Patents

Literature

42results about How to "Low leaching temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively recycling nickel-containing limonite

InactiveCN101407861ALow leaching temperatureLow leaching pressureProcess efficiency improvementCobalt hydroxideLiquid solid

The invention discloses a comprehensive recycling method for a limonite containing nickel, which is characterized by including the following steps: pressurizing and leaching are carried out on the ore material particles of the limonite containing nickel by using a mixed liquid of vitriol and nitric acid as a medium so as to prepare a leaching liquid; aluminum hydroxide, nickel hydroxide, cobalt hydroxide and magnesium hydrate are respectively deposited through using CaO or lime hydrate as a neutralizing agent and controlling the different pH values of the leaching liquid. The method realizes the comprehensive utilization of nickel, cobalt, aluminum, magnesium and iron in the limonite containing nickel; a pressurizing and leaching technique is adopted in a vitriol plus nitric acid medium; the leaching temperature and the leaching pressure are low, wherein, the iron is deposited into the slag in a hematite form, thus effectively inhibiting the leaching of the iron; the settlement performance of a soaked ore slurry is good; liquid-solid separation is easy; the CaO or the lime hydrate is adopted for depositing the aluminum, nickel, cobalt and magnesium by steps; and the leaching agent of the nitric acid can be recycled. The method has the advantages of high operating factor of resources, low energy consumption, environment friendliness, and the like.

Owner:ZHENGZHOU YONGTONG SPECIAL STEEL

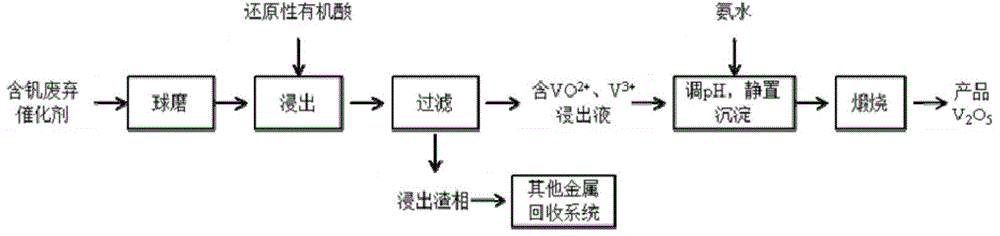

Method for extracting vanadium from vanadium-containing waste catalyst reductive organic acid

ActiveCN105986123AImprove leaching rateLow leaching temperatureProcess efficiency improvementSlagOxygen

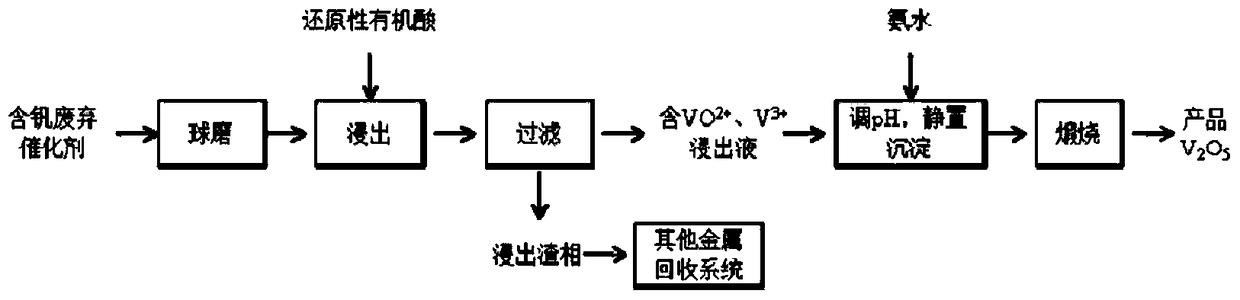

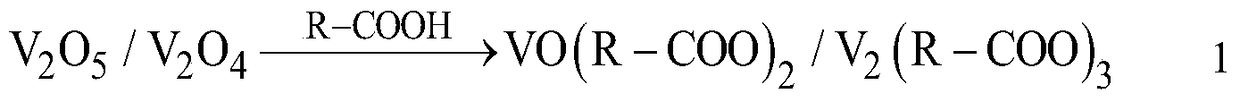

The invention relates to the field of non-ferrous metallurgy and resource recycling, in particular to a novel process for extracting vanadium from vanadium-containing waste catalyst reductive organic acid. The novel process comprise the steps that a vanadium-containing waste catalyst is directly extracted in a reductive organic acid system, and other reductive agents are not added, so that pentavalent or tetravalent vanadium is directly reduced into vanadium-oxygen-based ions or trivalent vanadium ions, the vanadium-oxygen-based ions or the trivalent vanadium ions are combined with organic acid radical anions and enter a solution, and vanadium-containing leaching liquid and vanadium-containing leaching slag are obtained; and ammonia water is added into the vanadium-containing leaching liquid to adjust pH so that ammonium vanadate can be formed and precipitated, and after separating is conducted, a vanadium pentoxide product is obtained by calcining precipitation slag. According to the novel process for extracting the vanadium from the vanadium-containing waste catalyst reductive organic acid, the vanadium is extracted by adopting the reductive organic acid system; the extracting condition is mild; the vanadium extracting rate is 95% or above and higher than the direct inorganic acid fluid extracting rate; and other impurity ions are not introduced in the extracting process, so that recycling of other metal elements in the waste catalyst is not affected.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

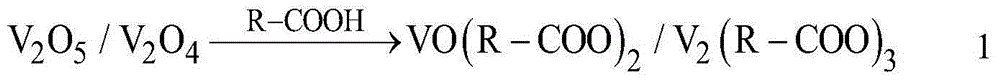

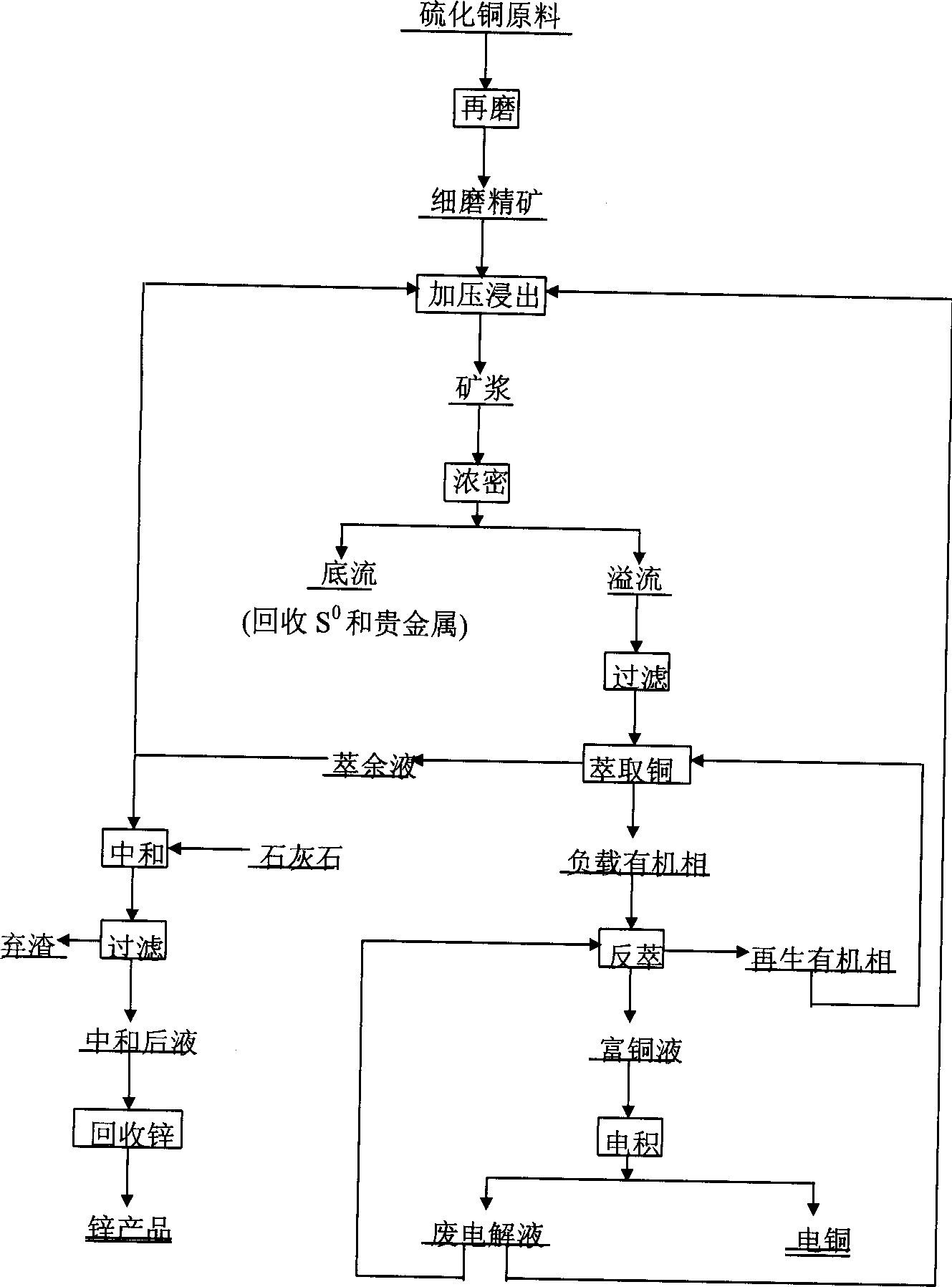

Method for extracting copper for copper containing sulfurized ore

InactiveCN1358871ALow leaching temperatureRelieve pressureProcess efficiency improvementSlagSulfide minerals

The method for extracting copper from copper-bearing sulfide mineral is characterized by leaching copper-bearing mineral under the condition of introduction of oxygen and in the presence of sulfuric acid and chlorine ion, the liquid-solid ratio of leaching-out liquor is 1-8:1, primary concentration of sulfuric acid is 5-70 g / L, leaching total pressure is 200-1000 kPa, partial pressure of oxygen is 100-800 kPa, temp. is 100-130 deg.C and time is 1-4 hr. The leaching temp. and pressure of said method are low, its selectivity is good, the pyrite can not be oxidated, and the harmful impurity, for example arsenic, can be solidifed in arsenic-ion slag, so that it is a process friendly to environment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

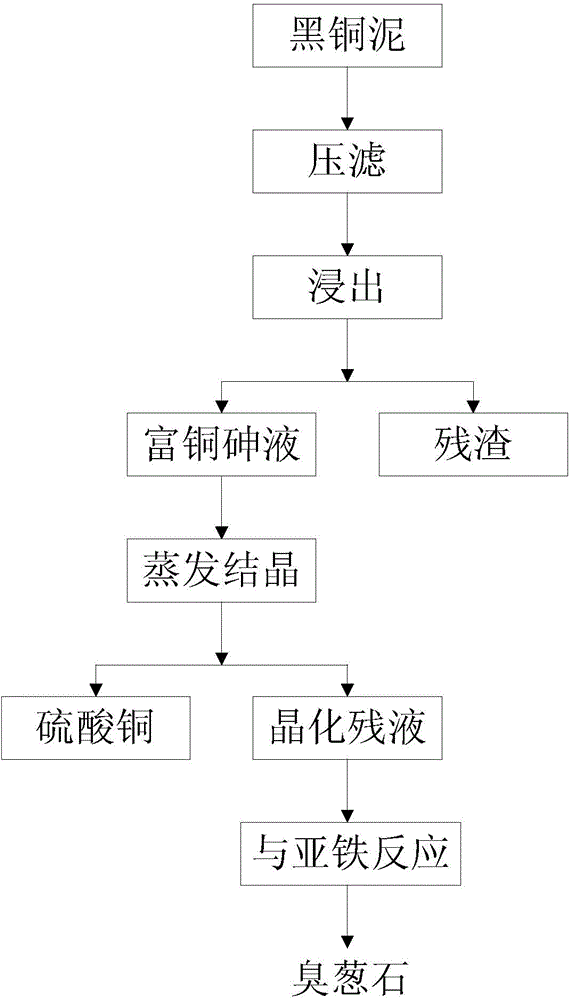

Method for separating copper and arsenic from black copper mud

InactiveCN106148702AImprove leaching rateImprove efficiencyProcess efficiency improvementCopperLeaching rate

The invention belongs to the field of metallurgy, and particularly relates to a method for separating copper and arsenic from black copper mud. The method comprises the following steps that (a1), the black copper mud is mixed with sulfuric acid, and a mixture composed of the black copper mud and the sulfuric acid is obtained; and (a2), hydrogen peroxide is added into the mixture for leaching, and copper-rich arsenic liquid is obtained after filtering, wherein the concentration of the hydrogen peroxide is 10-50 wt%, and the use ratio of the hydrogen peroxide to the black copper mud is 0.5-1 (L) : 1 (kg). According to the method for separating the copper and the arsenic from the black copper mud, the sulfuric acid and the hydrogen peroxide are used as a leaching reagent for the black copper mud, and the leaching rates of the copper and the arsenic in the black copper mud can be increased. Further, the leaching temperature is lowered, the leaching time is shortened, operation is simple and convenient, and the efficiency is high. According to experiment results, when the black copper mud is treated by adoption of the method provided by the invention, the leaching rate of the copper and the leaching rate of the arsenic can reach 98% and 89% correspondingly.

Owner:YANGGU XIANGGUANG COPPER

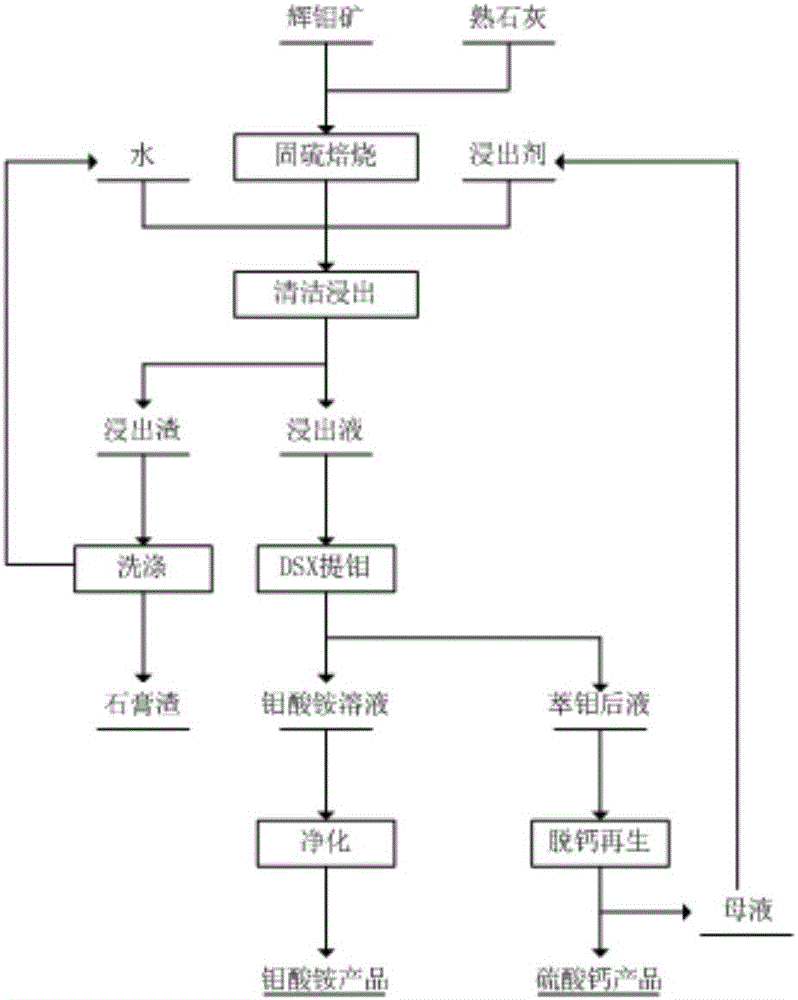

Efficient and clean molybdenum smelting method

ActiveCN105838908AHigh recovery rateSpeed up leachingProcess efficiency improvementEvaporationRaffinate

The invention provides an efficient and clean molybdenum smelting method. The method comprises the steps that lime sulphur-fixed roasting is conducted on molybdenite through a gradient heat preservation method; roasted products are leached with a leaching agent, namely roasted product, and molybdenum-contained leach liquid is obtained; the molybdenum-contained leach liquid is sequentially treated by an acid phosphorus extraction system for extracting molybdenum, and an ammonium hydroxide / ammonium salt system for back-extracting molybdenum, and molybdenum-contained strip liquid and molybdenum raffinate are obtained; impurities in the molybdenum-contained strip liquid are removed through a Mg(OH)2 one-step precipitation method, evaporation and concentration are conducted, and ammonium molybdate products are obtained; and sulfuric acid is added into the molybdenum raffinate for regeneration, calcium sulphate dihydrate products are obtained, and regenerated liquid serves as a leaching agent and is returned back to the leaching process. By the adoption of the method, molybdenum mineral raw materials can be cleaned and treated efficiently, and ammonium molybdate can be prepared, the molybdenum recovery rate reaches 99%, the sulfur fixing rate reaches 98% or over, reagent consumption is low, the production period is short, the process is easy to control, the reaching residue quantity is greatly reduced, zero emission of waste water is achieved, and industrialized application is achieved easily.

