Patents

Literature

82results about How to "Control the falling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

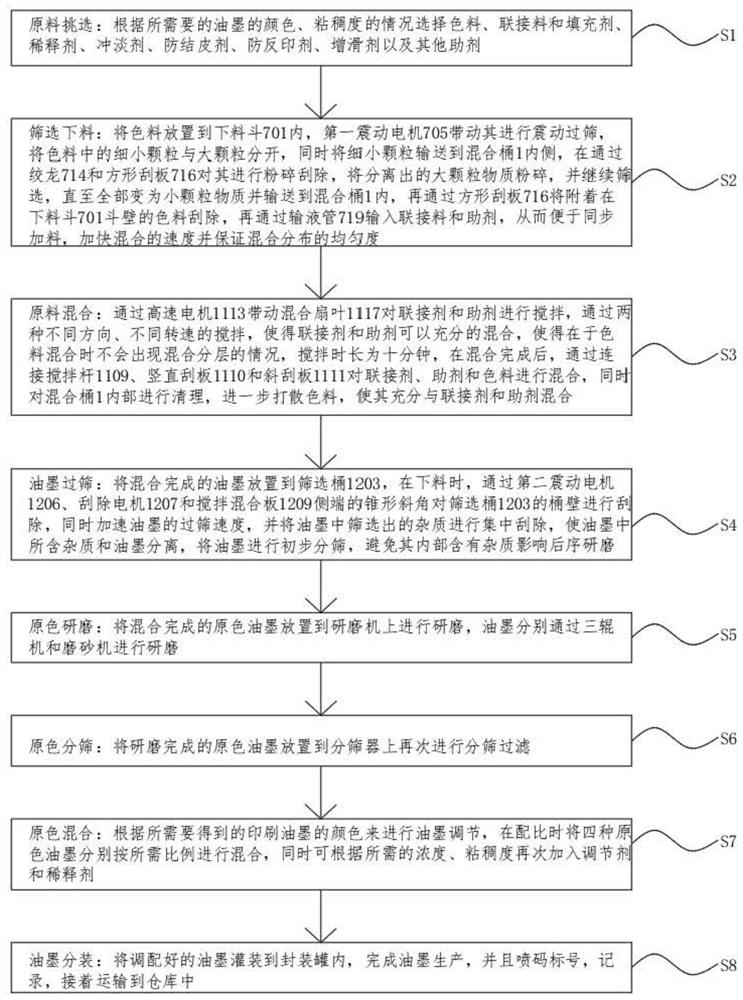

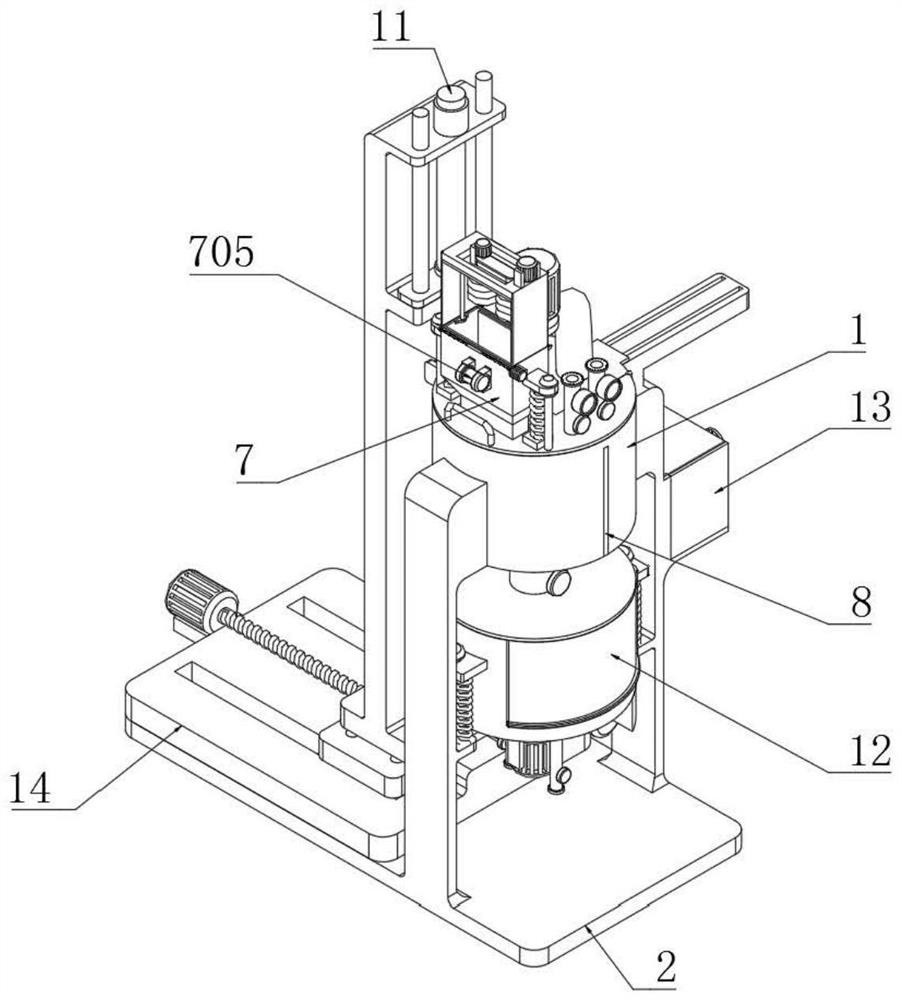

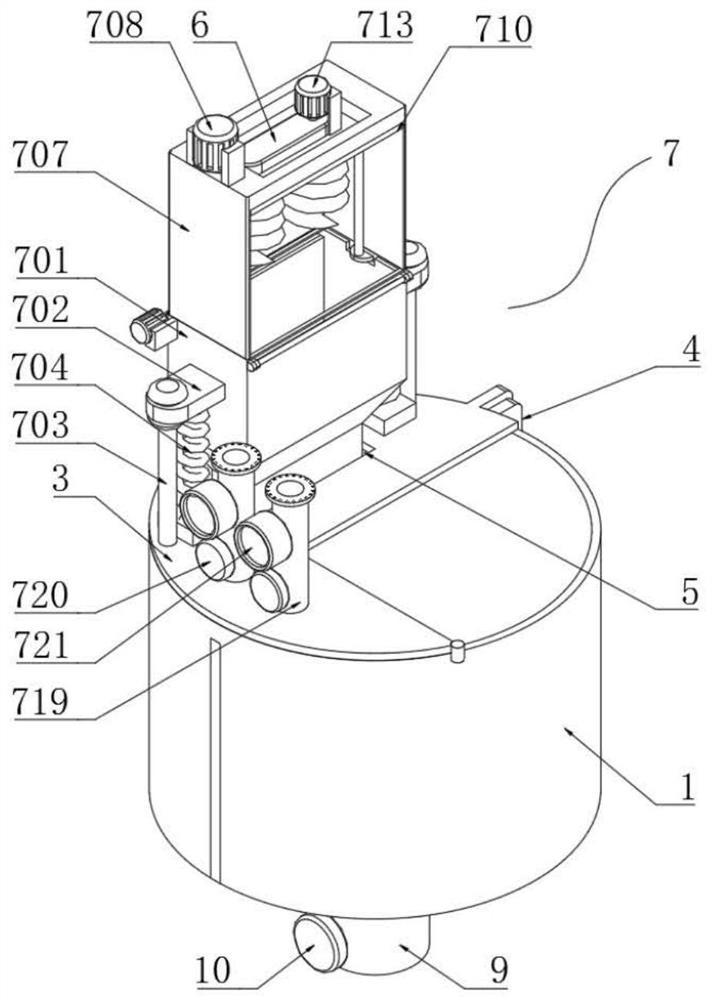

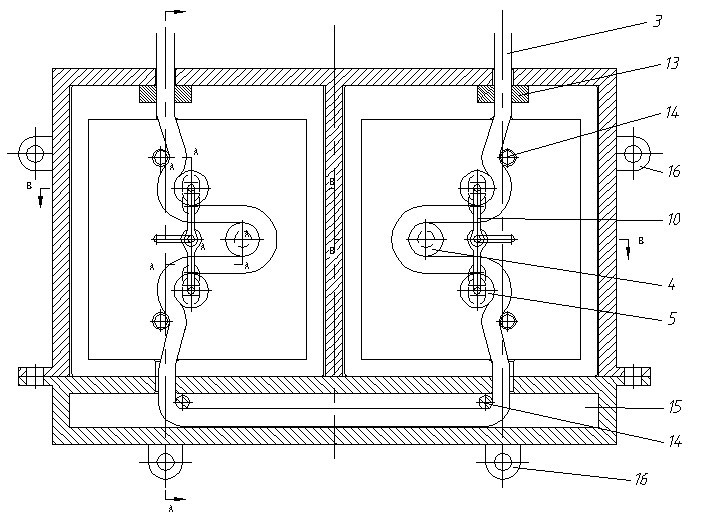

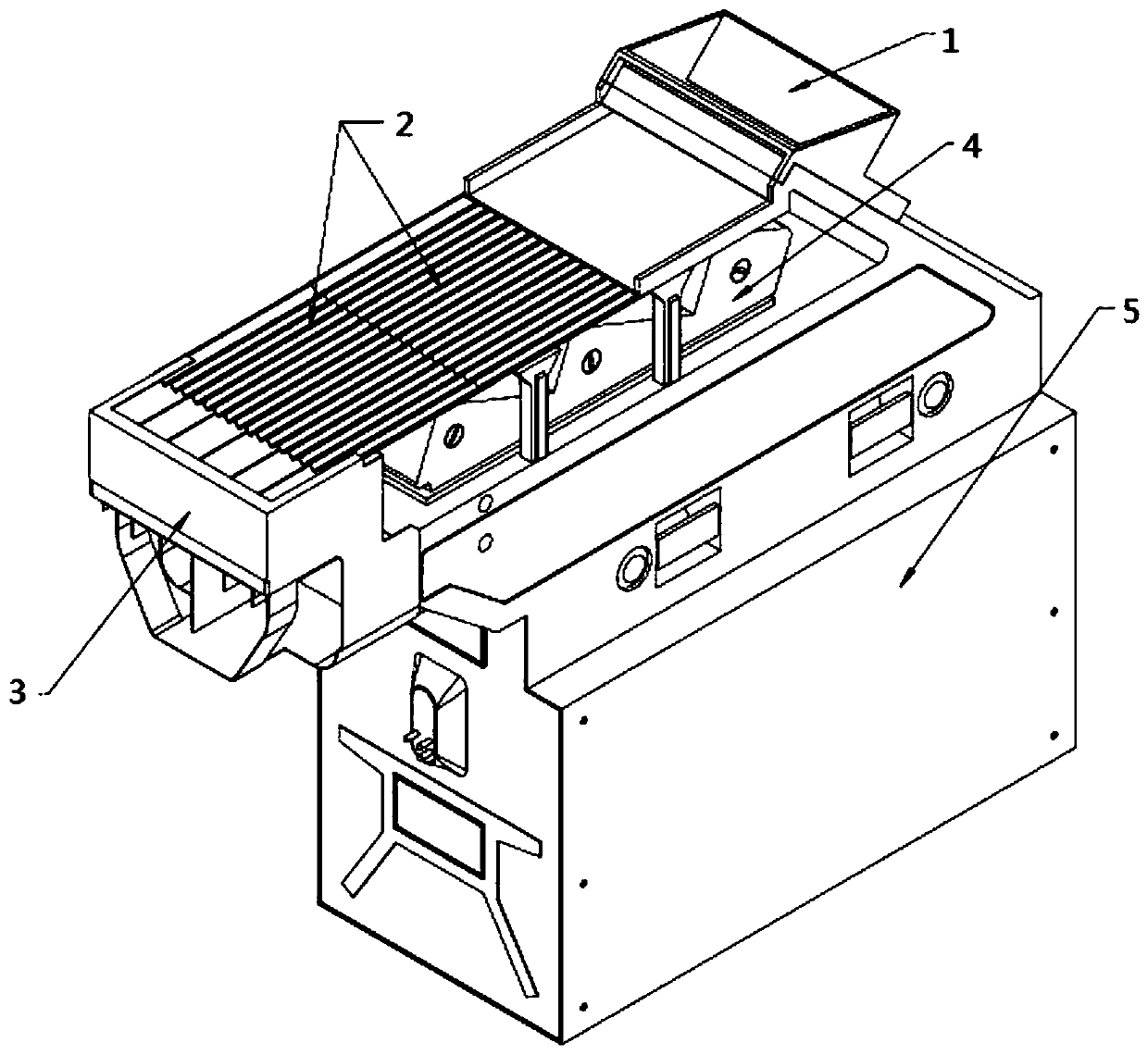

Preparation method of uniformly distributed ink for color printing

InactiveCN112473508AScientific and reasonable structureSafe and convenientRotary stirring mixersTransportation and packagingColor printingEngineering

The invention discloses a preparation method of uniformly distributed ink for color printing. A blanking hopper is placed on the inner side of a feeding port, hollow supporting blocks are welded to the two ends of the blanking hopper, first vibration springs are welded to the bottom ends of the hollow supporting blocks, one end of the blanking hopper is connected with a first vibration motor, anda fine screen is clamped to the inner side of the blanking hopper, a lifting motor is installed at the top end of a fixed installation frame, a linkage gear is connected with an auger in a welded modethrough a linkage rod, a square scraping plate is placed on the inner side of the blanking hopper, and pigment placed in the blanking hopper is screened and blanked through the vibration springs andthe vibration motor, therefore the pigment is filtered, and meanwhile lifting smashing is conducted through the auger and a lifting supporting plate, and the situation that in the blanking process, large-particle pigment blocks meshes is avoided, pigment particles become small and accordingly are more effectively mixed with a solvent, the pigment is scraped off through a scraper blade, and the situation that due to one-time large-amount blanking, uneven mixing is caused is avoided.

