Patents

Literature

118results about How to "Improve thermal energy utilization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignite drying device by aid of low-pressure superheated steam and method

ActiveCN102564095AImprove heat transfer coefficientReduce mass transfer resistanceDrying solid materials with heatDrying gas arrangementsAutomatic controlProcess engineering

Owner:天津格物兴业热能科技有限责任公司

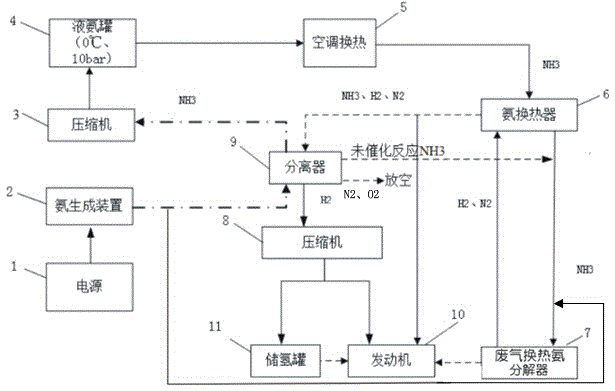

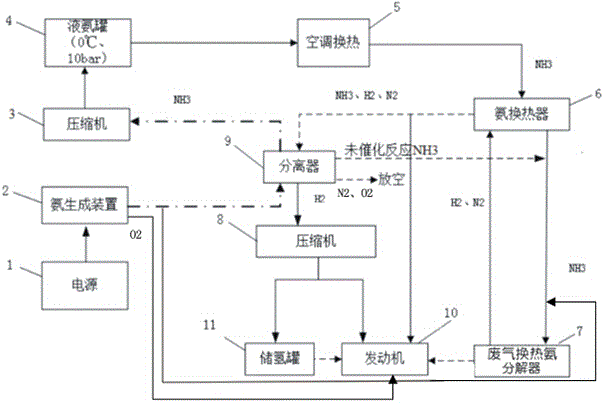

Novel automobile engine hydrogen and ammonia blended fuel supply device

ActiveCN104675580AImprove thermal energy utilization efficiencyEliminate emissionsInternal combustion piston enginesNon-fuel substance addition to fuelParticulatesEnvironmental resistance

The invention provides a novel automobile engine hydrogen and ammonia blended fuel supply device, which comprises an ammonia generation device, wherein an external power supply can be used for storing ammonia prepared from electrolysis into a liquid ammonia tank under a general condition of parking; hydrogen produced from ammonia decomposition can also be stored in a hydrogen storage tank, and the ammonia and the hydrogen can be jointly used as engine fuel when an engine works. The device can externally be added with ammonia fuel to guarantee fuel supply. The device is characterized in that catalytic decomposition can be carried out by the exhaust gas heat of the engine or with electric energy heating ammonia to effectively improve heat energy use efficiency; the ammonia and the hydrogen are used as the engine fuel to effectively eliminate the emission of greenhouse gases, such as CO2 and the like and substantially lighten pollution on the environment by harmful emissions, such as CO, PM (Particulate Matter) and the like; the overuse of petroleum can be effectively alleviated, and the blended fuel is used for replacing gasoline to serve as the green environmentally-friend fuel of the automobile. According to the device, the ratio of hydrogen and ammonia fuel can be controlled through an automobile electronic control unit (ECU) to improve engine combustion efficiency, and the ignition reliability of the fuel is extremely high.

