Method for preparing cerous fluoride

A technology of cerium trifluoride and oxidation roasting, applied in the direction of improving process efficiency, etc., can solve the problems of difficult removal, high sulfate content, low purity, etc., to increase the concentration of rare earths, reduce the leaching temperature, and realize the comprehensive utilization of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The method for preparing cerium trifluoride provided by the invention specifically comprises the following steps:

[0025] (1) Oxidize and roast Baotou ore at a temperature of 400-600°C for 60-90 minutes. The obtained roasted ore is leached with nitric acid solution, HNO 3 The concentration is 3-8M, the liquid-solid ratio is 3-6, the leaching time is 20-90 minutes, the leaching temperature is 20-50°C, suction filtration, washing to obtain Baotou Mine nitric acid leachate and monazite-rich slag. Monazite slag can be treated by acid method or alkali method, which is not considered in the present invention.

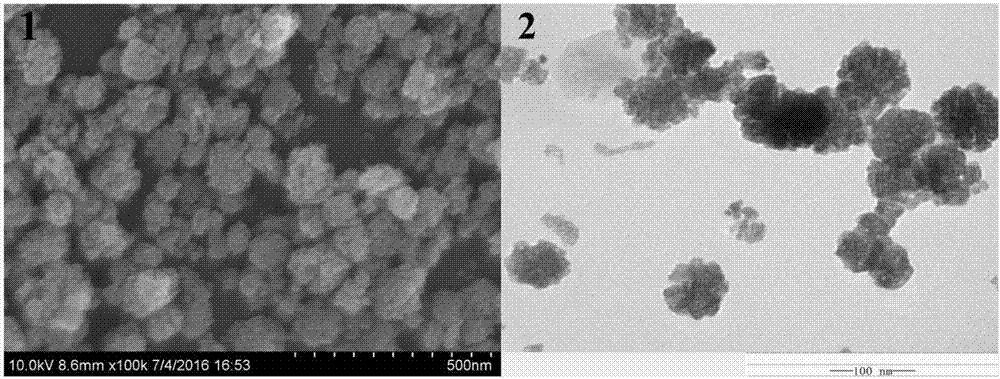

[0026] (2) Co-extract Ce from Baotou mine nitric acid leaching solution by neutral phosphorus extractant Cyanex923+isooctanol+n-heptane 4+ and F, then use a mass percentage of 0.1% H 2 o 2 Nano-CeF obtained by reduction stripping 3 , calcining the obtained cerium trifluoride in a muffle furnace at 200-400° C. for 30 minutes, preferably at a temperature of 350° C.,...

Embodiment 1

[0028] Take 100g of Baotou rare earth concentrate (50 ore), and oxidize and roast it in a muffle furnace at 400°C for 60 minutes. The obtained roasted ore was leached with 4M nitric acid solution, the solid-to-liquid ratio was 3, the leaching time was 90 minutes, and the leaching temperature was 20° C., and the nitric acid leaching solution of Baotou ore was obtained after filtration. [REO] = 60g / L in the leaching solution, where [Ce 4+ ]=25g / L, with 300mL 15% of Cyanex923+10% isooctyl alcohol+75% n-heptane as extractant, extract the Ce in the leachate 4+ and F - , the recovery rate of Ce is greater than 95%, and the recovery rate of F is 70%. Then with 0.1% H 2 o 2 Reductive stripping was carried out to obtain cerium trifluoride with an average particle diameter of 70 nm. Calcining the obtained cerium trifluoride in a muffle furnace at 350°C for 30 minutes to obtain high-purity cerium trifluoride with a purity greater than 99.99%. Adjust the acidity of the extracted wat...

Embodiment 2

[0031] Take 100g of Baotou rare earth concentrate (65 ore), and oxidize and roast it in a muffle furnace at 500°C for 60 minutes. The obtained roasted ore was leached with 3M nitric acid solution, the solid-to-liquid ratio was 4, the leaching time was 20 minutes, and the leaching temperature was 40°C. After filtration, the nitric acid leaching solution of Baotou ore was obtained. [REO] = 120g / L in the leaching solution, where [Ce 4+ ]=55g / L, with 300mL 30% of Cyanex923+10% isooctyl alcohol+60% n-heptane as extractant, extract the Ce in the leachate 4+ and F - , the recovery rate of Ce is greater than 95%, and the recovery rate of F is 70%. Then with 0.1% H 2 o 2 Reductive stripping was carried out to obtain cerium trifluoride with an average particle diameter of 70 nm. Calcining the obtained cerium trifluoride in a muffle furnace at 200°C for 30 minutes to obtain high-purity cerium trifluoride with a purity greater than 98.92%. Adjust the acidity of the extracted water p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com