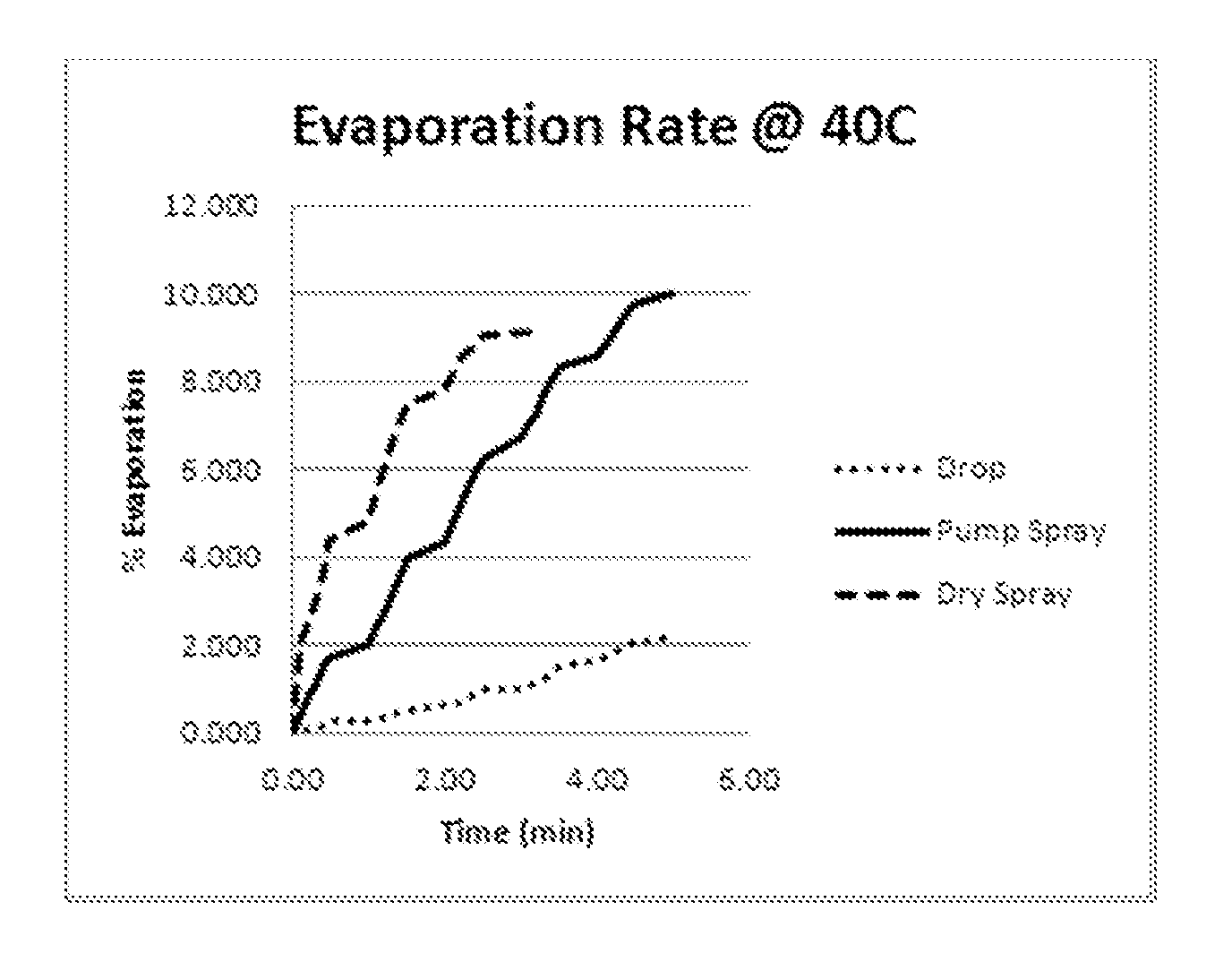

Temperature Management Composition

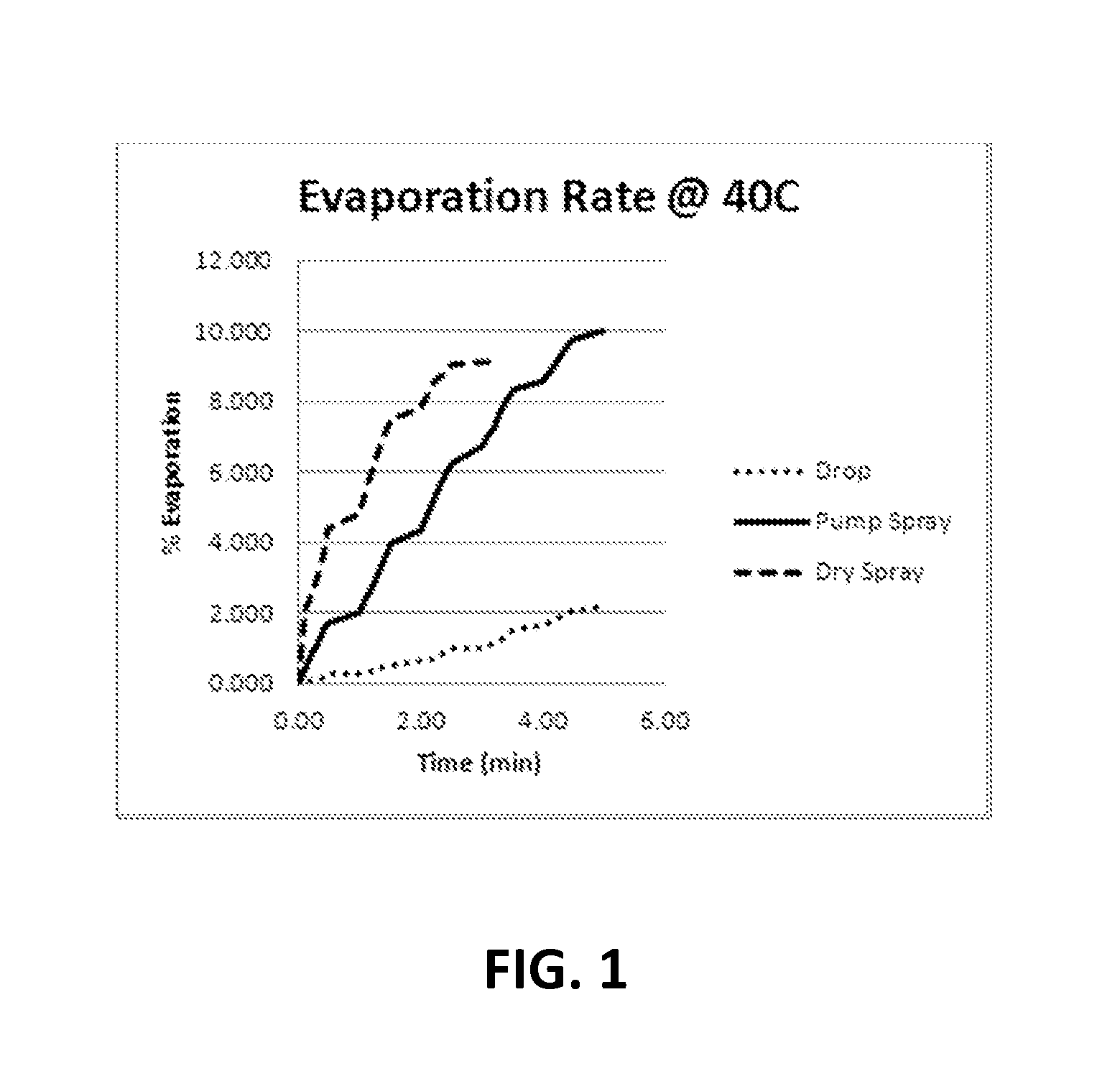

ActiveUS20120276033A1Reduces symptomEasily appliedCosmetic preparationsToilet preparationsSingle phaseAlcohol

The present invention relates to a single phase temperature management composition. The composition includes from 0.01% to 10% by weight of a neurosensory agent and from 0.01% to 30% by weight of an antiperspirant component. The composition also includes a polar carrier where the polar carrier includes water and monohydric alcohol. The ratio of water to monohydric alcohol ranges from 0.0625:1 to 1.5:1. The compositions of the invention have a viscosity at room temperature of less than 2500 centipoise.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Diagnosis system of deficient and forceful pulse

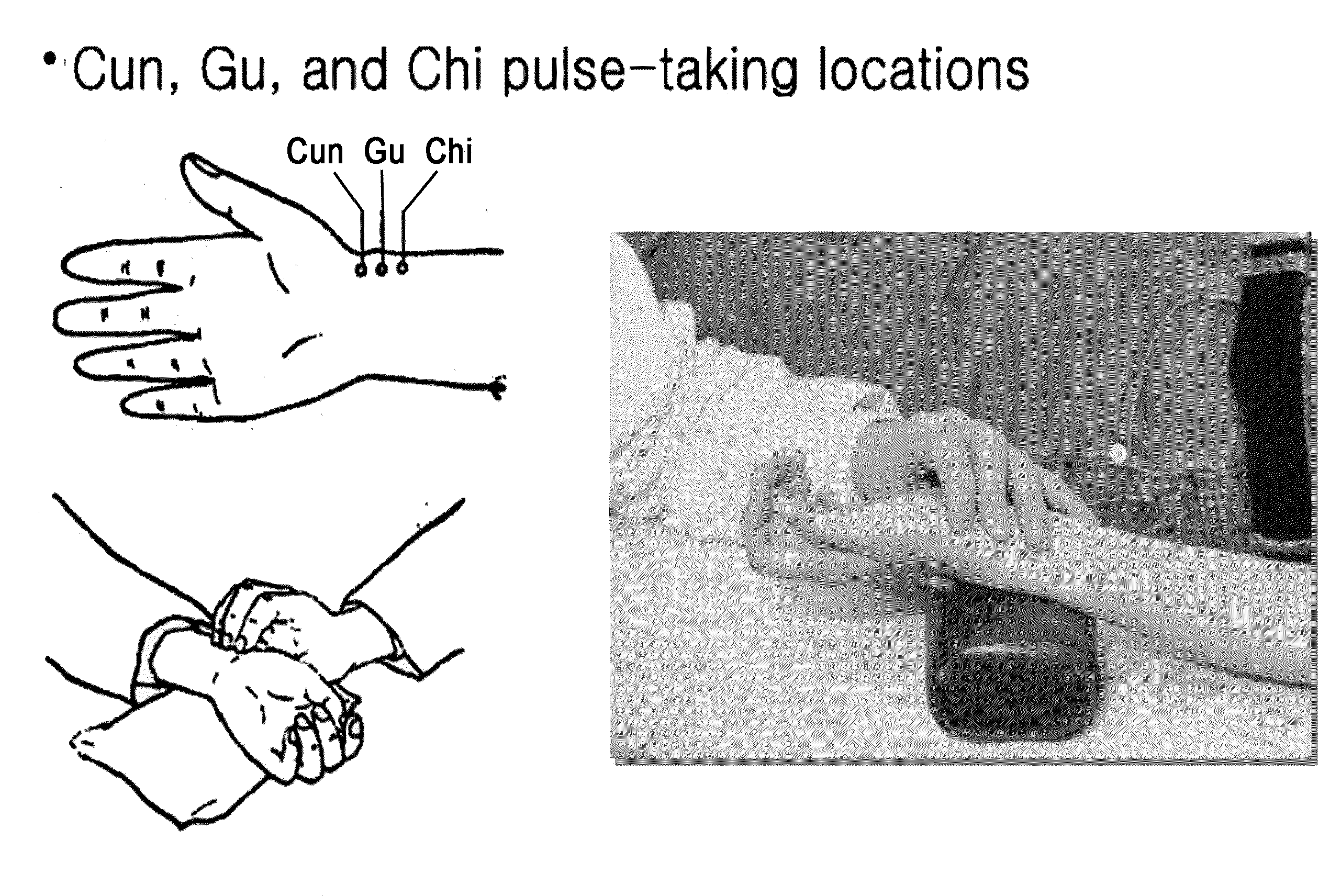

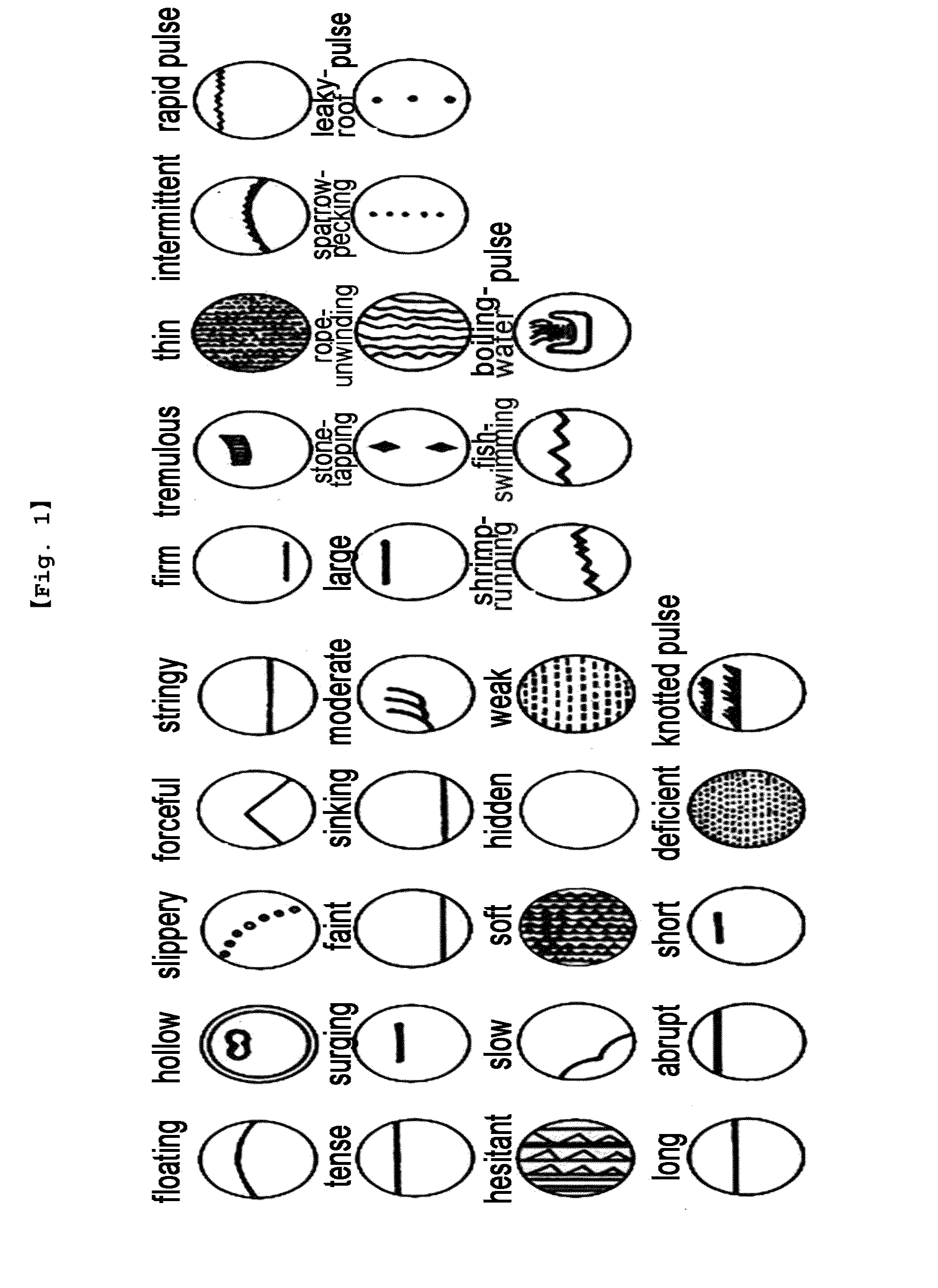

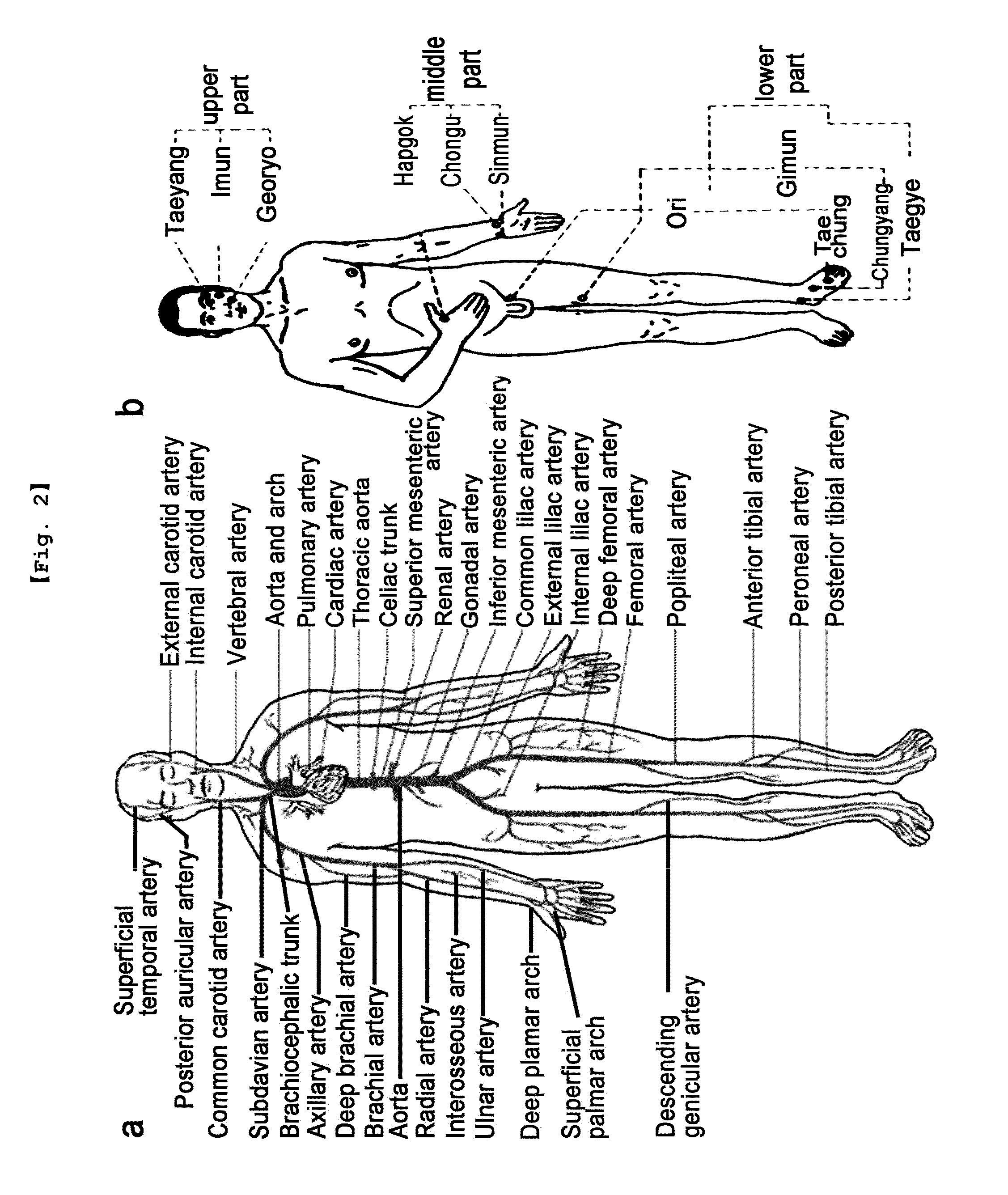

InactiveUS20100022895A1Easily appliedShorten periodEvaluation of blood vesselsCatheterPhysicsPulse taking