Owner:王海斌

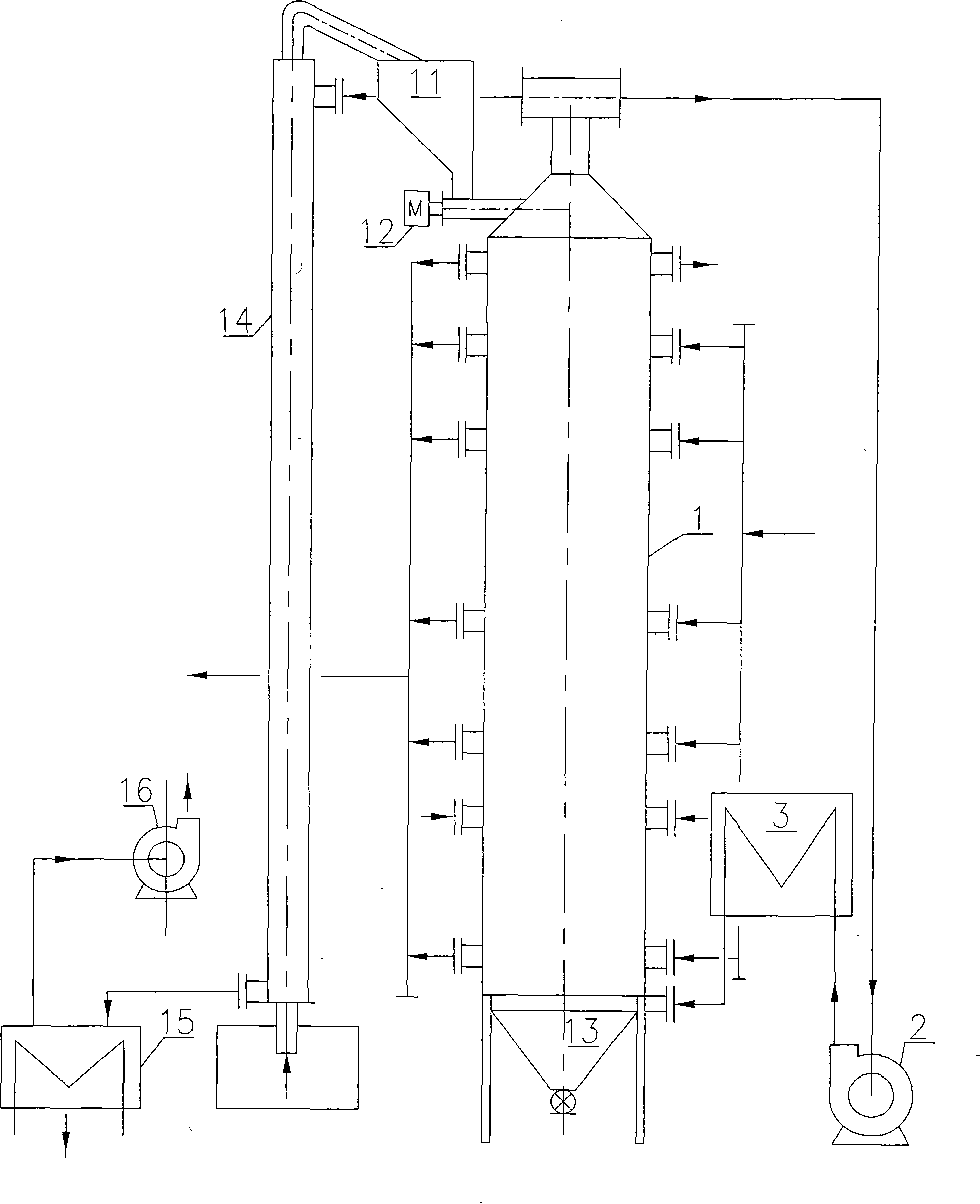

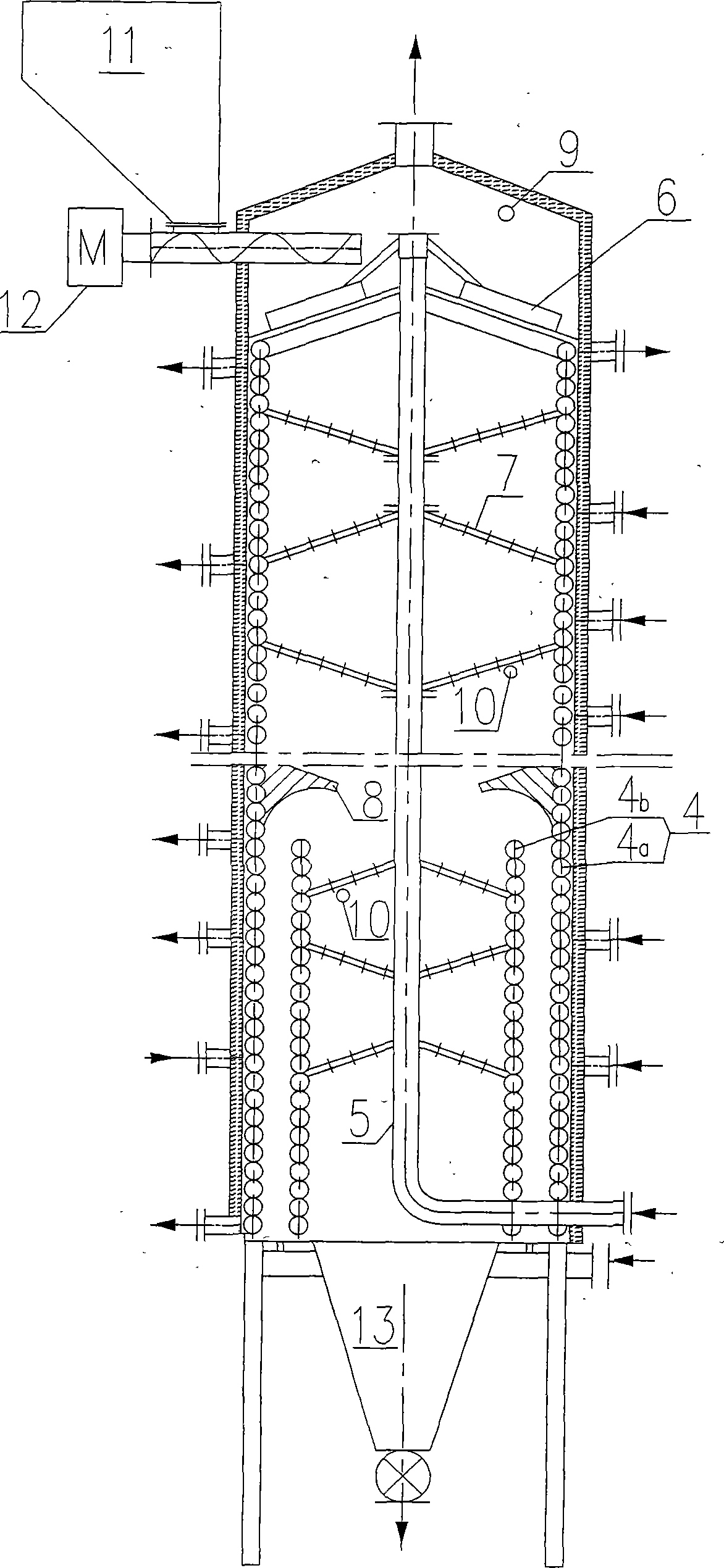

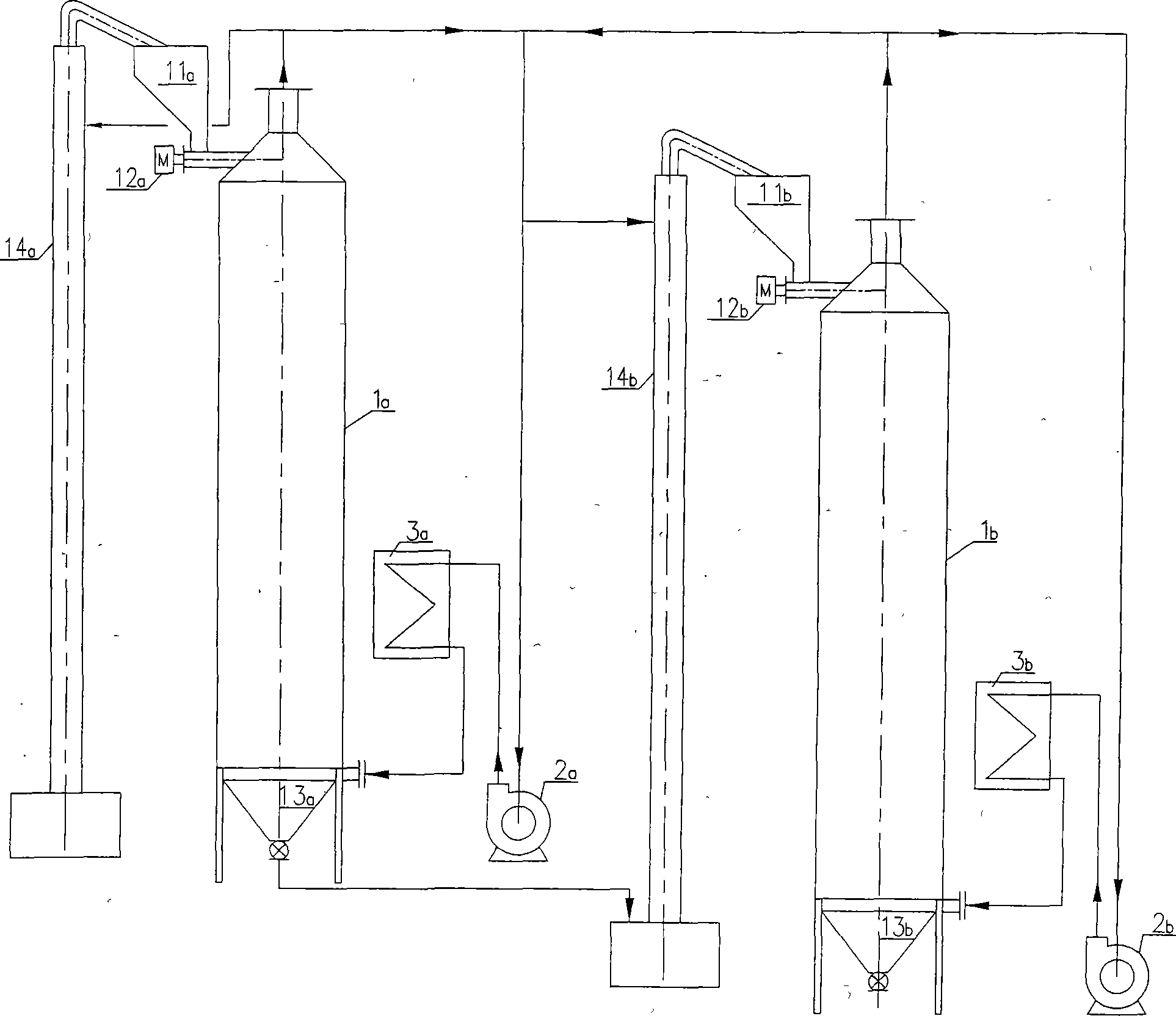

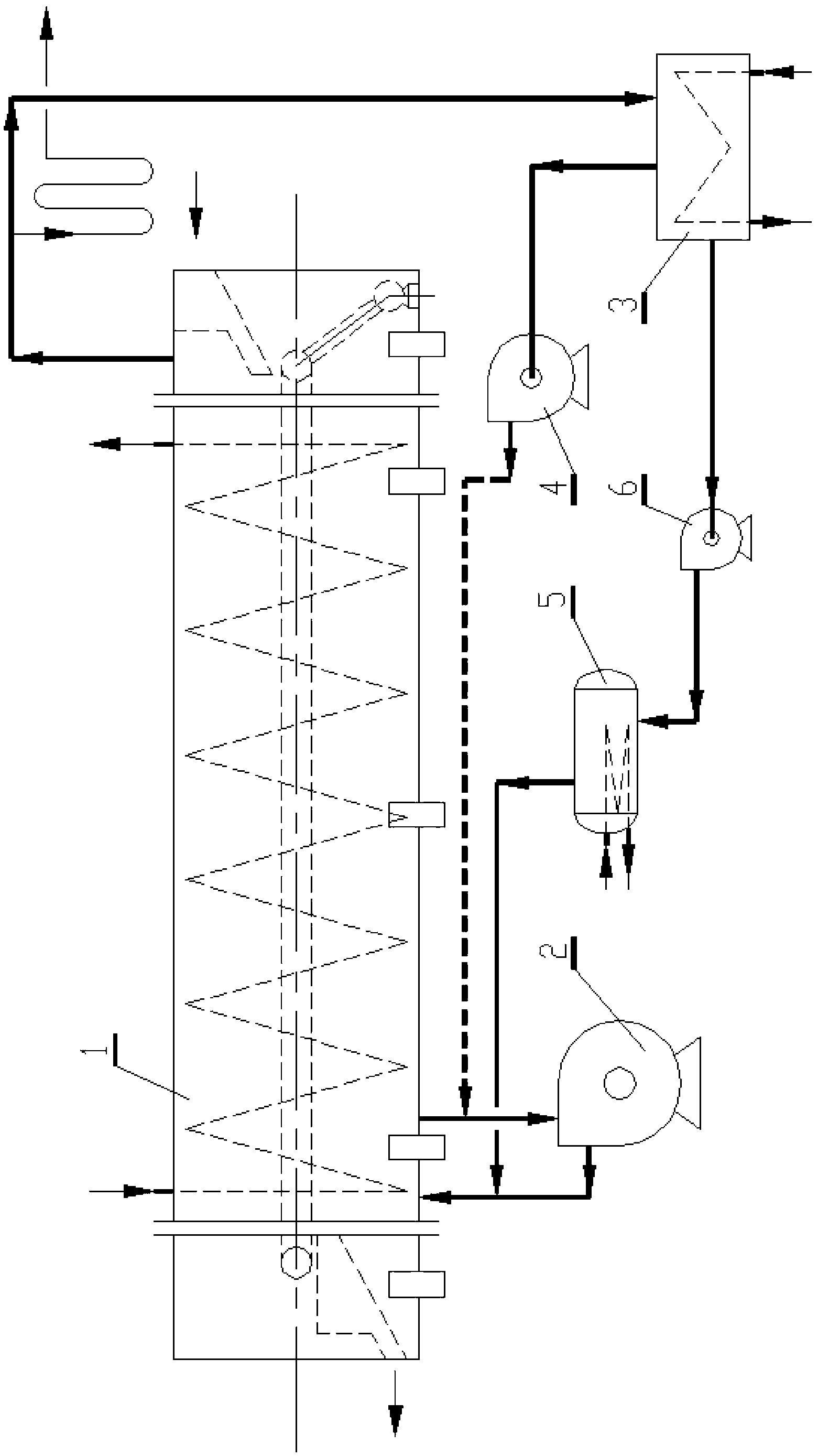

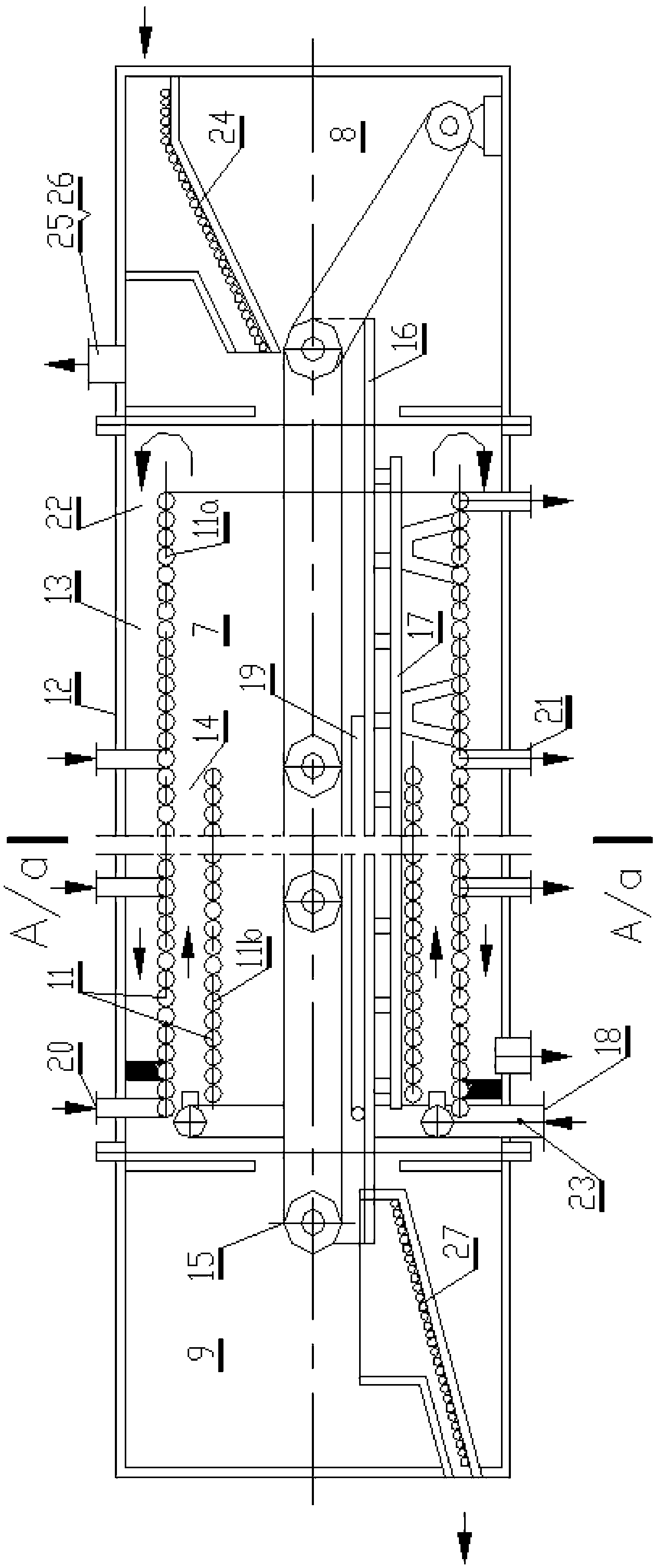

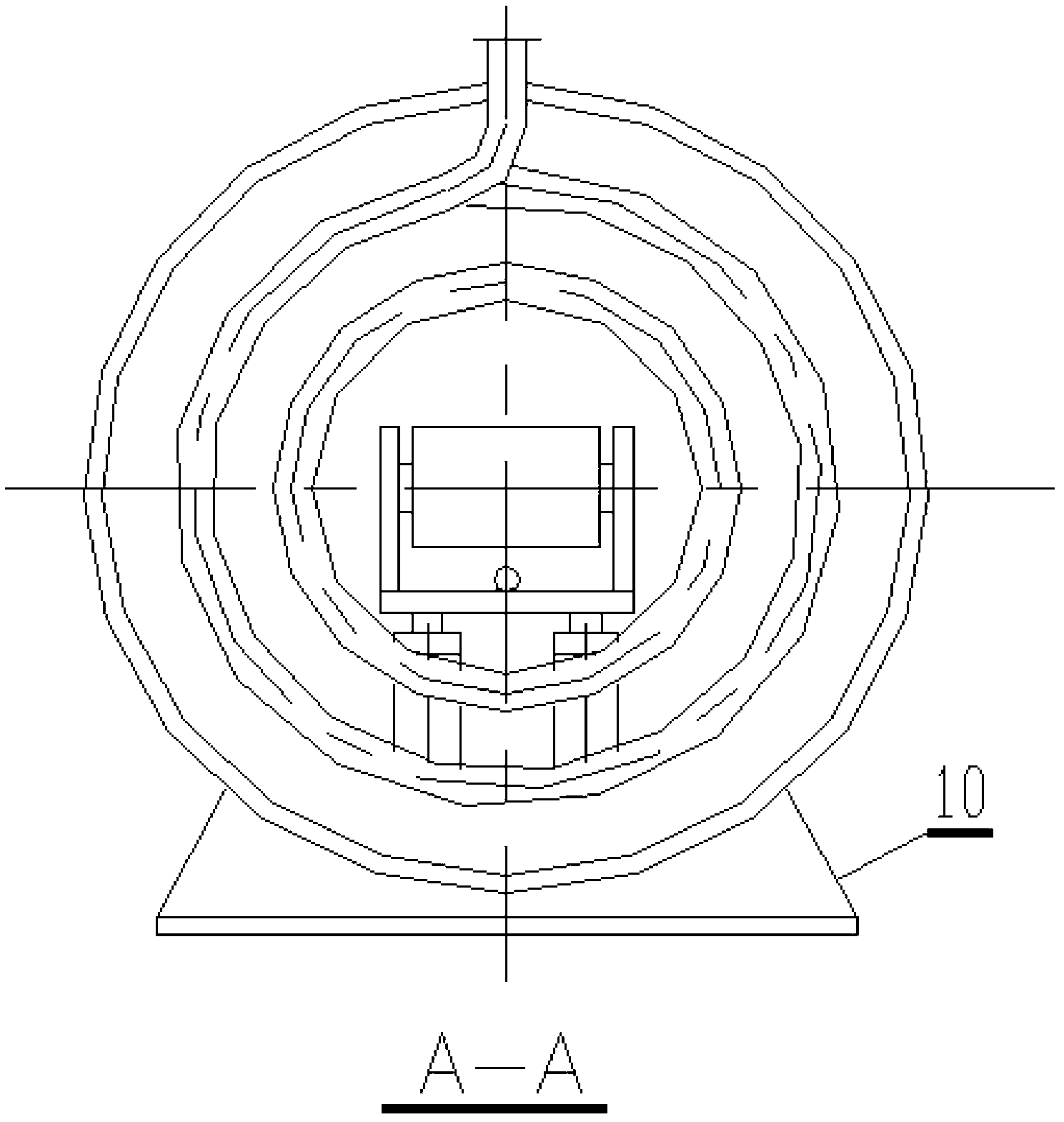

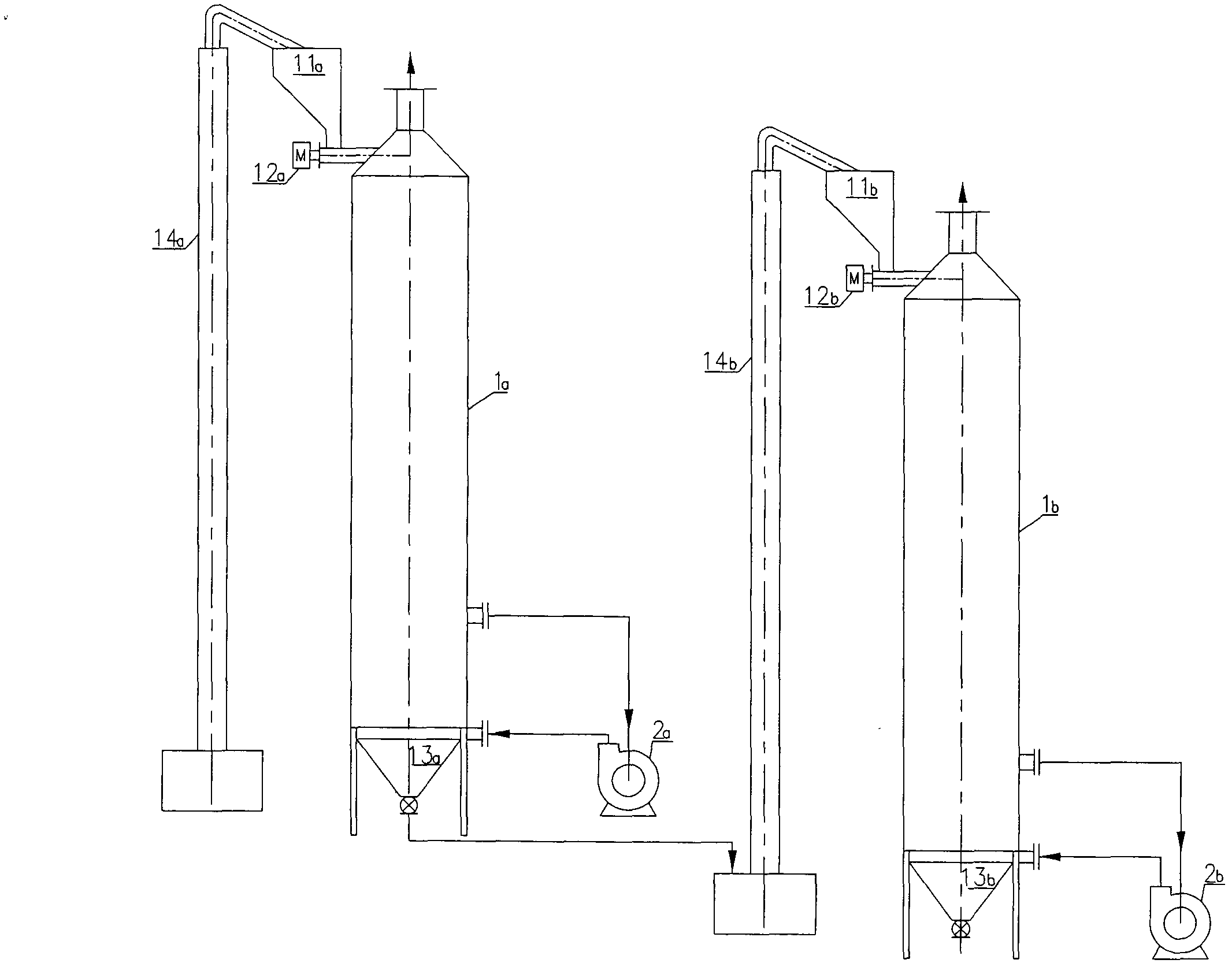

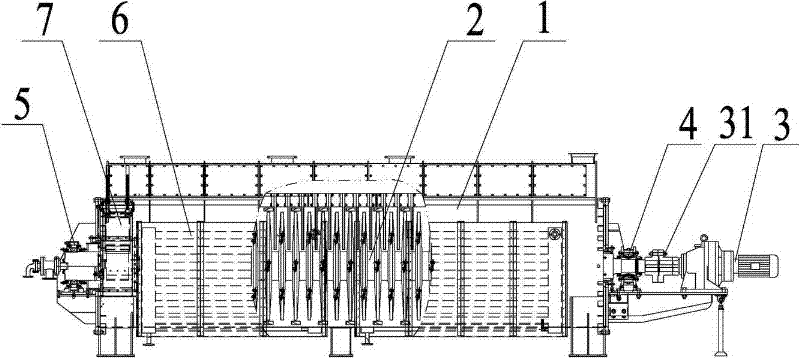

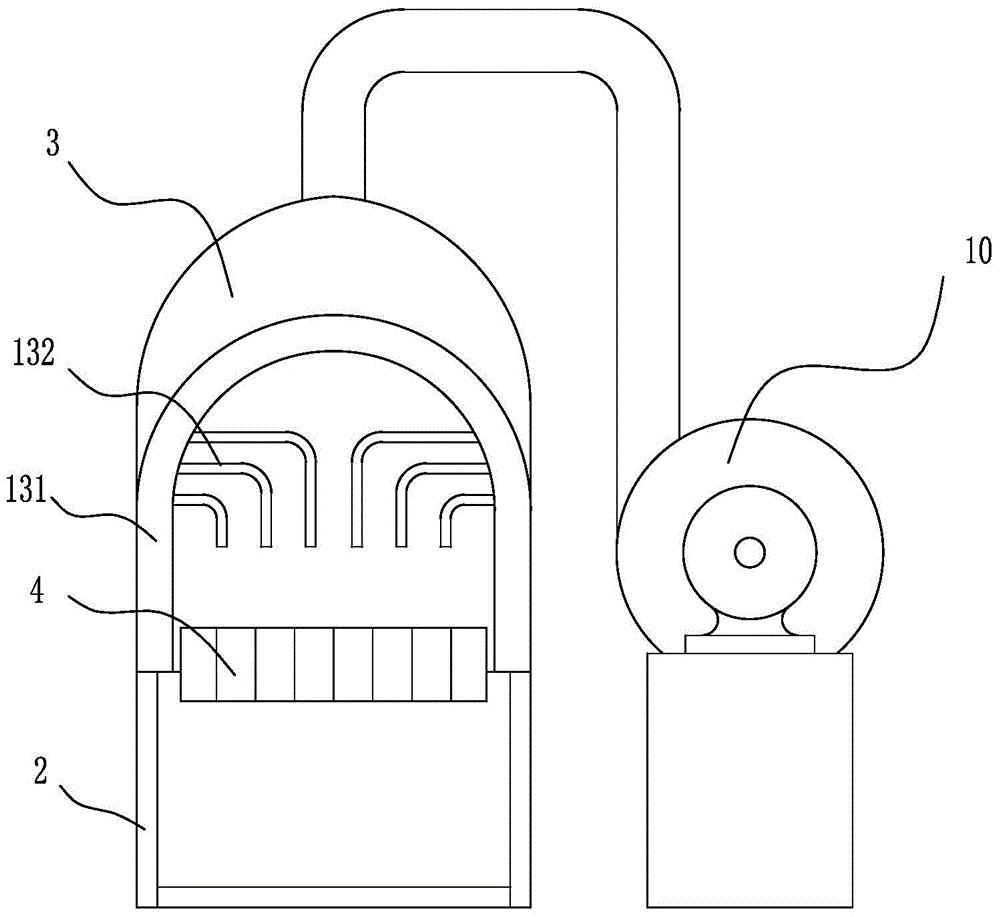

Belt type low-pressure superheat steam drying device

ActiveCN103162520AImprove heat transfer coefficientReduce mass transfer resistanceDrying gas arrangementsDrying machines with progressive movementsPulp and paper industryConvection heat

The invention relates to a belt type drying device capable of drying materials by using low-pressure superheat steam. The belt type drying device is a horizontal type pneumatic drying device with dual functions of heating drying media and drying the materials. A mode of internal heating is adopted by the belt type low-pressure superheat steam drying device, the low-pressure superheat steam circularly flowing inside the belt type low-pressure superheat steam drying device is continuously heated, the low-pressure superheat steam is circularly used as the drying media, the drying media is forced to flow inside the drying device and directly contact with wet materials which horizontally move along with a built-in belt type conveyer, and the purposes of heating and drying the materials are achieved through convection heat exchange and mass transfer diffusion between the drying media and the wet materials.

Owner:天津格物兴业热能科技有限责任公司

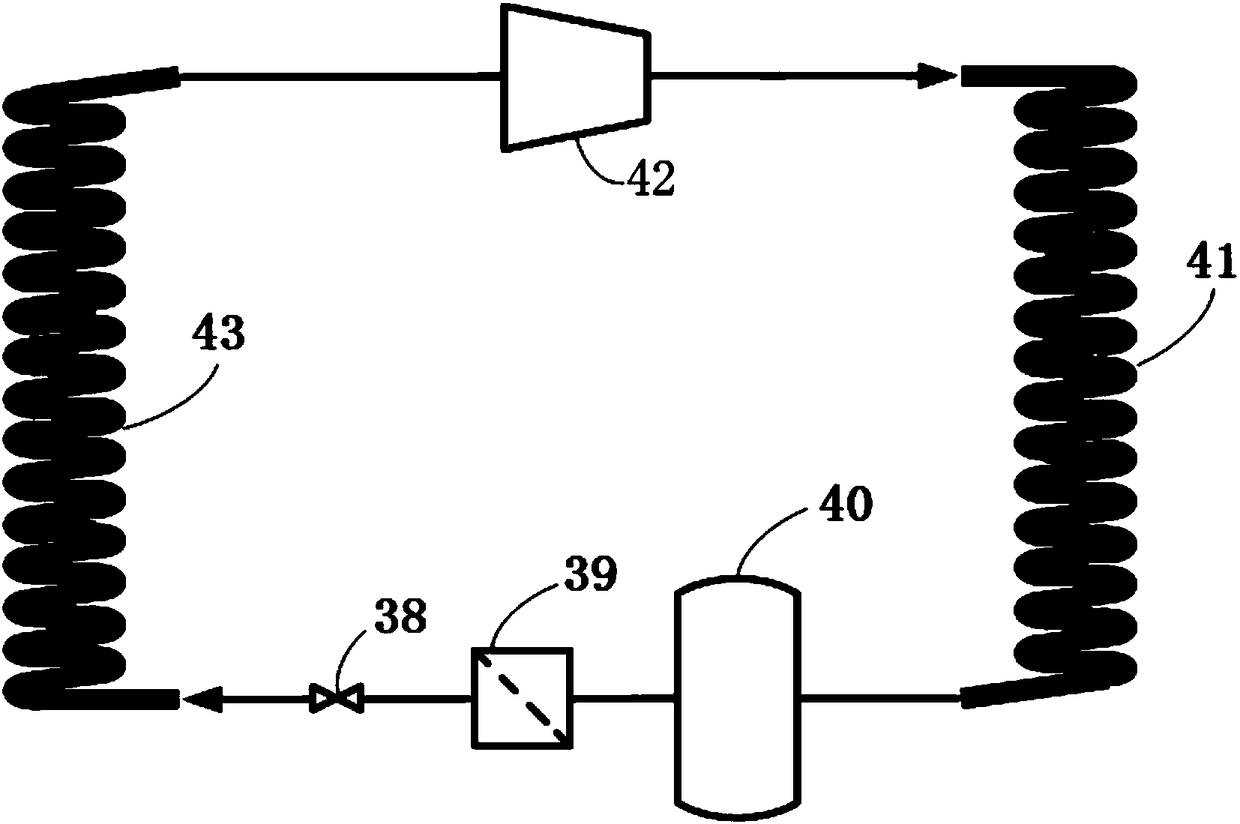

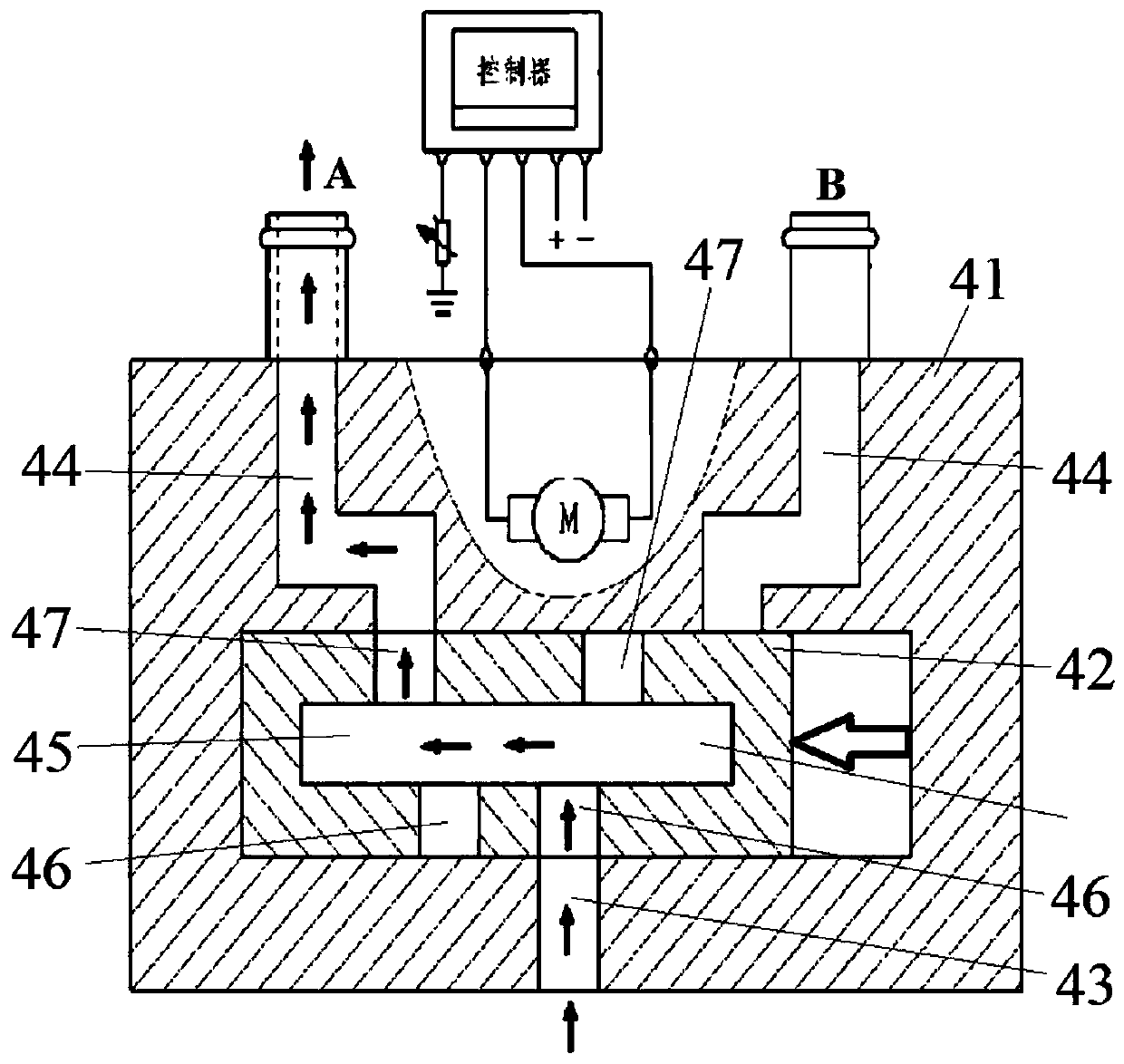

Cascaded recycling system for waste heat of internal combustion generating set

ActiveCN103206317AImprove recycling efficiencyLower exhaust gas temperatureInternal combustion piston enginesEngine componentsCombustionOrganic Rankine cycle

The invention provides a cascaded recycling system for waste heat of an internal combustion generating set and relates to a smoke waste heat recycling system of the internal combustion generating set, which solves the problems of high smoke temperature of the internal combustion generating set, low energy utilization efficiency and low generating efficiency as smoke waste heat of the existing internal combustion generating set is directly recycled by an organic Rankine cycle system. The cascaded recycling system for waste heat of the internal combustion generating set comprises a steam Rankine cycle subsystem and an organic Rankine cycle subsystem; the steam Rankine cycle subsystem comprises a waste heat boiler, a steam turbine, a first generator and a delivery pump; the organic Rankine cycle subsystem comprises an organic working medium evaporator, an organic working medium preheater, an organic turbine, a heat regenerator, an organic working medium condenser, an organic working medium pump and a second generator; a superheated steam outlet of the waste heat boiler is communicated with an acting cycle working medium inlet of the steam turbine, and the organic working medium condenser is communicated with a second inlet of the heat regenerator. The cascaded recycling system is used for smoke waste heat recycling of the internal combustion generating set.