Owner:张钰

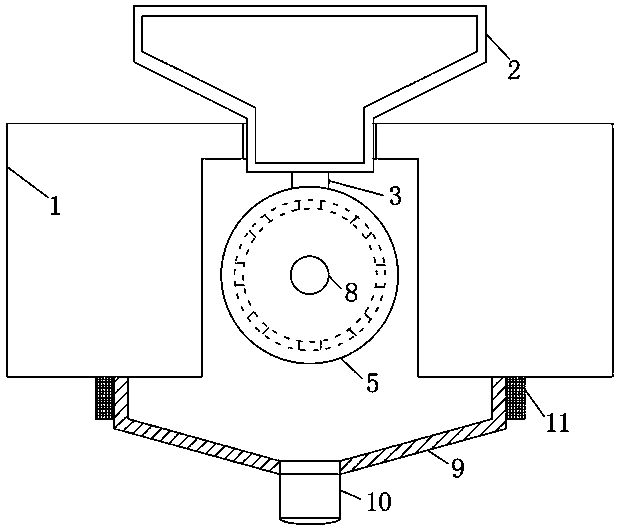

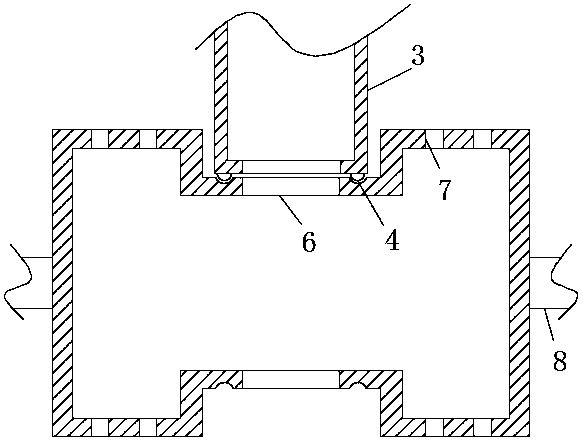

Overhead escape device of light rail

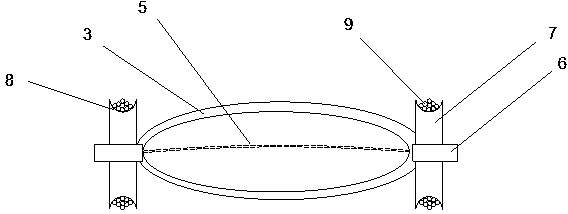

InactiveCN101898015ASimple structureDeceleration principle is clearBuilding rescueStatic frictionLight rail

The invention discloses an overhead escape device of a light rail. The device comprises an outer shell and an inner shell positioned in the outer shell, wherein an escape rope is arranged in the inner shell and two ends of the escape rope run through the same side of the outer shell and inner shell; a retarding mechanism is arranged in the inner shell and mainly comprises a round static friction block and two round kinetic friction blocks; the two movable friction blocks are symmetrically positioned on two sides of a centre line of the static friction block; the escape rope sequentially winds over one movable friction block, the static friction block and the other movable friction block; and the centre of the static friction block deviates for a certain distance from the connection line of the centres of the two movable friction blocks so that the escape rope forms a certain wrap angle with the kinetic friction blocks. The device has the advantages of low cost, convenient use, simple structure, reliable performance and convenient maintenance. The required time for the whole landing process is short and the device can be repeatedly and uninterruptedly used so that many people can conveniently and quickly escape.

Owner:CHONGQING UNIV OF TECH

Culture method of rice anther calluses

InactiveCN103355175ANo pollution in the processEasy to operateHorticulture methodsPlant tissue cultureThird generationNutrient solution

The invention discloses a culture method of rice anther calluses. The culture method comprises a step of disinfecting a rice ear, and removing tops of glumes; a step of suspending the rice ear, with the rice stalk upward and the rice ear downward, in a receiving flask containing nutrient solution to perform oscillation processing; a step of transferring the receiving flask after the oscillation processing is finished and performing induction culture in the absence of light to obtain the rice anther calluses. A formula of the nutrient solution is that an SK3 basic medium contains 2.5-3 g / L of proline, 0.4-0.6 g / L of glutamic acid, 1.8-2.5 mg / L of 2-4D and 1.8-2.5 mg / L of NAA. The culture method provided by the invention has advantages of anther collection convenience, high collection efficiency, and high inductivity and reduced pollution risk of the calluses.