Disclosed herein is a system for diagnosing a deficient pulse and an forceful pulse. The system includes a pulse diagnotic device, a deficient pulse and forceful pulse determining device, and an output device. The pulse diagnotic device measures pulse condition information at an examinee's Cun (˜\f˜) Gu (H), and Chi (,R) pulse-taking locations on his or her wrist using one or more pulse-taking sensors. The deficient pulse and forceful pulse determining device is operably connected to the pulse diagnotic device, analyzes the pulse pressure information measured by the pulse diagnotic device, calculates a quantified deficiency / forceful coefficient, and determines whether a pulse of interest is a deficient pulse or an forceful pulse. The output device is connected to the determining device and displays results of the determination.

Owner:KOREA INST OF ORIENTAL MEDICINE

Food and condiment container

InactiveUS20110309096A1Easily appliedEfficient use ofDispensing apparatusLarge containersSyringeFastener

A combination food and condiment container comprising: a food container with an open top; a condiment container designed so that manual pressure will expel condiment from it; a condiment delivery tube; and a sanitary seal. One end of the tube is attached through a wall of the condiment container. The other end of the tube is positioned for delivery of the condiment to the food inside the food container. The sanitary seal is removably attached to the other end of the tube. The tube is bendable and rotatable. The food and condiment containers are attached together a flange on the condiment container and a mating slide on the food container; contact adhesive; a strip of hook and loop fastener; etc. The condiment container may be a flexible pouch or a syringe. Alternatively, the flexible pouch could be surrounded by an enclosure and a linkage provided so that pressure can be applied from outside of the enclosure to the pouch inside the enclosure. A hole may also be provided through a wall of the food container so that the tube may be passed through the hole.

Owner:JONES DALE M

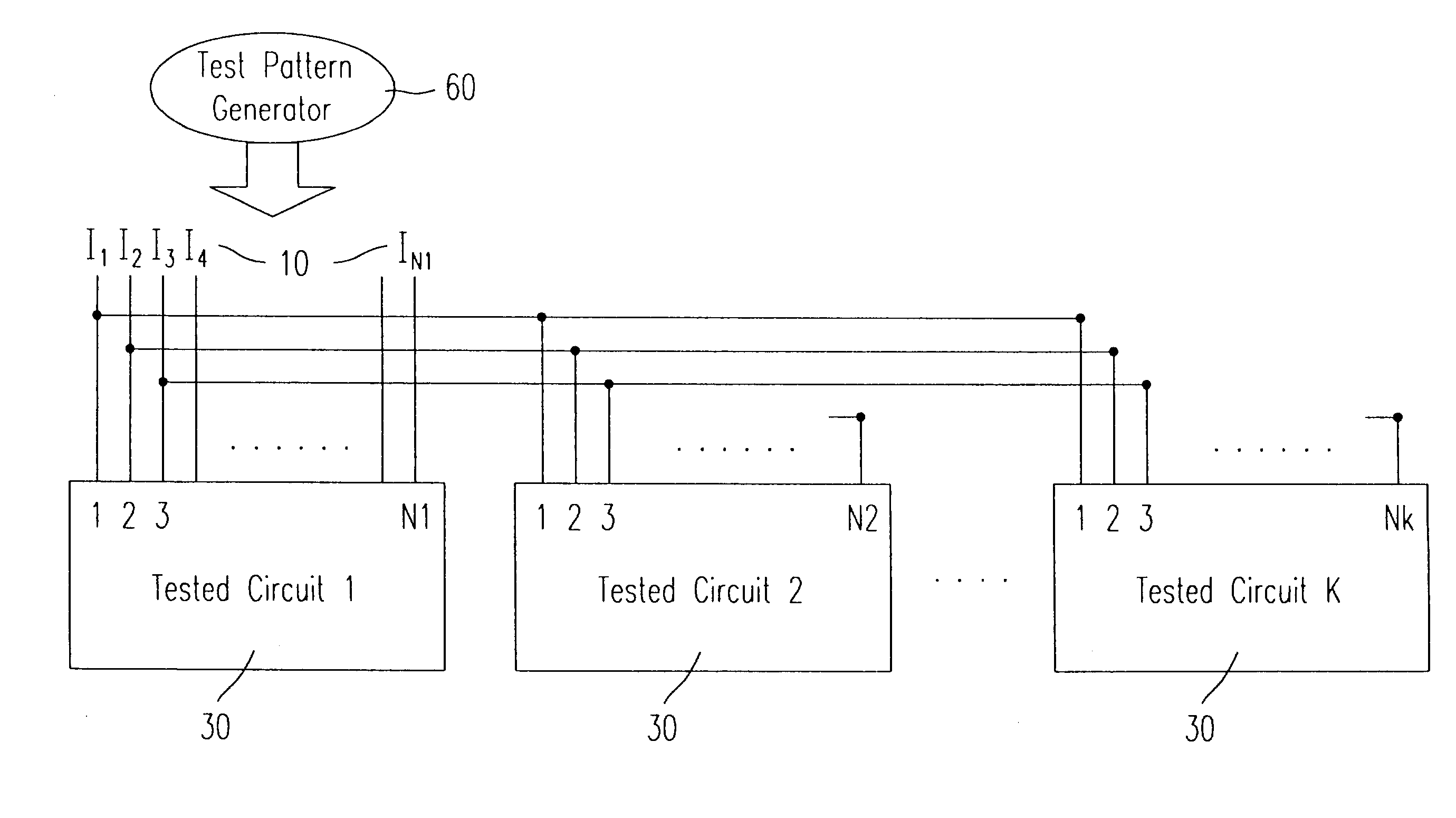

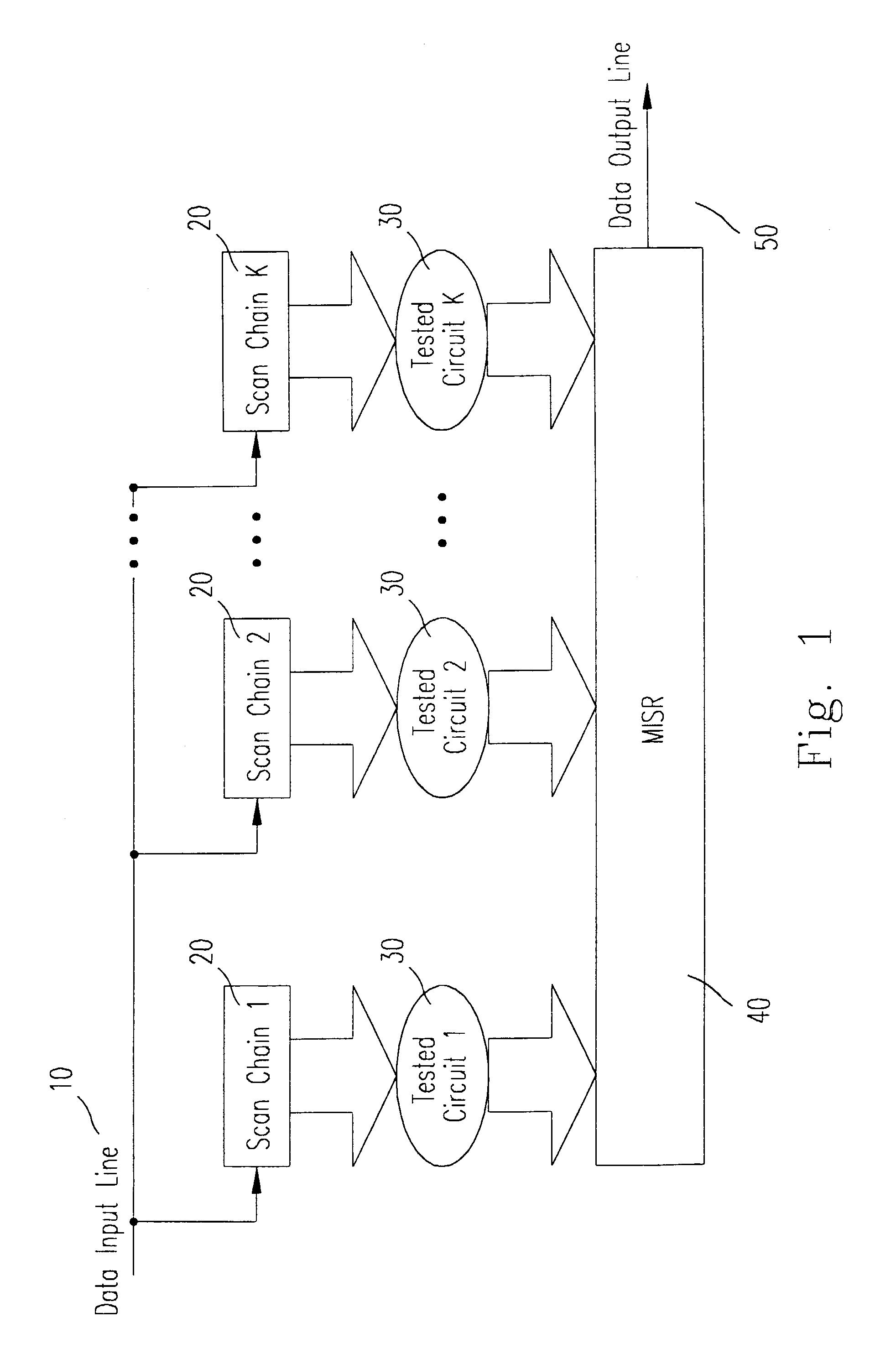

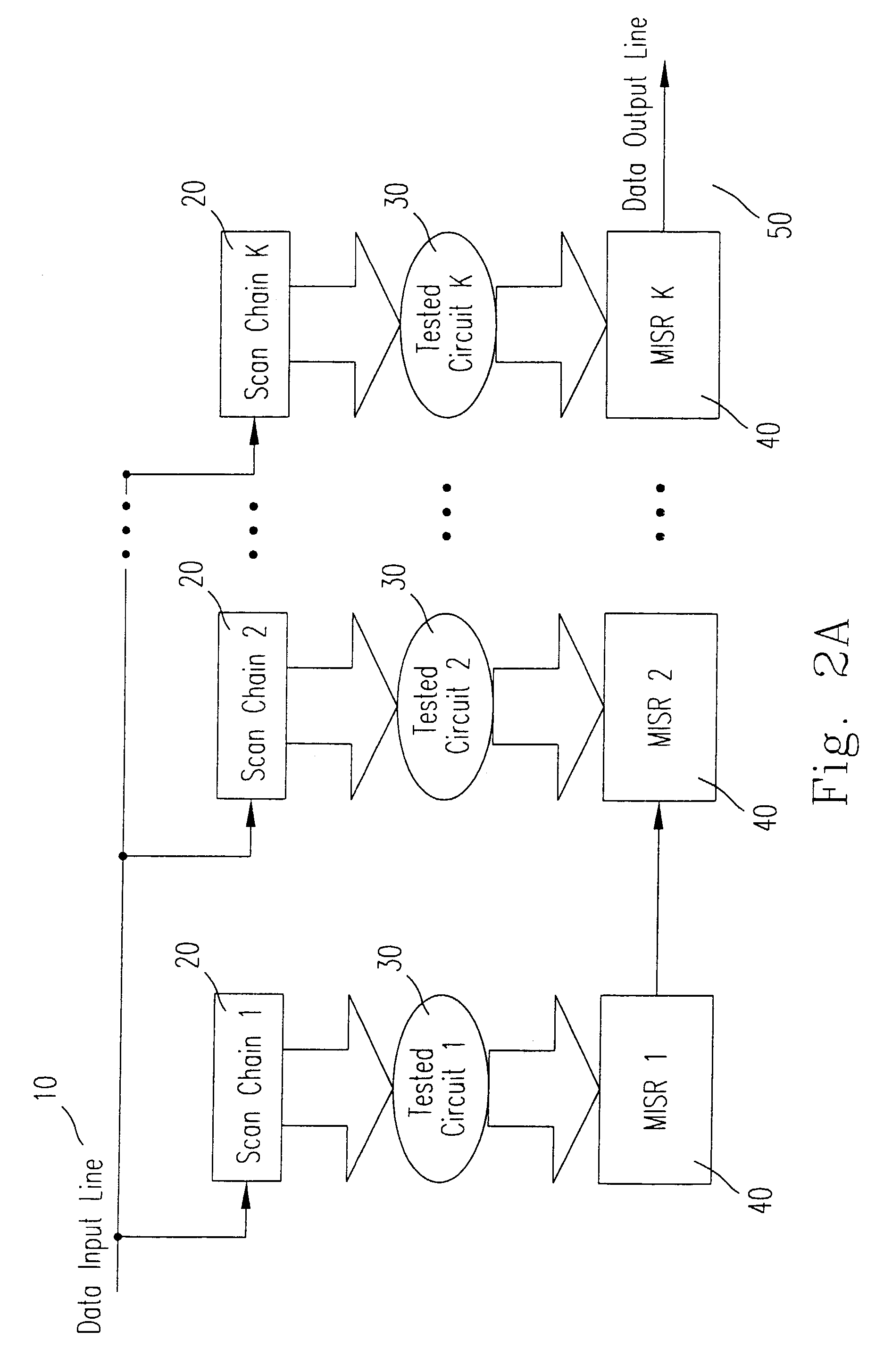

Test method and architecture for circuits having inputs

InactiveUS7159161B2Easily appliedEfficient use ofElectronic circuit testingError detection/correctionTested timeElectricity

A test method for a plurality of circuits respectively having inputs for greatly reducing the required test time and the control circuit complexity is provided. The method includes steps of providing a set of test patterns for detecting a characteristic of the circuits, providing a common data line, and electrically connecting the circuit inputs to the common data line so that the test pattern can be broadcasted to the circuits through the common data line. The present invention also provides an architecture for implementing such method.

