Patents

Literature

249results about How to "Fast oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

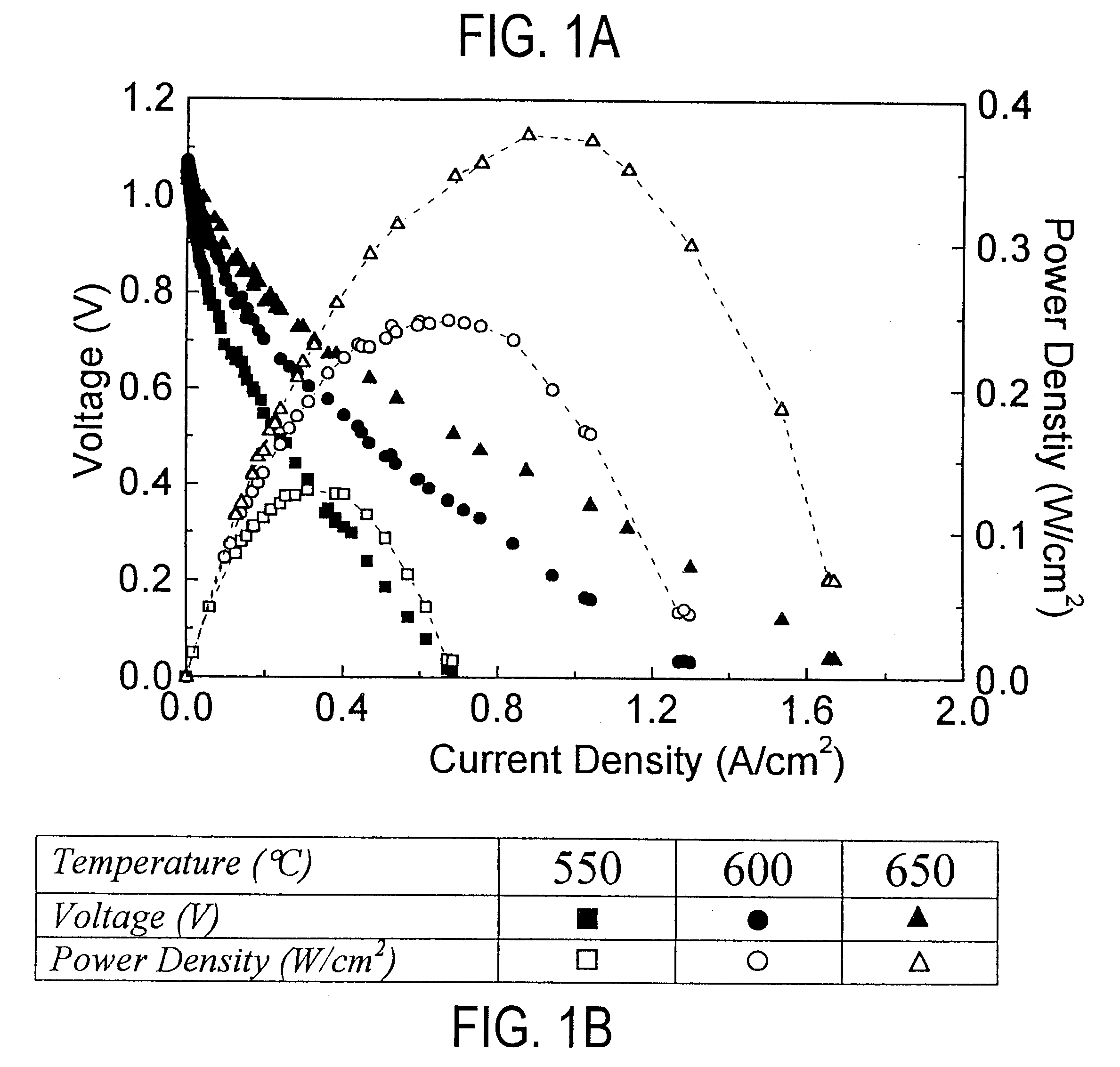

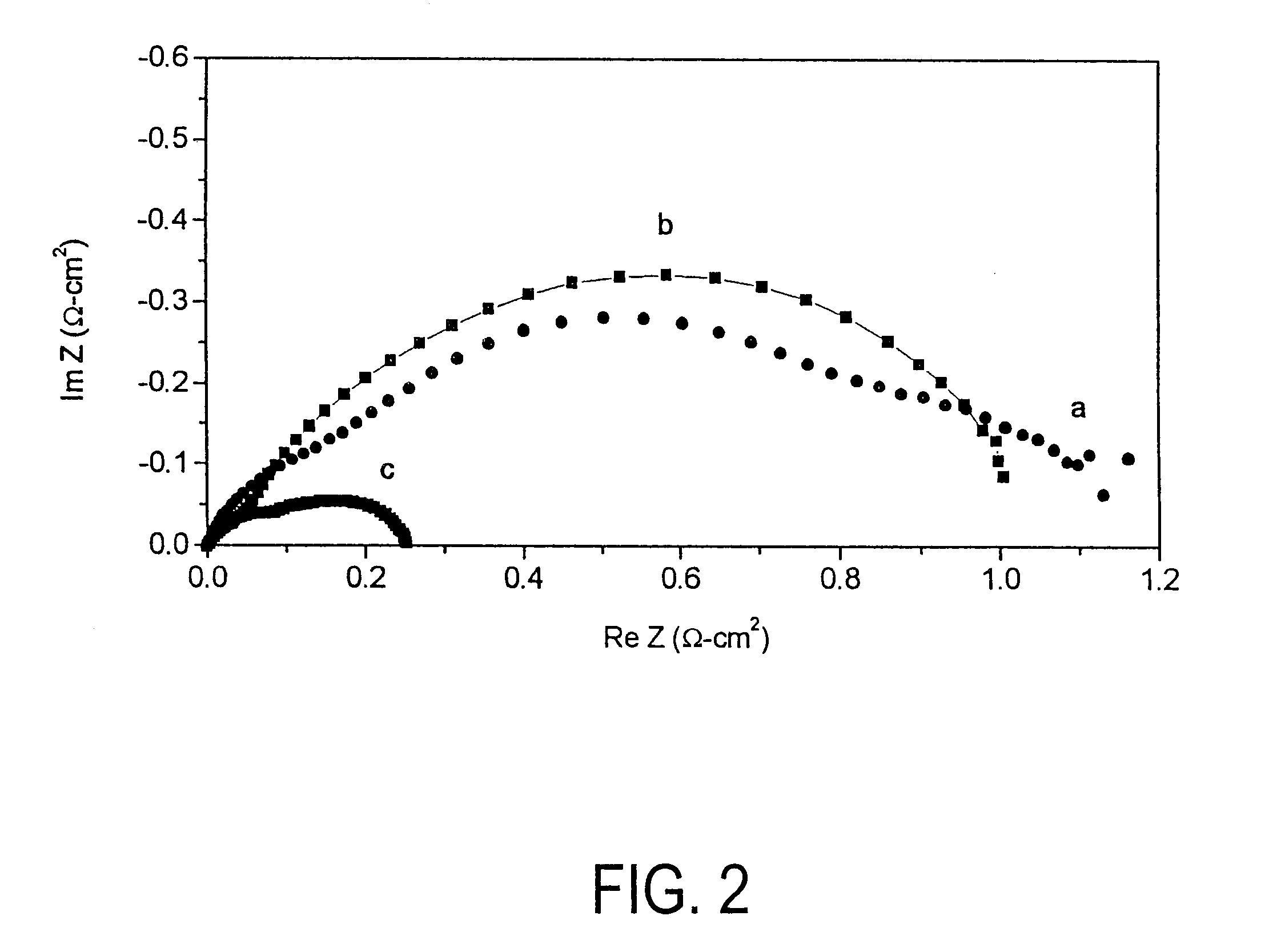

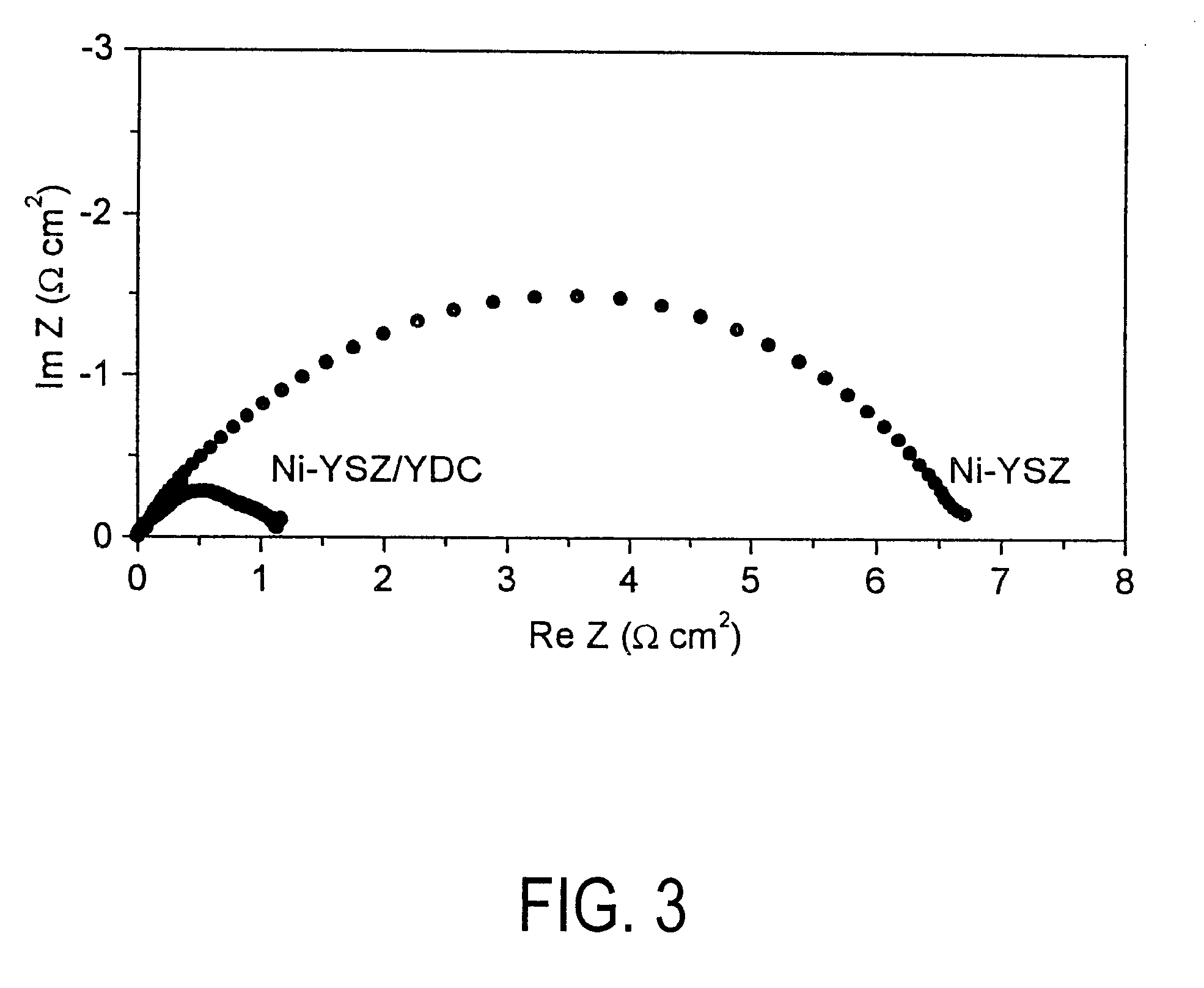

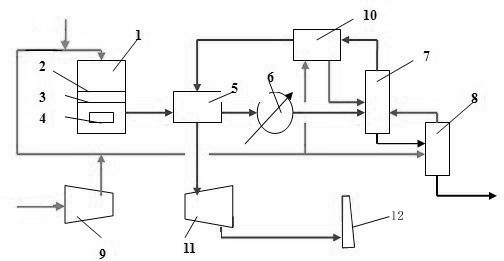

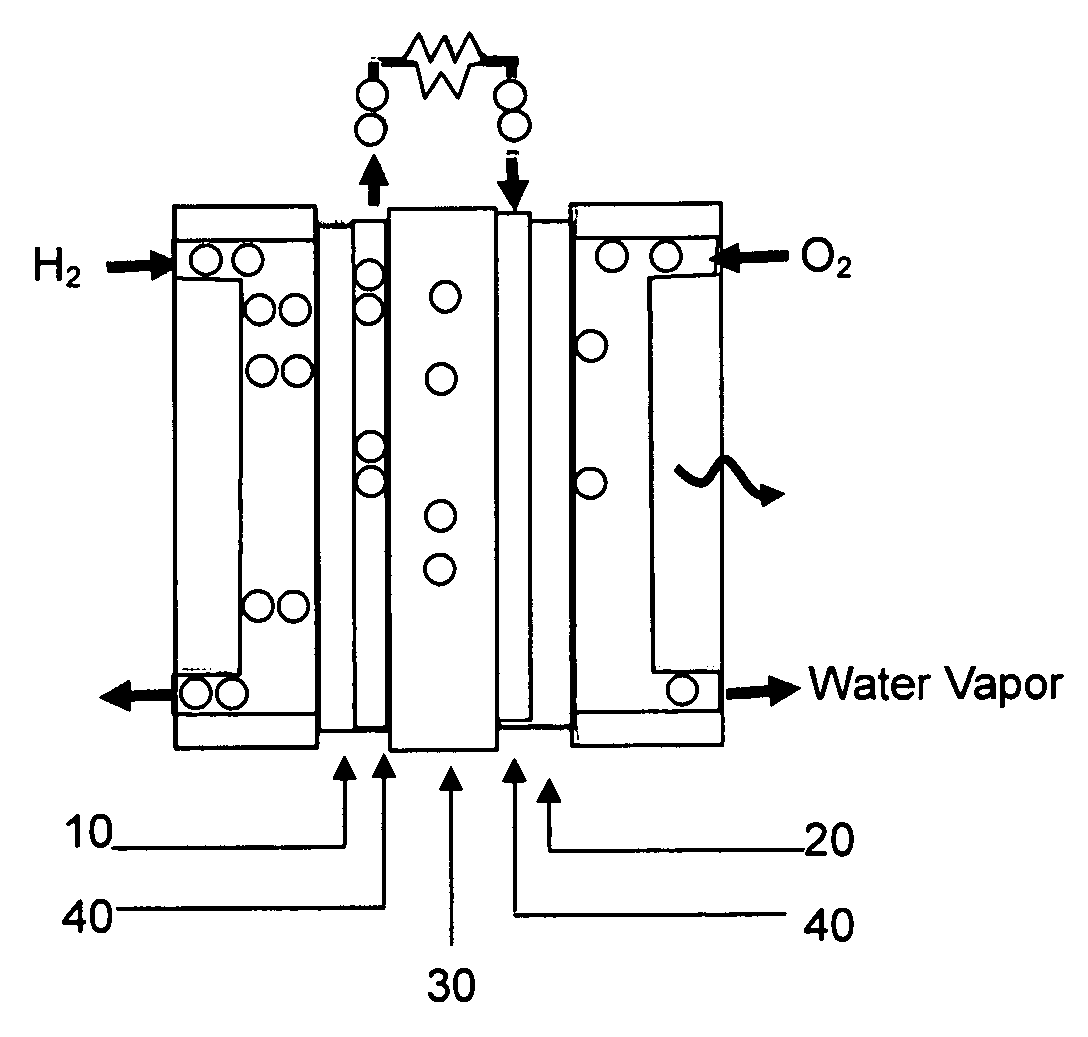

Direct hydrocarbon fuel cells

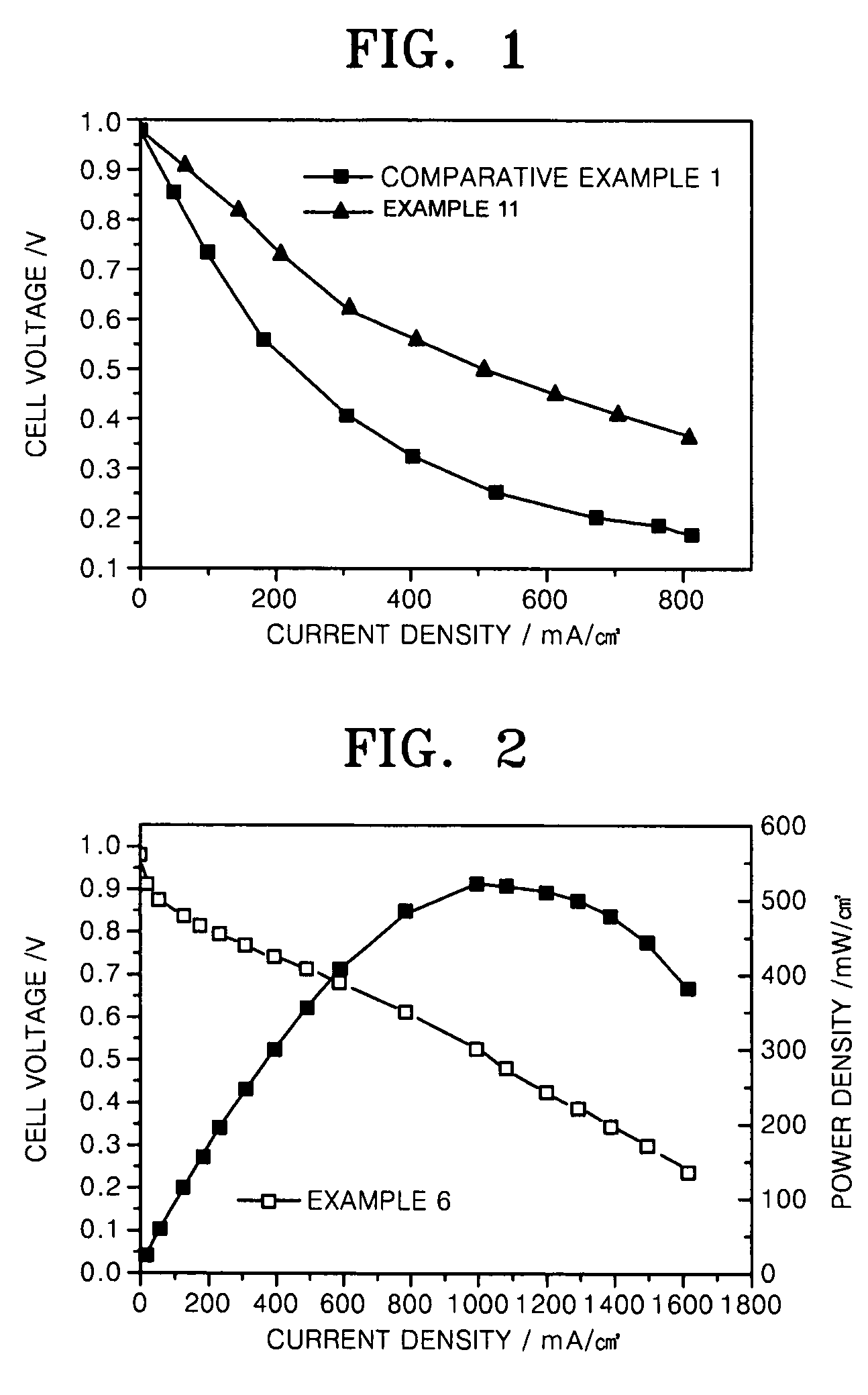

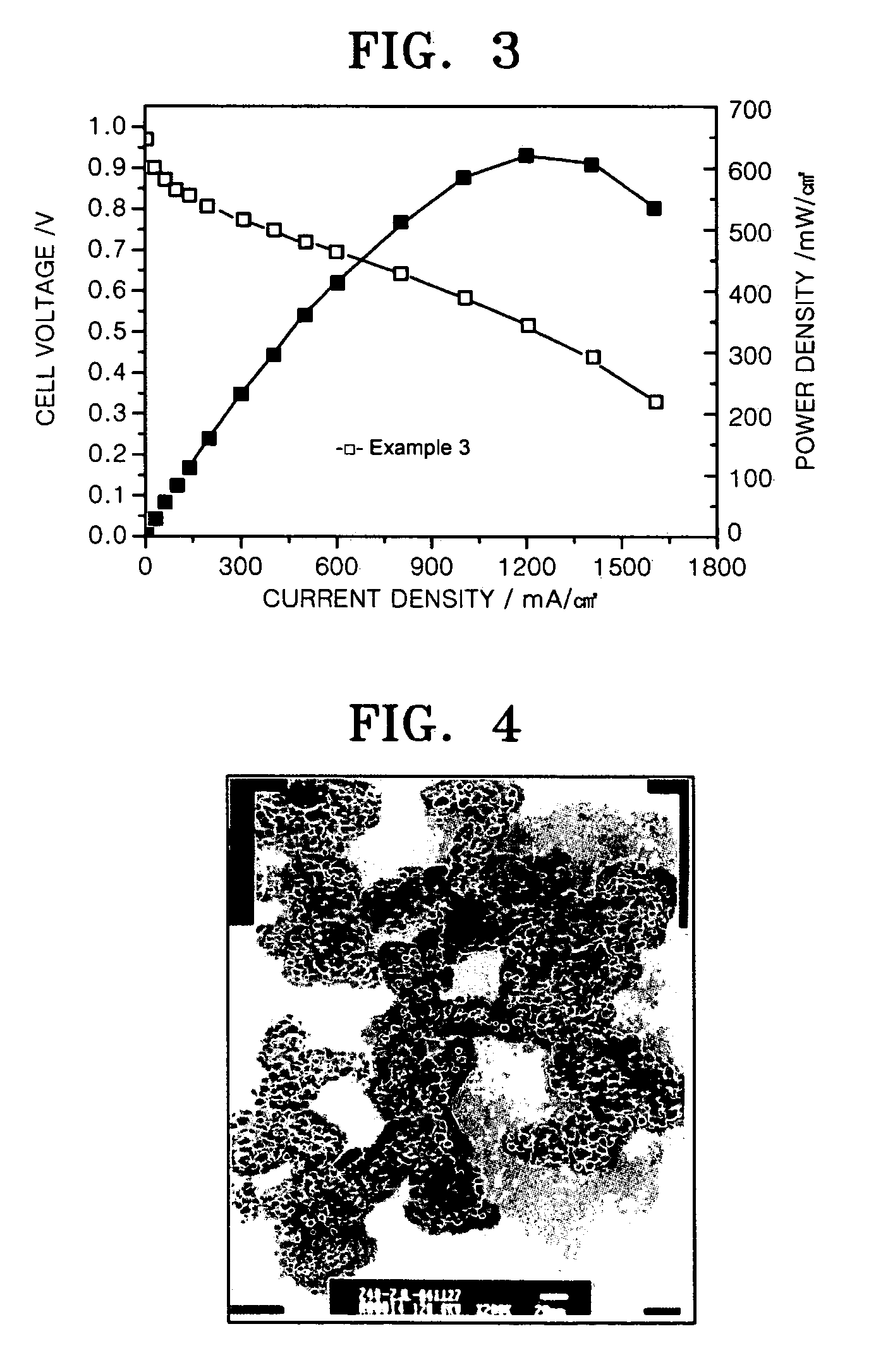

InactiveUS6214485B1Increase ratingsUseful power densityFuel cells groupingFinal product manufactureFuel cellsHydrogen

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures.

