Copper nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals

A technology of ammonium persulfate and valuable metals, applied in the field of non-ferrous metallurgy, can solve the problems of environmental pollution, increase of recycling cost, increase of cost, etc., and achieve the effect of protecting the environment, strong applicability, and avoiding SO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

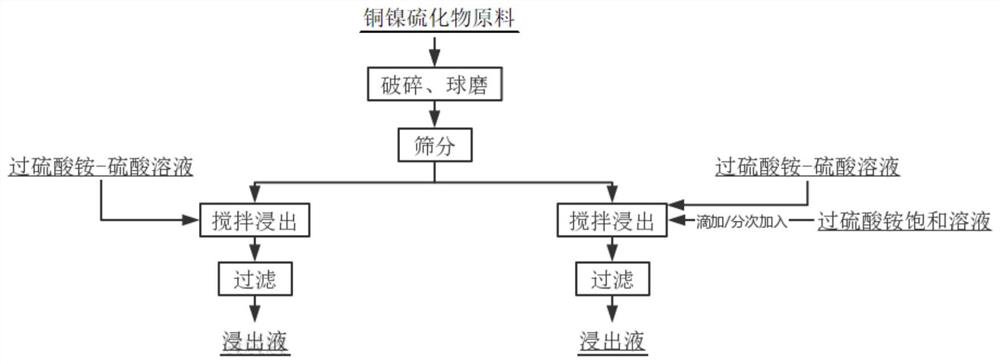

[0106] A copper-nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals, its process flow chart is as follows figure 1 shown, including the following steps:

[0107] Step 1: Crushing and screening

[0108] The copper-nickel sulfide ore is crushed, ball-milled, and passed through a 180-200-mesh sieve to obtain copper-nickel sulfide ore powder with a particle size of 75-80 μm. The main metal elements and their mass percentage contents of copper-nickel sulfide ore are shown in Table 1.

[0109] Table 1 Composition and mass percentage of main metal elements of copper-nickel sulfide ore

[0110]

[0111] Step 2: Oxidation Leaching

[0112] Weigh 15g of the sieved copper-nickel sulfide ore powder and pour it into the reaction vessel, add the mixed solution of ammonium persulfate and sulfuric acid according to the liquid-solid ratio (ml:g) 20:1, the concentration of sulfuric acid in the mixed solution is 0.3mol / L, the amount o...

Embodiment 1-2

[0119] A copper-nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals, the steps are the same as in Example 1, the difference is that the second method is adopted, and the ammonium persulfate is added in batches during the oxidation leaching process, and the first reaction A container with a mass of m 1 The mixed solution of ammonium persulfate and sulfuric acid, m 1 It is 30% of the total mass of ammonium persulfate, and the mixed solution is mixed evenly with copper-nickel sulfide ore powder. Then, under the condition that the mechanical stirring speed is 500r / min, the heating is turned on, and at the same time, the mass is m 2 A saturated solution of ammonium persulfate (solubility 80g / 100ml), where m 2 It is 70% of the total mass of ammonium persulfate. When the reaction temperature reached 80°C, time the reaction for 3 hours. The results of the metal extraction rate were as follows: the extraction rate of Ni was 95.8...

Embodiment 2-1

[0121] A copper-nickel sulfide ammonium persulfate-sulfuric acid oxidation leaching method for extracting valuable metals, comprising the following steps:

[0122] Step 1: Crushing and screening

[0123]The copper-nickel sulfide ore is crushed, ball-milled, and passed through a 160-180-mesh sieve to obtain copper-nickel sulfide ore powder with a particle size of 80-96 μm. The main metal elements and their mass percentage contents of copper-nickel sulfide ore are shown in Table 2.

[0124] Table 2 Composition and mass percentage of main metal elements of copper-nickel sulfide ore

[0125]

[0126] Step 2: Oxidation Leaching

[0127] Weigh 15 g of the sieved copper-nickel sulfide ore powder and pour it into a reaction vessel, and weigh the total mass of ammonium persulfate according to 3 times the mass of ammonium persulfate required for the complete reaction of all metals in the copper-nickel sulfide ore with ammonium persulfate. Then add to the reaction vessel by mass m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com