Processing technique for China-Hemp and paper straw mixed mat

A processing technology and mat technology, which can be applied to household utensils, bedspreads, applications, etc., can solve the problems of not being able to meet the requirements of washing, unfavorable mat maintenance, and affecting service life, etc., so as to improve market competitiveness, long service life, and strong adsorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, cut the washed kraft paper into sheets according to the specifications of the mat, then use the sheet-shaped washed kraft paper to wrap the flax core into a rope-shaped paper and roll it into a roll for weft, and hemp as warp for weaving to obtain the main body of the mat.

[0029] Then the main body of the mat is sprayed, heated, calendered and shrunk through the atomizer of the press to obtain the semi-finished mat; wherein, the diameter of the atomizer of the press is Φ2cm, and the water spray speed of the control press is 0.8m / min. It is foggy; the heating temperature is 70°C, the heating time is 1.5min; the calendering pressure is 120kgf / cm 2 , the calendering temperature is 110°C, and the calendering time is 0.3min; the shrinkage is treated by ordinary shrinkage process; the main body of the mat runs at a speed of 1m / min in the press.

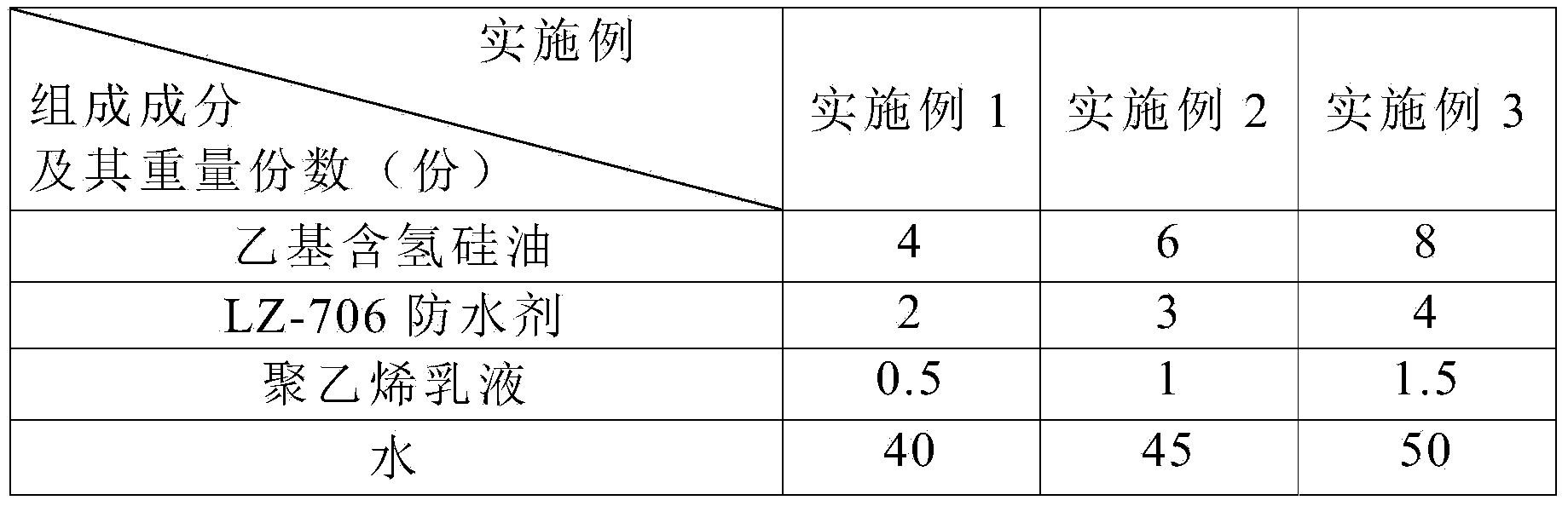

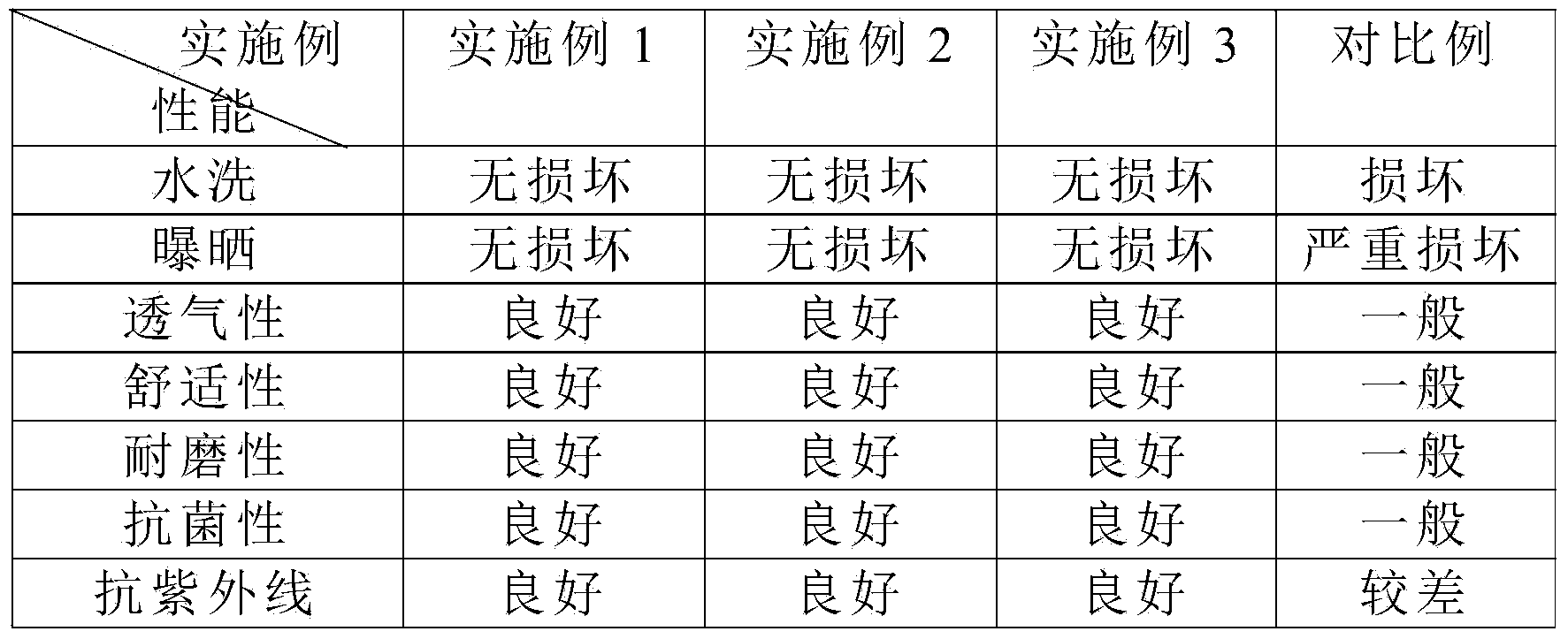

[0030] Then, take the raw materials by the main constituents and parts by weight of the waterproofing agent in Example 1 i...

Embodiment 2

[0033] First, cut the washed kraft paper into sheets according to the specifications of the mat, then use the sheet-shaped washed kraft paper to wrap the flax core into a rope-shaped paper and roll it into a roll for weft, and hemp as warp for weaving to obtain the main body of the mat.