Owner:GRAND NEW POWER

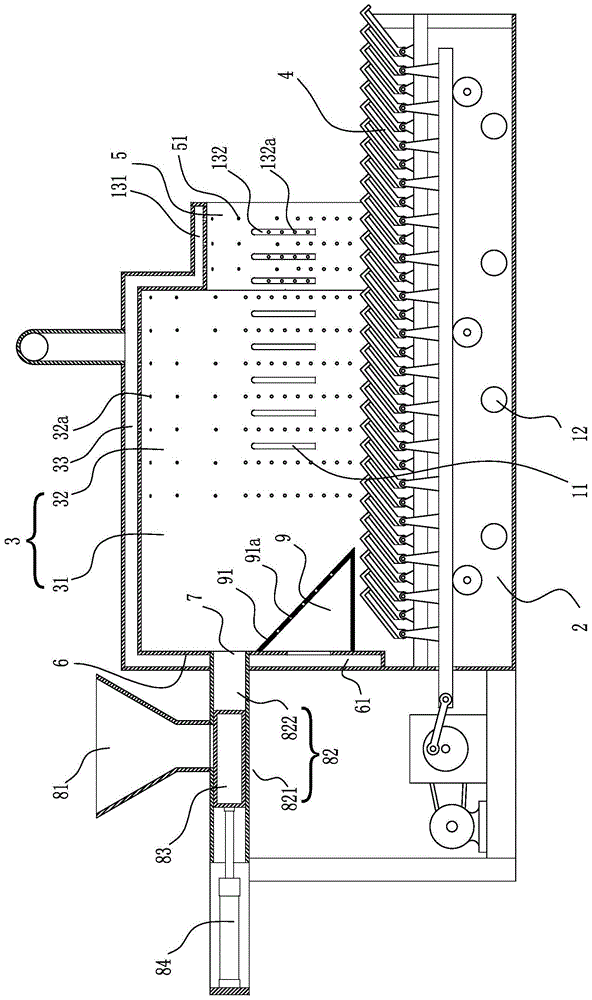

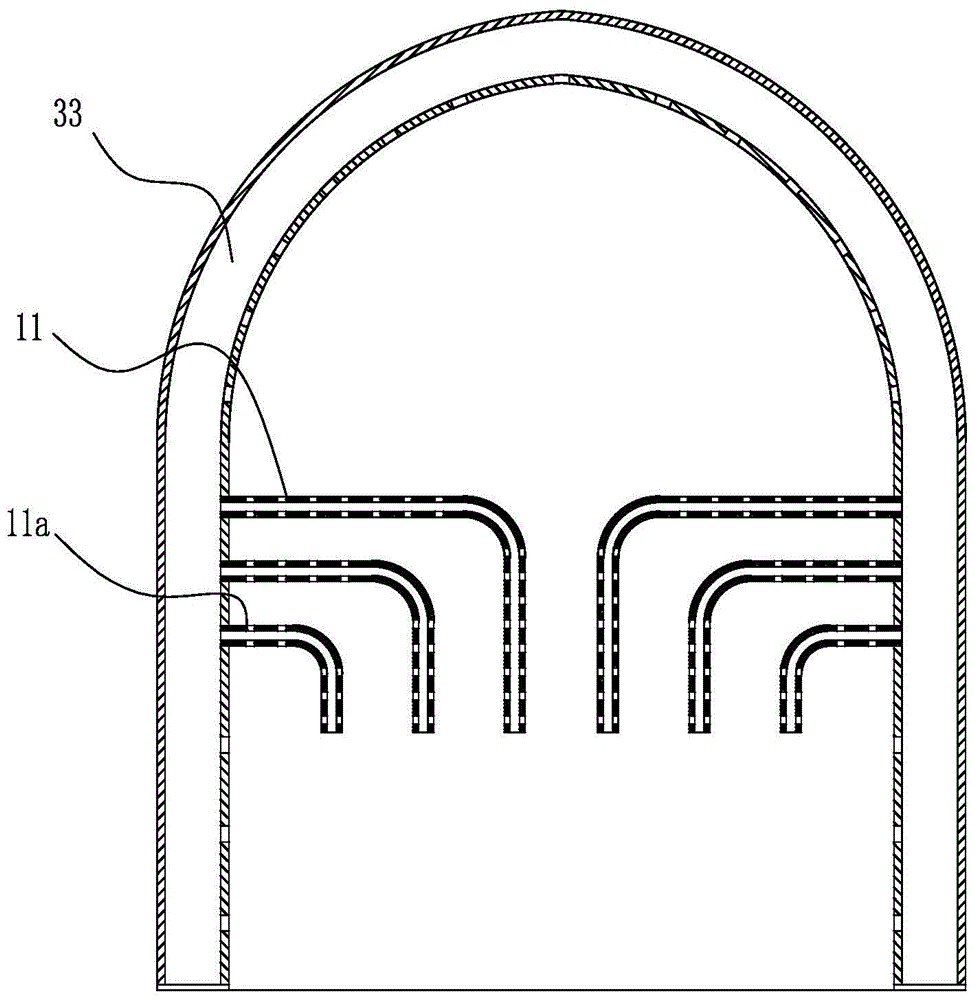

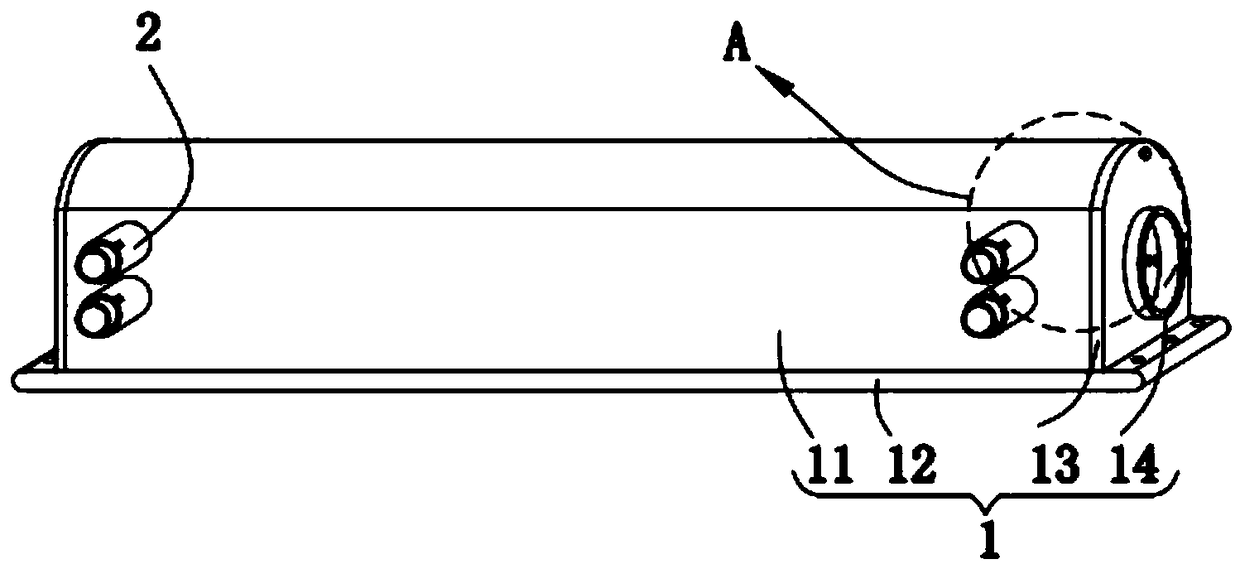

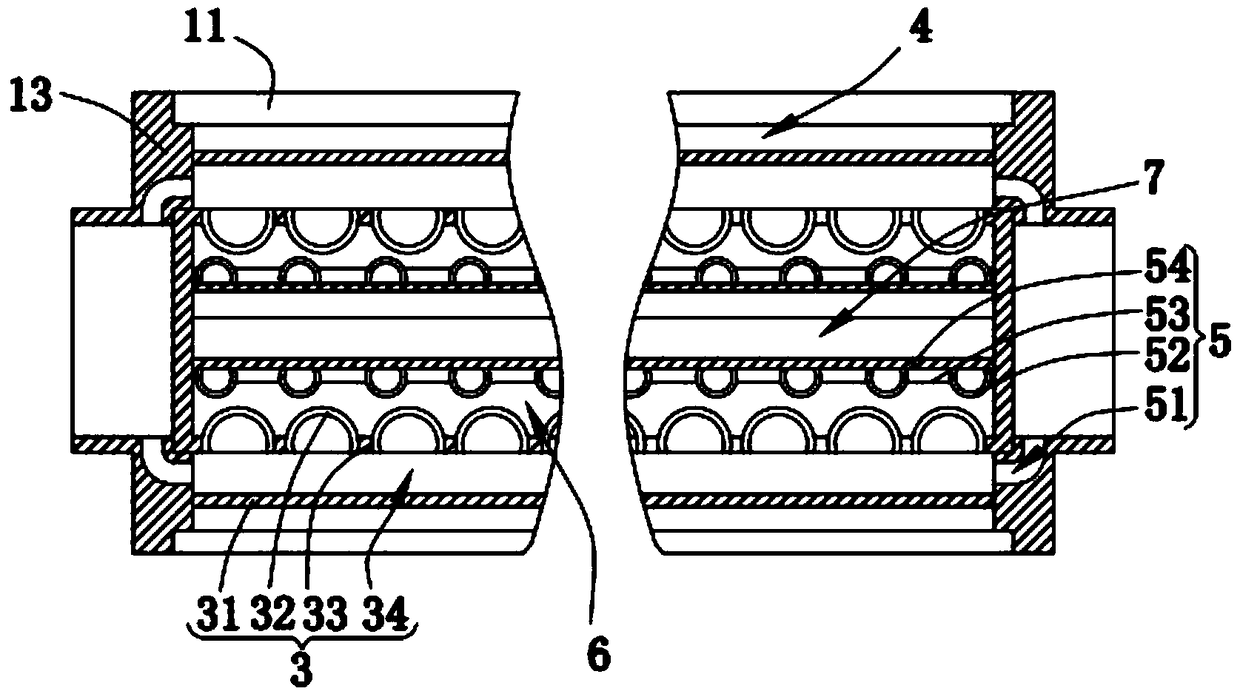

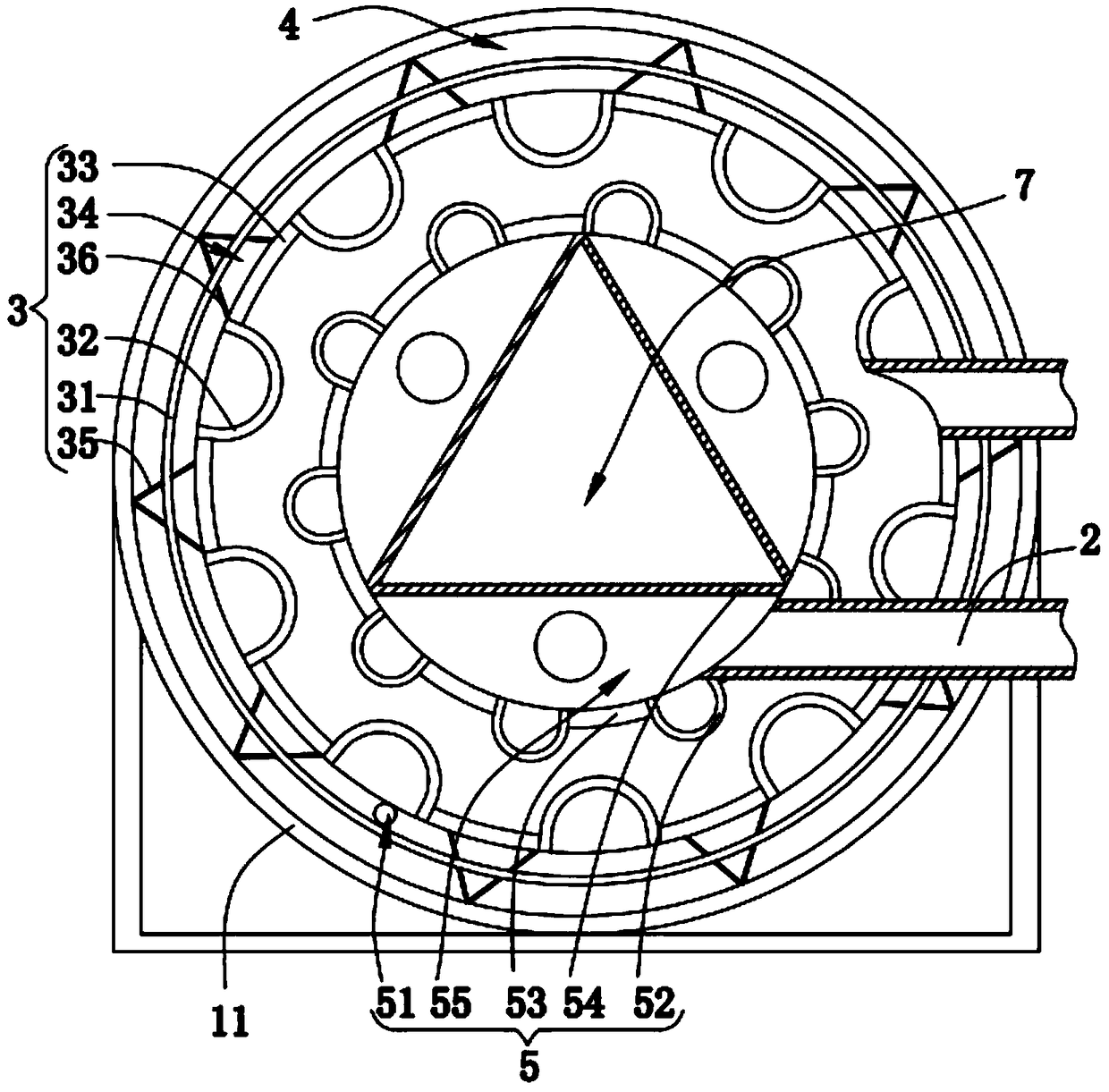

Wafer loading disc for MOCVD (metal organic chemical vapor deposition) reactor and MOCVD reactor

ActiveCN103526186AImprove protectionImprove thermal energy utilization efficiencyChemical vapor deposition coatingEngineeringHeat energy

The invention discloses a wafer loading disc for an MOCVD (metal organic chemical vapor deposition) reactor and an MOCVD reactor. In order to expand the range of a uniform-temperature field on the surface of the wafer loading disc to the greatest degree, the wafer loading disc for the MOCVD reactor comprises a wafer loading disc body, wherein a groove for placing a wafer is formed in the upper surface of the wafer loading disc body, and the periphery of the lower surface of the wafer loading disc body extends downward to form an annular bulge so that the whole wafer loading disc is of an inverted barrel shape. The MOCVD reactor is provided with the wafer loading disc with the annular bulge and a matched heater, wherein the heater is divided into an inner part, a middle part and an outer part, wherein an inner ring and an outer ring of the heater are vertically arranged in a cylindrical manner, and a middle ring is horizontally arranged in an omega shape. By adopting the wafer loading disc and the MOCVD reactor disclosed by the invention, the utilization efficiency of heat energy is improved; the heating device is separated from a reactant so as to better protect the heating device; meanwhile, the consistent-temperature area on the surface of the wafer loading disc is expanded, thereby increasing the single-batch output.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

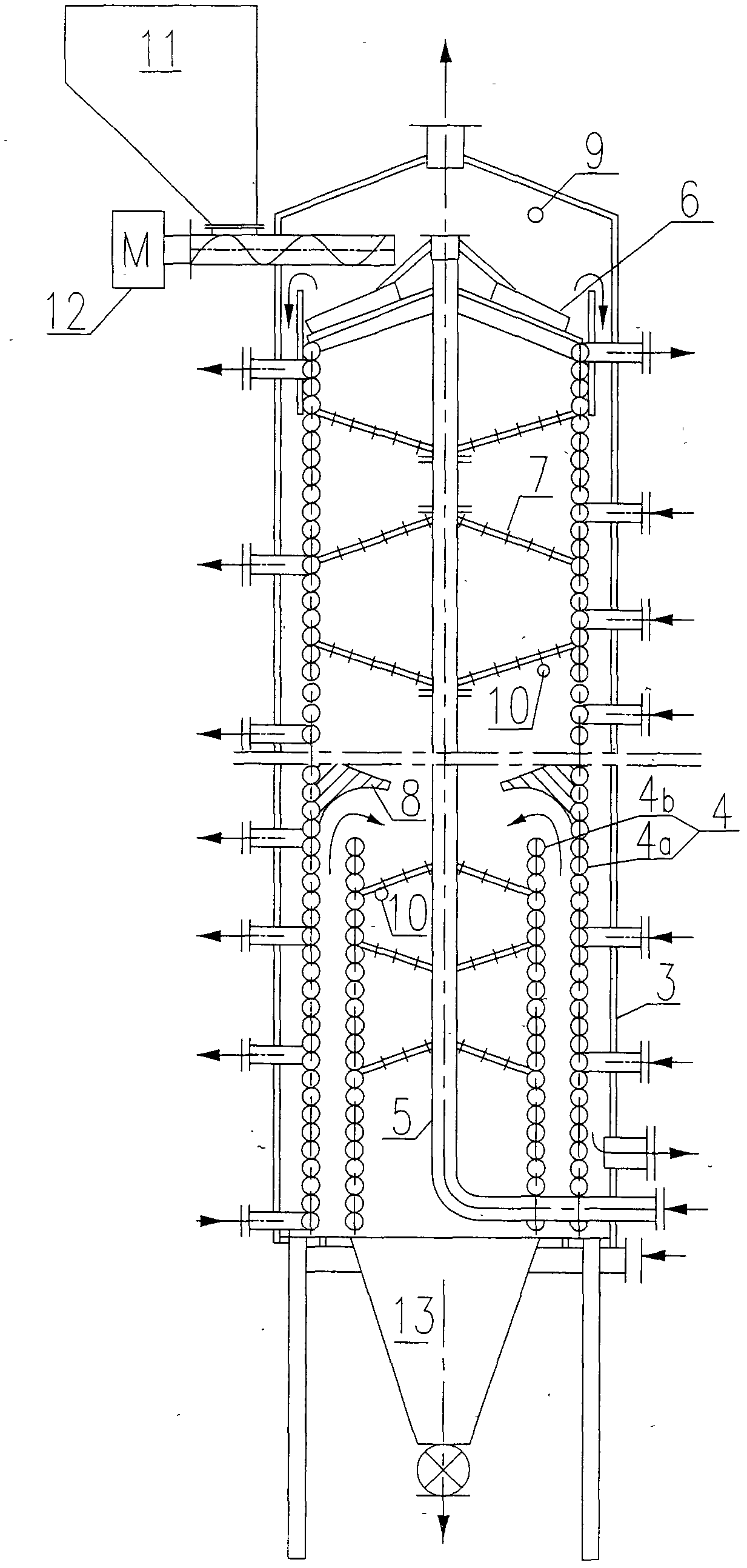

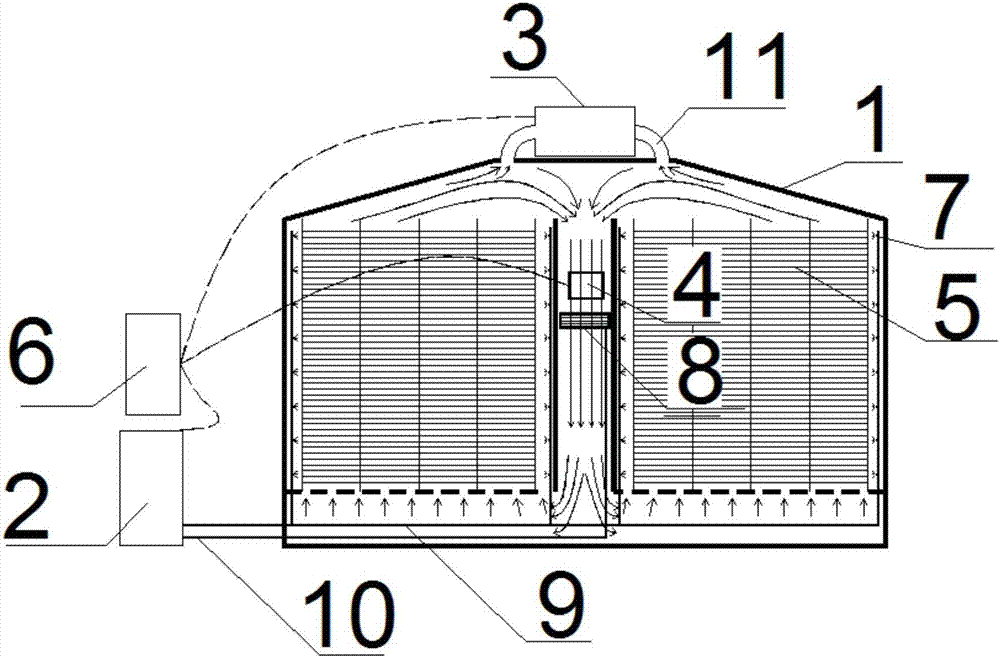

Device used for drying materials by aid of low-pressure superheated steam

ActiveCN102564096AImprove heat transfer coefficientReduce mass transfer resistanceDrying gas arrangementsHeat conductingEngineering

The invention relates to a device with a material drying function. Low-pressure superheated steam is generated when wet materials are dried, and the low-pressure superheated steam is used as internal circulating drying media to realize the material drying function of the device. An external heat-conducting oil circulating system supplies high-temperature heat-conducting oil to be used as a heat transfer medium of the drying device, the low-pressure superheated steam in reheating cycle is used as a partial drying medium of the drying device, the two working media at different temperatures supply heat required by the heating device, steam evaporated in a material drying process and the low-pressure superheated steam which is in pressurization and reheating and then enters the drying device to realize internal circulation are heated by a built-in heat-conducting oil heating coil, accordingly, the steam is always properly superheated in a heat exchange process, the low-pressure superheated steam in the drying device directly contacts with materials moving from top to bottom when the low-pressure superheated steam flows from bottom to top, and purposes of heating and drying the materials are achieved by means of convection heat exchange and mass transfer diffusion between the steam and the materials.

Owner:天津格物兴业热能科技有限责任公司

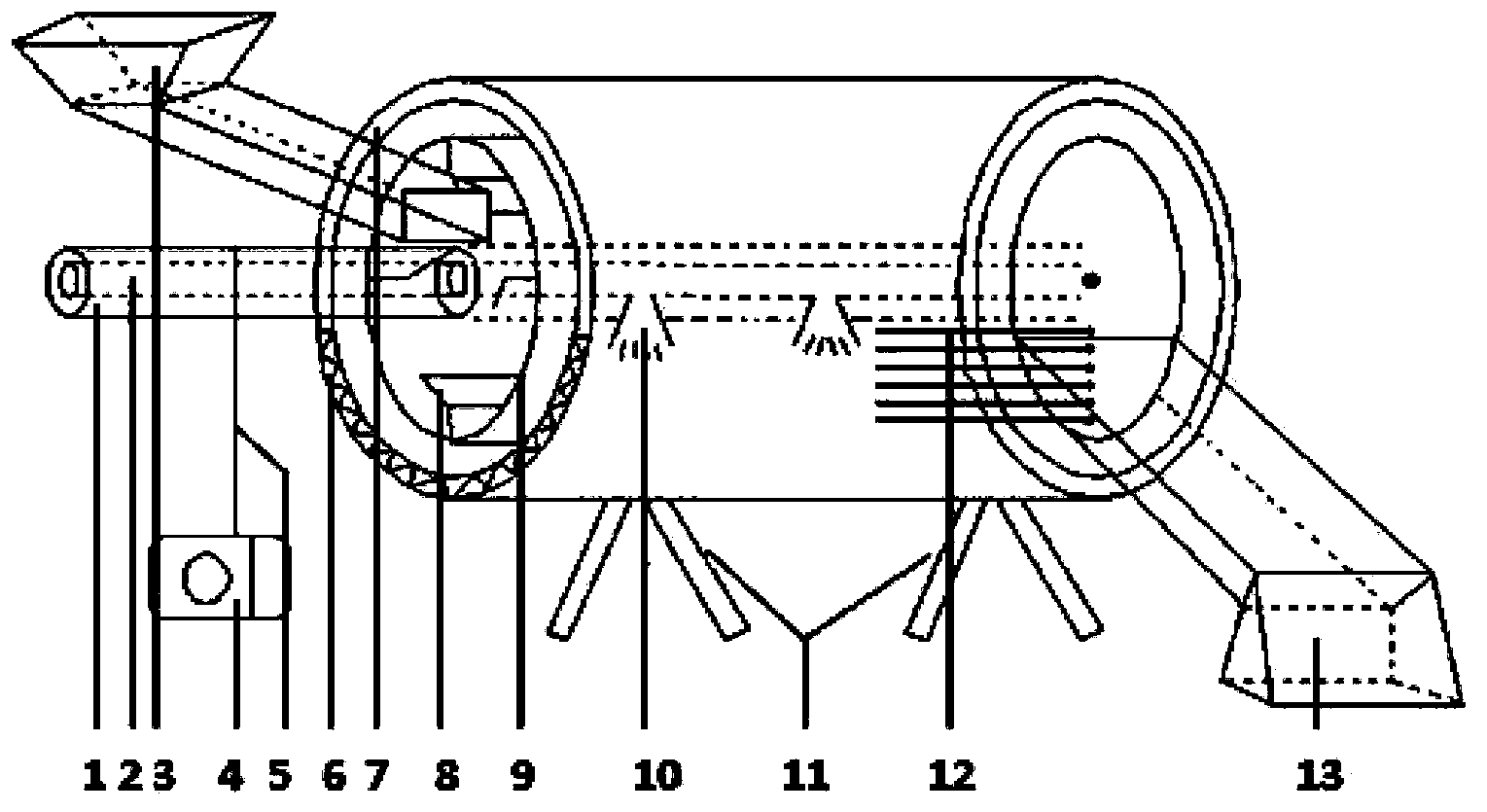

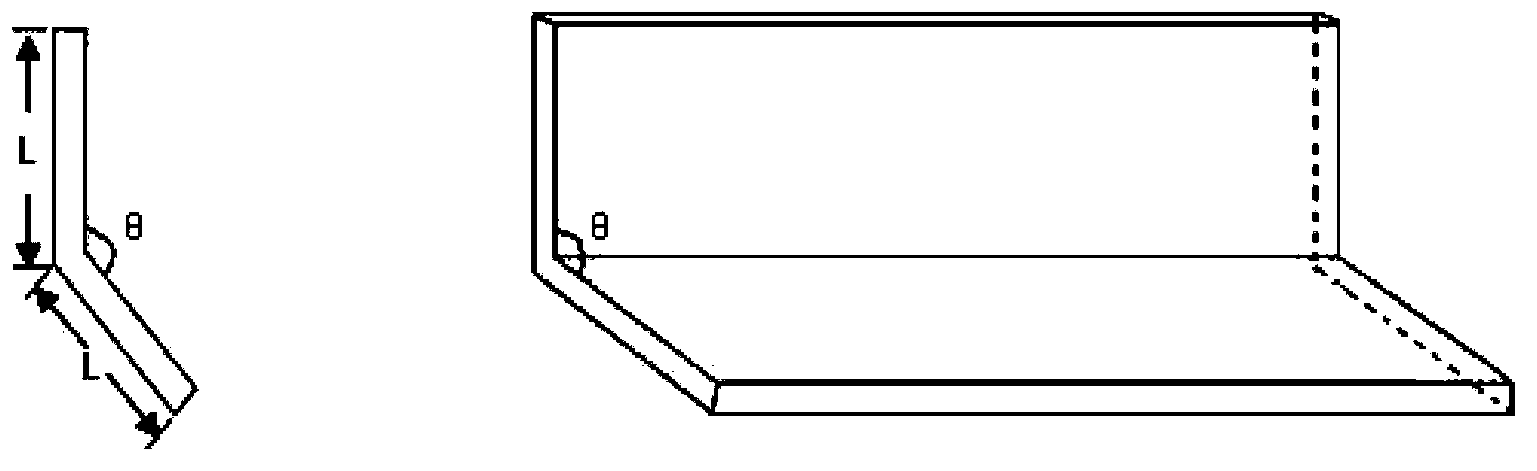

Drum type herbal medicine roaster with built-in L-shaped baffle

ActiveCN103767873AEvenly heatedHeating up fastFood processingPharmaceutical product form changeInsulation layerEngineering

The invention discloses a drum type herbal medicine roaster with a built-in L-shaped baffle. A series of problems that the existing herbal medicine roaster is poor in stir-frying effect, non-uniform in heating, high in energy consumption and the like are solved. The L-shaped baffle is arranged inside the drum type herbal medicine roaster and accordingly the stir-frying of materials can be full, the heat transfer can be uniform, the energy and time can be saved, and the loss of the mechanical device can be reduced; an inner cylinder and an outer cylinder are of a sleeve structure, the outer cylinder is used for performing heating, the inner cylinder rotates, an insulation layer is arranged outside the outer cylinder, and accordingly the energy utilization rate can be improved; the rotational speed of the inner cylinder can be adjusted, the cross section of the inner cylinder is provided with an embedded temperature measuring thermocouple, and accordingly real-time monitoring can be performed on the temperature variation of different positions in a drum; the length of a support which is arranged at the bottom can be controlled and accordingly the feeding and discharging can be convenient; roast juices can be sprayed and the device can be cleaned due to a spraying device. The drum type herbal medicine roaster with the built-in L-shaped baffle can be widely applied to pharmaceutical factories, Chinese medicine decoction piece factories, hospitals, individual clinics and the like for roasting of various Chinese herbal medicine raw materials.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

