Nano holing method on surface of low-voltage anode foil for aluminium electrolytic capacitor

A technology for aluminum electrolytic capacitors and low-voltage anode foils, which is applied in the direction of electrolytic capacitors, capacitors, capacitor manufacturing, etc., can solve the problems of poor general process applicability, large quality dispersion of electrolytic aluminum foils, and increased industrial costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

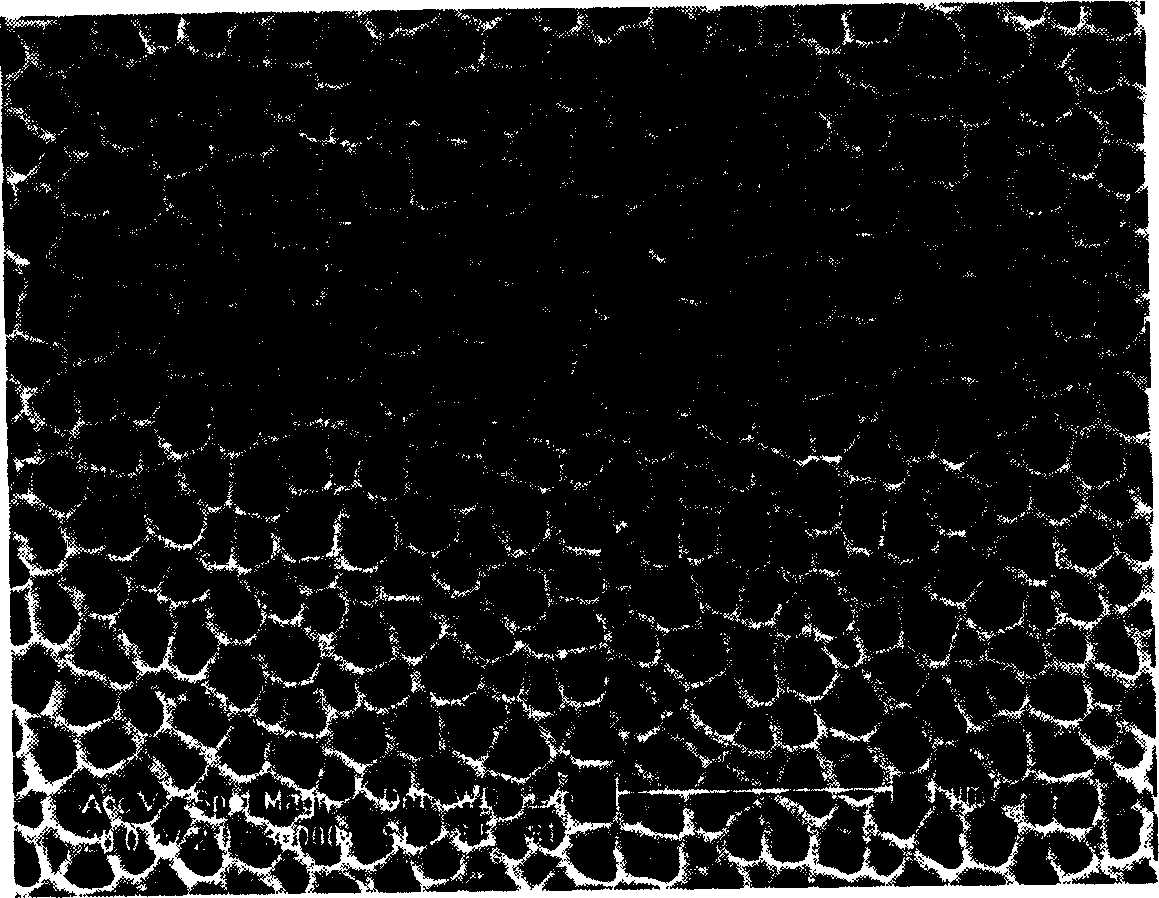

[0017] Example 1: Use acetone to remove the surface grease on the surface of the aluminum foil, remove the oxide film with NaOH, then place it in a polishing solution at 70 ° C, apply a voltage of 10 V to perform electrochemical polishing for about 5 minutes, and the composition of the polishing solution is phosphoric acid: Sulfuric acid: glycerol (v / v) = 115: 0.5: 85; using 3% (wt) H 3 PO 4 For the electrolyte, an anodic oxidation was performed once at 60V for 15 minutes, and a mixed solution of 15% (wt) phosphoric acid and 5% (wt) chromic acid was used to remove the film at 60°C until the surface exposed the aluminum matrix, and then the second oxidation and removal Membranes, the conditions were the same as the first time. figure 1 The SEM photo of the surface of the aluminum foil after secondary oxidation by the above process shows that the surface is distributed with corrosion holes of relatively uniform size, the size of the holes is between 93 and 220nm, and the averag...