Owner:NAT SCI COUNCIL

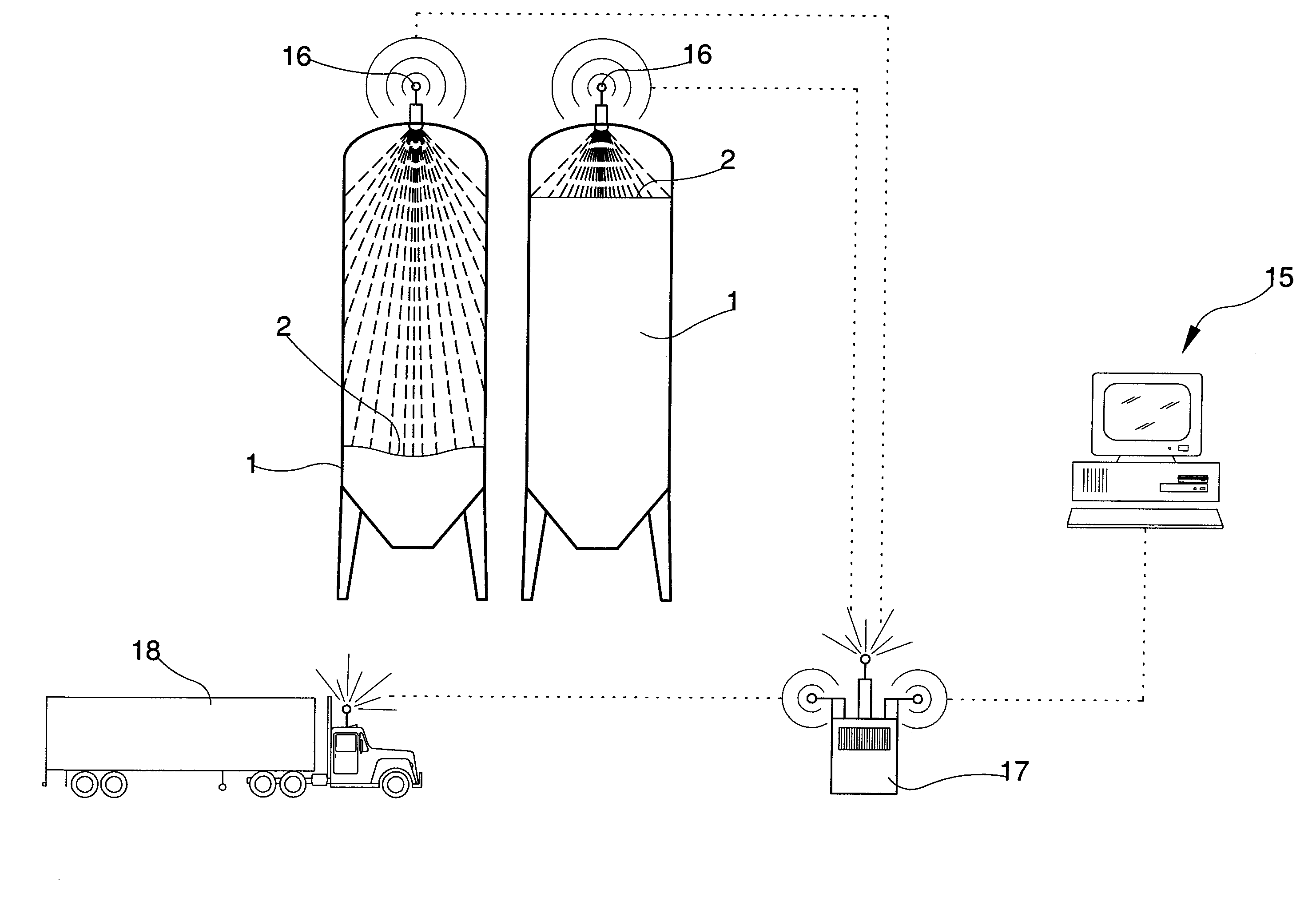

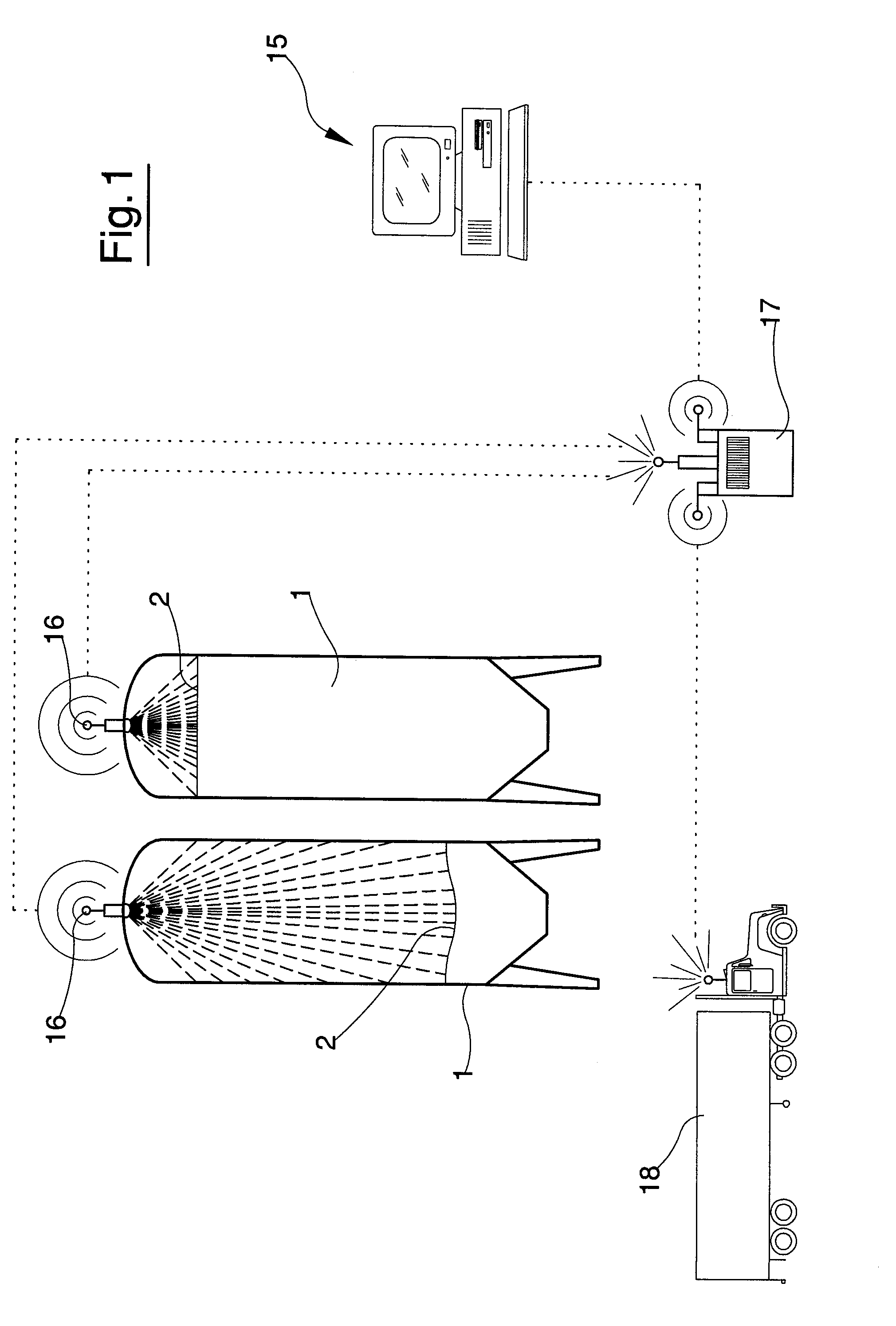

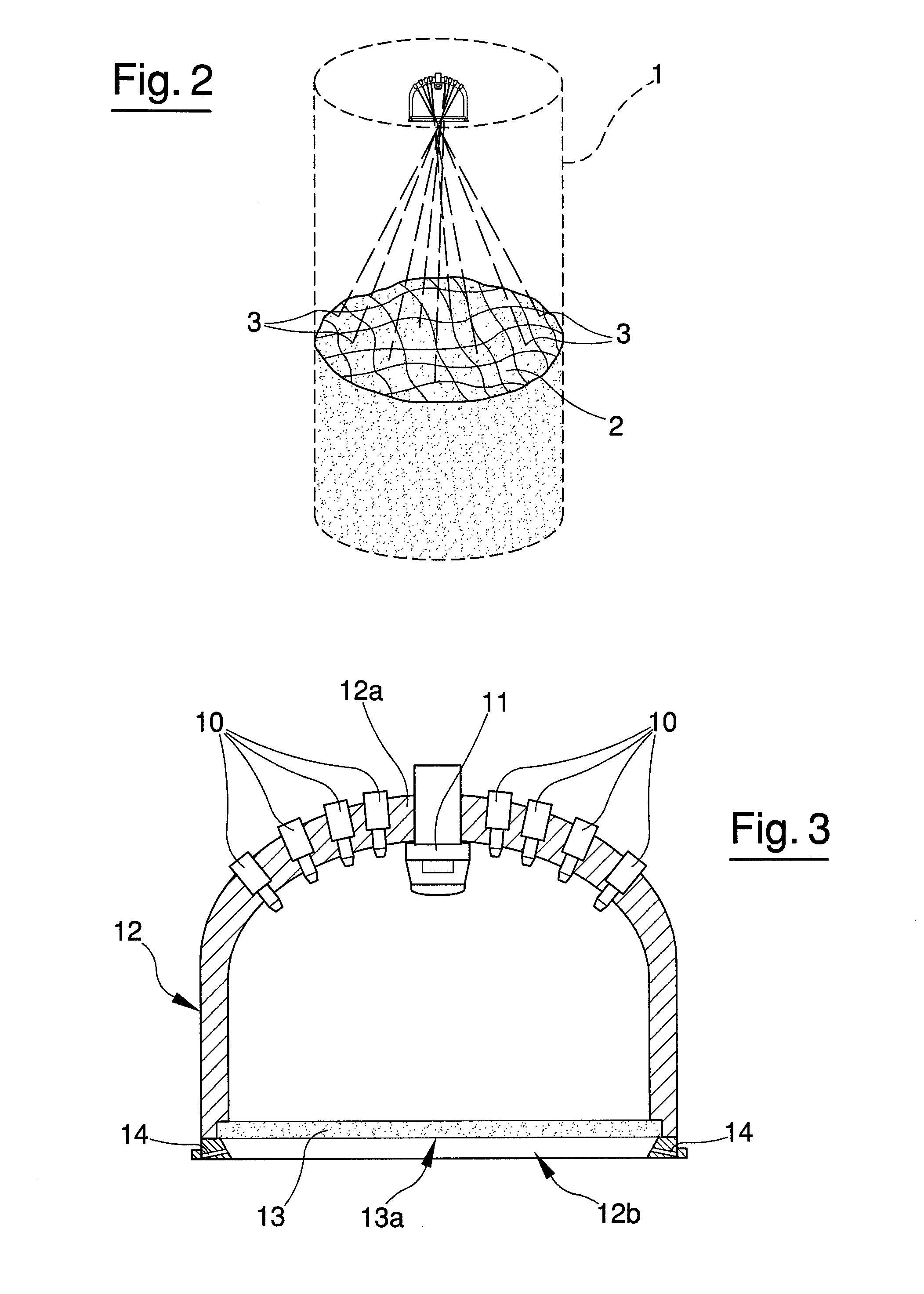

Process and device for controlling a filling level of silos containing loose materials

InactiveUS20080309948A1Easily appliedSimple maintenanceUsing optical meansLevel indicatorsLaser beamsElectric signal

The process comprises a stage of highlighting a plurality of light points of a free surface of the material contained in the silo, of detecting a position of each of the light points and obtaining electrical signals which are proportional to the detected position of each point, and processing the signals to obtain a virtual reproduction of the free surface of the material which when processed provide desired data. The device for realising the process comprises lasers, which project a laser beam towards the free surface of the material contained in the silo, an optical sensor which detects the position of the light points defined by each laser beam on the free surface, and a data processing system which processes the data relating to the position of the lasers, the inclination of the laser beams, and the detected positions of the light points in such a way as to construct a virtual free surface of the material.

Owner:WAM SPA

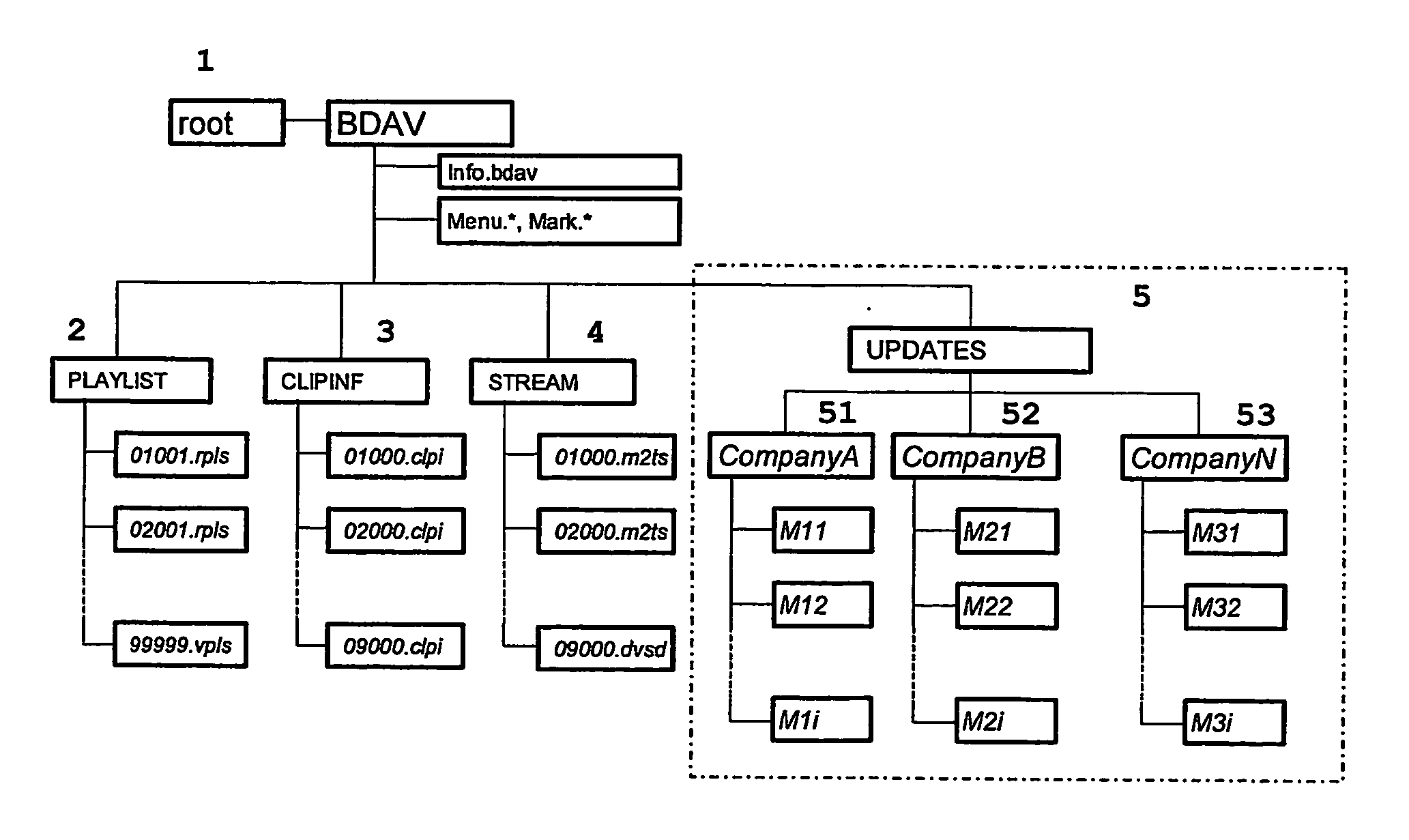

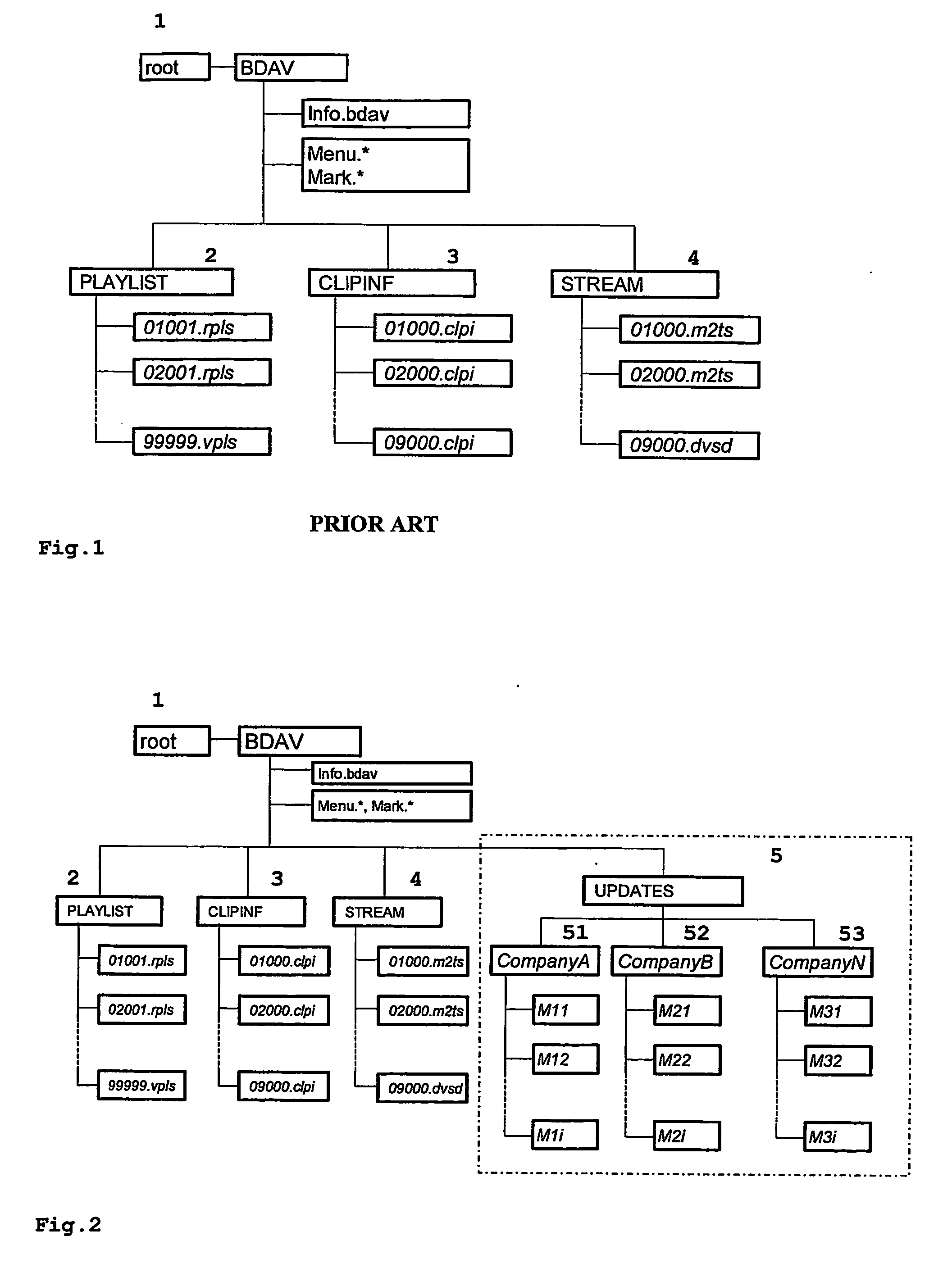

Removable Storage Medium for Audio-Visual Data

InactiveUS20070212026A1Easily obtainedEasily appliedColor television signals processingRecord information storageBlu-ray discDVD player

Playback devices, e.g. DVD players, for removable mass storage media used for the distribution of multimedia content contain a lot of firmware to control its functions. Typically, such firmware may be updated several times during the lifetime of the device. For playback devices that are already at a consumer's site and cannot be updated online, it is possible to update the firmware without using separate media, such as update-CDs, by storing firmware update data on removable storage media such as DVDs or Blu-ray discs that contain primarily audio-visual contents. Thus, it is possible to utilize unused storage space on e.g. optical discs, and to distribute and install firmware updates easily without requiring separate media or technical knowledge of the user.