Owner:CENT SOUTH UNIV

Method for strengthening agitation leaching of cuprite red copper ore type copper oxide

ActiveCN103194617AFast leachingFast oxidationProcess efficiency improvementMining engineeringCopper oxide

The invention relates to a method for strengthening agitation leaching of cuprite red copper ore type copper oxide. For copper oxide ore which is fine in ore granularity, low in content of calcium and magnesium existing in the form of carbonates, ozone and hydrogen peroxide are added to ore pulp for heating sulfuric acid leaching; with the addition of an active oxidant, the leaching temperature is reduced, the leaching time is shortened, the leaching efficiency is improved and the leaching cost is reduced; therefore, the cuprite red copper ore type copper oxide difficult to be treated is recycled economically and efficiently.

Owner:KUNMING UNIV OF SCI & TECH

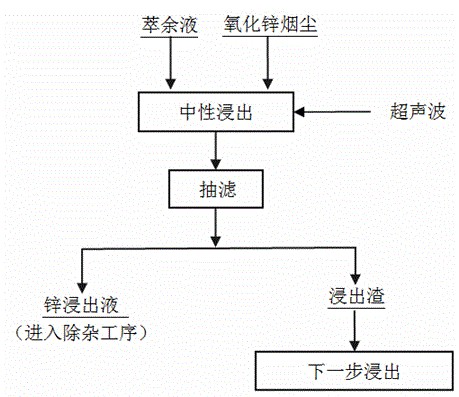

Method for recovery of zinc by ultrasonic neutral leaching of zinc oxide flue dust

ActiveCN104131176ALow leaching temperatureShorten the leaching timeProcess efficiency improvementUltrasonic cavitationHydrometallurgy

Belonging to the technical field of hydrometallurgy, the invention relates to a method for recovery of zinc by ultrasonic neutral leaching of zinc oxide flue dust. The method includes: firstly adding the zinc oxide flue dust into a raffinate at 30DEG C-40DEG C according to a liquid-solid ratio of 5-25:1, conducting neutral leaching at a stirring speed of 100-600rpm for 10-100min under ultrasonic conditions so as to obtain leaching residue and a zinc leaching solution at the end of leaching, subjecting the zinc leaching solution to an impurity removal process, and getting the leaching residue ready for next step leaching. According to the method, ultrasonic wave is employed to reinforce neutral leaching of the zinc oxide flue dust directly, and the ultrasonic cavitation effect is employed to generate intense impact and high speed micro-jet erosion to a reactant surface so as to accelerate the leaching reaction, improve the leaching rate of zinc and increase recycle of secondary resources.

Owner:KUNMING UNIV OF SCI & TECH

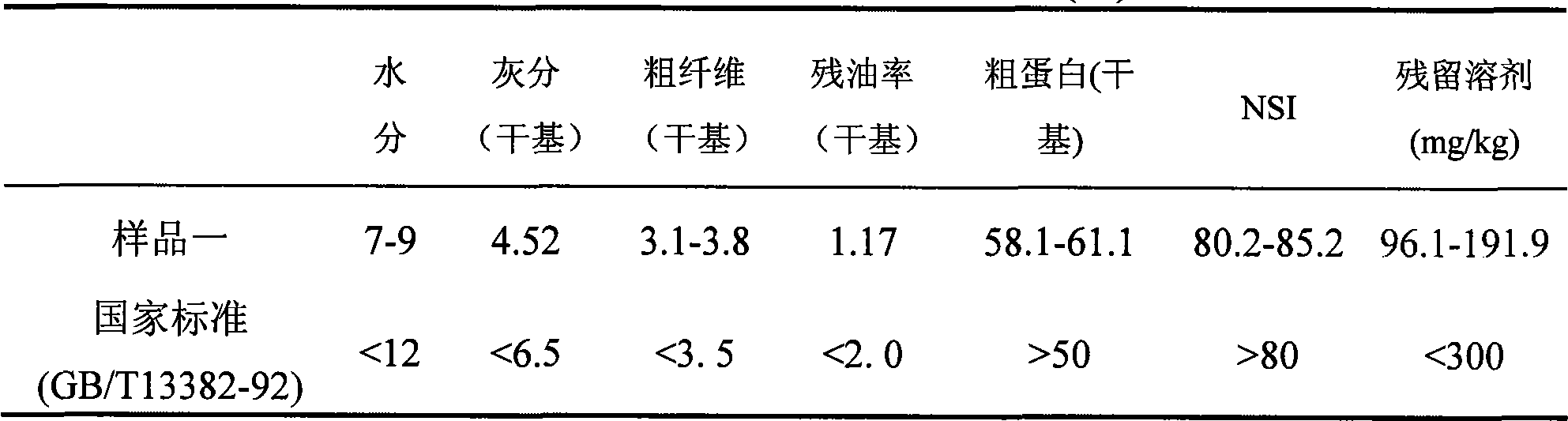

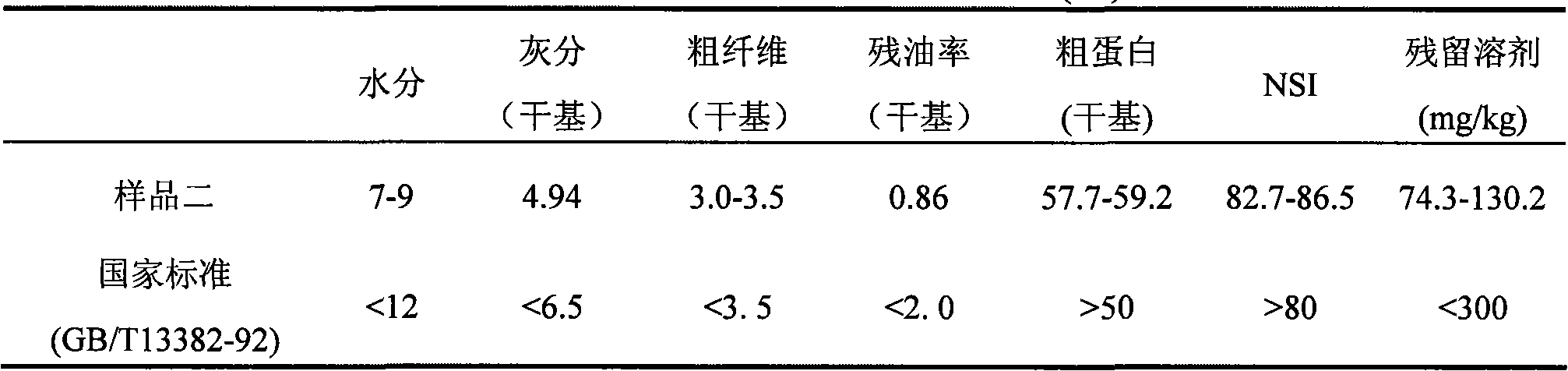

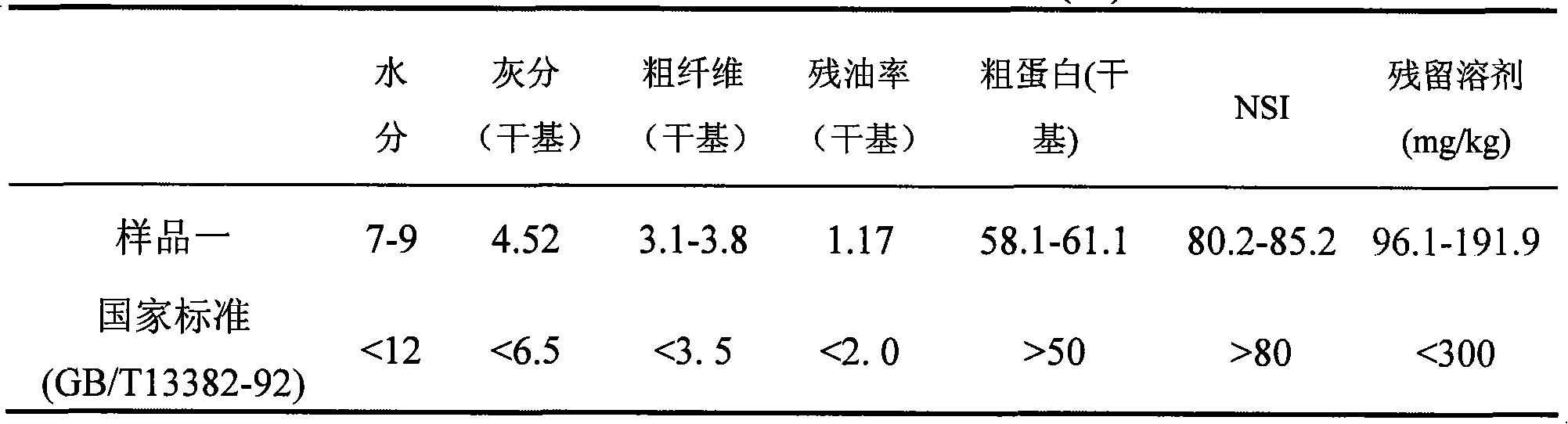

Method for producing low-temperature bean pulp with solvent extraction

The invention relates to a method for producing low-temperature soybean meal by the leaching method, belonging to the food industry low-temperature soybean meal production field. The method takes a soybean slice as a raw material and uses pentane as leaching solvent to perform degreasing, and then wet meal is obtained; and the wet meal enters into a desolventizer-toaster for vacuum low-temperature exsolution, and then the low-temperature soybean meal is obtained. The leaching temperature is between 15 and 35 DEG C, the leaching time is between 20 and 35 minutes and the leaching frequency is 3; the residual oil rate of the soybean meal is reduced to below 1 percent; the vacuum degree of exsolution of the wet meal is between 73 and 86 kPa; the exsolution temperature is between 40 and 60 DEG C and the exsolution time is between 0.5 to 1 hour; the residual oil rate of the low-temperature soybean meal produced can reach blow 1 percent and residual solvent is below 200 milligrams per kilogram; and the NSI value of proteins of the soybean meal exceeds 80 percent. The low-temperature soybean meal produced by the method has high protein content, complete shape, white color and no foreign odor.

Owner:JIANGNAN UNIV

Method for acid-leaching gallium from coal ash through microwave heating

ActiveCN103074498AReduce consumptionSimple leaching processProcess efficiency improvementPregnant leach solutionFoaming agent

The invention discloses a production process for floating gallium from coal ash. The production process comprises the following steps: a, adding a certain amount of coal ash of Qinghai Western Mining Industry Tanghu Power Plant into a floatation machine, wherein the gallium content of the coal ash is 25 g / ton; b, adding a certain amount of floatation regulator such as sodium silicate, octadecylamine floatation agent and foaming agent such as 2# oil into the floatation machine; c, performing floatation at room temperature by a rough sweeping floatation process; and d, obtaining the gallium concentrate, wherein the gallium grade is 40 g / ton and the recovery rate is 90 percent. By the production process, the problems of high recovering cost, high consumption of raw materials and serious environmental pollution caused by relatively low gallium content of the coal ash, large treatment quantity of direct acid-leaching and alkali-leaching process and large quantity of required leaching liquid in the conventional process for directly leaching the gallium from the coal ahs are solved; and by the process for floating the gallium from the coal ash, the quantity of mine to be treated is reduced by 50 percent under the condition of slightly reducing the recovery rate, and the leaching cost is greatly saved.