Owner:NORTHWESTERN UNIV

Preparation method of catalytic wet oxidation catalyst and treatment method of organic wastewater

ActiveCN103041818AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationHigh concentrationOrganic acid

The invention discloses a preparation method of a catalytic wet oxidation catalyst and a treatment method of organic wastewater. The preparation method comprises the following steps of: (1) taking a porous inert material as a carrier, and performing pre-impregnation treatment on the carrier by adopting an organic acid solution; and (2) preparing an impregnating solution with a water-soluble compound containing transition metal elements and a water-soluble compound containing auxiliary elements, impregnating the carrier after treatment in the step (1) with the impregnating solution, drying in shade for 12-48 hours in air at appropriate humidity, then drying and roasting to obtain a final catalyst. When the catalyst prepared by the method disclosed by the invention is used for high-concentration organic wastewater, the characteristics of high activity, good stability and the like are realized, and the energy consumption and the investment can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

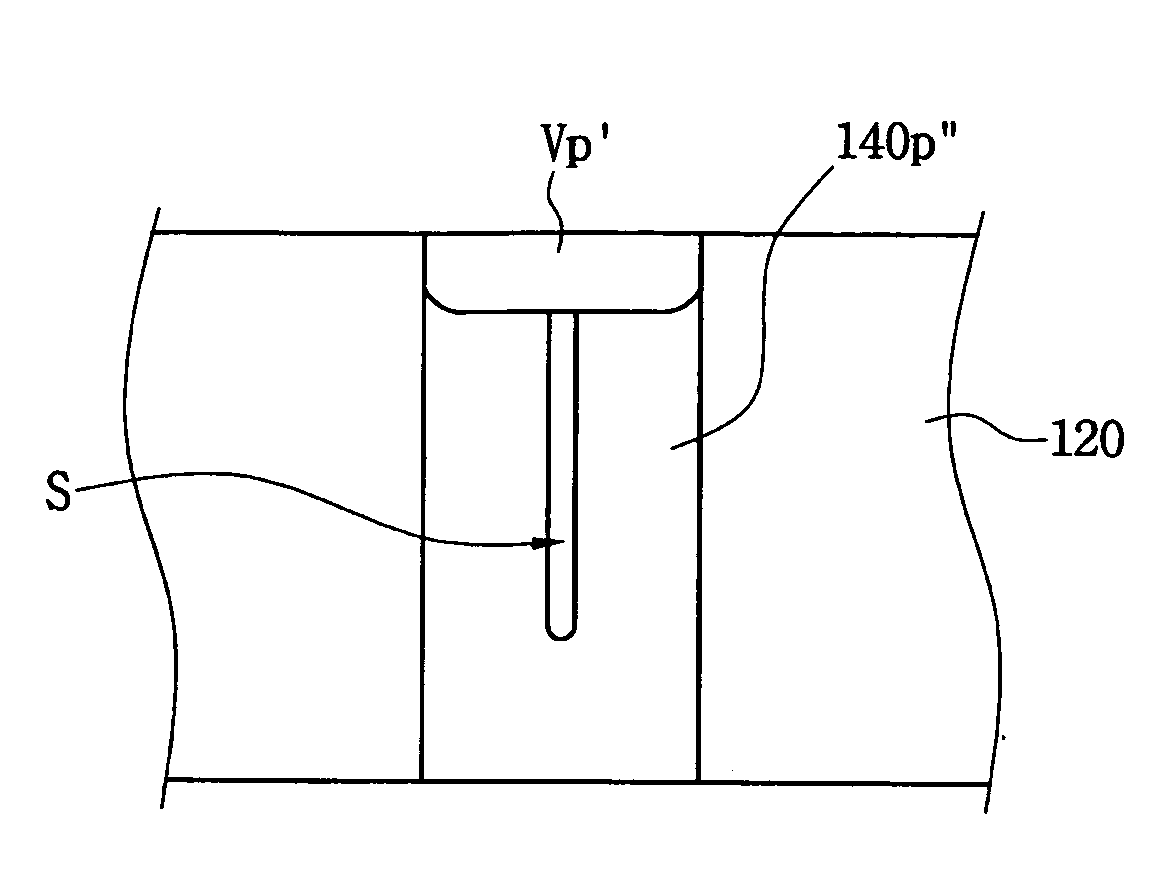

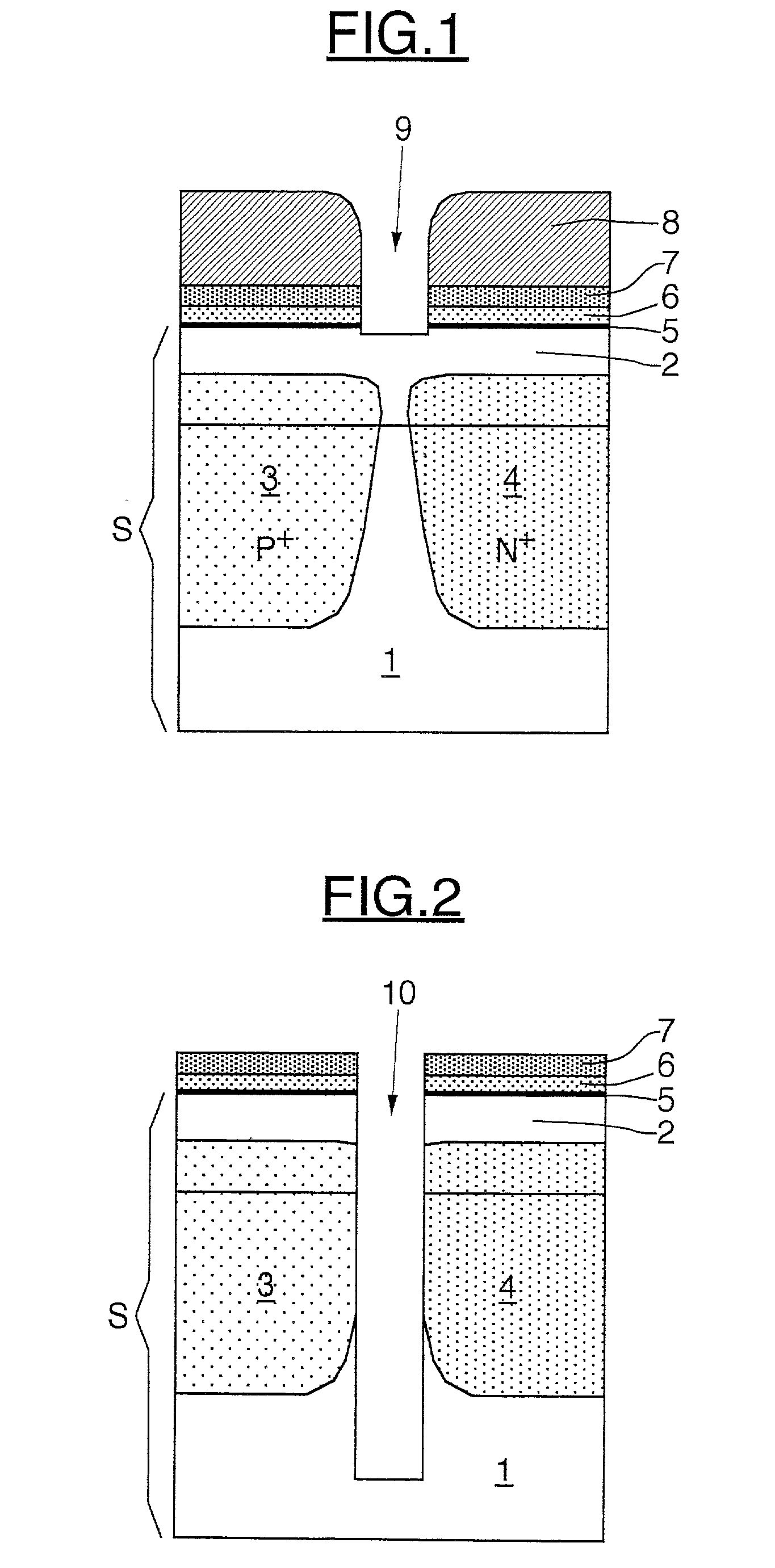

Methods of fabricating semiconductor devices and semiconductor devices including a contact plug processed by rapid thermal annealing

ActiveUS20100203725A1Rapidly hydrogenateLow resistivitySemiconductor/solid-state device manufacturingCoffinsChemical-mechanical planarizationContact hole

A method of fabricating a semiconductor device includes depositing tungsten on an insulating layer in which a contact hole is formed by chemical vapor deposition (CVD), performing chemical mechanical planarization (CMP) on the tungsten to expose the insulating layer and form a tungsten contact plug, and performing rapid thermal oxidation (RTO) on the tungsten contact plug in an oxygen atmosphere such that the tungsten expands volumetrically into tungsten oxide (WξOψ).

Owner:SAMSUNG ELECTRONICS CO LTD

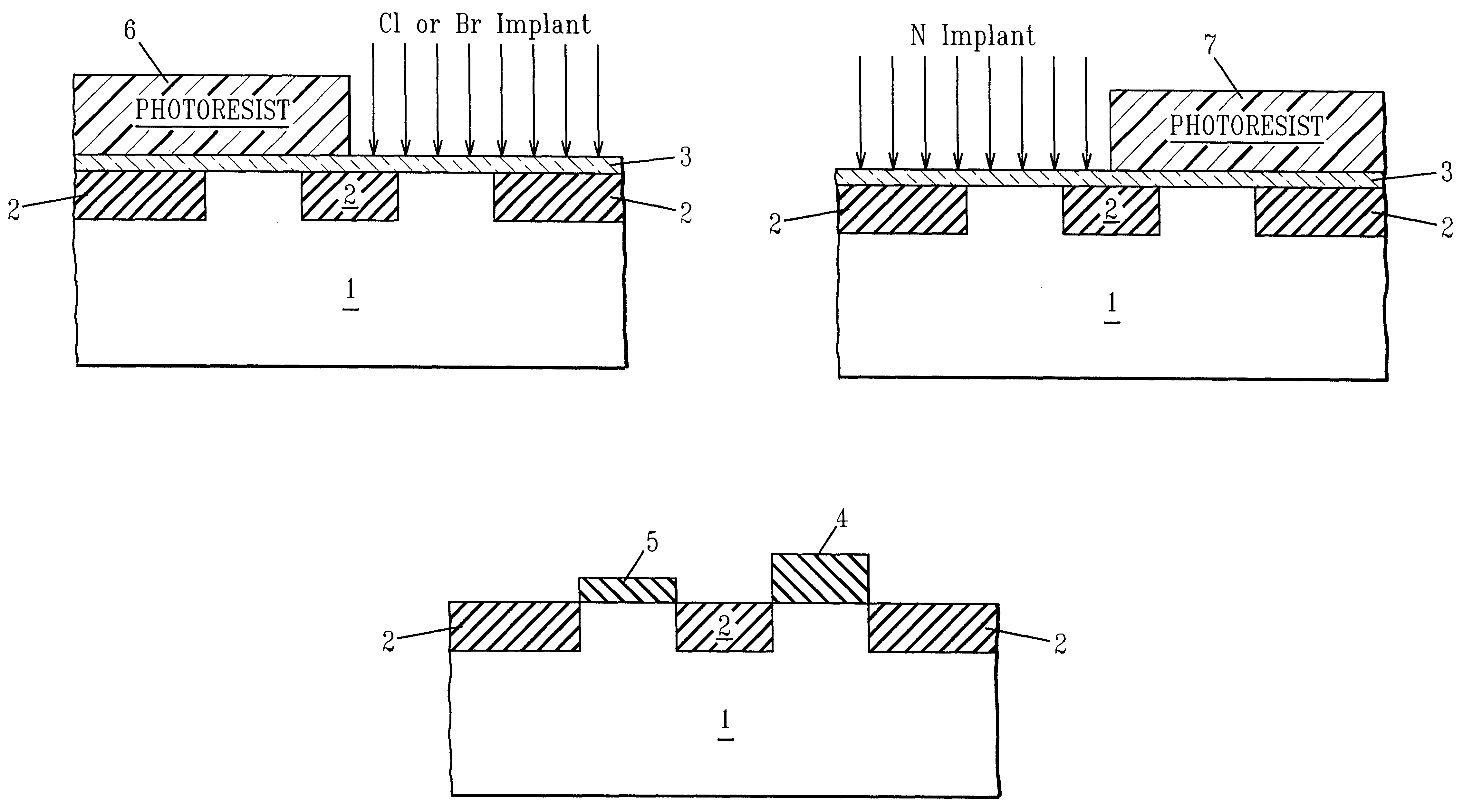

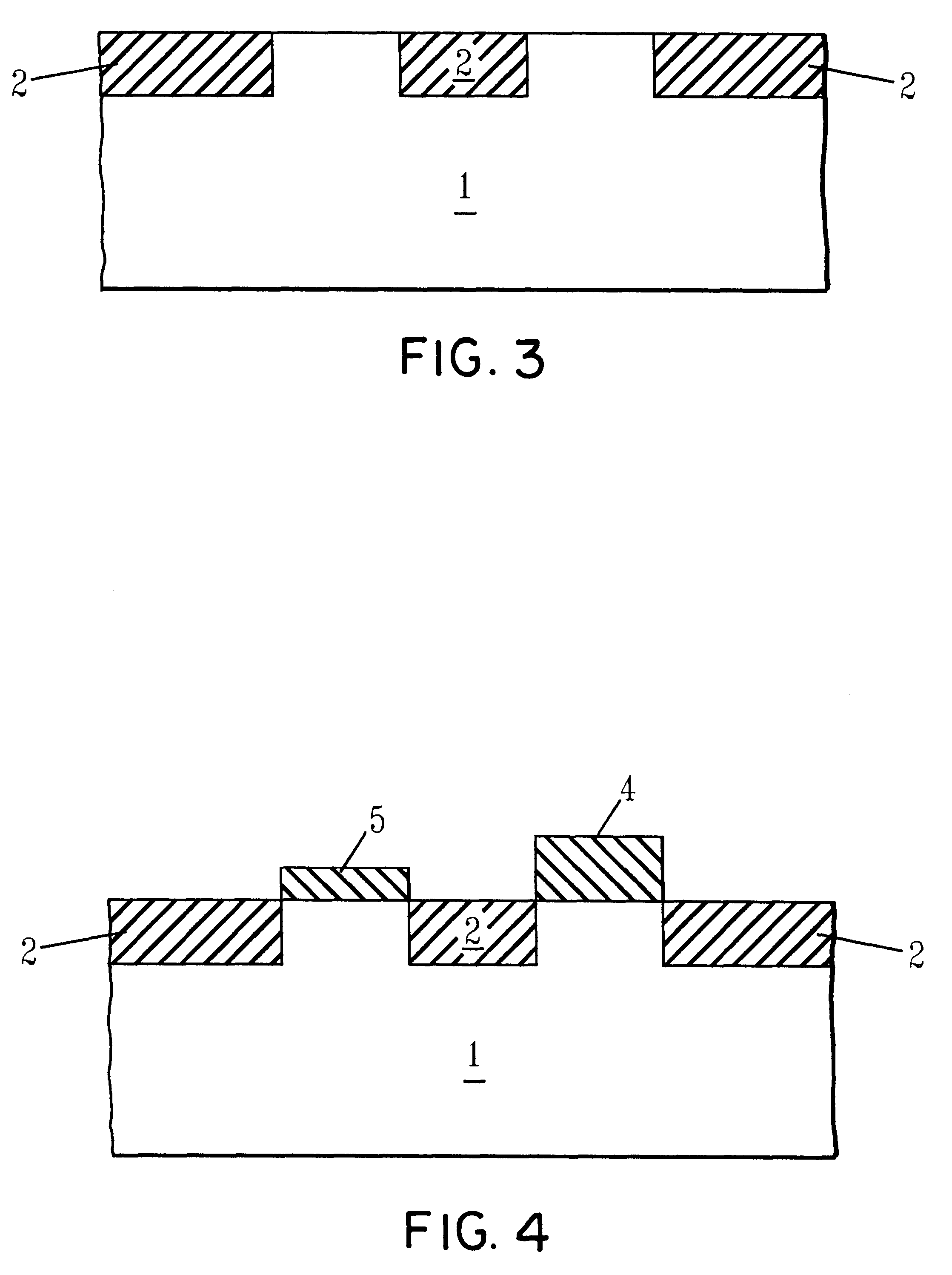

Method for fabricating different gate oxide thicknesses within the same chip

InactiveUS6335262B1Increase rangeSlow and reduced rateSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureBromine

Owner:GLOBALFOUNDRIES INC

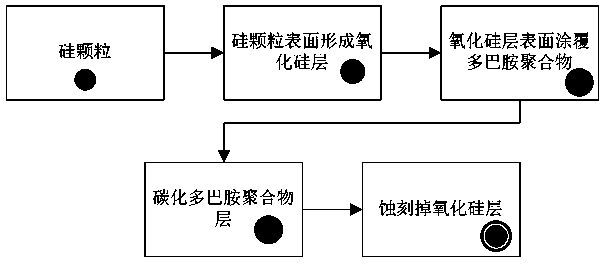

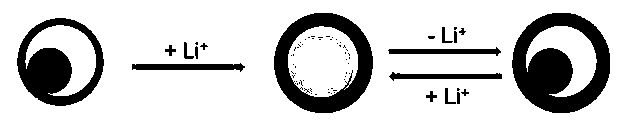

Hollow structure material as well as preparation method and use thereof

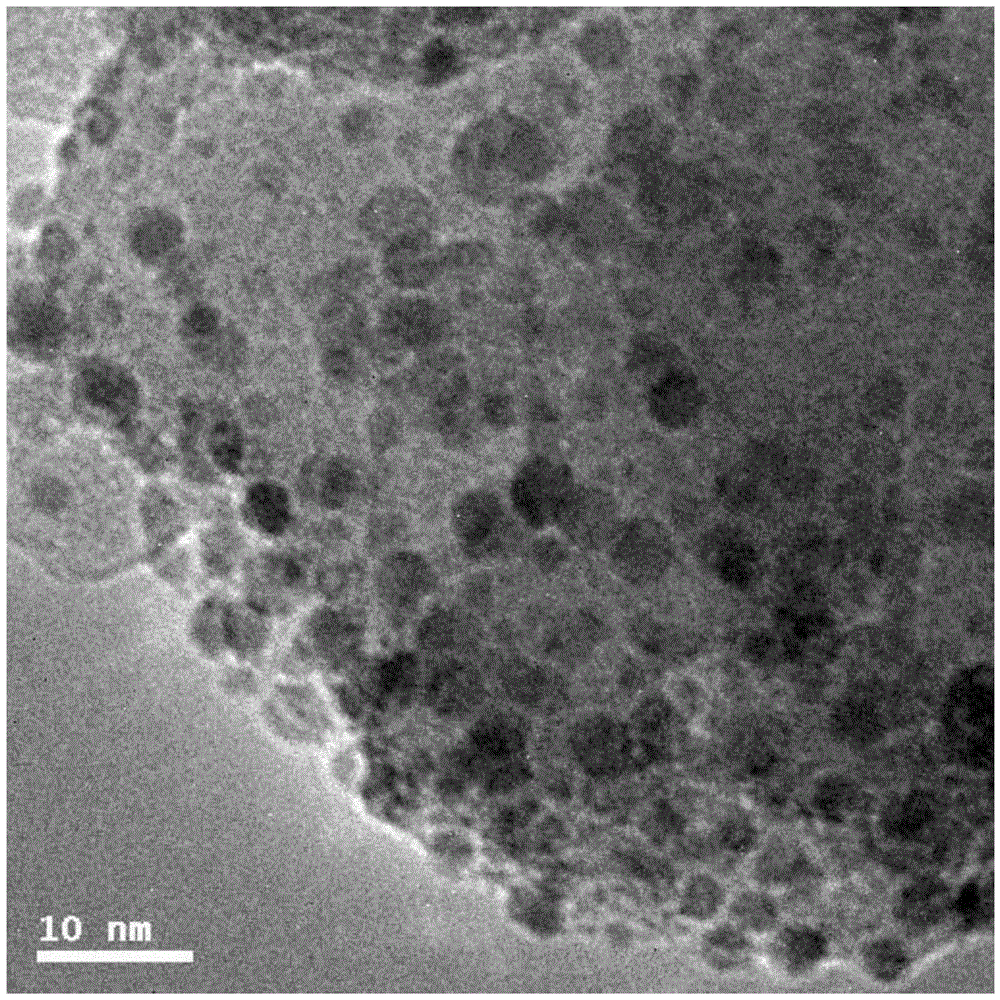

InactiveCN103779546AImprove electronic conductivityImprove ionic conductivityMaterial nanotechnologyCell electrodesComposite materialSilicon particle

The invention discloses a hollow structure material. The hollow structure material comprises silicon particles and an amorphous carbon shell, wherein the silicon particles are arranged in the amorphous carbon shell. The hollow structure material has the advantages that a hollow part between a silicon kernel and the carbon shell can be used for volume expansion of silicon; direct contact between the silicon and an electrolyte solution is blocked by a carbon shell membrane of a surface layer, so that a steady solid-state electrolyte solution interface can be formed on the surface of the carbon shell; and amorphous carbon is high in electronic conductivity and high in ionic conductivity, so that lithium ions and electrons can be freely transported through the amorphous carbon. A carbon-coated hollow material is applied to an existing slurry coating method electrode preparation technology and lays a foundation for industrial application. The invention also discloses a preparation method of the hollow structure material. The preparation method does not relate to dangerous gas such as silicane or similar expensive instruments for chemical vapor deposition. The large-scale production manufacturing of the hollow structure material is easily realized. A production condition control requirement is not strict, so that the hollow structure material is high in repeatability.