Owner:THOMSON LICENSING SA

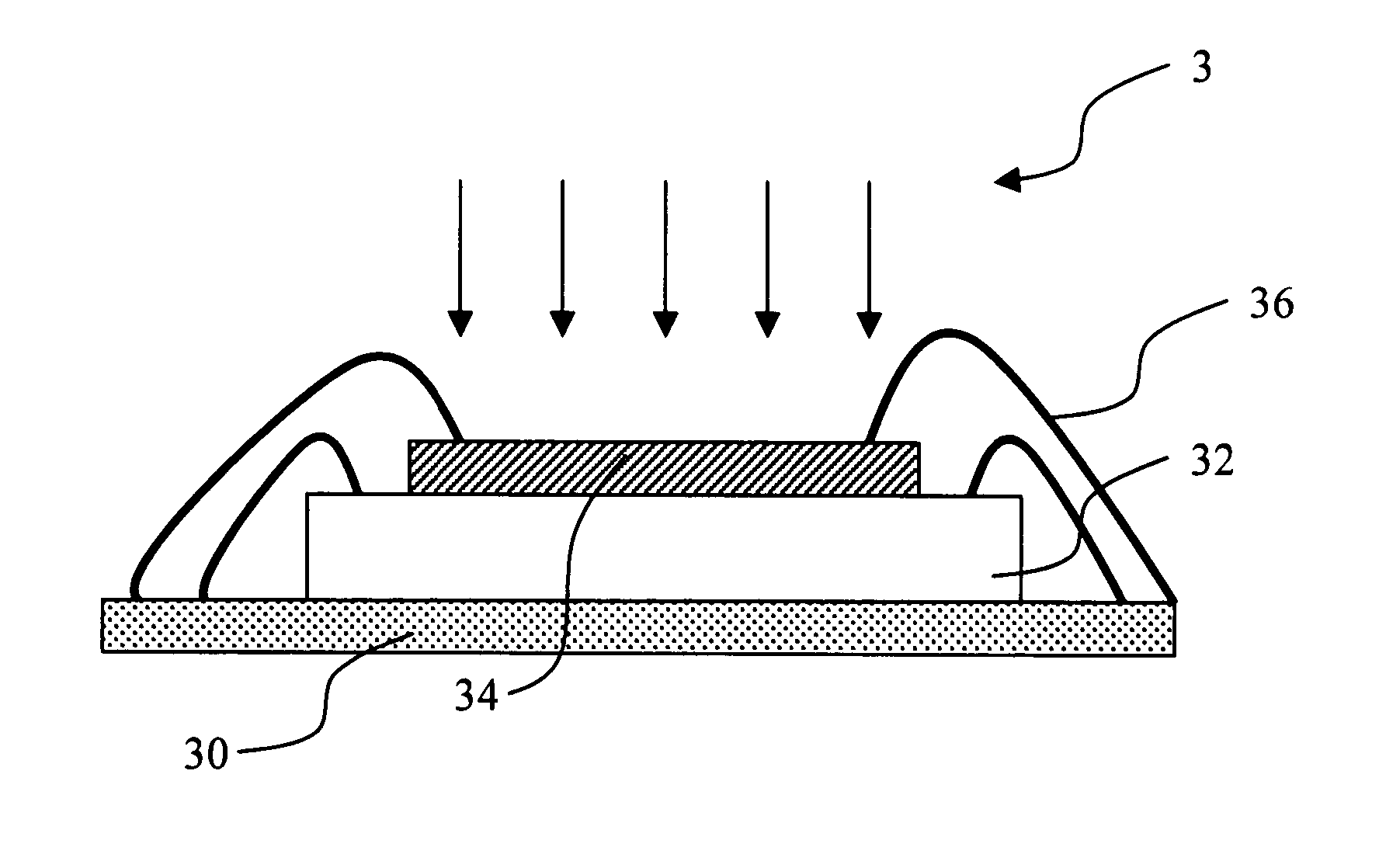

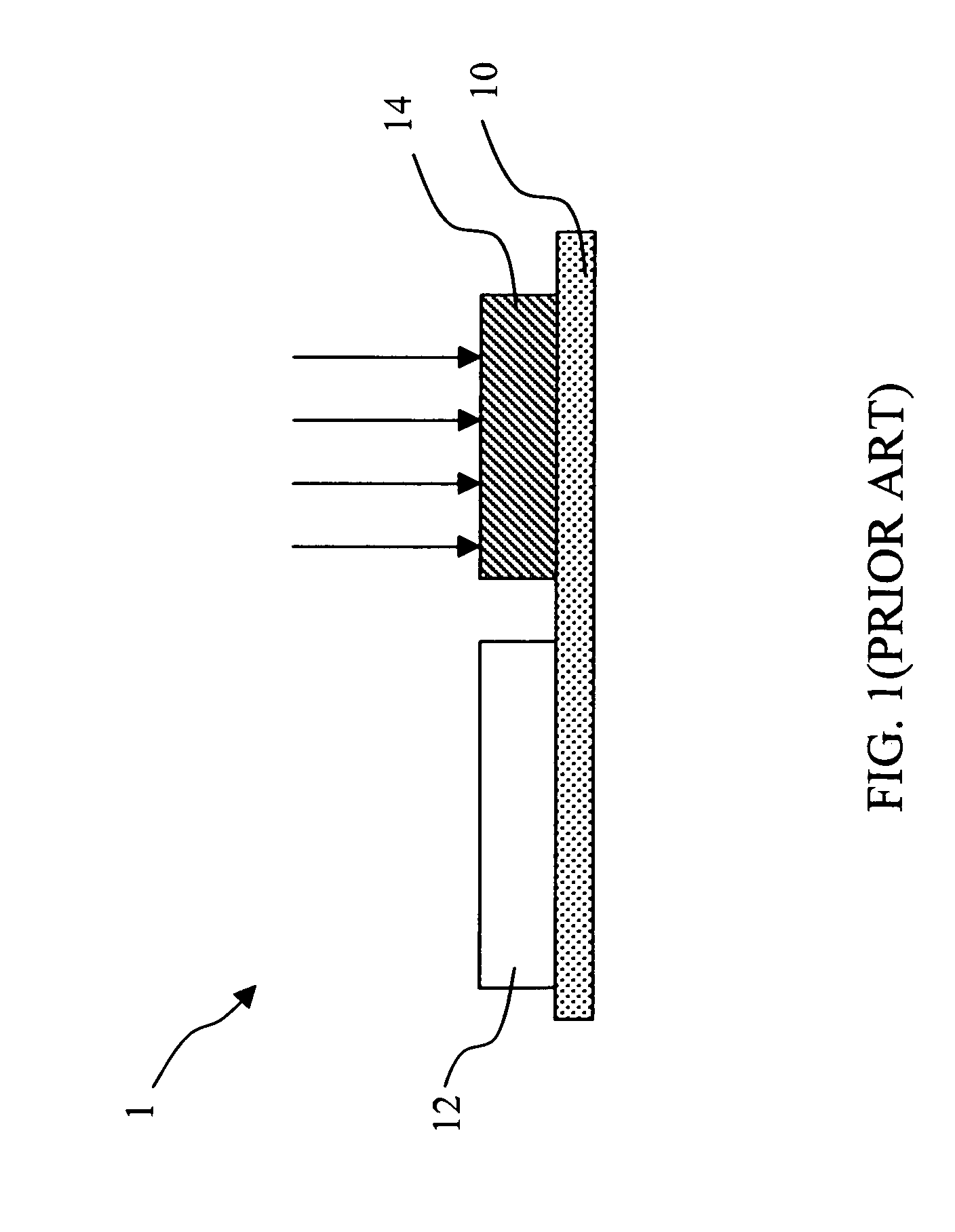

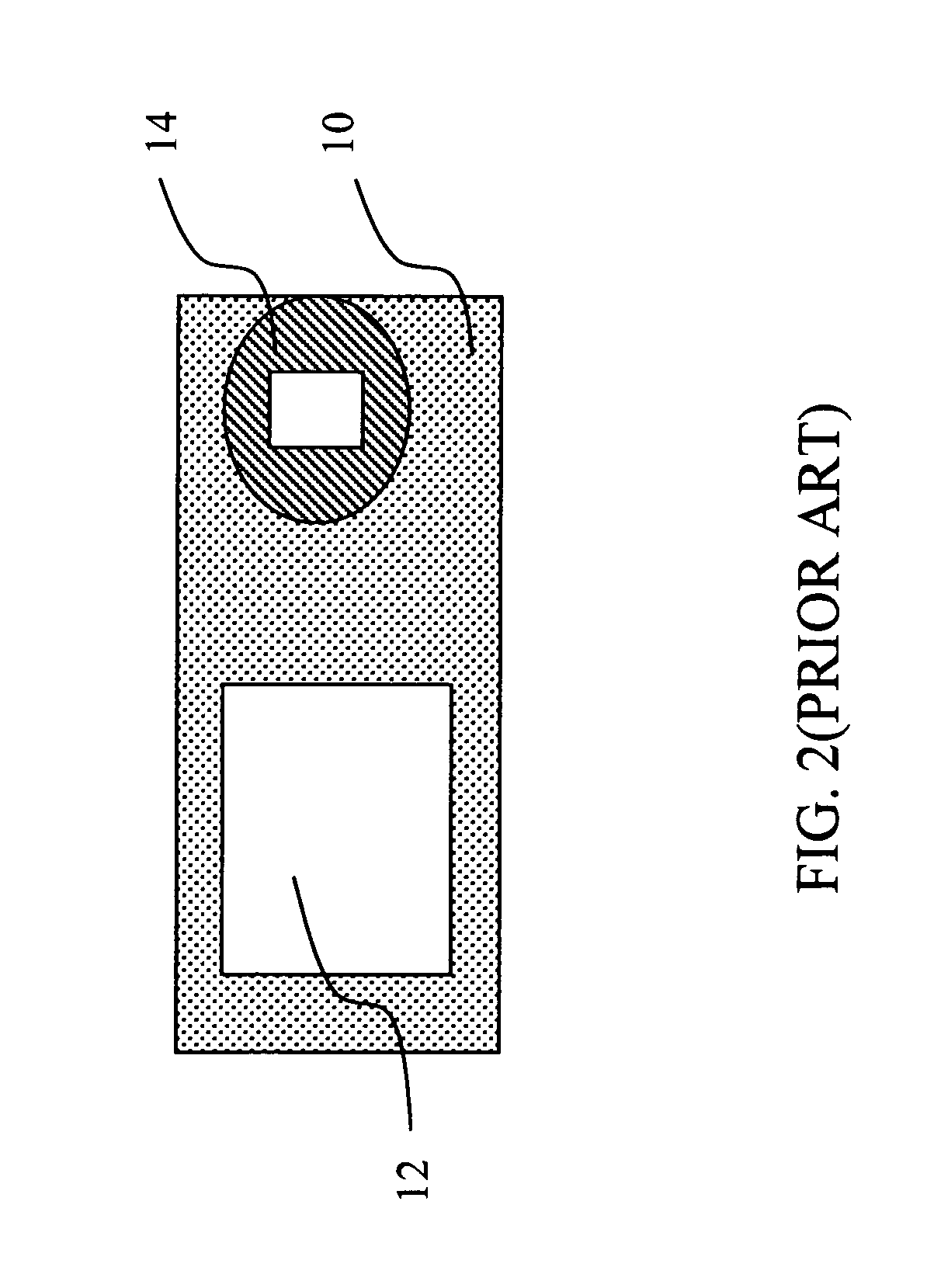

Package structure of a stack-type light-sensing element and package method thereof

InactiveUS20050247859A1Easily appliedReduce volumeSolid-state devicesMaterial analysis by optical meansElectronic circuitDisplay device

The present invention discloses a package structure of a stack-type light-sensing element and a package method thereof, wherein firstly, a substrate is provided; next, a signal-processing IC chip and a light-sensing chip are sequentially stacked above the substrate in bottom-up sequence; next, lead lines are used to electrically connect the substrate with the signal-processing IC chip and the light-sensing chip in order to form a unitary light-sensing element. The present invention has the advantages that light-sensor signals are directly processed and then output to a display device, and that the volume of a light-sensing element can be reduced to such an extent that it can be easily applied to miniature electronic products. In contrast with the conventional light-sensing element needing massive volume of electronic circuits to process signal and also needing minute and complicated assemblage, the present invention has superior novelty and futurity.