Owner:WESTERN MINING CO LTD

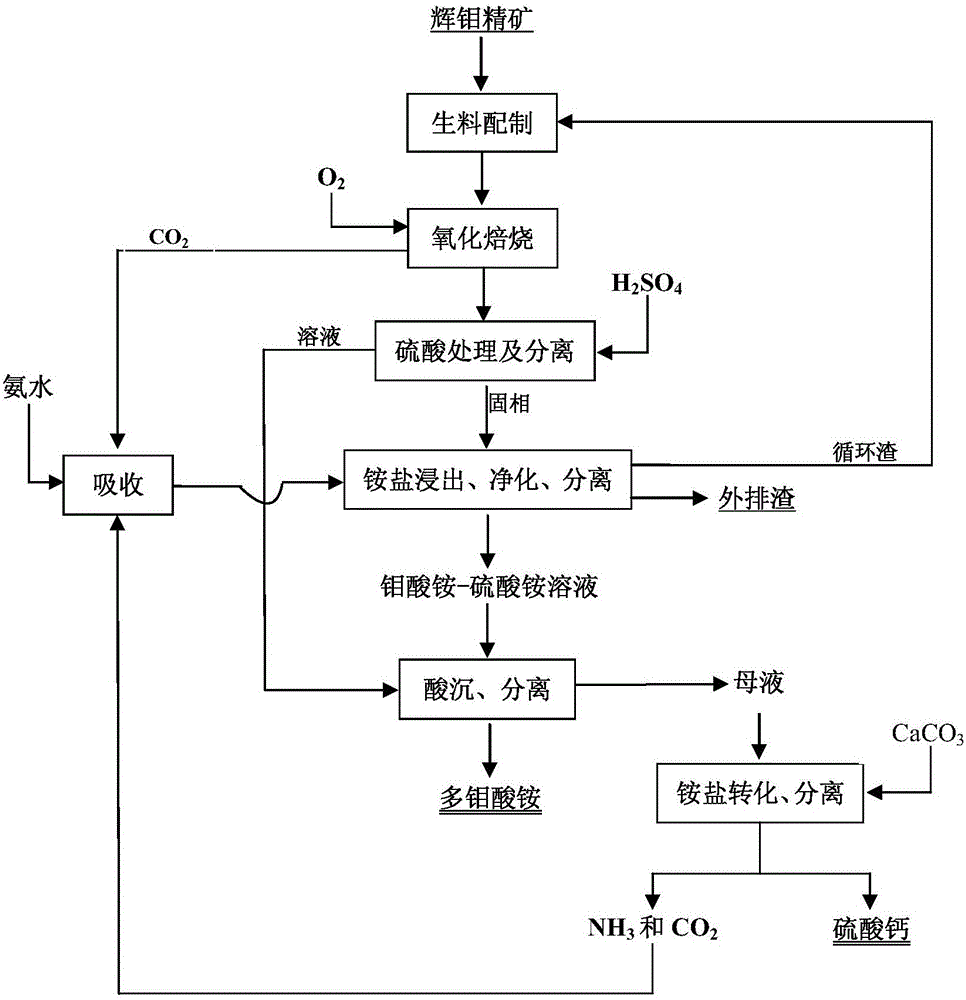

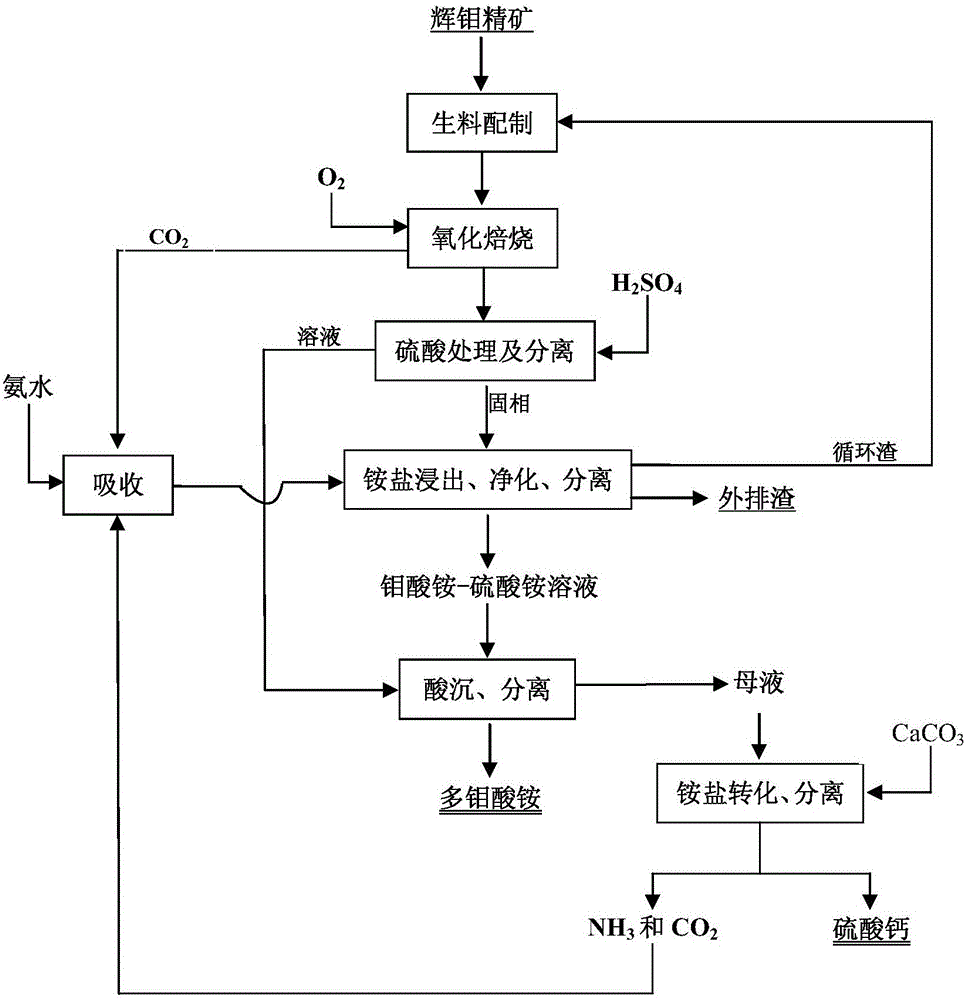

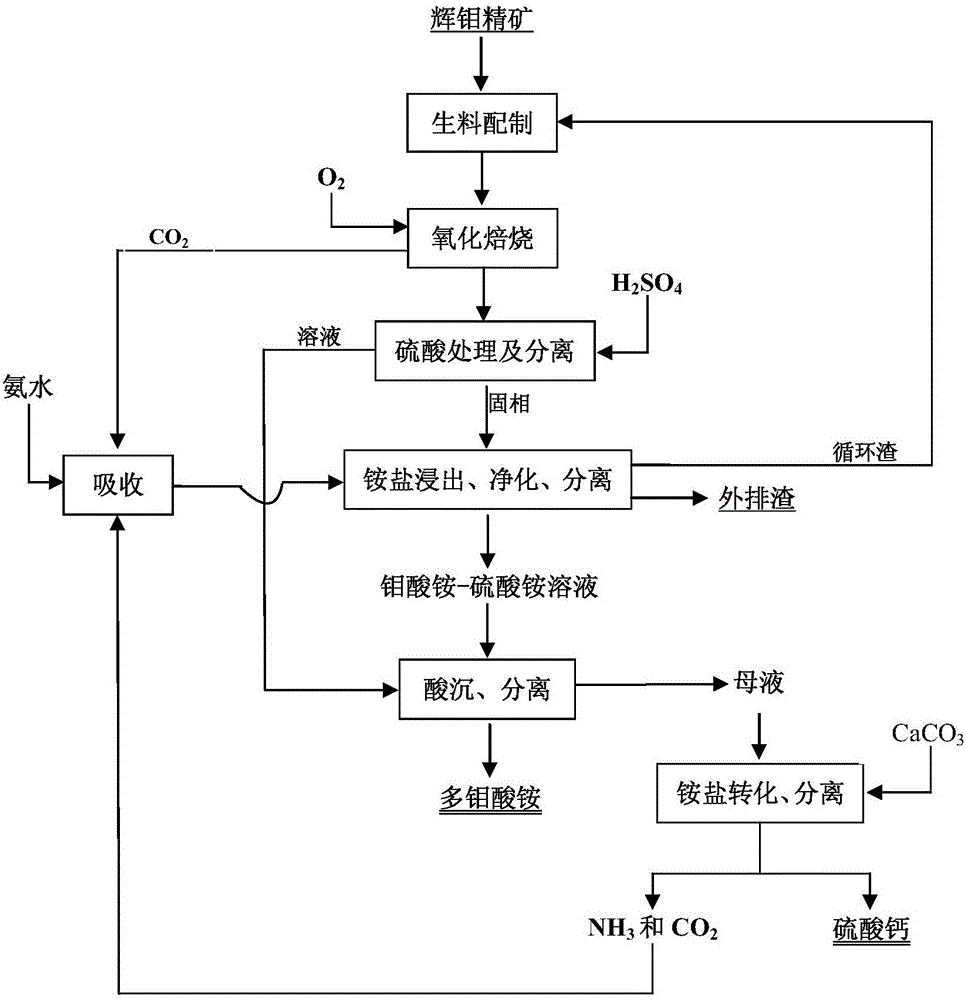

Clean metallurgical process for preparing ammonium molybdate by using molybdenite concentrate

InactiveCN105969976AReduce manufacturing costAchieve cycleProcess efficiency improvementDiammonium carbonateAmmonium sulfate

The invention discloses a clean metallurgical process for preparing ammonium molybdate by using molybdenite concentrate. The clean metallurgical process abandons a traditional limestone baking-ammonium carbonate solution leaching method so that an ammonium sulfate solution in mother liquor does not generate a low-value sulfide ammonium byproduct discharged from a production system, but cheap calcium carbonate which is easy to get is added and is efficiently transformed into an ammonium carbonate solution to realize circulation of ammonium / ammonia in the system; therefore all solutions in the system can be cyclically utilized, the intermediate product is polyammonium molybdate obtained by means of acid precipitation, and thus convenience can be provided for a subsequent molybdenum product preparation process. The clean metallurgical process specifically comprises the following steps: preparation of raw materials; oxidization and baking; pretreatment; leaching, purification and separation of ammonium salt; acid precipitation and separation; transformation and separation of the ammonium salt; recycle and adsorption, wherein NH3 and CO2 gases obtained in the production process are absorbed to obtain the ammonium carbonate solution, and a proper amount of ammonia water is replenished to prepare an ammonium salt solution leaching agent required by the leaching step. The clean metallurgical process disclosed by the invention is low in production cost and high in production efficiency.

Owner:CENT SOUTH UNIV +1

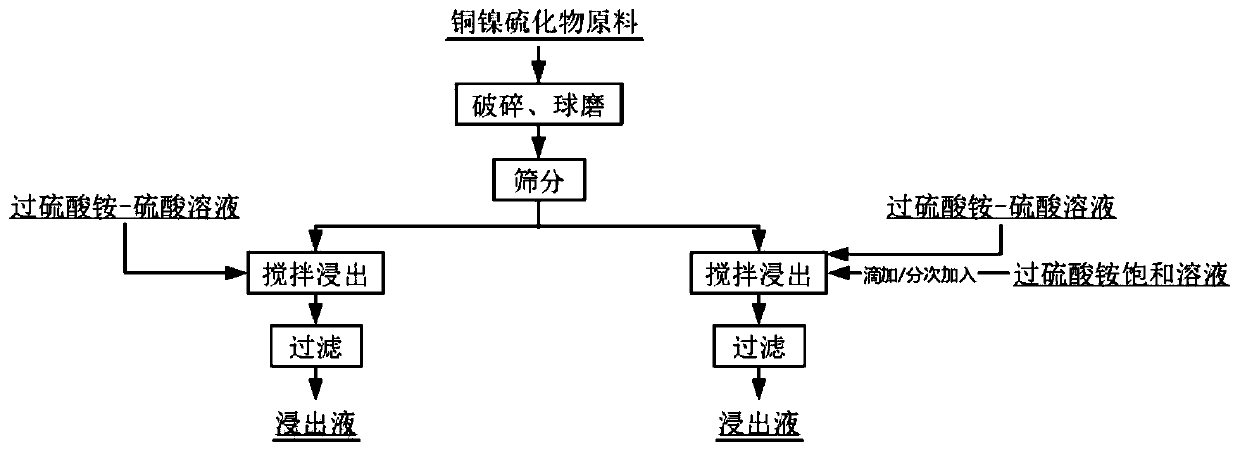

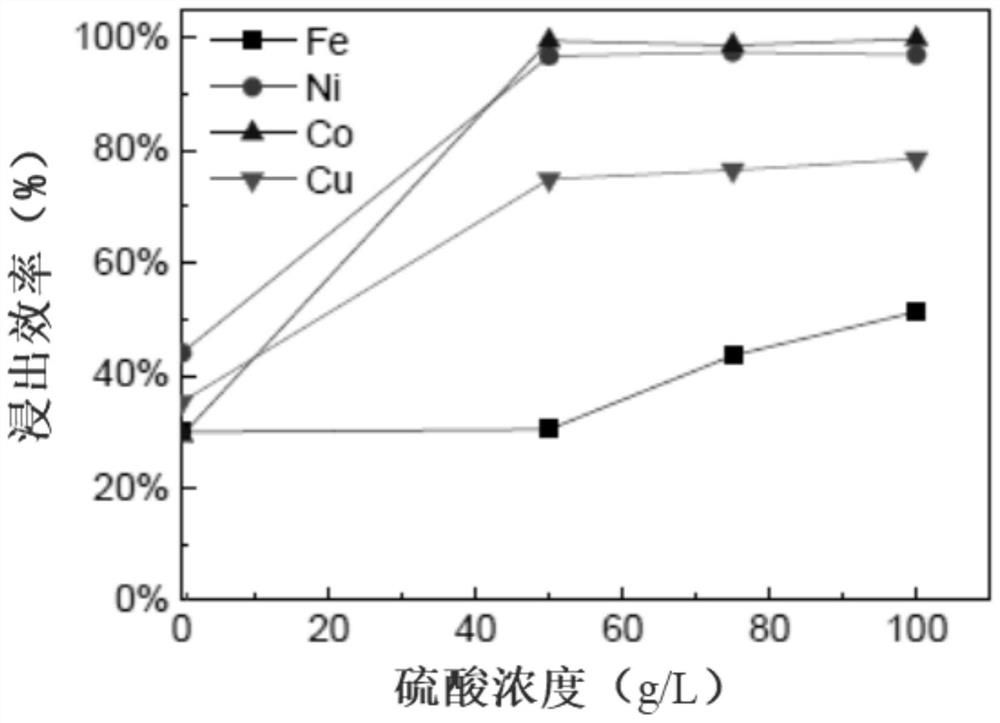

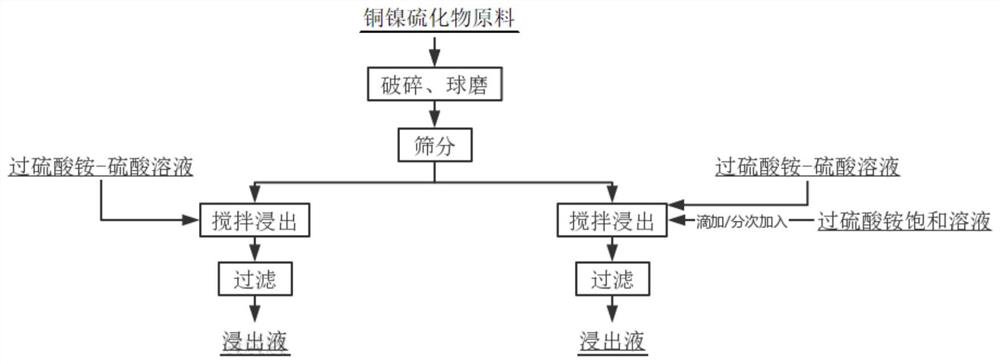

Method for extracting valuable metal from copper nickel sulfide through ammonium persulfate-sulfuric acid oxidation leaching

ActiveCN111411222ALow leaching temperatureLow concentration of sulfuric acidProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention discloses a method for extracting valuable metal from copper nickel sulfide through ammonium persulfate-sulfuric acid oxidation leaching. The method comprises the steps of screening low-grade copper nickel sulfide raw materials to obtain copper nickel sulfide mineral powder, according to the proportion, taking ammonium persulfate and sulfuric acid raw materials, adopting one (1) of the two manners in the ammonium persulfate to be completely mixed with sulfuric acid to form a mixture, and then uniformly mixing the mixture with mineral powder according to the proportion; and secondly, enabling the ammonium persulfate to be partly mixed with the sulfuric acid, partly making a saturated solution, under the specific temperature and system pH, performing a constant-temperature leaching reaction, in the leaching process, adding a saturated ammonium persulfate solution, finishing leaching and filtering, and obtaining leaching liquid, wherein the extraction rate of valuable metalNi in the leaching liquid is 90.4 to 97.5%, the extraction rate of Cu is 93.4 to 99.9%, and the extraction rate of Co is 92.7 to 99.6%. The method is low in leaching temperature, low in sulfuric acidconcentration, small in use amount, simple in process flow, and wide in application range, ore raw materials are limited by areas, ore, grade and the like, the extraction rate of the valuable metal ishigher, and no SO2 is emitted.