Owner:无锡哈勃生物种业技术研究院有限公司 +1

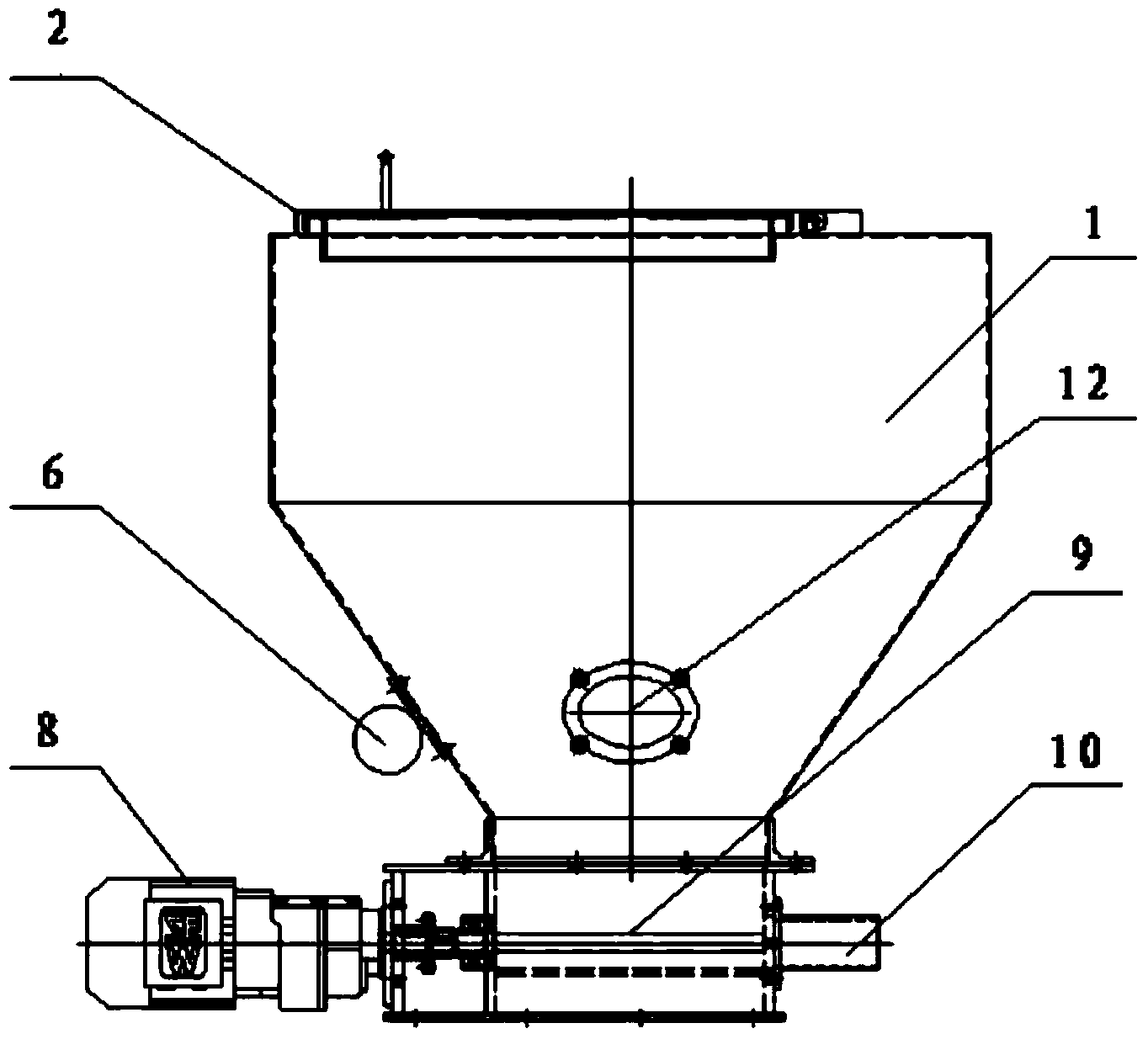

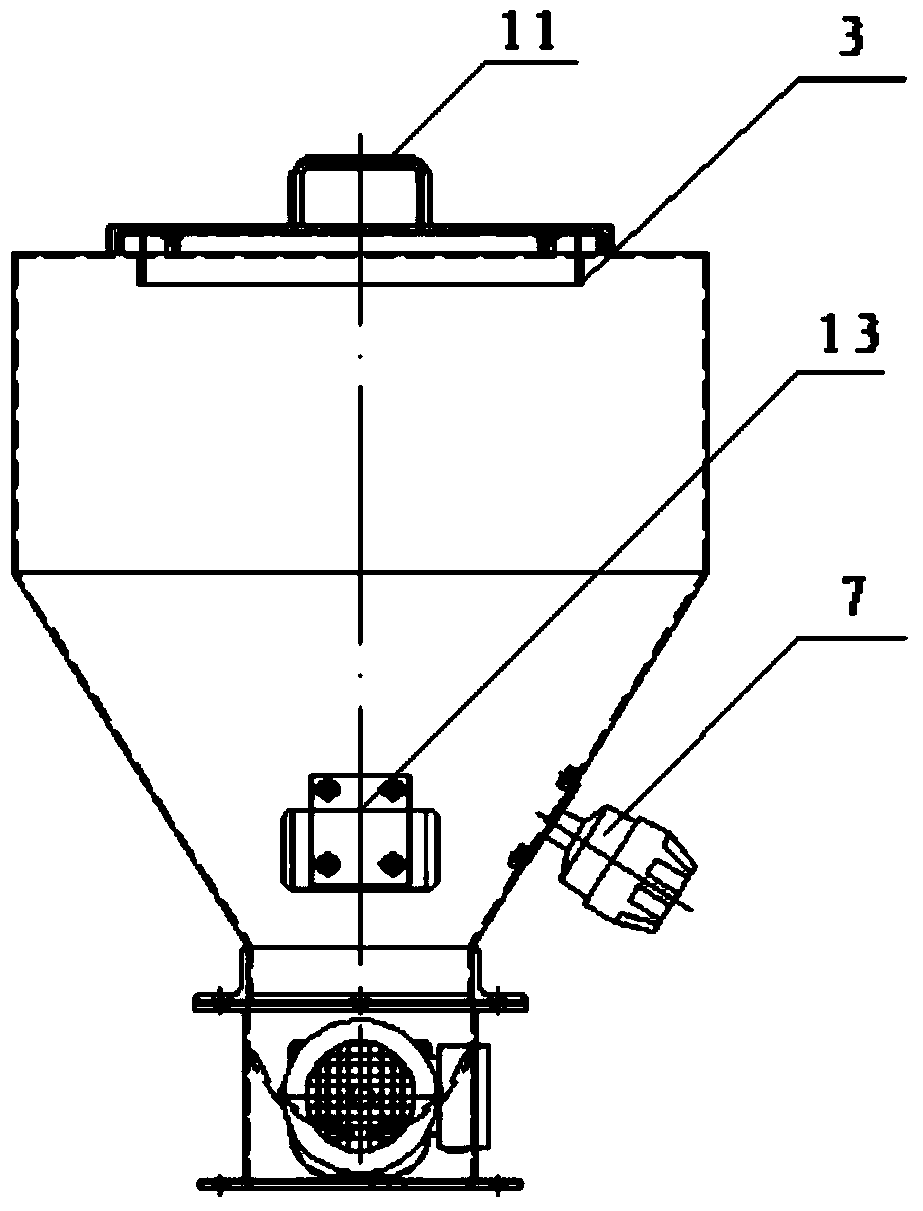

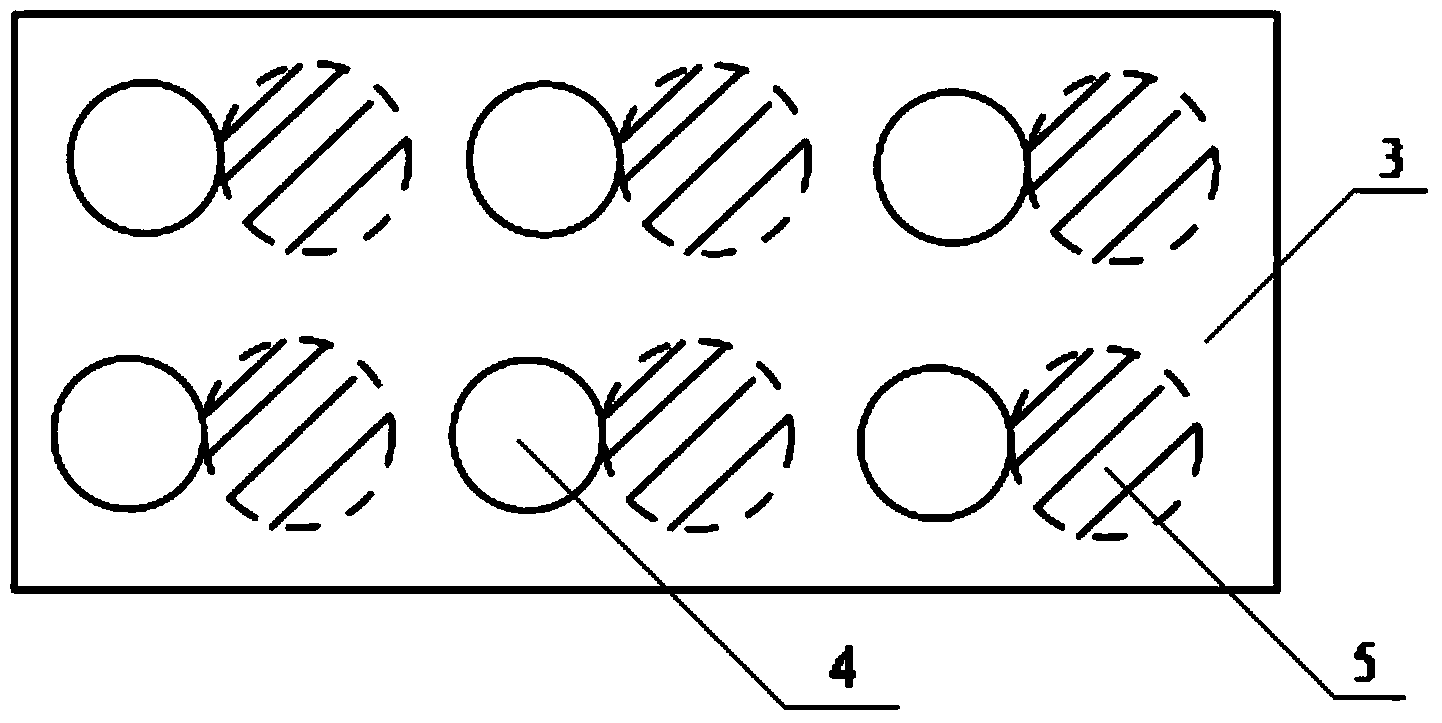

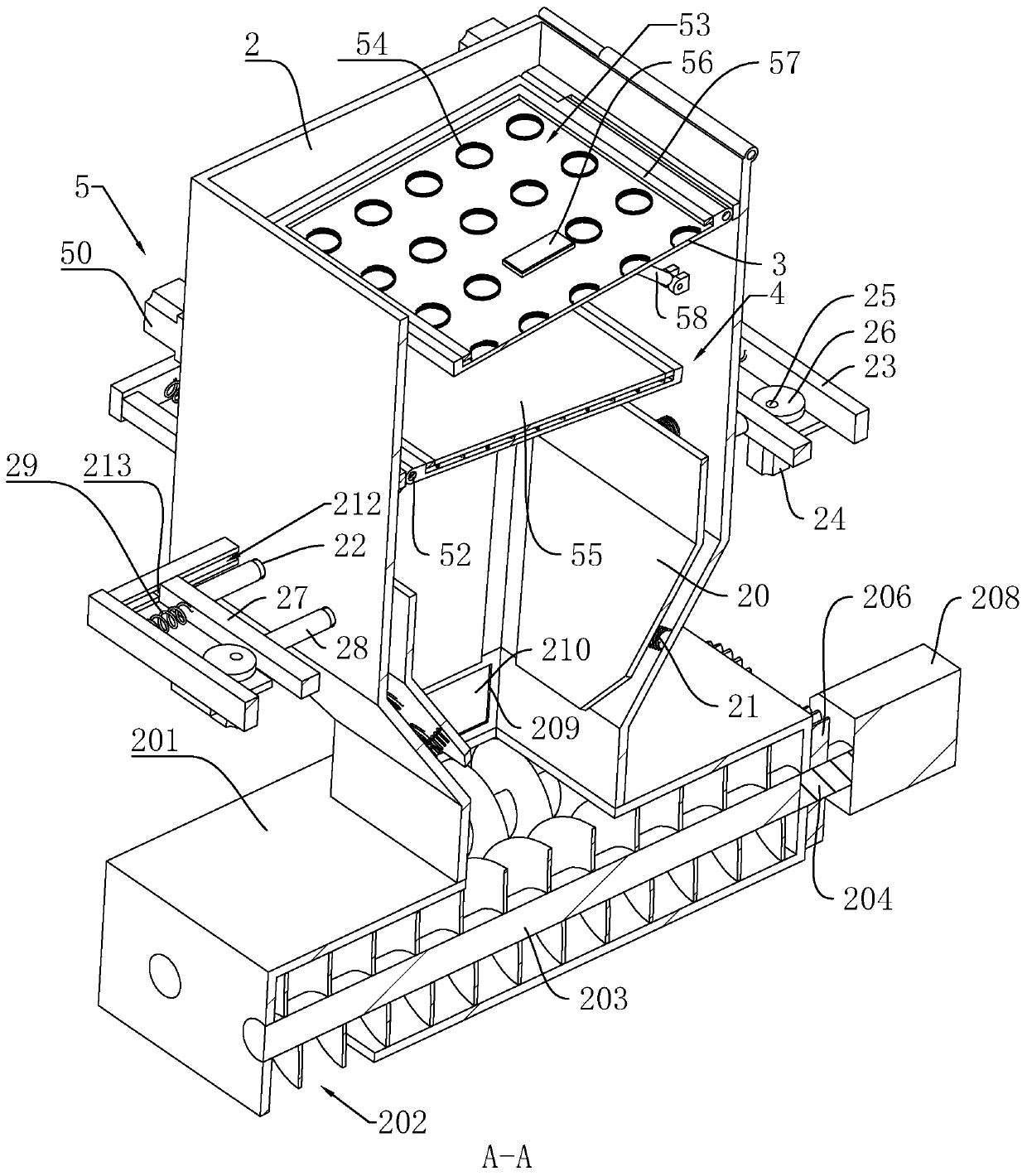

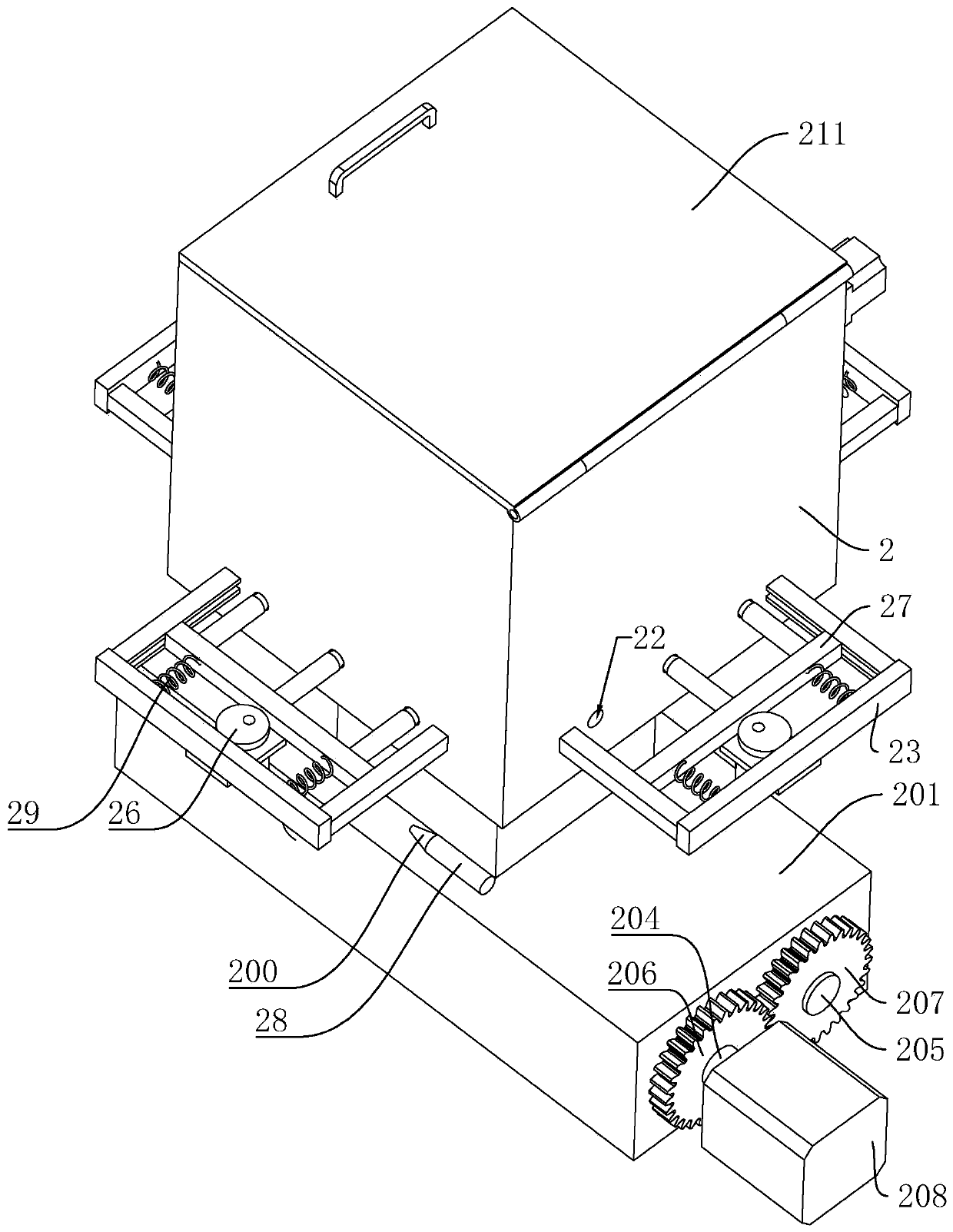

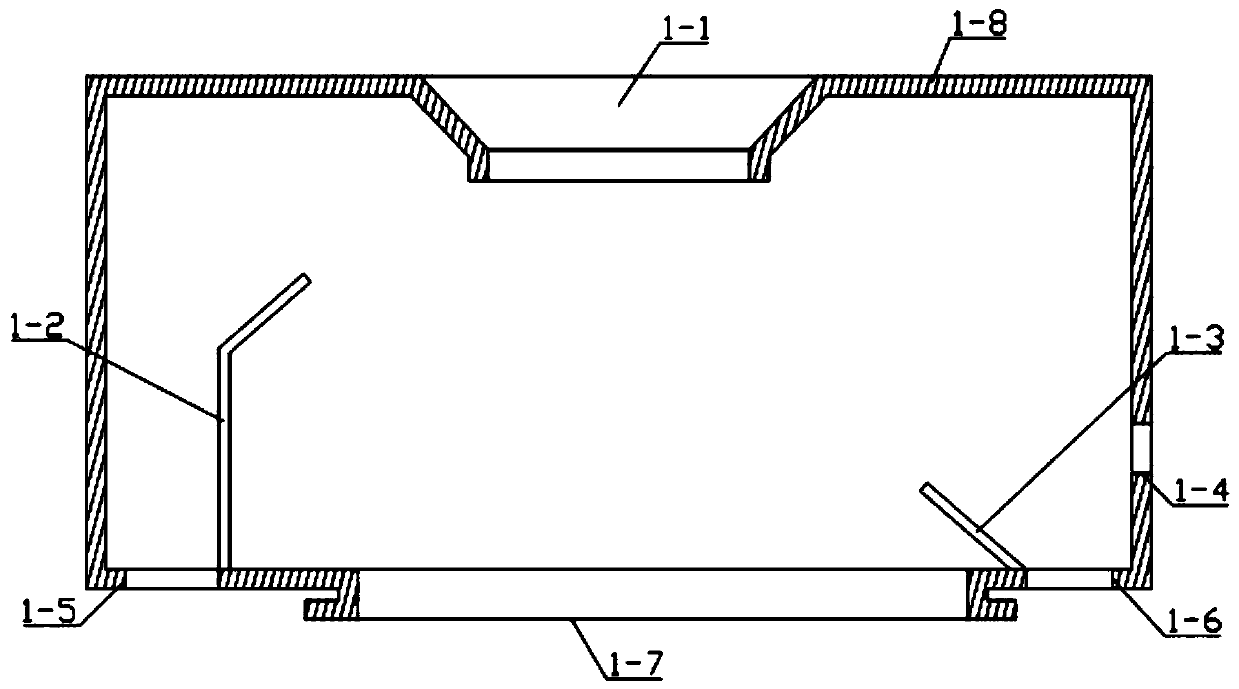

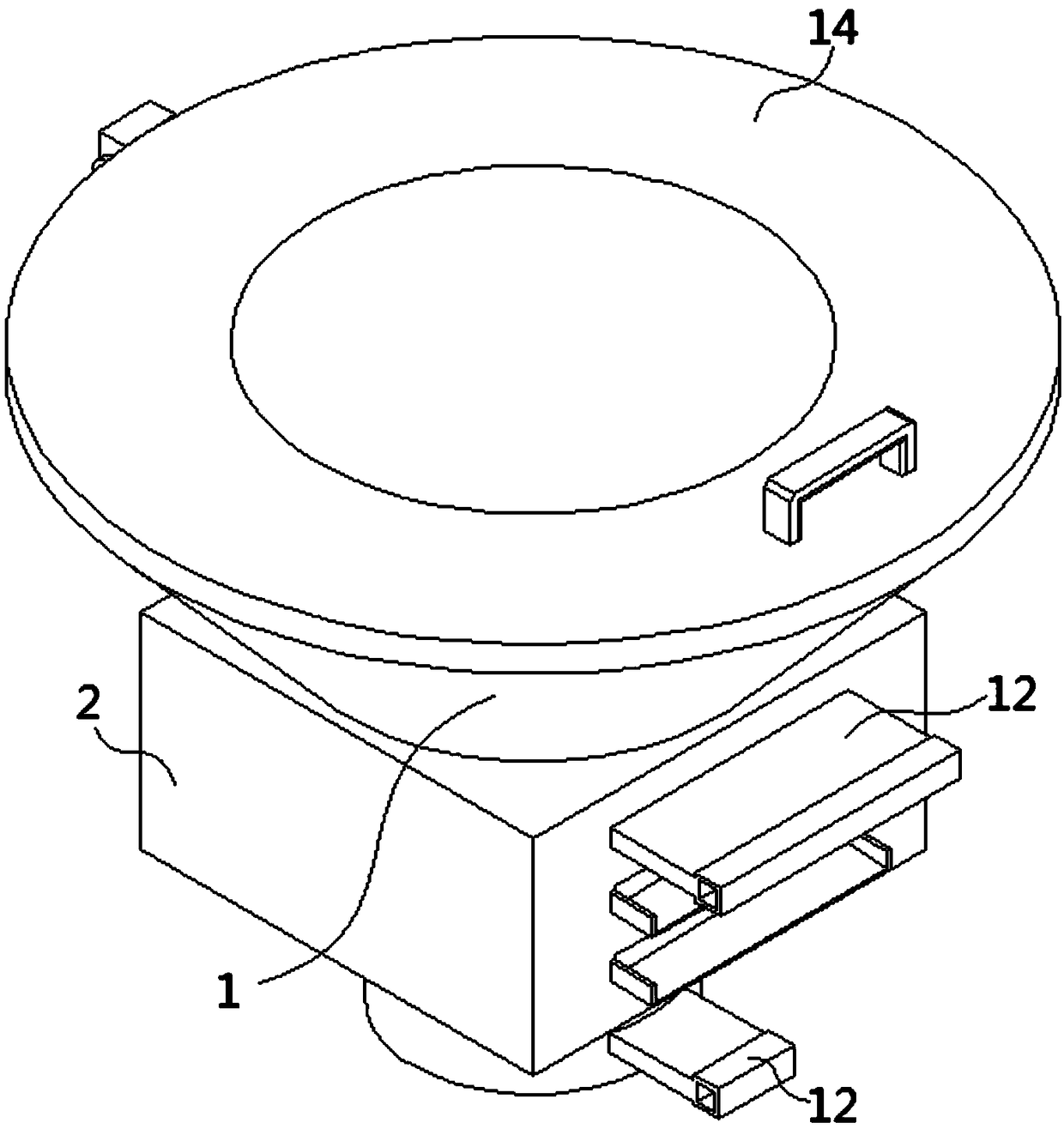

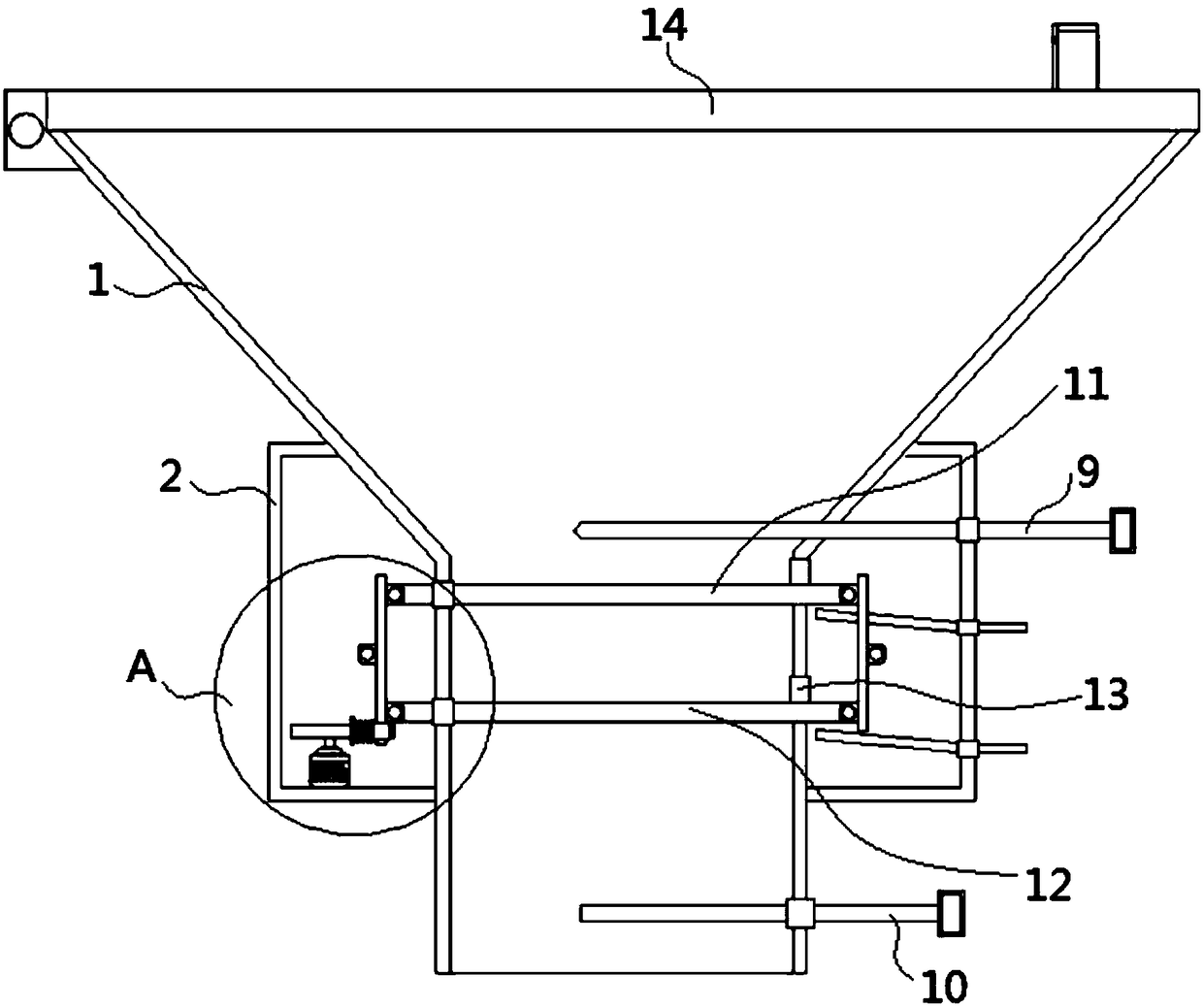

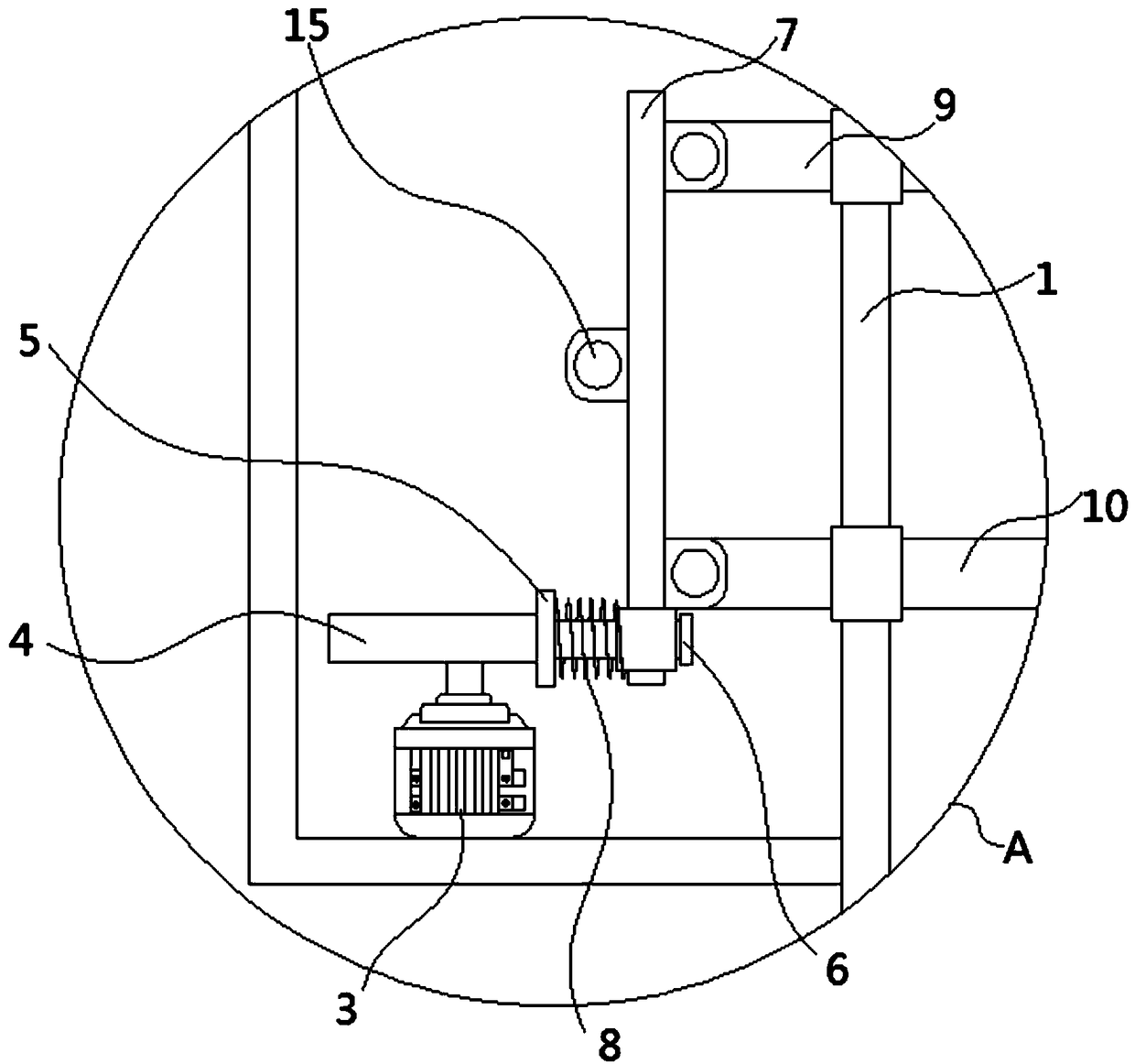

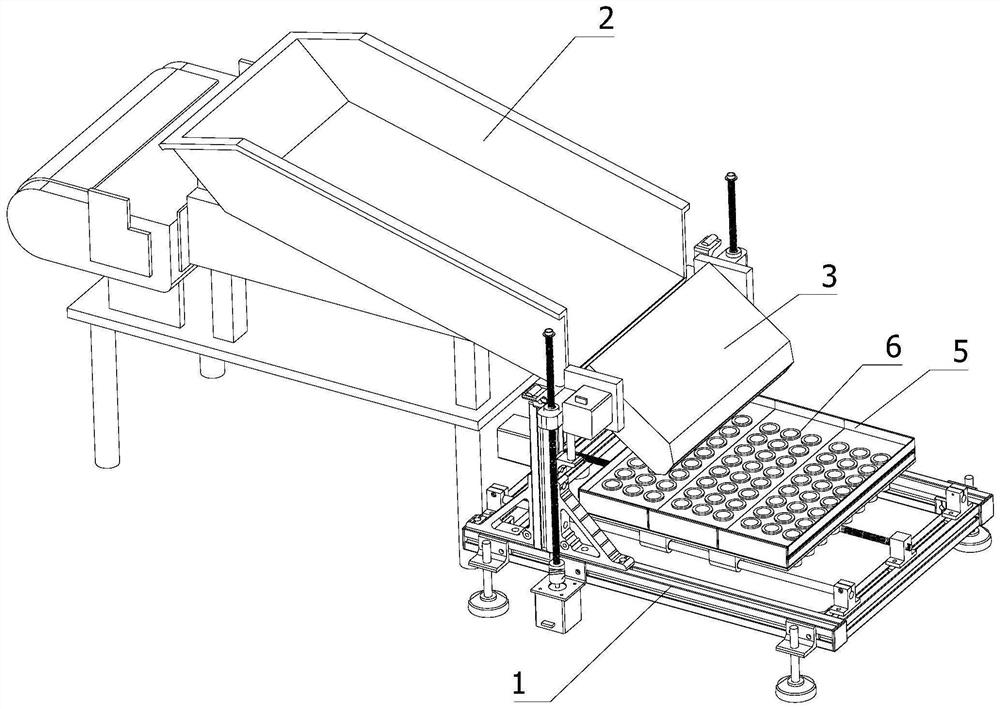

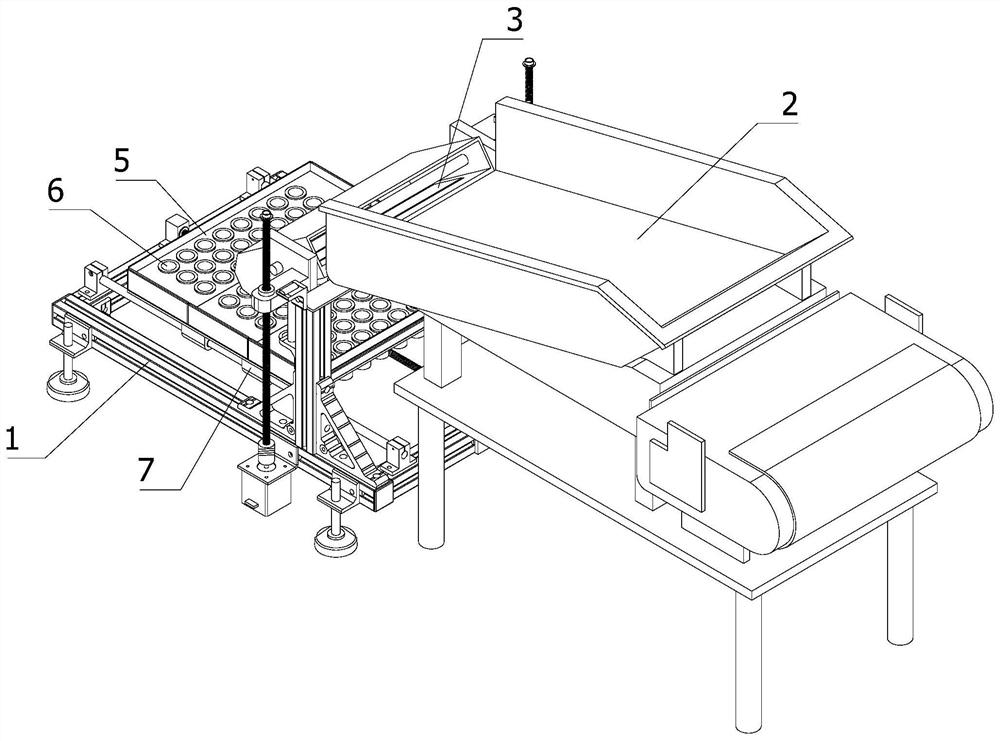

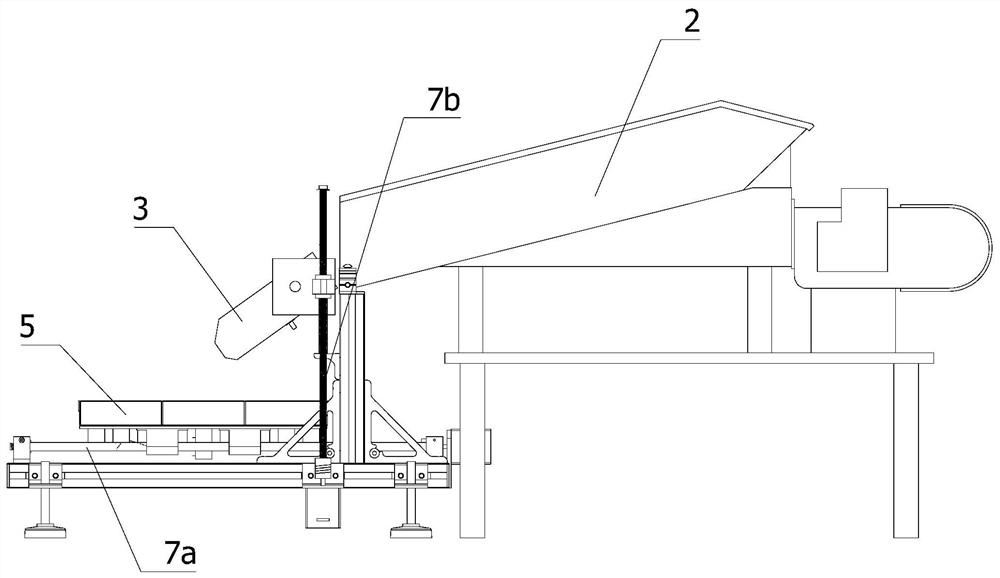

Novel automatic screw feeding device

InactiveCN104097958AReduce labor intensitySimple and fast operationLarge containersLoading/unloadingAutomatic controlProgrammable logic controller

The invention provides a novel automatic screw feeding device. The novel automatic screw feeding device comprises a hopper, and a hopper upper cover arranged above the hopper, wherein a rotatable filter plate is arranged in the upper opening of the hopper; the filter plate is provided with a plurality of circular holes; rotatable circular baffle plates are arranged inside the filter plate; the inner diameters of the circular baffle plates are greater than the inner diameters of the circular