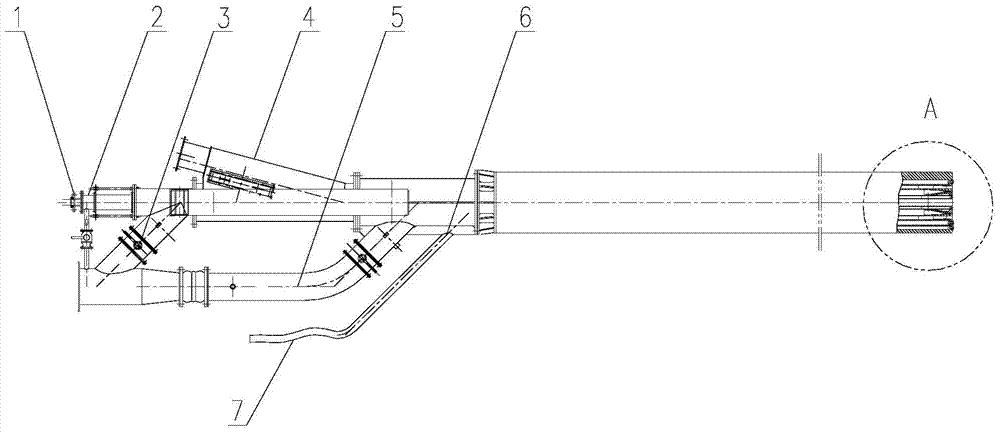

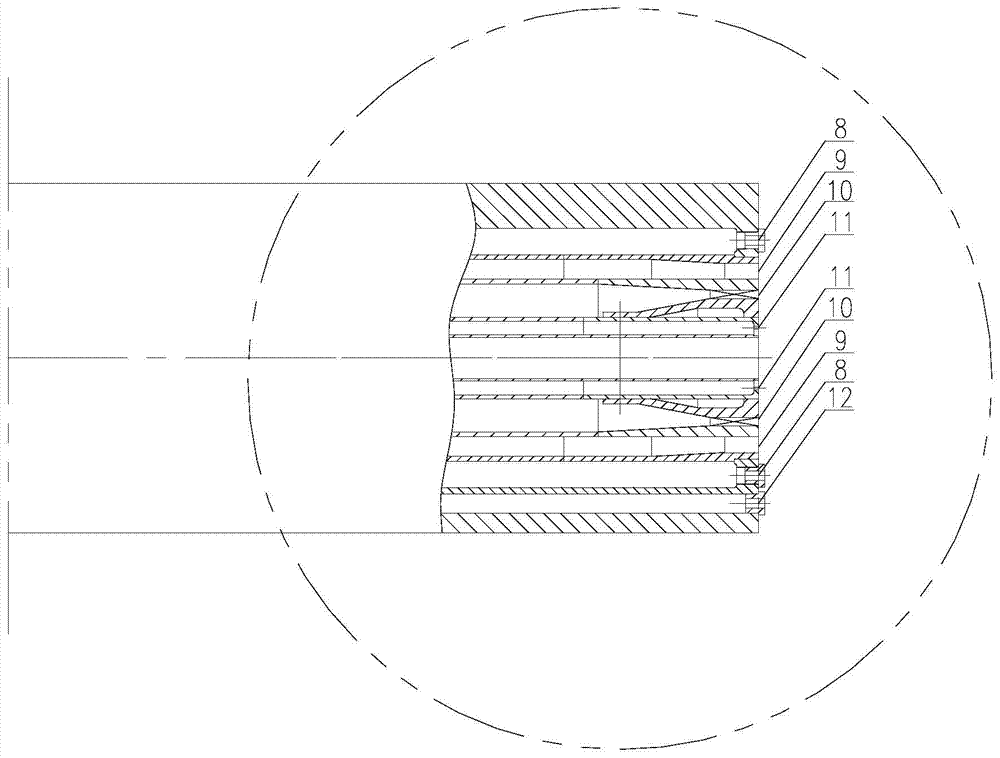

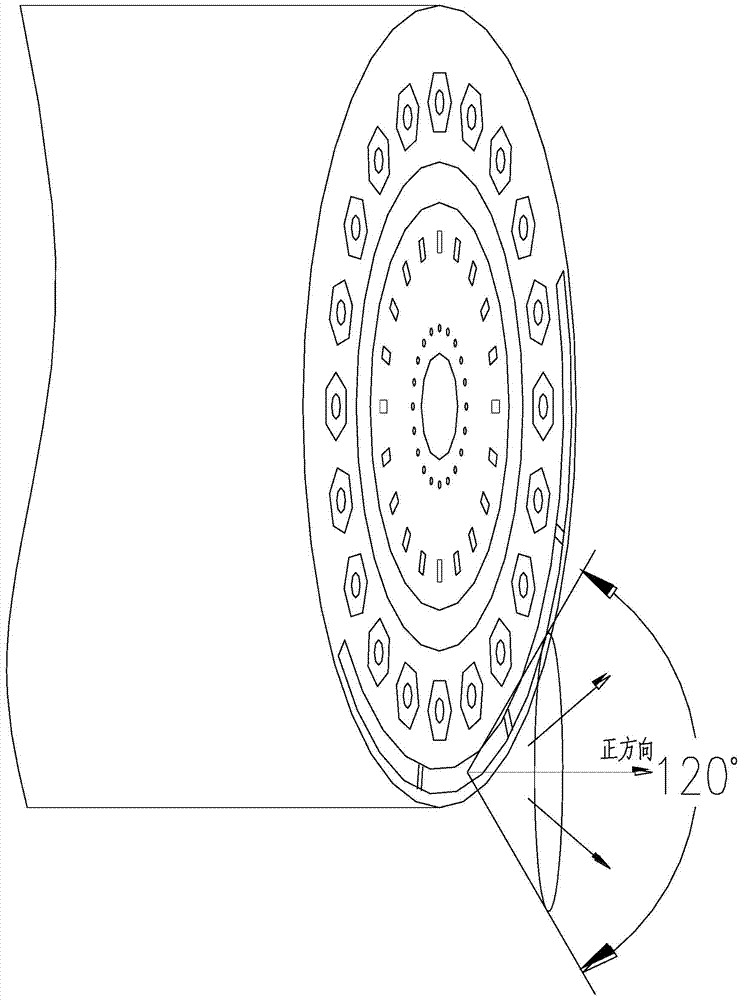

Local oxygen-enriched combustor for cement kiln furnace

InactiveCN103672886AImprove thermal energy utilization efficiencyStandard coal consumption decreasedPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCement kilnRotary kiln

The invention relates to a local oxygen-enriched combustor for a cement kiln furnace. Through the arrangement of an oxygen-enriched air passage outside an axial flow air passage of the combustor and the arrangement of a spray nozzle at an outlet of the oxygen-enriched air passage, the spray nozzle is arranged at the lower part of the outer side circumference of the air flow air spray nozzle and is near the clinker or analogue side, so the local concentration of the oxygen gas at the contact side of the lower part of the combustor and the oxygen-enriched air passage is raised, the combustion speed of the fuel can be accelerated, the local heat accumulation is directly caused, the adjacent fuel also begins to combust along with the proceeding of the diffusion, heat transfer and heat radiation processes, the temperature of the direct contact side of the clinker or analogue of a rotary kiln with the oxygen-enriched air passage is obviously raised, and the response to the raw material mass fluctuation caused by proportioning can be realized. In addition, a center angle corresponding to a distribution region in the circumferential direction is set to be smaller than or equal to 270 degrees, the angle range can completely cover the region of the fuel and the cement clinker or analogue rotating along with the rotary kiln, and the use precision and the economization of oxygen-enriched air can be ensured.

Owner:NANJING KISEN INT ENG

Day lily enzyme-deactivating and drying integrated device and process

PendingCN107514901ASolve the drying problemRealize processing integrationFood processingFood treatmentProcess engineeringIntegrated processing

The invention provides a day lily enzyme-deactivating and drying integrated device and process. The day lily enzyme-deactivating and drying integrated device comprises steam nozzles and at least one condenser which are mounted in an operating room. According to the day lily enzyme-deactivating and drying integrated device provided by the invention, the day lily enzyme-deactivating operation and the day lily drying operation are combined by utilizing hot steam and the condenser; by adoption of the efficient heat pump technology and the heat recovery technology, the heat energy utilization efficiency and the day lily rough-processing efficiency are improved, the problem about the drying of day lily on rainy days is solved, and the integrated processing of day lily is achieved; and furthermore, the overall structure is simple, and the labor cost is greatly reduced by utilizing the modern industrial control technology.

Owner:昆山同益热泵科技有限公司

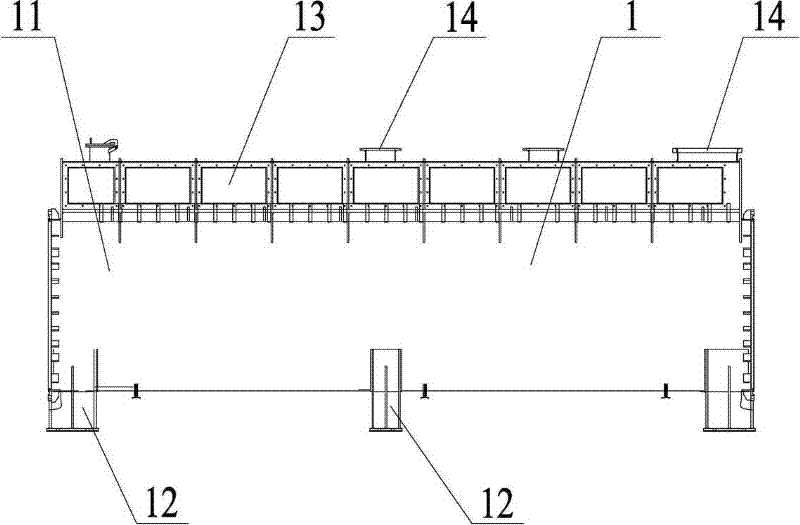

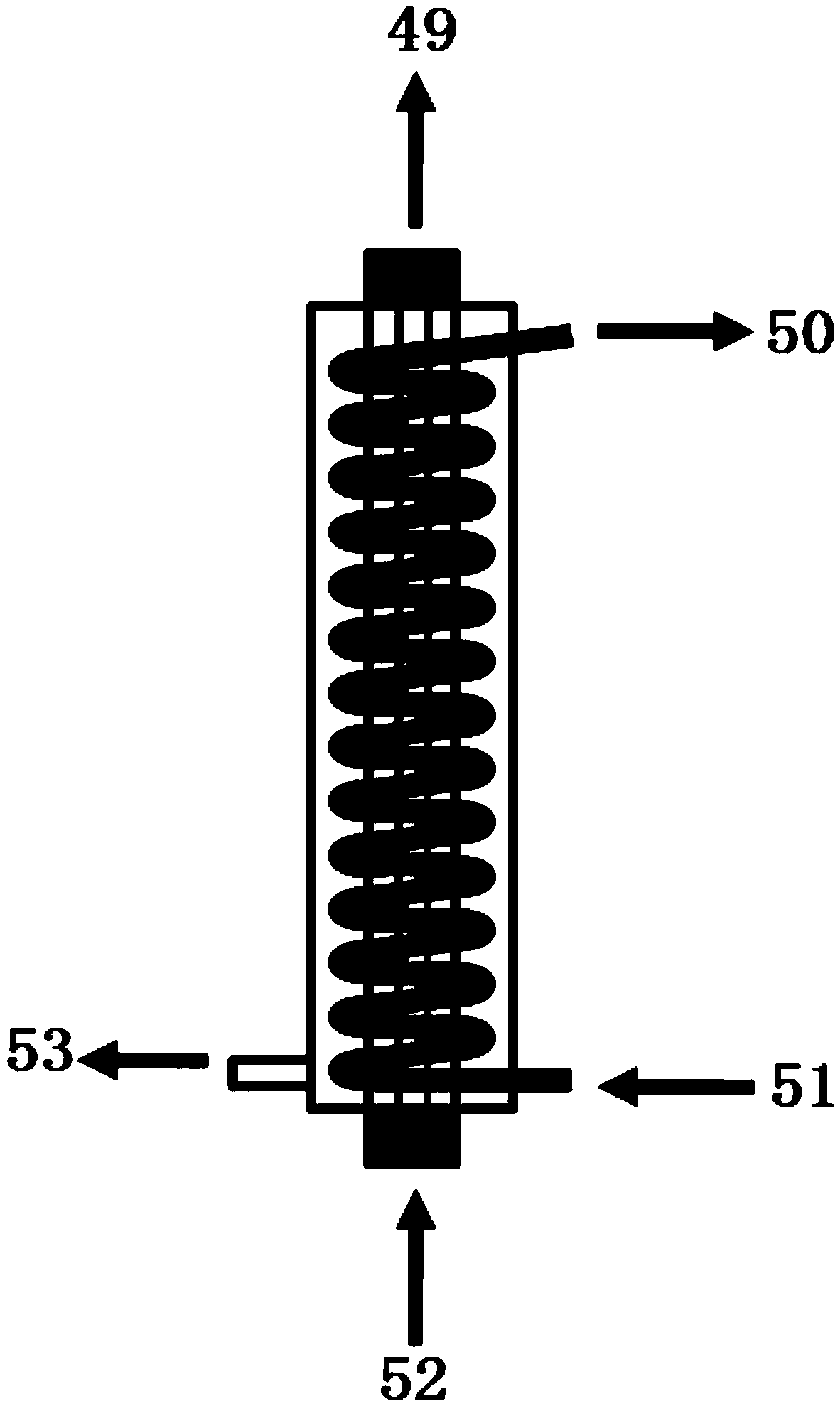

Disc type sludge dryer

InactiveCN102363550ASmall footprintEasy to useSludge treatment by de-watering/drying/thickeningSludgeElectric machine

The invention relates to a disc type sludge dryer which comprises a shell body, a main shaft system, a speed reduction motor, a transmission end bearing device, a steam end bearing device, a heating and heat insulation device and a discharge device, wherein the main shaft system and the heating and heat insulation device are contained in the shell body; the transmission end bearing device and thesteam end bearing device are respectively installed at the two ends of the main shaft system; the speed reduction motor is connected with the main shaft system through a coupling and drives the main shaft system to rotate; and the discharge device is installed at one side of the shell body adjacent to the steam end bearing device. The disc type sludge dryer has the advantages that the disc type sludge dryer is simple in structure, has small floor area and good heating and heat insulation performance, completely agitates and dries, saves energy sources and the like.

Owner:绍兴三原重工业机械有限公司

Biomass high-temperature gasifying combustion furnace

ActiveCN105114941APromote combustionPromote lysisSolid fuel combustionIndirect carbon-dioxide mitigationSocial benefitsSurface layer

The invention discloses a biomass high-temperature gasifying combustion furnace. The biomass high-temperature gasifying combustion furnace comprises a furnace body. A high-temperature gasifying combustion cavity is arranged in the furnace body. A plurality of air spraying pipes spraying towards the surfaces of combustion materials are arranged on a cavity top plate of the high-temperature gasifying combustion cavity. According to the biomass high-temperature gasifying combustion furnace, a traditional fire bar and fire grate structure is eliminated, a sealed cavity bottom plate is used as a material supporting plate for material combustion, and the materials on the cavity bottom plate start to be combusted from the surface layer; air is forcibly supplied to the surfaces of the materials through the air spraying pipes, oxygen-enriched combustion of a combustion layer is achieved, a large amount of heat is generated and blown towards the materials on the inner layer, the materials on the inner layer is subjected to thermal decomposition, and combustible gas is generated; the combustible gas is driven by wind of the air spraying pipes to move towards the cavity bottom plate and passes through the combustion layer on the material surface layer again through the rebound of the cavity bottom plate, the combustion layer is combusted rapidly under sufficient oxygen supply of the air spraying pipes, and the temperature of the highest combustion point can reach 1100-1300 DEG C, and harmful gas such as dioxin is decomposed completely at the high temperature; the biomass high-temperature gasifying combustion furnace has extremely great economic benefits and social benefits.

Owner:WEIFANG JINSIDA NEW ENERGY SCI & TECH

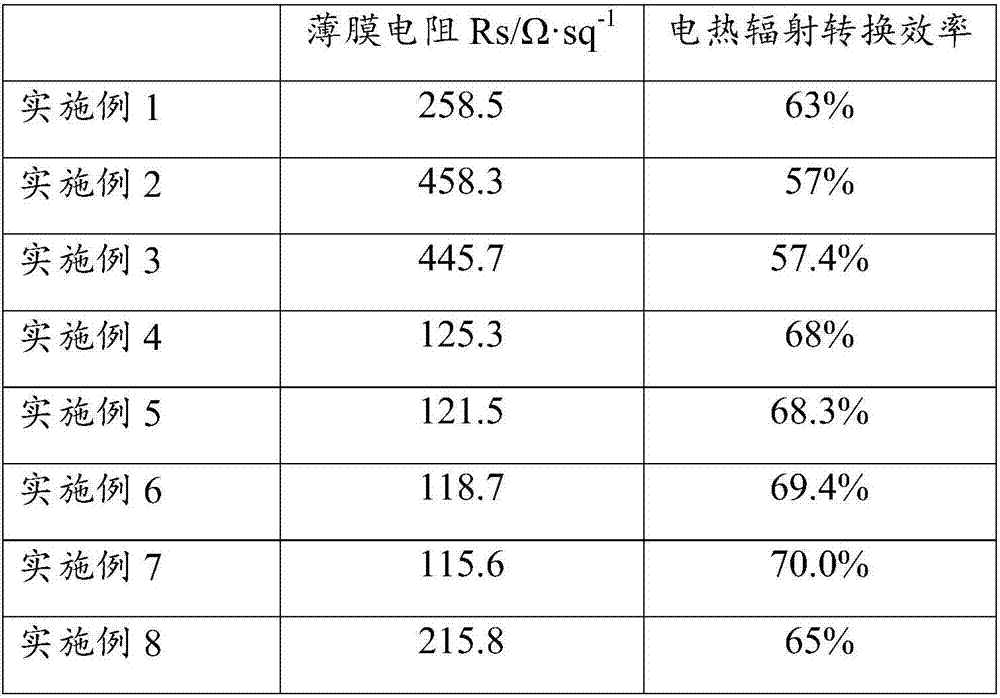

Graphene oxide modified electric heating membrane and preparation method and application thereof

InactiveCN107995704ASimple processImprove performanceHeating element materialsEpoxy resin coatingsPrinting inkPre treatment

The invention provides a graphene oxide modified electric heating membrane and a preparation method and application thereof. According to the preparation method of the graphene oxide modified electricheating membrane, the electric heating membrane comprises a conductive layer and a heating layer which are stacked; the heating layer is a layer formed by irradiating printing ink containing grapheneoxide; the printing ink containing the graphene oxide at least comprises graphene oxide, water, a free radical catching agent and a resin binder. The preparation method does not need to introduce a chemical reducing agent with relatively high toxicity and a curing agent, pretreatment is not needed, and the method has the advantages of being environmentally friendly, simple in process, high in production efficiency and the like.

Owner:山东省圣泉生物质石墨烯研究院

Coconut shell carbonization material activation furnace

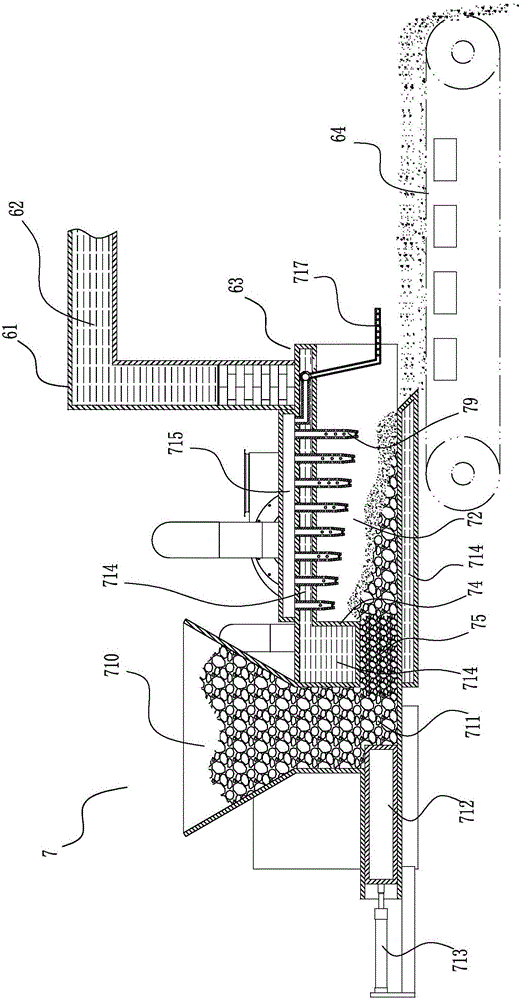

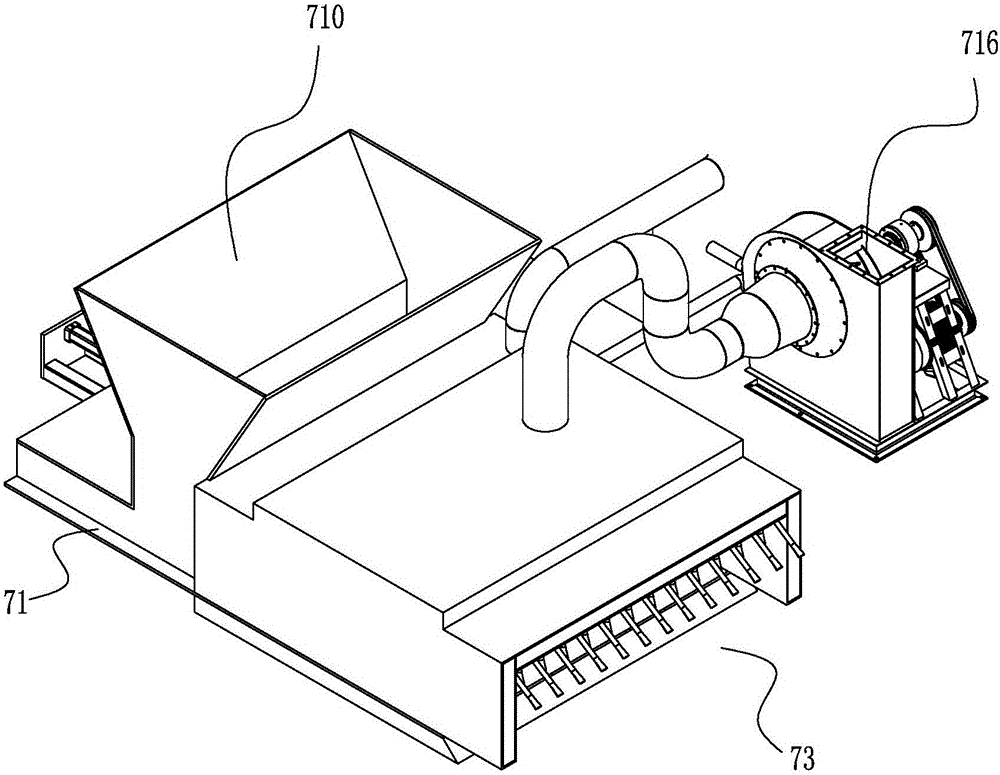

ActiveCN103523779AControl the falling speedImprove efficiencyCarbon compoundsActivated carbonCombustion chamber

The invention discloses a coconut shell carbonization material activation furnace. The coconut shell carbonization material activation furnace comprises a combustion chamber and a furnace body, wherein the furnace body comprises a furnace wall, a hearth and a cooling section, the combustion chamber and the hearth are communicated through a first gas pipeline, a carbonization section, an additional carbonization section and an activation section which are communicated with one another are arranged in the hearth, the carbonization section is communicated with a material feeding hole, a plurality of material channels are arranged in the carbonization section, a plurality of first filter screens are arranged in each material channel, the additional carbonization section is arranged at the lower part of the carbonization section, a plurality of second filter screens are arranged in the additional carbonization section, the activation section is arranged below the additional carbonization section, a wave-shaped plate body is arranged at the bottom of the activation section, a plurality of small holes are formed in the plate body, the cooling section is communicated with the activation section, and a material outlet is formed in the cooling section. The coconut shell carbonization material activation furnace is concise in structure, economical and practical, compared with the traditional activation furnace, the coconut shell carbonization material activation furnace has the activation rate increased by 20%, and besides, the quality of a coconut shell activated carbon finished product is high, and the surface of the coconut shell activated carbon finished product is not cracked.

