Method of producing synthetic rutile utilizing high-titanium slag

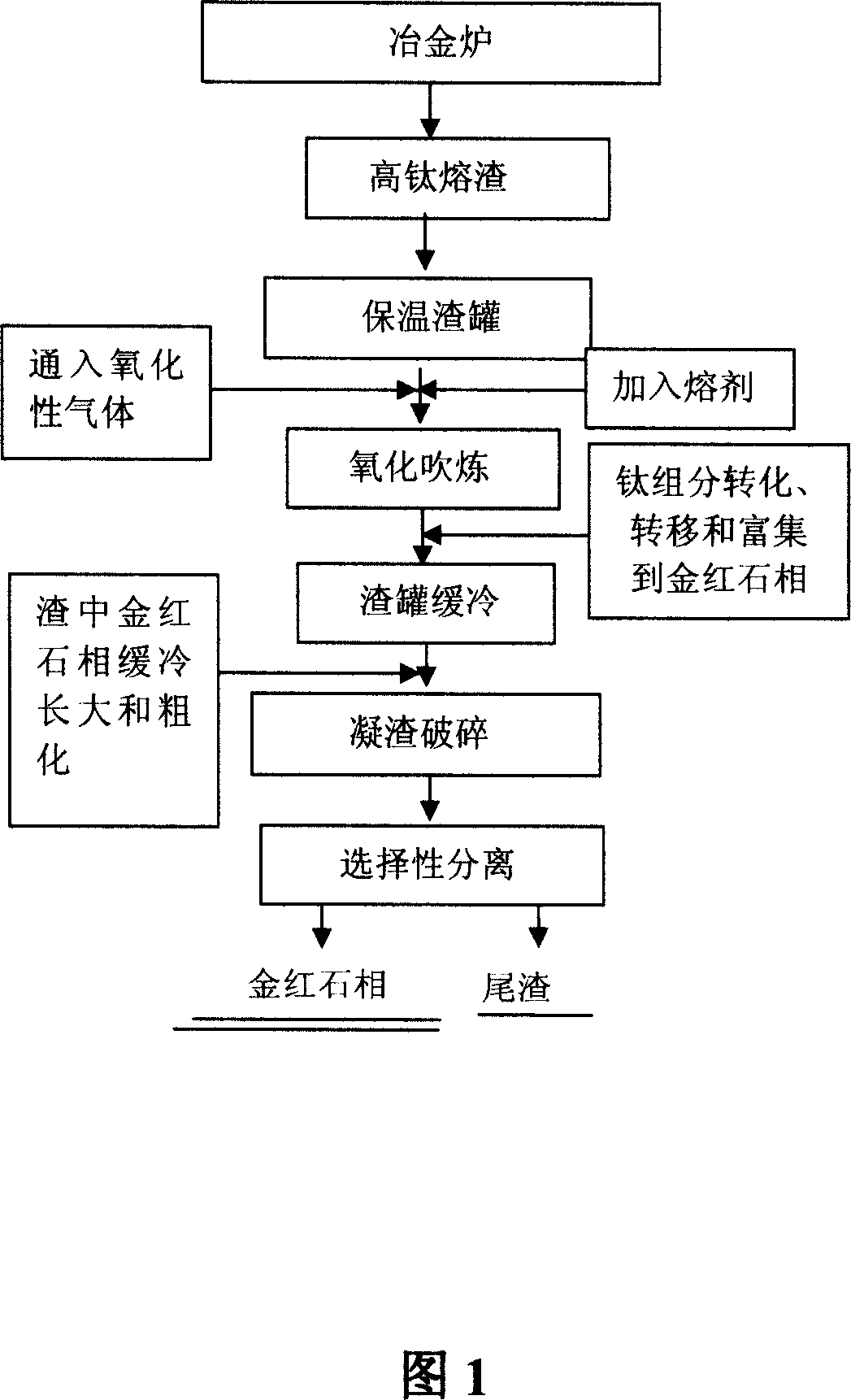

An artificial rutile, rutile phase technology, applied in the removal of titanium dioxide, solid waste, titanium oxide/hydroxide, etc., can solve the problems of high labor intensity, high production cost, large equipment investment, etc., to promote chemical reactions, The effect of high thermal energy utilization efficiency and large physical heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0055] Weigh 200g of electric furnace smelting titanium slag, its composition is 74.79%TiO 2 , 3.14% CaO, 8.89% MgO, 3.86% Al 2 o 3 , 3.10% FeO. Put the weighed titanium slag in the slag tank, heat the titanium slag until it melts, and control the temperature of the slag at about 1550°C; when the temperature is constant, add additives CaO6g and P to the slag in the slag tank 2 o 5 14g. While (or after) adding the additive, blow oxygen into the molten slag, the oxidation time is 5min, and the partial pressure of oxygen is controlled at 10 -2 In the range of -1 atm, the titanium component is selectively enriched in the rutile phase. Afterwards, the temperature of the slag increases by about 40°C due to oxidation, reaching 1590°C; the cooling rate is controlled at 2°C / min within the temperature range of 1590-1300°C, and the rutile phase grows selectively as the furnace cools to room temperature. The cooled oxidized slag is crushed and ground to a particle size of +200 mesh ...

Embodiment approach 2

[0057] Weigh 200g of electric furnace smelting titanium slag, its composition is 74.79%TiO 2 , 3.14% CaO, 8.89% MgO, 3.86% Al 2 o 3 , 3.10% FeO. The slag is melted by resistance heating, and the temperature continues to rise. When the temperature reaches 1550C, the temperature is kept constant, and oxygen is introduced in the molten state, and the additives CaO 4g and Na are added at the same time. 3 PO 4 14g, the oxidation time is 5min, and the partial pressure of oxygen is controlled at 10 -2 In the range of -1atm, the temperature of the slag after oxidation rises to 1590°C and cools down in the temperature range of 1590-1300°C, with a cooling rate of 5°C / min. The cooled oxidized slag is crushed and ground, with a particle size of +200 mesh to -300 mesh. It is leached with 16% hydrochloric acid, the immersion temperature is 55°C, the stirring speed is 4 rpm, and the immersion time is 40min. After filtering and drying, the final product containing 90.06% TiO 2 artifici...

Embodiment approach 3

[0059] Weigh 200g of electric furnace smelting titanium slag, its composition is 74.79%TiO 2 , 3.14% CaO, 8.89% MgO, 3.86% Al 2 o 3 , 3.10% FeO. The slag is melted by resistance heating, and the temperature continues to rise. When the temperature reaches 1530C, the temperature is kept constant, and oxygen is introduced in the molten state, and the additive CaF is added at the same time. 2 6g and P 2 o 5 12g, the oxidation time is 5min, and the partial pressure of oxygen is controlled at 10 -2 In the range of -1atm, the slag temperature rises to 1570℃ after oxidation. Cool down within the temperature range of 1570-1300°C, and the cooling rate is 1.0°C / min. The cooled oxidized slag is crushed and ground, with a particle size of +200 mesh to -300 mesh. It is leached with 10% hydrochloric acid, the immersion temperature is 45°C, the stirring speed is 4 rpm, and the immersion time is 50min. After filtering and drying, the final product containing 89.28% TiO 2 artificial ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com