holes; the bottom of the hopper is connected with a vibrating motor and a damped rotation type level gage respectively; the lower opening of the hopper is connected with a screw charging device; the screw charging device comprises a speed reducing motor, a screw rod and a discharging guide sleeve which are connected in sequence. The novel automatic screw feeding device has the beneficial effects that operation is simple and convenient through PLC (Programmable Logic Controller) automatic control; by arranging the filter plate, the falling speed of medical powder is controlled, and large blocks of medical powder are prevented from entering the hopper; by arranging the vibrating motor, the medical powder is prevented from coagulating; by arranging the damped rotation type level gage, the medical powder amount can be detected and controlled.

Owner:TIANJIN DUOLEPENG TECH

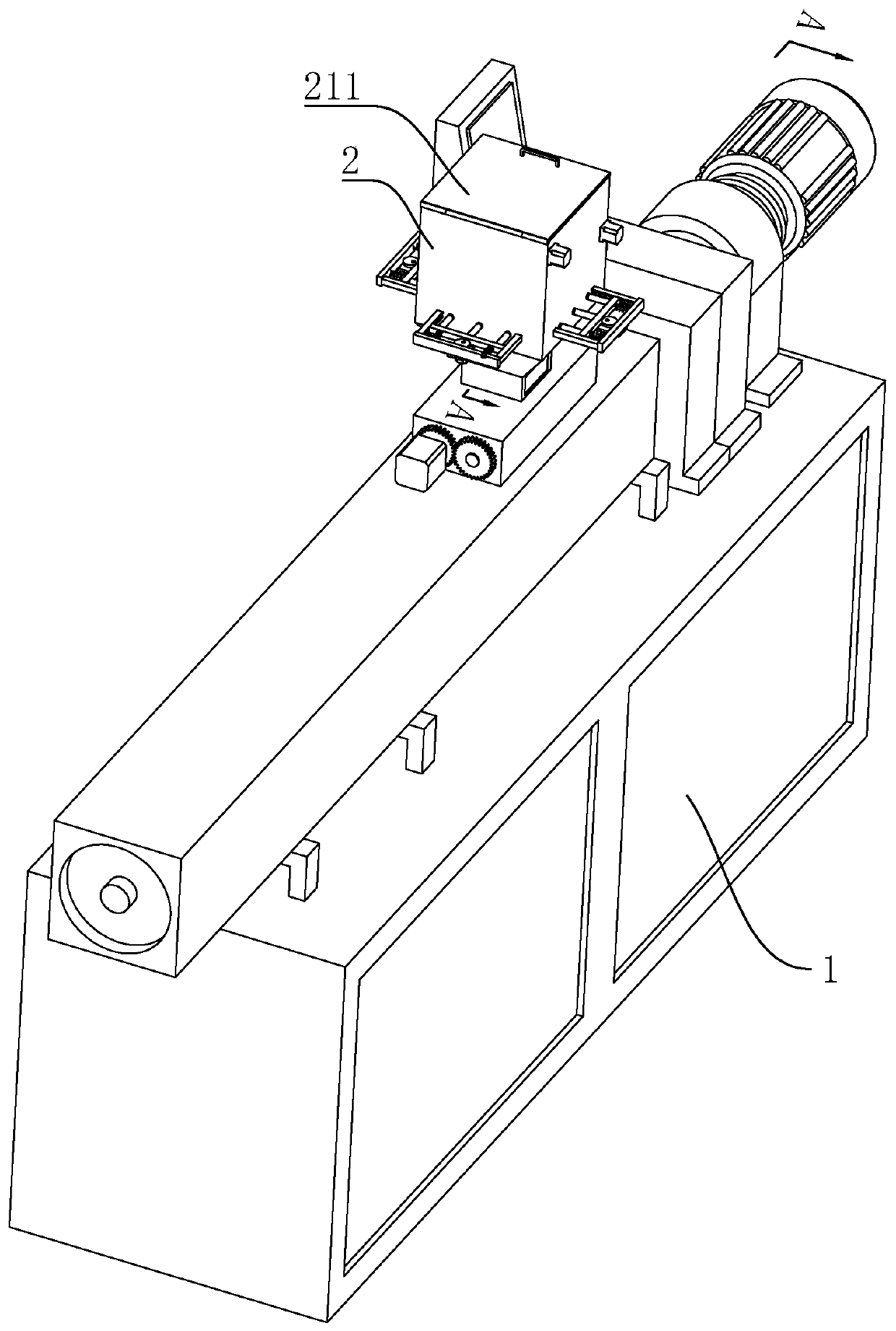

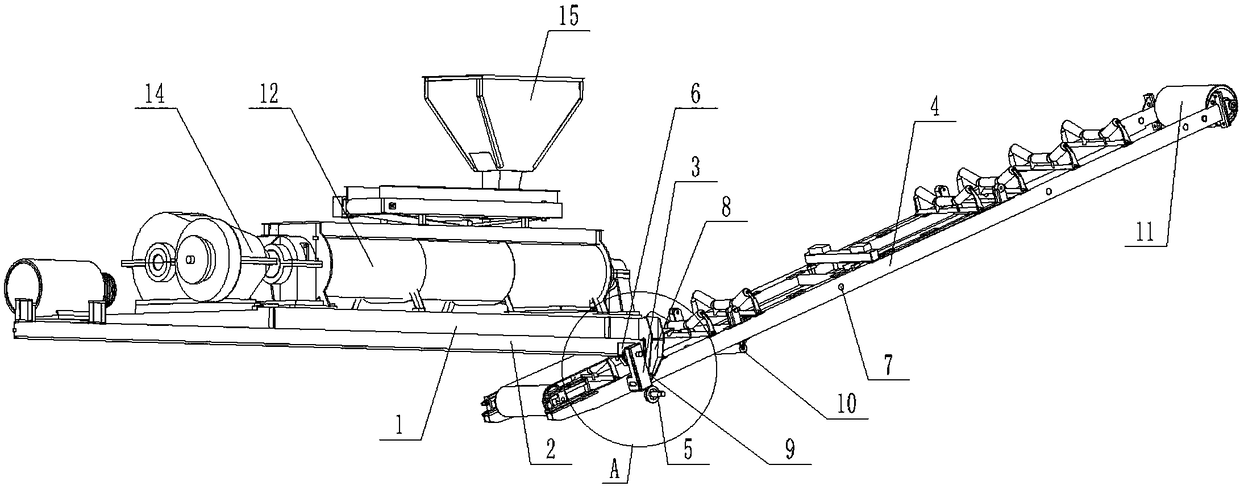

Energy-saving and environment-friendly screw extruder

The invention discloses an energy-saving and environment-friendly screw extruder, relates to an extruder and aims to solve the technical problems that the extruder in the prior art is easy to block materials and waste the materials. The energy-saving and environment-friendly screw extruder is characterized by comprising an extruder body and a hopper arranged on the extruder body; at least two receiving plates are rotatably arranged in the hopper, the receiving plates are located at the lower part of a material inlet of the hopper, material conveying spaces for conveying the materials are keptbetween the receiving plates and the inner side wall of the hopper, the adjacent receiving plates are arranged in an up-down mode, the adjacent material conveying spaces are arranged in a staggered mode, and a power assembly is arranged on the hopper; when the materials need to be fed in, the materials are poured into the hopper and fall on the receiving plates, the power assembly drives the receiving plates to rotate, therefore, the speed of feeding the materials into the extruder body is controlled, and the materials may get into the extruder body smoothly; and thus, materials are reduced, which are all piled up at the hopper bottom, causing remaining materials; and extravagant materials are reduced, and the energy-saving and environment-friendly screw extruder is energy-saving and environment-friendly.