Owner:东北大学秦皇岛分校

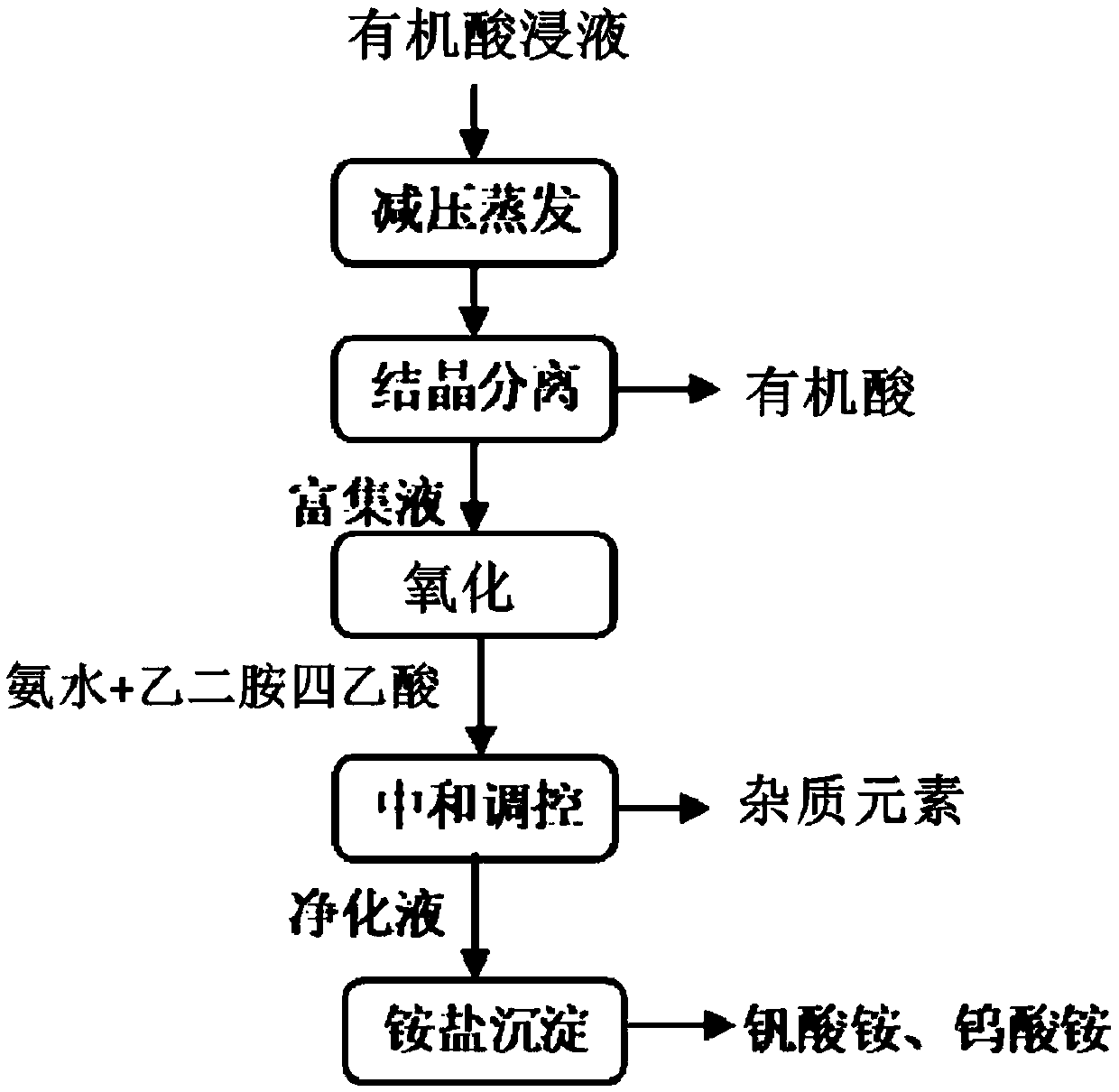

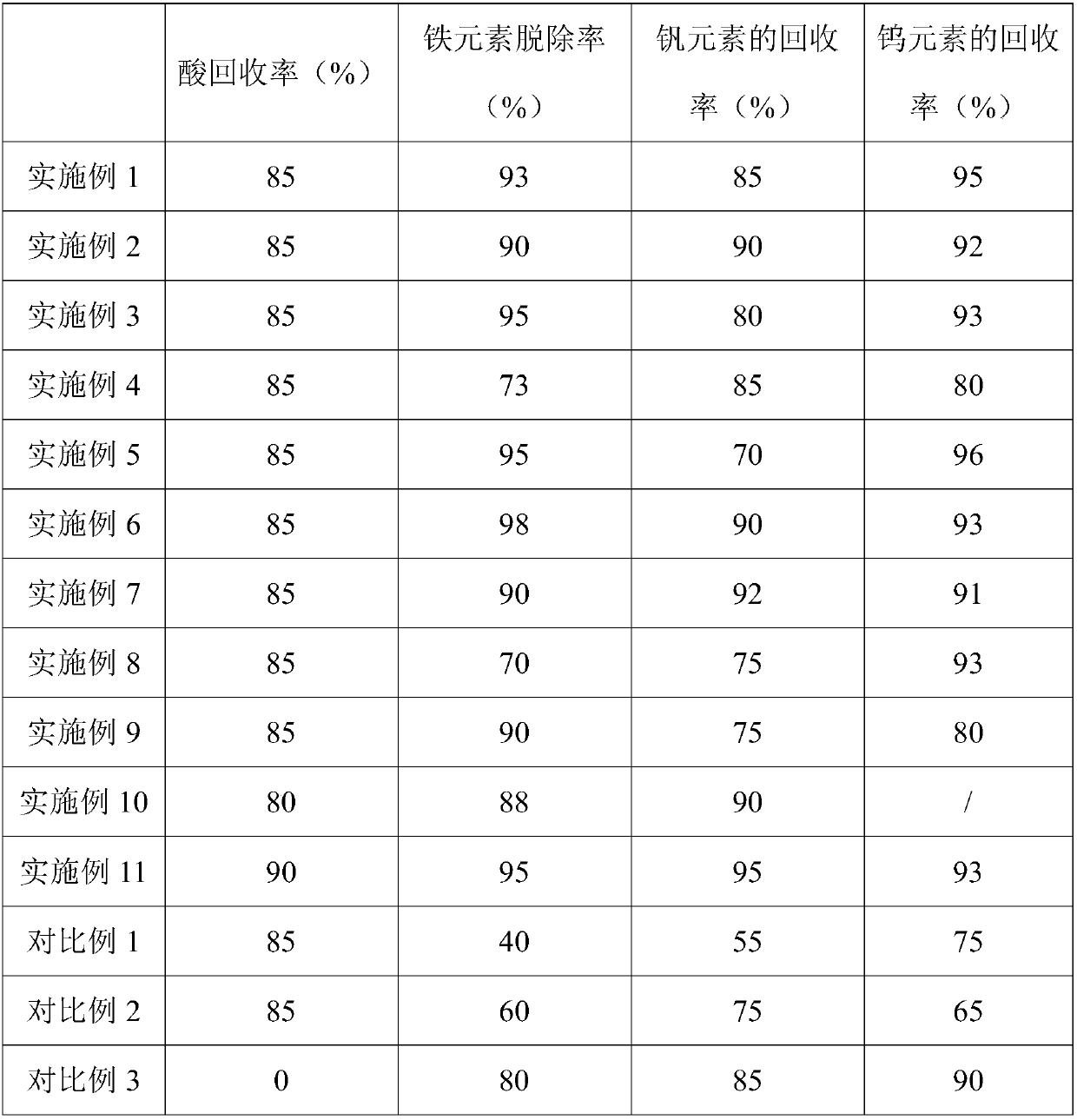

Method for recovering acid liquor and separating vanadium in process of reducing acid leaching vanadium-containing waste catalyst

ActiveCN111485105AImprove leaching rateAchieve recyclingProcess efficiency improvementVanadium CompoundsOrganic acid

The invention relates to a method for recovering acid liquor and separating vanadium in a process of reducing an acid leaching vanadium-containing waste catalyst. The method comprises the following steps: (1) carrying out acid leaching on the vanadium-containing waste catalyst by using an organic acid to obtain an organic acid leaching solution, and separating the organic acid to obtain an enrichment solution; and (2) oxidizing the enrichment solution, removing iron elements in the oxidized enrichment solution to obtain a purification solution, and then carrying out a vanadium element precipitation process on the purification solution to obtain a recovery product, wherein the recovery product is a vanadium compound. According to the method, the organic acid is recovered at first, the recovery rate reaches 80-90%, then the enrichment solution is oxidized, Fe2+ and V4+ in the enrichment solution are oxidized into Fe3+ and V5+ in the oxidation process, then the iron element is removed, the loss of the vanadium element in the iron element removal process is avoided, and the recovery rate of the vanadium compound is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recycling zinc from smelting waste residues

ActiveCN111926196AAvoid leachingReduce consumptionProcess efficiency improvementCalcium hypochloriteAmmonium sulfate

The invention discloses a method for recycling zinc from smelting waste residues. The method comprises the following steps: uniformly mixing the smelting waste residues with calcium hypochlorite, androasting at a high temperature to obtain a roasted product; uniformly mixing one coordination agent in citric acid or citrate with one coordination agent in tartaric acid or tartrate to obtain a coordination mixture, adding water, adding an ammonia water solution and ammonium sulfate after uniformly adding, uniformly mixing to form a coordination leaching agent; putting the obtained roasted product in the coordination leaching agent to subject to ultrasonic reaction to obtain a zinc leaching solution; adding zinc powder into the obtained leaching solution to react for certain time, then, filtering, and performing high-temperature roasting on the obtained filtrate to obtain zinc oxide. While a leaching rate of zinc in the smelting waste residues is guaranteed, impurity irons therein are prevented from leaching out; and the obtained zinc leaching solution can be roasted at a high temperature to directly obtain a high-purity zinc oxide product, so that zinc in the smelting waste residuesis conveniently recycled to apply in the industry.

Owner:LIUPANSHUI NORMAL UNIV

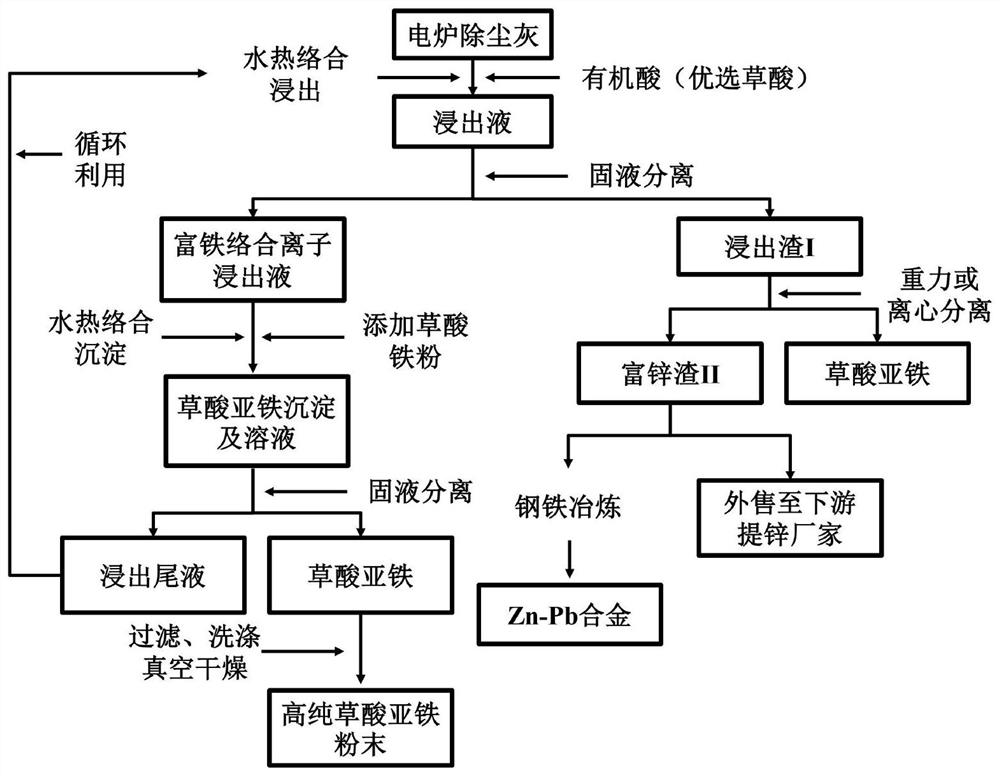

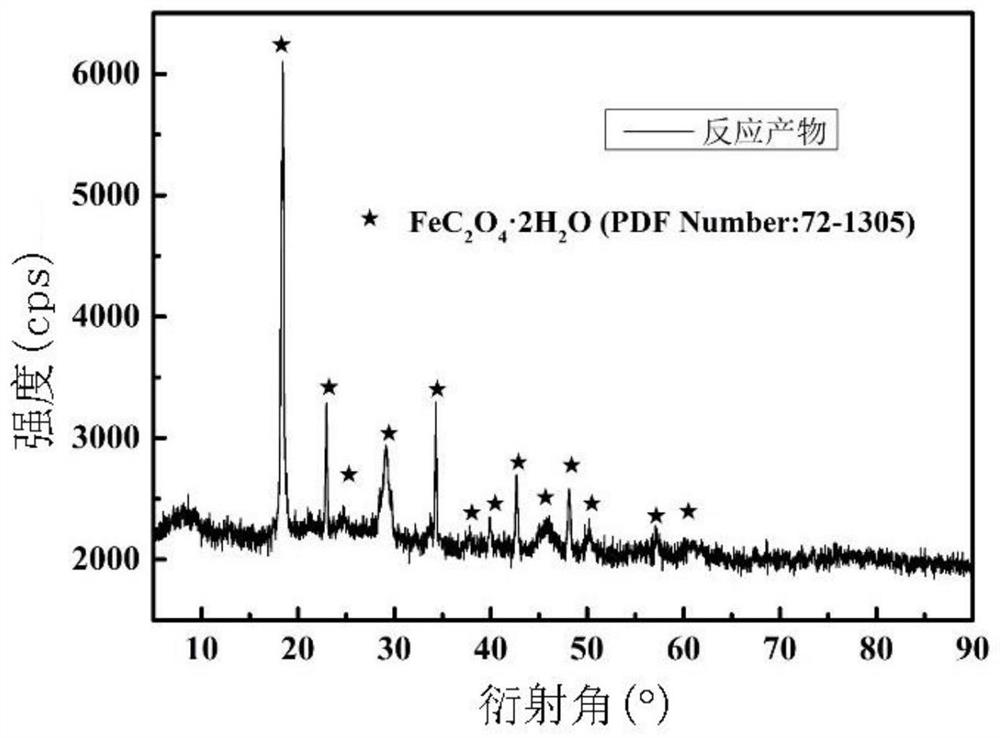

Method for extracting Fe, Zn and Pb from electric furnace fly ash and utilizing Fe, Zn and Pb in high-value mode

InactiveCN113787085AFine granularityHigh recovery rateSolid waste disposalProcess efficiency improvementOXALIC ACID DIHYDRATEReaction temperature

The invention discloses a method for extracting Fe, Zn and Pb from electric furnace fly ash and utilizing Fe, Zn and Pb in a high-value mode. A large amount of dangerous waste electric furnace fly ash is used as a raw material, oxalic acid is used as a leaching agent, and a complex reaction is performed under the reaction conditions of low temperature and normal pressure, so that the purpose of stepwise separating iron and zinc resources is achieved. Under the conditions that the concentration of the oxalic acid is 5-30%, the liquid-solid ratio is 10:1-50:1, the reaction temperature is 30-90 DEG C and the reaction time is 0.5-4 h, the leaching rate of Fe in the electric furnace fly ash can reach 92% or above, the content of Zn (in terms of ZnO) in leaching residues can reach 36% or above, and the purity of finally obtained ferrous oxalate can reach 97% or above. The method is simple in process, low in energy consumption and low in reaction cost; and the obtained ferrous oxalate and zinc-rich residues have higher additional value, meanwhile, the influence on the environment is smaller, and the method has good market application prospects.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

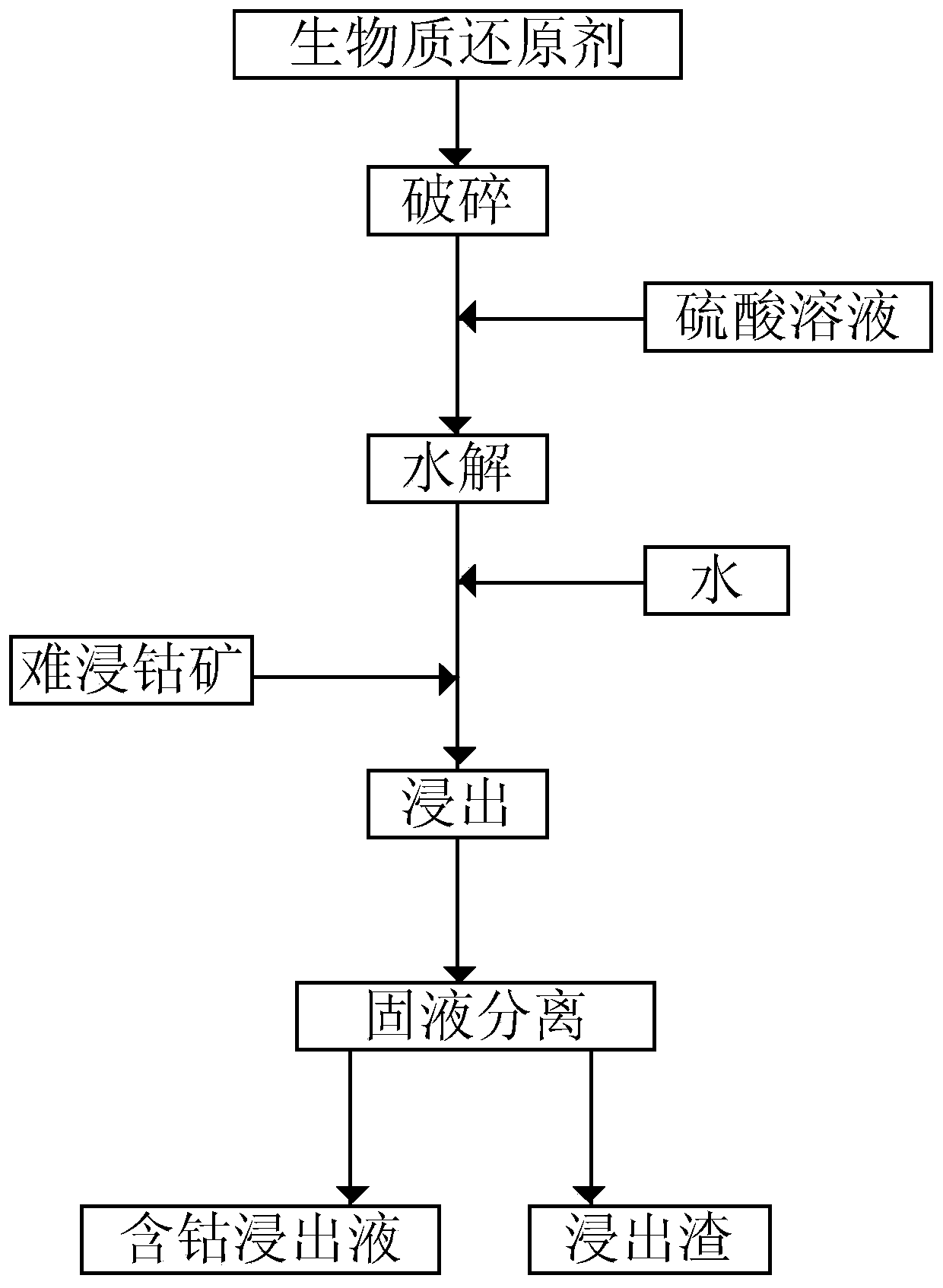

Leaching method of refractory cobalt ore

ActiveCN110184455AWide variety of sourcesLow leaching temperatureRotary drum furnacesCrucible furnacesRefractoryEconomic benefits

The invention discloses a leaching method of refractory cobalt ore. The leaching method of the refractory cobalt ore comprises the following steps that (1), after a biomass reducing agent is crushed,a sulfuric acid solution is added for hydrolysis, wherein the biomass reducing agent is poplar or straw; (2) a hydrolyzed material is dissolved in water, and then the refractory cobalt ore is placed in for leaching; and (3) the leached material is subjected to solid-liquid separation to obtain a cobalt-containing leachate. In the method, the leaching reducing agent is wide in raw material source,environmentally friendly, low in leaching temperature and short in leaching time. No harmful gas is produced in the leaching process, environmental pollution of enterprises is reduced, the productioncost is reduced, and economic benefits and the yield are improved.