Embodiment 2

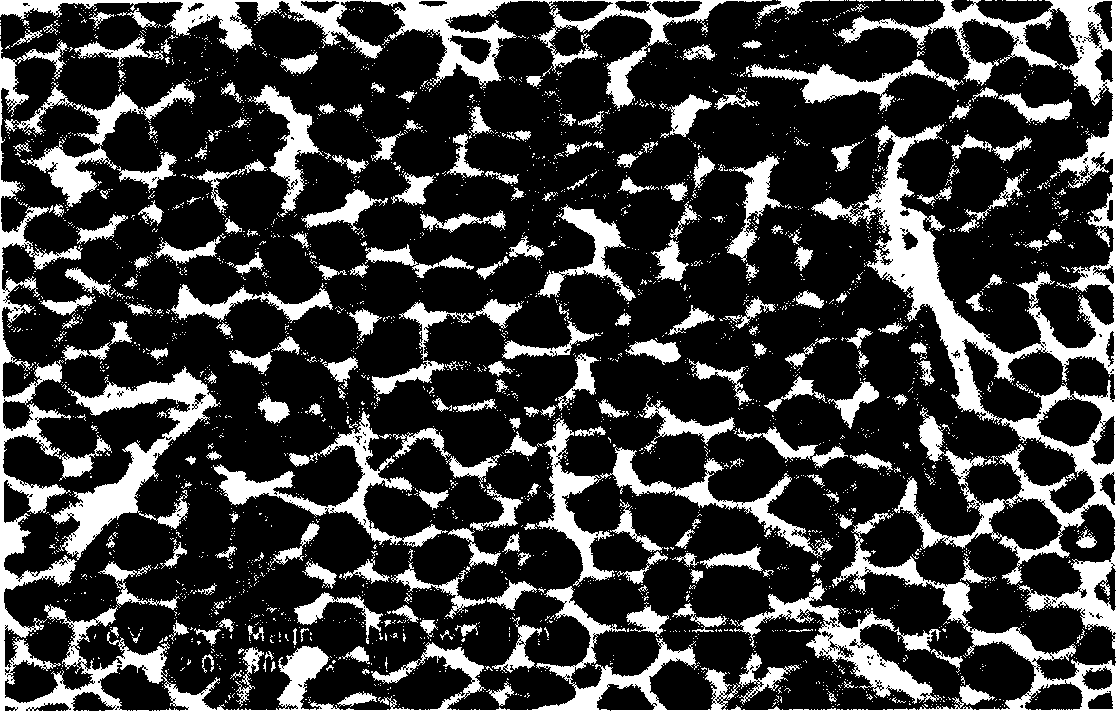

[0018] Example 2: According to the method in Example 1, the surface of the aluminum foil is routinely cleaned to remove oil and oxide film, and then it is placed in a polishing solution at 40°C, and a voltage of 6V is applied for electrochemical polishing for about 25 minutes. The composition is phosphoric acid: sulfuric acid: glycerol=150:0.7:100. Using 10% (wt) H 3 PO 4 As an electrolyte, an anodic oxidation is performed once at a voltage of 30V for 30 minutes, and a mixed solution of 6% (wt) phosphoric acid and 2% (wt) chromic acid is used to remove the film at 80°C until the surface exposes the aluminum matrix, and then perform secondary oxidation and removal. Membranes, the conditions were the same as the first time. On the surface of the aluminum foil, corrosion holes with a relatively uniform size were obtained, with an average pore diameter of 78nm.

