A rare earth leaching mother liquor concentration and enrichment process and obtained products

A technology of leaching and rare earth, which is applied in the field of mining technology, can solve the problems of high content of non-rare earth impurities, unfavorable process processing, decomposition and impurity removal, etc., and achieve the effect of high rare earth concentration, comprehensive cost reduction and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

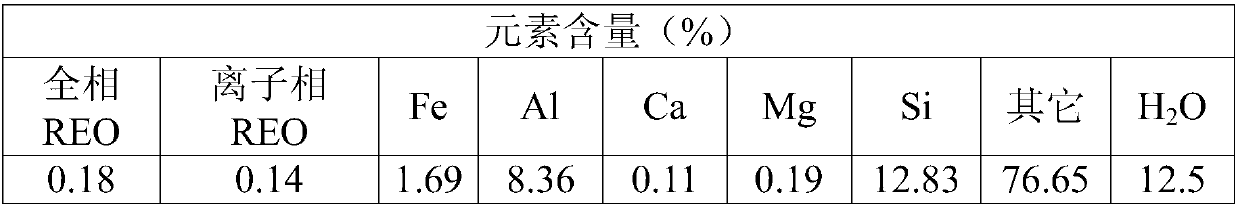

[0033] The ionic rare earth ore in this example comes from a rare earth mine in Xunwu, Ganzhou, and the main chemical composition of the ore sample is shown in Table 1.

[0034] Table 1 The main components of an ion-type rare earth ore in Xunwu

[0035]

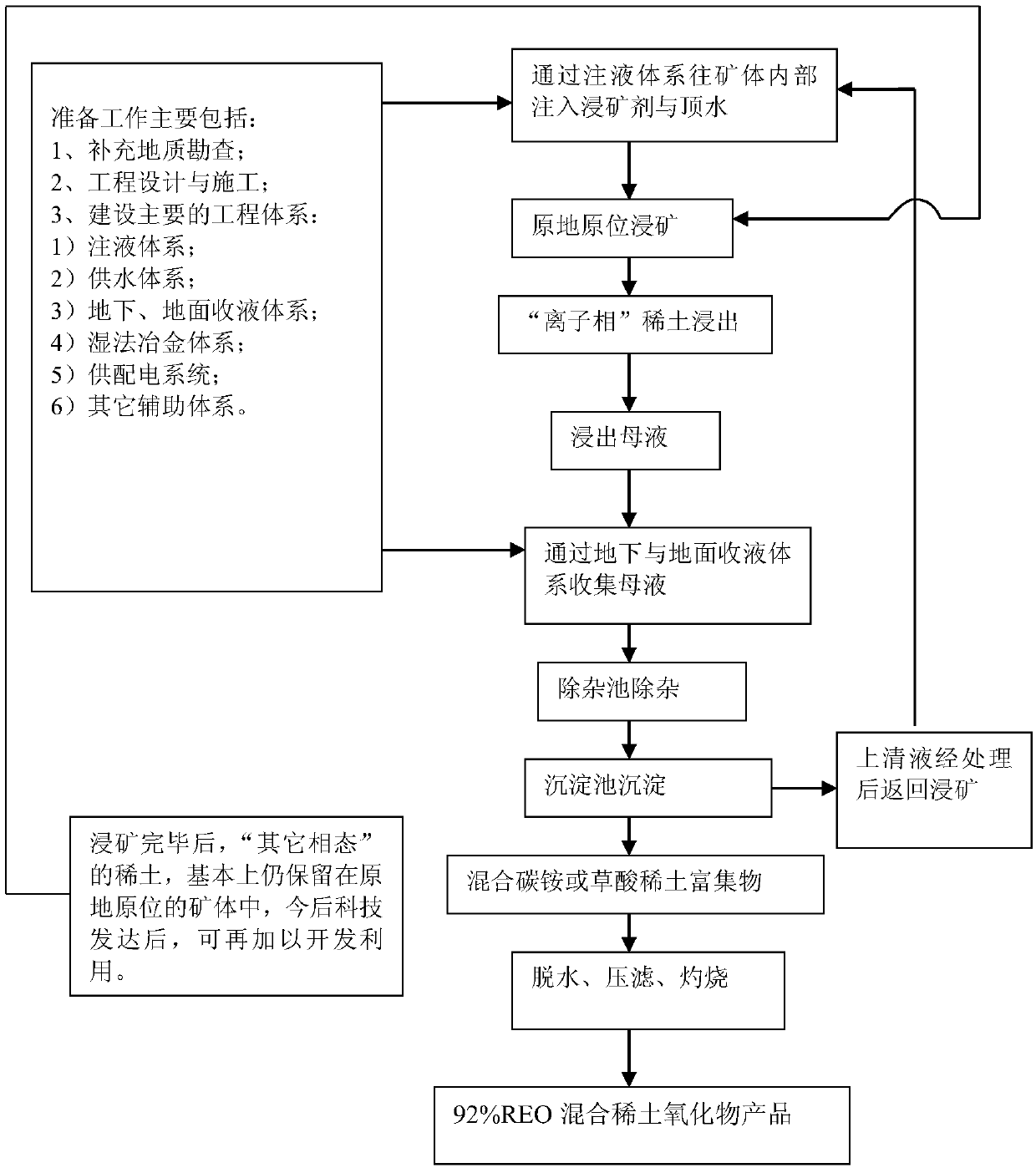

[0036] First, do the preparatory work:

[0037] 1. Supplementary geological exploration;

[0038] 2. Engineering design and construction;

[0039] 3. Main construction projects:

[0040] (1) Liquid injection system;

[0041] (2) Water supply system;

[0042] (3) Underground and ground liquid collection systems;

[0043] (4) Hydrometallurgy system;

[0044] (5) Power supply and distribution system;

[0045] (6) Other auxiliary systems;

[0046] (7) Ion adsorption and impurity removal, enrichment system and storage tank (vehicle).

[0047] Then, start the leaching and enrichment work:

[0048] Step 1: inject ore leaching agent and shrinkage agent into the ore body, in situ leaching ore leaching to leach "ionic phas...

Embodiment 2

[0064] Measure 4L of low-concentration mixed rare earth leaching mother liquor (as shown in Table 3), add it to a beaker, start stirring, add lime milk dropwise, monitor the pH value with a pH meter, adjust the pH value to 5.0, continue stirring for 30 minutes, and adjust the pH value to 5.0. The value remains unchanged, after the end point is filtered, the filter cake is washed and dried. Under the above test conditions, Fe<0.01g / L, Al 0.07g / L, Ca 0.05g / L, and Mg 1.80g in the liquid after aluminum removal (that is, the rare earth supernatant obtained after leaching the mother liquor after aluminum removal) / L, Si are 0.03g / L, the rare earth concentration is 0.962g / L, and the rare earth yield is 99.39%.

Embodiment 3

[0066] Measure 4L of low-concentration mixed rare earth leaching mother liquor (as shown in Table 3), add it to a beaker, start stirring, add lime milk dropwise, monitor the pH value with a pH meter, adjust the pH value to 5.15, continue stirring for 30 minutes, and adjust the pH value to 5.15. The value remains unchanged, after the end point is filtered, the filter cake is washed and dried. Under the above test conditions, Fe<0.01g / L, Al 0.02g / L, Ca 0.05g / L, and Mg 1.75g in the solution after aluminum removal (that is, the rare earth supernatant obtained after leaching the mother liquor after aluminum removal) / L, Si are 0.03g / L, the rare earth concentration is 0.941g / L, and the rare earth yield is 98.90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com