Owner:BEIHAI HERONG ACTIVE CARBON TECH

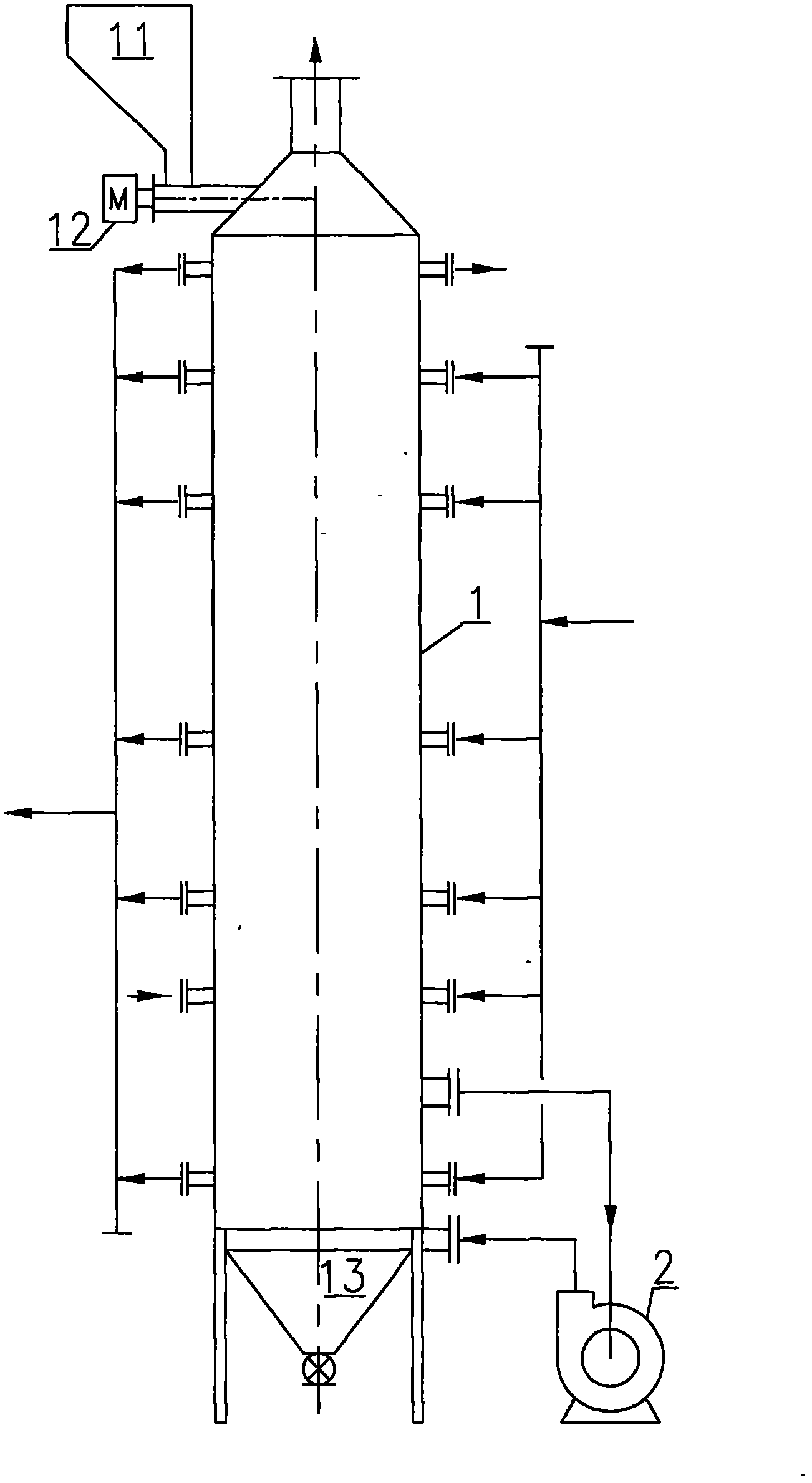

Multi-tower type ventilation air methane temperature swing adsorption concentration device

ActiveCN103301711AImprove thermal energy utilization efficiencyReduce energy consumptionGaseous fuelsDispersed particle separationDesorptionFlue gas

The invention discloses a multi-tower type ventilation air methane temperature swing adsorption concentration device. The multi-tower type ventilation air methane temperature swing adsorption concentration device comprises a ventilation air methane inlet pipe, a hot flue gas pipe, a sweeping gas inlet pipe, a ventilation air methane outlet pipe, a desorption gas outlet pipe, a sweeping gas outlet pipe and at least three adsorption towers, wherein a first pipe joint and a second pipe joint are formed in each adsorption tower, and a methane adsorption device is arranged between the first pipe joint and the second pipe joint in each adsorption tower. By virtue of a multi-adsorption-tower structure, the quantity of the combined adsorption towers can be selected according to the flow size of ventilation air; according to the characteristics of normal-temperature methane adsorption and high-temperature methane desorption of the methane adsorption devices, ventilation air methane can be concentrated through a temperature swing adsorption process; the methane desorption can be realized through waste heat flue gas of a subsequent heat storage oxidization device, and a system is low in energy consumption. Each adsorption tower in the device has cyclic functions of normal-temperature adsorption, heating desorption and cooling regeneration. The whole device is high in utilization rate and high in methane concentration capacity.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

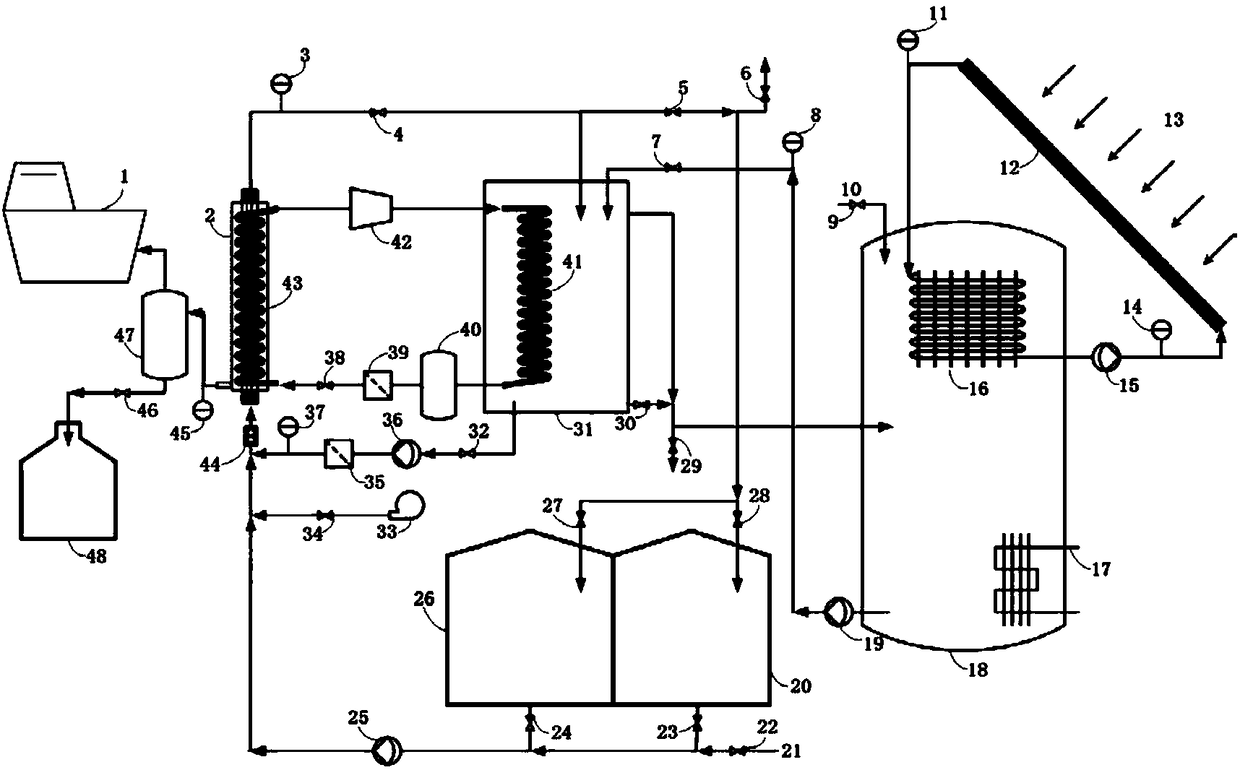

A solar energy film distillation system combining heat pump technology

ActiveCN108622982AEfficient recyclingImprove thermal energy utilization efficiencyGeneral water supply conservationHeat recovery systemsElectricityDistillation

The invention discloses a solar energy film distillation system combining heat pump technology, and is aim at utilizing a solar energy heat-collecting device to heat the raw water to reach the purposethat the energy consumption of the film distillation process is reduced as a whole. The full recovery of water vapor heat of transformation is realized by the application of the heat pump in the system, and the heat efficiency of the process is improved. Especially in the condition that auxiliary heating is performed by utilizing an electric heating rod in need, the energy saving effect that theheat pump can achieve is more obvious. The film distillation component and an evaporator of the heat pump system can be organically integrated by the heat pump-solar energy film distillation device, the integration level of the system is improved, and the operation flow is simplified and the other running costs are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biomass high-temperature gasification boiler burner

ActiveCN105674243ABurn fullyRelease fullySolid fuel combustionAir/fuel supply for combustionSlagBiomass

The invention discloses a biomass high-temperature gasification boiler burner. The biomass high-temperature gasification boiler burner comprises a furnace body; a furnace cavity is formed in the furnace body; multiple gasification combustion assisting air distribution pipes injected to surfaces of combustion materials are arranged on the side wall of the furnace cavity; a reciprocating fire grate, with a slag outlet end positioned in a boiler hearth, is arranged at the bottom of the furnace cavity; an injecting combustion channel, inserted in the boiler hearth, is arranged at the front end of the furnace cavity; and a smoke stop combustion assisting air supply device for forming an air curtain in the injecting combustion channel is arranged on the side wall of the injecting combustion channel. The biomass high-temperature gasification boiler burner uses the characteristic of hot air upwards moving for building a similarly closed biomass high-temperature gasification combustion environment in the furnace body; the highest combustion point temperature can reach 1200-1300 DEG C; all harmful gas, such as dioxin, is totally decomposed; and the biomass high-temperature gasification boiler burner greatly improves the heat energy use efficiency of materials, largely reduces the material combustion smoke discharge, improves the prior art in a breakthrough manner, and provides full guarantee for total resource utilization of the materials, in particular biomass.

Owner:刘振亮

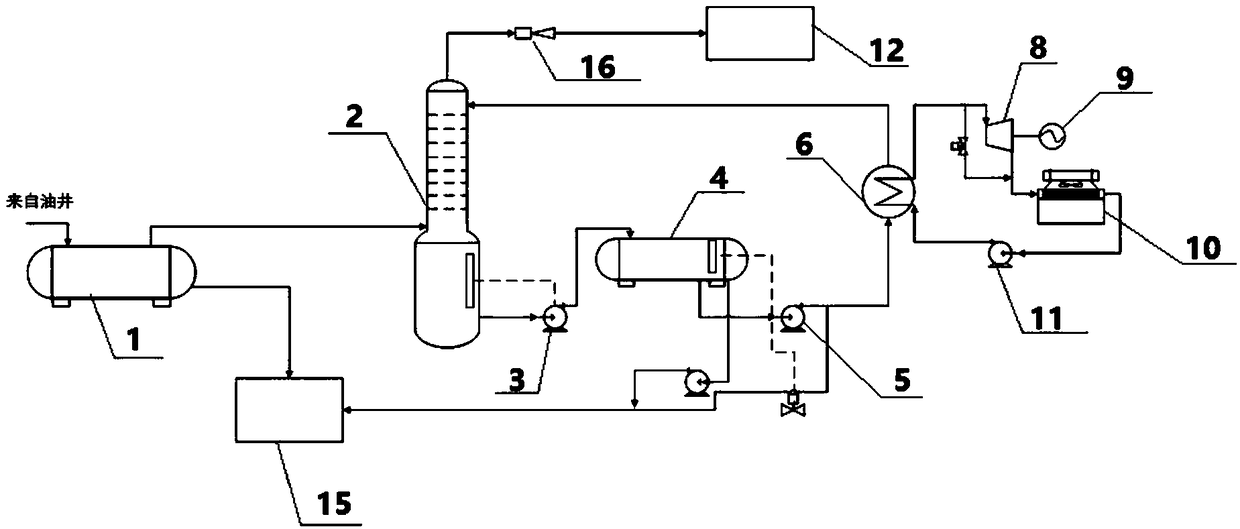

Oil field high-temperature produced liquid waste heat recovery and power generation system

PendingCN108386242ASolve pollutionSolve the technical problem of heat wasteFluid removalSteam engine plantsLiquid wasteEngineering

The invention belongs to the technical field of petroleum exploitation and particularly relates to an oil field high-temperature produced liquid waste heat recovery and power generation system. By adopting the oil field high-temperature produced liquid waste heat recovery and power generation system, high-temperature produced liquid is separated into a low-temperature produced liquid and an oil-containing waste steam through a normal-pressure separator; a high-temperature condensate is produced with the oil-containing waste steam through a spray tower, and a low-temperature noncondensable gasis separated out; the high-temperature condensate is separated into an oil portion and a water portion through an oil-water separator, and the water portion is conveyed to a heat exchanger to performheat exchange with an organic medium gas of an ORC power generation system and is then conveyed to the spray tower for circulating utilization after being cooled by the heat exchanger; high-temperature and high-pressure organic medium gas obtained with heat exchange does work in an expander, and the expander drives the power generator for power generation; and a low-temperature and low-pressure organic medium liquid which is produced with the high-temperature and high-pressure organic medium gas finally can be reused to the heat exchanger. The technical scheme of the invention solves the problems of pollution and heat waste caused by the oil field high-temperature produced liquid in the temperature and pressure lowering process in the prior art.

Owner:XINJIANG DUNHUA PETROLEUM TECH CO LTD

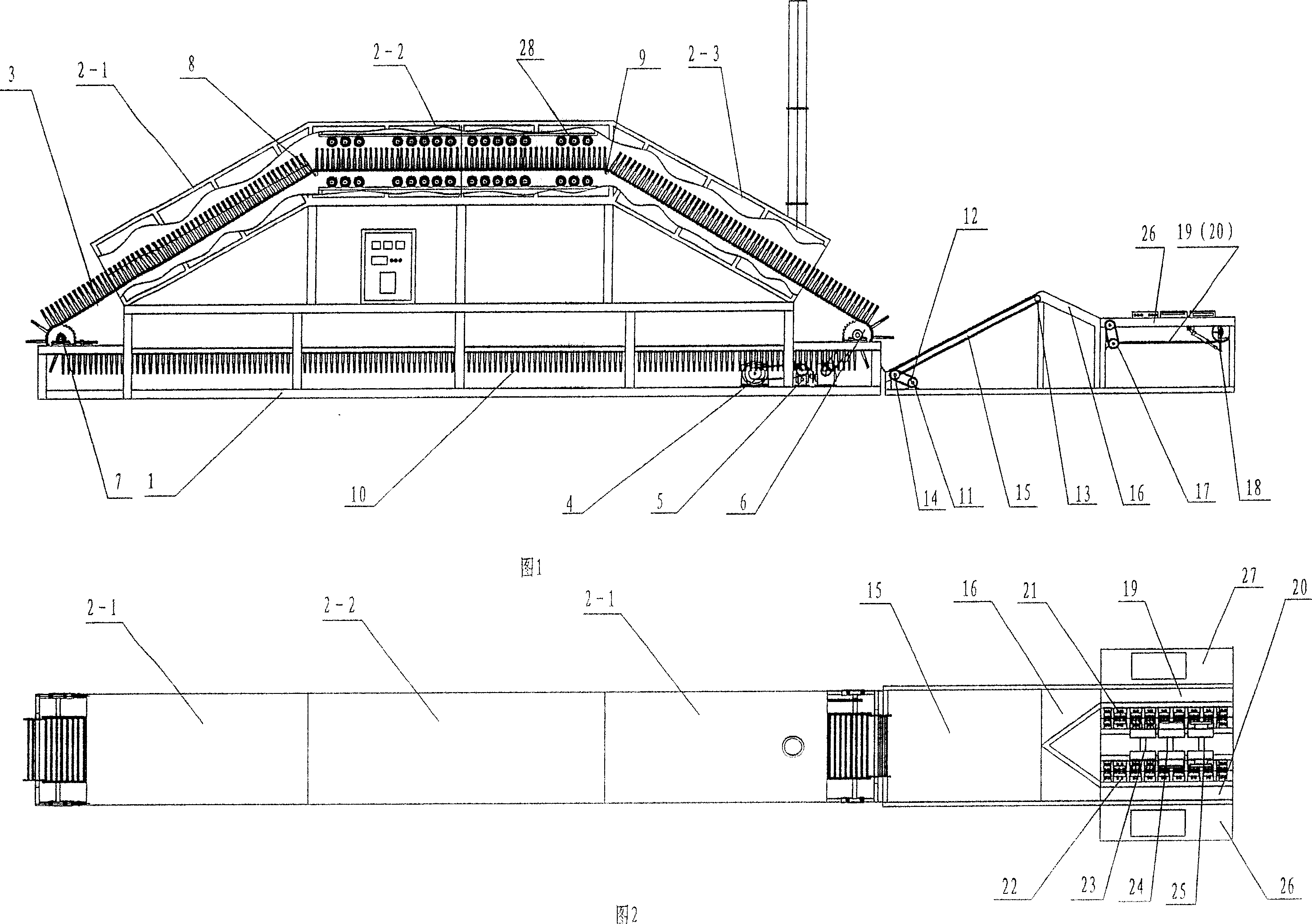

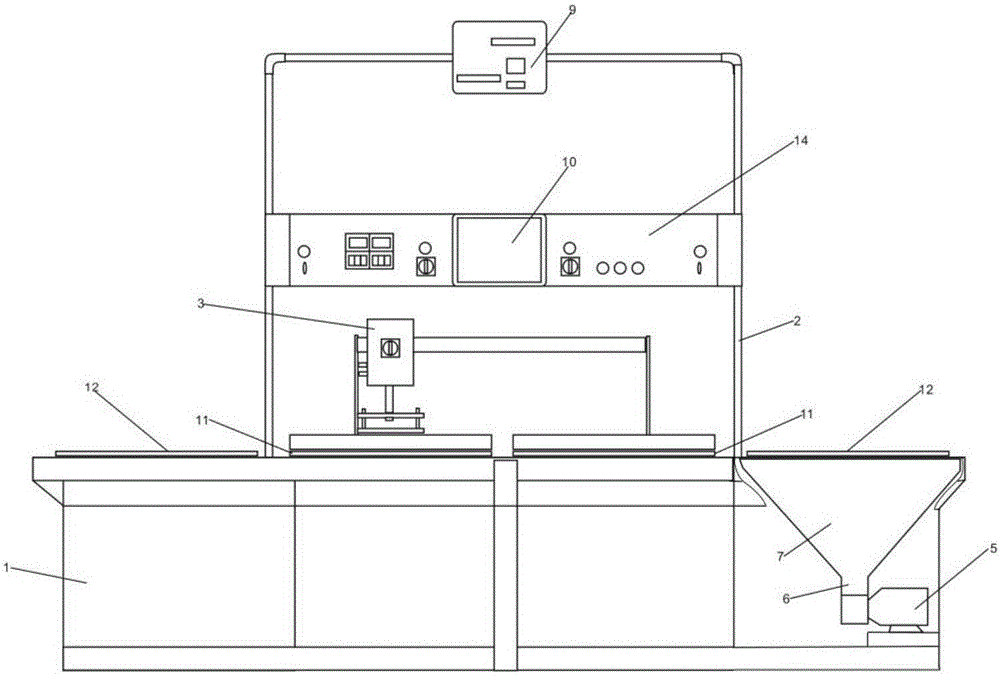

Baking machine for energy-saving tube

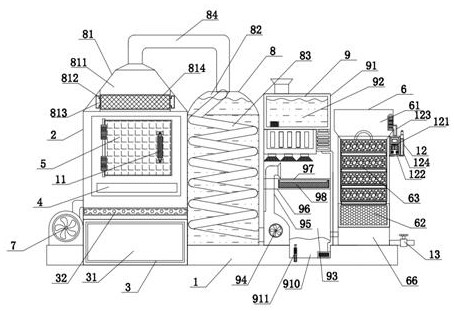

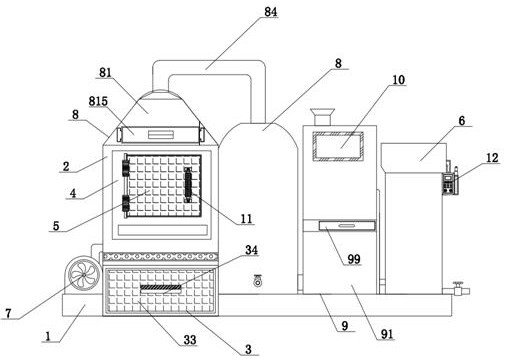

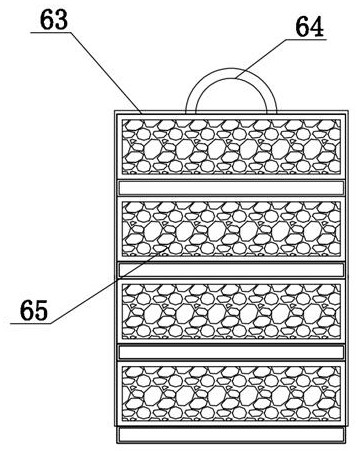

InactiveCN101000847AImprove thermal energy utilization efficiencyReduce consumptionLuminescent coatings applicationThermal energyTubing types

A baker of energy-saving lamp tube type is prepared as setting a roasting box at top of body-frame, arranging middle part of baking box to be at highest point and setting two ends of baking box to be near to ground gradually, arranging ring form of chain conveying unit in baking box on body-frame, firm-jointing lamp tube hanging frame on ring form of chain conveying unit.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

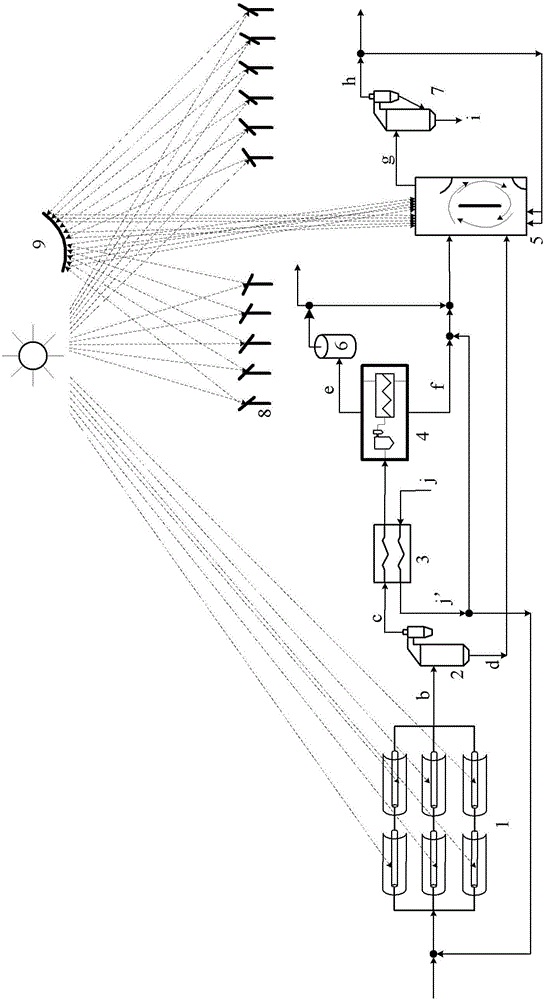

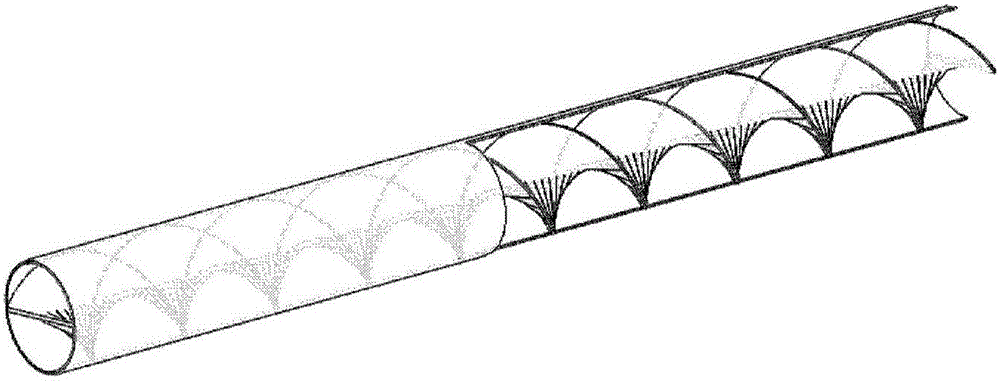

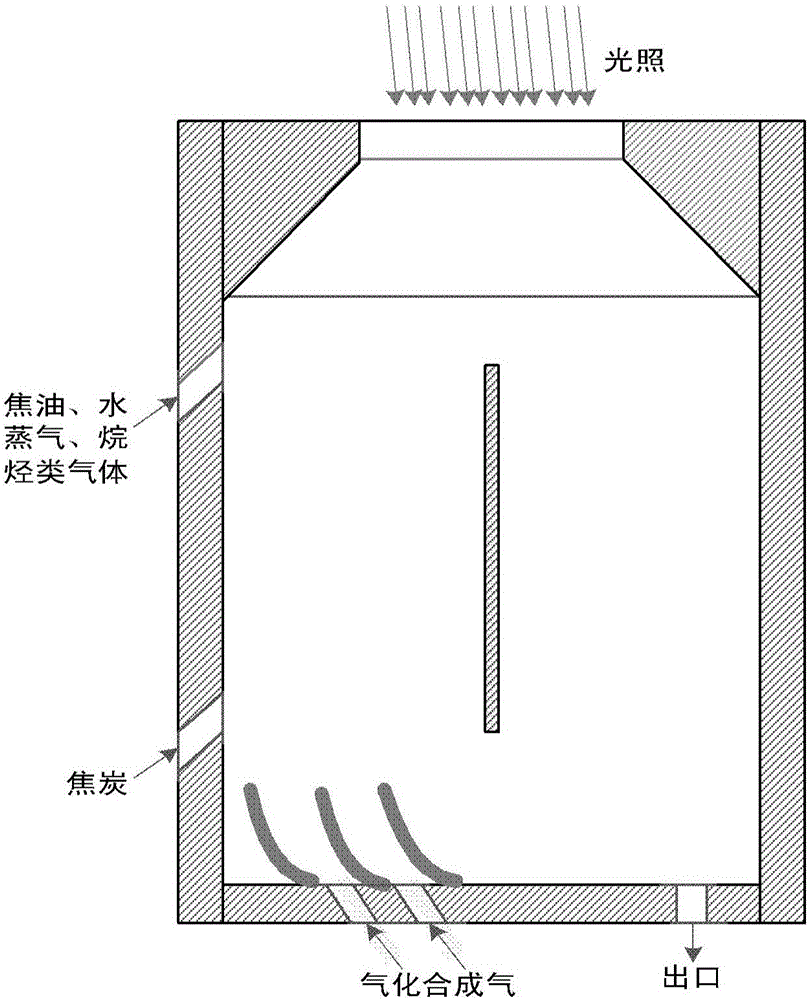

Biomass-solar thermal chemical utilization system capable of realizing multi-product output

InactiveCN105838450AReduce irreversible lossGood spotlightSolar heating energyEnergy inputThermal energySolar power

The invention discloses a biomass-solar thermal chemical utilization system capable of realizing multi-product output. The system comprises a slot-type medium temperature solar pyrolysis absorption reactor, a coke separator, a waste heat recoverer, a tar condensation purifier, a high-temperature solar fluidized bed gasification reactor, an oil storage tank, a cyclone separator, a heliostats field and a hyperboloid reflector. By the aid of the system, high-temperature concentrating solar power is utilized to drive biomass to be subjected to pyrolysis and gasification reaction sequentially and independently according to the principle of 'parallel temperature', medium-temperature thermal energy at the temperature below 450 DEG C obtained by a parabolic slot-type equal line-focusing solar thermal collection device is utilized fully to drive the biomass to be subjected to pyrolytic reaction, carbon residue, tar and the like generated by reaction are subjected to gasification by utilizing high-temperature thermal energy at the temperature over 800 DEG C generated by a high-temperature solar concentrating thermal collection device, the concentrating and thermal collection process of the system is optimized, gasification efficiency of the biomass is improved, and tar content in gasification syngas is lowered.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Commercial gas stove waste heat utilization device

InactiveCN103375828AEfficient use ofHigh thermal efficiencyLighting and heating apparatusWater heating stoves/rangesWater storageThermal insulation

The invention relates to a commercial gas stove waste heat utilization device which is composed of a water-jacket-type hearth, a water storage box, a hearth water inlet pipe, a hearth water outlet pipe, a water outlet valve, a ball float valve and a cold water inlet, wherein the partial waste heat which is not utilized by the cooking among the heat generated by gas combustion is absorbed by water in a hearth through the water-jacket-type hearth; after the water is heated in the hearth, the water automatically flows from the hearth water inlet pipe into the hearth water outlet pipe; the hearth water outlet pipe is connected with a hot water box; the hearth water inlet pipe is communicated with a cold water box; the upper parts of the hot water box and the cold water box are separated by a thermal-insulation baffle plate; the bottoms of the hot water box and the cold water box are communicated. Thus, under the flowing of the water in the hearth, the water in the cold water box is driven to flow into the hearth, so that the water in the hearth flows into the hot water box; the relatively cold water at the bottom of the hot water box flows into the cold water box. Therefore, the water in water boxes is heated circularly. As a result, the heat scattered on the hearth during the gas combustion is collected effectively.

