Method for leaching rubidium potassium aluminum from rubidium-containing mica ore

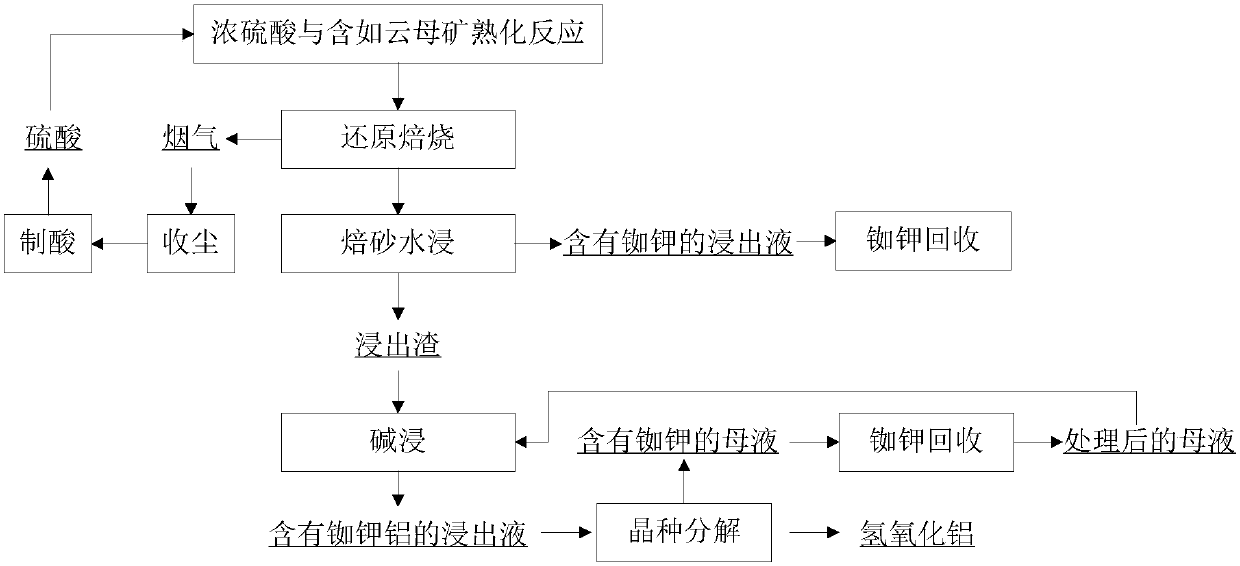

A mica ore and leaching technology, which is applied in the field of leaching rubidium, potassium and aluminum, can solve the problems of low resource utilization, high reagent consumption, environmental pollution, etc., and achieve the effects of improving utilization, less waste residue output, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for leaching rubidium potassium aluminum from rubidium-containing mica ore, comprising the following steps:

[0040] Step 1: Mix 30 g of rubidium-containing mica ore with concentrated sulfuric acid, and then carry out a slaking reaction to obtain a slaking material. Among them, the mass fraction of rubidium in rubidium-containing mica ore is 0.1%, the mass fraction of alumina is 21%, the mass fraction of potassium oxide is 7.5%, and the mass or volume of concentrated sulfuric acid accounts for 40% of the mass of rubidium-containing mica ore; The reaction temperature is 300° C., and the aging reaction time is 3 hours.

[0041] Step 2: Grinding the matured material obtained in step 1 first, mixing the pulverized coal with the ground matured material, and then performing reduction roasting to obtain calcined sand and flue gas. Among them, pulverized coal accounts for 6% of the mass fraction of the ground matured material, the reduction roasting temperature is 750...

Embodiment 2

[0048] A method for leaching rubidium potassium aluminum from rubidium-containing mica ore, comprising the following steps:

[0049] Step 1: Mix 30 g of rubidium-containing mica ore with concentrated sulfuric acid, and then carry out a slaking reaction to obtain a slaking material. Among them, the mass fraction of rubidium in rubidium-containing mica ore is 0.15%, the mass fraction of alumina is 17%, the mass fraction of potassium oxide is 6%, and the mass or volume of concentrated sulfuric acid accounts for 37% of the mass of rubidium-containing mica ore; The reaction temperature is 310° C., and the aging reaction time is 3 hours.

[0050] Step 2: Grinding the matured material obtained in step 1 first, mixing the pulverized coal with the ground matured material, and then performing reduction roasting to obtain calcined sand and flue gas. Among them, pulverized coal accounts for 7% of the mass fraction of the ground matured material, the reduction roasting temperature is 770°...

Embodiment 3

[0057] A method for leaching rubidium potassium aluminum from rubidium-containing mica ore, comprising the following steps:

[0058] Step 1: Mix 30 g of rubidium-containing mica ore with concentrated sulfuric acid, and then carry out a slaking reaction to obtain a slaking material. Among them, the mass fraction of rubidium in rubidium-containing mica ore is 0.5%, the mass fraction of alumina is 35%, the mass fraction of potassium oxide is 24%, and the mass or volume of concentrated sulfuric acid accounts for 50% of the mass of rubidium-containing mica ore; The reaction temperature is 120° C., and the aging reaction time is 48 hours.

[0059] Step 2: Grinding the matured material obtained in step 1 first, mixing the pulverized coal with the ground matured material, and then performing reduction roasting to obtain calcined sand and flue gas. Among them, pulverized coal accounts for 15% of the mass fraction of the ground matured material, the reduction roasting temperature is 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com