Owner:NORTHEASTERN UNIV

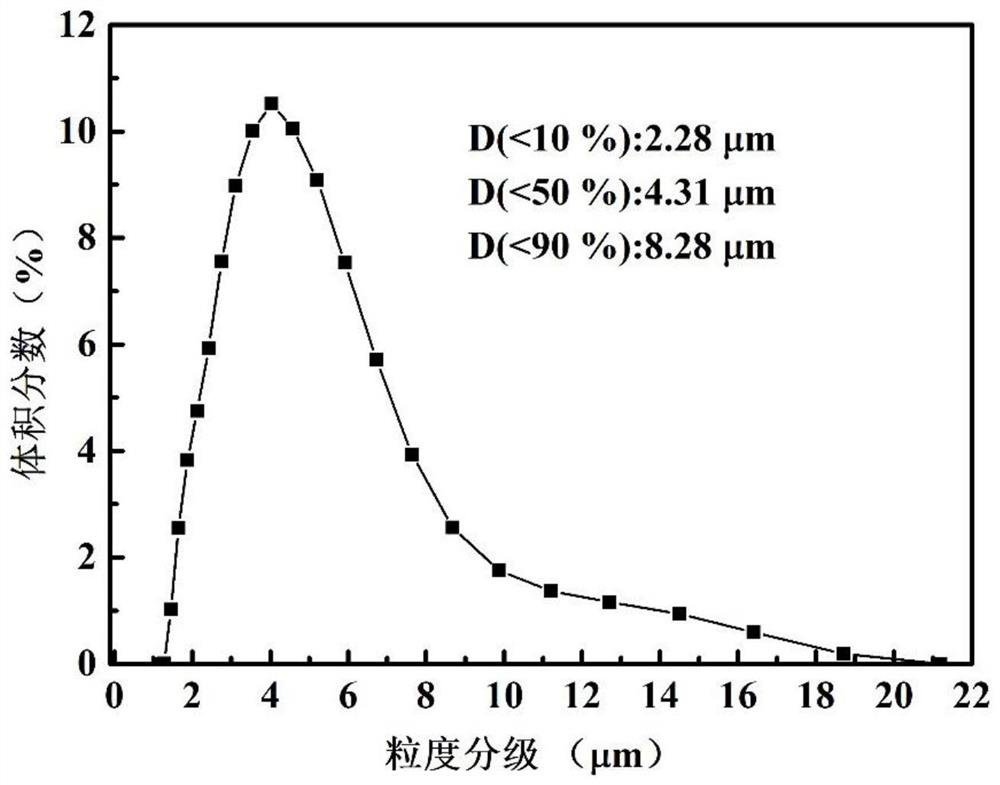

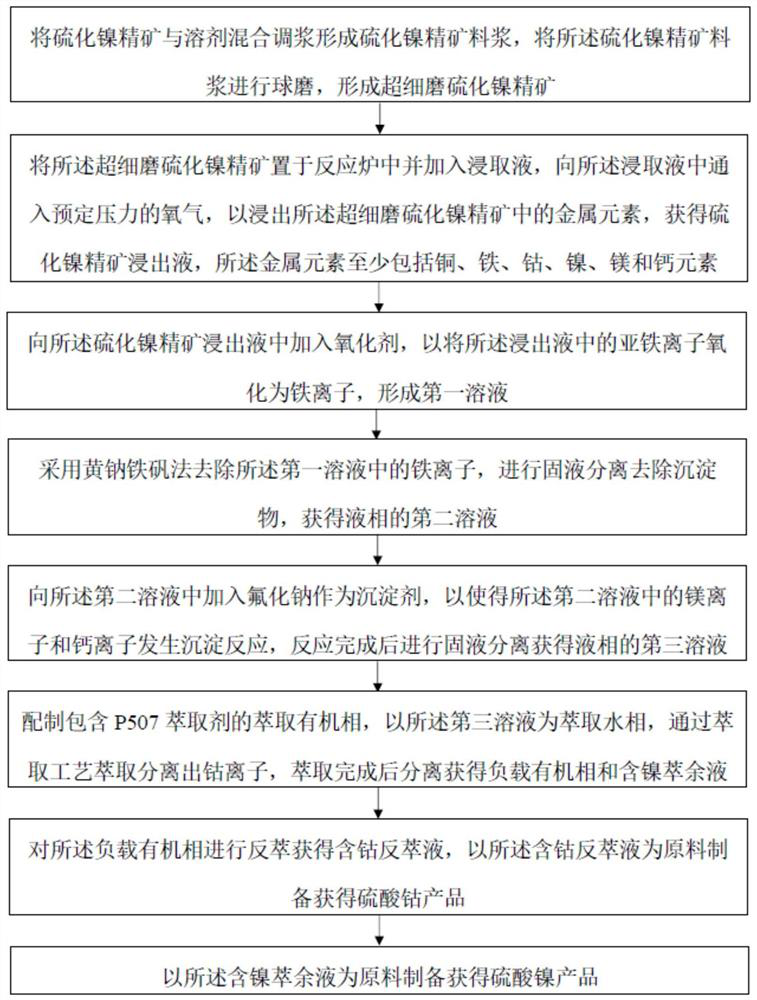

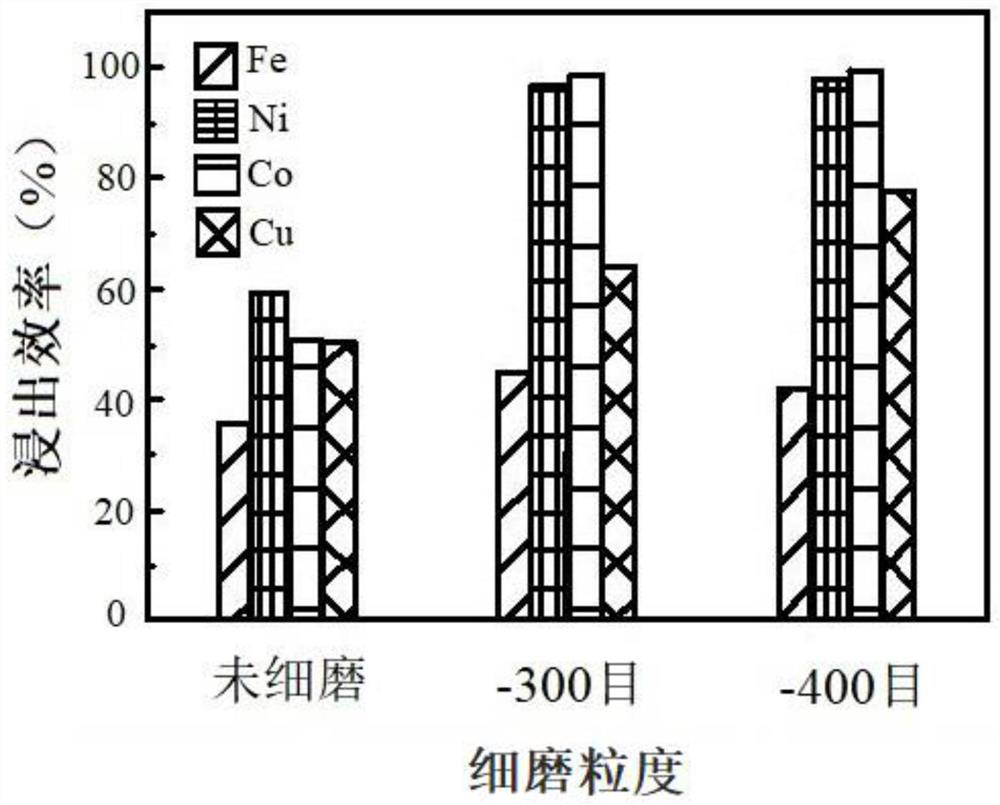

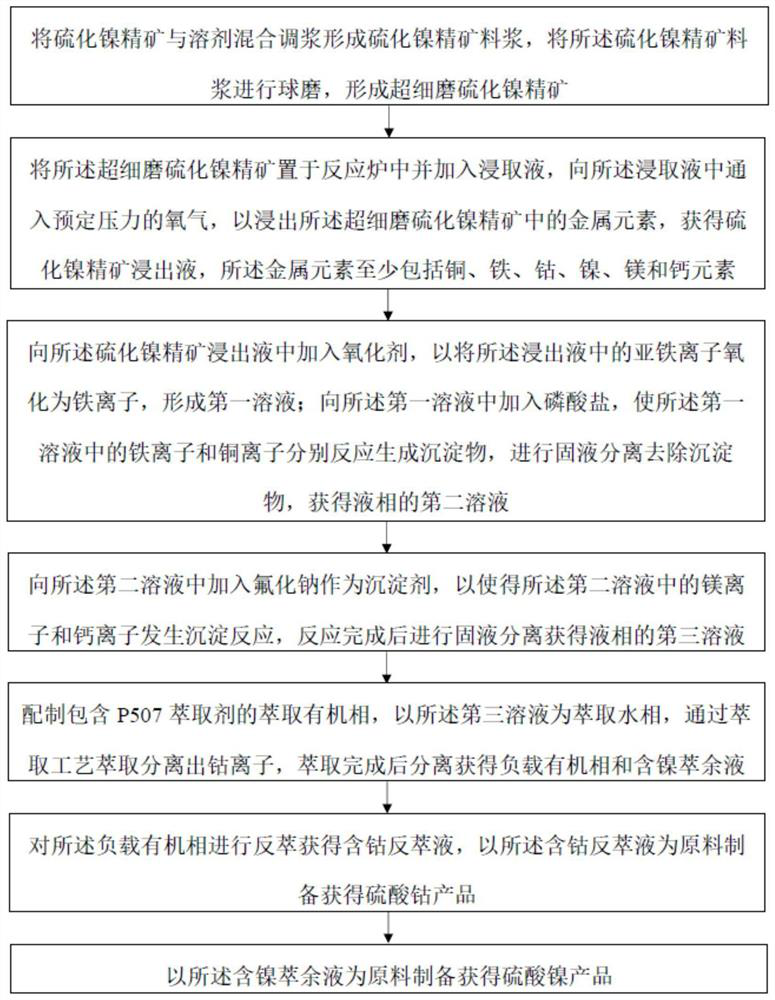

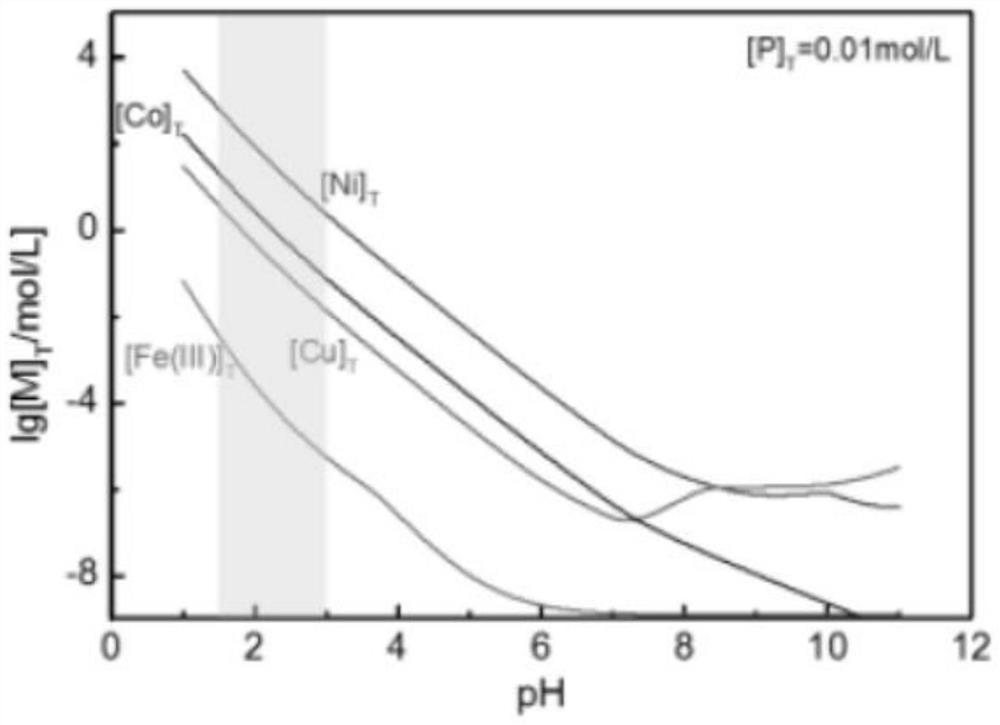

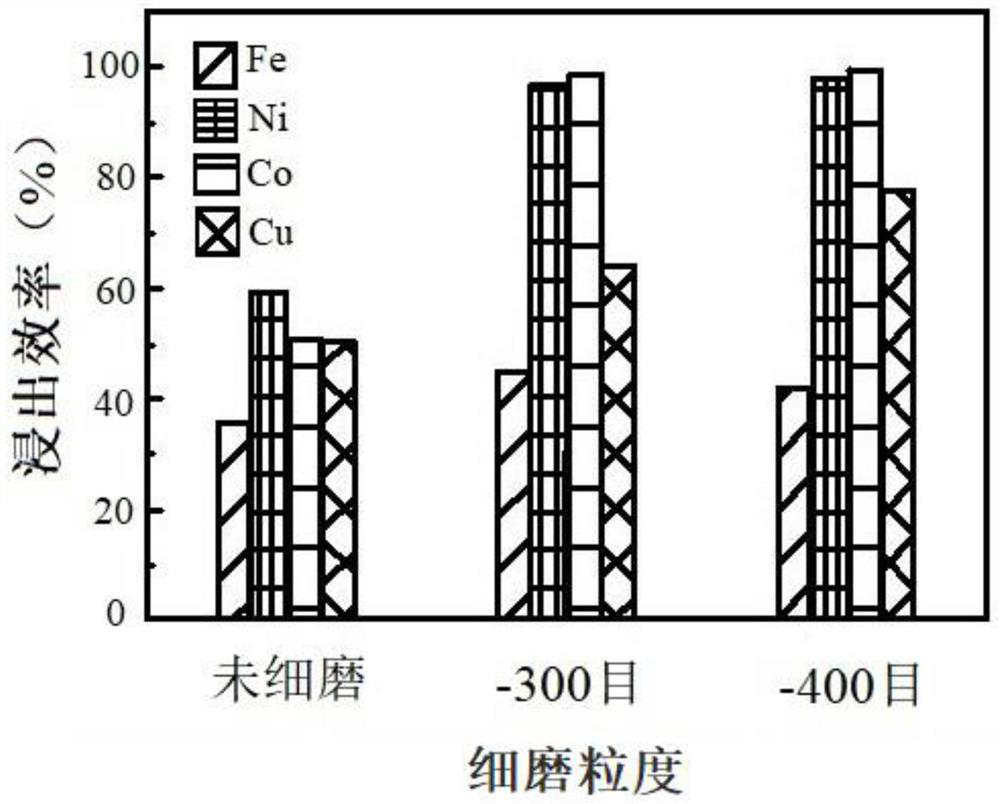

Method for selectively extracting cobalt and nickel from nickel sulfide concentrate