Embodiment 3

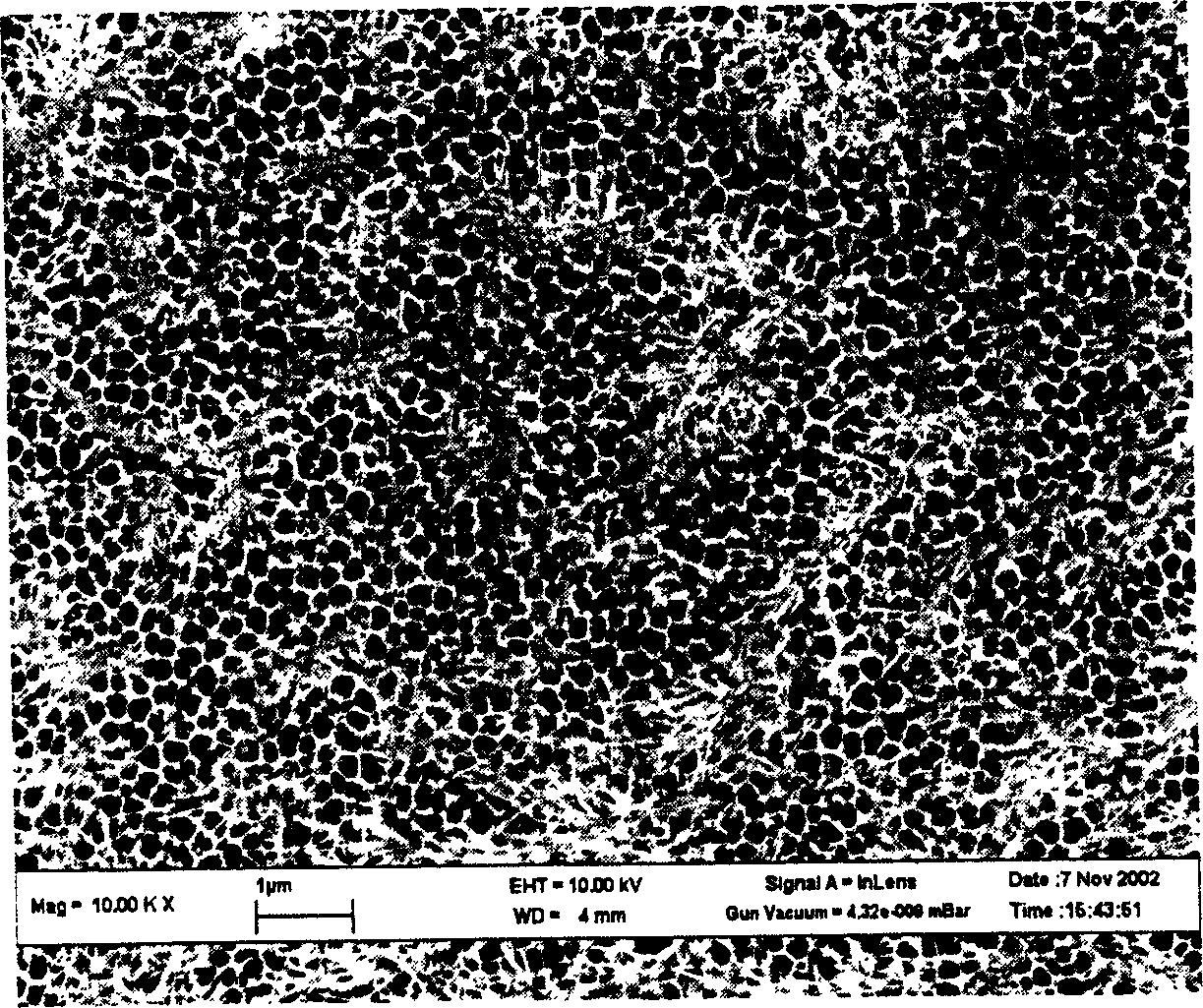

[0019] Example 3: The surface of the aluminum foil is subjected to conventional surface cleaning such as degreasing and oxide film removal, and then it is placed in a polishing solution at 70° C., and a voltage of 18 V is applied for electrochemical polishing for about 3 minutes. The composition of the polishing solution is phosphoric acid: Sulfuric acid: glycerol=90:0.3:60. Using 8% (wt) H 3 PO 4 As an electrolyte, an anodic oxidation was performed once at a voltage of 80V for 15 minutes, and a mixed solution of 27% (wt) phosphoric acid and 10% (wt) chromic acid was used to remove the film at 40°C until the surface exposed the aluminum matrix, and then the second oxidation and removal Membranes, the conditions were the same as the first time. On the surface of the aluminum foil, pits with relatively uniform size are obtained (see figure 2 ), the pore size is between 136 and 274nm, and the average pore diameter is 220nm. exist figure 2 The middle and thin lines are the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com