Owner:南京盛驰橡塑机械制造有限公司

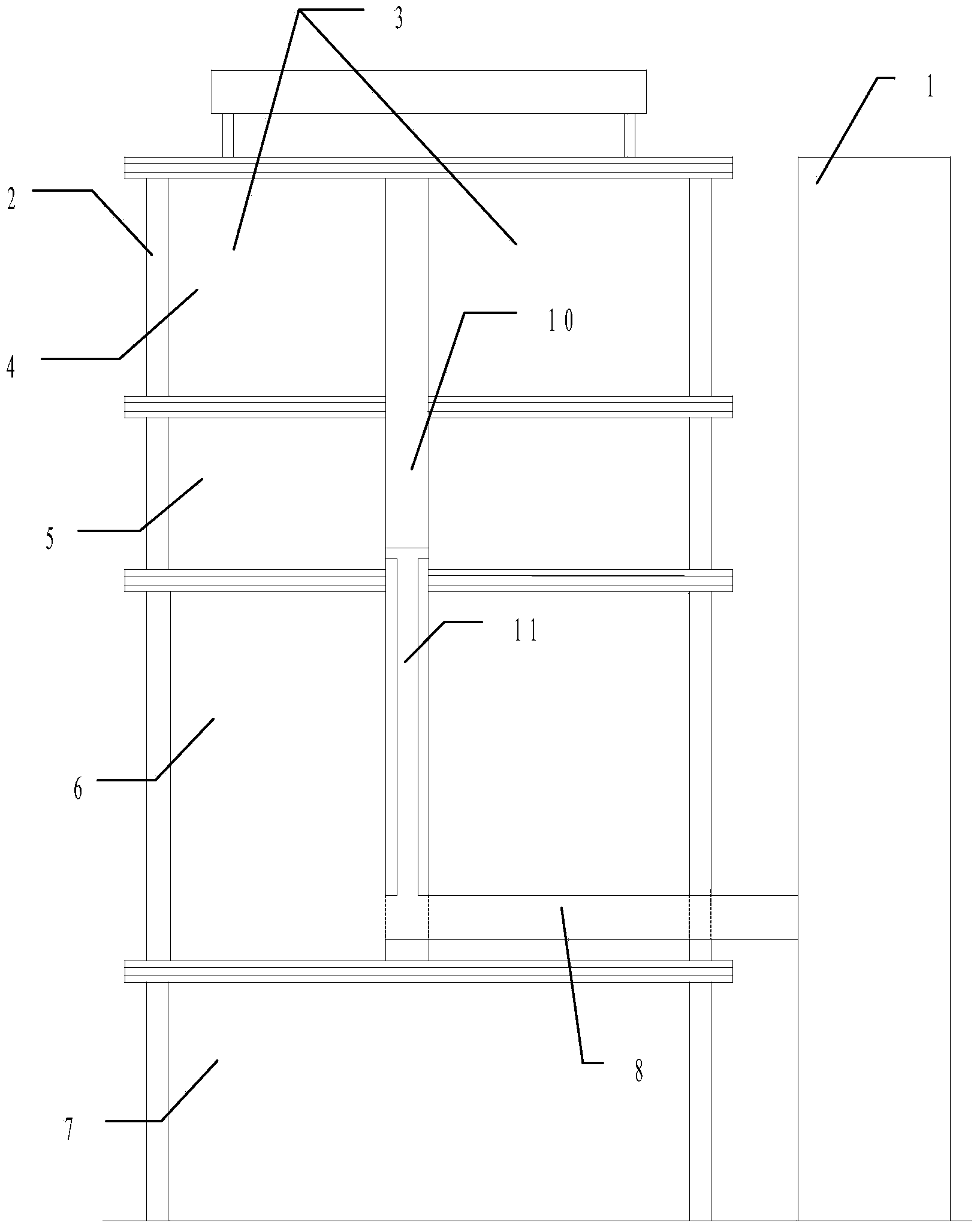

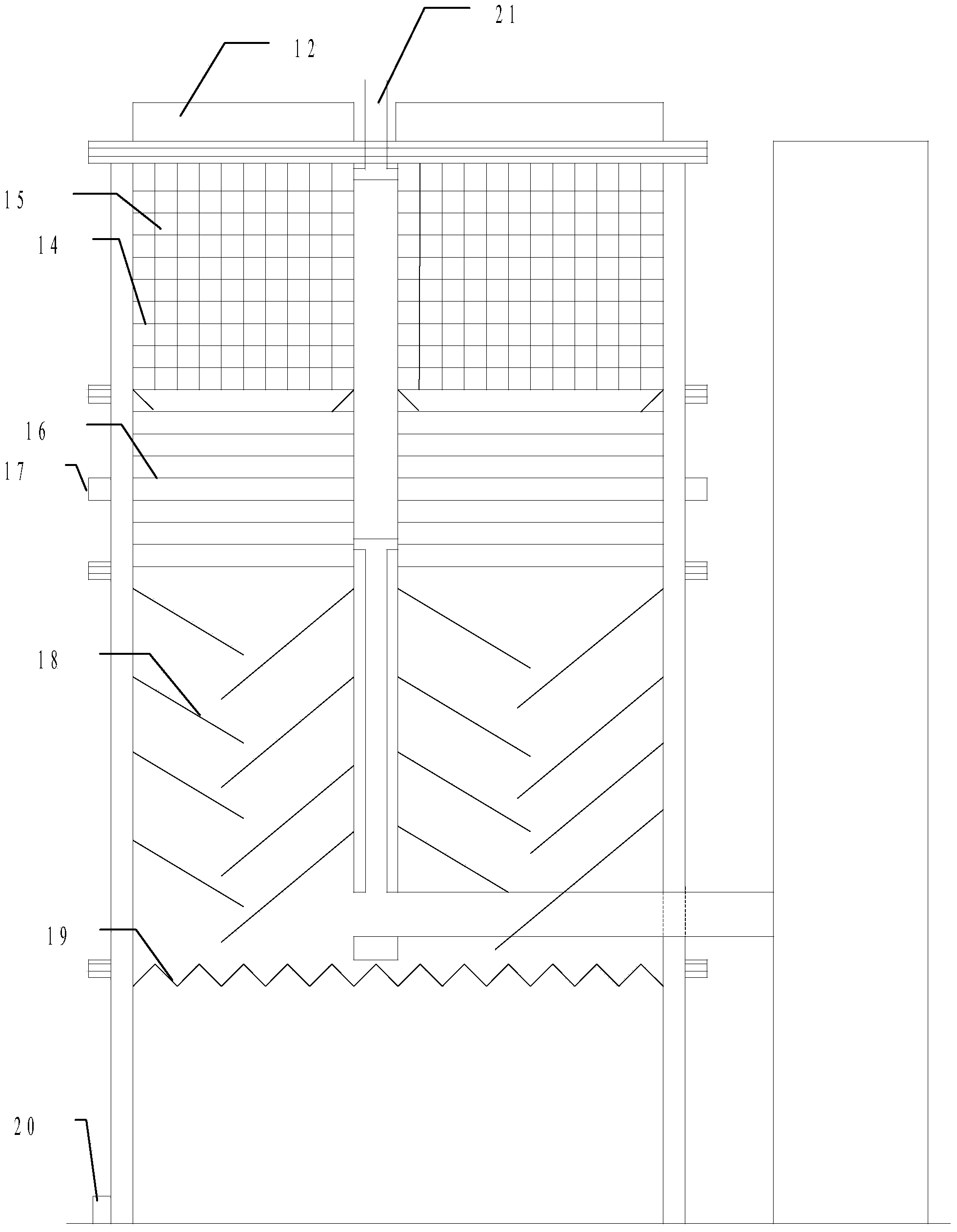

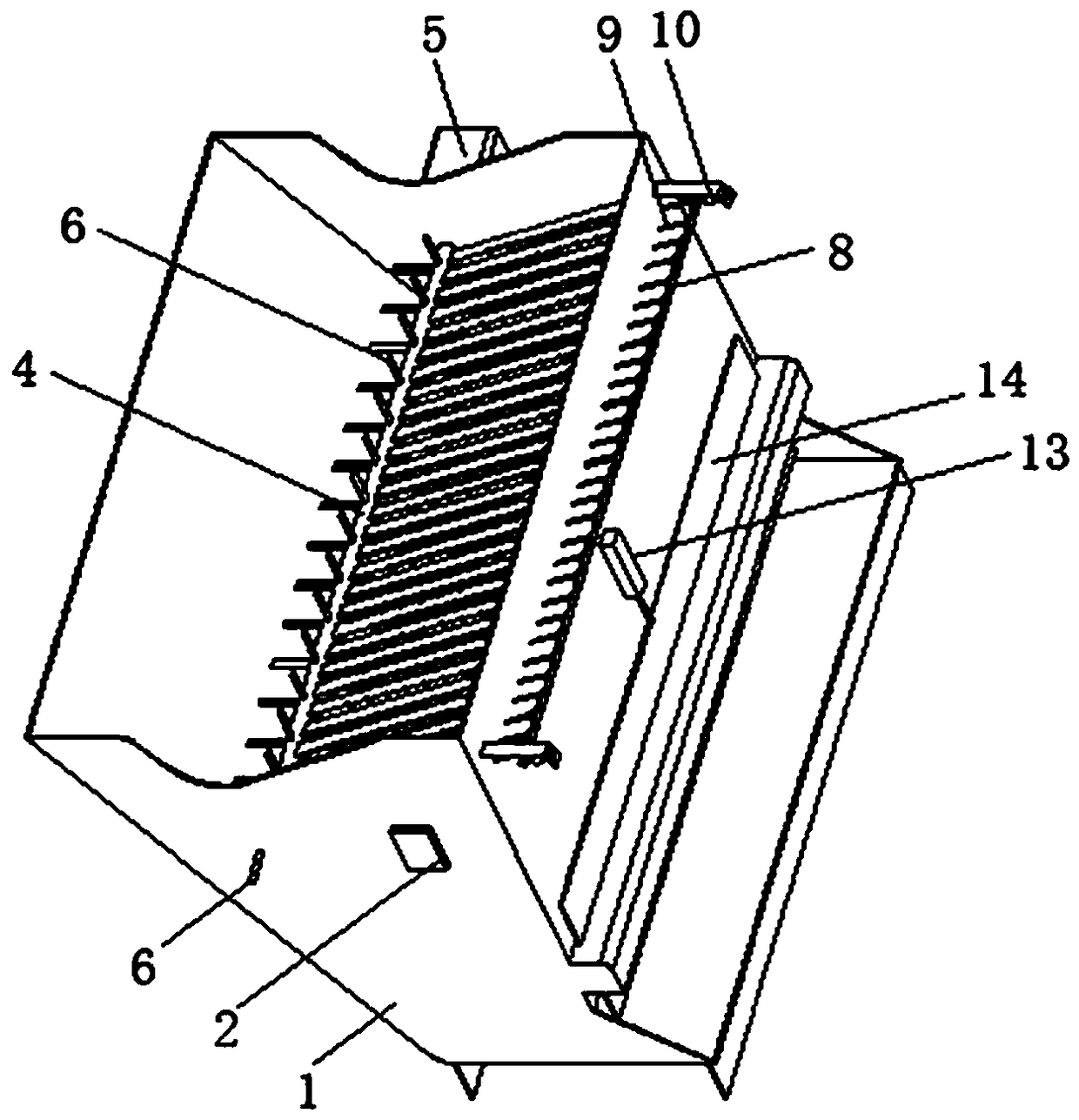

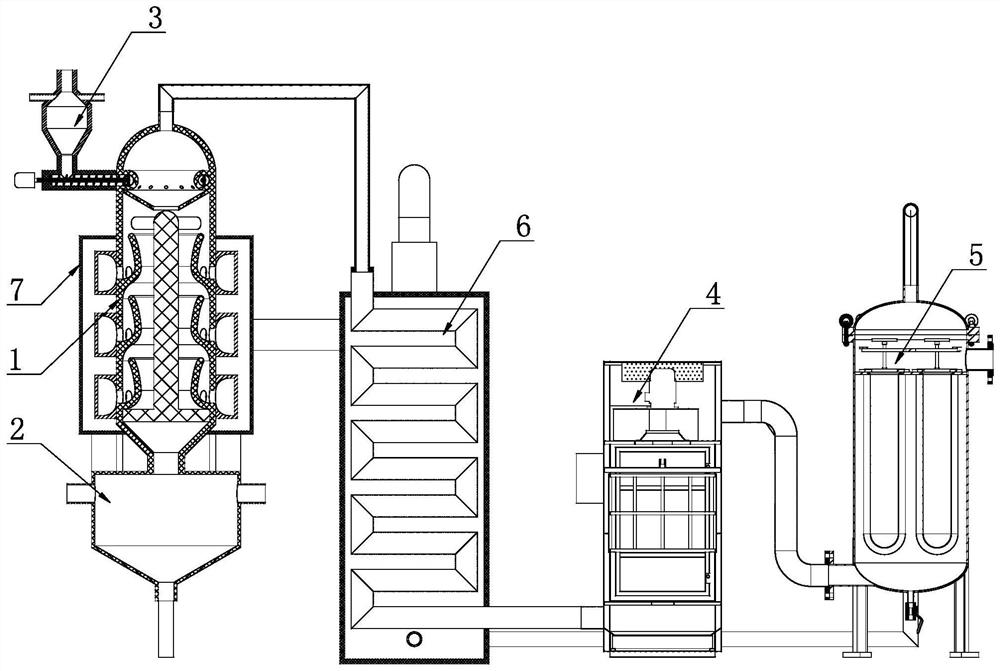

Coconut shell carbonization material activation furnace

ActiveCN103523779AControl the falling speedImprove efficiencyCarbon compoundsActivated carbonCombustion chamber

The invention discloses a coconut shell carbonization material activation furnace. The coconut shell carbonization material activation furnace comprises a combustion chamber and a furnace body, wherein the furnace body comprises a furnace wall, a hearth and a cooling section, the combustion chamber and the hearth are communicated through a first gas pipeline, a carbonization section, an additional carbonization section and an activation section which are communicated with one another are arranged in the hearth, the carbonization section is communicated with a material feeding hole, a plurality of material channels are arranged in the carbonization section, a plurality of first filter screens are arranged in each material channel, the additional carbonization section is arranged at the lower part of the carbonization section, a plurality of second filter screens are arranged in the additional carbonization section, the activation section is arranged below the additional carbonization section, a wave-shaped plate body is arranged at the bottom of the activation section, a plurality of small holes are formed in the plate body, the cooling section is communicated with the activation section, and a material outlet is formed in the cooling section. The coconut shell carbonization material activation furnace is concise in structure, economical and practical, compared with the traditional activation furnace, the coconut shell carbonization material activation furnace has the activation rate increased by 20%, and besides, the quality of a coconut shell activated carbon finished product is high, and the surface of the coconut shell activated carbon finished product is not cracked.