PendingCN113416856ALow leaching temperatureReduce leaching energy consumptionProcess efficiency improvementNickel sulfideMaterials science

The invention provides a method for selectively extracting cobalt and nickel from nickel sulfide concentrate. The method comprises the following steps: metal elements in the nickel sulfide concentrate are selectively leached through a superfine grinding-oxygen pressure leaching process to obtain nickel sulfide concentrate leachate, wherein the metal elements at least comprise copper, iron, cobalt, nickel, magnesium and calcium elements; an oxidizing agent is added into the nickel sulfide concentrate leachate to generate precipitates containing iron ions, and therefore the iron ions in the leachate are removed through a sodium jarosite method; sodium fluoride is added as a precipitator to carry out precipitation reaction so as to remove calcium ions and magnesium ions in the leachate; and cobalt ions and nickel ions are extracted and separated through an extraction process to prepare a cobalt sulfate product and a nickel sulfate product. According to the method, efficient recycling of the nickel element in the nickel sulfide concentrate is achieved, other metal elements are further utilized to reduce environmental pollution, and the resource utilization rate and the utilization value of raw materials are improved.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +3

Method for leaching gallium from fly ash acid by microwave heating

ActiveCN103074498BReduce consumptionSimple leaching processProcess efficiency improvementPregnant leach solutionFoaming agent

The invention discloses a production process for gallium flotation in fly ash, which comprises the following steps: a. Take a certain amount of fly ash from Qinghai West Mining Tanghu Power Plant and add it to the flotation machine, and the powder Gallium content is 25 grams per ton in the coal ash; b. add a certain amount of flotation adjustment agent such as water glass, octadecylamine flotation agent and foaming agent such as No. 2 oil etc. in the flotation machine; c. adopt a coarse Flotation is carried out at room temperature in the one-sweep flotation process; d. Gain a gallium concentrate with a gallium grade of 40 g / t, and the recovery rate is 90%. The invention solves the problem that the gallium content in the fly ash that exists in the existing process of directly leaching gallium from the fly ash is relatively low, the processing capacity of the direct acid leaching or alkali leaching process is large, and the amount of leachate required is also large, resulting in High recovery cost, large consumption of raw materials, and serious environmental pollution. By using the fly ash flotation gallium process, the amount of ore to be processed can be reduced by 50% without reducing the recovery rate much, which greatly saves the cost of leaching. .

Owner:WESTERN MINING CO LTD

Clean metallurgic method for preparing ammonium molybdate from molybdenite concentrates

InactiveCN105861814AReduce manufacturing costAchieve cycleMolybdeum compoundsProcess efficiency improvementDiammonium carbonateAmmonium sulfate

The invention discloses a clean metallurgic method for preparing ammonium molybdate from molybdenite concentrates. The traditional limestone roasting and ammonium carbonate solution leaching method is abandoned to ensure that an ammonium sulfate solution in a mother solution does not form a low-value ammonium sulfate byproduct to be discharged from a production system again, but is efficiently converted into an ammonium carbonate solution through adding cheap and available calcium carbonate, so that the circulation of ammonium / ammonia in the system is realized, and furthermore all the solutions in the system can be recycled; in addition, an intermediate product is ammonium polymolybdate obtained through acid precipitation so as to facilitate carrying out a preparation process for a subsequent molybdenum product. The clean metallurgic method concretely comprises the steps of raw material configuration; oxidizing roasting; pretreatment; ammonium salt leaching; purification and separation; acid precipitation and separation; ammonium salt conversion and separation; and recovery and absorption, wherein an ammonium salt solution leaching agent required in the leaching step is prepared by adding the NH3 and CO2 gases obtained in the production process and the ammonium carbonate solution obtained after absorption and replenishing a proper quantity of ammonia water. The clean metallurgic method is low in production cost and high in production efficiency.

Owner:江钨高技术开发应用有限公司 +1

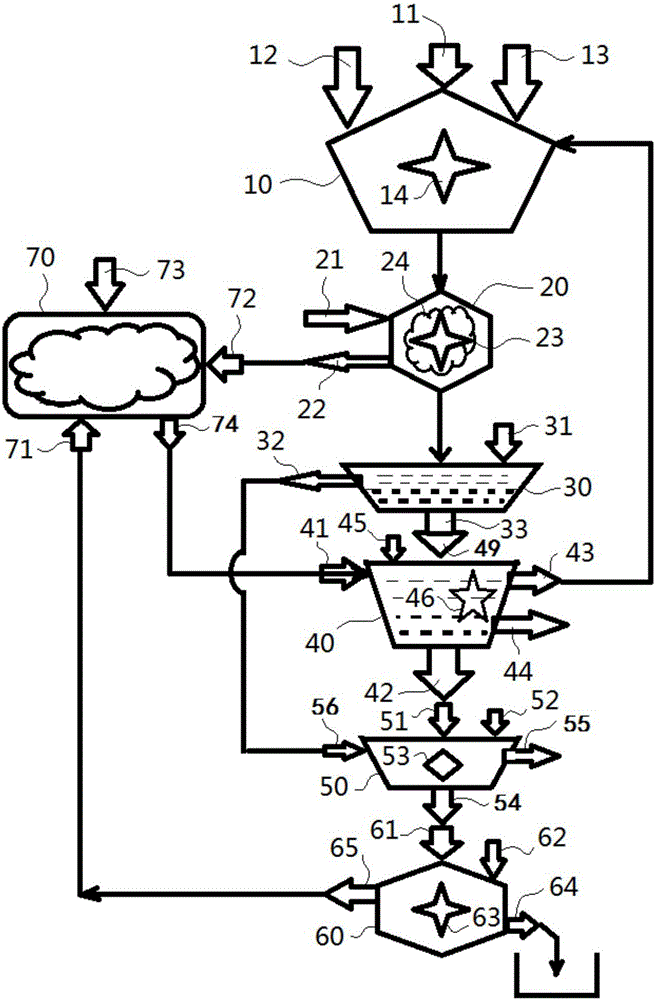

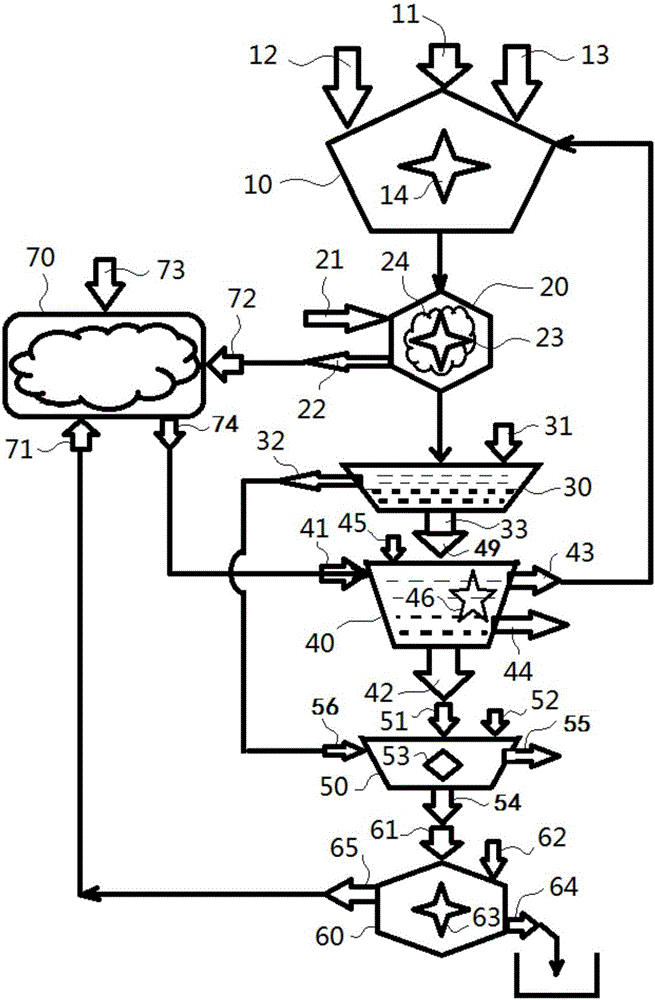

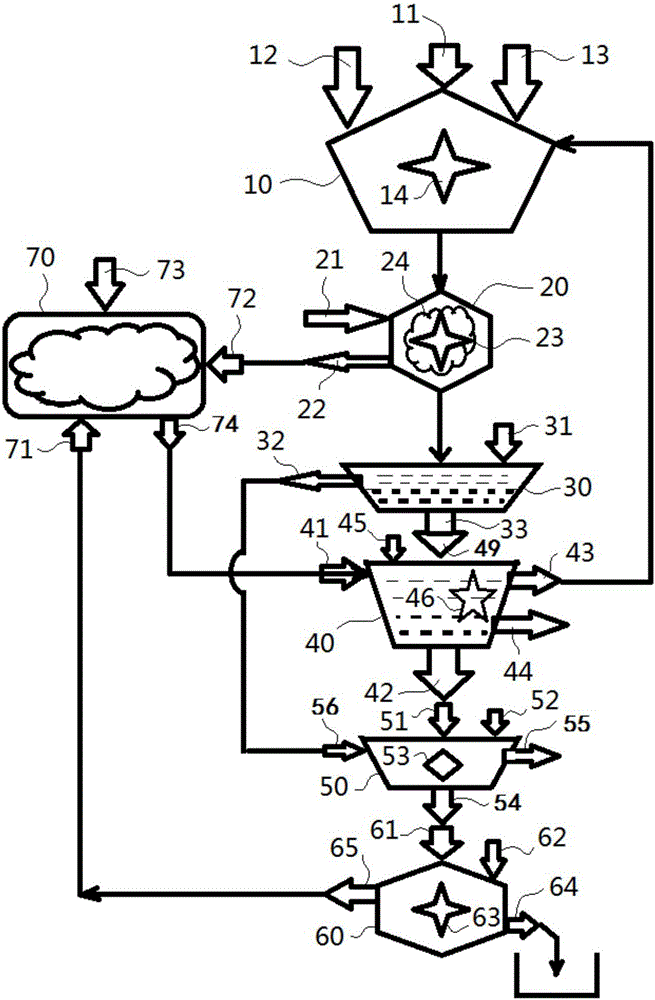

Clean metallurgical system for preparing ammonium molybdate from molybdenite concentrate

The clean metallurgical system for preparing ammonium molybdate from a molybdenite concentrate comprises a raw material preparation device, a clinker generating device, a clinker pretreatment device, an ammonium salt leaching, purifying and separating device, an acid precipitation and separation device, an ammonium salt conversion and separation device and an absorption device, wherein the raw material preparation device is provided with a molybdenite inlet and a calcium carbonate inlet; the clinker generating device is provided with a roaster, an oxygen inlet, a carbon dioxide outlet and a clinker fine-grinder; the clinker pretreatment device is provided with a pretreatment solution outlet and a pretreatment slag outlet; the ammonium salt leaching, purifying and separating device is provided with a leaching agent inlet, a solution purifying and liquid-solid separating device, a coarse ammonium molybdate solution outlet and a leaching residue returning outlet; the acid precipitation and separation device is provided with a precipitator inlet, a solid-liquid separator, a multiple ammonium molybdate intermediate product outlet, an acid precipitation mother liquor outlet and a pretreatment solution inlet; the ammonium salt conversion and separation device is provided with a size solid-liquid separator, a calcium sulfate solid-phase outlet, and an NH3 and CO2 gas outlet; and the absorption device is provided with an NH3 and CO2 gas recovery inlet, a CO2 gas recovery inlet, an ammonia water supplementing inlet and a re-synthesized leaching agent outlet. The clean metallurgical system is low in production cost, high in production efficiency and free from pollution.

Owner:江钨高技术开发应用有限公司 +1

Method for preparing zinc oxide from material recovered from zinc-containing anticorrosive paint waste

InactiveCN110878391ASolve the dosageSolve process problemsProcess efficiency improvementPregnant leach solutionHigh energy

The invention relates to the technical field of novel material processing, and discloses a method for preparing zinc oxide from a material recovered from zinc-containing anticorrosive paint waste. Through pretreatment of the zinc-containing anticorrosive paint waste, the influence of hydrolysis of organic matter in paint on leaching extraction separation purification in a next step is reduced, theleaching rate is improved, the separation difficulty is reduced, the leaching time is shortened, the leaching temperature is reduced, and the acidity of a leaching solution can be selected at a lowerlevel range; in the extraction process, an extraction reagent and control conditions are selected to achieve high-efficiency low-energy consumption extraction results, finally the zinc oxide is prepared through recovery, the recovery rate is increased by 15-20%, the impurity content is less than 0.001%, and the purity reaches a class-I standard; and the method can significantly improve the quality of the zinc oxide prepared through recovery, reduce energy consumption and save costs, the recovery rate reaches 94% or more, the problems of a complex process, high energy consumption, a low yieldand low quality of current raw ore zinc pyrometallurgy can be solved, and the economic and social benefits are significantly improved.

