Antibacterial chromo board coating and antibacterial chromo board

A technology for copper-plate cards and coatings, which can be used in pigment-containing coatings, textiles and papermaking, defoaming agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

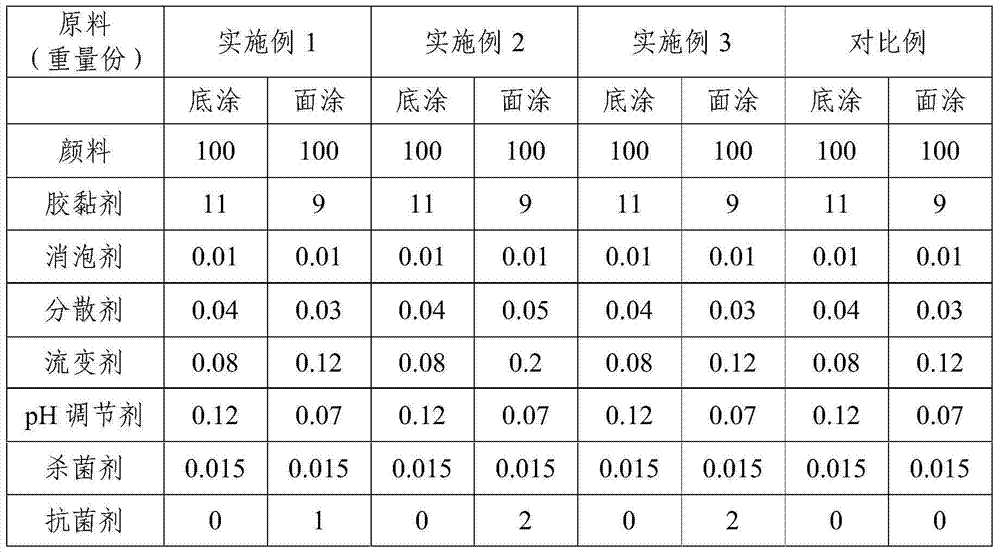

Embodiment 1

[0043] 1) Preparation of bottom coating for copperplate card

[0044] Add the following raw materials in sequence according to the ratio, among which pigments, adhesives, defoamers, dispersants, rheological agents, pH regulators, and fungicides are all added in the form of aqueous dispersions, and then directly add antibacterial solids, and mix at high speed After uniform dispersion, the solid content is 70%, ready to use.

[0045] Primer coating ratio: calcium carbonate 100g, styrene-butadiene latex 11g, fatty acid antifoaming agent 0.01g, sodium hexametaphosphate 0.04g, sodium carboxymethylcellulose 0.08g, sodium hydroxide 0.12g, isothiazole Linone 0.015g;

[0046] 2) Preparation of copperplate card surface coating

[0047] Add the following raw materials in sequence according to the ratio, among which pigments, adhesives, defoamers, dispersants, rheological agents, pH regulators, and fungicides are all added in the form of aqueous dispersions, and then directly add antiba...

Embodiment 2

[0052] 1) Preparation of bottom coating for copperplate card

[0053] Add the following raw materials in order according to the ratio, among which pigments, adhesives, defoamers, dispersants, rheological agents, pH regulators, and fungicides are all added in the form of aqueous dispersions, and then directly add antibacterial solids, and mix at high speed After uniform dispersion, the solid content is 70%, ready to use.

[0054] Primer coating ratio: 100g titanium dioxide, 11g styrene-butadiene latex, 0.01g polyethylene glycol, 0.04g sodium hexametaphosphate, 0.08g polyamide polyurea, 0.12g sodium hydroxide, 0.015g sandan oil ;

[0055] 2) Preparation of copperplate card surface coating

[0056] Add the following raw materials in order according to the ratio, among which pigments, adhesives, defoamers, dispersants, rheological agents, pH regulators, and fungicides are all added in the form of aqueous dispersions, and then directly add antibacterial solids, and mix at high sp...

Embodiment 3

[0060] 1) Preparation of bottom coating for copperplate card

[0061] Add the following raw materials in order according to the ratio, among which pigments, adhesives, defoamers, dispersants, rheological agents, pH regulators, and fungicides are all added in the form of aqueous dispersions, and then directly add antibacterial solids, and mix at high speed After uniform dispersion, the solid content is 65%. After mixing at high speed and uniform dispersion, it is ready for use.

[0062] Primer coating ratio: calcium carbonate 100g, styrene-butadiene latex 11g, fatty acid antifoaming agent 0.01g, sodium hexametaphosphate 0.04g, sodium carboxymethylcellulose 0.08g, sodium hydroxide 0.12g, isothiazole Linone 0.015g;

[0063] 2) Preparation of copperplate card surface coating

[0064] Add the following raw materials in order according to the ratio, among which pigments, adhesives, defoamers, dispersants, rheological agents, pH regulators, and fungicides are all added in the form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com