Owner:CLEAVAGE ENTERPRISE

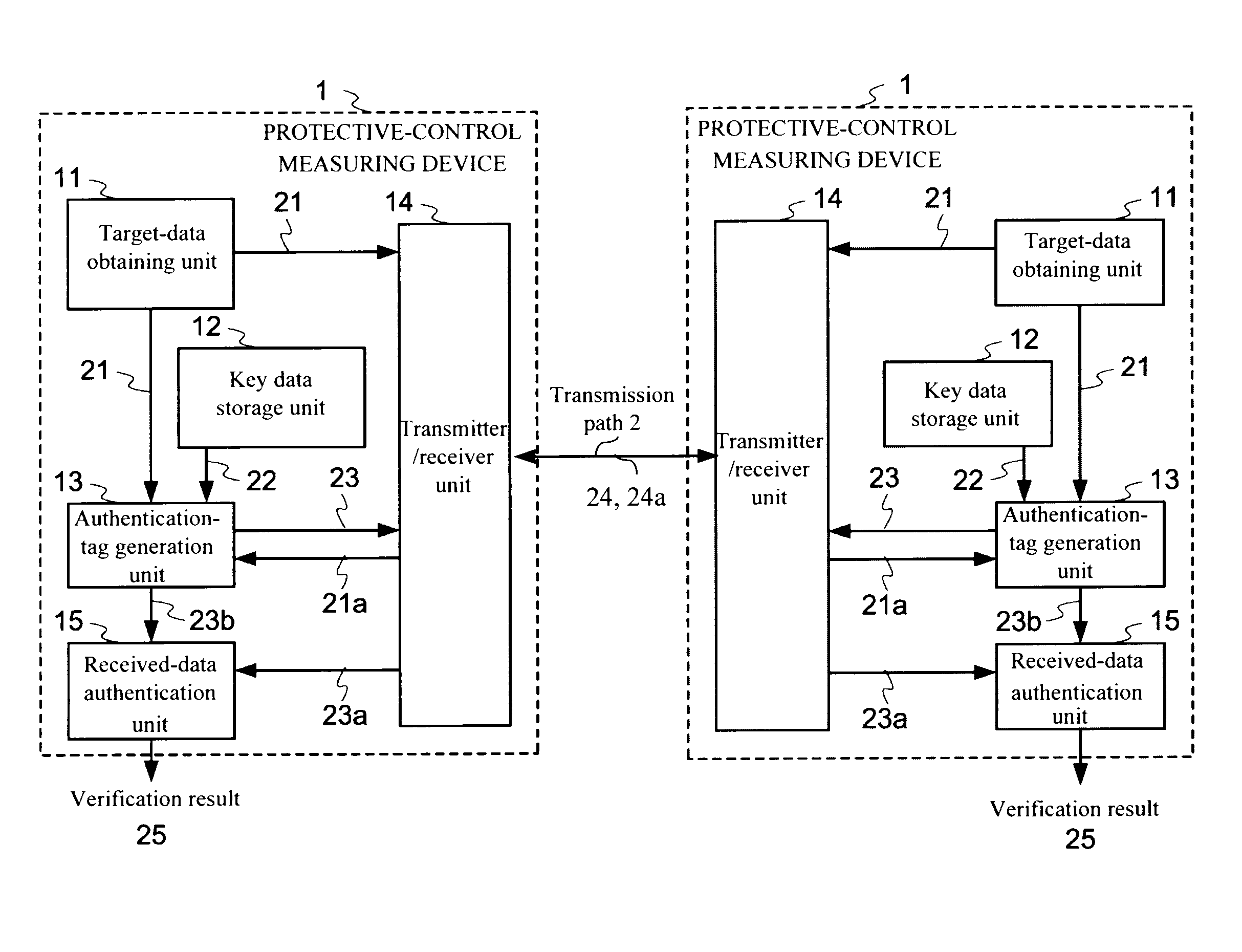

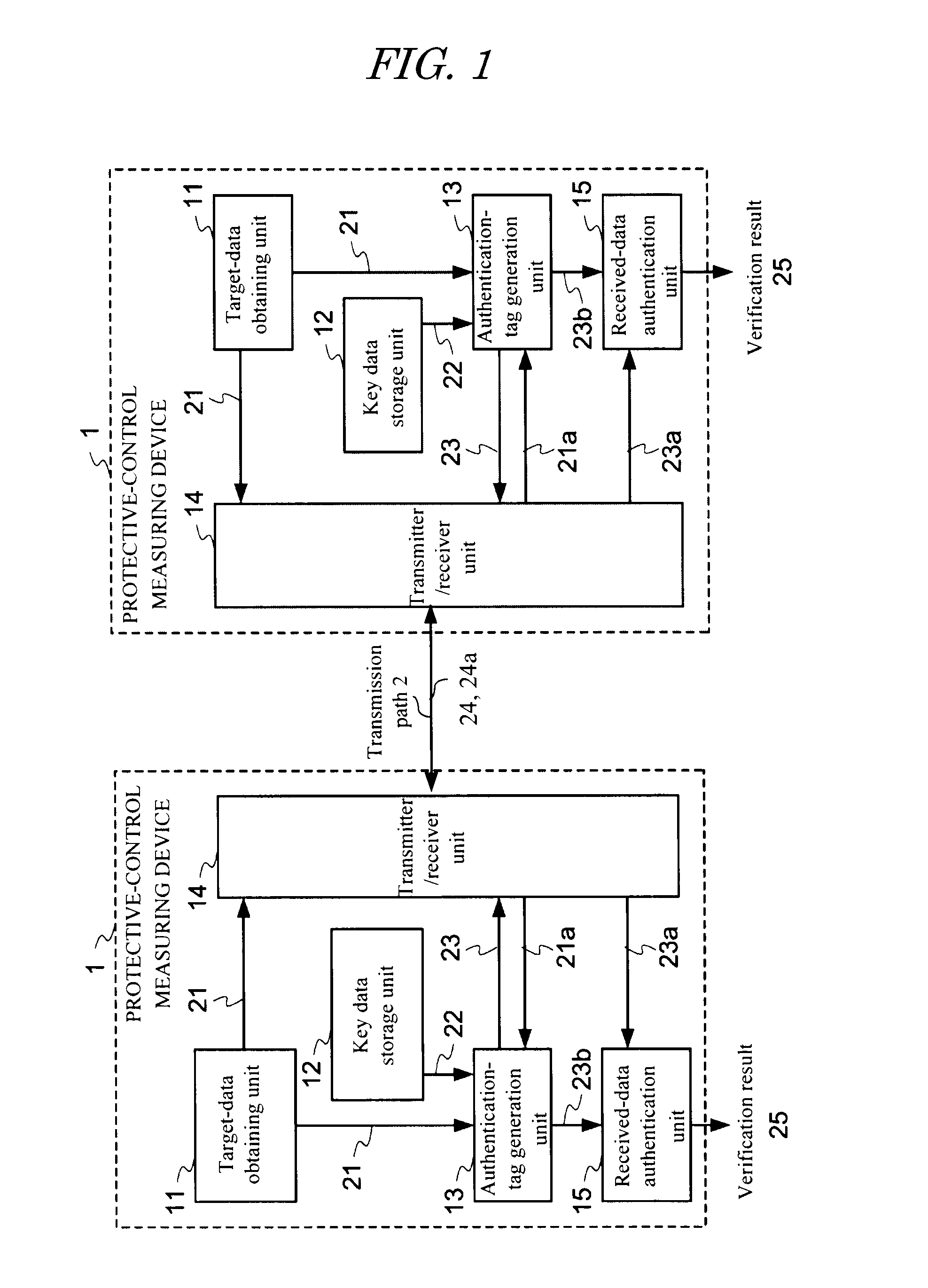

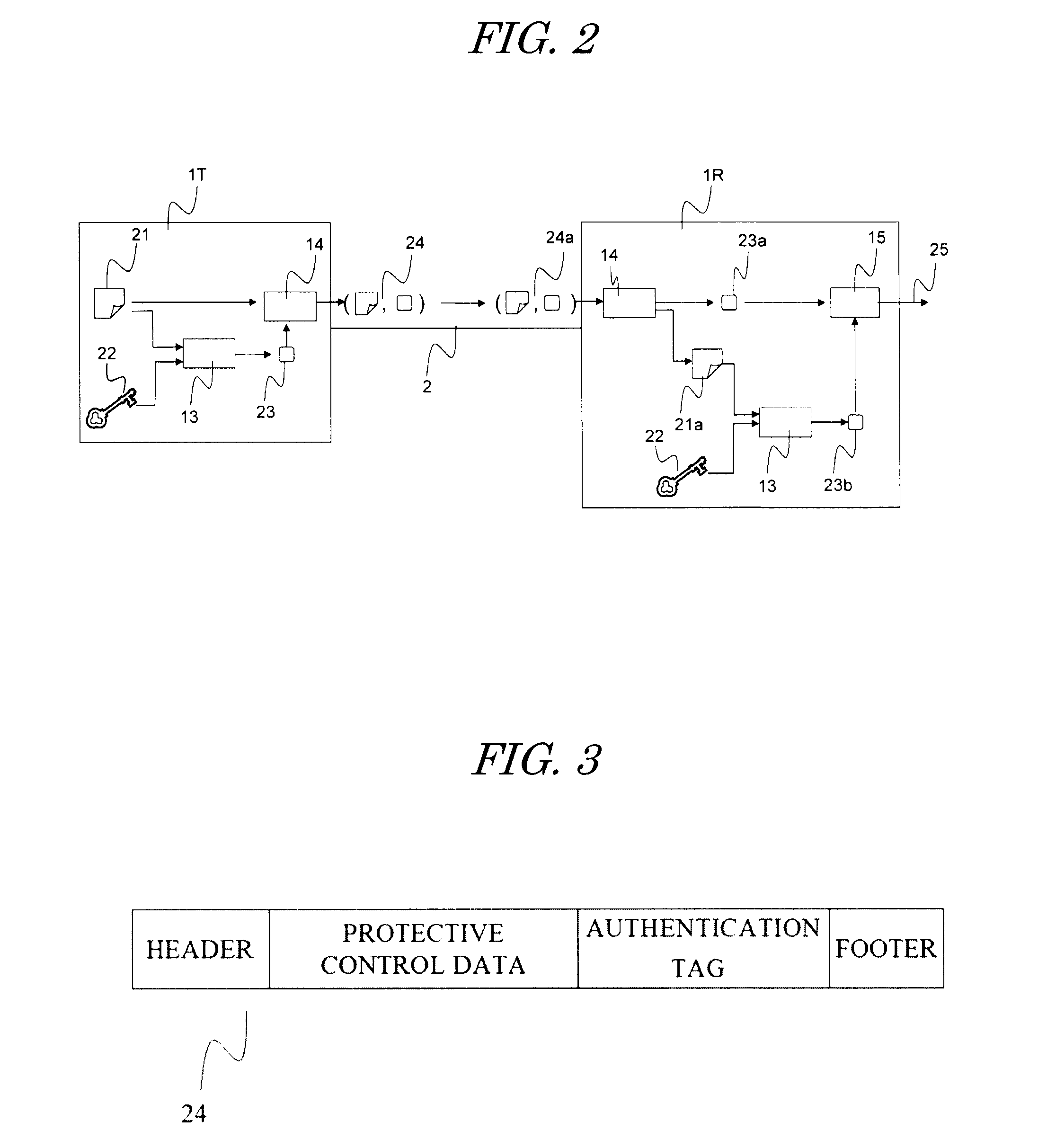

Protective-control measuring system and device and data transmission method

InactiveUS20120019355A1Easily appliedHighly secure and reliableElectric signal transmission systemsMultiple keys/algorithms usageData transmissionControl measure

According to one embodiment, when sending a transmission target main data 21, an authentication-tag generator unit 13 generates an authentication tag 23 by using a main data 21 and a key data 22 stored in a key-data storage unit 12. A transmitter / receiver unit 14 adds the authentication tag 23 to the main data 32 sends as a transmission data. When receiving the received data 24a, the transmitter / receiver unit 14 divides the received data into a main data 21a and an authentication tag 23a. The authentication-tag generator unit 13 generates an authentication tag 23b for comparison. A received-data authentication unit 15 determines whether or not those the received authentication tag 23a and the authentication tag for comparison 23b match with each other. A different key data is used every time upon the authentication-tag generation and use time of each key data during a set period is restricted.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV +1

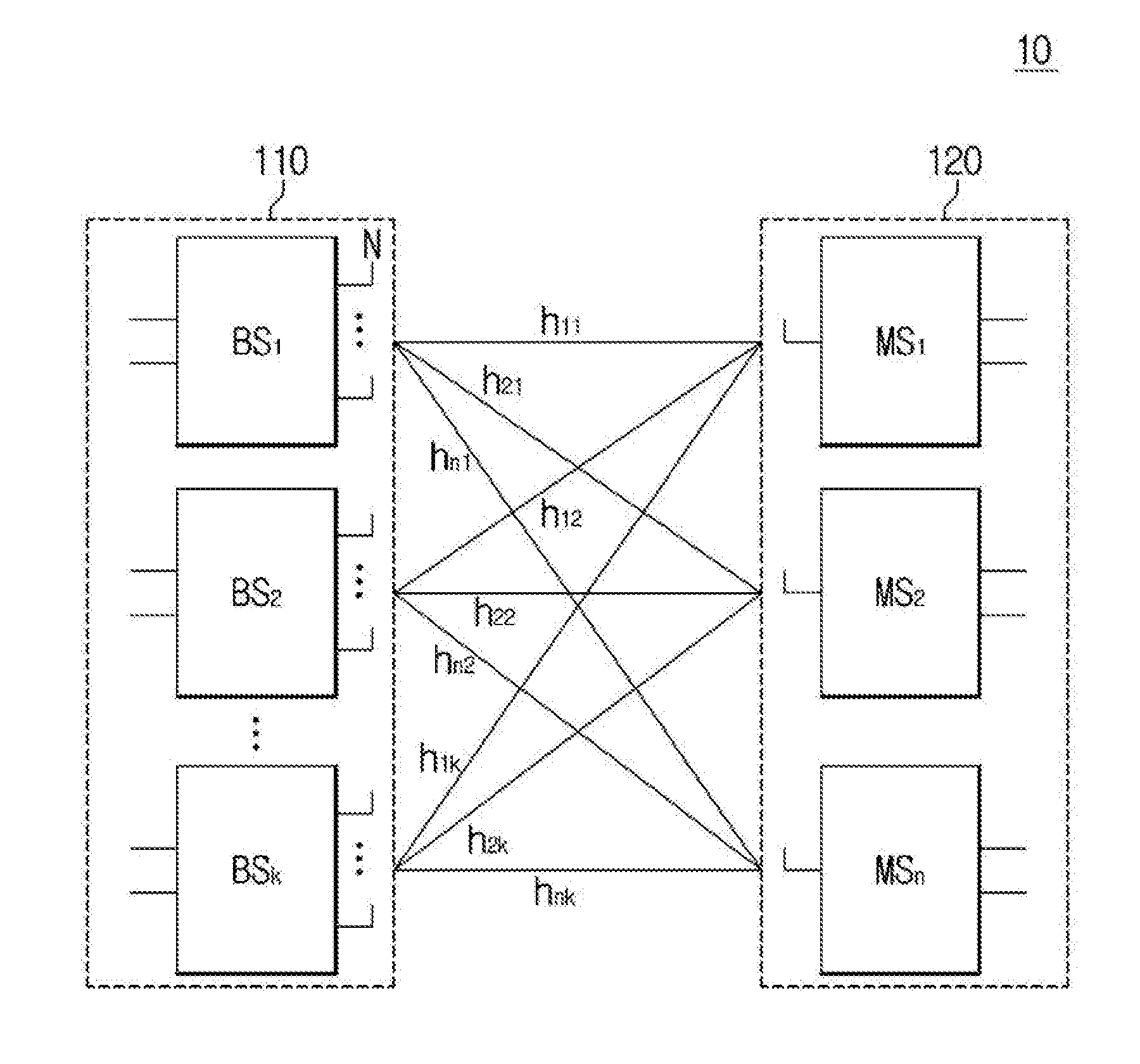

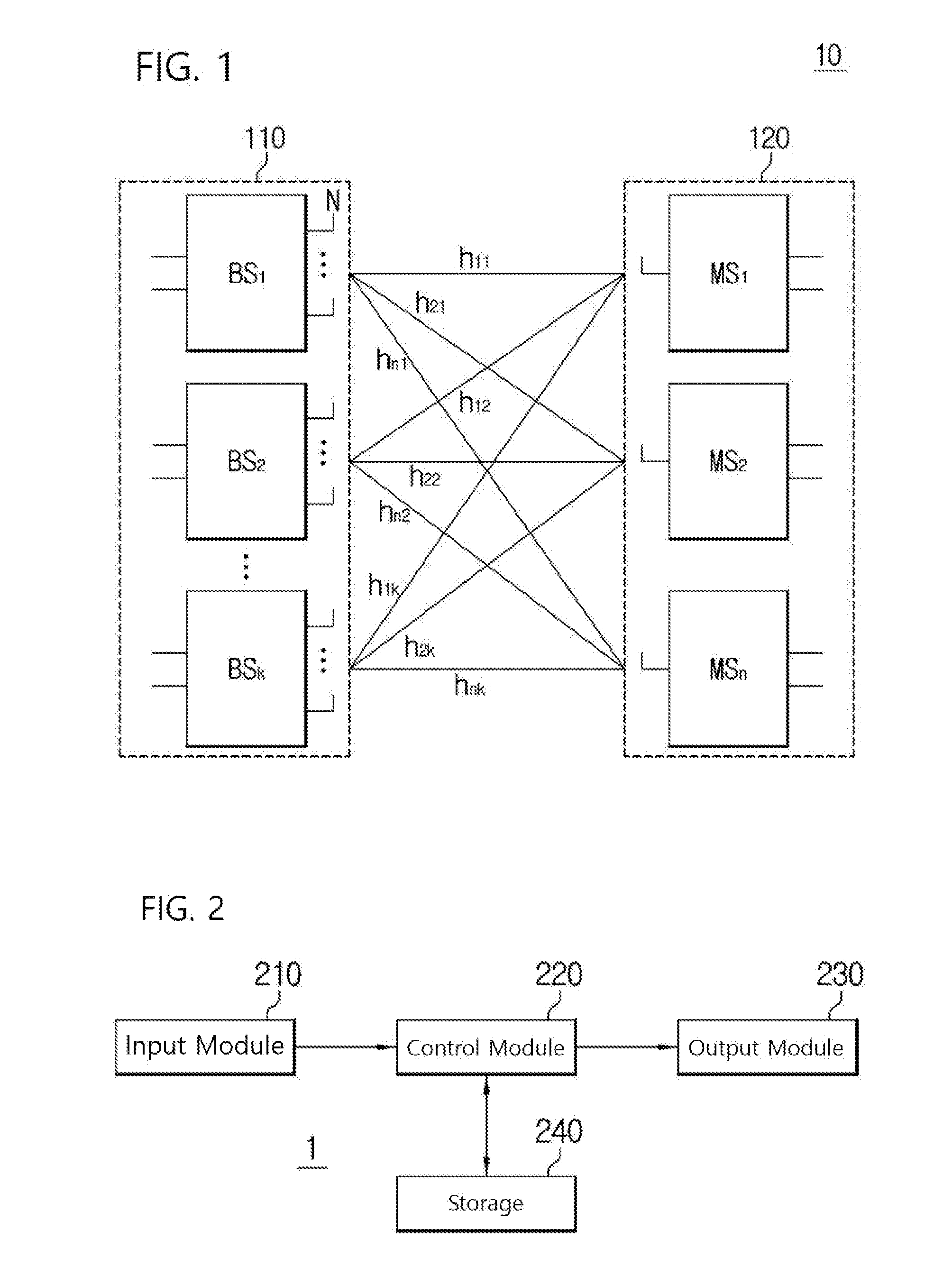

System and Apparatus for Providing Beamforming Vector for Wireless Network Systems, Method, Program and Recording Media Using Thereof