Owner:安徽泰龙锌业有限责任公司

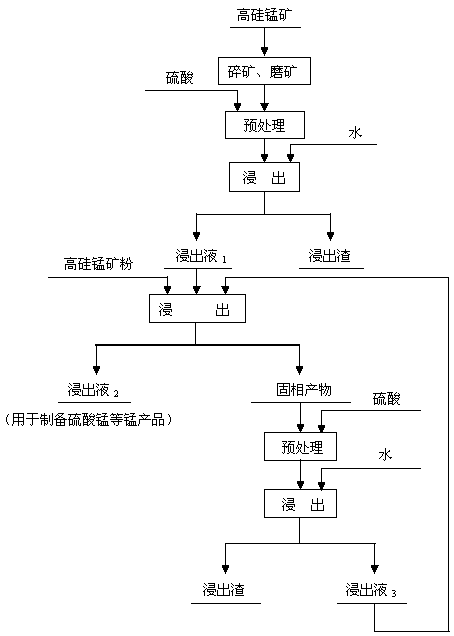

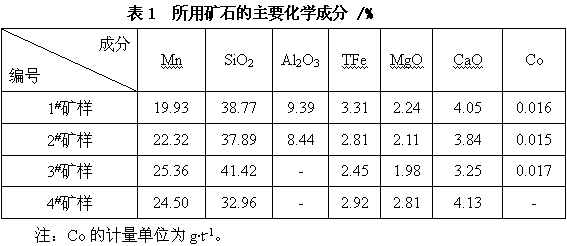

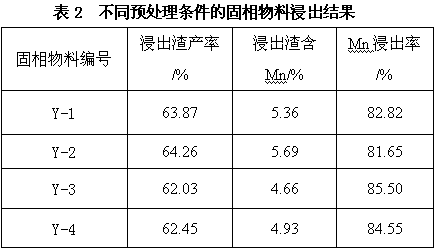

A method for extracting manganese from manganese ore containing manganese silicate minerals

ActiveCN107400790BReduce utilizationImprove leaching rateProcess efficiency improvementHydrometallurgySilicate minerals

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Process for extracting bacterial cell coenzyme Q10

InactiveCN101274884BIncreasing concentration gradientDiffusion thinQuinone separation/purificationBacteroidesMicroorganism

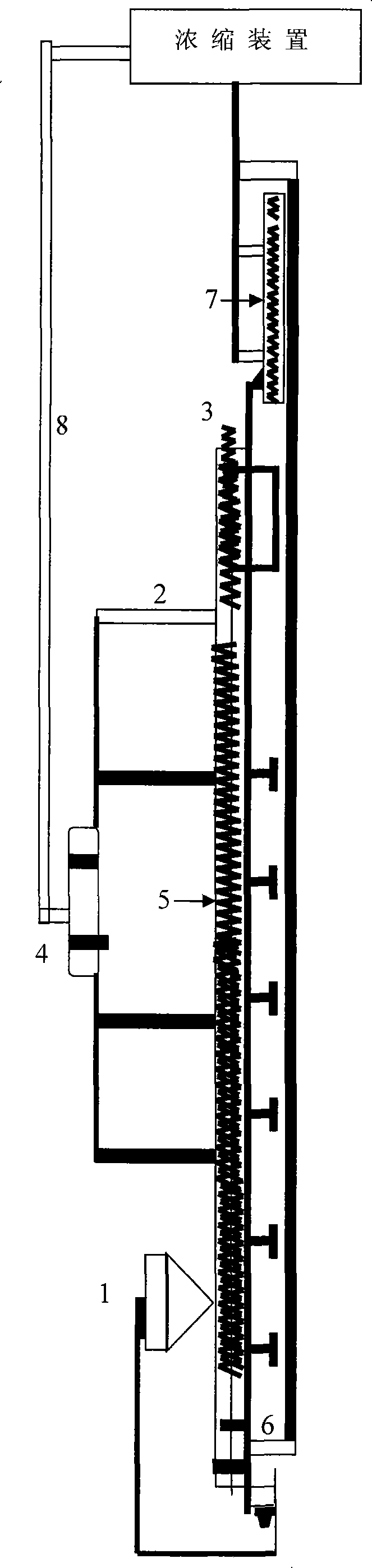

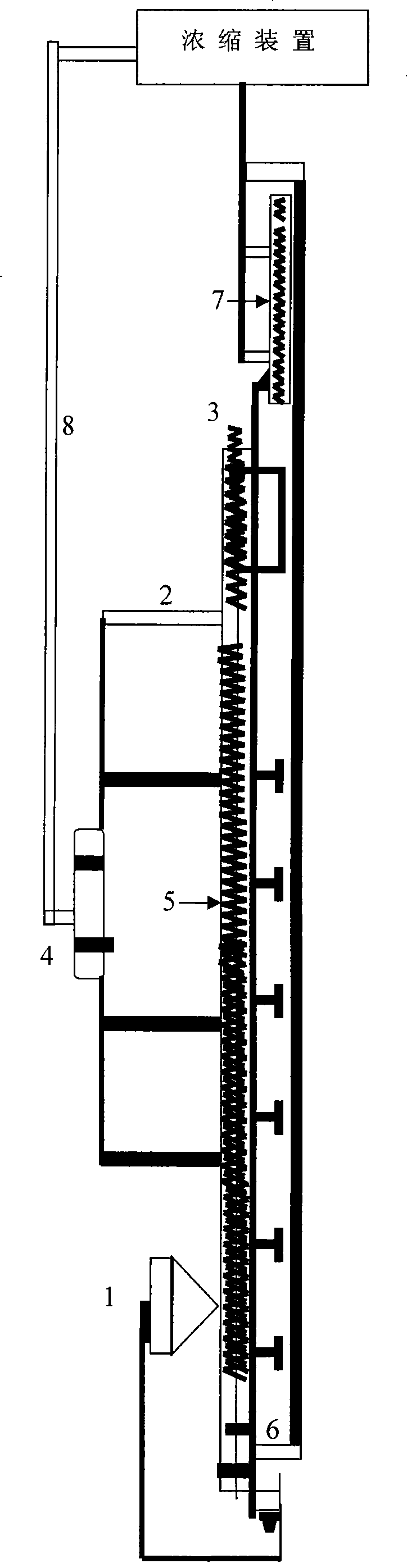

The invention relates to a technology for extracting coenzyme Q10 in bacterial cells, which pertains to the technical field of microbiology engineering. Thalli is automatically and quantitatively put into from the dog-house of a continuous countercurrent device under the control of a weigh-instrument, a solvent is injected from a solvent inlet under the control of a flowmeter and the leaching solution and the thalli form reverse continuous countercurrent leaching process under the push of a shovel-like thruster; the concentration gradient is large, relative movement exists between the solventand the thalli and the thalli moves from the left end to the right end of an extraction container continuously under the function of the shovel-like thruster while the solvent moves from the right end to the left end of the container under the action of pressure; a diffusion boundary layer is thin and fast to be updated and the coenzyme Q10 is extracted after 2 to 10 hours of reaction of the thalli which enters from the left end of the device after the contact of the solvent and the thalli; the thalli enters a rake type dryer from the right end of an extraction device by press treatment and residual organic solvent in the thalli is treated with drying treatment in the rake type dryer; the yield of the coenzyme Q10 reaches more than 90 percent.

Owner:SHENZHOUSPACEBIOTECHGRP +1

A method for extracting vanadium by reductive organic acid leaching of spent vanadium-containing catalyst

ActiveCN105986123BImprove leaching rateLow leaching temperatureProcess efficiency improvementSlagOxygen

The invention relates to the field of non-ferrous metallurgy and resource recycling, in particular to a novel process for extracting vanadium from vanadium-containing waste catalyst reductive organic acid. The novel process comprise the steps that a vanadium-containing waste catalyst is directly extracted in a reductive organic acid system, and other reductive agents are not added, so that pentavalent or tetravalent vanadium is directly reduced into vanadium-oxygen-based ions or trivalent vanadium ions, the vanadium-oxygen-based ions or the trivalent vanadium ions are combined with organic acid radical anions and enter a solution, and vanadium-containing leaching liquid and vanadium-containing leaching slag are obtained; and ammonia water is added into the vanadium-containing leaching liquid to adjust pH so that ammonium vanadate can be formed and precipitated, and after separating is conducted, a vanadium pentoxide product is obtained by calcining precipitation slag. According to the novel process for extracting the vanadium from the vanadium-containing waste catalyst reductive organic acid, the vanadium is extracted by adopting the reductive organic acid system; the extracting condition is mild; the vanadium extracting rate is 95% or above and higher than the direct inorganic acid fluid extracting rate; and other impurity ions are not introduced in the extracting process, so that recycling of other metal elements in the waste catalyst is not affected.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for selectively extracting cobalt and nickel from nickel sulfide concentrate

PendingCN113430370ALow leaching temperatureReduce leaching energy consumptionCobalt sulfatesNickel sulfatesPhosphateSlag

The invention provides a method for selectively extracting cobalt and nickel from nickel sulfide concentrate. The method comprises the following steps: metal elements in the nickel sulfide concentrate are selectively leached through a superfine grinding-oxygen pressure leaching process to obtain nickel sulfide concentrate leachate, wherein the metal elements at least comprise copper, iron, cobalt, nickel, magnesium and calcium elements; phosphate is added into the nickel sulfide concentrate leachate to generate iron phosphate slag and phosphate slag precipitates so as to remove iron ions and copper ions in the leachate; sodium fluoride is added as a precipitant to carry out precipitation reaction so as to remove calcium ions and magnesium ions in the leachate; and cobalt ions and nickel ions are extracted and separated through an extraction process correspondingly to prepare a cobalt sulfate product and a nickel sulfate product. According to the method, efficient recycling of the nickel element in the nickel sulfide concentrate is achieved, other metal elements are further utilized to reduce environmental pollution, and the resource utilization rate and the utilization value of raw materials are improved.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +3

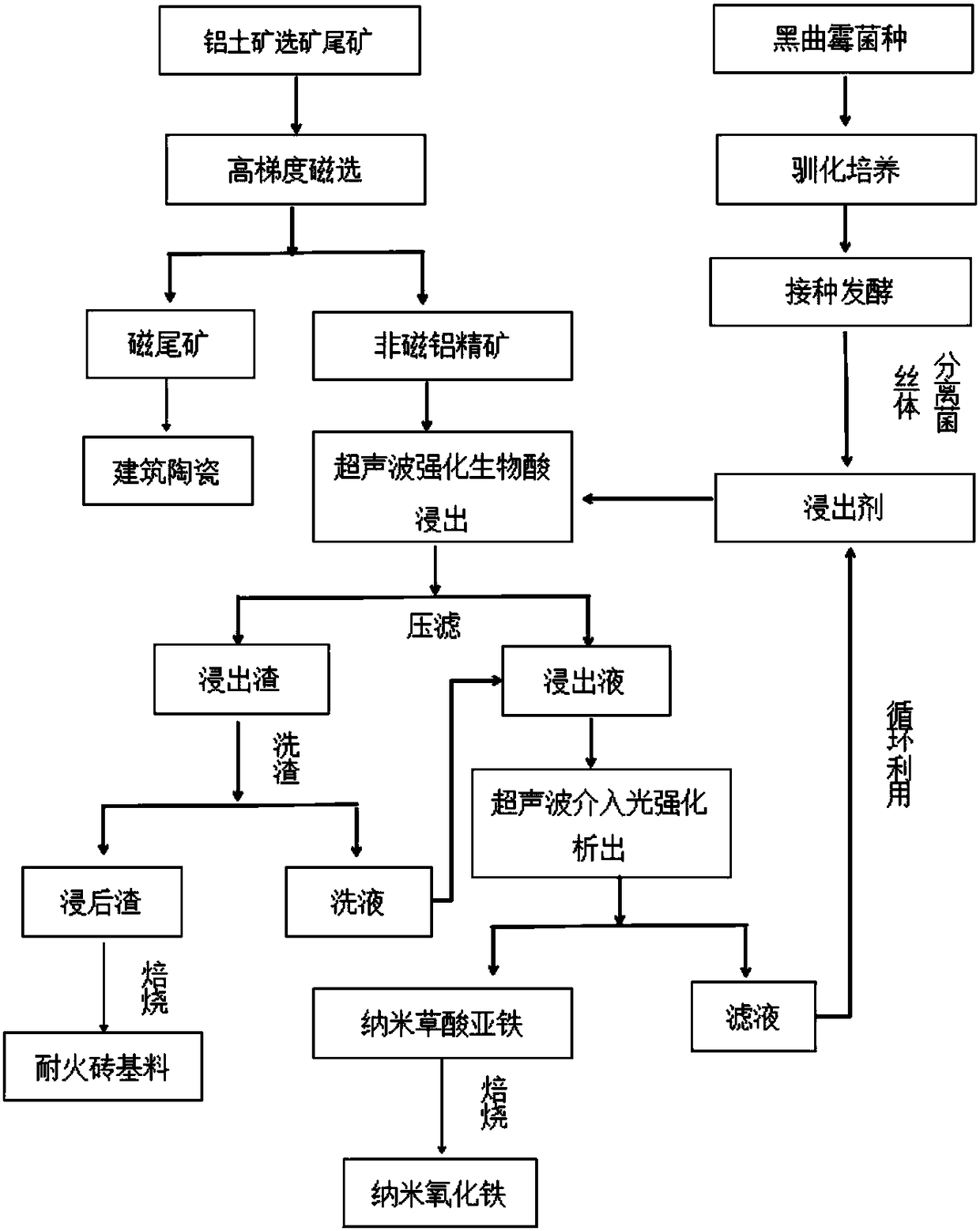

Method for preparing low-iron refractory brick base material and coproducing nano iron oxide by utilizing bauxite tailings

PendingCN108530092AReduce iron contentIncrease temperatureNanotechnologyFerric oxidesBrickResource utilization

The invention discloses a method for preparing a low-iron refractory brick base material and coproducing nano iron oxide by utilizing bauxite tailings, and belongs to the field of comprehensive utilization of the bauxite tailings. According to the method disclosed by the invention, through a technological process of magnetic separation in advance-ultrasonic intensification on microbiological leachate: bauxite tailings-roasting of leach residue, the iron content in the leach residue of the bauxite tailings is selectively reduced to a large extent, so that the low-iron refractory brick base material is prepared; by virtue of ultrasonic dispersion and enrichment effects, the leachate is intensified and radiated through light, so that an ultrafine ferrous oxalate byproduct with high added value is obtained; finally, by roasting the obtained ultrafine ferrous oxalate in an oxygen flow, a high-value nano ferric oxide material can be further produced. Through the technological method disclosed by the invention, the refractoriness under load and the refractoriness of the prepared low-iron refractory brick are greatly increased, and black spots on a prepared product are reduced; meanwhile,large-amount consumption and resource utilization of aluminum industry residue of the bauxite tailings are realized, replaceable mineral resources of refractory clay are also increased, and the economic benefit, the social benefit and the economic benefit are important.

Owner:HUNAN CHEM VOCATIONAL TECH COLLEGE

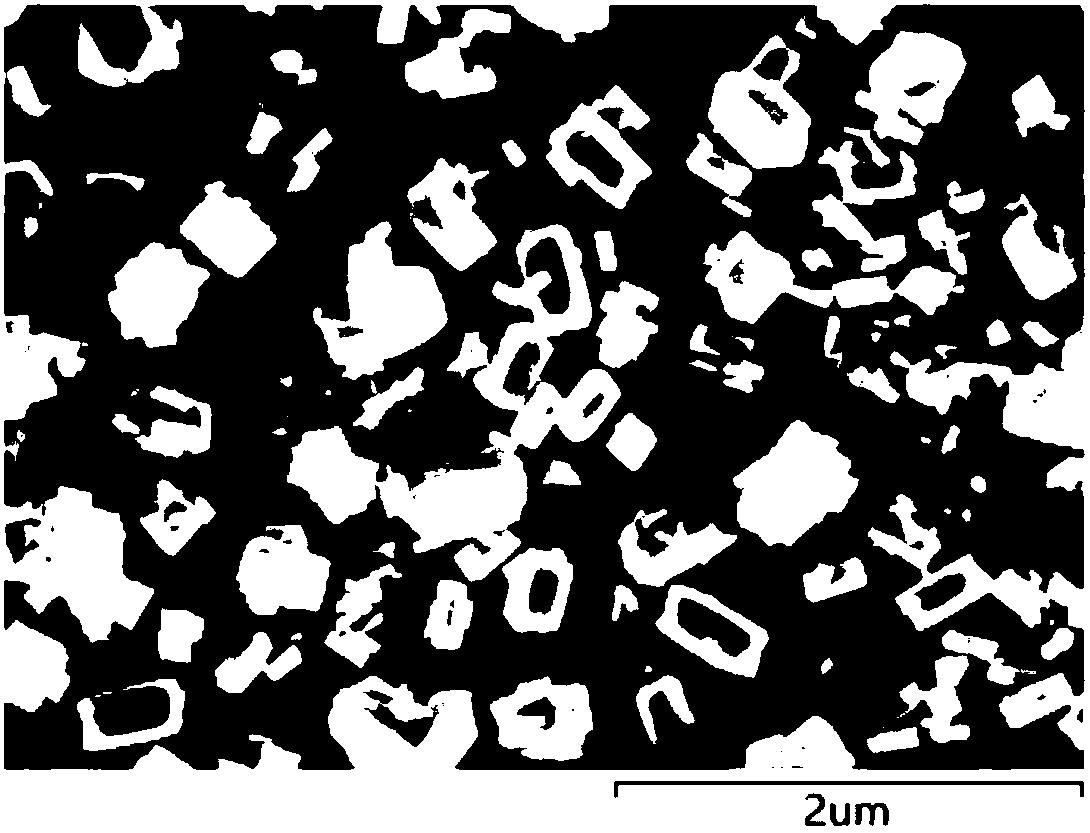

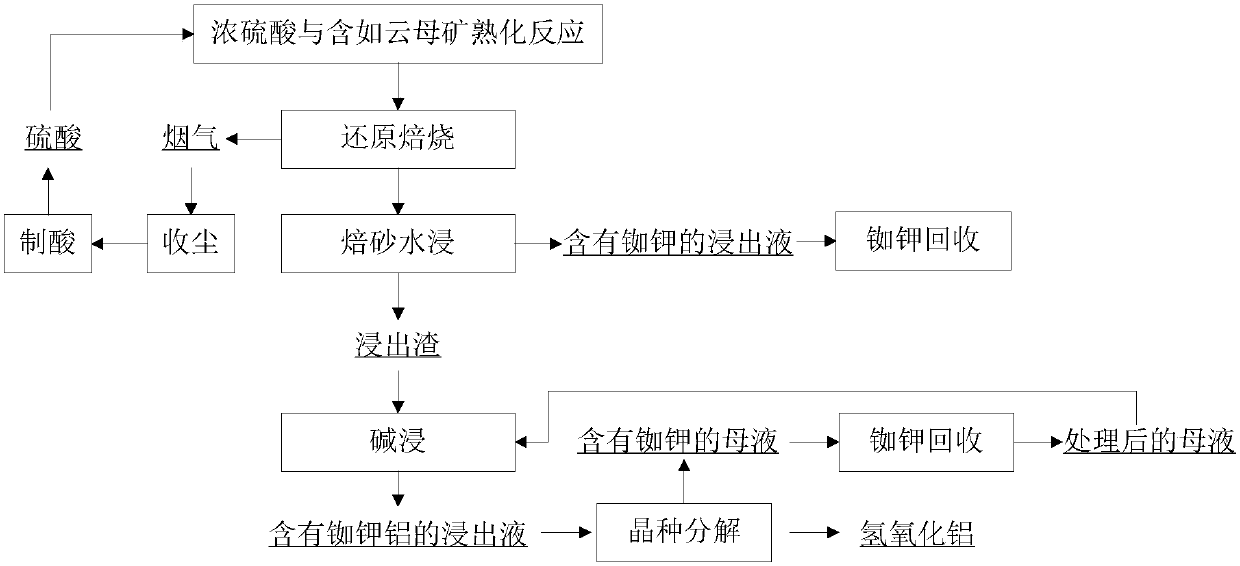

Method for leaching rubidium potassium aluminum from rubidium-containing mica ore