Owner:BEIHAI HERONG ACTIVE CARBON TECH

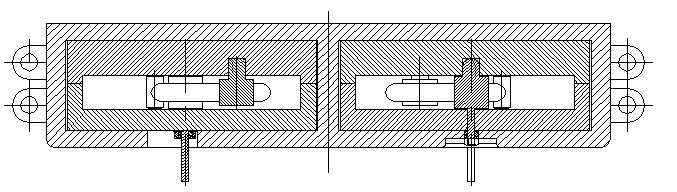

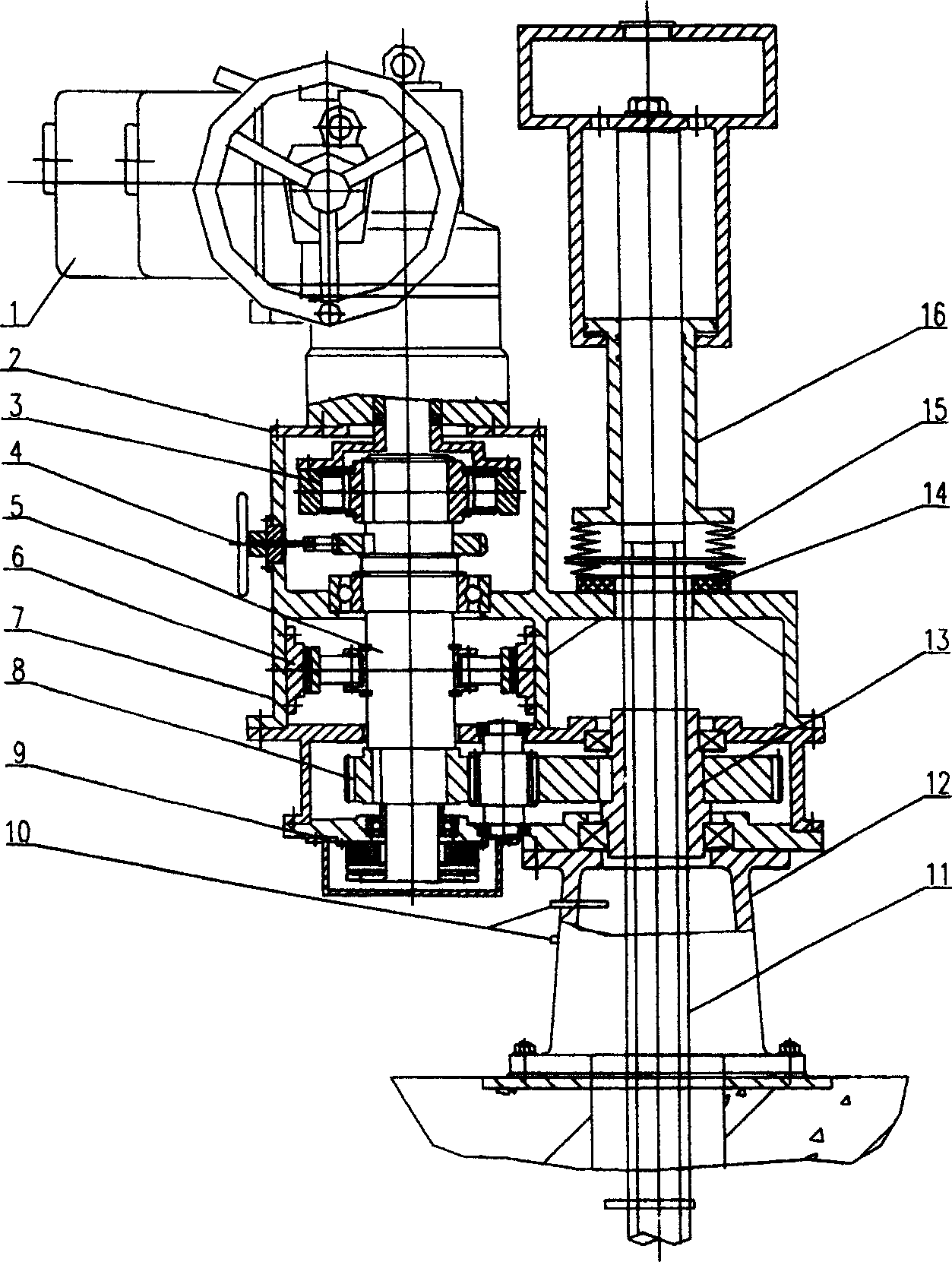

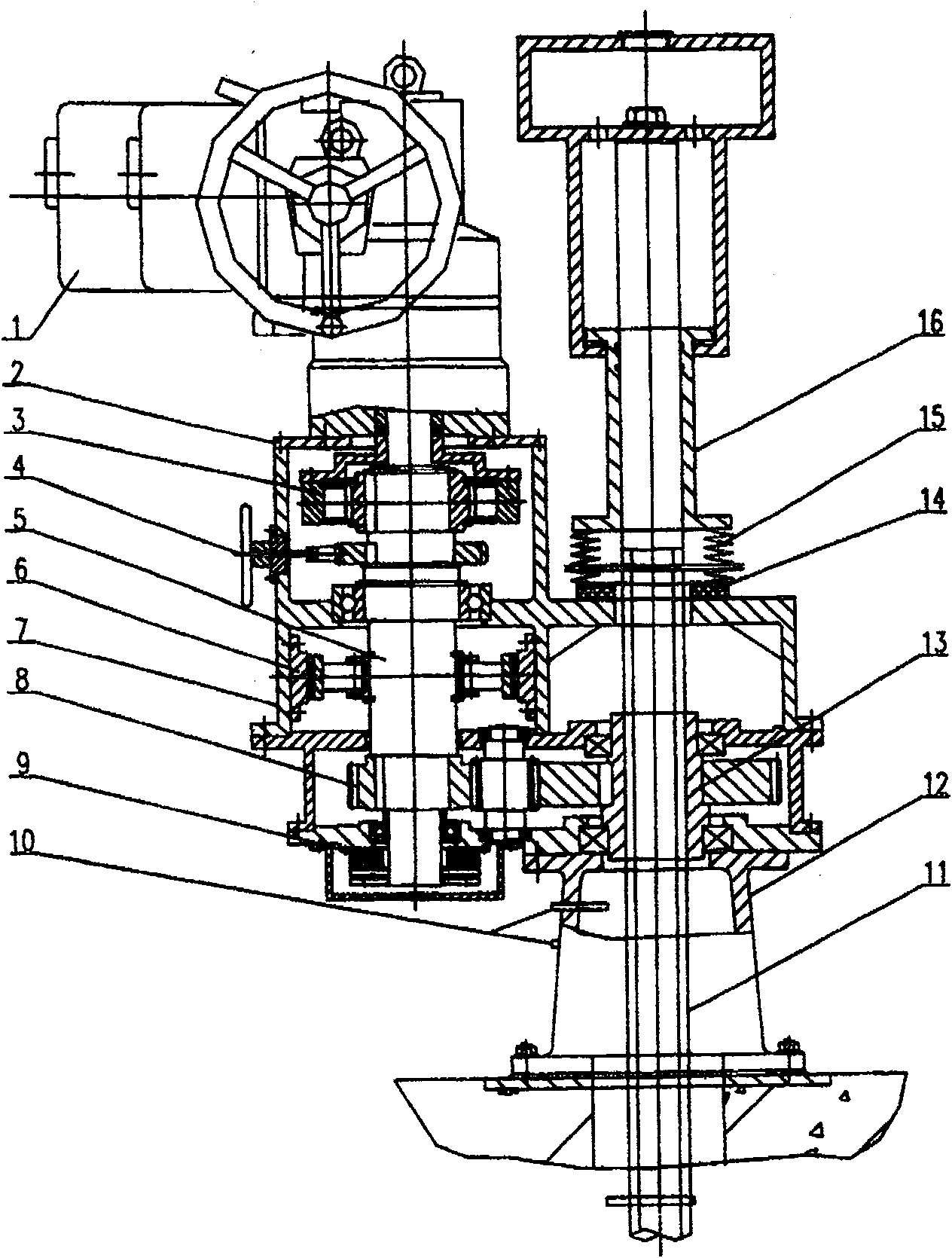

Gate hoist

The invention relates to a gate control device that could quick show down the gate, comprising a base, a controlling device, a drive motor, a driving device and a box body, the driving axis of the driving device is connected arranged inside the screw of the box body via a driving gear, the screw is provided with an internal feed screw, the bottom of the feed screw is connected with the gate, comprising a retaining clutch, a speed-limiting device and a cushion cylinder, the motor axis is connected with the driving axis via the retaining clutch, the central part of the rotation axis is provided with a speed-limiting device fixed connected with the box body, the top end of the feed screw is connected with a cushion cylinder. When The invention is power off, the magnetic brake is released, and the gate drops and shuts down by the weight. When the gate automatically drops, the drive motor will be reversely drove by the driving device, to prevent the magnetic electricity generated by the reverse rotation of the motor from damaging the drive motor, to control the rotation speed of the driving axis, to prevent the direct burst of the weight, to effectively protect the gate and the base, and to mutually prolong the durability of the cushion cylinder.

