Method for recovery of zinc by ultrasonic neutral leaching of zinc oxide flue dust

A zinc oxide and ultrasonic technology, applied in the field of hydrometallurgy, can solve the problems of increasing the production process and production cost, and achieve the effects of shortening the leaching time, increasing the recovery rate, and improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

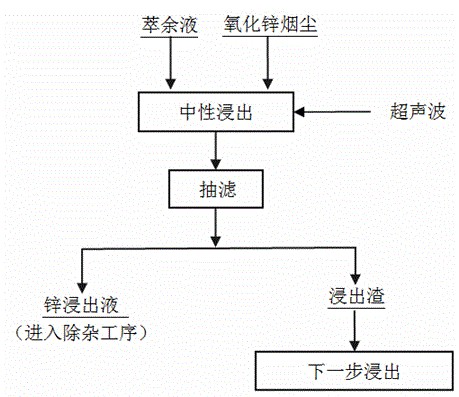

[0022] like figure 1 As shown, the ultrasonic neutral leaching of zinc oxide fume to recover zinc, the specific steps are as follows: first, the zinc oxide fume is added into the raffinate at a temperature of 35 ° C according to the liquid-solid ratio of 5:1, and the stirring speed is under ultrasonic conditions. 100rpm for neutral leaching for 40min, until the final pH value is 4.08. After the end, the leaching residue and zinc leaching solution are obtained. The zinc leaching solution enters the impurity removal process, and the leaching residue is ready for the next step of leaching.

[0023] Among them, the zinc oxide dust includes the following components in mass percentage: 34.79% zinc, 10.06% lead, 12.29% iron, 0.045% scattered metal indium, and 3% silicon dioxide content. Zinc oxide and iron indium acid are mainly used in zinc oxide dust Zinc exists in the form; the raffinate comes from the indium extraction process in the hydrometallurgy process of a zinc smelter, inc...

Embodiment 2

[0026] like figure 1 As shown, the ultrasonic neutral leaching zinc oxide soot recovery zinc method, its specific steps are as follows: first the zinc oxide soot according to the liquid-solid ratio is 10:1 to add the temperature is 30 ℃ raffinate under ultrasonic conditions, the stirring speed is Neutral leaching was performed at 600rpm for 90min until the final pH value was 4.13. After leaching, leaching slag and zinc leaching solution were obtained. The zinc leaching solution entered the impurity removal process, and the leaching slag was ready for the next step of leaching.

[0027] Among them, the zinc oxide dust includes the following components in mass percentage: 34.79% zinc, 10.06% lead, 12.29% iron, 0.045% scattered metal indium, and 3% silicon dioxide content. Zinc oxide and iron indium acid are mainly used in zinc oxide dust Zinc exists in the form; the raffinate comes from the indium extraction process in the hydrometallurgy process of a zinc smelter, including the...

Embodiment 3

[0030] like figure 1 As shown, the ultrasonic neutral leaching zinc oxide soot recovery zinc method, its specific steps are as follows: first the zinc oxide soot according to the liquid-solid ratio is 20:1 into the raffinate at a temperature of 35 ° C under ultrasonic conditions, the stirring speed is Neutral leaching at 400 rpm for 20 minutes until the final pH value is 4.30. After leaching, leach slag and zinc leaching solution are obtained. The zinc leaching solution enters the impurity removal process, and the leaching residue is ready for the next step of leaching.

[0031] Among them, the zinc oxide dust includes the following components in mass percentage: 34.79% zinc, 10.06% lead, 12.29% iron, 0.045% scattered metal indium, and 3% silicon dioxide content. Zinc oxide and iron indium acid are mainly used in zinc oxide dust Zinc exists in the form; the raffinate comes from the indium extraction process in the hydrometallurgy process of a zinc smelter, including the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com