ActiveCN107475513BAchieving Collaborative ExtractionIncrease profitProcess efficiency improvementSlagRubidium

Owner:光鼎国际控股集团有限公司

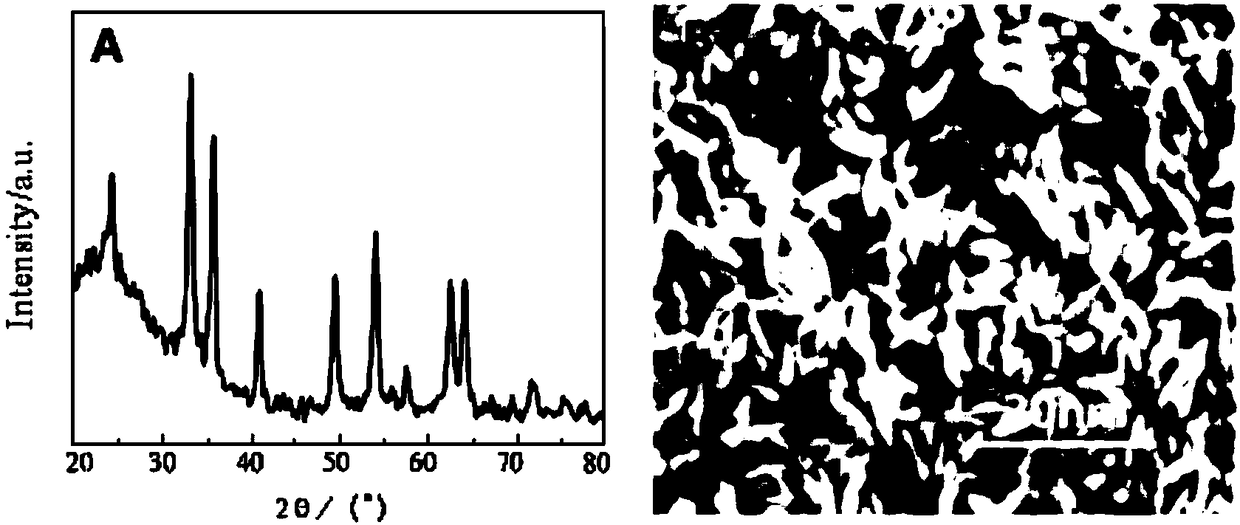

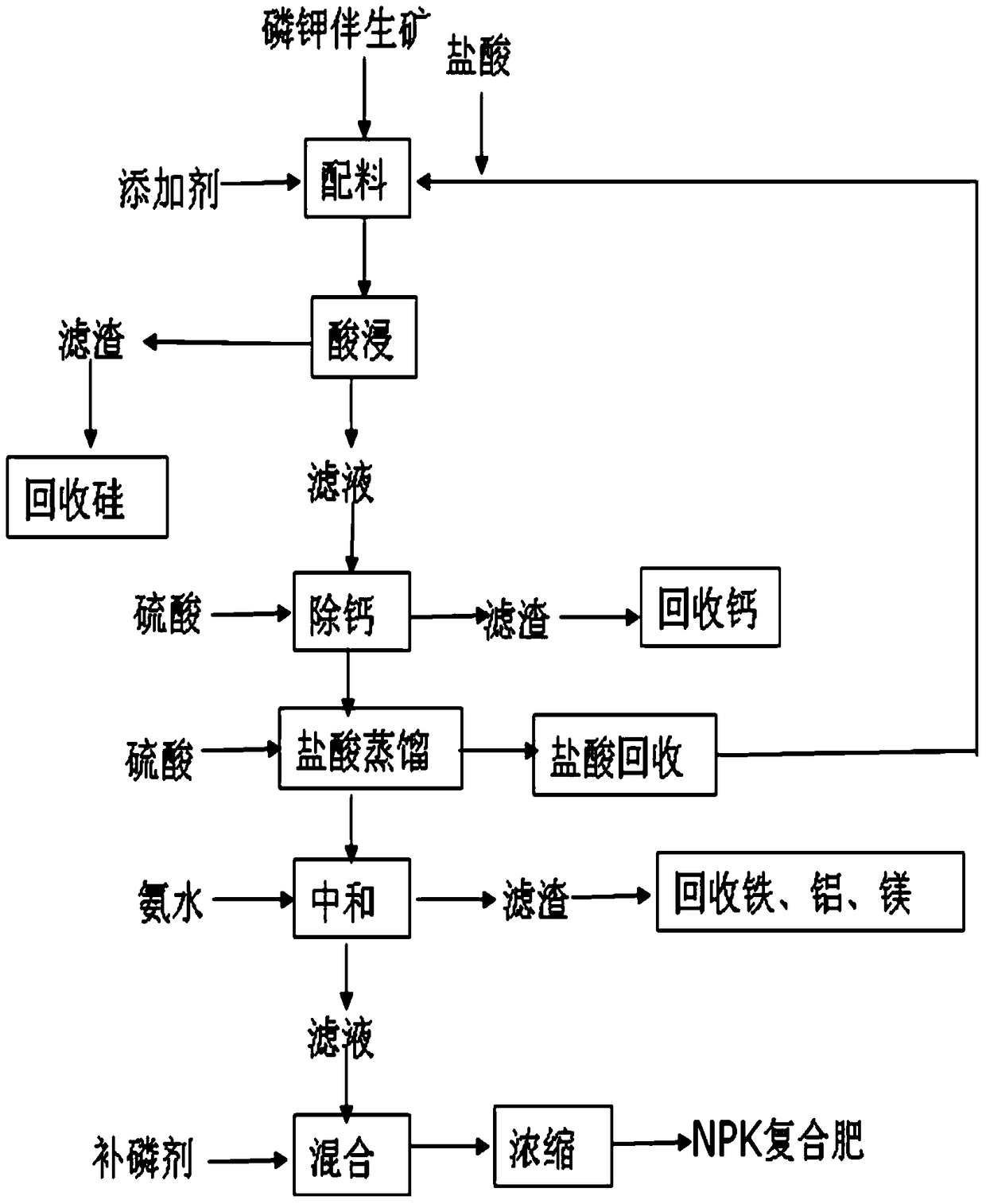

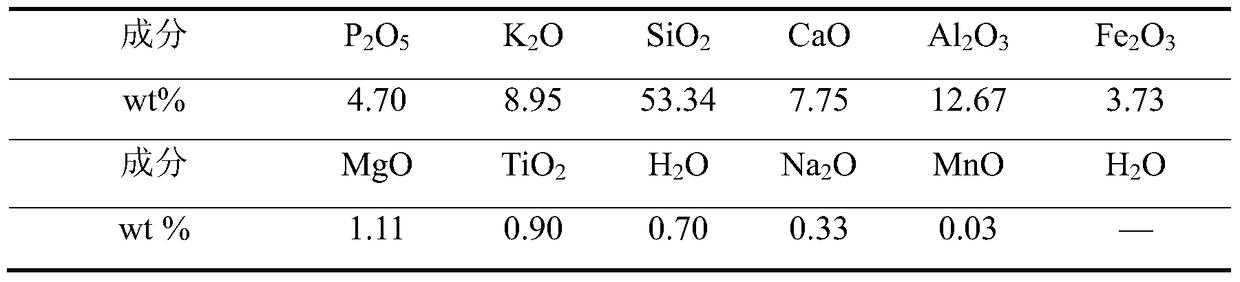

A multi-element comprehensive utilization process of phosphorus and potassium associated ore

ActiveCN105367176BRealize the comprehensive utilization of multiple elementsRealize comprehensive utilizationFertilizer mixturesHigh concentrationDistillation

The present invention discloses a multi-element comprehensive utilization process for phosphorus-potassium associated ore. The process comprises: firstly, a fluorine-containing compound is used as an additional aid, and a leaching reaction of the phosphorus-potassium associated ore at a low temperature under an acidic condition is implemented, so as to obtain a silica residue and a leachate. The steps of calcium removal, hydrochloric acid distillation and neutralization are then performed successively to the resulting leachate, so as to obtain a calcium sulfate residue, a heavy iron residue, a heavy aluminum residue, a heavy magnesium residue, and a filtrate. The resulting filtrate is then supplemented with phosphorus, evaporated, and concentrated, so as to obtain a high concentration of NPK compound fertilizer. According to the process provided by the present invention, the fluorine-containing compound is used as the additional aid and hydrochloric acid is used as a leaching agent to process the phosphorus-potassium associated ore. Potassium feldspar is decomposed by means of a reaction of villiaumite and an acid to generate hydrofluoric acid in situ, effectively implementing a process of complete decomposition, complete separation and complete utilization. The process has advantages of low energy consumption, a high element leaching rate, and simple subsequent treatment processes, etc. No discharge problem of three waste exists in the treatment process. In addition, the involved process is simple and the reaction conditions are mild, so that the process is easy to implement and is suitable for popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

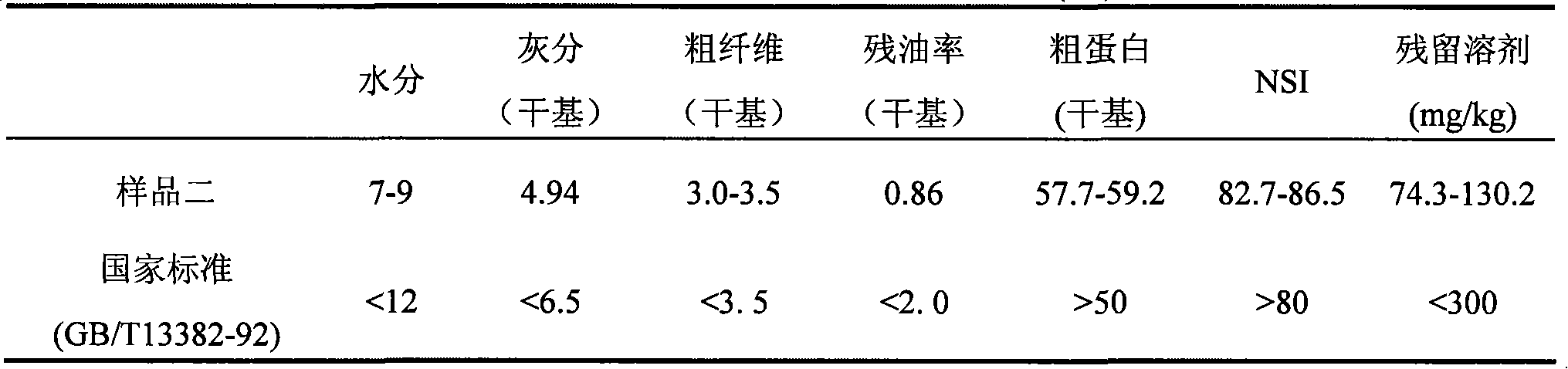

Method for producing low-temperature bean pulp with solvent extraction

The invention relates to a method for producing low-temperature soybean meal by the leaching method, belonging to the food industry low-temperature soybean meal production field. The method takes a soybean slice as a raw material and uses pentane as leaching solvent to perform degreasing, and then wet meal is obtained; and the wet meal enters into a desolventizer-toaster for vacuum low-temperature exsolution, and then the low-temperature soybean meal is obtained. The leaching temperature is between 15 and 35 DEG C, the leaching time is between 20 and 35 minutes and the leaching frequency is 3; the residual oil rate of the soybean meal is reduced to below 1 percent; the vacuum degree of exsolution of the wet meal is between 73 and 86 kPa; the exsolution temperature is between 40 and 60 DEGC and the exsolution time is between 0.5 to 1 hour; the residual oil rate of the low-temperature soybean meal produced can reach blow 1 percent and residual solvent is below 200 milligrams per kilogram; and the NSI value of proteins of the soybean meal exceeds 80 percent. The low-temperature soybean meal produced by the method has high protein content, complete shape, white color and no foreign odor.

Owner:JIANGNAN UNIV

Copper nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals

ActiveCN111411222BLow leaching temperatureLow concentration of sulfuric acidProcess efficiency improvementPregnant leach solutionSulfate

The copper-nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals of the present invention comprises the following steps: sieve the low-grade copper-nickel sulfide raw material to obtain copper-nickel sulfide mineral powder, and take ammonium persulfate and sulfuric acid raw materials in proportion , ammonium persulfate adopts one of two methods (1) after mixing all of it with sulfuric acid, mix it with mineral powder in proportion; (2) mix part of ammonium persulfate with sulfuric acid, and partly make a saturated solution; The constant temperature leaching reaction is carried out under the temperature and system pH. The saturated ammonium persulfate solution is added during the leaching process, and the leaching and filtration are completed to obtain a leaching solution. The extraction rate of valuable metal Ni in the leaching solution is 90.4-97.5%, and the extraction rate of Cu is 93.4-99.9%. The Co extraction rate is 92.7‑99.6%. This method has low leaching temperature, low concentration of sulfuric acid, less dosage, simple process flow, wide application range, ore raw materials are not limited by region, ore position, grade, etc.; the extraction rate of valuable metals is high, and there is no SO 2 emission.

Owner:东北大学秦皇岛分校

Method for preparing cerous fluoride

InactiveCN107287409AIncreased concentration of rare earthsSolve pollutionProcess efficiency improvementSulfate radicalsPhosphoric acid

The invention relates to a method for preparing cerous fluoride, and belongs to the technical field of hydrometallurgy. The technical problem that in the prior art, the purity of CeF3 prepared with Baotou rare earth mine sulfuric acid leaching liquid as a raw material is not high, the content of sulfate radical in the product is high and difficult to removal is solved. The method includes the steps that roasting mine obtained agter oxidizing roasting of baotite is leached by a salpeter solution, and baotite nitric acid leaching liquid is obtained; a neutral organophosphorus reagent Cyanex923 is used for conducting Ce4+ and F joint extraction from the baotite nitric acid leaching liquid, the recovery rate of Ce is larger than 95%, and the recovery rate of F is larger than 70%; reduction and reextraction are carried out to obtain nanometer cerous fluoride, the obtained cerous fluoride is roasted in a muffle furnace for 30 minutes at 200 DEG C to 400 DEG C, and the high-purity cerous fluoride is obtained. Phosphoric acid rare earth sediment can be obtained from raffinate by adjusting the nitric acid concentration, and the recovery rate of P is larger than 95%. By means of the method, the high-purity cerous fluoride can be prepared, recycling of the Ce, the F and the P in the Baotou rare earth mine sulfuric acid leaching liquid can be achieved, and F and P separation is achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com