Owner:NANJING AMPRIUS

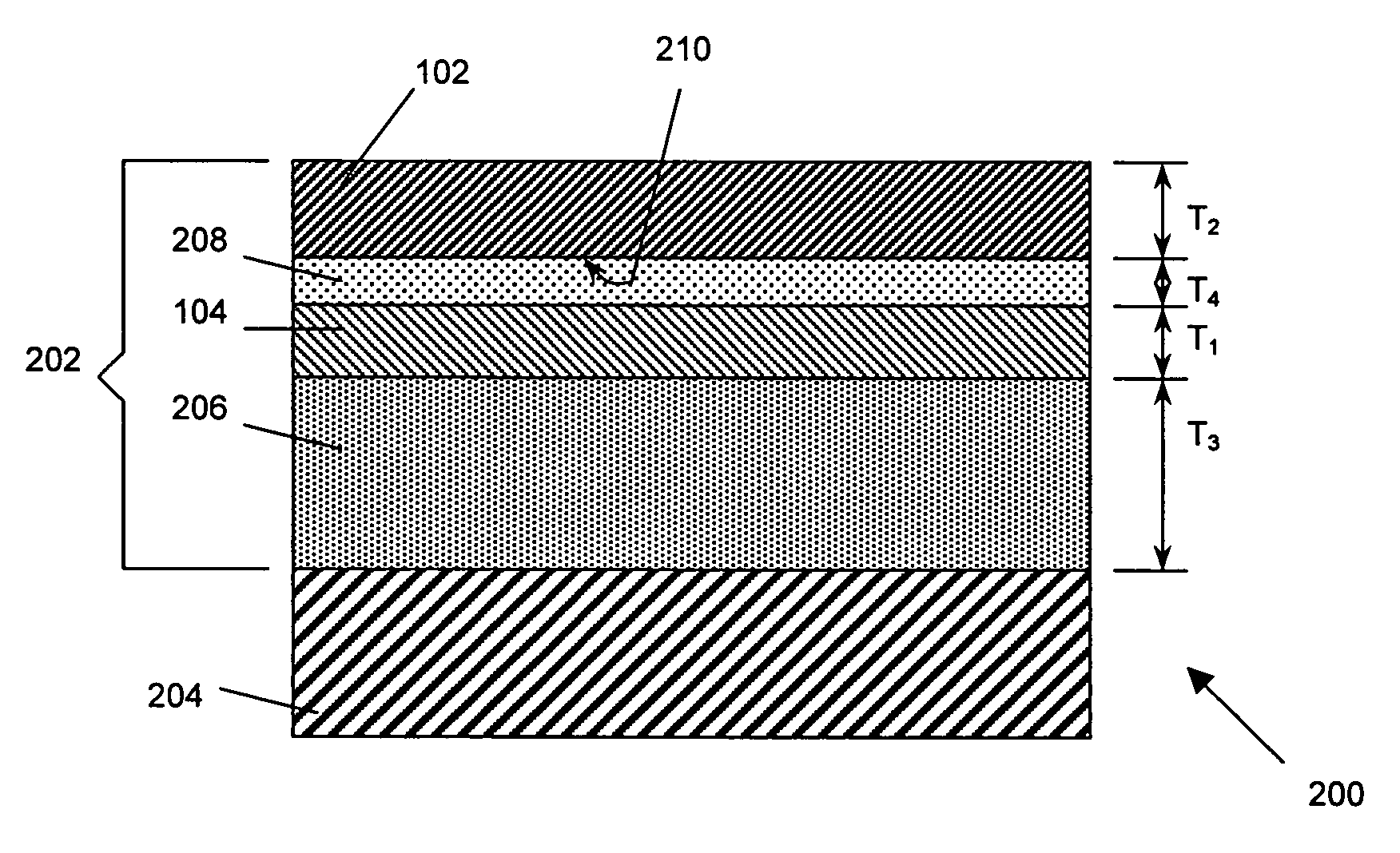

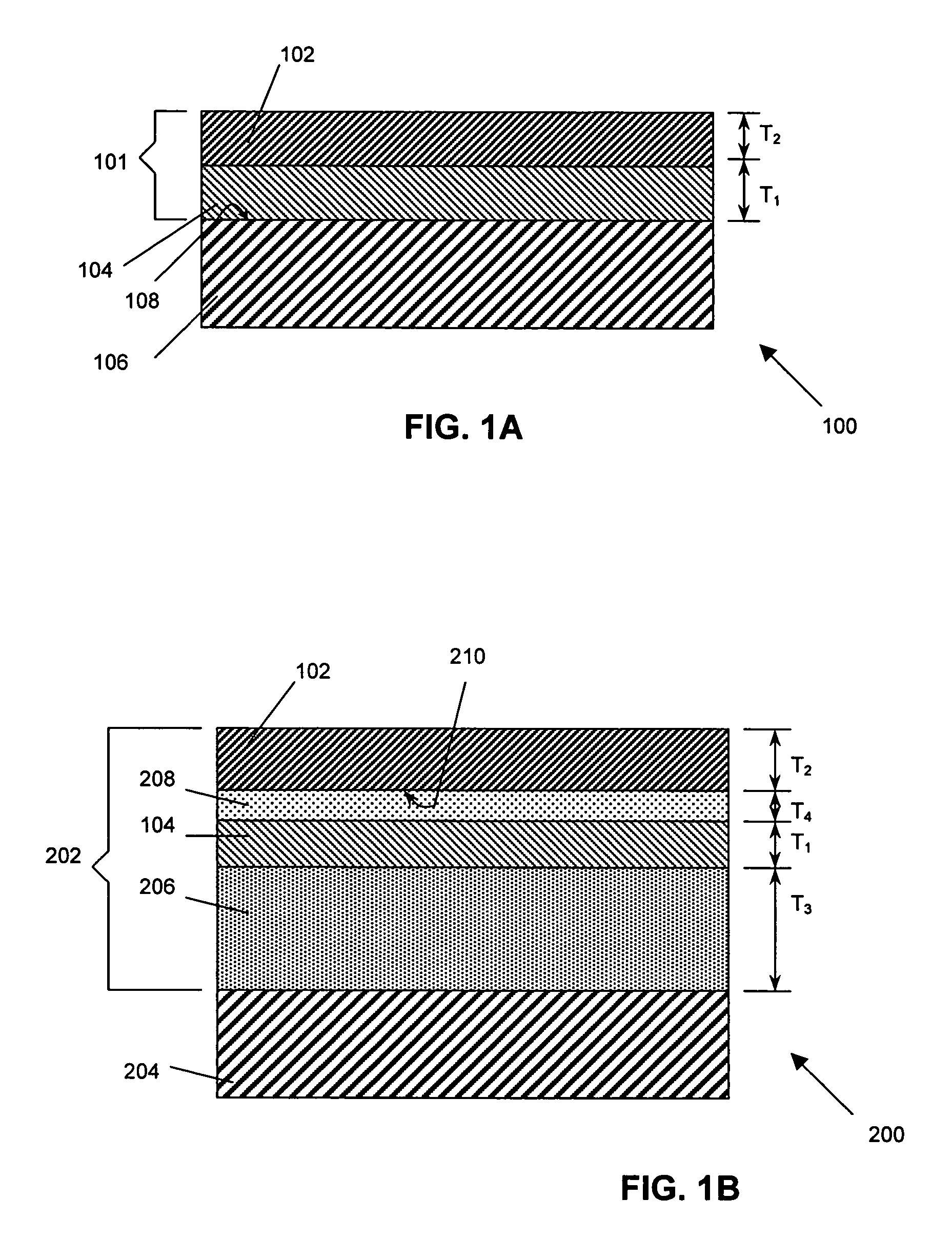

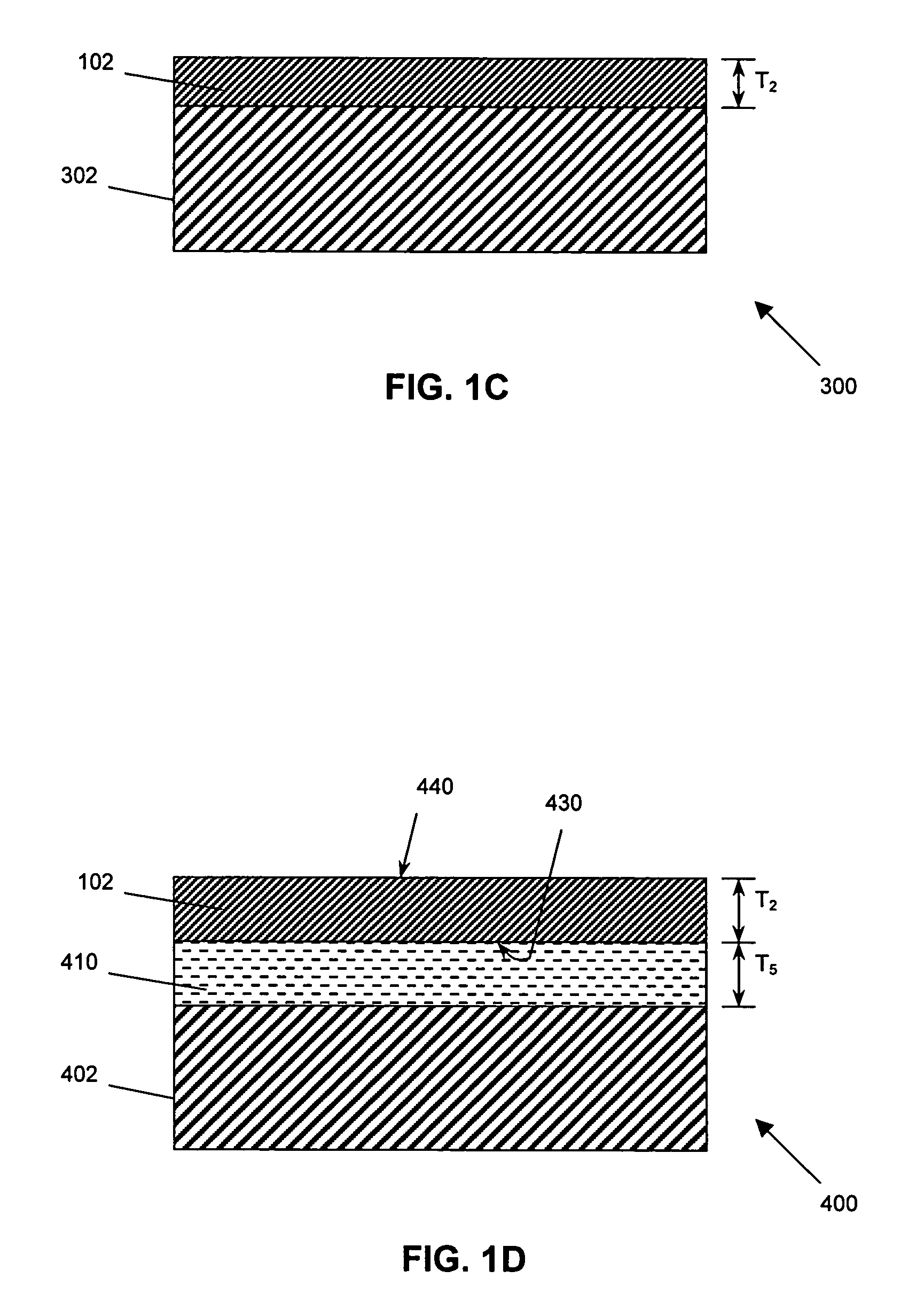

Methods for preserving strained semiconductor substrate layers during CMOS processing

InactiveUS7071014B2Fast oxidationSurfaces with very littleSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSSurface layer

Oxidation methods, which avoid consuming undesirably large amounts of surface material in Si / SiGe heterostructure-based wafers, replace various intermediate CMOS thermal oxidation steps. First, by using oxide deposition methods, arbitrarily thick oxides may be formed with little or no consumption of surface silicon. These oxides, such as screening oxide and pad oxide, are formed by deposition onto, rather than reaction with and consumption of the surface layer. Alternatively, oxide deposition is preceded by a thermal oxidation step of short duration, e.g., rapid thermal oxidation. Here, the short thermal oxidation consumes little surface Si, and the Si / oxide interface is of high quality. The oxide may then be thickened to a desired final thickness by deposition. Furthermore, the thin thermal oxide may act as a barrier layer to prevent contamination associated with subsequent oxide deposition.

Owner:TAIWAN SEMICON MFG CO LTD

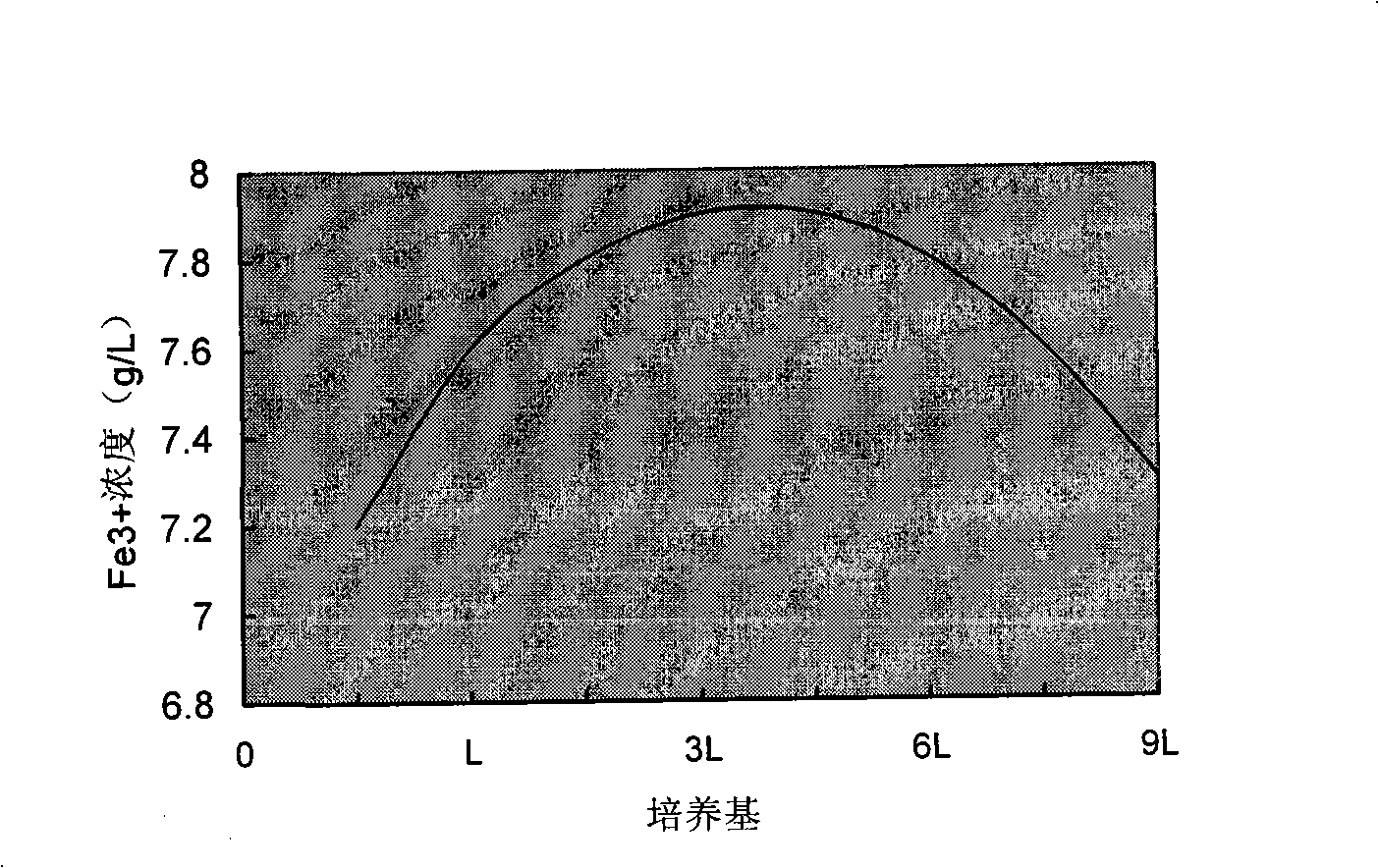

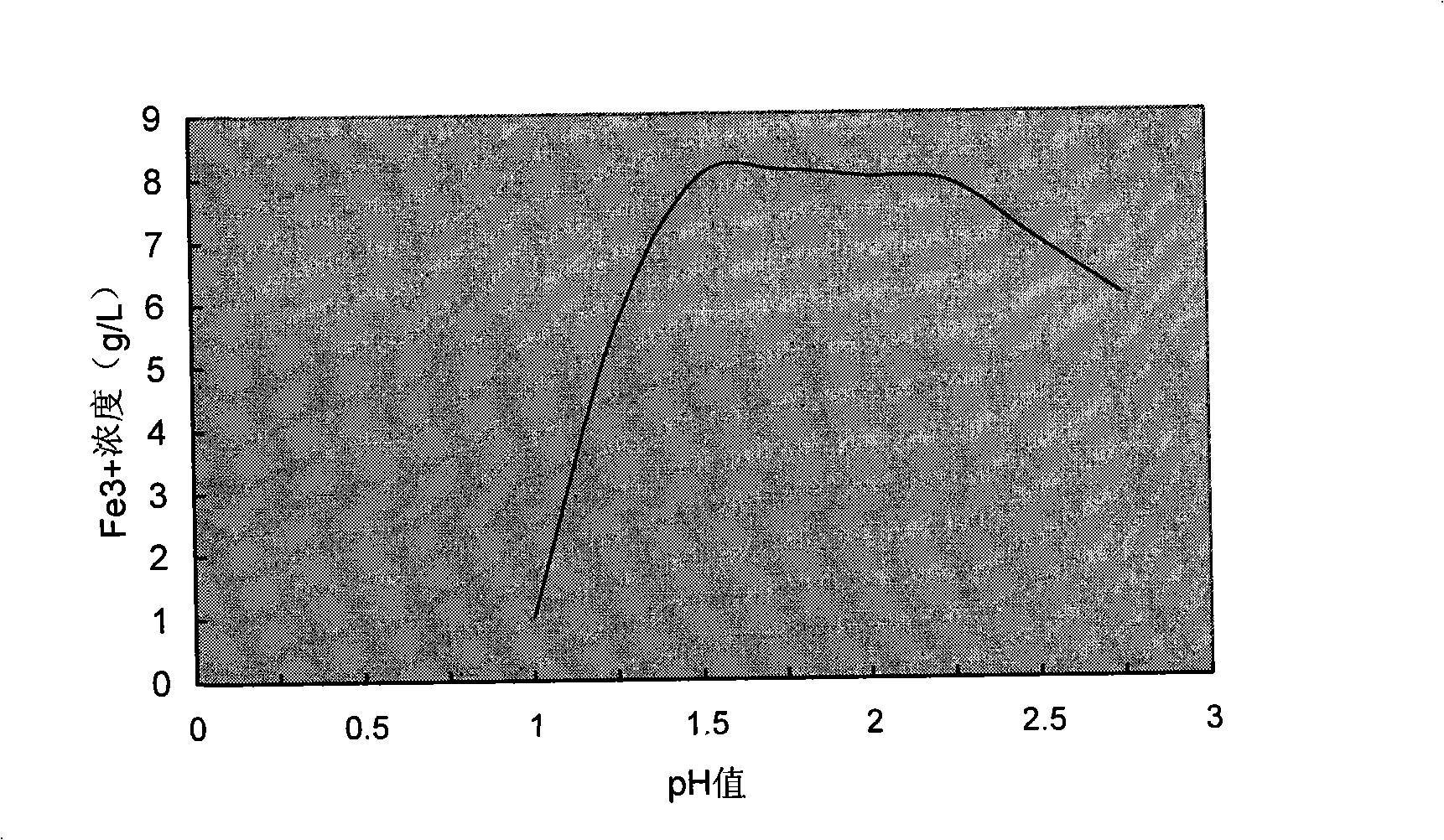

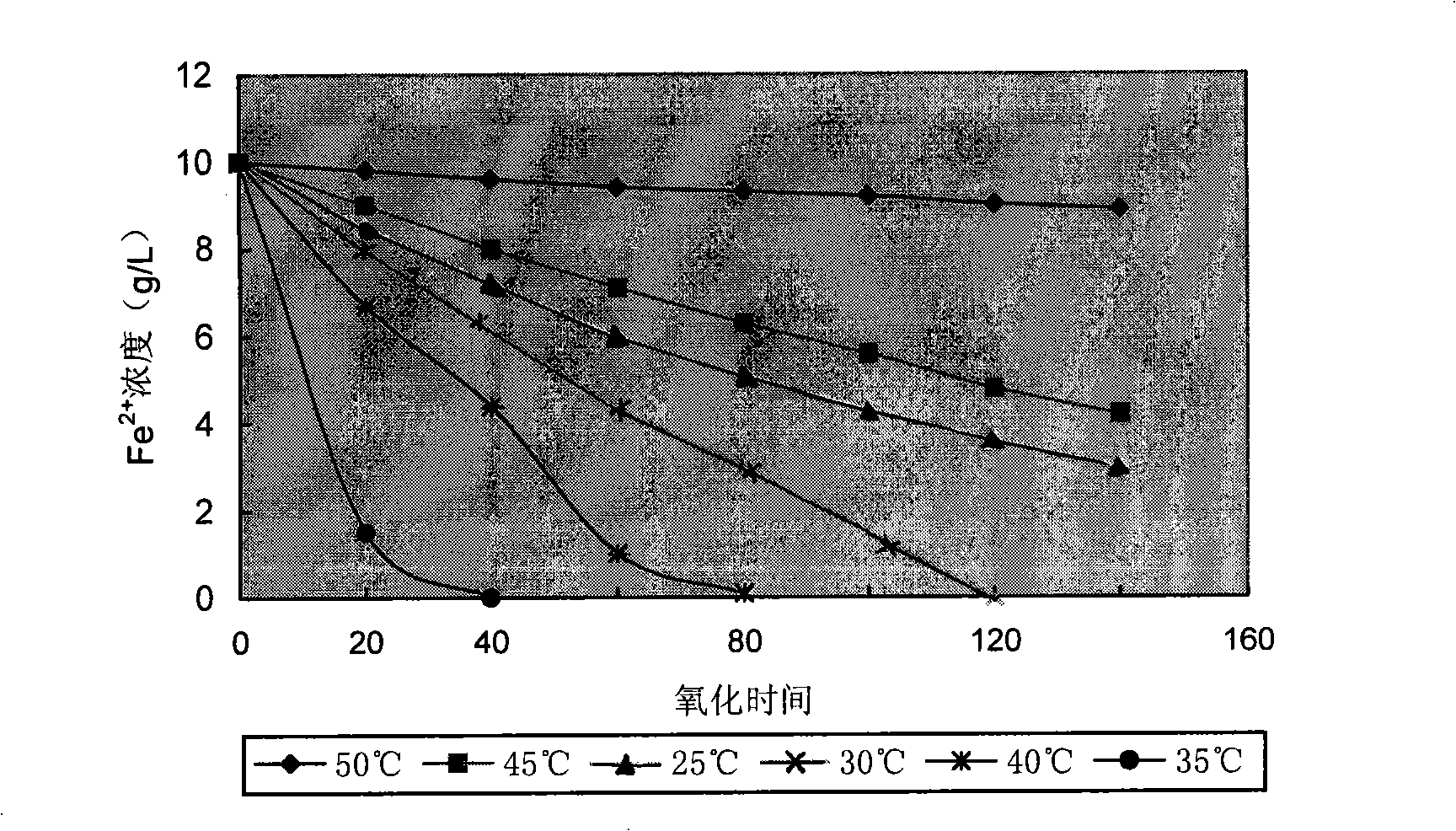

Composite mineral-leaching bacteria colony and use of same in biological metallurgy

ActiveCN101538540AImprove efficiencyBroaden the scope of ore processingBacteriaMicroorganism based processesIonLaboratory culture

The invention relates to a composite mineral-leaching bacteria colony and use of the same in biological metallurgy. The composite mineral-leaching bacteria colony has a preserving number of CGMCC No.2395 in the Common Micro-organism Center of China General Microbiological Culture Collection Center. The composite mineral-leaching bacteria colony has strong oxidative activity within a temperature range from 30 to 52 DEG C as well as a working pH value of between 0.8 and 2.25 and an arsenic ion tolerance of 0 to 20 g / L. The composite mineral-leaching bacteria colony is used for extracting and recovering gold or copper, and greatly expands the use range of biological metallurgy in gold mines. Meanwhile, due to the wide temperature adaptation range, the composite mineral-leaching bacteria colony improves the oxidation speed and reduces production cost. Therefore, the composite mineral-leaching bacteria colony has a significant application prospect in biological metallurgy industry.