Owner:金元革

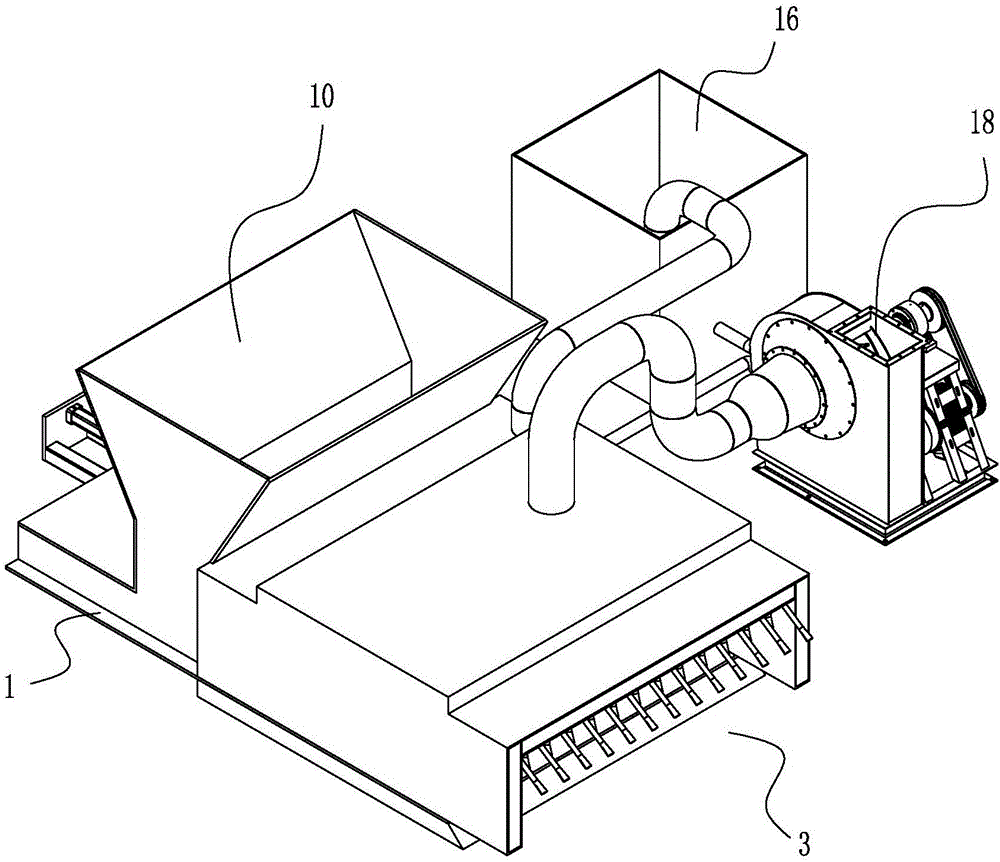

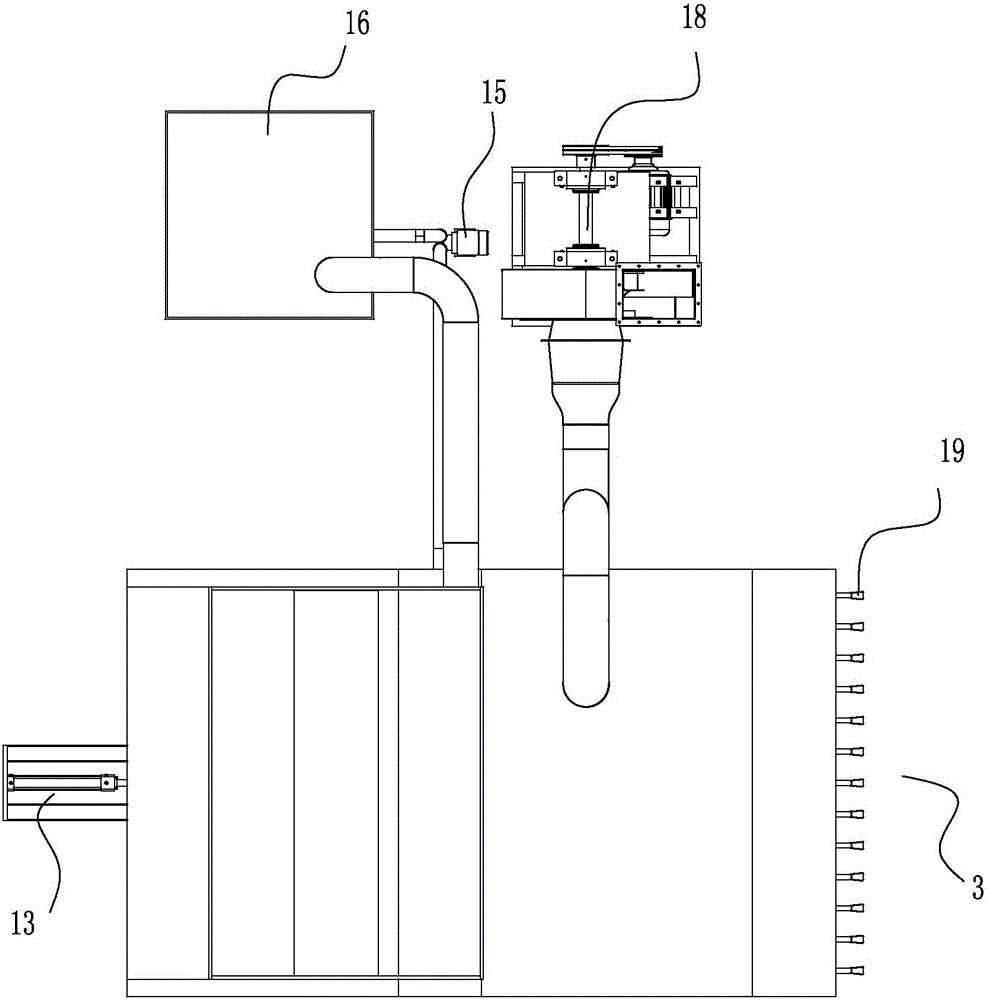

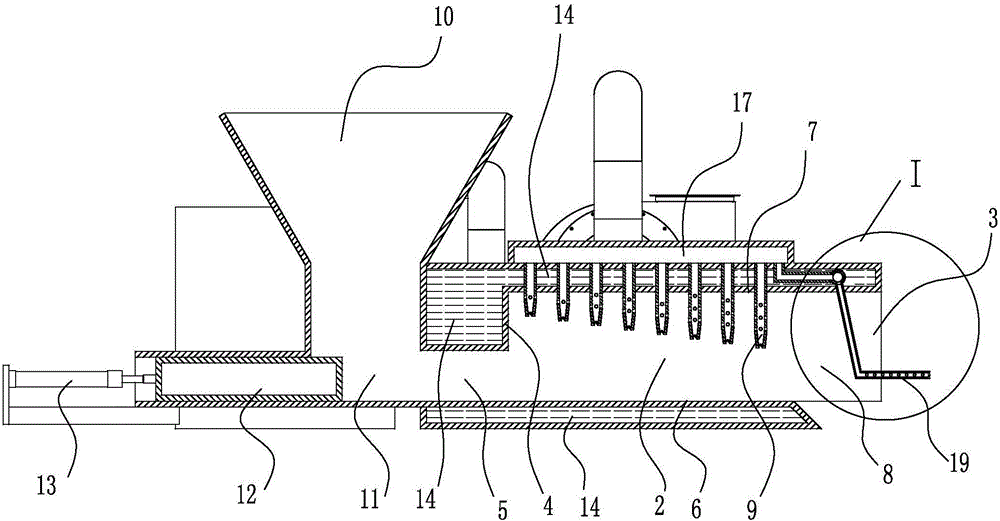

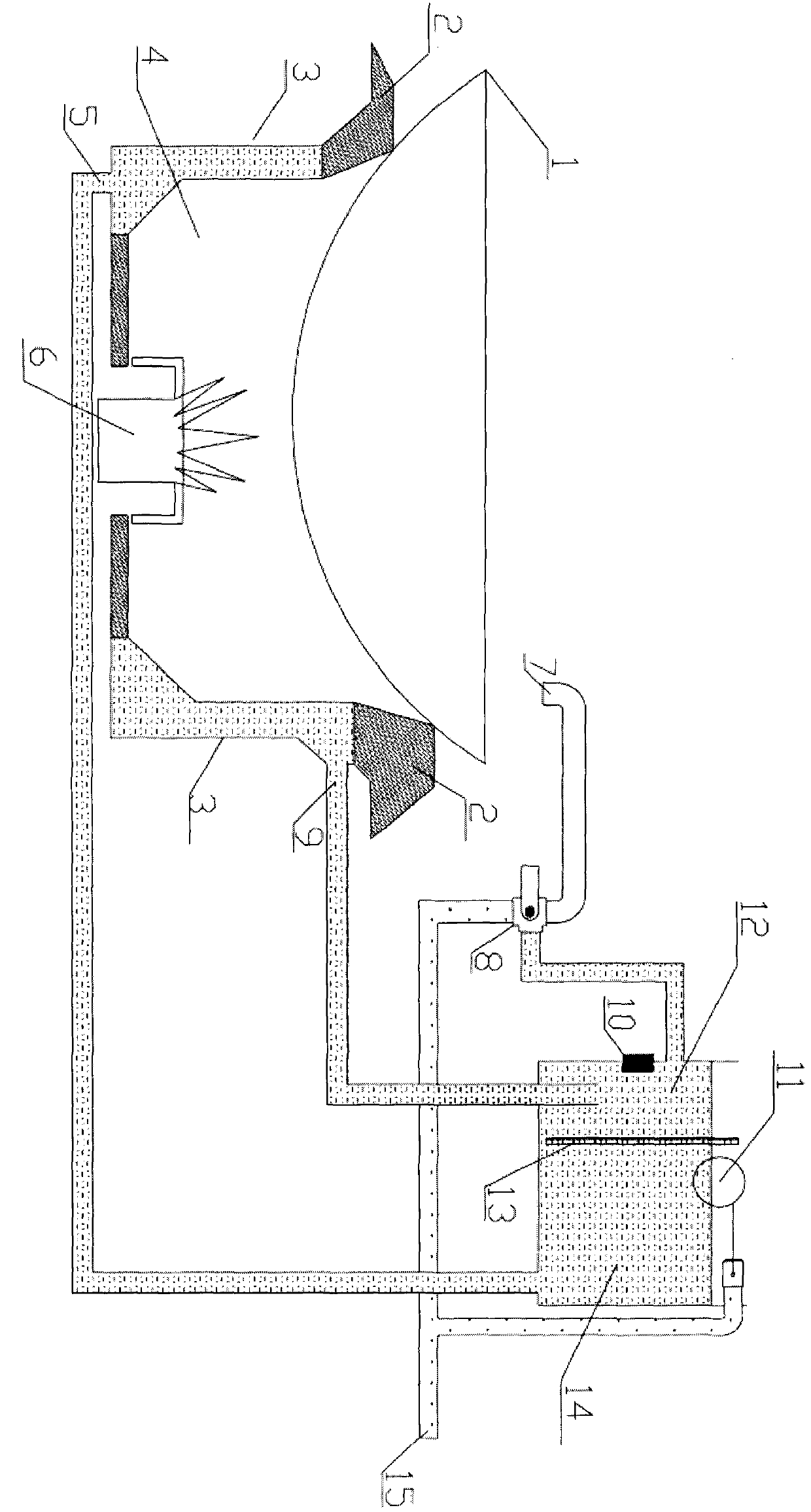

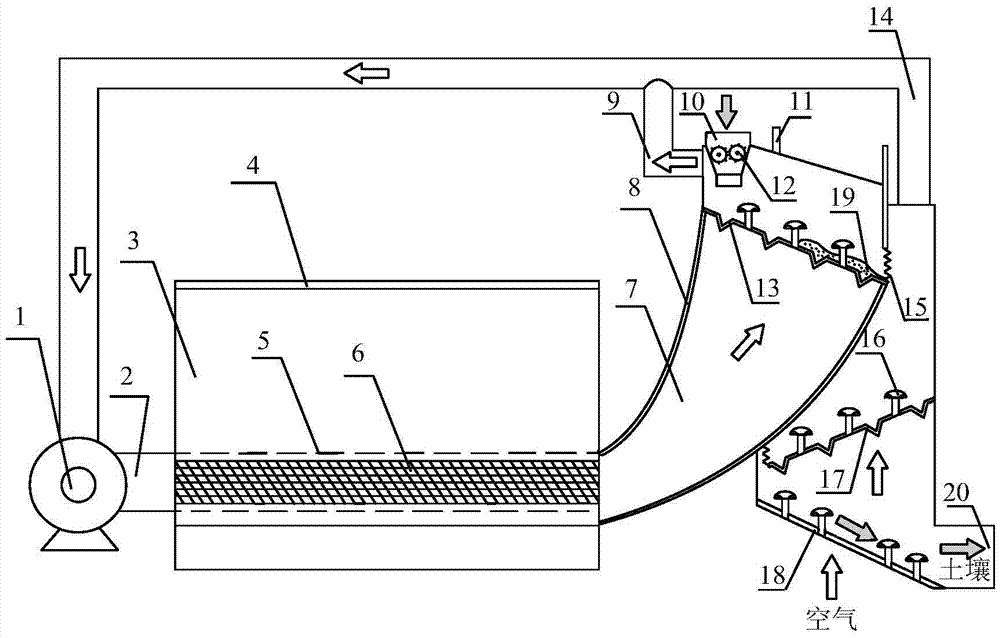

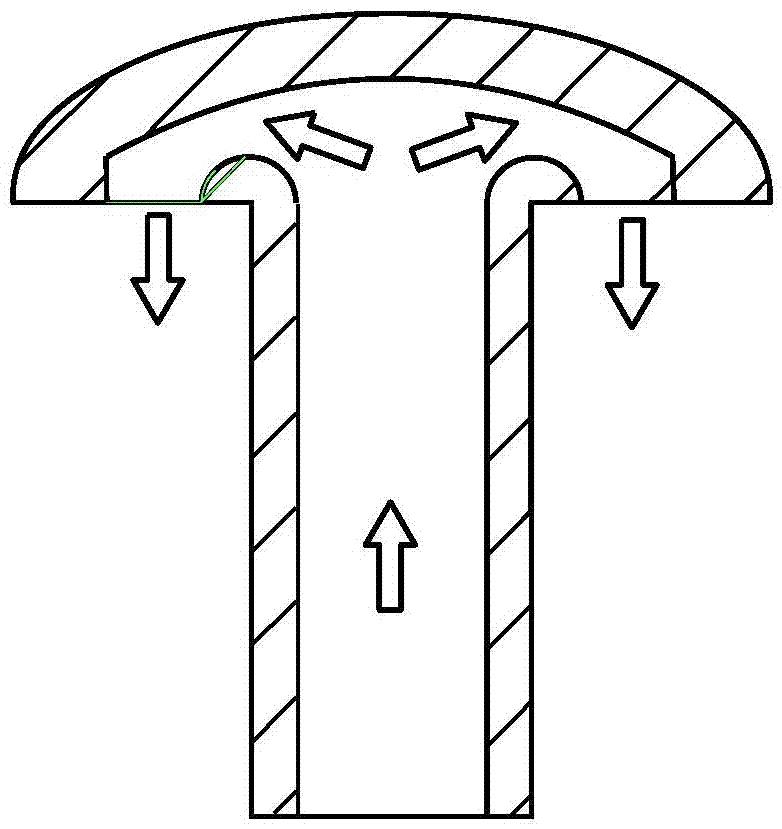

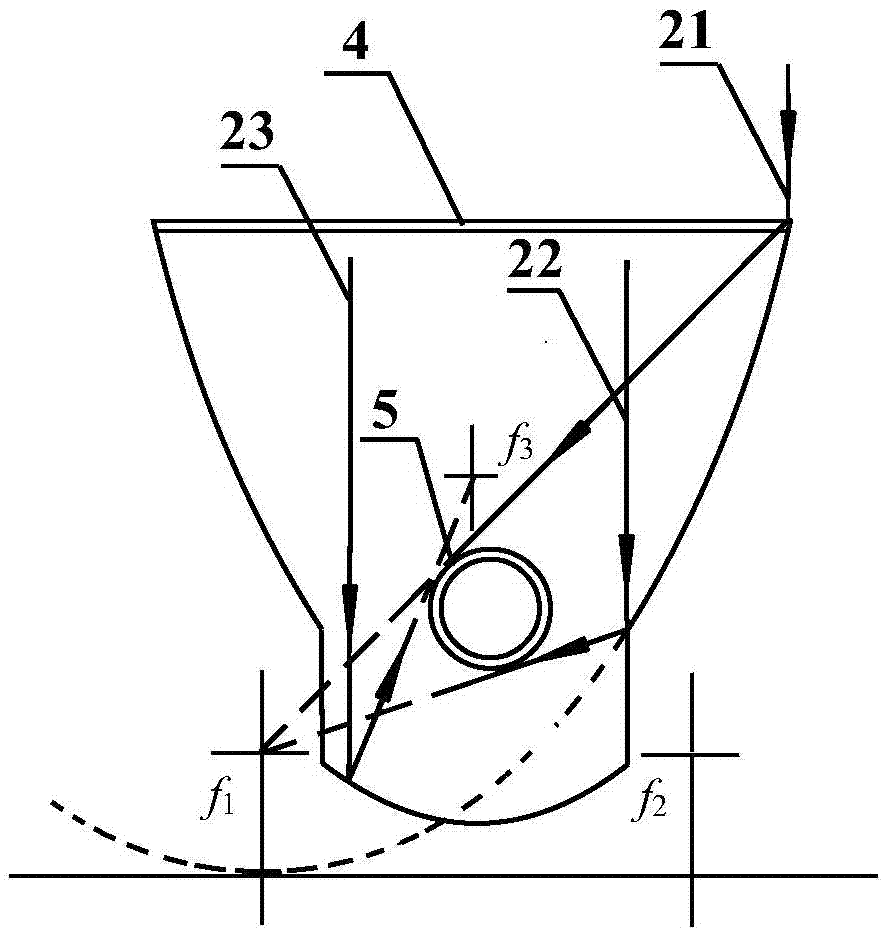

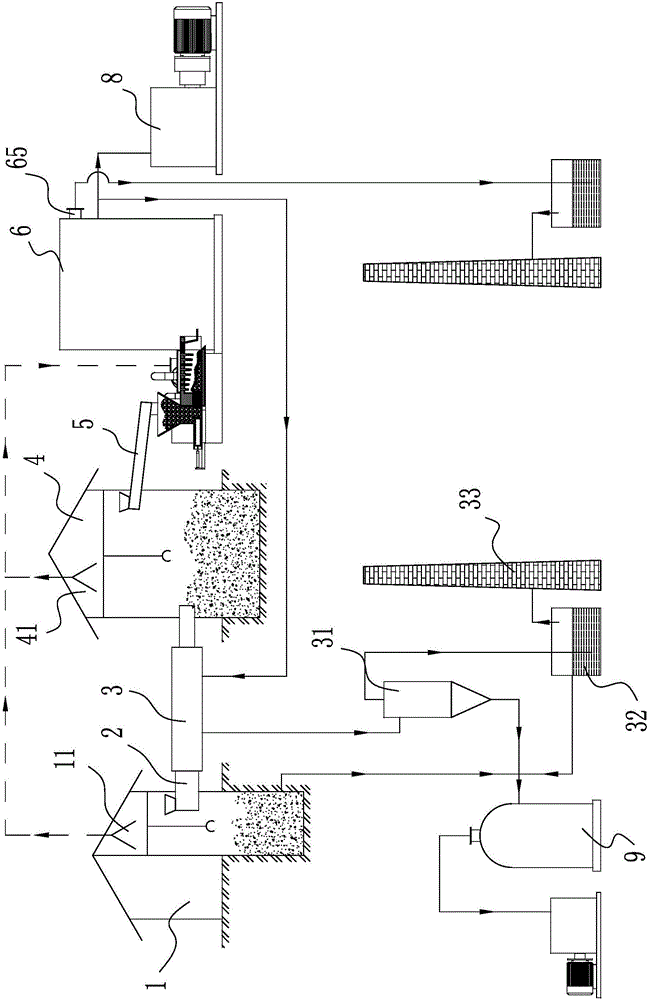

Light gathering and heat returning type soil disinfecting and repairing device

ActiveCN105432176AWon't clogRealize automatic slidingSoil lifting machinesRenewable energy machinesSoil treatmentGlass cover

The invention belongs to a solar application device, and particularly relates to a soil treatment device. A light gathering and heat returning type soil disinfecting and repairing device comprises an induced draft fan (1), an air outlet flue (2), a groove type multi-hook-face solar condenser (3), a glass cover plate (4), a double-layer glass vacuum pipe (5), a ventilation heat absorbing body (6), an insulating layer (8), a hot air cavity (7), a first-level metal heat exchange plate (13), a feeding hopper (10), a mushroom-shaped ventilation channel (16), a tail air backflow channel (9), an exhaust pipe (11), a natural vibration spring (15), a second-level metal heat exchange plate (17), a soil sliding conveying belt (18), a feeding air channel (14) and a discharging port (20). Soil is heated through high-temperature air heated through solar energy, then disinfecting and killing of injurious insects, pathogenic bacteria and weed seeds in the soil and separation of volatile organic compounds in the soil are carried out, the fossil energy does not need to be consumed, pollution to the soil is avoided, and food safety is effectively guaranteed.