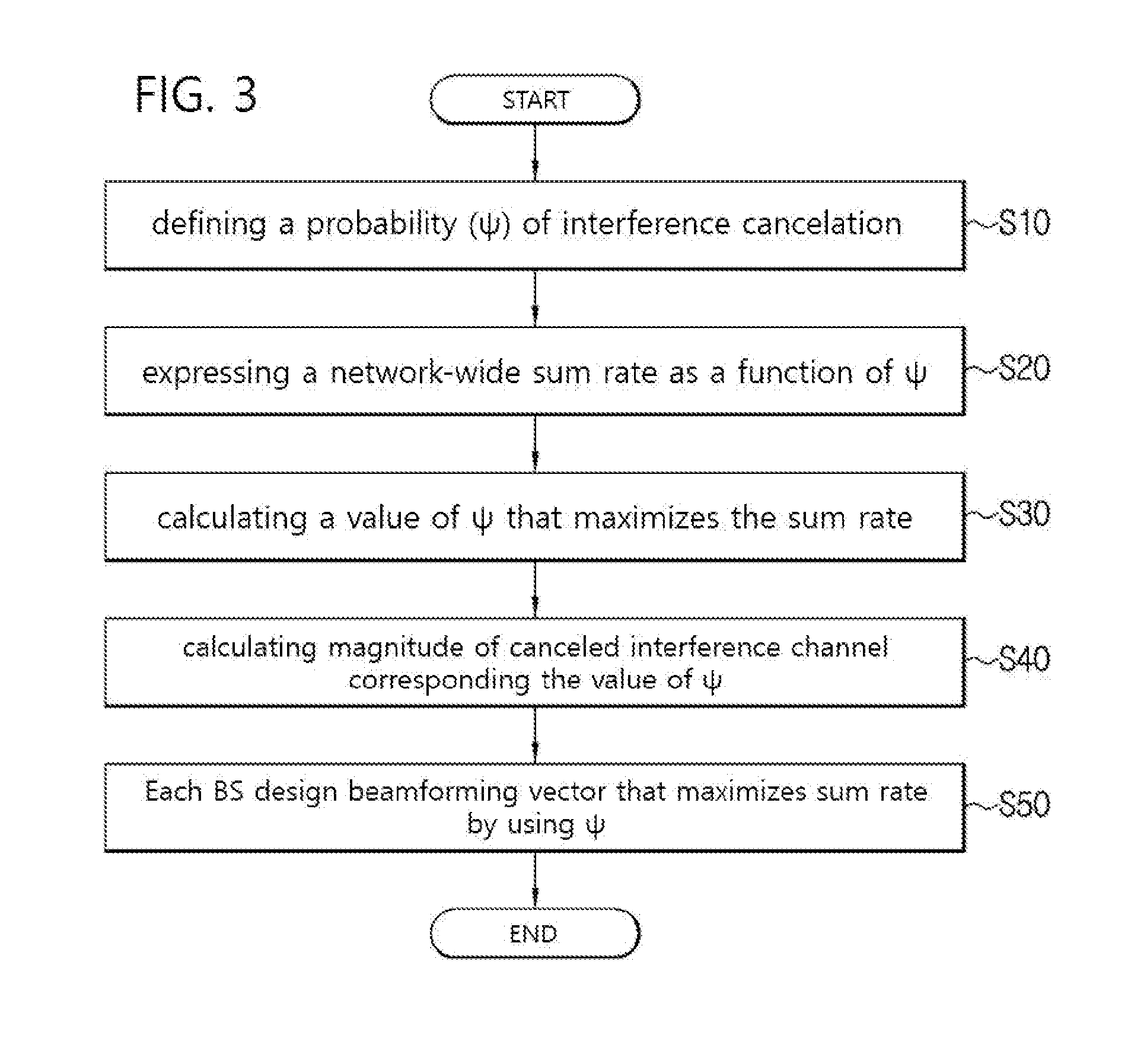

ActiveUS20160285523A1Easily appliedUltra-high densitySite diversitySpatial transmit diversityCellular networkControl vector

The present invention relates to a system and an apparatus for providing beamforming vector for a very high density cellular networks, a method, a program and a recording medium using thereof. A transmitter that comprises a plurality of cell and an apparatus for providing beamforming vector, wherein the apparatus for providing beamforming vector controls a signal transmission of each of the plurality of cell; the apparatus for providing beamforming vector that defines a probability (ψ) of interference cancelation, expresses a network-wide sum rate as a function of ψ, calculates a value of ψ that maximizes the network-wide sum rate and calculates magnitude of canceled interference channel corresponding the value of ψ; and a receiver that receives a signal from the transmitter and comprises at least one mobile station and designs the beamforming vector that maximizes the network-wide sum rate by using ψ.