Owner:CHINA NAT GOLD GROUP CORP TECH CENT +1

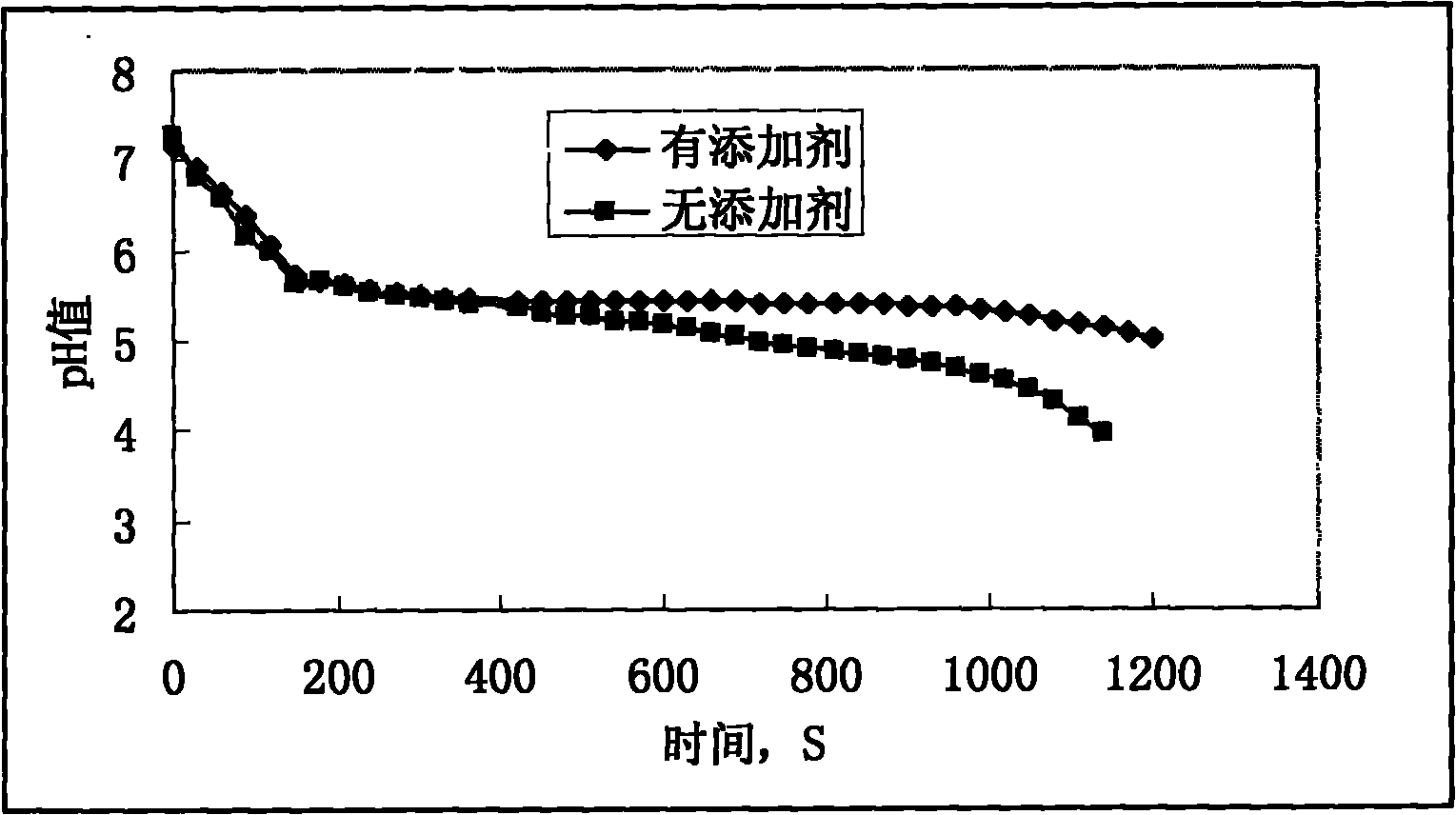

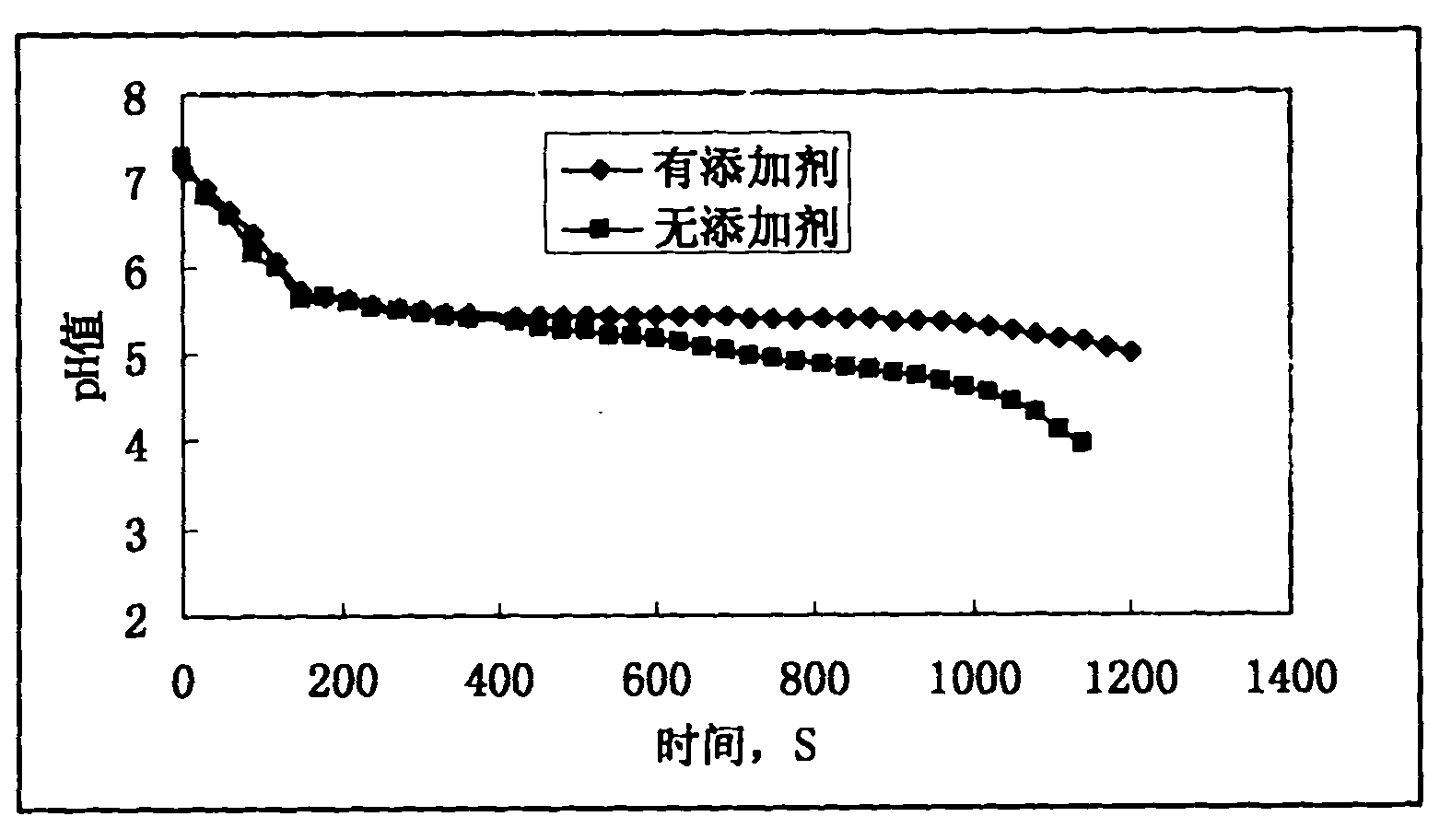

Multifunctional composite additive for wet-method flue gas desulfuration process and using method thereof

InactiveCN102019138AImprove solubilityFacilitate absorption reactionDispersed particle separationDissolutionSlurry

The invention belongs to the technical field of a limestone-gypsum wet-method flue gas desulfuration process and relates to a multifunctional composite additive for a wet-method flue gas desulfuration process and a using method thereof. The composite additive comprises the following components in percentage by mass: 31 to 45 percent of nylon acid, 31 to 45 percent of sodium humate, 6 to 9 percentof organic silicon defoaming agent, 2 to 5 percent of potassium formate, 2 to 5 percent of manganese sulfate and 2 to 5 percent of p-hydroxybenzoic acid. The composite additive can promote the dissolution of the limestone and reduce the using amount of the limestone, has an enhancement factor for improving an absorption reaction of sulfur dioxide (SO2), accelerates the migration speed of SO2 gas liquid, promotes the adsorption reaction of the SO2 in a liquid membrane, inhibits the soft scales of calcium sulfate (CaSO3) from generating, improves the pH value buffer capacity of limestone slurry, slows down the reducing speed of the pH value in the process of absorbing the SO2 by the desulfuration slurry continuously, and achieves the effect of avoiding bubbling and overflow of the desulfuration slurry.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Oxidation polysilacidiron coagulant and preparation thereof

InactiveCN1778701AImprove the efficiency of removing organic matter (especially dissolved organic matter)Improve the coagulation effectWater/sewage treatment by flocculation/precipitationSulfateSilicic acid

An oxidized polysilicate iron coagulating agent and its production are disclosed. The process is carried out by mixing activating silicic acid with low-polymerization degree with acid ferrous sulfate solution, adding into oxidant, additive and stabilizer, aging to obtain liquefied product or curing to obtain product. Its advantages include short period, better stability, simple process and good coagulating effect.

Owner:HARBIN INST OF TECH +2

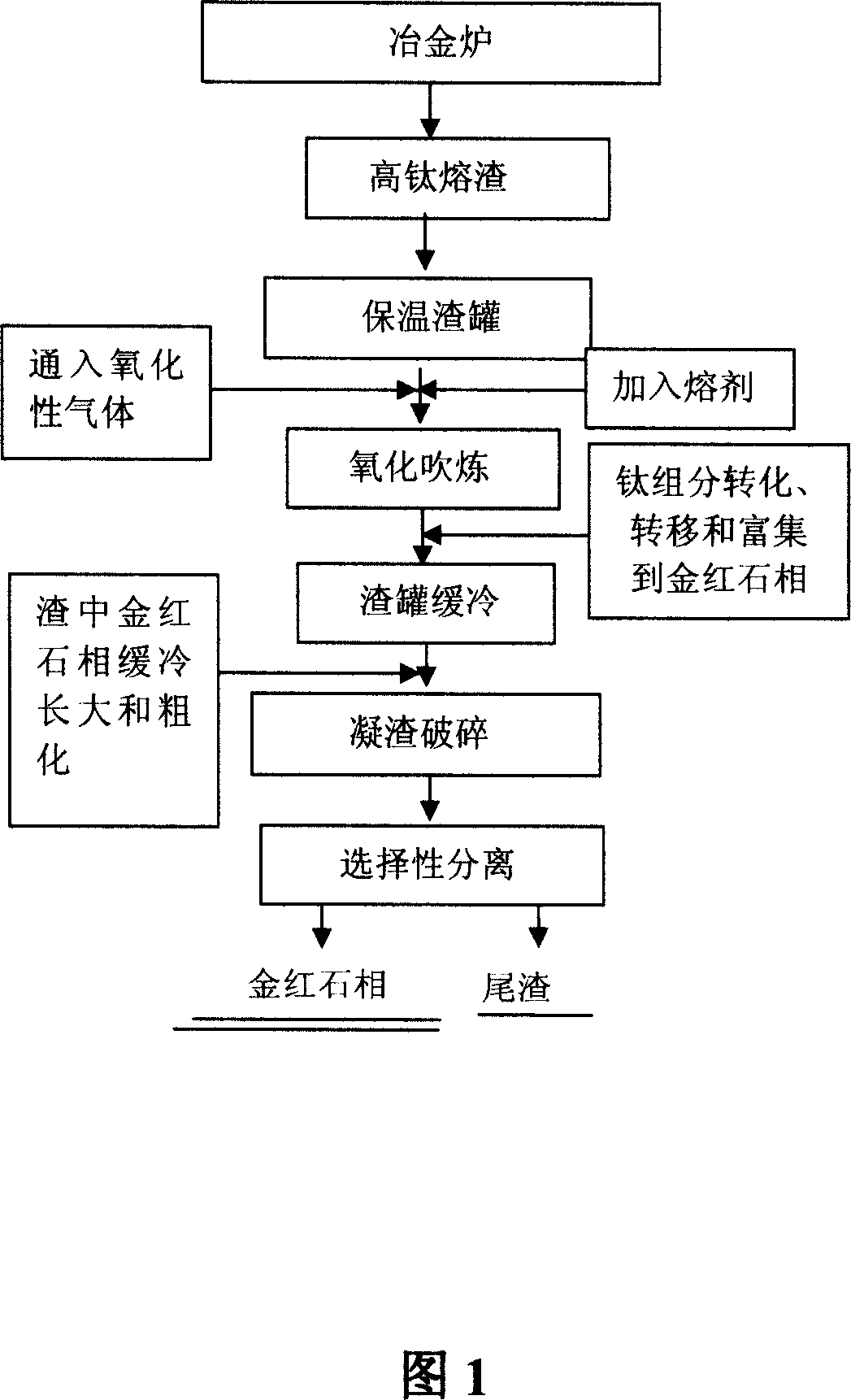

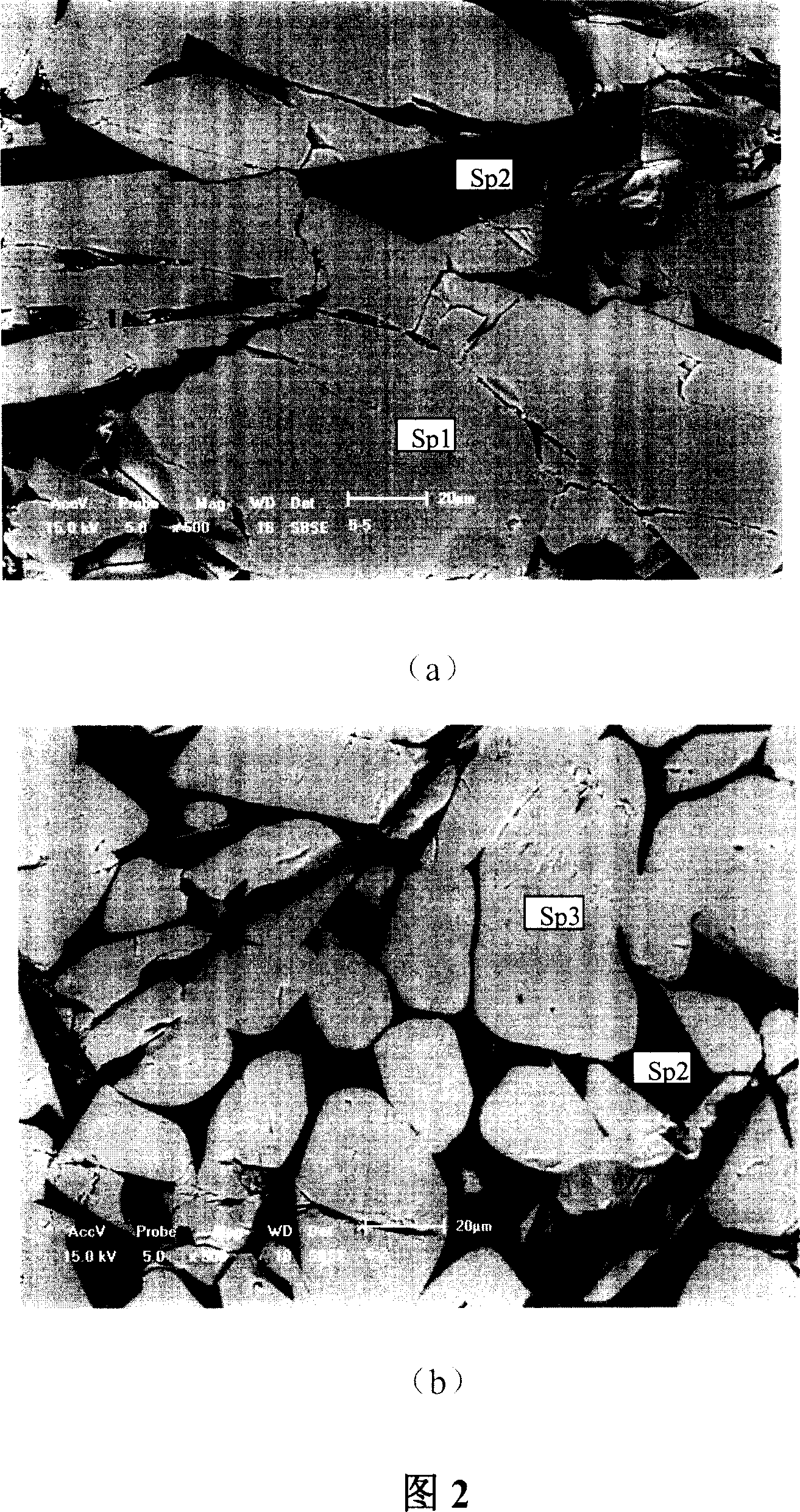

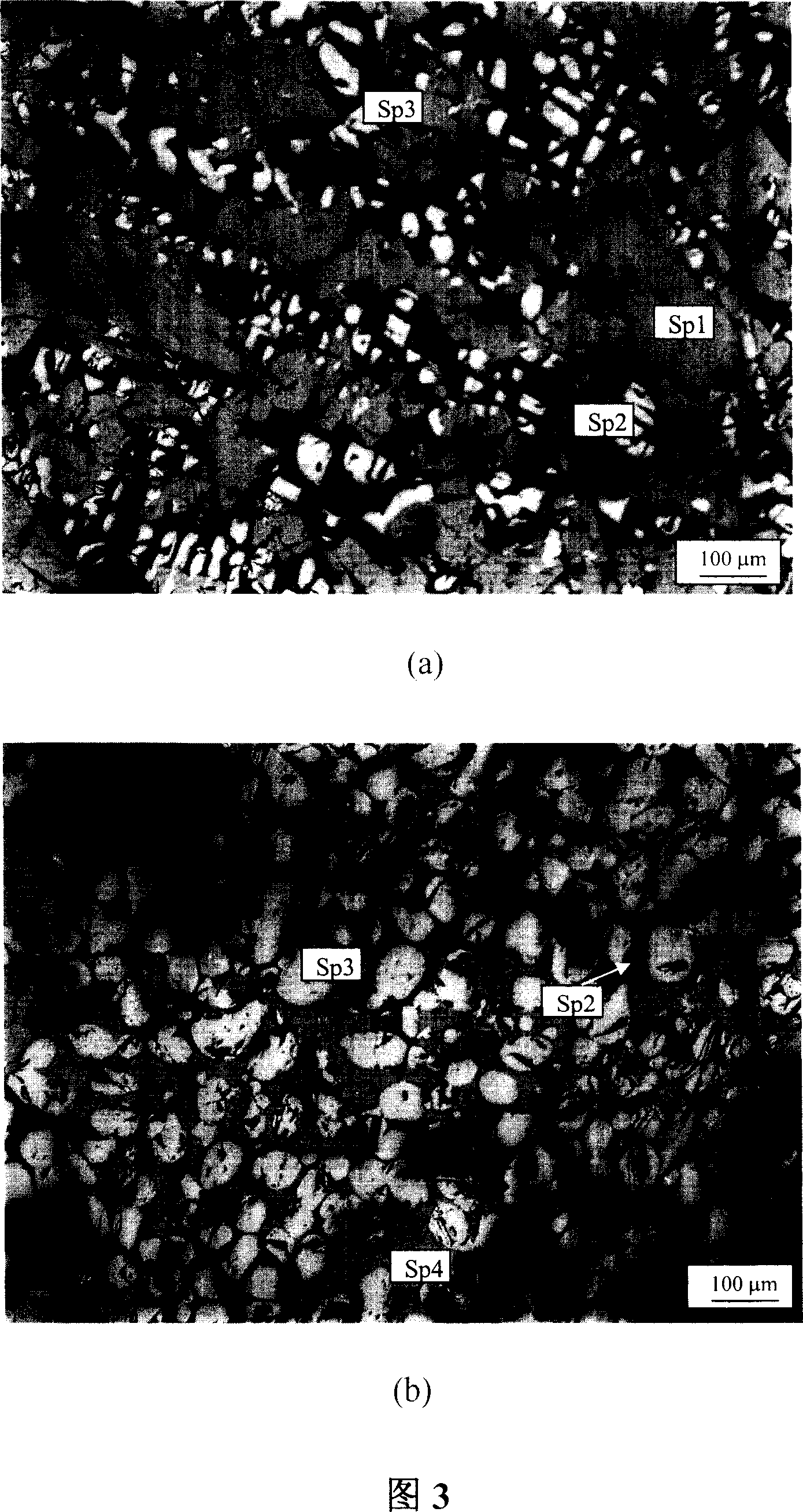

Method of producing synthetic rutile utilizing high-titanium slag

InactiveCN1919740AFacilitate chemical reactionsReasonable process designSolid waste disposalTitanium dioxideHydrometallurgyRutile

The invention discloses a manufacturing method of artificial rutile through high-titanium slag, which comprises the following steps: heating to fuse titanium slag in the slag container; adding addictive in the slag tank; blowing oxidized gas in the slag; making titanium component enriched in the rutile selectively; controlling the cooling velocity to cool slag to indoor temperature; growing rutile phase selectively; grinding the cooled condensed slag; fining; adopting wet metallurgical separating method or ore dressing separating method to separate rutile from condensed slag; obtaining artificial rutile with high-grade TiO2.