[0034] Then the main body of the mat is sprayed, heated, calendered and shrunk through the atomizer of the press to obtain the semi-finished mat; wherein, the diameter of the atomizer of the press is Φ2cm, the water spray speed of the control press is 1m / min, and the water is Fog; heating temperature is 80°C, heating time is 1.8min; calendering pressure is 150kgf / cm 2 , the calendering temperature is 140°C, and the calendering time is 0.5min; the shrinkage is treated by ordinary shrinkage process; the main body of the mat runs at a speed of 1m / min in the press.

[0035] Then, take the raw materials by the main constituents and parts by weight of the water repellant in Example 2 in Table 1, be m...

Embodiment 3

[0038] First, cut the washed kraft paper into sheets according to the specifications of the mat, then use the sheet-shaped washed kraft paper to wrap the flax core into a rope-shaped paper and roll it into a roll for weft, and hemp as warp for weaving to obtain the main body of the mat.

[0039] Then the main body of the mat is sprayed, heated, calendered and shrunk through the atomizer of the press to obtain the semi-finished mat; wherein, the diameter of the atomizer of the press is Φ2cm, and the water spray speed of the control press is 1.2m / min. It is foggy; the heating temperature is 85°C, the heating time is 2min; the calendering pressure is 180kgf / cm 2 , the calendering temperature is 170°C, and the calendering time is 0.8min; the shrinkage is treated by ordinary shrinkage process; the main body of the mat runs at a speed of 1.2m / min in the press.

[0040] Then, take the raw materials by the main constituents and parts by weight of the water repellant in Example 3 in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com