Owner:SEOUL NAT UNIV R&DB FOUND

Lens barrel and electron imaging device using the same

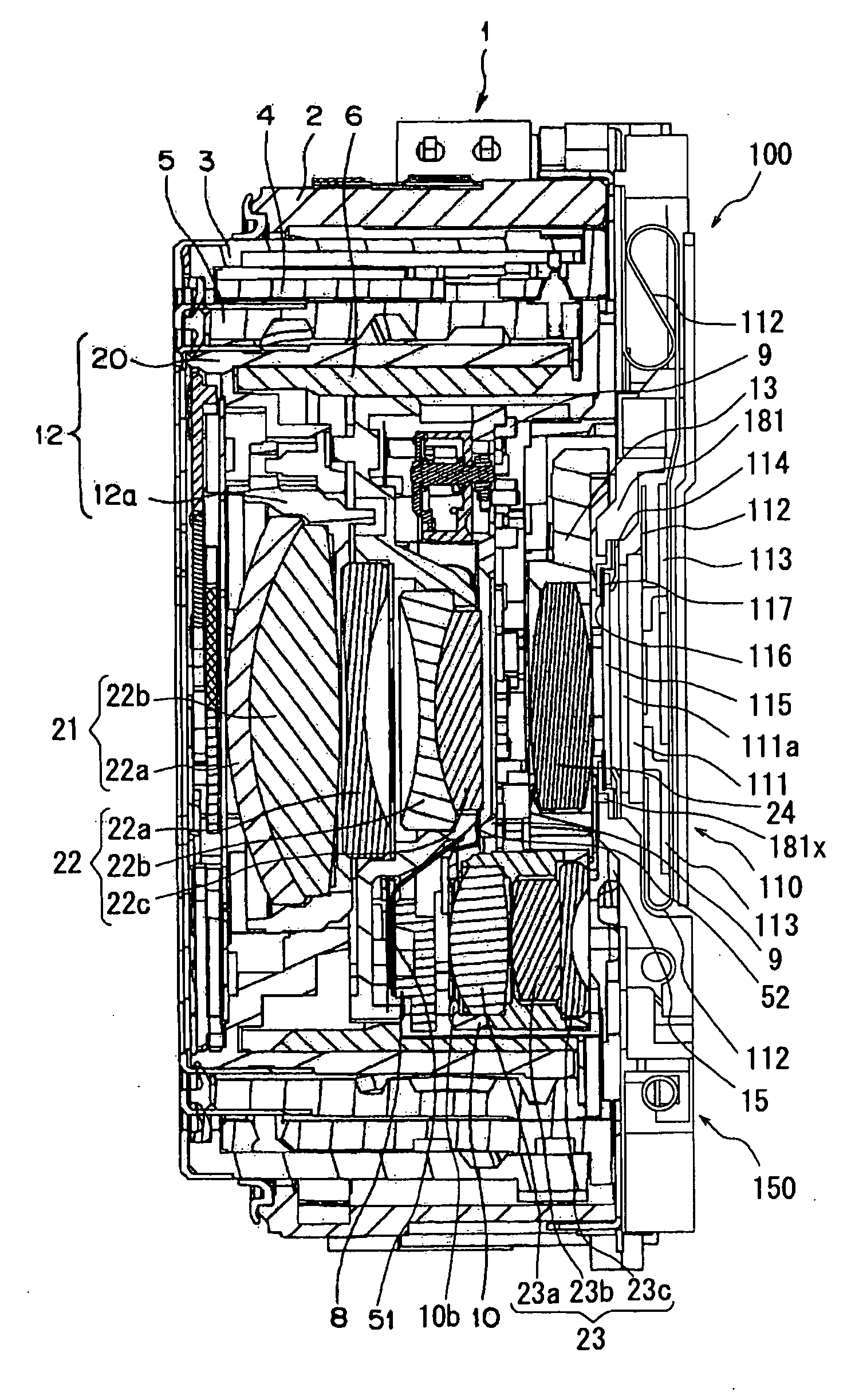

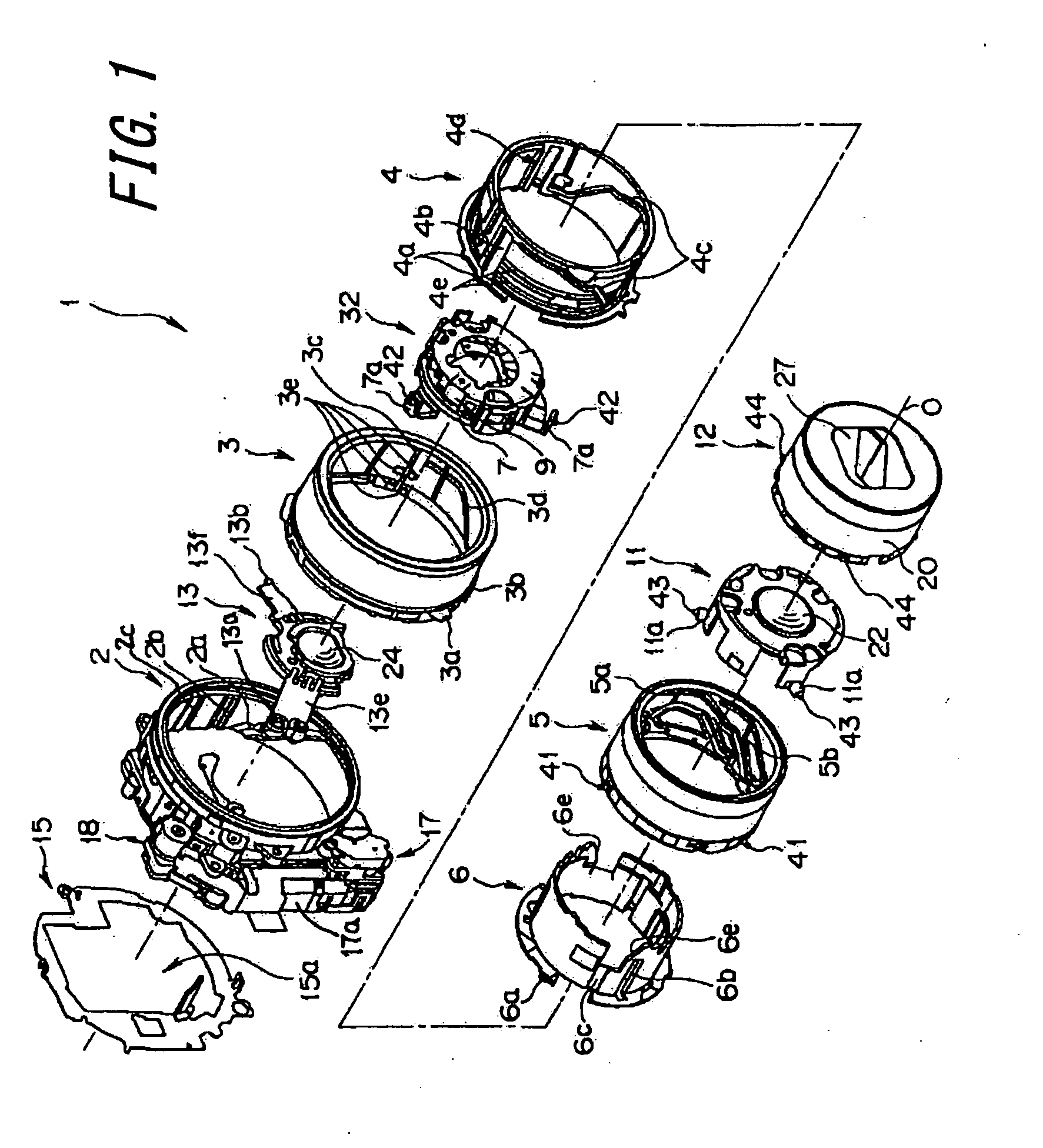

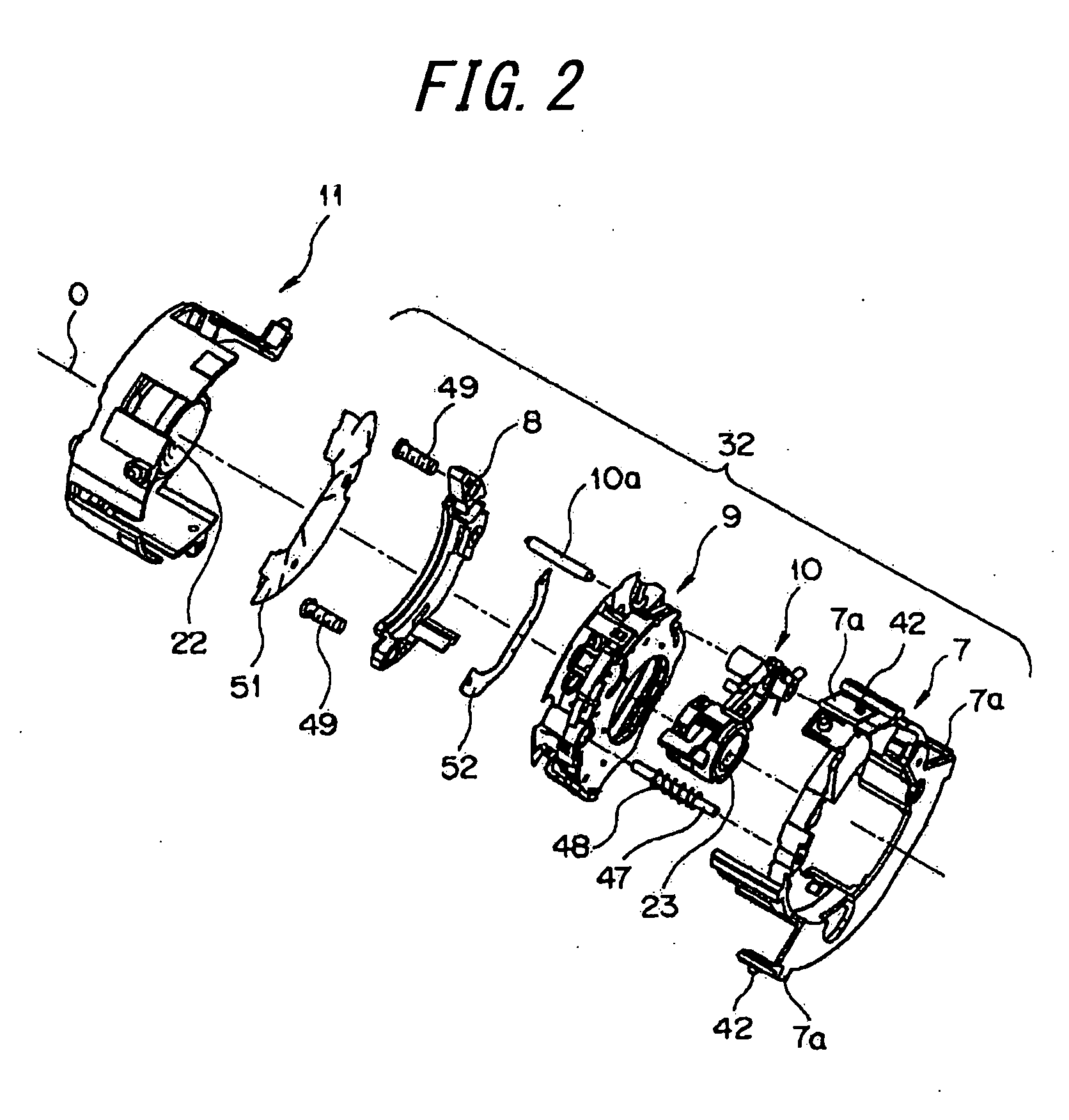

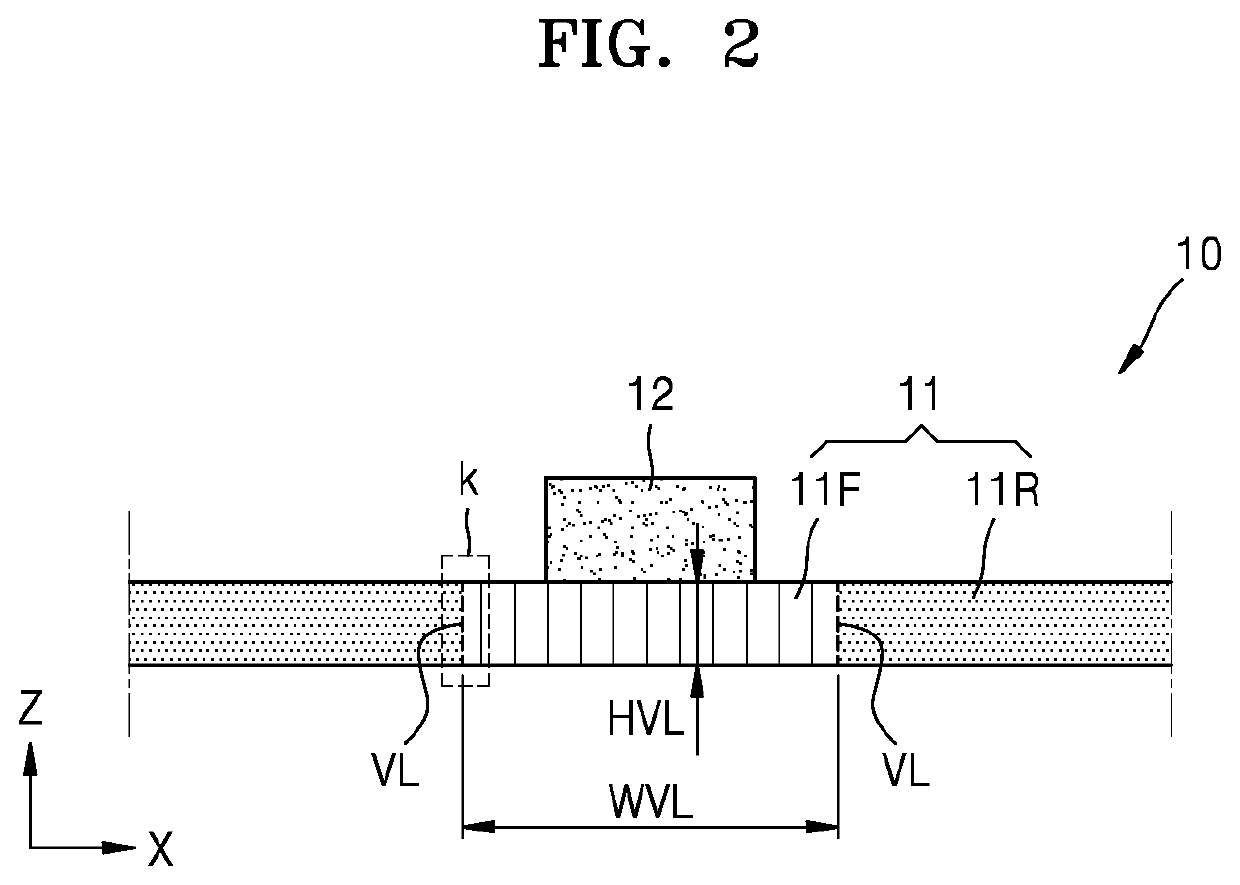

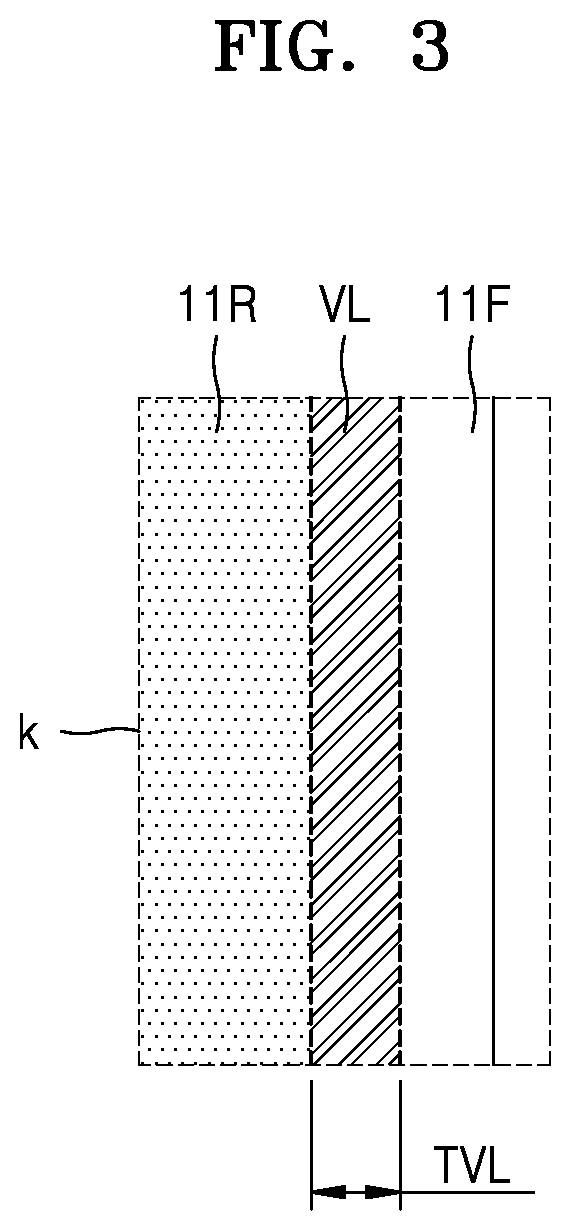

The inventive lens barrel comprises: a first group frame 12 retaining the first group lens 21 with a positive refractivity and being movable on the optical axis; a second group frame 11 retaining the second group lens 22 with a negative refractivity and being movable on the optical axis; a third group frame 10 retaining an aperture diaphragm 10b and the third group lens 23, and being movable on the optical axis and pivotable perpendicular to the optical axis in such a manner that the third group frame 10 can move the aperture diaphragm 10b and the third group lens 23 to the position on the optical axis O in a imaging standby state, in which the lens barrel 1 is extended, and move them to the position out of the optical axis O in the retracted state, in which the lens barrel 1 is shortened; and, a fourth group frame 13 retaining the fourth group frame 24 with a positive refractivity, and being movable on the optical axis, and being arranged such that it can retract the aperture diaphragm 10b and the third group lens 23 to a space between the object side end of the second group image side lens of the second group lens 22, which has a relatively smaller outer shape, and the image side end of the fourth group lens 24, in view from the direction perpendicular to the optical axis, under the retracted state.

Owner:OLYMPUS CORP

Deodorising composition

InactiveUS20140066869A1Simple and cheap to produceEasily appliedCosmetic preparationsToilet preparationsMedicineAnti-Microbial Agents

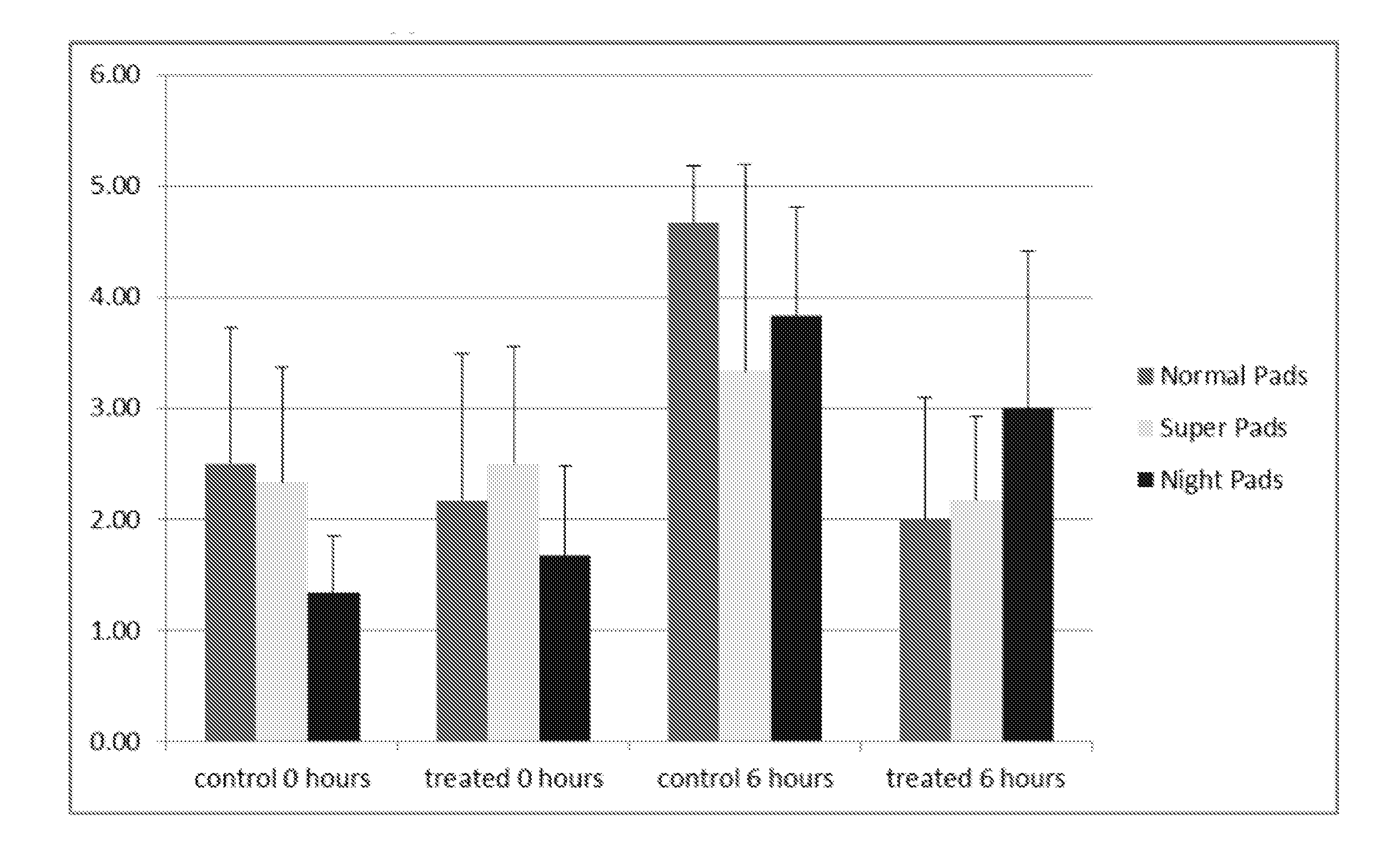

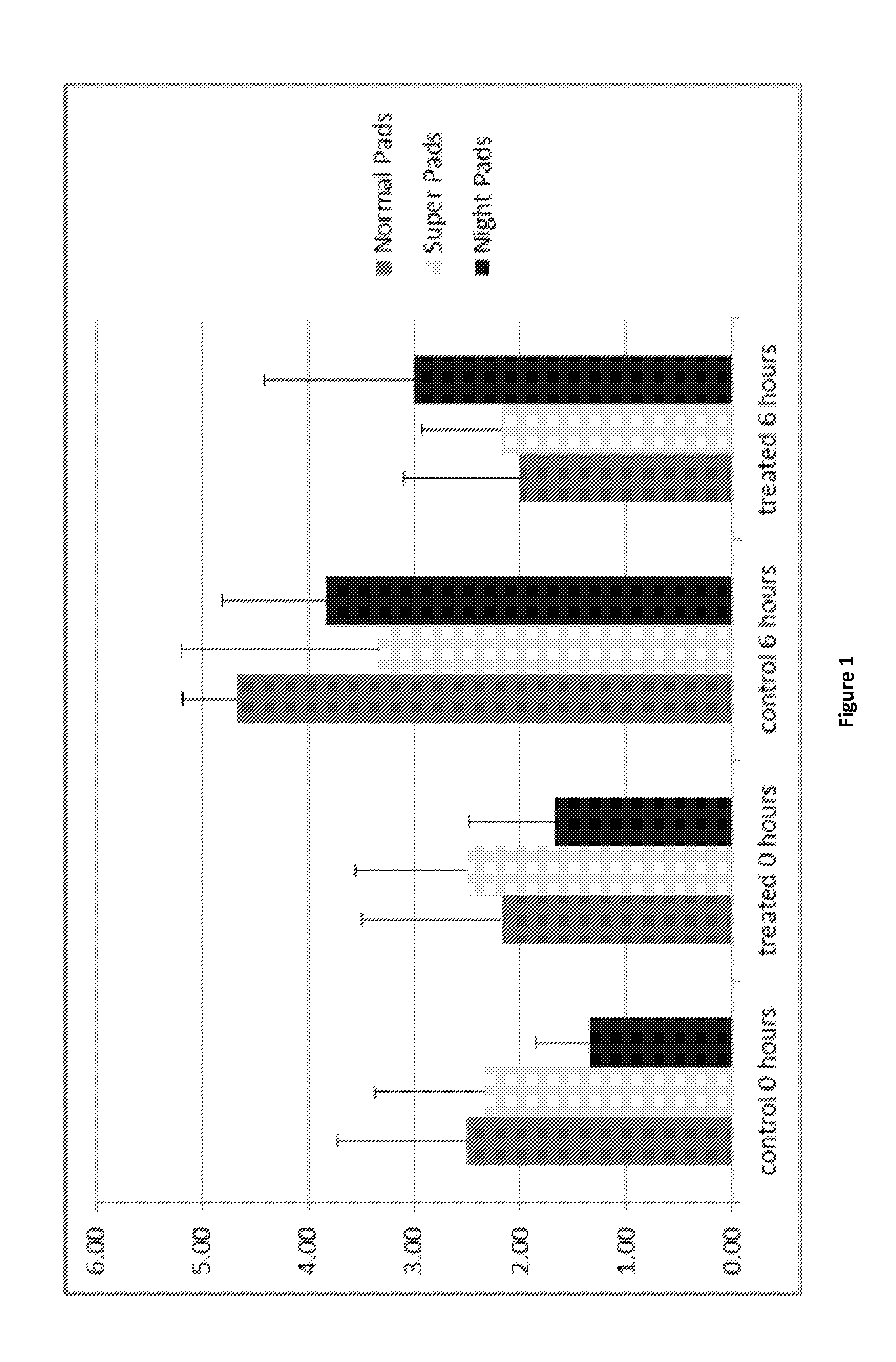

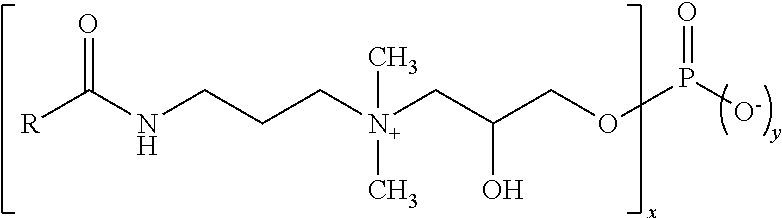

The present invention relates to an absorbent article, such as a sanitary towel, impregnated or coated with a deodorizing composition comprising a buffering component, a deodorizing agent, and an antimicrobial agent. Such deodorizing compositions help to reduce or eliminate odours emanating from the bodily fluids absorbed into the article during use.

Owner:BIOCIDE DEV CO LTD

Protective gel for an electrical connection

InactiveUS20080286471A1Easily appliedEfficient use ofOther chemical processesCoupling device detailsElectricityElectrical connection

An electrical connection for a trailer hitch on a vehicle joins a trailer electrical connection. These electrical connectors join together to carry the power to illuminate the trailer lights on the trailer and carry out other functions. Both connections are protected by a protective gel for the electrical connections having a thickening agent, a cleaning agent, a chelating agent, a reducing agent, anti-corrosive agent, a buffer, and an antifreeze agent.