Owner:隋智通 +1

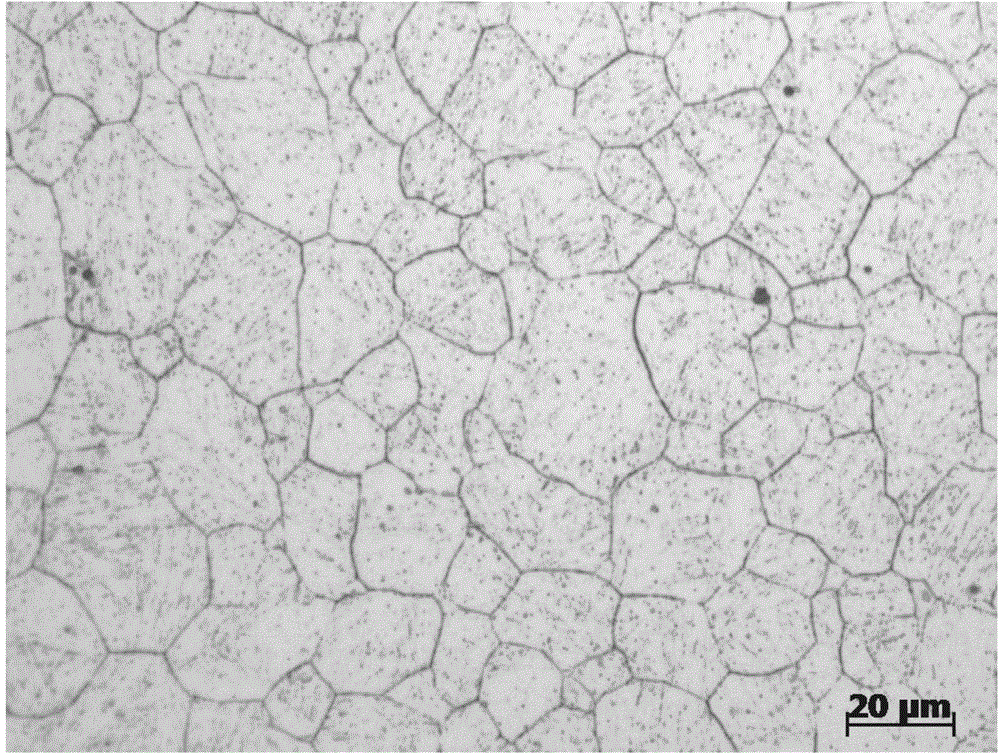

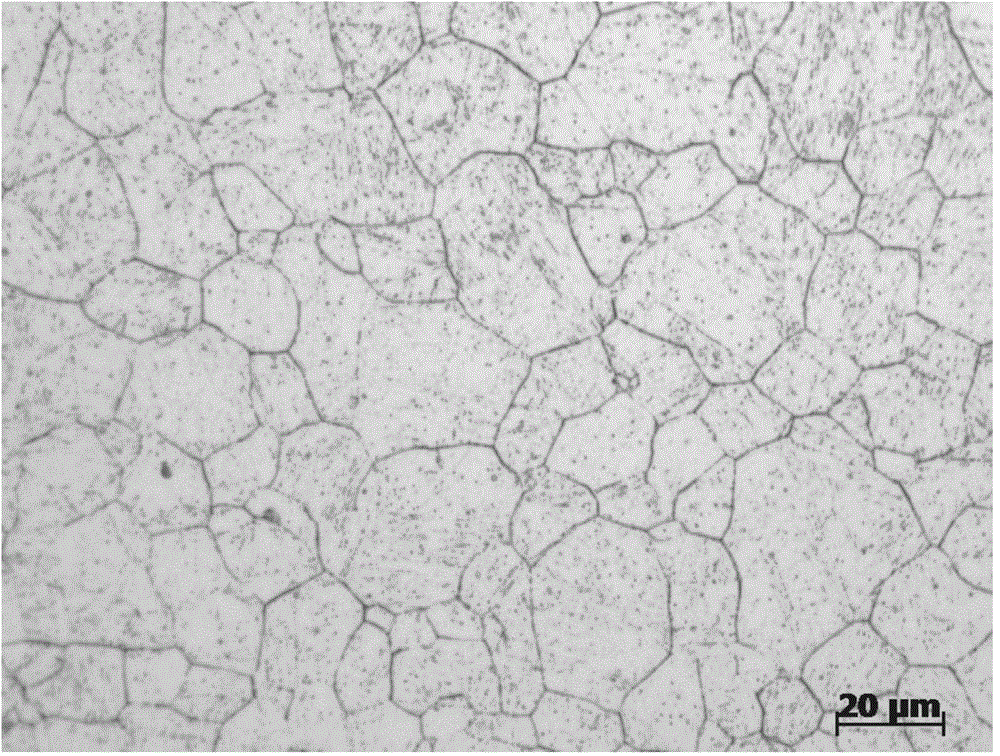

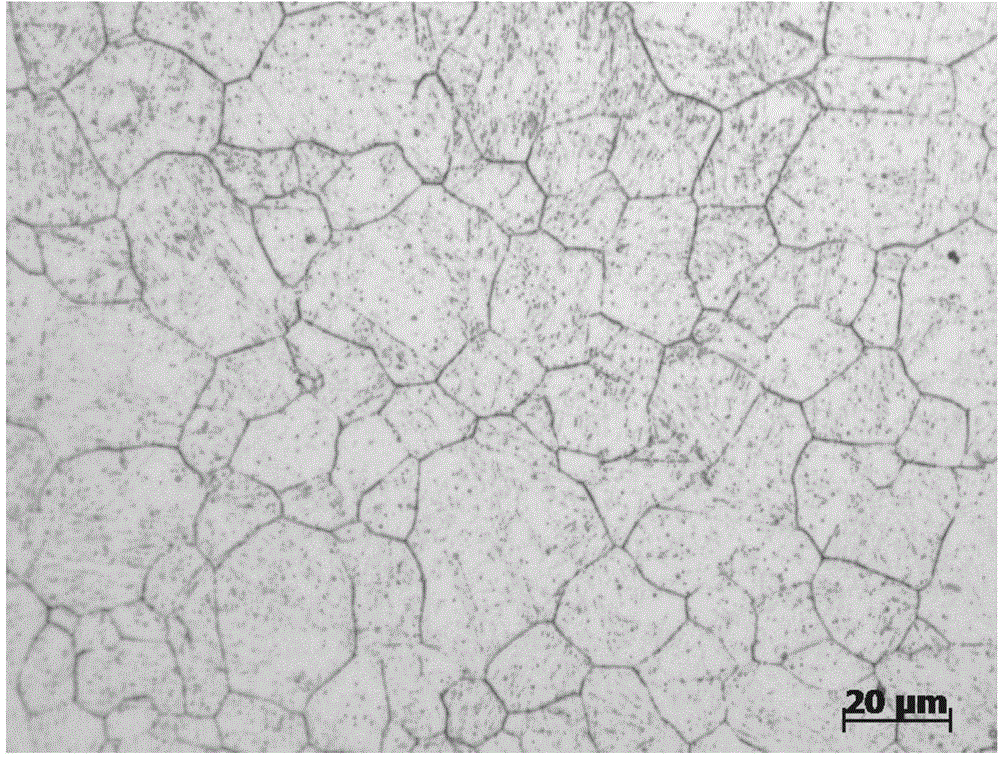

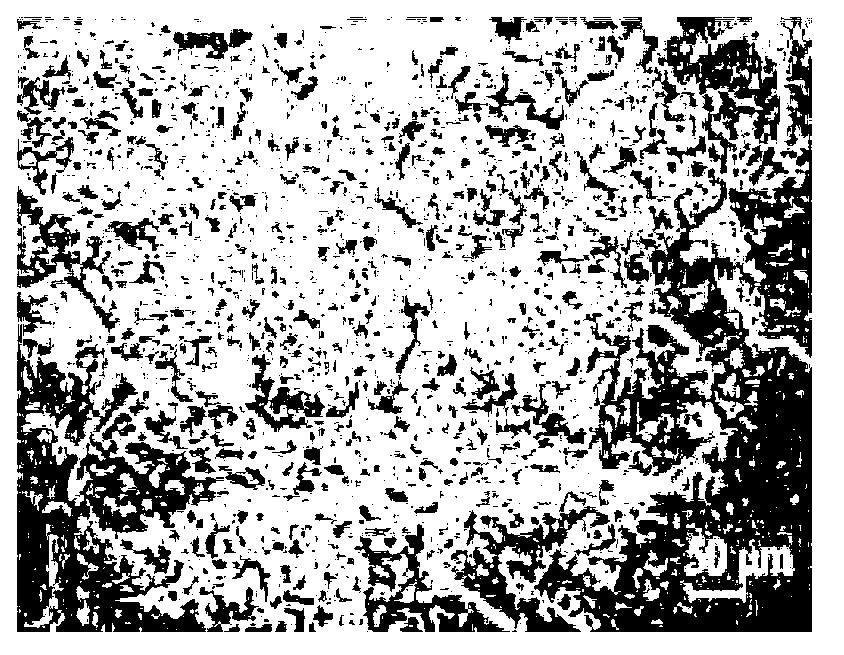

Method for displaying original austenite grain boundaries of maraging stainless steel

InactiveCN104483179AEffective displayDisplay clear and completePreparing sample for investigationMetallic material coating processesElectrolysisEtching

The invention provides a method for displaying original austenite grain boundaries of maraging stainless steel. The displaying of the original austenite grain boundaries is completed by three steps, namely, preparing a sample, carrying out passivation treatment with concentrated nitric acid and carrying out electrolytic etching with concentrated nitric acid. The method comprises the following steps: firstly preparing the sample, grinding and polishing one surface of the sample and grinding the other surfaces of the sample; placing the polished sample in 55-65% (volume fraction) aqueous nitric acid solution and carrying out passivation treatment for 3-5 minutes; carrying out electrolytic etching on the sample at room temperature for 3-5 minutes by adopting stainless steel sheet as a cathode and the passivated sample as an anode at the electrolytic voltage of 5-8V; after the electrolysis, completely rinsing the sample with tap water, rinsing the sample with alcohol and carrying out blow-drying and then observing the clear and complete microstructure-interference-free original austenite grain boundaries under the microscope. The method has the advantages that after the passivation treatment, the grain boundaries are preferentially displayed as compared with microstructures; no residual etching products are caused; the voltage is relatively low and the etching end point is easy to control.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for removing subaqueous organic matter with catalysis ozone oxidization

InactiveCN101269892AIncrease profitSolve for uniformityMultistage water/sewage treatmentWater/sewage treatment by reductionFilling materialsTower

The invention relates to a method of catalytic ozone oxidation organic matter removal in water, which belongs to the water treatment technical field. The method solves the problems that: in the existing method of catalytic ozone oxidation organic matter removal in water, the utilization ratio of ozone is low, the organic pollutant is not enough oxidized, the cost is higher, and catalyzer is easily lost by adopting the metal catalytic ozone oxidation technology, the application is difficult to use in mass production, uneven surface exists on the solid catalyzer, and the inner diffusion velocity is lower. The method has the steps that: firstly, water containing the organic pollutant enters into an ozone contact tower; secondly, output water of the ozone contact tower enters into a catalyzing bed the inner part of which is filled with zerovalent ferric and filling material. The method solves the problems that uneven surface exists on the solid catalyzer and the inner diffusion velocity is lower, has the advantages of high catalytic activity, low cost, homogeneous catalysis oxidation and heterocatalysis oxidation of the catalyzer easily separating from water, improves the utilization ration of the ozone, and can be applied to the mass production.

Owner:HARBIN INST OF TECH

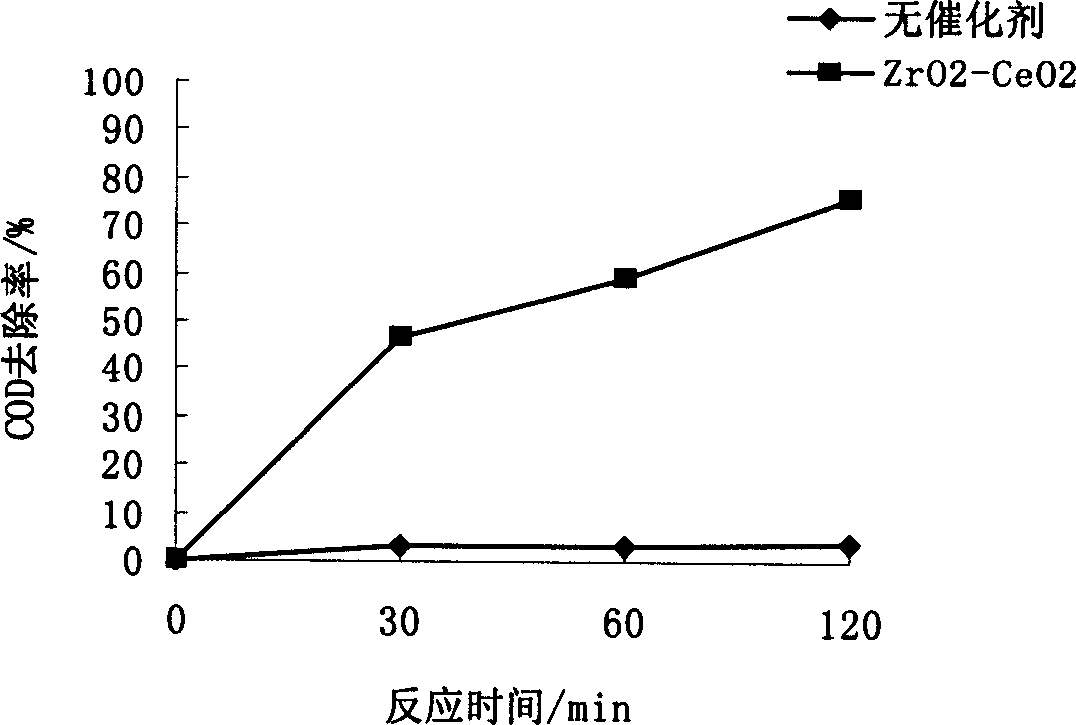

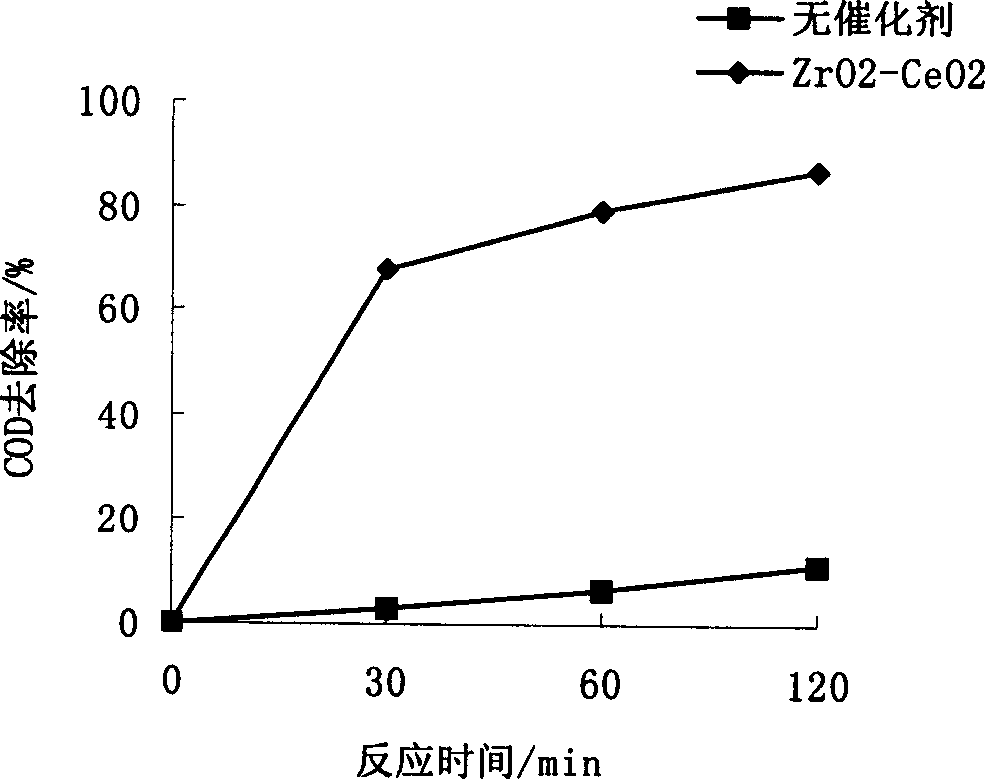

Rare earth composite oxide catalyst in catalytic wet oxidation process and preparing method thereof

InactiveCN1669643ALower operating temperatureReduce pressureMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationAlkalinityOrganic acid

The invention discloses a method for preparing the rare-earth compound oxide catalyst, wherein the component is the composite oxides of ZrO2 and CeO2, and the molar ratio of the Zr and Ce is 1:1~1:11. The preparing method comprises the following steps: a) formulating the mixed solution of zircon salt and cerium salt, b) dropping the solution slowly to the alkaline solution which has been stirred vigorously, getting the gelatin deposit and filtering, c) dispersing the deposit again into the deionized water, adjusting the PH to alkalinity, refluxing in the hot alkali liquor, drying and baking and getting the catalyst.

Owner:TSINGHUA UNIV

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Hydrogen peroxide working solution and its application in preparation of hydrogen peroxide

ActiveCN103588177AReduce solubilityImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention belongs to the technical field of hydrogen peroxide, and especially relates to a hydrogen peroxide working solution and its application in the preparation of hydrogen peroxide. The hydrogen peroxide working solution comprises 2-ethylanthraquinone having a mass concentration of 120-200g / L and an organic solvent, and the organic solvent comprises, by volume, 70-80% of a C9-C10 aromatic hydrocarbon, 14-20% of trioctyl phosphate, 4-10% of 2-methylcyclohexyl acetate and 0.4-0.9% of tertiary amine When the hydrogen peroxide working solution is used in the preparation of hydrogen peroxide, the hydrogen peroxide working solution can greatly improve the hydrogenation efficiency and the oxidation efficiency of 2-ethylanthraquinone, and has the advantages of low production cost, no peculiar smell and product yield improvement.

Owner:WEIFANG MENJIE CHEM

Nano holing method on surface of low-voltage anode foil for aluminium electrolytic capacitor

ActiveCN1598985AHigh densityLarge apertureElectrolytic capacitorsCapacitor manufactureLow voltagePhosphoric acid

The aluminium electrolytic capacitor uses the superficial nanometer hole siting on the low-voltage anodic foil and relates to the hole siting on the surface of the foil, especially the method of the superficial nanometer hole siting on the low-voltage anodic foil used in the aluminium electrolytic capacitor. The aluminum foil is cleaned and electro chemically polished by the polishing fluid, whose components are phosphoric acid: vitriol: glycerin=80-160:0.1-1:50-100. After polishing, the aluminum foil is put into the phosphoric acid solution, goes through the preliminary anodic oxidation at the voltage of between 20V and 120V and is got rid of the film with the mixed solution of phosphoric acid and chromic acid until the aluminium matrix is naked. In the same condition with that of the preliminary anodic oxidation, the aluminum foil passes through the secondary oxidation and secondary film-eliminating. By adjusting the technological parameters, the pore space's density and aperture can be adjusted and the aperture varies between the 50nm and 300nm to adopt itself to the applied scale of the low-pressure foil.

Owner:GUANGDONG HUAFENG NEW ENERGY TECH CO LTD +1

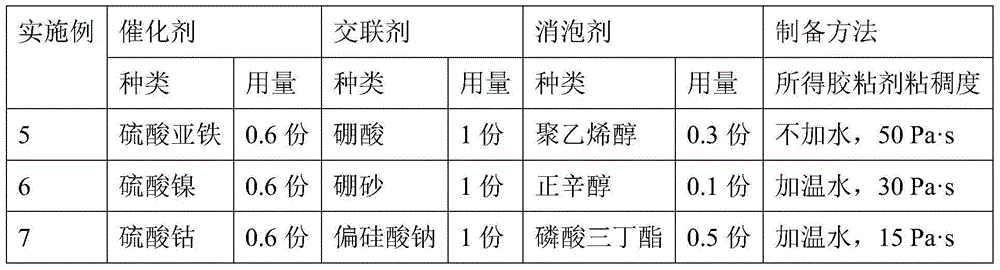

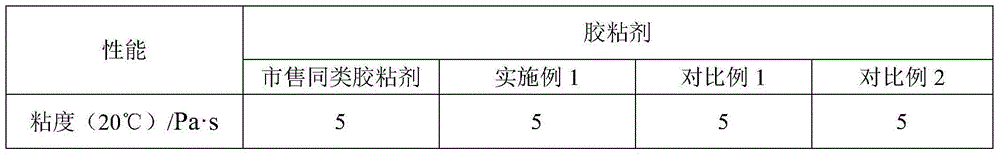

Oxidized starch adhesive and preparation method thereof

InactiveCN104861892AReduce usageFast oxidationNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesivePapermaking

The invention discloses an oxidized starch adhesive and a preparation method thereof. The oxidized starch adhesive is mainly prepared from the raw materials of, by weight, 100 parts of starch, 3-5 parts of hydrogen peroxide, 0.1-0.5 parts of a potassium permanganate solution, 0.4-1 part of s catalyst, 9-11 parts of sodium hydroxide, 1-3 parts of a crosslinking agent, 300-500 parts of water, and 0-0.5 parts of a defoaming agent. According to the invention, hydrogen peroxide and the potassium permanganate solution are both used as oxidizing agents, and cooperates to provide a synergistic effect in carrying out oxidization treatment upon the starch material. The oxidization speed is high, and the dose of oxidizing agent is low. The obtained oxidized adhesive has the advantages of high bonding strength, good stability, good gelling resistance, long storage time, short drying time, good environment friendliness, and low cost. The adhesive is nontoxic and harmless, and can be widely applied in the fields of papermaking, trademark, textile, and the like.

