Method for producing low-temperature bean pulp with solvent extraction

A technology of low-temperature soybean meal and leaching method, which is applied in the field of low-temperature soybean meal production in the food industry, can solve the problems of high degree of water-soluble protein denaturation, influence on protein quality, low protein yield, etc., and achieves high protein content, moderate moisture content, and desolvation temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

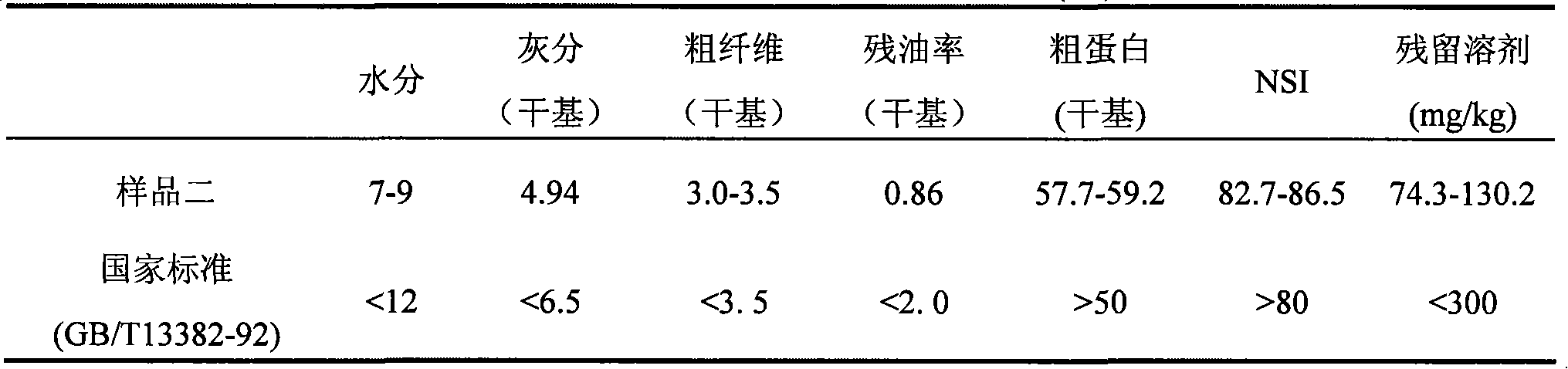

Embodiment 2

[0017] The difference between embodiment 2 and embodiment 1 lies in leaching temperature, desolventization time and desolventization vacuum degree.

Embodiment 1

[0019] The solvent n-pentane and soybean flakes are put into the leaching container according to the ratio of material to liquid 1:1.2, and are leached and degreased by simple tank group. The number of leaching is 3 times, the leaching time is 20min, and the leaching temperature is 25°C. After the leaching is finished, the mixed oil is discharged, the soybean meal is drained, and the wet meal content is determined to be 30.5% to 42.3%.

[0020] The soybean meal enters the steamer for low-temperature vacuum precipitation, the precipitation time is 0.5h, the precipitation temperature is 40°C, and the vacuum degree is 78.5kPa. The obtained soybean meal has a complete shape, a white color and no peculiar smell. Other quality indicators are listed in Table 1.

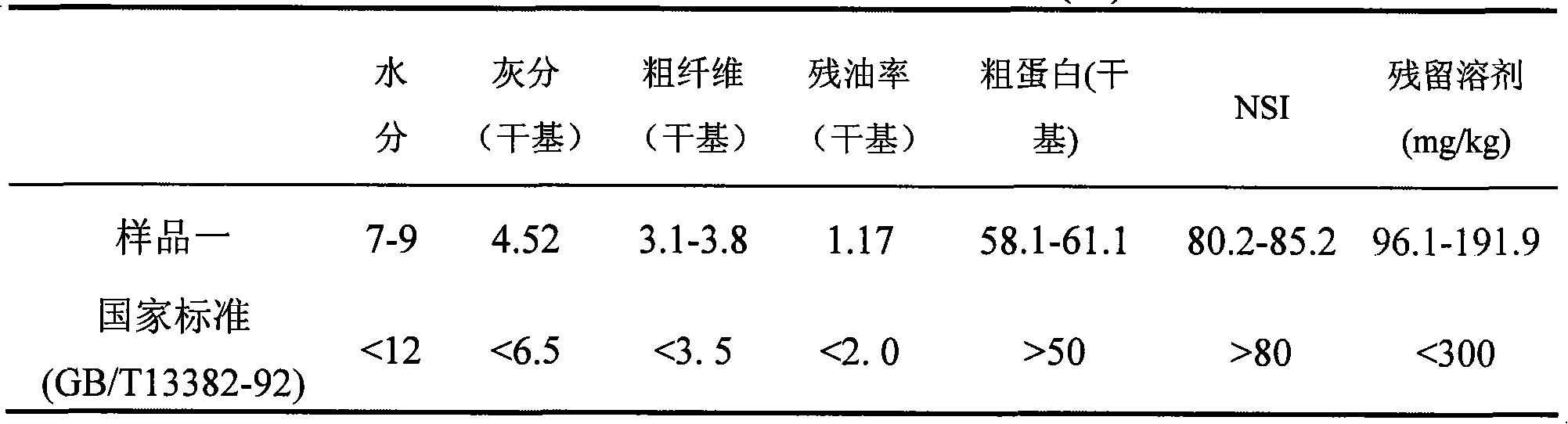

[0021] Table 1 Quality Evaluation of Low Temperature Soybean Meal (%)

[0022]

[0023] The results show that under the conditions of low extraction temperature, extraction time and precipitation vacuum, the basic comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com