Method for extracting Fe, Zn and Pb from electric furnace fly ash and utilizing Fe, Zn and Pb in high-value mode

A high-value, electric furnace technology, applied in the direction of solid waste removal, etc., can solve the problems of serious secondary pollution, high equipment investment cost, and low comprehensive recycling rate, so as to achieve low production cost, reduce beneficiation cost, and process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

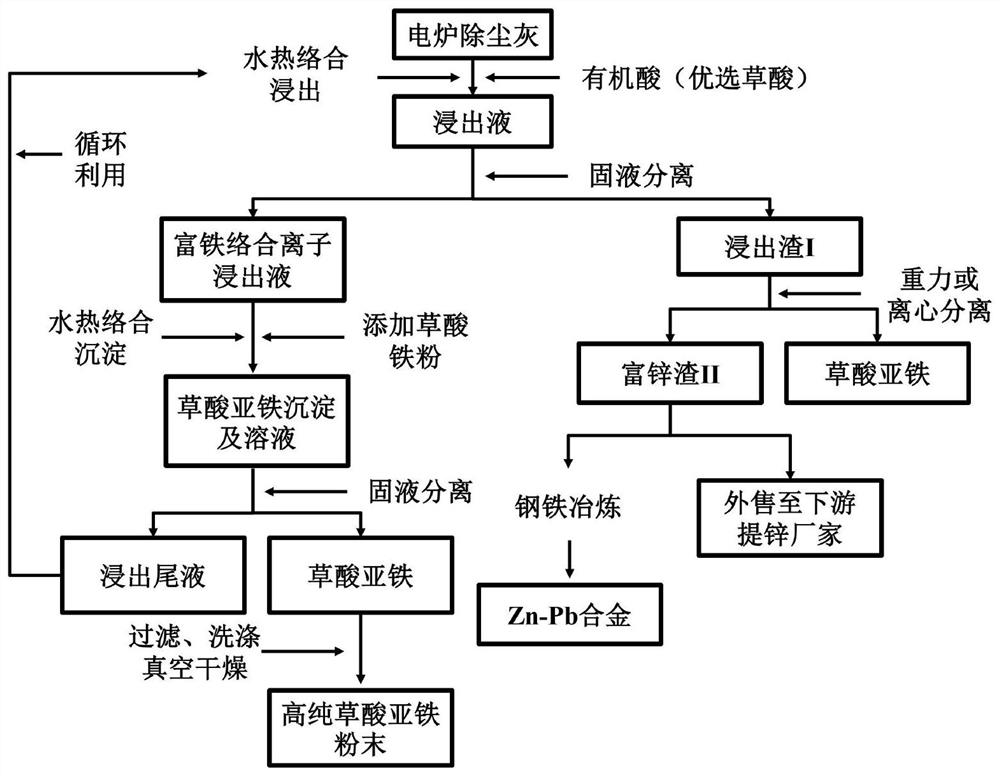

Method used

Image

Examples

Embodiment 1

[0034] Weigh 1g of dust removal dust from the electric furnace of iron and steel enterprises, prepare an oxalic acid solution with a concentration of 15%, and a liquid-solid ratio of 30:1, mix it into a uniformly distributed slurry, then inject the slurry into a three-necked flask, and then start the reaction. The specific reaction conditions are as follows: the leaching temperature is 90° C., the reaction time is 2 hours, and the stirring speed is 300 r / min.

[0035] After the reaction, the leachate was cooled to room temperature for solid-liquid separation. After the reaction product is filtered and washed, the iron-rich complex ion leaching solution A and leaching residue I are obtained, and the ferrous oxalate and zinc-rich slag in the leaching residue are fully separated by centrifugation. After ICP-AES detection, in the obtained leachate A, the concentration of Fe ions was 1602 mg / L, and the leaching rate of Fe element was converted to 92.35%; the Zn content (calculated ...

Embodiment 2

[0038] Weigh 1g of dust removal dust from the electric furnace of iron and steel enterprises, prepare oxalic acid solution with a concentration of 10%, and the liquid-solid ratio is 50:1, mix to form a uniformly distributed slurry, then inject the slurry into a three-necked flask, and then start the reaction. The specific reaction conditions are as follows: the leaching temperature is 90° C., the reaction time is 4 hours, and the stirring speed is 300 r / min.

[0039] After the reaction, the leachate was cooled to room temperature for solid-liquid separation. After the reaction product is filtered and washed, the iron-rich complex ion leaching solution A and leaching residue I are obtained, and the ferrous oxalate and zinc-rich slag in the leaching residue are fully separated by centrifugation. After ICP-AES detection, in the obtained leaching solution A, the concentration of Fe ions was 1495 mg / L, and the leaching rate of Fe element was 86.78%; the Zn content (calculated as Zn...

Embodiment 3

[0042] Weigh 1g of dust removal dust from the electric furnace of iron and steel enterprises, prepare oxalic acid solution with a concentration of 20%, and the liquid-solid ratio is 50:1, mix to form a uniformly distributed slurry, then inject the slurry into a three-necked flask, and then start the reaction. The specific reaction conditions are as follows: the leaching temperature is 90° C., the reaction time is 1 h, and the stirring speed is 300 r / min.

[0043] After the reaction, the leachate was cooled to room temperature for solid-liquid separation. After the reaction product is filtered and washed, the iron-rich complex ion leaching solution A and leaching residue I are obtained, and the ferrous oxalate and zinc-rich slag in the leaching residue are fully separated by centrifugation. After ICP-AES detection, in the obtained leachate A, the concentration of Fe ions was 1539 mg / L, and the leaching rate of Fe element was 88.38%; the Zn content (calculated as ZnO) in the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com