Multi-element comprehensive utilization process for phosphorus-potassium associated ore

A phosphorus-potassium associated ore, multi-element technology, applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problems of affecting normal production, unavailability of tailings, waste of resources, etc., to achieve easy implementation, good promotion and application prospects, leaching low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

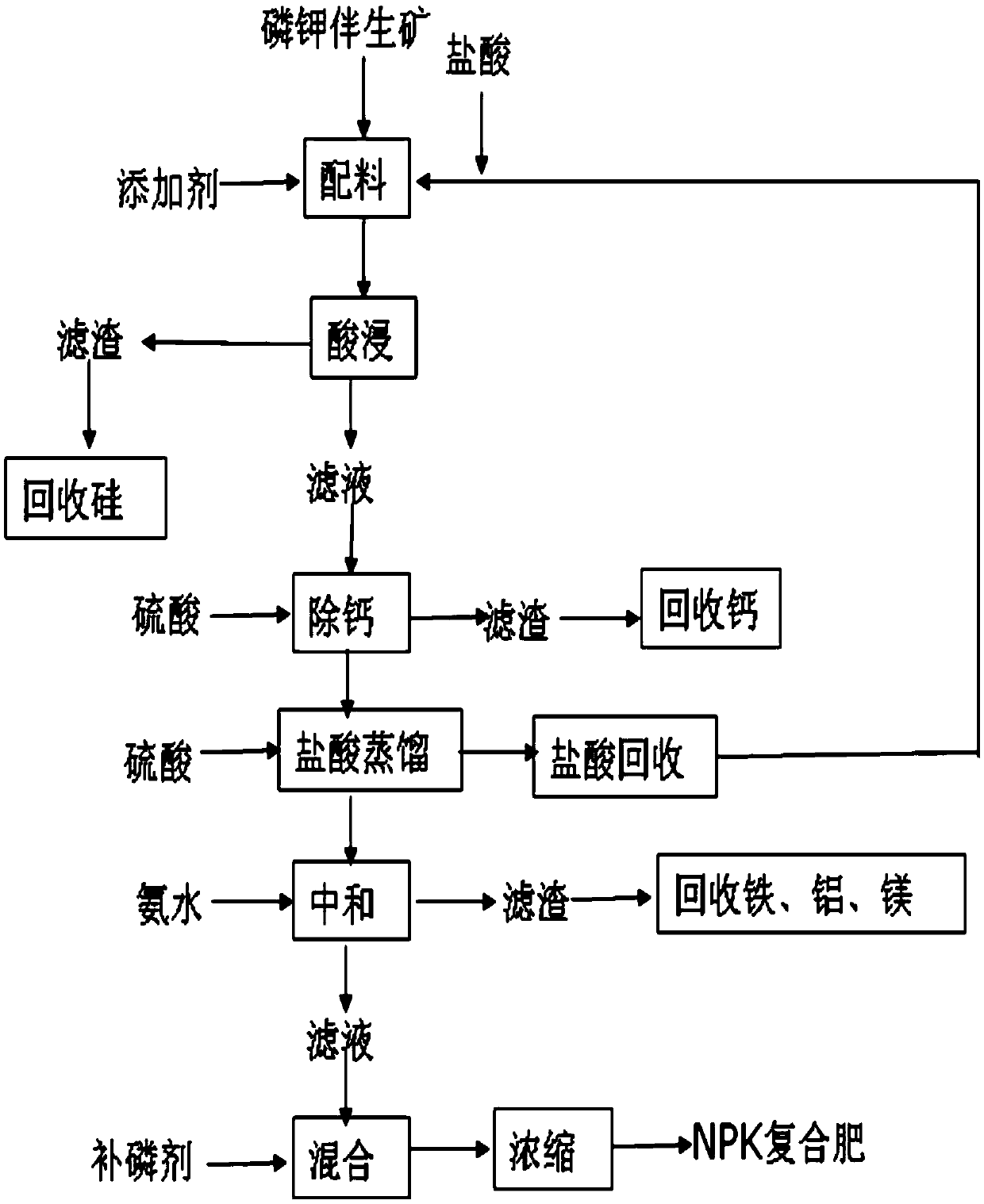

[0054] A multi-element comprehensive utilization process of phosphorus and potassium associated ore, the process flow chart is shown in figure 1 , including the following steps:

