Sulfuric acid rare earth roasted ore treatment method

A technology of rare earth sulfate and a treatment method, which is applied in the direction of improving process efficiency, can solve the problems of high cost, increased difficulty in leaching rare earth, increased difficulty in disposal, etc., and achieves the effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

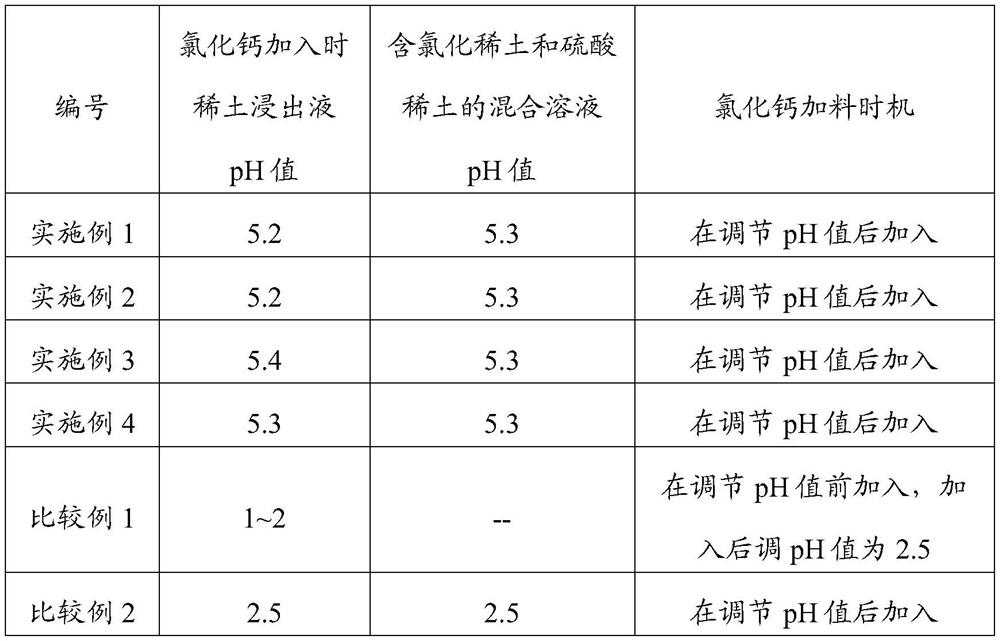

Embodiment 1

[0059] 1) Mix and leach rare earth sulfate roasted ore and water at a weight ratio of 1:7, filter to obtain the first mother liquor and the first water leaching residue; add calcium oxide to the first mother liquor to adjust the pH value to 5.2, filter to obtain REO Concentration is 31.5g / L rare earth sulfuric acid water immersion liquid and the first neutralization slag; With rare earth sulfuric acid water immersion liquid and calcium chloride solid (the mol ratio of sulfate ion and calcium chloride is 1 in the rare earth sulfuric acid water immersion liquid: 1.1) Mix and react, filter to obtain calcium sulfate solid and rare earth chloride solution I;

[0060] 2) mixing and leaching the rare earth chloride solution I and the roasted rare earth sulfate ore (the weight ratio of the roasted rare earth sulfate ore and the rare earth chloride solution I is 1:7), and filtering to obtain the second mother liquor and the second water leaching residue, Adjust the pH value of the seco...

Embodiment 2

[0065] 1) Mix and leach the rare earth sulfate roasted ore and water at a weight ratio of 1:7, filter to obtain the first mother liquor and the first water leaching residue, add calcium oxide to the first mother liquor to adjust the pH value to 5.2, and filter to obtain REO Concentration is 36.4g / L rare earth sulfuric acid water immersion liquid and the first neutralization slag; The sulfuric acid rare earth water immersion liquid and saturated calcium chloride solution (the mol ratio of sulfate ion and calcium chloride in the rare earth sulfuric acid water immersion liquid is 1 : 1.1) mix and react, filter, obtain calcium sulfate solid and rare earth chloride solution I;

[0066] 2) mixing and leaching the rare earth chloride solution I and the roasted rare earth sulfate ore (the weight ratio of the roasted rare earth sulfate ore and the rare earth chloride solution I is 1:7), and filtering to obtain the second mother liquor and the second water leaching residue, Adjust the p...

Embodiment 3

[0071] 1) Mix and leach the rare earth sulfate roasted ore and water at a weight ratio of 1:7, filter to obtain the first mother liquor and the first water leaching residue, add calcium oxide to the first mother liquor to adjust the pH value to 5.4, and filter to obtain REO Concentration is 32.8g / L rare earth sulfuric acid water immersion liquid and the first neutralization slag; With rare earth sulfuric acid water immersion liquid and calcium chloride solid (the mol ratio of sulfate ion and calcium chloride is 1 in the rare earth sulfuric acid water immersion liquid: 1.2) Mix and react, filter to obtain calcium sulfate solid and rare earth chloride solution I;

[0072]2) mixing and leaching the rare earth chloride solution I and the roasted rare earth sulfate ore (the weight ratio of the roasted rare earth sulfate ore and the rare earth chloride solution I is 1:7), and filtering to obtain the second mother liquor and the second water leaching residue, Adjust the pH value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com