Method for preparing low-iron refractory brick base material and coproducing nano iron oxide by utilizing bauxite tailings

A technology of nano-iron oxide and bauxite, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of large environmental pollution, weak iron removal effect, equipment corrosion, etc., and achieve good separation effect , Improve the load softening temperature and refractoriness, and reduce the effect of leaching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

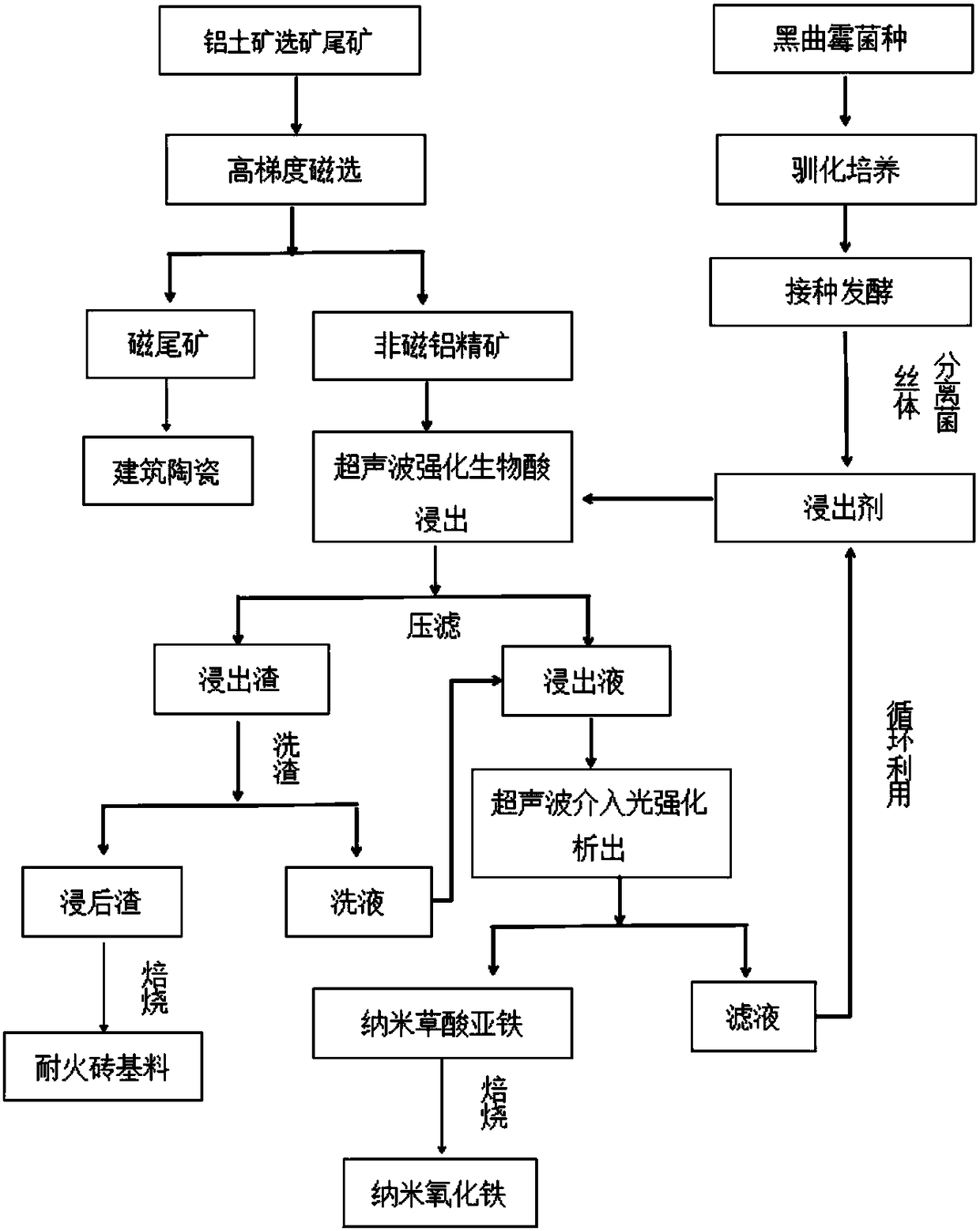

[0035] This embodiment provides a method for preparing low-iron refractory brick base material from bauxite tailings, see figure 1 , this embodiment includes the following steps:

[0036] S1. Pre-magnetic separation: firstly, the bauxite tailings slurry is pre-magnetically separated through a high-gradient magnetic separator, the feed concentration is 25%, the background field strength is 1.16T, the magnetic rod medium is Φ1mm, and the magnetic tailings and non-magnetic Aluminum concentrate separation;

[0037] S2. Ultrasonic enhanced mineral leaching: the power of the ultrasonic pulverizer is 200W, and the bio-acid leaching agent is added to the non-magnetic aluminum concentrate obtained in step 1, the liquid-solid ratio is 10:1, the leaching temperature is 25°C, the stirring speed is 200r / min, and the leaching time is After 30 minutes, the leach residue and leachate were obtained after pressure filtration;

[0038] S3. Roasting: cleaning the leached slag, and roasting the ...

Embodiment 2

[0046] This embodiment provides a method for preparing low-iron refractory brick base material from bauxite tailings, see figure 1 , this embodiment includes the following steps:

[0047] S1. Pre-magnetic separation: firstly, the bauxite tailings slurry is pre-magnetically separated through a high-gradient magnetic separator, the feed concentration is 30%, the background field strength is 1.0T, the magnetic rod medium is Φ1.5mm, and the magnetic tailings and Separation of non-magnetic aluminum concentrate;

[0048] S2. Ultrasonic enhanced mineral leaching: the power of the ultrasonic pulverizer is 150W, and the bio-acid leaching agent is added to the non-magnetic aluminum concentrate obtained in step 1, the liquid-solid ratio is 8:1, the leaching temperature is 30°C, the stirring speed is 150r / min, and the leaching time is 20min, then press filter to leach the suspension to obtain leach residue and leachate;

[0049] S3. Roasting: cleaning the leached slag, and roasting the ...

Embodiment 3

[0057] This embodiment provides a method for preparing low-iron refractory brick base material from bauxite tailings, see figure 1 , this embodiment includes the following steps:

[0058] S1. Pre-magnetic separation: firstly, pre-magnetic separation of bauxite tailings slurry through a high-gradient magnetic separator, the feed concentration is 35%, the background field strength is 0.8T, the magnetic rod medium is Φ2mm, and the magnetic tailings and non-magnetic Aluminum concentrate separation;

[0059] S2. Ultrasonic enhanced mineral leaching: the power of the ultrasonic pulverizer is 100W, and the bio-acid leaching agent is added to the non-magnetic aluminum concentrate obtained in step 1, the liquid-solid ratio is 5:1, the leaching temperature is 40°C, the stirring speed is 100r / min, and the leaching time is 15min, then press filter to leach the suspension to obtain leach residue and leachate;

[0060] S3. Roasting: wash the leached slag, and roast the washed leached slag a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com