Owner:INNER MONGOLIA UNIV OF TECH

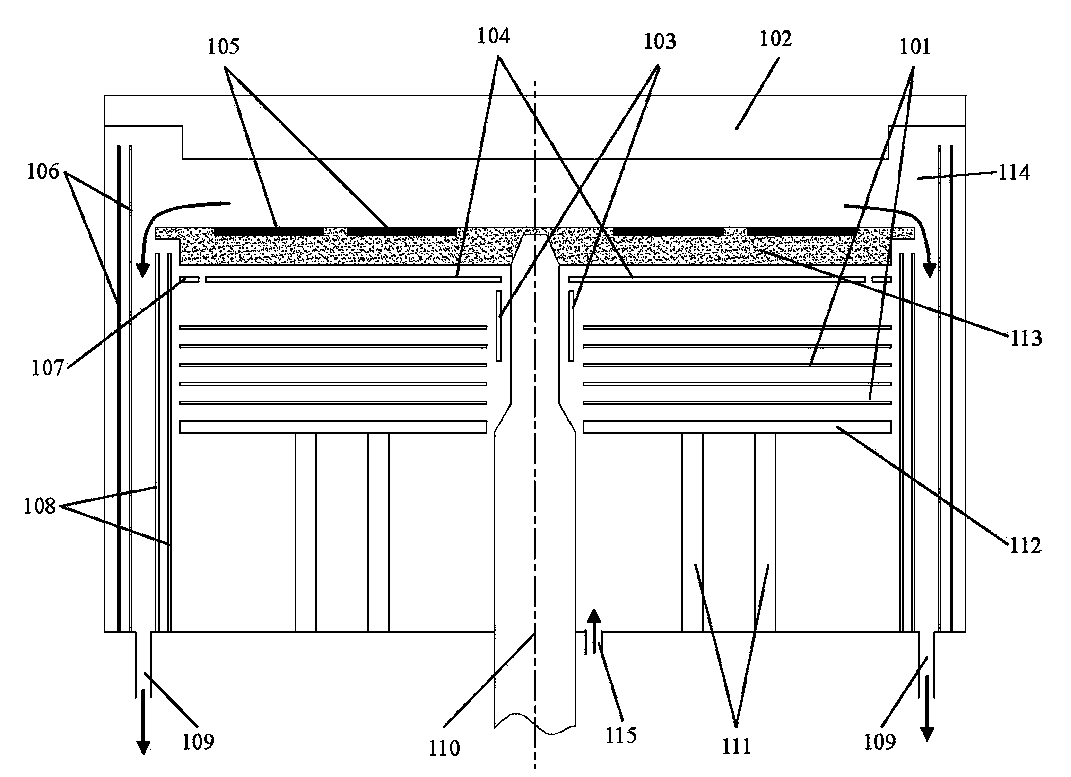

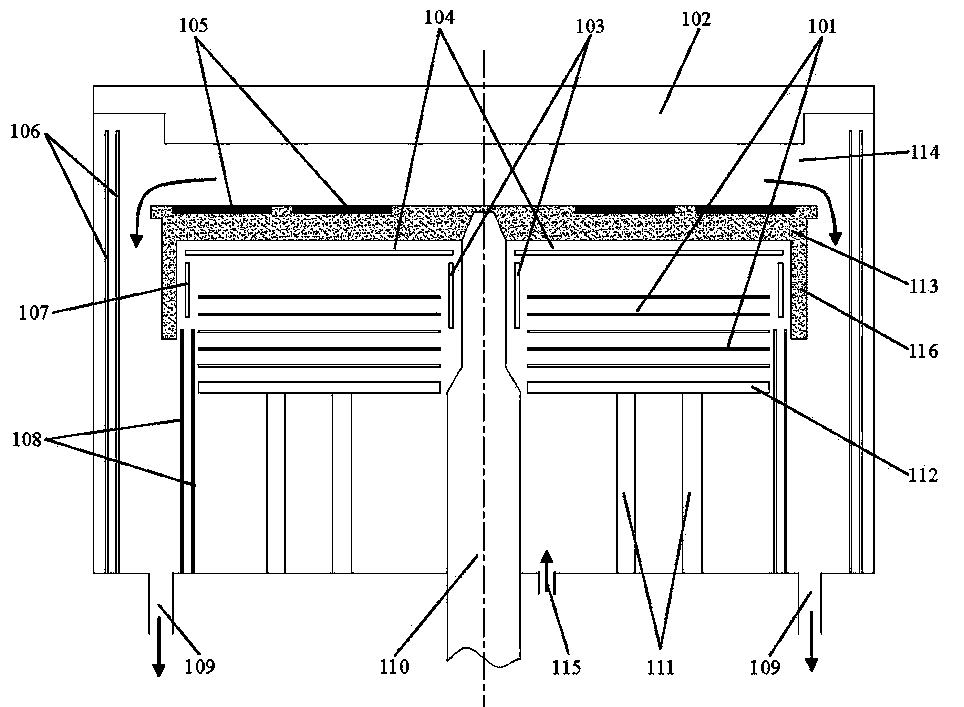

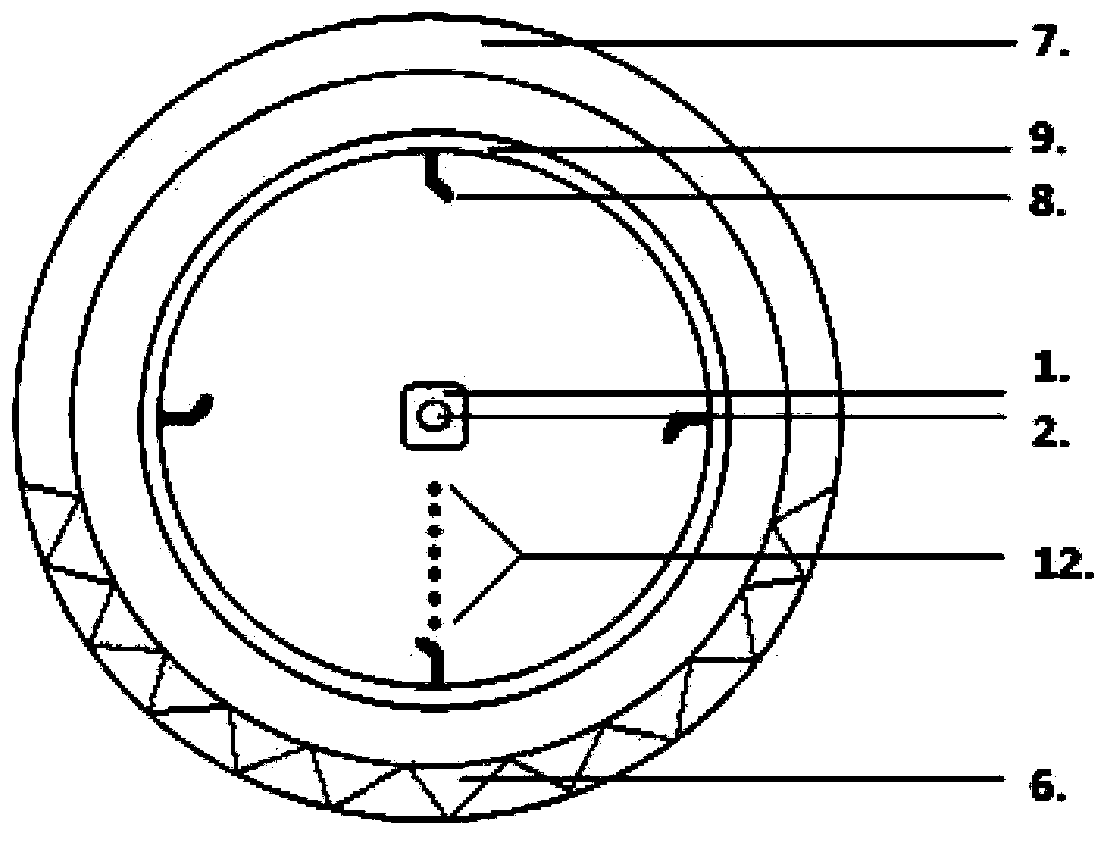

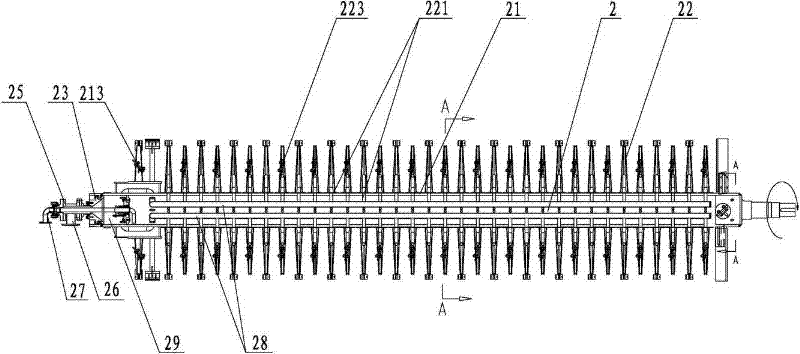

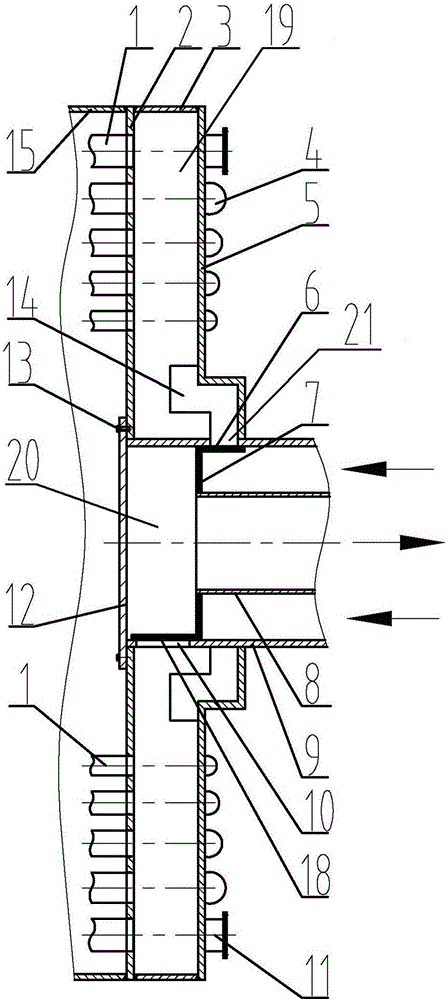

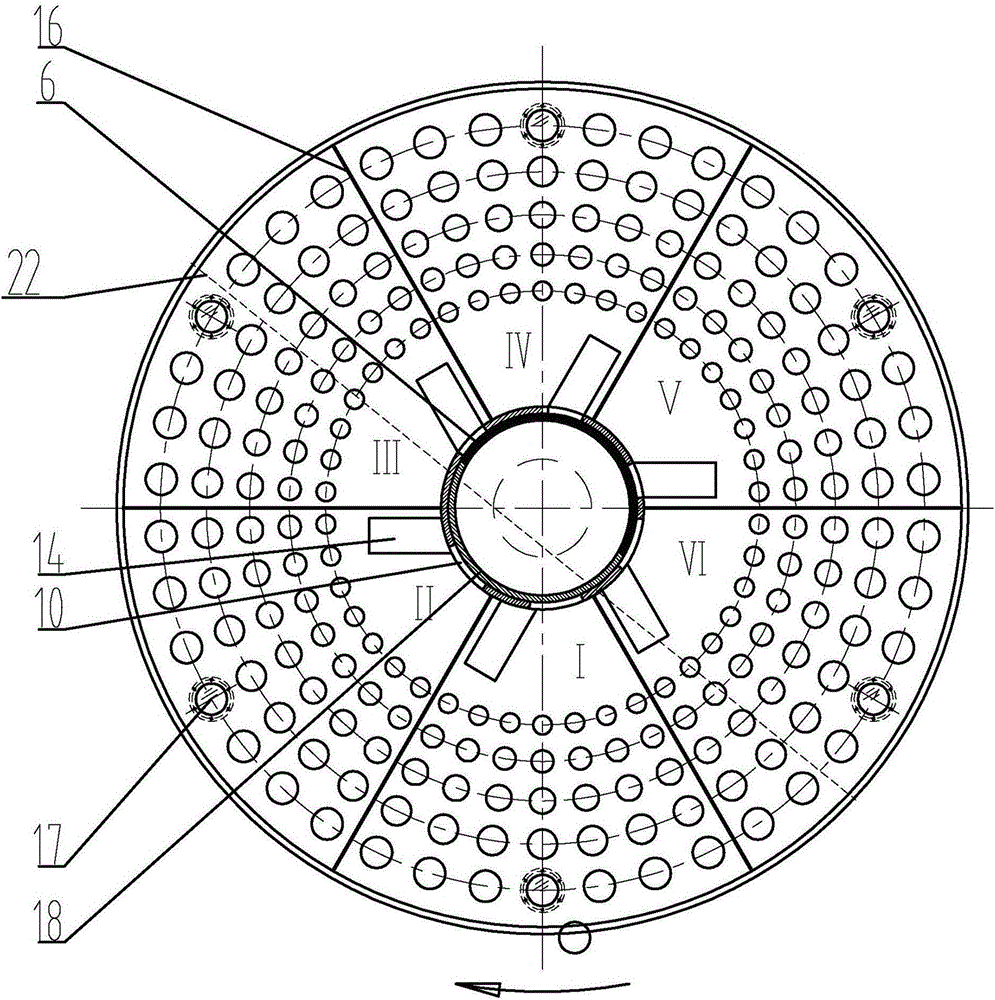

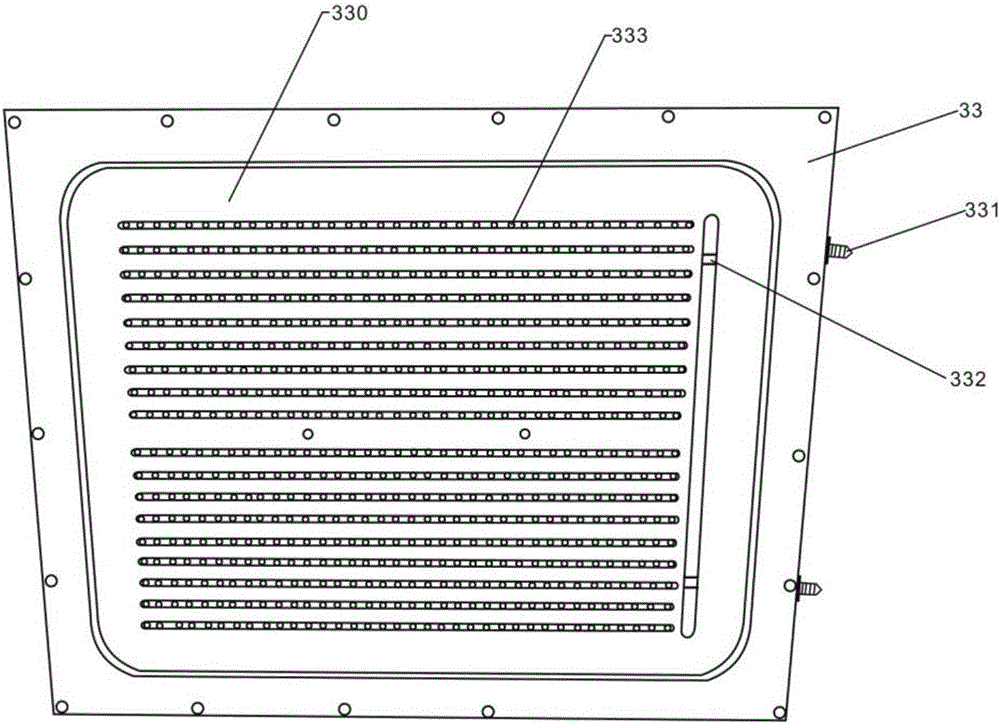

Drying machine steam chamber structure capable of adjusting steam feeding and steam shutting regionally

InactiveCN105972986AImprove heat transfer efficiencyImprove thermal energy utilization efficiencyHeating arrangementThermal energyEngineering

The invention relates to a steam chamber structure of a steam rotary type drying machine, in particular to a drying machine steam chamber structure capable of adjusting steam feeding and steam shutting regionally. The drying machine steam chamber structure comprises a closed cavity with heat exchange pipes, fan-shaped chambers formed by dividing the cavity through steam chamber division plates communicate with a steam supply channel through respective steam inlets and communicate with a drainage device through respective water outlet holes, a steam-blocking semi-ring plate is arranged inside the steam supply channel, and a water-blocking semi-ring plate is arranged inside the drainage device. In the rotation process of a cylinder body of the drying machine, the steam inlets of the fan-shaped chambers where the heat exchange pipes located above a material surface are located are blocked by the steam-blocking semi-ring plate, the water outlet holes of the fan-shaped chambers where the heat exchange pipes located above the material surface are located are not blocked, the water outlet holes of the fan-shaped chambers where the heat exchange pipes located below the material surface are located are blocked by the water-blocking semi-ring plate, and the steam inlets of the fan-shaped chambers where the heat exchange pipes located below the material surface are located are not blocked. According to the steam chamber structure, the function of feeding steam to the chambers corresponding to the heat exchange pipes in the material coverage area inside the cylinder body of the drying machine and stopping feeding steam to the other chambers is realized, the heat exchange efficiency of the drying machine is greatly improved, and the utilization efficiency of the heat energy of the high-temperature steam is greatly improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

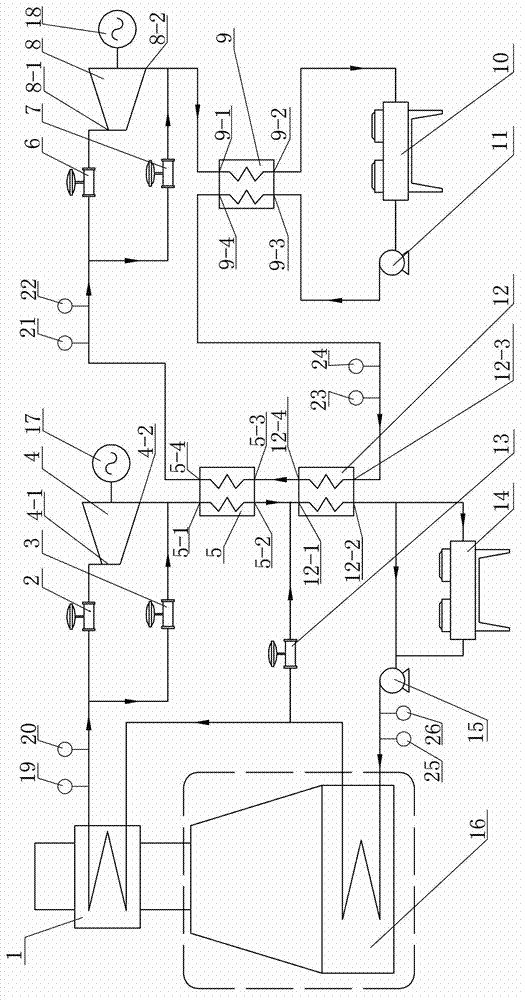

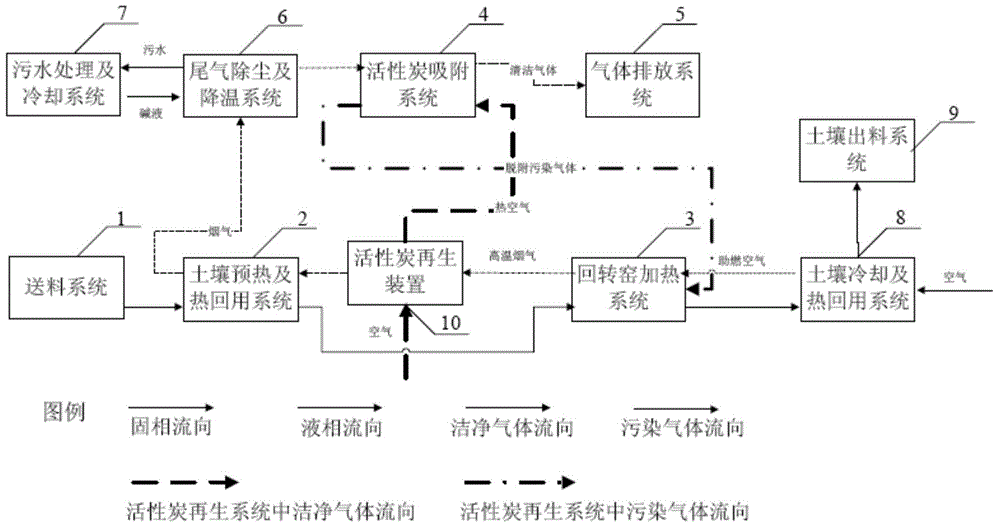

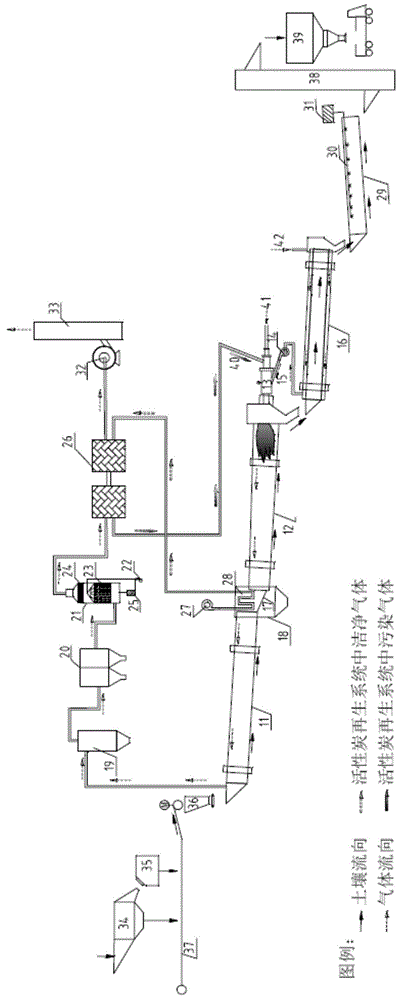

An energy-saving thermal desorption remediation system for organic polluted soil

The invention relates to an energy-saving type thermal-desorption repairing treatment system for organic polluted soil and aims at providing a system for thermal-desorption repairing treatment of the organic polluted soil, which can recycle waste heat of the system fully and save resources. The energy-saving type thermal-desorption repairing treatment system comprises a feeding system, a soil preheating and heat recycling system, a rotary kiln heating system, a soil cooling and heat recycling system, a soil discharging system, a tail-gas dust removing and temperature reducing system, a sewage treatment and cooling system, an active-carbon absorbing system, an active-carbon regeneration device, a gas exhausting system and a network monitoring system.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

High-temperature rubbish gasification power generation system

ActiveCN105114956AImprove thermal energy utilization efficiencyBreakthrough improvementBioreactor/fermenter combinationsBiological substance pretreatmentsThermal energyRefuse collection

The invention discloses a high-temperature rubbish gasification power generation system. The high-temperature rubbish gasification power generation system comprises a rubbish collection stock bin, a rubbish crusher, a rubbish drying machine, a dried rubbish stock bin, a high-temperature gasification spray-burning boiler and a steam turbine power generation set. According to the high-temperature rubbish gasification power generation system, an efficient high-temperature gasification burning environment is established in the high-temperature gasification spray-burning boiler, oxygen-enriched combustion of the surfaces of materials is achieved by forcibly supplying air to the surfaces of the materials, a high-temperature burning face layer is formed, and a great amount of heat is generated and blown to the inner layer of the materials, so that gasification burning is more violent and faster; the temperature of the highest burning point can reach 1100-1300 DEG C, and all macromolecule functional groups generated after gasification and all harmful gas, such as dioxin, generated after gasification are heated, gasified and decomposed repeatedly and participate in burning. The heat utilization rate of the materials is greatly increased, the breakthrough improvement on the boiler combustion heating principle is achieved, and complete recycling of rubbish is sufficiently guaranteed; in addition, emission is environmentally friendly, and the high-temperature rubbish gasification power generation system has great economic benefits and social benefits.