Owner:HENAN UNIV OF URBAN CONSTR

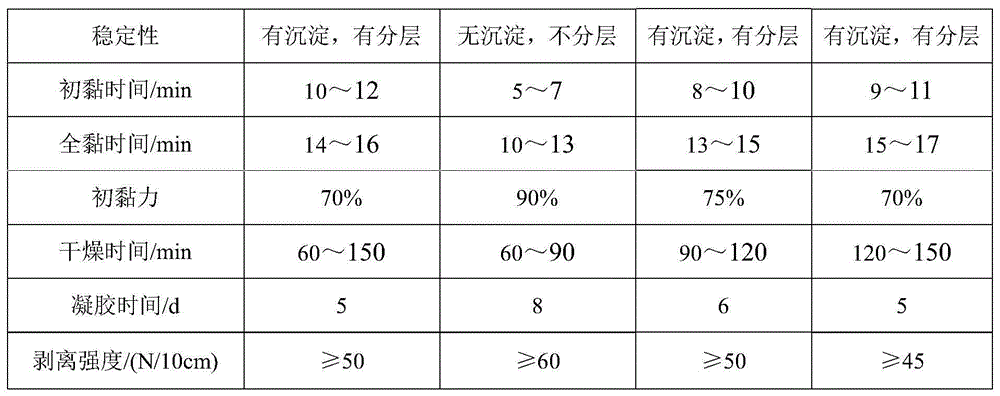

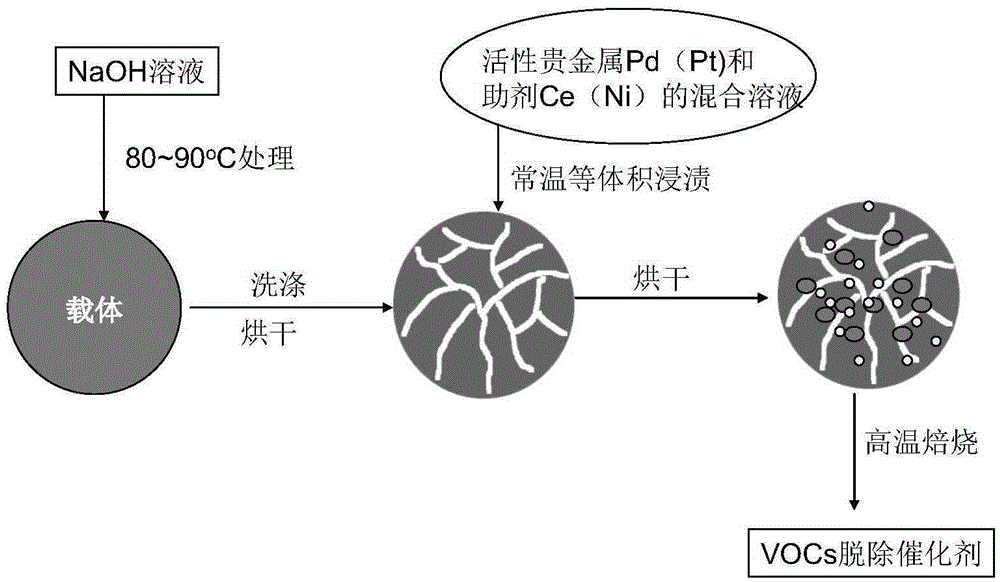

Preparation method of catalyst used for carrying out catalytic combustion on volatile organic compound containing low-concentration methane

InactiveCN105289650AGood dispersionFast oxidationIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsElement by elementBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a catalyst used for carrying out catalytic combustion on a volatile organic compound containing low-concentration methane. The catalyst consists of an active carrier, noble metal and assistant metallic oxide, wherein the noble metal and the assistant metallic oxide are loaded on the active carrier; the quality of the noble metal is 0.05 percent to 0.8 percent of active elements by element quality in final catalyst; the quality of the assistant metallic oxide is 0.0 percent to 20 percent of the quality of the final catalyst; the catalyst is prepared in a way that active ingredients are used as a carrier, and after the active ingredients are processed by aqueous alkali, the active ingredients dip in a solution which loads compound containing the active elements of the noble metal and the assistant metallic oxide, and the obtained product is dried in the shade, dried and roasted. The catalyst is used for the organic volatilization hydrocarbon catalytic combustion which contains low-concentration methane, and the catalytic combustion transformation effect of the methane is excellent while almost complete non-methane hydrocarbon transformation can be obtained.

Owner:JIANGSU EVERGREEN NEW MATERIAL TECH

Method for preparing polyaluminium ferric chloride flocculating agent by pickling waste liquid and waste aluminium material

ActiveCN103043759ARealize comprehensive utilizationReduce pollutionWater/sewage treatment by flocculation/precipitationLiquid wasteAluminium chlorohydrate

The invention discloses a method for preparing a polyaluminium ferric chloride flocculating agent by pickling waste liquids and waste aluminium materials. The method for preparing a polyaluminium ferric chloride flocculating agent, comprises: mixing waste aluminium materials after acid dissolution and pickling waste liquids, regulating a pH value by sodium hydroxide, and oxidizing and polymerizing the mixture by a strong oxide to obtain the polyaluminium ferric chloride flocculating agent. Compared with the prior art, the method uses the raw materials which are cheap and wide in source, and has advantages of simple process and easy operation. The addition of waste aluminium materials is controlled to regulate the pH valve, thereby effectively reducing the cost. The proportion of aluminium to iron in the raw materials is flexibly controlled, and the application range is winder.

Owner:GUANGDONG UNIV OF TECH

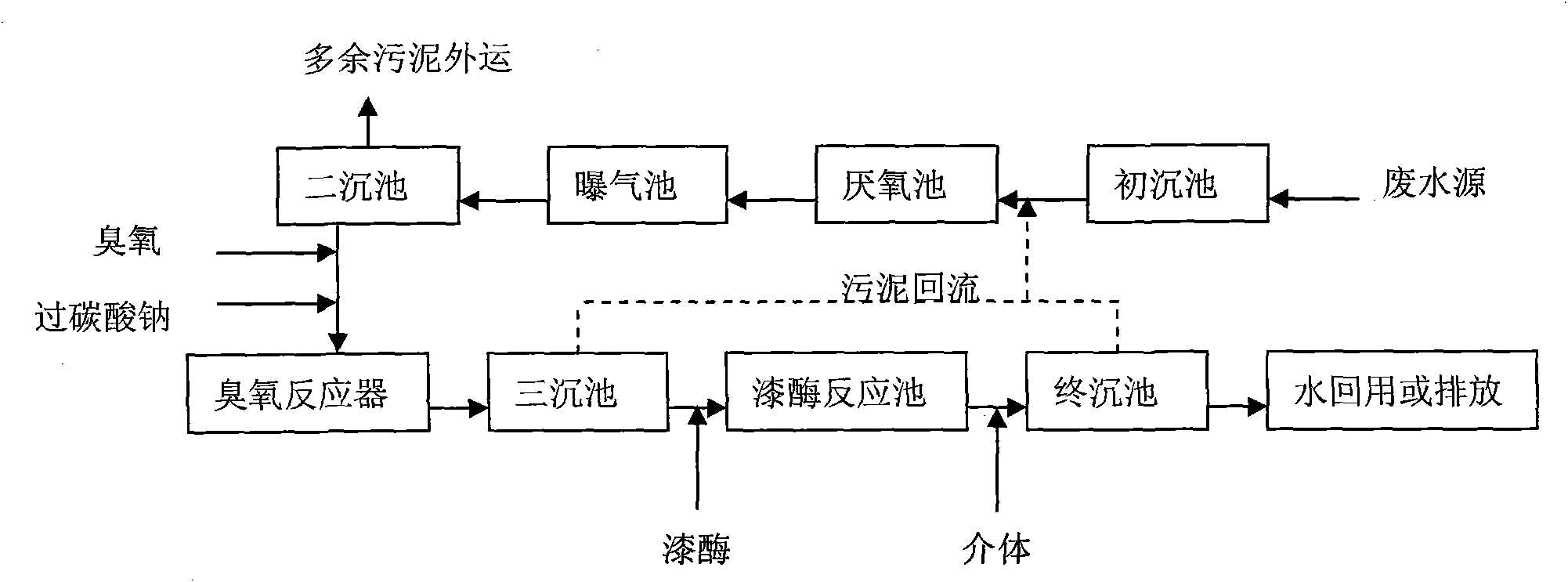

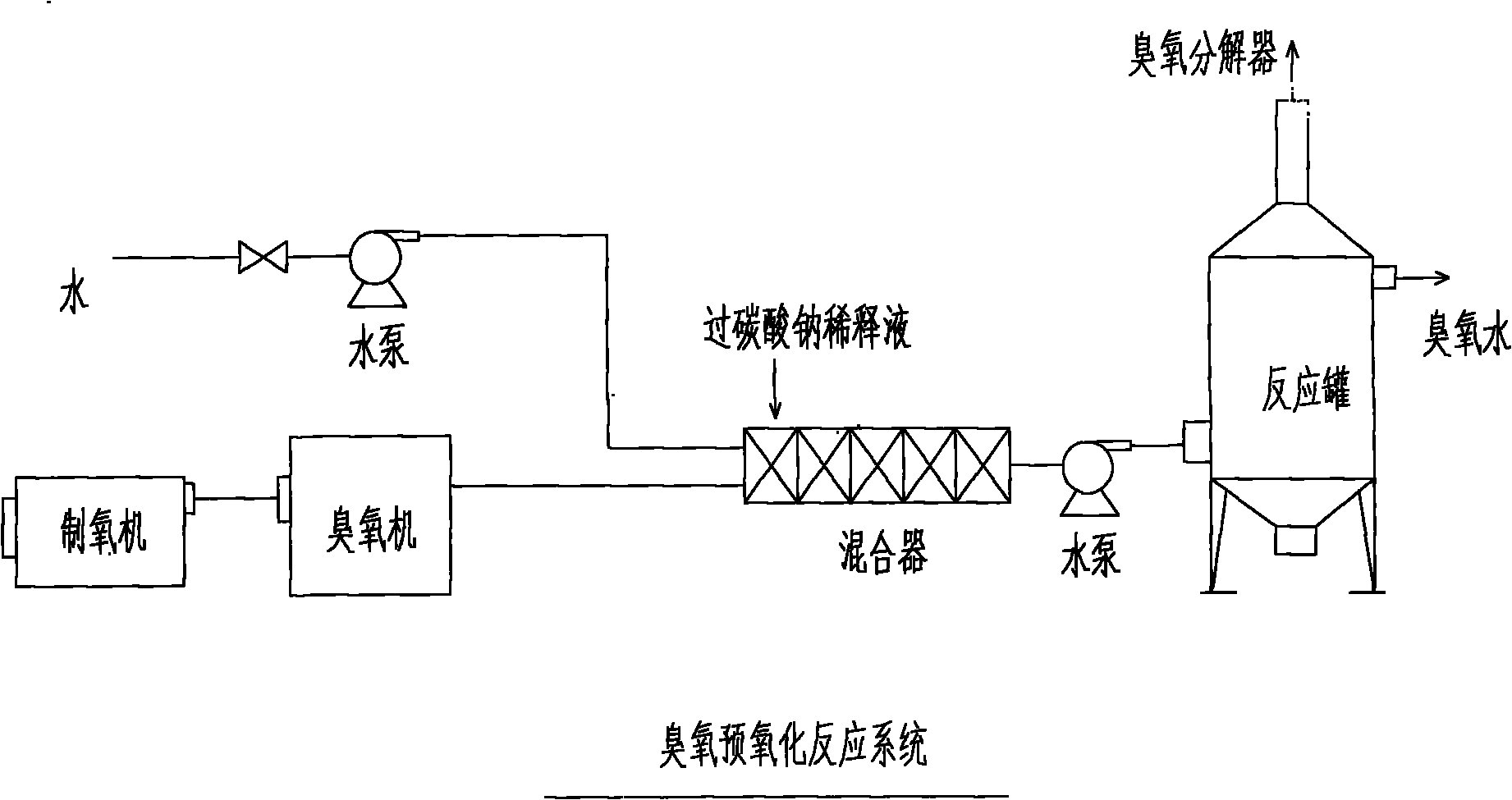

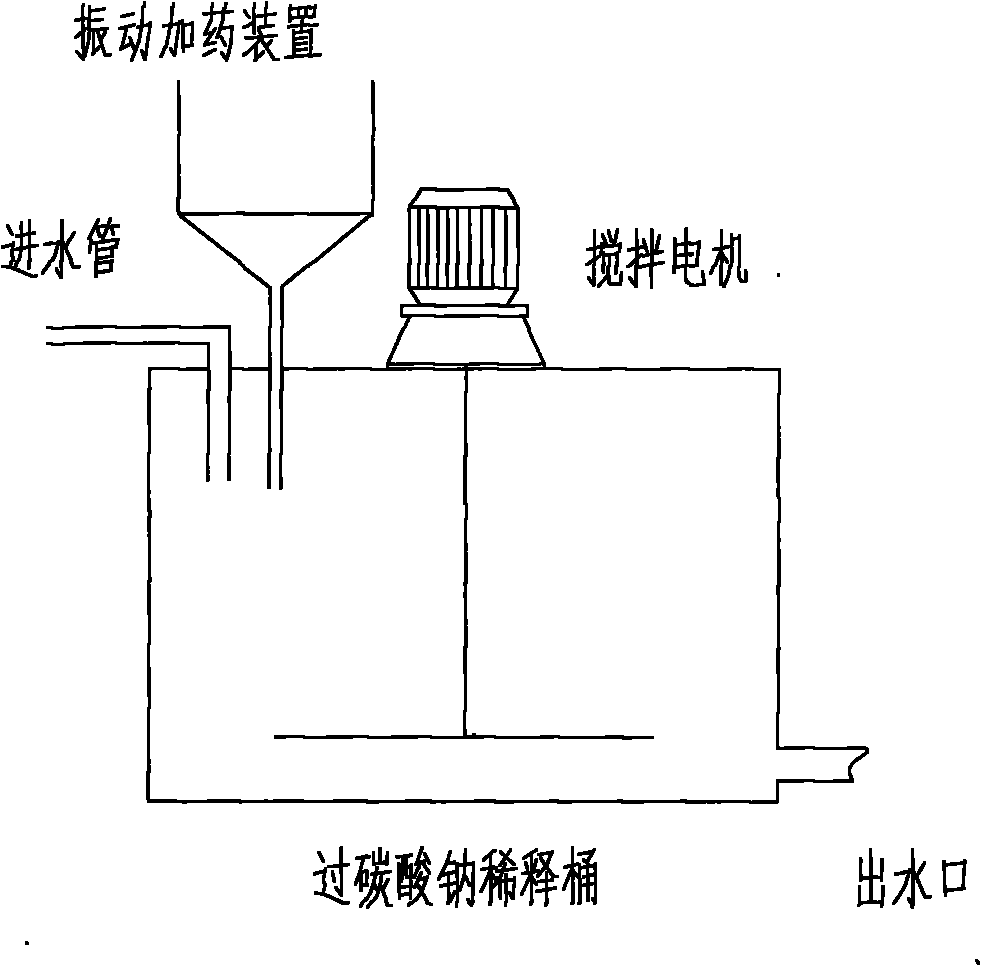

Ozone pre-oxidation and laccase advanced water treatment method

ActiveCN101817622AReduce chromaImprove biodegradabilityMultistage water/sewage treatmentDecompositionTherapeutic effect

The invention relates to an ozone pre-oxidation and laccase advanced water treatment method, which comprises the following steps of: mixing waste water, ozone and sodium percarbonate in a mixer; adding the mixture in an ozone reactor device for stirred reaction; making the mixture enter a tertiary sedimentation basin for solid-liquid separation; adding the separated supernate and laccase into a laccase reaction tank, and fully mixing the laccase with the waste water for reaction; mixing the diluted mediator and the effluent from the laccase reaction tank, and performing flocculent settling solid-liquid separation on the mixture in a final sedimentation basin; and performing anaerobic and aerobic biochemical treatment on the effluent. The method overcomes the defects of over-high cost, low efficiency of enzyme treatment, high enzyme consumption, difficult sedimentation and separation of enzyme per se, and the like. The method only makes two processing units of ozone pre-oxidation and laccase-mediator catalytic polymerization achieve good mutual acceleration and gradient treatment effects, accelerates decomposition of O3 to make micro-flocculation effect of the ozone pre-oxidation in the optimized pH value range, is favorable for reducing the coagulant consumption, can recycle the waste water, and has scale application.

Owner:NANJING SHENKELONG ENVIRONMENTAL PROTECTION

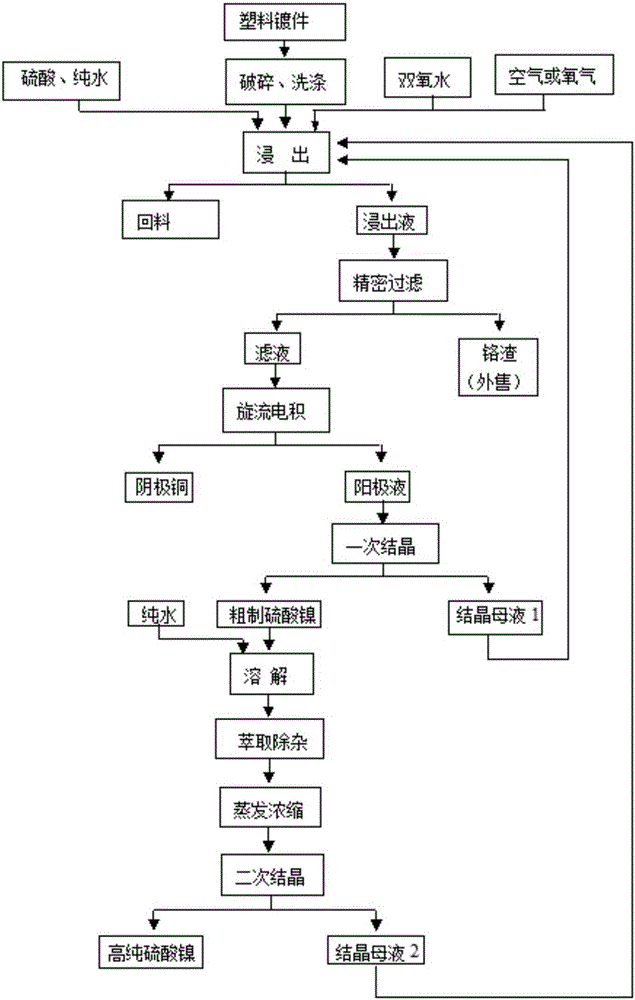

Method of recovering copper and nickel from plastic plated parts

ActiveCN105200238ANo discoloration etc.Increase contentProcess efficiency improvementCycloneClosed loop

The invention belongs to the field of metallurgy and relates to a method of recovering copper and nickel from plastic plated parts. The method is mainly characterized in that by means of sulfuric acid leaching and using hydrogen peroxide and air or oxygen as oxidizing agents, a micro-bubble generator is used to blow the air or oxygen into a reactor in a micro-bubble form, leached solution is treated by cyclone electrowinning to produce cathode copper, anode liquor is frozen and crystallized to produce crude nickel sulfate, and the crude nickel sulfate is subjected to the steps such as dissolving, impurity removal by extracting, evaporation concentration, and cooling crystallization to produce high-purity nickel sulfate. The method has the advantages that reaction speed is high, no other impurities are introduced, metal recovery rate is high, solution circulates in a closed loop, no wastewater or waste residue is produced, few auxiliaries are used, energy consumption is low, and low carbon, energy conservation and emission reduction can be achieved.

Owner:广西银亿再生资源有限公司 +1

Method and device for removing SO2 in flue gas with copper extracting tailings and recycling copper extracting tailings

ActiveCN106422716AWith spray densityIncrease contact areaGas treatmentDispersed particle separationMetasilicateAmmonium sulfide

The invention relates to a method and device for removing SO2 in flue gas with copper extracting tailings and recycling the copper extracting tailings, and belongs to the technical field of environmental protection. Ferrous metasilicate (Fe2SiO4), magnesium ferrite (MgFe2O4), hedenbergite (CaFeSi2O6) and other sulfur removal active substances in the copper extracting tailings are used for reacting with SO2 in the flue gas in an aqueous solution to generate sulfite, then sulfate is generated under the action of oxygen in the flue gas, the SO2-containing flue gas makes contact with copper extracting tailing slurry, SO2 is absorbed, and thus the flue gas is purified; by adding ammonium sulfide, ammonium bicarbonate and lime milk step by step, iron ions, zinc ions, copper ions, ammonium ions and other ions in the sulfur removal slurry can be resourcelized to be reused.

Owner:KUNMING UNIV OF SCI & TECH

Continuous casting crystallizer casting powder for ultra-low-carbon steel

ActiveCN103817301ADoes not affect the melting rateAvoid the phenomenon of carbonizationActivated carbonMetallurgy

The invention discloses a continuous casting crystallizer casting powder for ultra-low-carbon steel. Active carbon is added in the casting powder, so that air can be made to pass through a casting powder layer to enable the carbon to be oxidized rapidly to generate carbon dioxide gas to be discharged; the active carbon itself has a powerful adsorption function and a part of air is stored, so that the oxidation rate is improved, it is guaranteed that the carbon is removed rapidly after the casting powder is melted rapidly and the casting powder does not contain the carbon, and therefore the recarburization phenomenon of the ultra-low-carbon steel is prevented from occurring from the source. After the active carbon is oxidized rapidly, gaps disappear due to consumption of the active carbon, and the casting powder enables steel billet to be sealed and isolated from the air rapidly so as to prevent the steel billet from being oxidized again. The continuous casting crystallizer casting powder for the ultra-low-carbon steel is low in cost, practical, good in effect and worthy of popularization and application.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

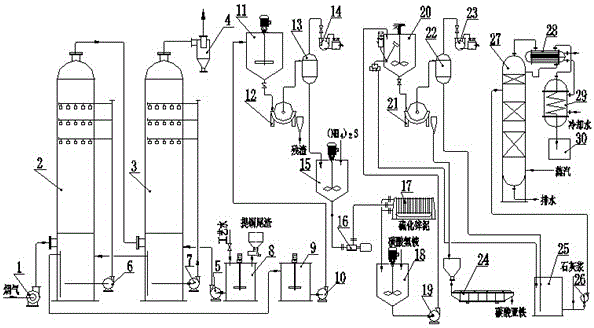

Low-consumption and low-emission nitric acid production method and production equipment thereof

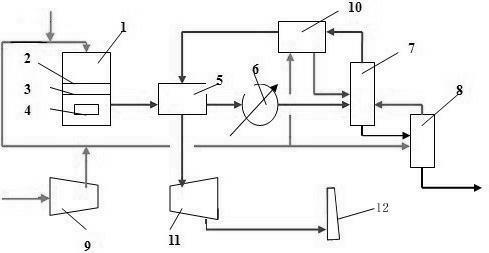

InactiveCN102491292AReduce consumptionEmission reductionEnergy inputNitric acidDecompositionNitric oxide gas

The invention discloses a low-consumption and low-emission nitric acid production method and production equipment thereof. The method and the equipment adopts the same low-pressure level for oxidation and absorption, the double-pressurization high-pressure level is omitted, a molecular sieve absorption device is adopted for tail gas treatment of a nitric acid absorption tower, in addition, secondary air is used for taking reaction with nitric oxide absorbed in the molecular sieve absorption device to form regenerated gas, the regenerated gas is sent into the nitric acid absorption tower to be recovered and reutilized, the nitrogen oxide content in the tail gas is lower than 100mg / Nm<3>, in addition, the yield of the nitric acid can also be improved through the recovery and the utilization of regeneration gas, a layer of silk screen is arranged on a sieve plate tower disc of an oxidation section of the nitric acid absorption tower, the oxidation speed at high pressure and low pressure can be effectively accelerated, and an N20 decomposition catalyst layer is also additionally arranged in an oxidation reaction vessel, so the N20 content in the nitric oxide gas in the oxidation reaction vessel can be reduced to about 100PPM. The nitric acid production method does not need to adopt two pressure levels, no nitric oxide compressor is adopted, no tail gas ammonification re-treatment device is adopted, the investment is greatly saved, and the consumption is reduced.