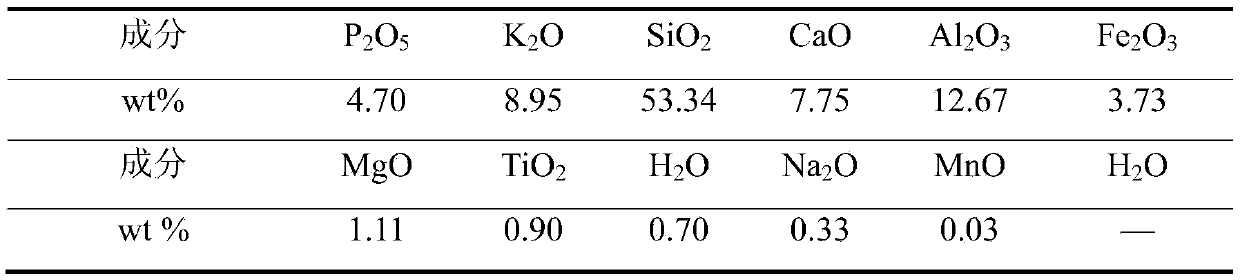

[0055] 1) Ingredients: Crushing and grinding the phosphorus and potassium associated ore, taking 80 g of the ground phosphorus and potassium associated ore, mixing with 8 g of calcium fluoride and 320 mL of hydrochloric acid solution (mass concentration: 22.5%) to obtain a mixture liquid;

[0056] 2) Acid leaching: carry out the leaching reaction of the mixed material liquid obtained in step 1) at a temperature of 90° C., and carry out solid-liquid separation after 4 hours of reaction to obtain silica filter residue and filtrate I; The leaching rate of potassium element is 92.5%, the leaching rate of aluminum element is 93%, the leaching rate of phosphorus, calcium and magnesium elements is nearly 99%, the leaching rate of iron element is 52%, and about 8% of silicon element exists in the leach solut...

Embodiment 2

[0062] A multi-element comprehensive utilization process of phosphorus and potassium associated ore, specifically comprising the following steps:

[0063] 1) Ingredients: crush and grind the phosphorus and potassium associated ore, take 80 g of the ground phosphorus and potassium associated ore, mix it with 4 g of magnesium fluoride and 160 mL of hydrochloric acid solution (mass concentration: 15%), to obtain a mixture liquid;

[0064] 2) Acid leaching: carry out the leaching reaction of the mixed material liquid obtained in step 1) at a temperature of 70°C, and perform solid-liquid separation after 4 hours of reaction to obtain silica filter residue and filtrate I; the leaching rate of potassium element in the ore is detected by AAS 72.5%, the leaching rate of aluminum is 80.5%, the leaching rate of phosphorus, calcium, and magnesium is nearly 80%, the leaching rate of iron is 45%, and about 6% of silicon exists in the leaching solution; the obtained silica filter residue is w...

Embodiment 3

[0070] A multi-element comprehensive utilization process of phosphorus and potassium associated ore, specifically comprising the following steps:

[0071] 1) Ingredients: crush and grind the phosphorus and potassium associated ore, take 80 g of the ground phosphorus and potassium associated ore, mix it with 4 g of magnesium fluoride and 160 mL of hydrochloric acid solution (mass concentration: 15%), to obtain a mixture liquid;

[0072] 2) Acid leaching: carry out the leaching reaction of the mixed material liquid obtained in step 1) at a temperature of 70°C, and perform solid-liquid separation after 4 hours of reaction to obtain silica filter residue and filtrate I; the leaching rate of potassium element in the ore is detected by AAS 72.5%, the leaching rate of aluminum is 80.5%, the leaching rate of phosphorus, calcium, and magnesium is nearly 80%, the leaching rate of iron is 45%, and about 6% of silicon exists in the leaching solution; the obtained silica filter residue is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com