Owner:DOUBLEDAY MARC D

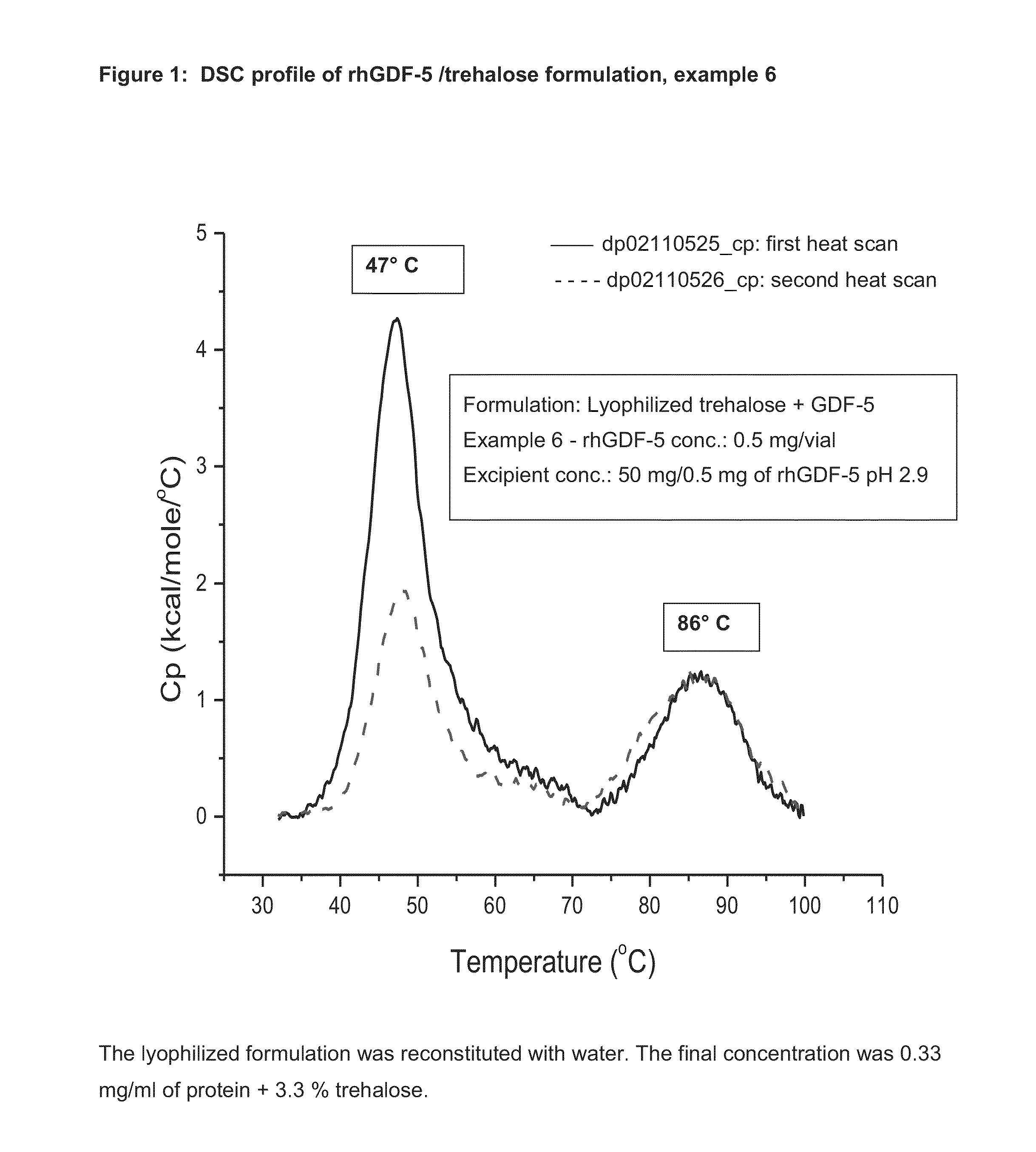

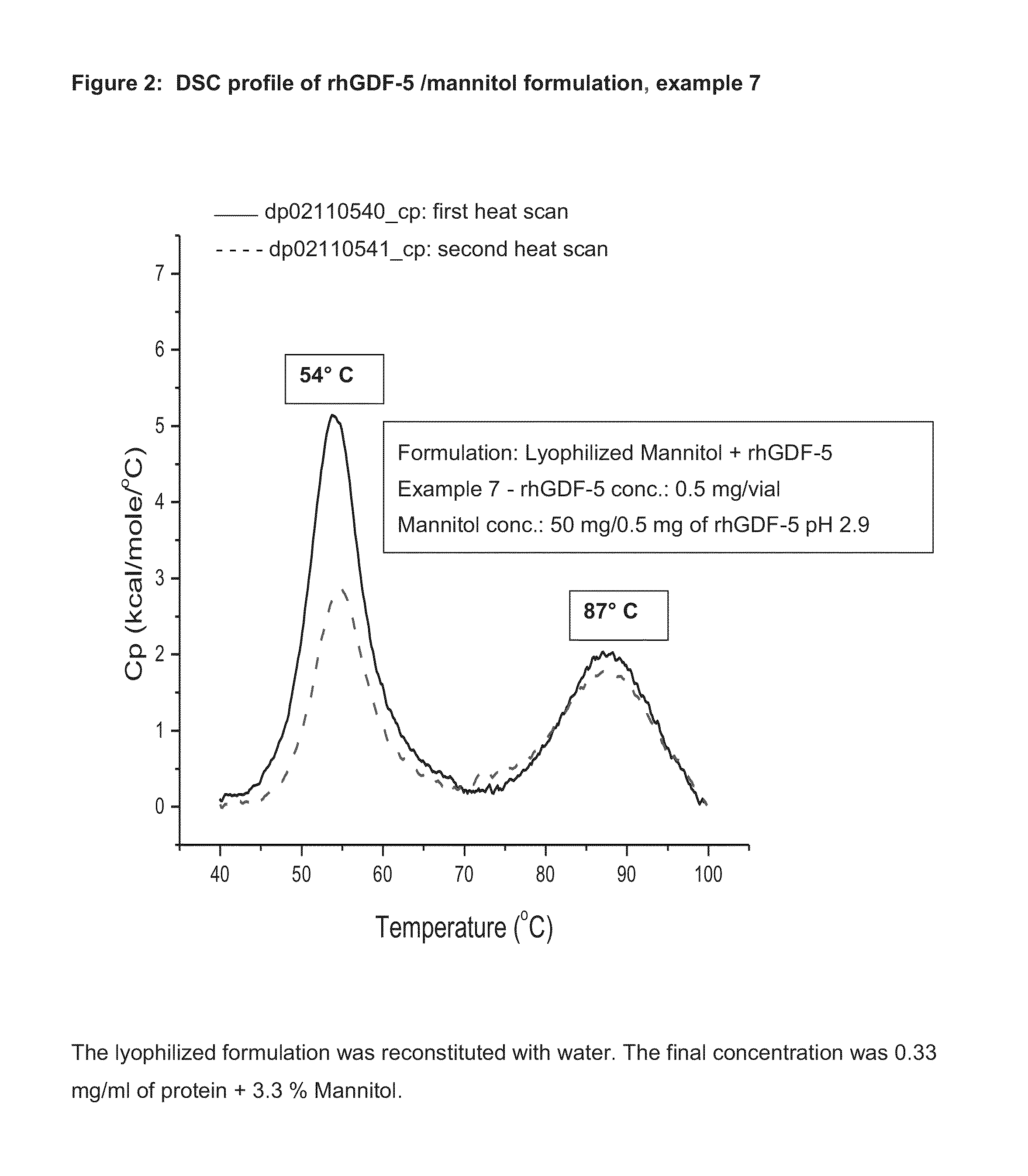

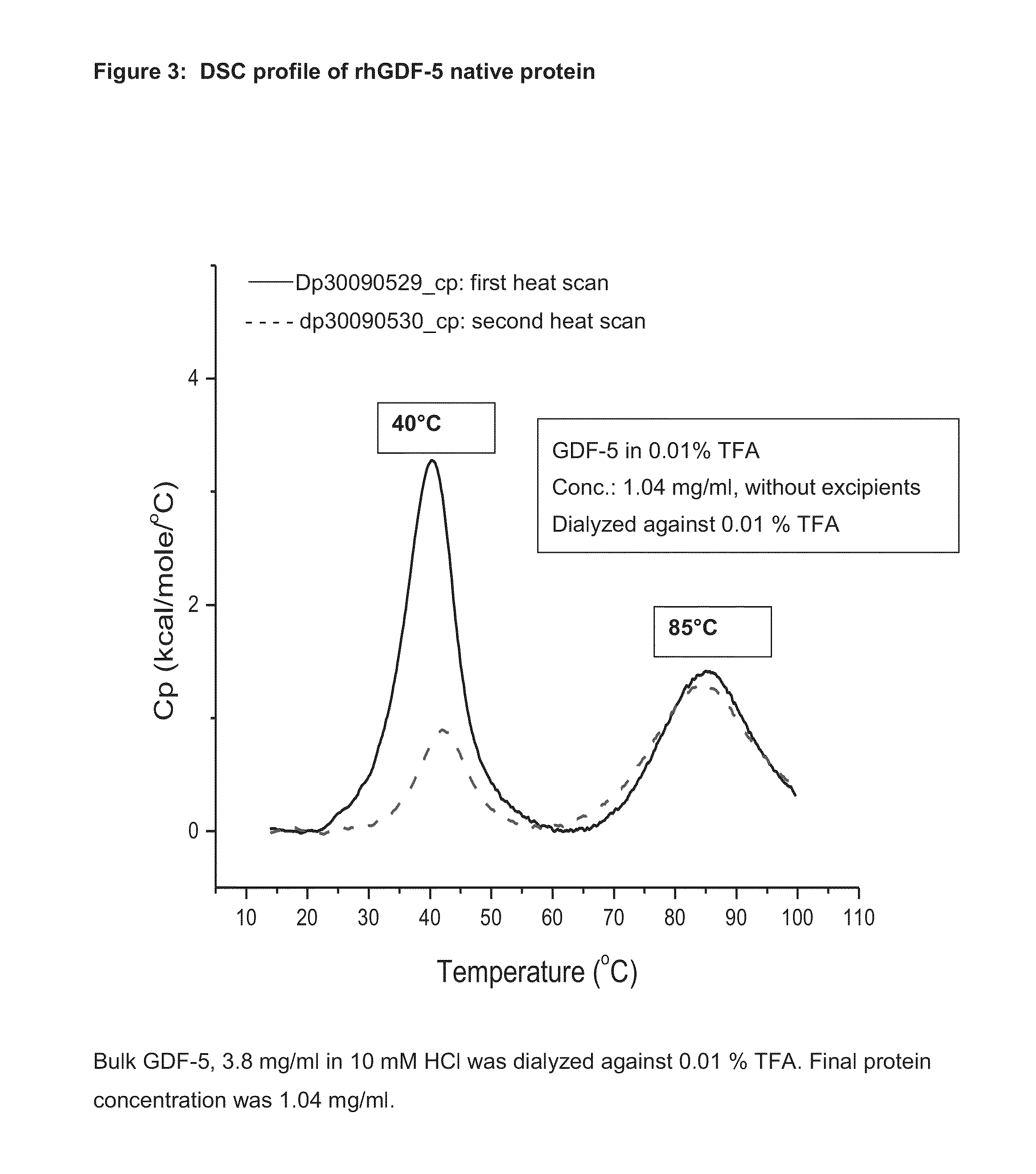

Protein stabilization formulations

InactiveUS20150079145A1More riskEasily appliedPowder deliveryPeptide/protein ingredientsBone morphogenetic proteinTrehalose

The present invention is directed to stabilizing Bone Morphogenetic Protein in various lyophilized formulations and compositions. The present invention comprises formulations primarily including trehalose as an excipient for lyophilized compositions and their subsequent storage and reconstitution, and can also optionally include other excipients, including buffers and surfactants.

Owner:DEPUY SYNTHES PROD INC

Method for the detection of mastitis and milk quality and mastitis sensor

InactiveUS20120115184A1Easily appliedReduce product costBioreactor/fermenter combinationsBiological substance pretreatmentsNon invasiveMastitis

A mastitis sensor and a method for detection of mastitis and determination of milk quality in real time (on-line). Methods and apparatuses for the rapid non-invasive determination of the concentration of dissolved molecular oxygen in milked milk are disclosed. Mastitis sensors are disclosed that include a fiberoptic, amperometric or potentiometric device for the determination of oxygen concentration, a device for data acquisition and processing, mastitis indicator and a device that generates a signal for the automatic on-line elimination of substandard milk of infected animals to prevent the pollution of bigger quantities of milk.

Owner:UNIV OF TARTU

Method for controlling current path range by using electric field, and electronic circuit

ActiveUS20210249975A1Easily appliedEfficient use ofDigital storageResistors adjusted by short-circuiting resistive elementsSpontaneous polarizationElectric field

A method of controlling a current path range using an electric field is disclosed, and the method of controlling a current path range includes applying an electric field to an active layer including a spontaneous polarization material through an application electrode disposed adjacent to the active layer to form a polarization region of the active layer, and forming a variable low resistance region corresponding to a boundary of the polarization region, wherein the variable low resistance region is a region of the active layer having a lower electrical resistance than another region of the active layer adjacent to the variable low resistance region and allows an electrical path to be formed.

Owner:VMEMORY CORP

Human body impedance measurement device

InactiveUS20170065201A1Easily appliedEasy to arrangeDiagnostic recording/measuringSensorsMeasurement deviceBiomedical engineering

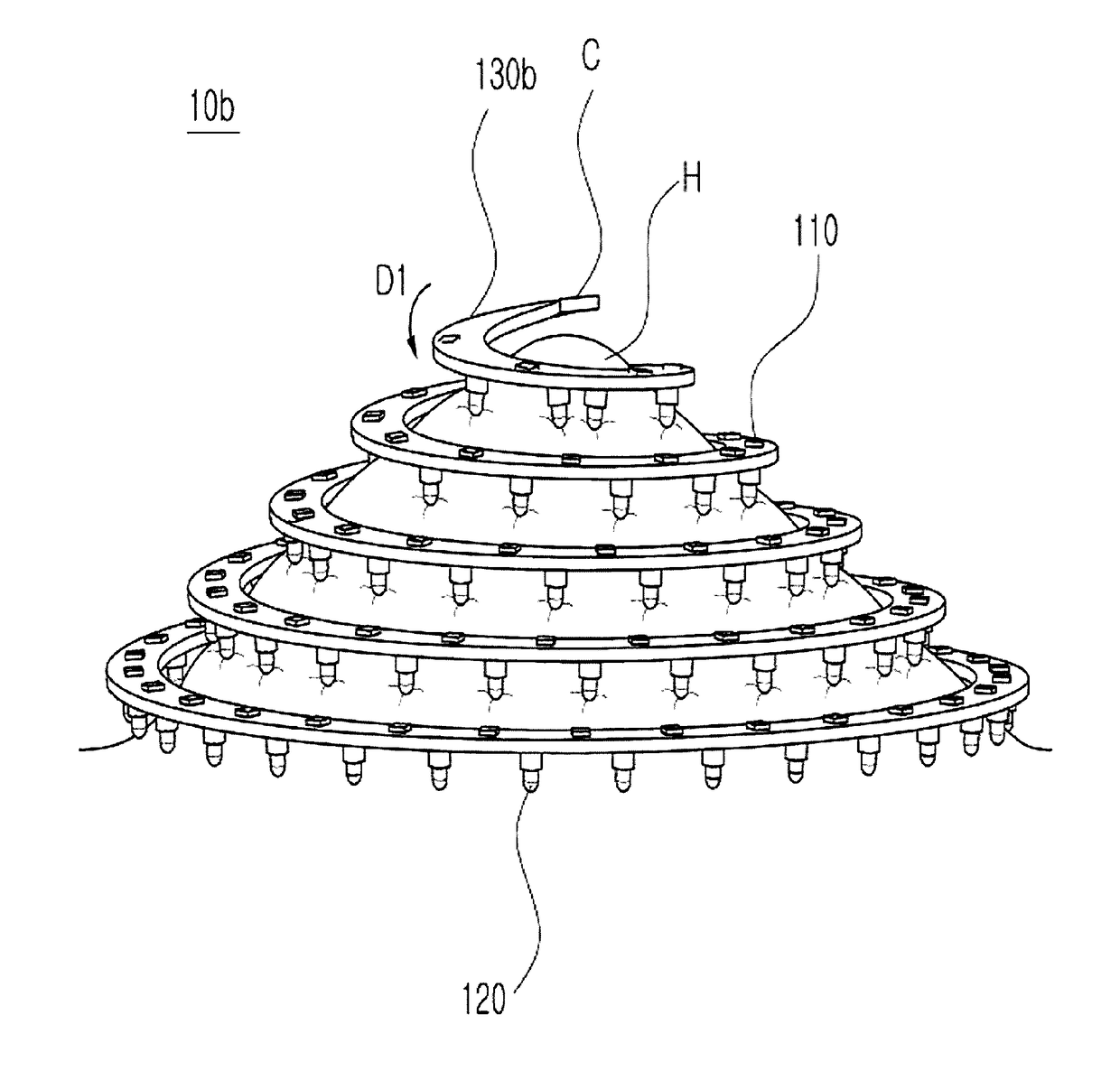

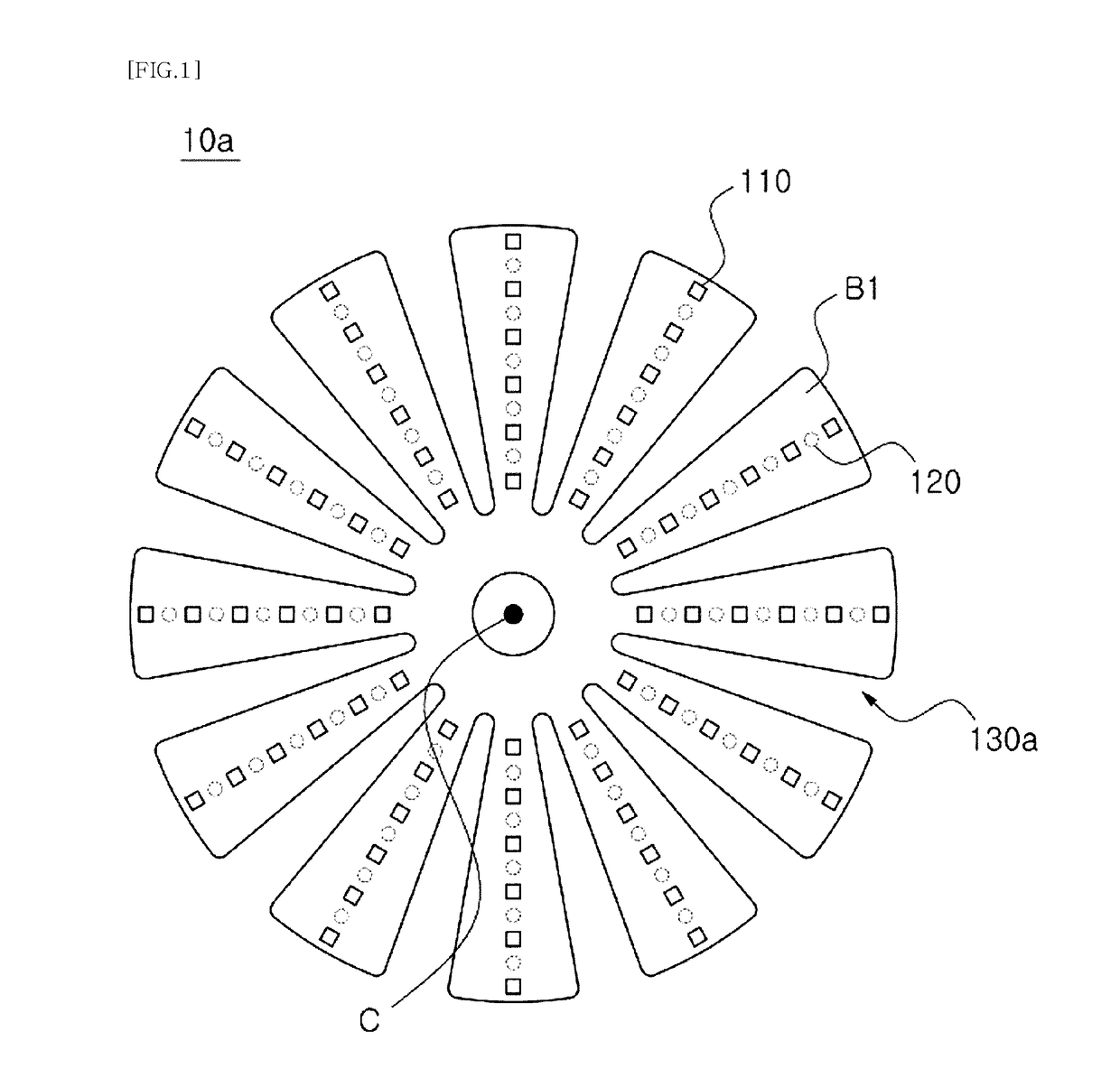

Disclosed is a device for measuring impedance within a human body, including: a spiral base plate; a plurality of electrodes arranged along the spiral base plate; and a plurality of first and second power lines connected to the plurality of electrodes. According to the present invention, the spiral base plate is used, so that it is possible to easily apply the device in accordance with a curve of a human body.

Owner:MSP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com