Owner:CHINA CHENGDA ENG

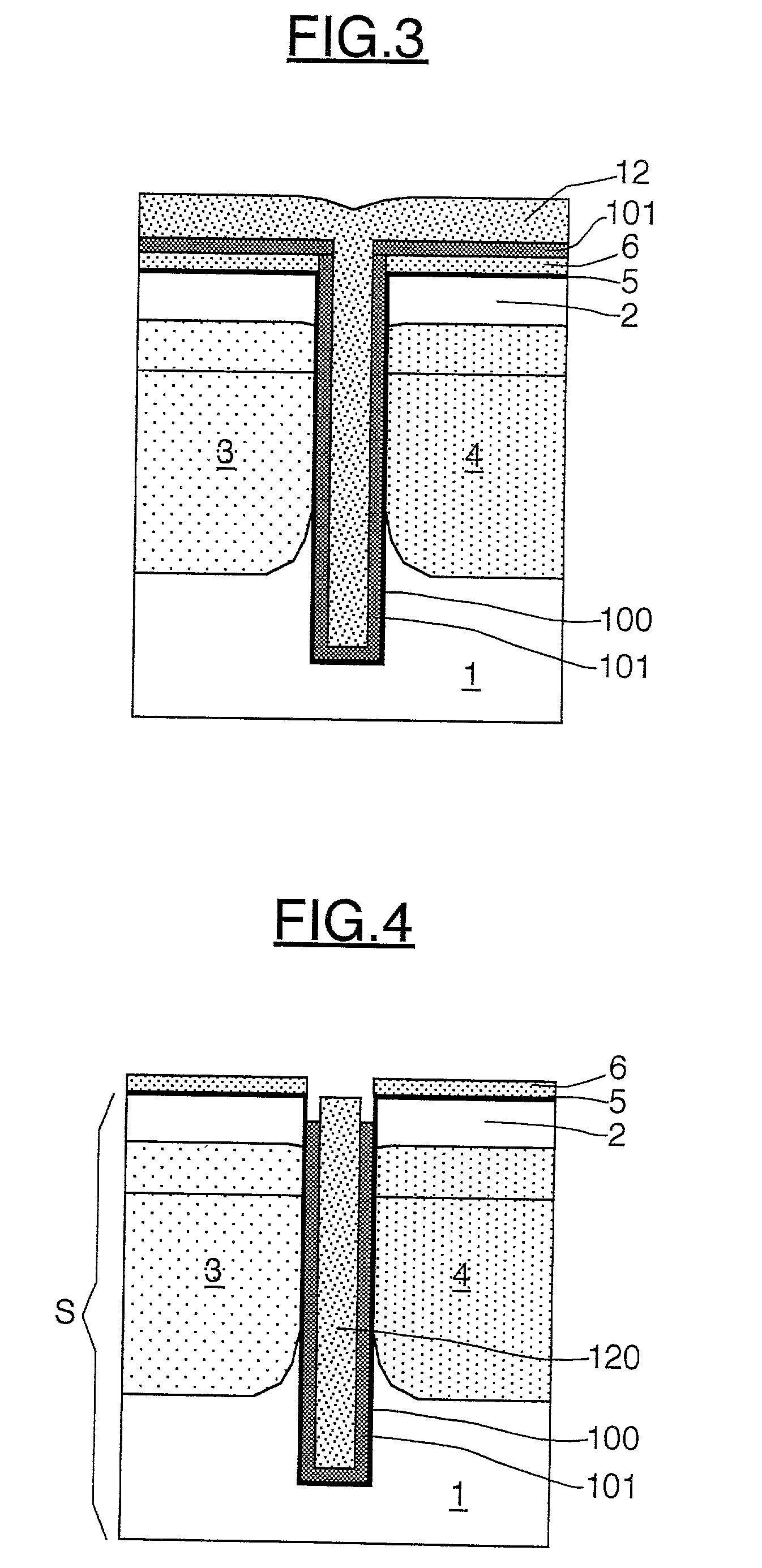

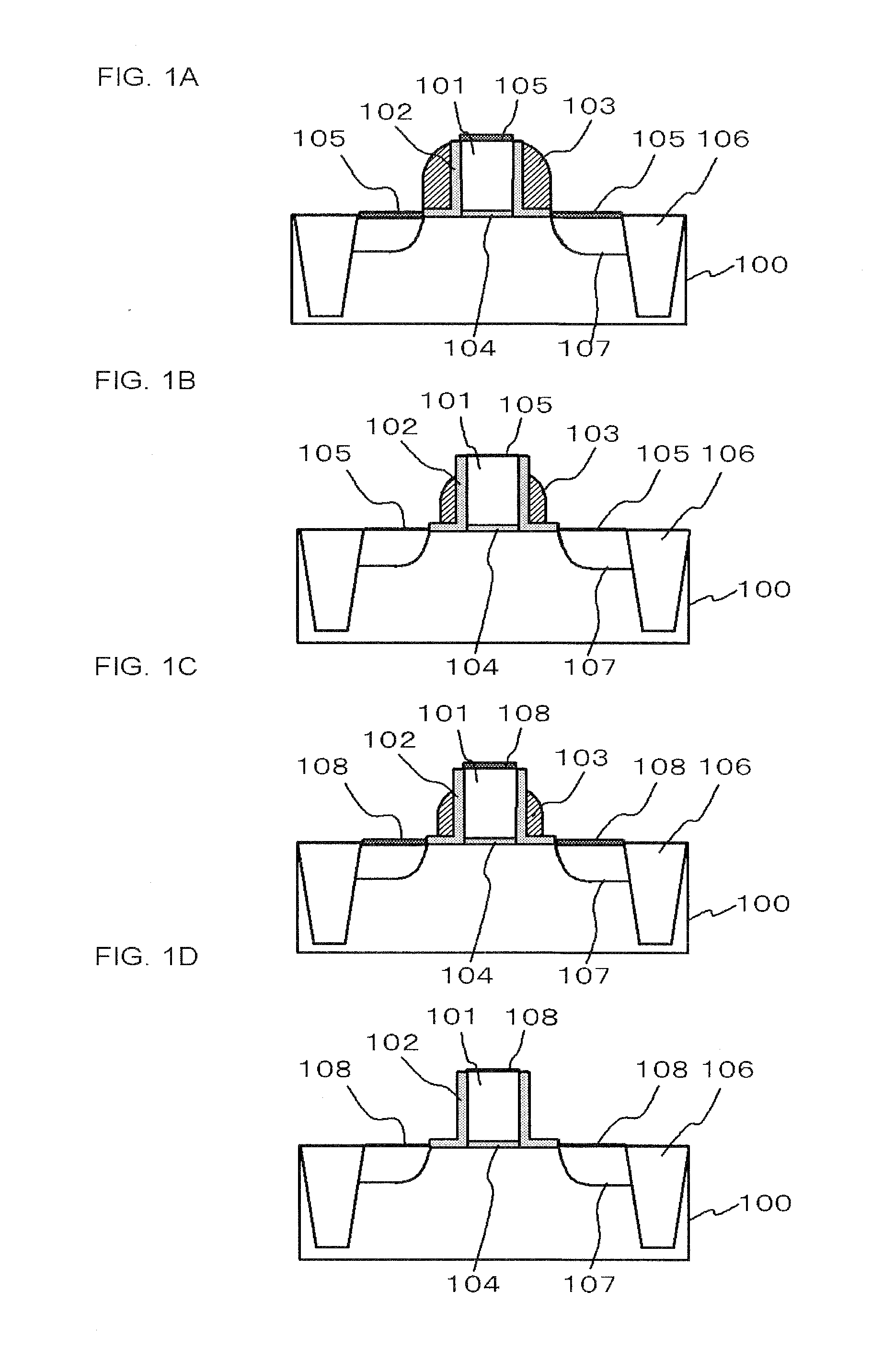

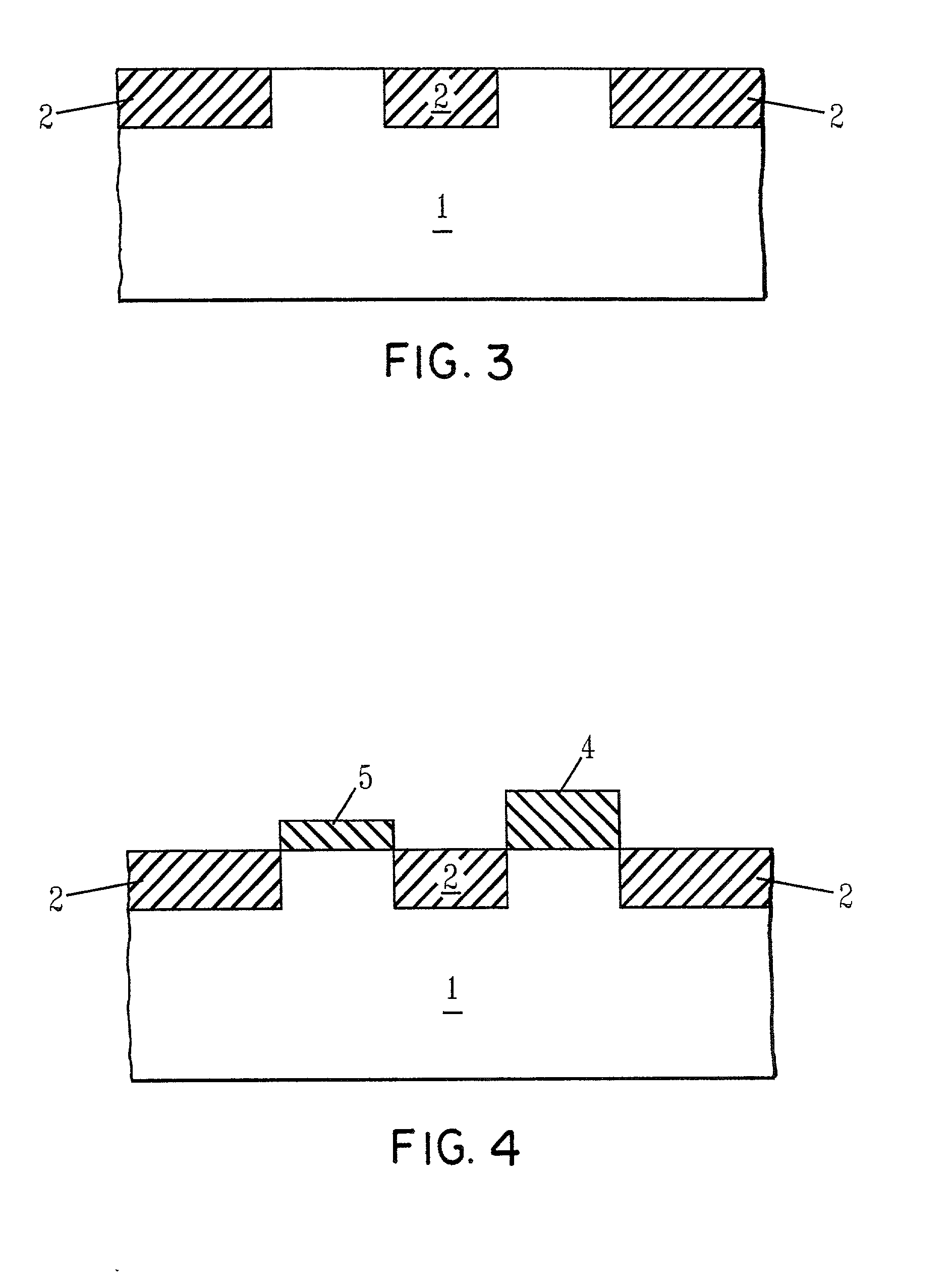

Process for forming deep and shallow insulative regions of an integrated circuit

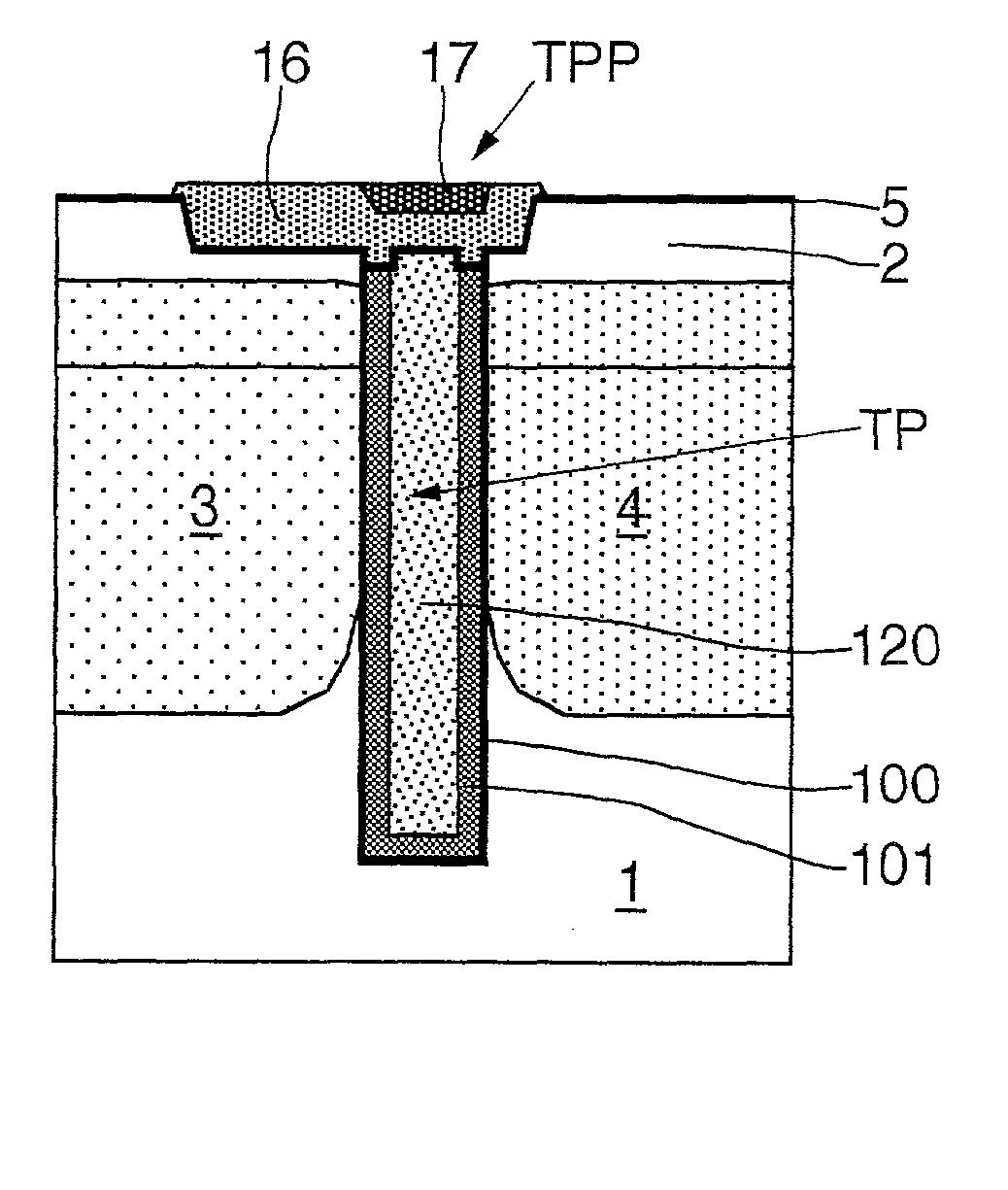

InactiveUS20020014676A1Fast oxidationMininizes the thermal balanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSilicon

Prior fabricating the transistors, a phase of forming a deep insulative trench in the substrate is followed by a phase of forming a shallow insulative trench in the substrate and extending the deep trench. The phase of forming the deep trench includes coating the inside walls of the deep trench with an initial oxide layer and filling the deep trench with silicon inside an envelope formed from an insulative material. The phase of forming the shallow trench includes coating the inside walls of the shallow trench with an initial oxide layer and filling the shallow trench with an insulative material.

Owner:STMICROELECTRONICS SRL

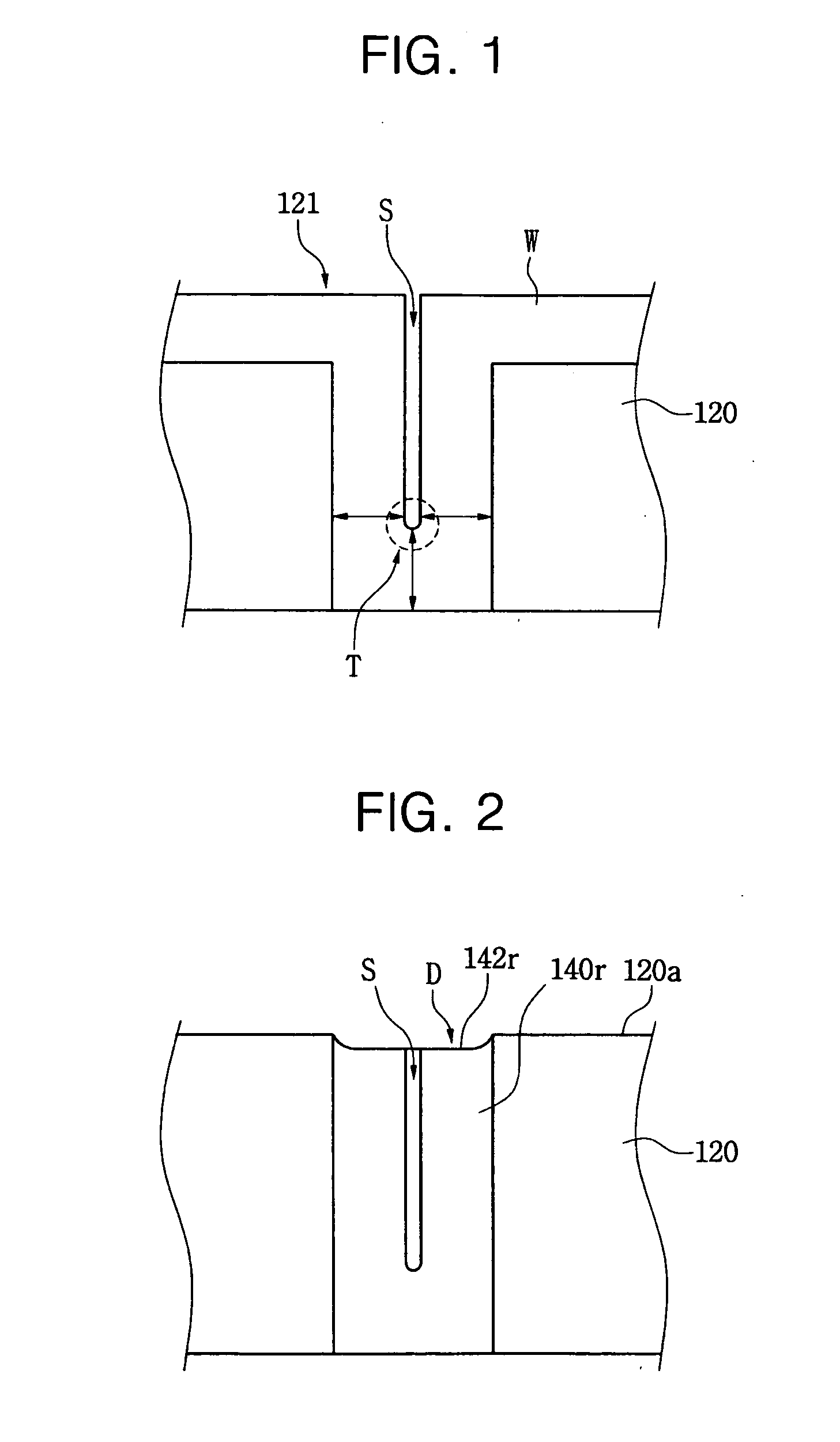

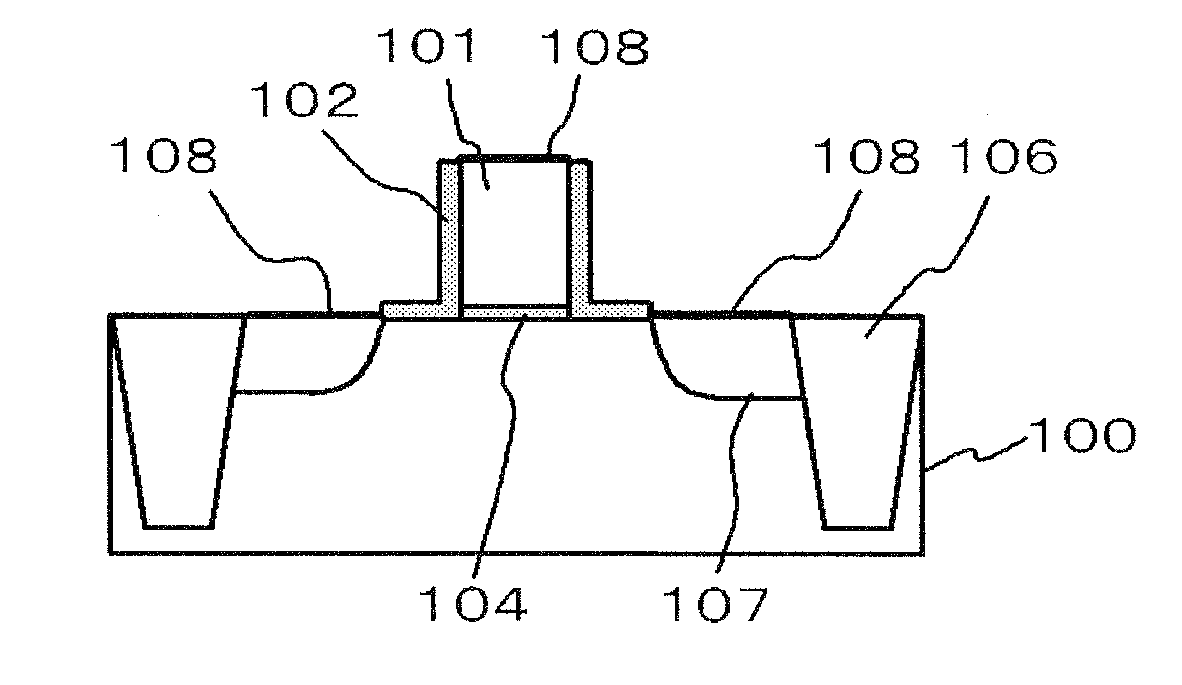

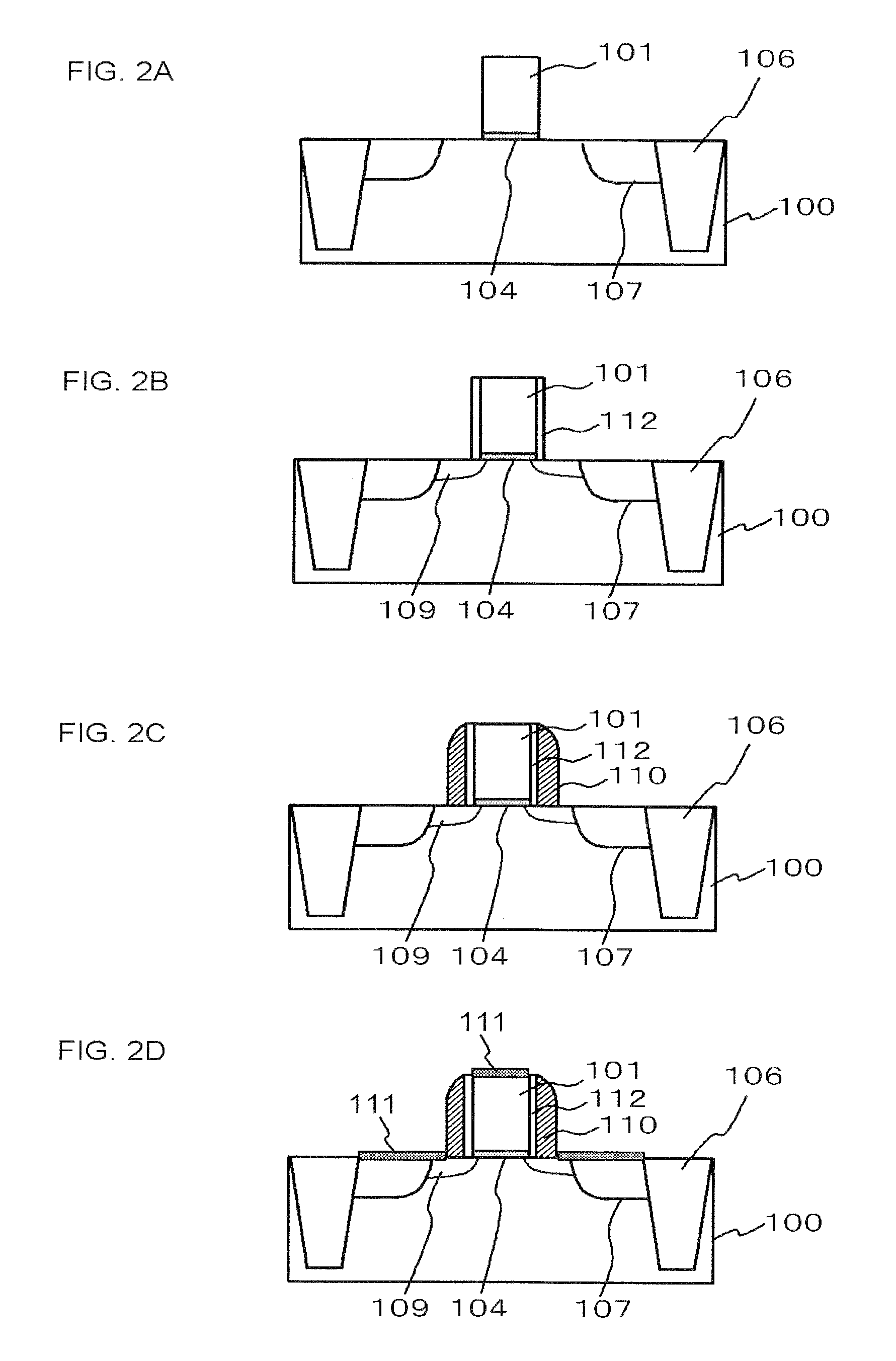

Method of manufacturing semiconductor device

InactiveUS20080206947A1Rapid thermal oxidationQuality improvementTransistorSemiconductor/solid-state device manufacturingEtchingChemical solution