Owner:刘振亮

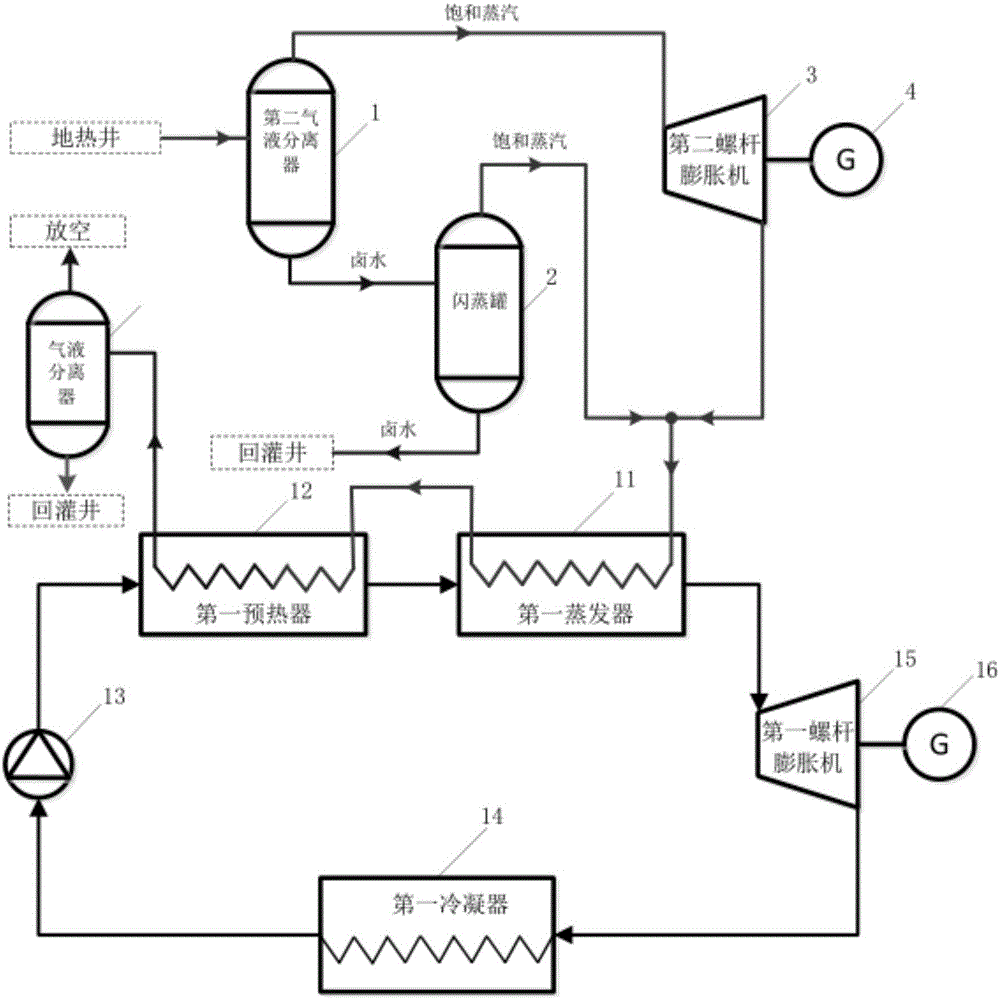

Geothermal well opening power station system and power generation method thereof

InactiveCN105736263AImprove utilization efficiencyTo achieve hierarchical utilizationGeothermal energy generationGeothermal systemsVapor–liquid separatorPower station

The invention discloses a geothermal well opening power station system and a power generation method thereof. The geothermal well opening power station system comprises a second gas-liquid separator, a flash evaporation tank, a second screw expander, a second electric generator and a steam ORC system; the second screw expander is connected with the second electric generator; the first end of the second gas-liquid separator is connected with the second screw expander, and the second end of the second gas-liquid separator is connected with the flash evaporation tank; saturated steam enters the second screw expander, and high-temperature and high-pressure brine enters the flash evaporation tank; steam obtained by flash evaporation is mixed in an outlet of the second screw expander and then enters the steam ORC system through a first evaporator, and the brine obtained by flash evaporation is conveyed to a recharge well through a first conveying mechanism and is injected into the underground again; and according to the geothermal well opening power station system and the power generation method thereof, the utilization efficiency of the geothermy can be improved.

Owner:SHANGHAI KAISHAN ENERGY EQUIP +1

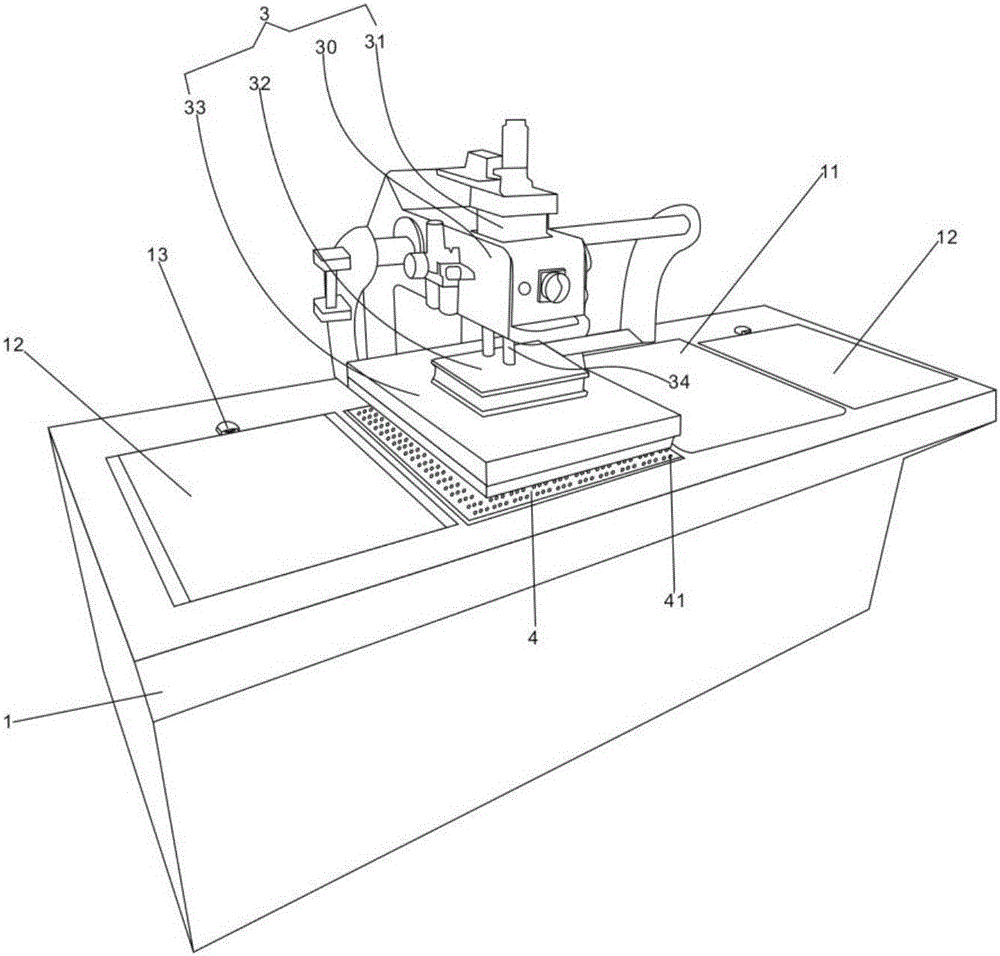

Fully-woven upper sheet ironing setter

InactiveCN106676805AImprove thermal conductivitySmall coefficient of thermal expansionHeating/cooling textile fabricsLight touchSetter

The invention discloses a fully-woven upper sheet ironing setter which comprises a workbench, a machine frame, a steam ironing device and a control device, wherein the machine frame, the steam ironing device and the control device are mounted on the workbench; the surface of the workbench comprises ironing regions and cooling regions; emery sheet fixing plates are mounted in the ironing regions, are thin plates of which the surfaces are coated with an emery coating, and are provided with penetration holes; cover lids, air pipes and cooling fans are connected in the workbench at the lower parts of the cooling regions; the steam ironing device is mounted at the upper parts of the ironing regions, and comprises a cylinder base, a cylinder, a lifting plate and a steam ironing plate; light touch push switches are mounted on the edges of the upper ends of the cooling regions, and are connected with a delay control line to control the cooling fans. The ironing setter also comprises a projection control device and a projector, wherein the ironing regions are covered by a projection region of the projector. The emery sheet fixing plates can be matched with sheet fixing claw pieces. According to the ironing setter, an upper sheet can be set more rapidly and smoothly, operation is convenient, the labor intensity and the production cost are reduced, and the production efficiency and benefits are improved.

Owner:金翰

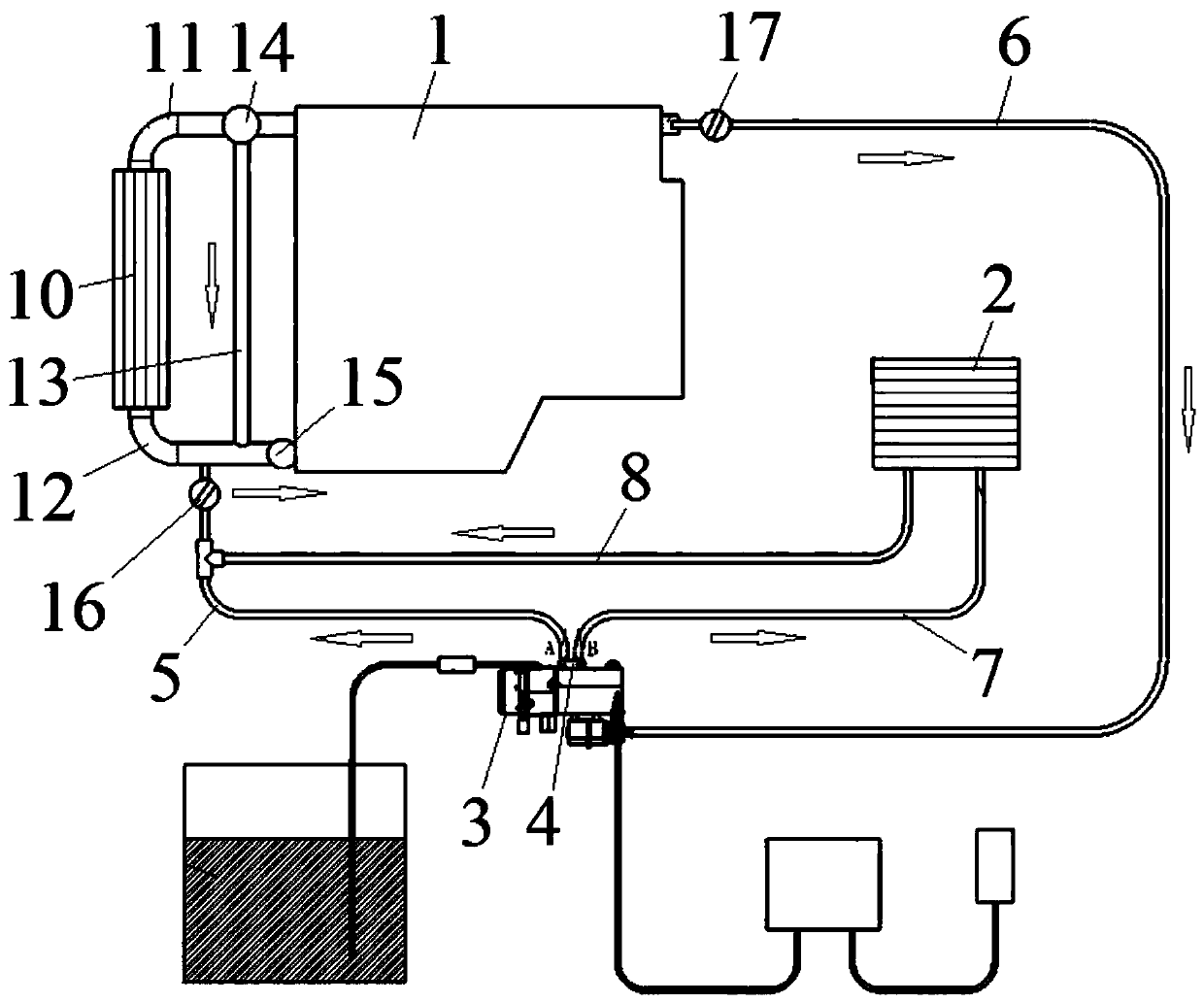

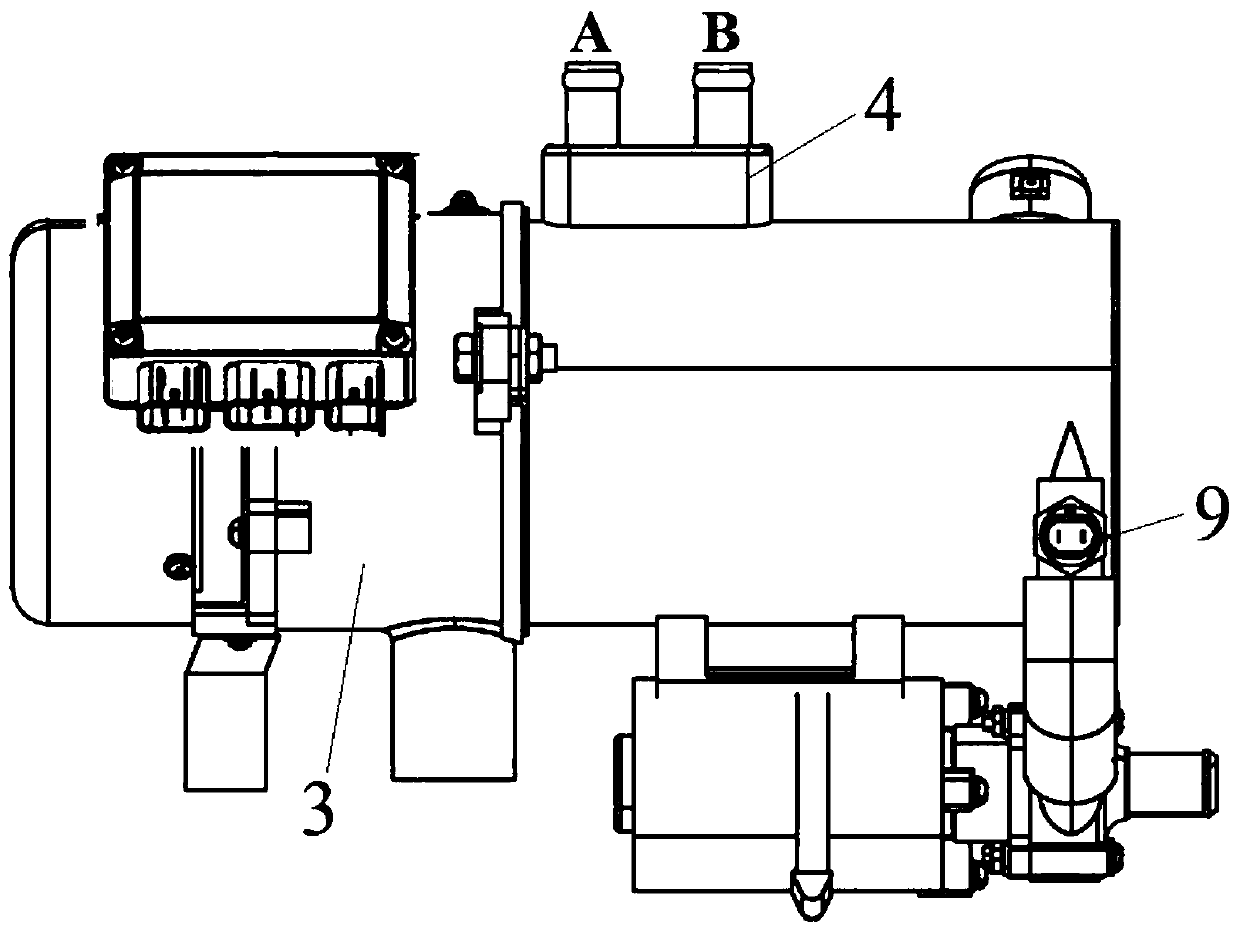

Engine low-temperature starting preheating and cab warm air system

InactiveCN110714829AStarter Priority SatisfactionStarting preheating priority is satisfiedLiquid coolingAir-treating devicesControl valvesHeat energy

The invention relates to the technical field of automobile part structures, and specifically relates to an engine low-temperature starting preheating and cab warm air system. The engine low-temperature starting preheating and cab warm air system comprises an engine, a warm air device and a heater, wherein a three-way electromagnetic control valve is mounted at an outlet of the heater; the three-way electromagnetic control valve is of a valve structure which is provided with a water inlet and two water outlets and can be switched between the two water outlets according to the temperature; one water outlet of the three-way electromagnetic control valve communicates with a water pump water inlet of the engine through an engine water inlet pipe, and the other water outlet of the three-way electromagnetic control valve communicates with the warm air device through a warm air water inlet pipe; the warm air device communicates with the engine water inlet pipe through a warm air water outlet pipe; a water inlet of the heater communicates with a first water outlet of the engine through an engine water outlet pipe; and a temperature sensor is arranged at the water inlet of the heater. The engine low-temperature starting preheating and cab warm air system is simple in pipeline structure, convenient to operate, capable of dealing with the situations that the engine is started at a low temperature and the engine does not start and starts the warm air system independently, and high in heat exchange and heat energy utilization efficiency.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

Solid oxide fuel cell high temperature gas heat exchanger

ActiveCN108871013AImprove efficiencyImprove thermal energy utilization efficiencyHeat exhanger sealing arrangementStationary tubular conduit assembliesProcess engineeringOxide

The invention relates to the field of heat exchanger equipment, in particular to a solid oxide fuel cell high temperature gas heat exchanger. The solid oxide fuel cell high temperature gas heat exchanger comprises a fixing structure, a pipe connecting structure, a first flue gas heat exchange structure, a vacuum chamber, a second flue gas heat exchange structure, a fuel gas preheating channel, anair preheating channel and a sealing structure; the first flue gas heat exchange structure and the second flue gas heat exchange structure which are used for heat exchange are arranged in the fixing structure, the fuel gas preheating channel used for preheating the fuel gas is arranged between the first heat exchange structure and the second flue gas heat exchange structure, and the air preheatingchannel for preheating the air is arranged in the second flue gas heat exchange structure; and the vacuum chamber and the sealing structure which are used for heat insulation and isolation are arranged between the first flue gas heat exchange structure and the flue gas heat exchange structure. According to the solid oxide fuel cell high temperature gas heat exchanger, the heat exchange efficiencyof the fuel gas preheating channel and the air in the air preheating channel are improved by using the first flue gas heat exchange structure and the second flue gas heat exchange structure, the efficiency of the flue gas heat exchange is greatly improved, and the heat energy utilization efficiency of the flue gas is improved.

Owner:JINGJIANG SHENJU VESSEL MFG

Waste gas purification equipment for waste incineration power generation

PendingCN112555837AEasy to collectCollection components that make good use of theIncinerator apparatusFlue gasThermal insulation

The invention discloses waste gas purification equipment for waste incineration power generation. The waste gas purification equipment comprises a base, an incinerator is fixedly installed on the leftside of the top of the base, a waste collecting assembly is arranged at the bottom in the incinerator, and an incineration power generation equipment body is arranged at the top of the waste collecting assembly in the incinerator. A thermal insulation ceramic door is hinged to the position, corresponding to the incineration power generation equipment body, of the front face of the incinerator, abridge type handrail is fixedly installed on the right side of the front face of the thermal insulation ceramic door, and an air blower is fixedly installed at the lower end of the left side of the incinerator at the top of the base. The output end of the air blower is communicated with the incineration power generation equipment body. A flue gas circulation cooling device is fixedly installed inthe middle of the top of the base, a spraying treatment device is fixedly installed on the right side of the flue gas circulation cooling device at the top of the base, then flue gas is effectively treated, and operation of the equipment can be intelligently controlled by arranging a control device. And therefore, the practicability and operation convenience of the equipment are improved.

Owner:杨克瑞

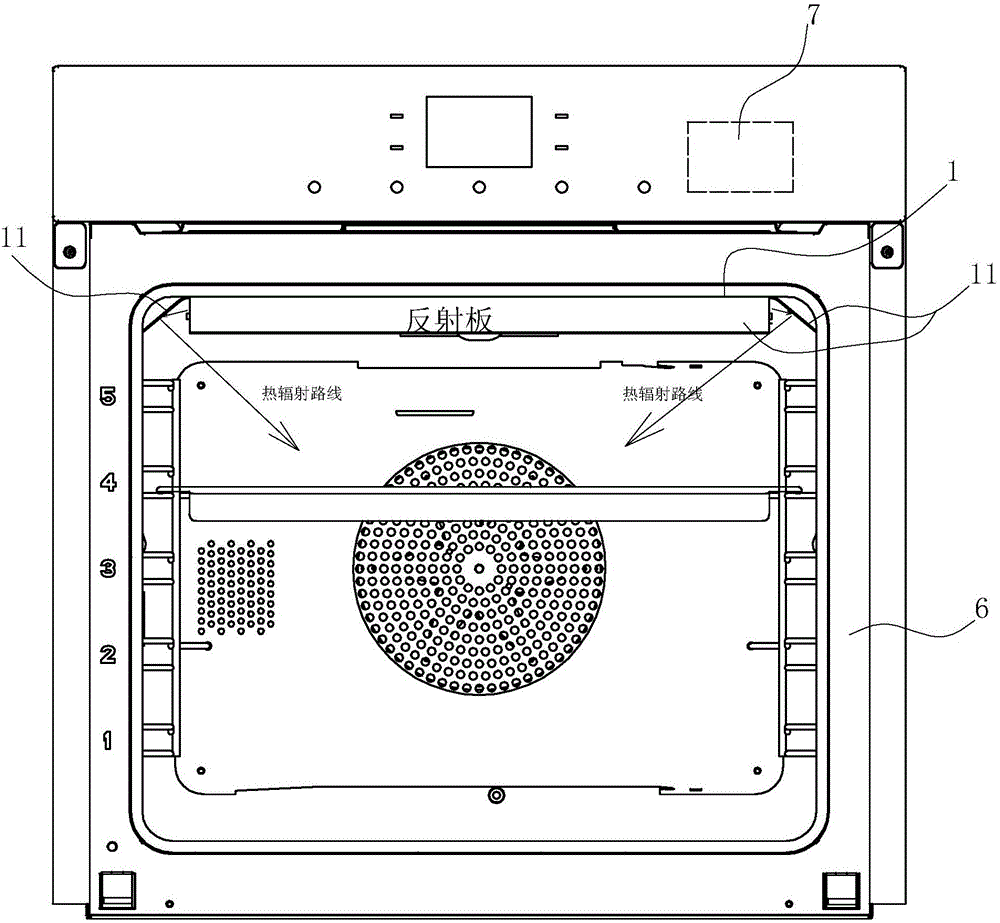

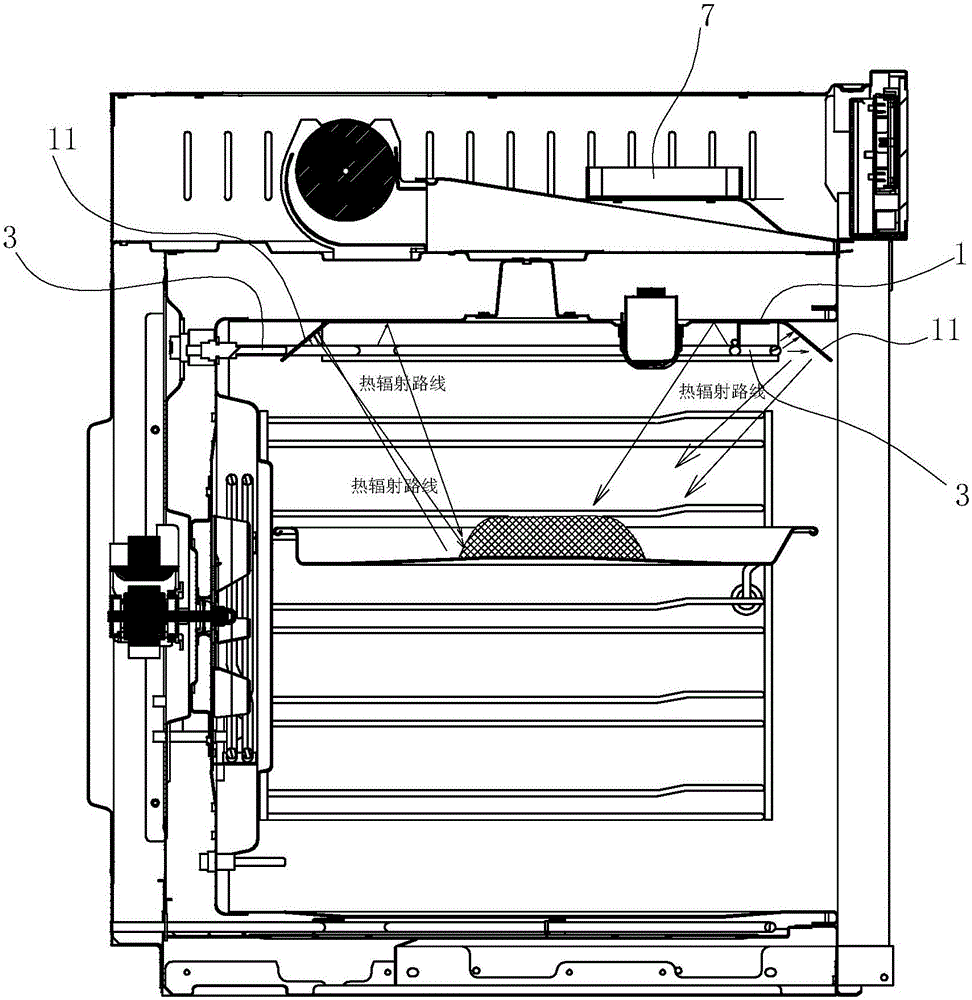

Electric oven and control method thereof

InactiveCN106175479AImprove thermal energy utilization efficiencyTemperature control using electric meansRoasters/grillsThermal energyEngineering

The invention relates to an electric oven and a control method thereof. The electric oven comprises an inner container with a cooking chamber, an upper electric heating tube arranged at the top of the inner container, and a control panel connected with the upper electric heating tube and capable of controlling working of the upper electric heating tube, and is characterized in that a reflective plate capable of reflecting heat radiation generated by the upper electric heating tube back into the inner container is mounted inside the inner container and above the upper electric heating tube and the reflective plate can cover the whole upper electric heating tube. Compared with the prior art, the electric oven has the advantages as follows: through mounting of the reflective plate capable of reflecting the heat radiation generated by the upper electric heating tube back into the inner container above the upper electric heating tube, the heat energy utilization efficiency of the upper heating tube can be greatly improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com