A method of manufacturing the semiconductor device is provided, which provides a prevention for a “dug” of a silicon substrate caused by the etching in regions except a region for forming a film during a removal of the film with a chemical solution. A method of manufacturing a semiconductor device according to an embodiment of the present invention includes forming a first silicon oxide film on a surface of a silicon substrate or on a surface of a gate electrode when a silicon nitride film for a dummy side wall is etched off, to provide a protection for such surfaces, and then etching a portion of the silicon nitride film with a chemical solution, and then a second oxide film for supplementing a simultaneously-etched portion of the first silicon oxide film is formed, and eventually performing an etching for completely removing the silicon nitride film for the dummy side wall.

Owner:RENESAS ELECTRONICS CORP

Carbon monoxide tolerant electrochemical catalyst for proton exchange membrane fuel cell and method of preparing the same

InactiveUS20060258527A1High affinityFast oxidationPhysical/chemical process catalystsCell electrodesChemistryActive component

A CO tolerant electrochemical catalyst for proton exchange membrane fuel cells (PEFC) and a method of preparing includes a PtAu-MxOy / C supported electrochemical catalyst for the PEFC. The electrochemical catalyst has high catalytic activity and has uniformly distributed active components. The method is simple, is easily managed, and is environmentally friendly.

Owner:SAMSUNG SDI CO LTD

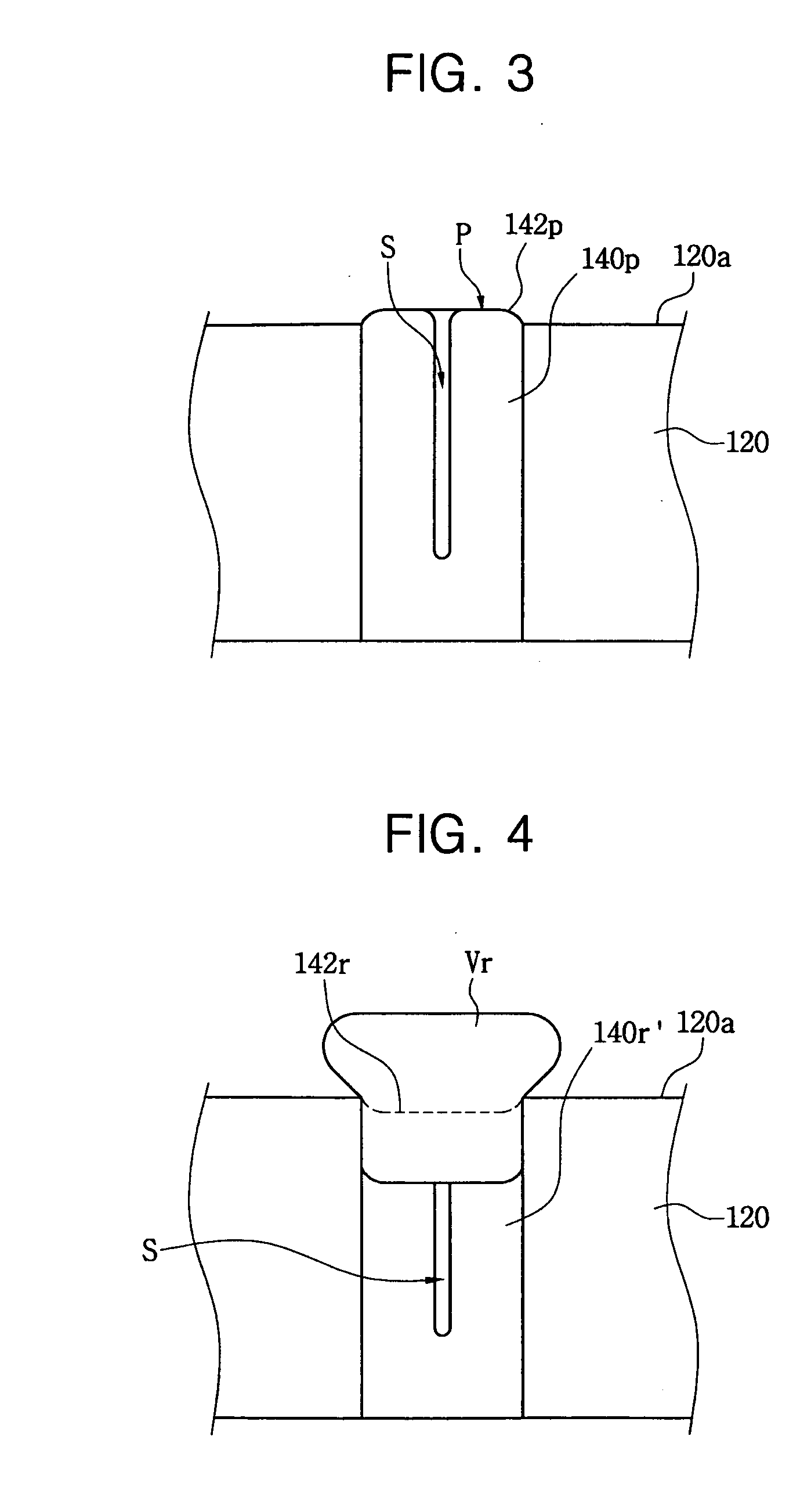

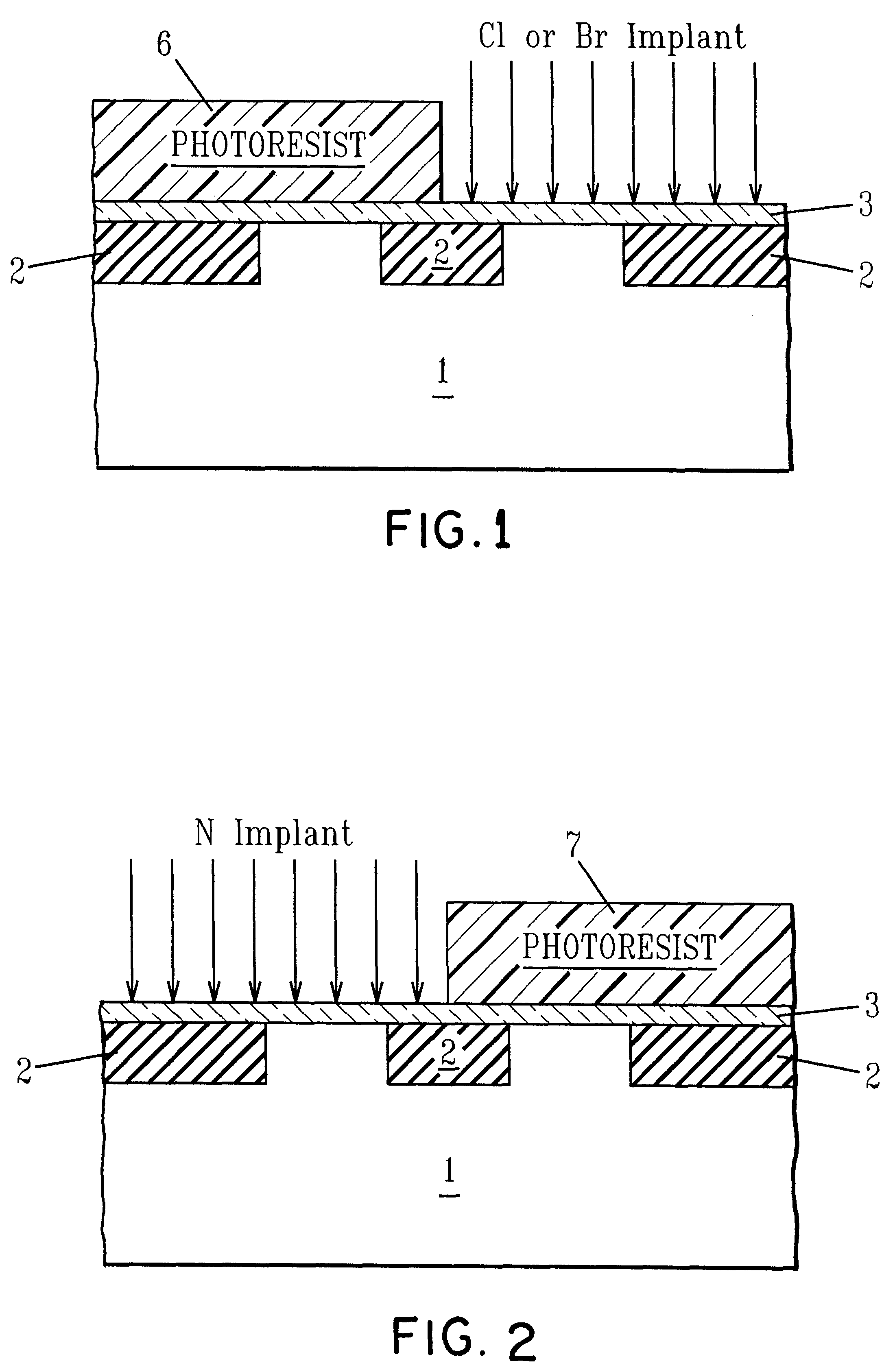

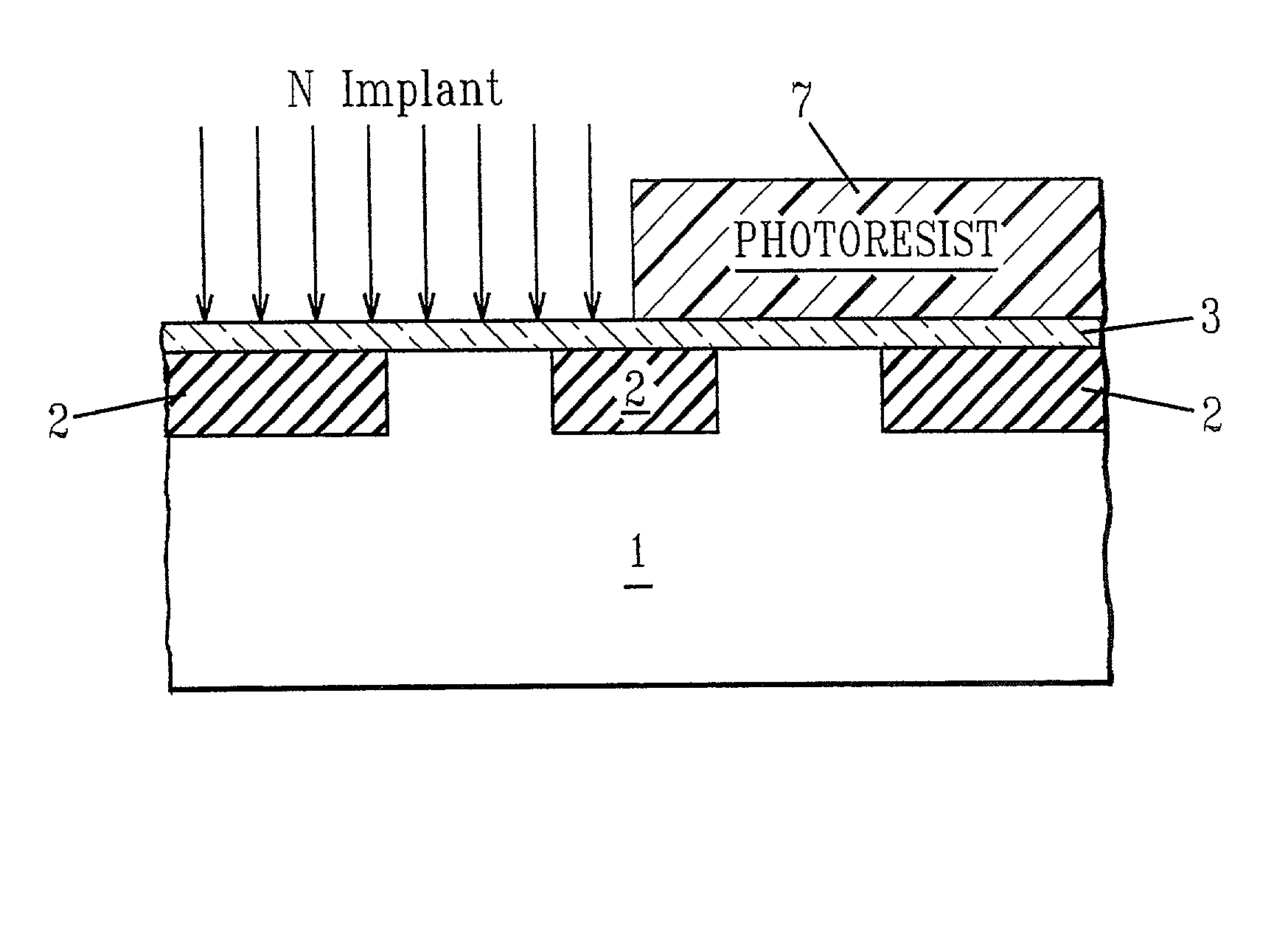

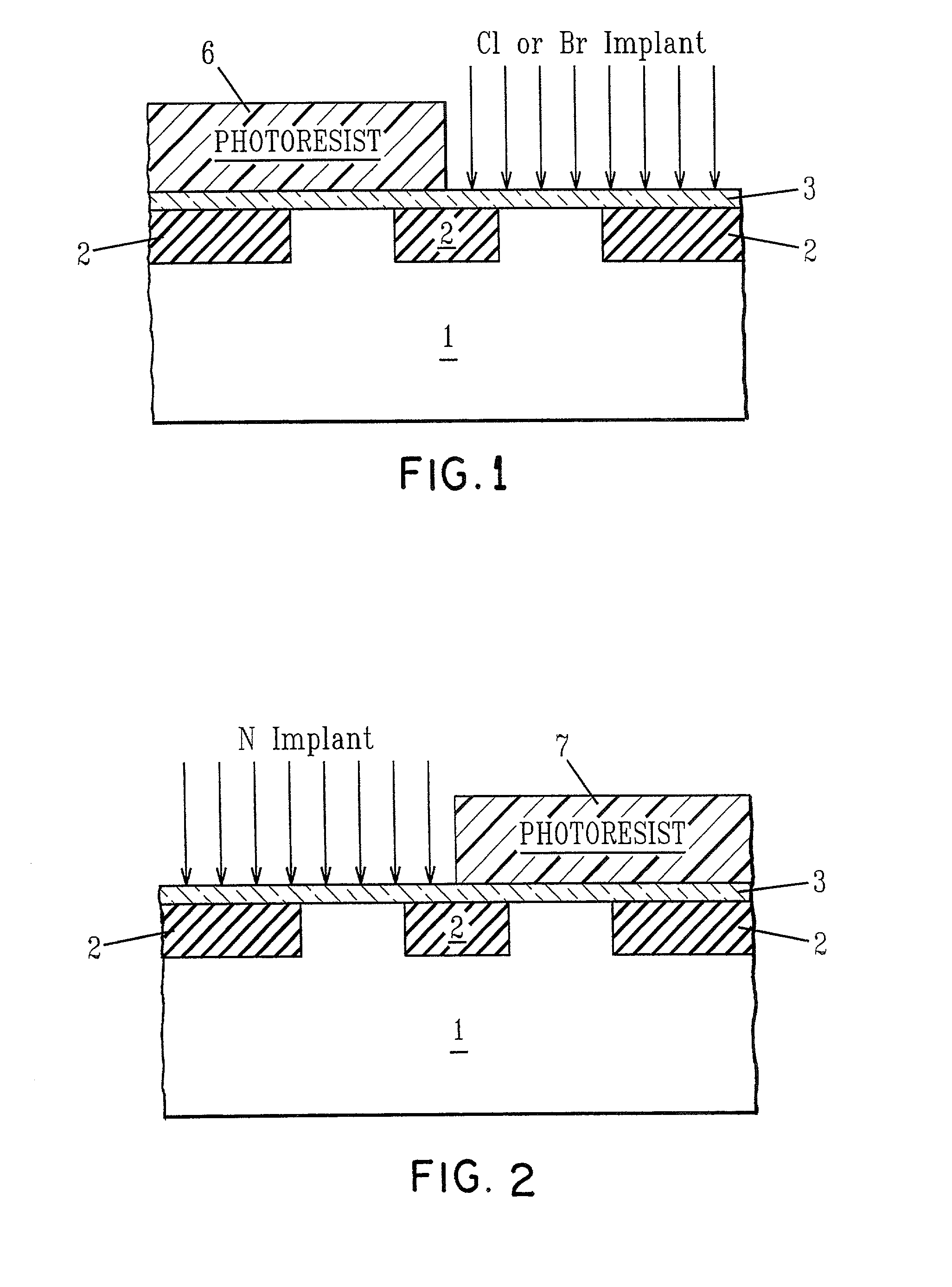

Method for fabricating different gate oxide thickness within the same chip

InactiveUS20030094660A1Increase rangeSlow and reduced rateSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureBromine

A semiconductor structure having silicon dioxide layers of different thicknesses is fabricated by forming a sacrificial silicon dioxide layer on the surface of a substrate; implanting nitrogen ions through the sacrificial silicon dioxide layer into first areas of the semiconductor substrate; implanting chlorine and / or bromine ions through the sacrificial silicon dioxide layer into second areas of the semiconductor substrate where silicon dioxide having the highest thickness is to be formed; removing the sacrificial silicon dioxide layer; and then growing a layer of silicon dioxide on the surface of the semiconductor substrate. The growth rate of the silicon dioxide will be faster in the areas containing the chlorine and / or bromine ions and therefore the silicon dioxide layer will be thicker in those regions as compared to the silicon dioxide layer in the regions not containing the chlorine and / or bromine ions. The growth rate of the silicon dioxide will be slower in the areas containing the nitrogen ions and therefore the silicon dioxide layer will be thinner in those regions as compared to the silicon dioxide layer in the regions not containing the nitrogen ions. Also provided are structures obtained by the above process.

Owner:GLOBALFOUNDRIES INC

Regeneration method of alkylated waste sulfuric acid

InactiveCN106744723AFast oxidationHigh removal rateSulfur-trioxide/sulfuric-acidChemistryCarbon dioxide

The invention relates to a regeneration method of waste sulfuric acid, in particular to a regeneration method of alkylated waste sulfuric acid. Waste sulfuric acid is in contact with hydrogen peroxide under redox conditions; organic matters or tiny carbon granules in the waste sulfuric acid react with hydrogen peroxide and are translated into carbon dioxide, nitrogen and water; and steam-stripping removing is performed, so as to obtain regenerated sulfuric acid. The regeneration method of alkylated waste sulfuric acid has the advantages that the required reaction temperature is comparatively low, the operation is simple, and the maintenance cost of a device is low.

Owner:广西防城港五星环保科技股份有限公司

Preparation method of refined silver tin oxide crystal grain

The invention provides a preparation method of refined silver tin oxide crystal grains, which comprises the following steps: (1) performing water atomization of Ag and Sn, or performing water atomization of Ag, Sn, and additives to obtain AgSn powder; (2) mixing the AgSn powder with oxidation powder to obtain AgSn mixed powder; (3) pressing the AgSn mixed powder through isostatic pressing to obtain an AgSn ingot; (4) extruding the AgSn ingot to obtain AgSn wires, drawing, punching, and oxidizing the wires; (5) performing compression and extrusion of the oxidized wires, drawing to obtain AgSnO2 wires. Compared with previous preparation methods in which AgSn ingots are cast by an alloy phase of multiple elements of Ag / Sn / Cu, are extruded into wires, and are oxidized internally, the preparation method of the invention provides higher oxygen content of AgSn wires, and more dislocation; wire oxidation is performed later, which can reduce the oxidation energy barrier, and refine the crystal boundary and the crystal grain; the smaller the crystal boundary is, the more uniformly the oxide particles distribute on a silver matrix; the smaller the oxide particles are, the better the melting welding resistance is; and the risk of incomplete oxidation is reduced.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com