Owner:JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

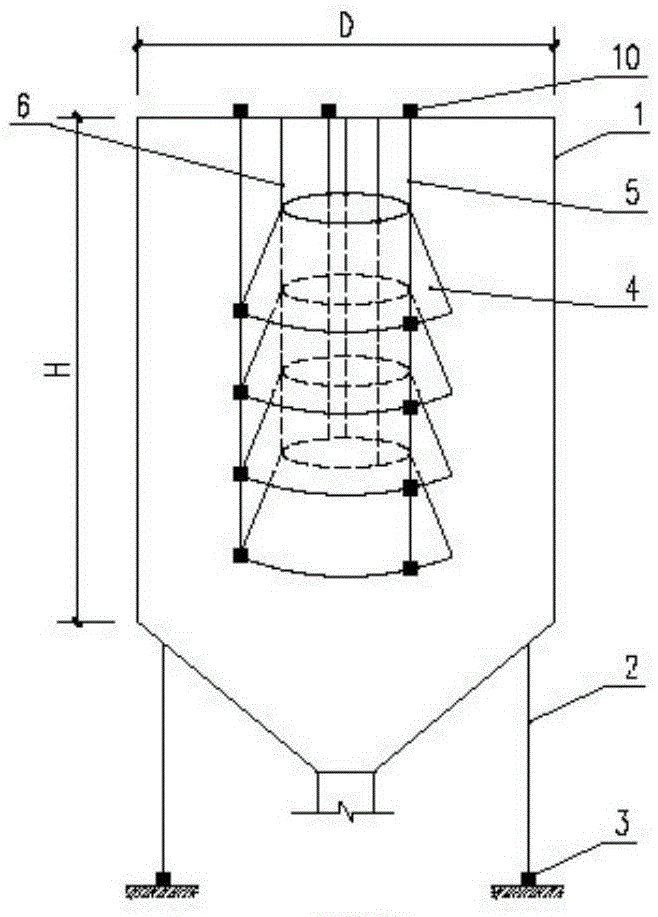

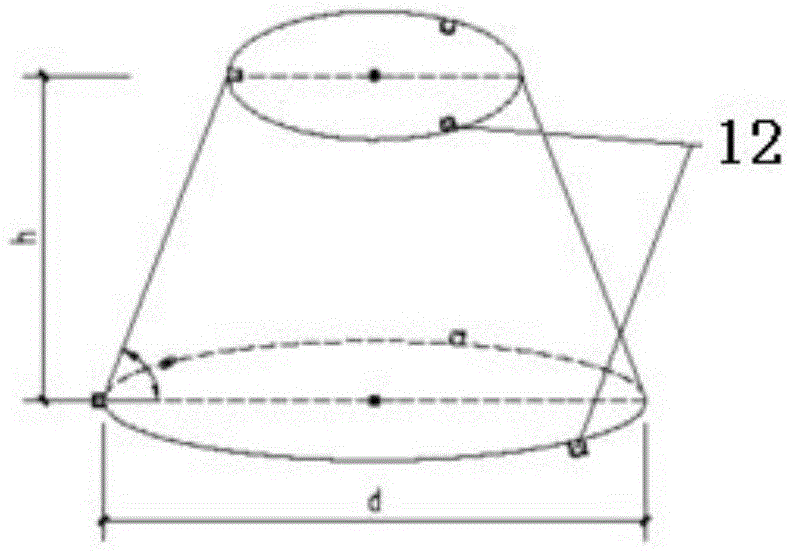

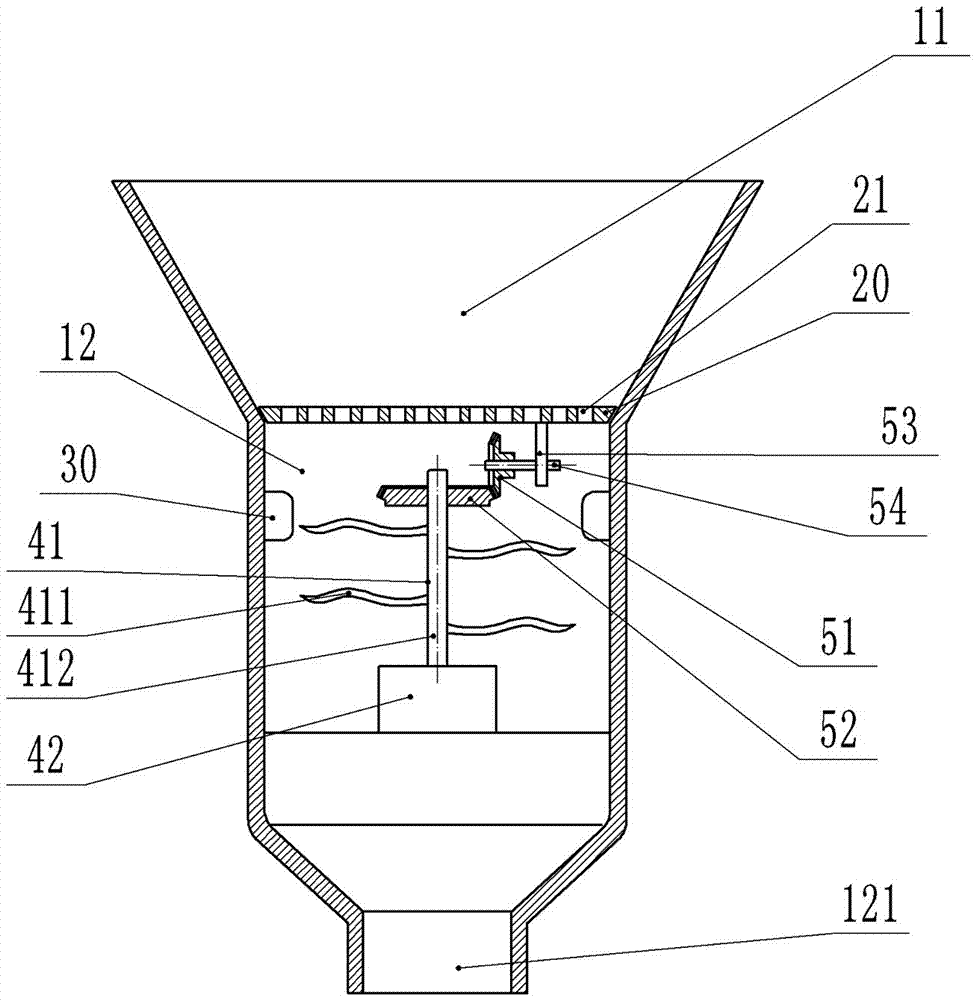

Anti-separation device for dry-mixed mortar bin

PendingCN105645138AShorten the fall distanceAchieve a second dropLoading/unloadingCouplingComputer module

The invention discloses an anti-separation device for a dry-mixed mortar bin. The anti-separation device for the dry-mixed mortar bin is composed of a plurality of sleeves, a lifting device and a connecting module, wherein the sleeves are arranged in the bin, the lifting device is arranged outside the bin, and the connecting module is located between the sleeves and the lifting device. Each sleeve is in the shape of a circular truncated cone, wherein the upper portion and the lower portion of the sleeve are open, and the area of the lower opening is larger than that of the upper opening. The sleeves are connected in a sleeved mode, connected through the connecting module and vertically hung in the bin. The connecting module is composed of steel wire ropes which are fixed to the outer circumference of the bottommost sleeve and fixed pulleys at the top of the bin and soft connecting ropes which are fixed to the inner circumferences of the sleeves and the inner wall of the top of the bin. The lifting device is arranged on the top surface of the bin and comprises a motor. A plurality of take-up and pay-off rollers are connected with the motor through couplings and spaced form the motor by a certain distance. One fixed pulley is correspondingly arranged in the position a certain distance away from each take-up and pay-off roller in the vertical direction. The fixed pulleys are evenly arranged along the circle center of the top surface of the bin, so that the effect that the connecting device and the sleeve are balanced is guaranteed. The anti-separation device for the dry-mixed mortar bin is exquisite in design, low in cost and outstanding in effect and has extremely high commercial promotional value.

Owner:广西建筑材料科学研究设计院有限公司

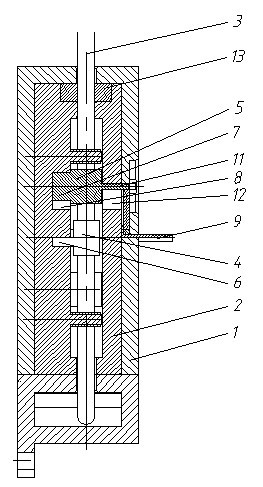

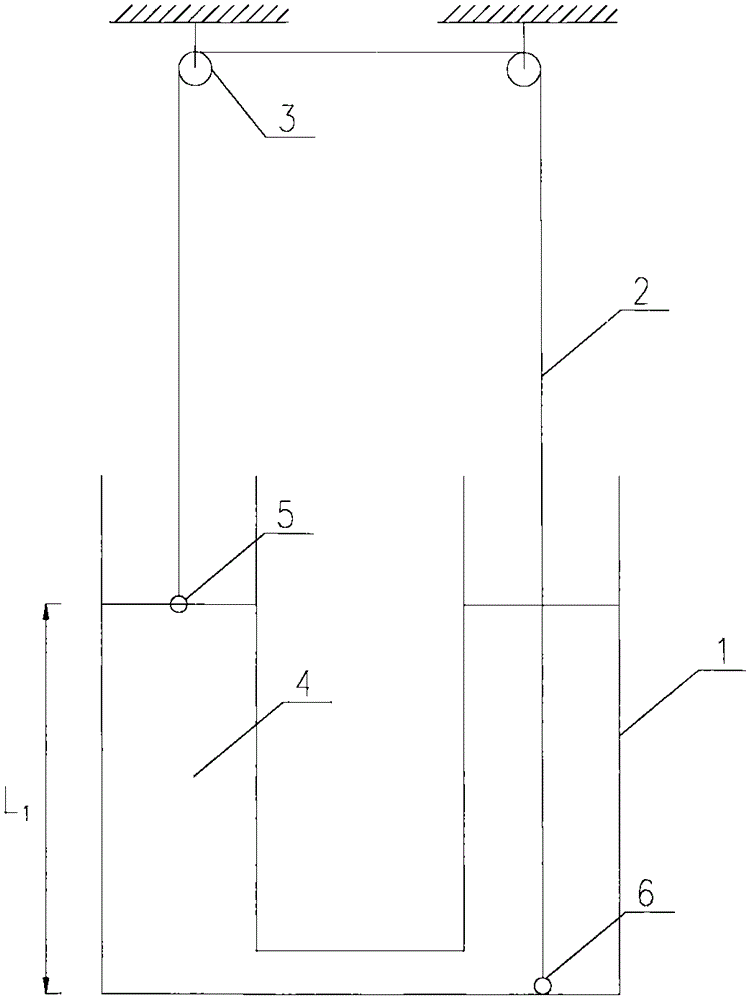

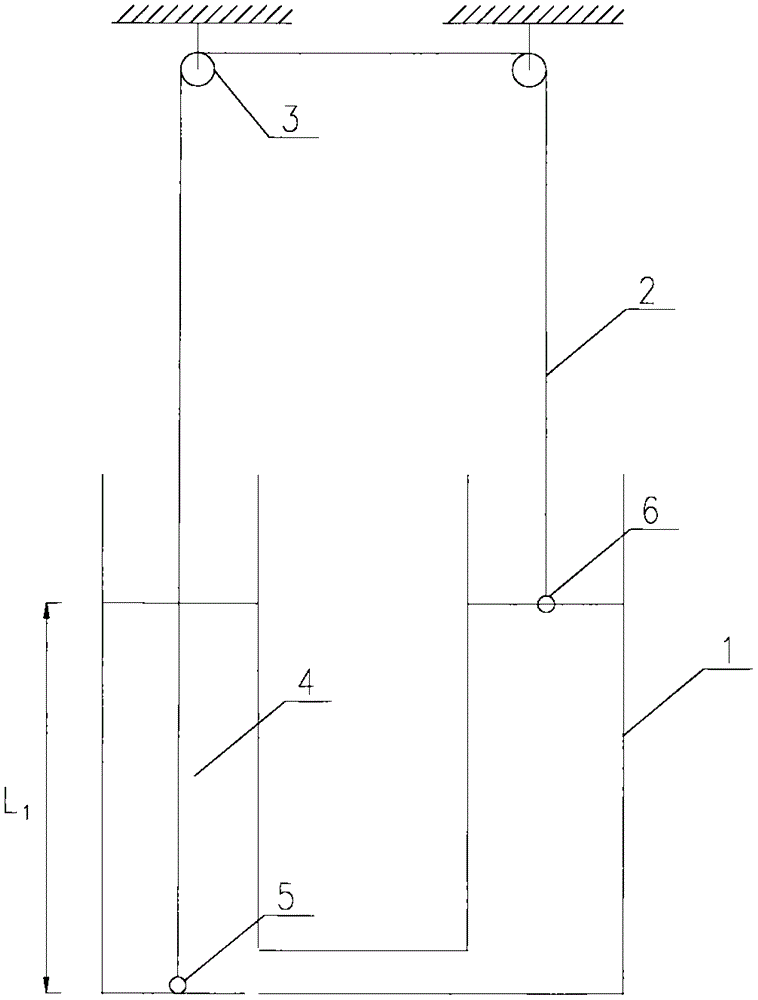

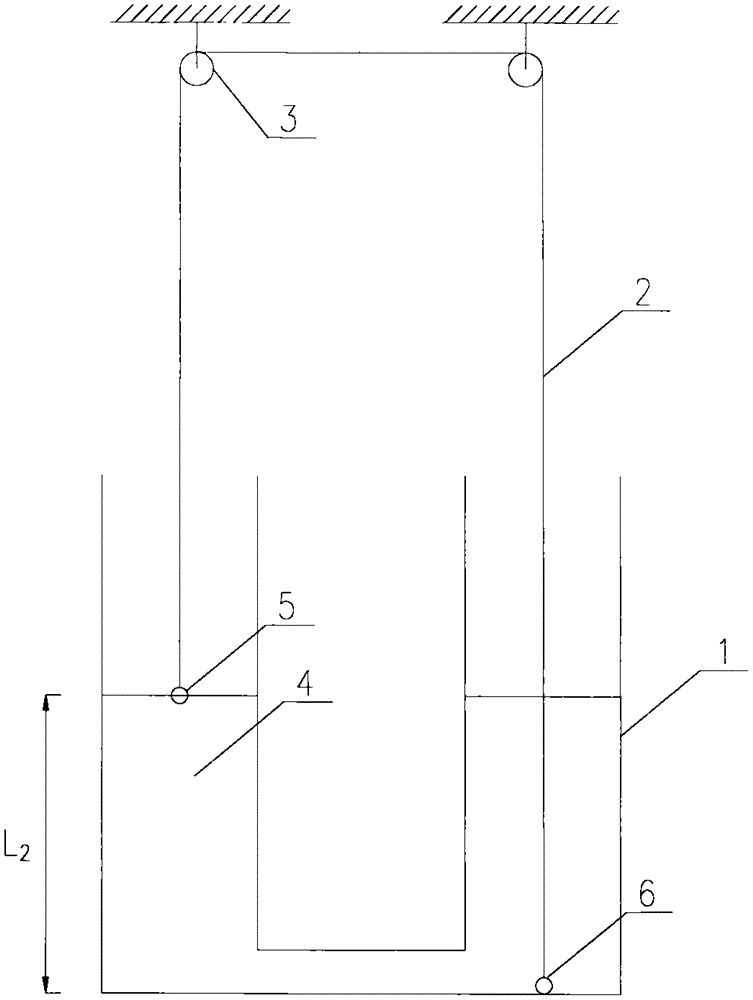

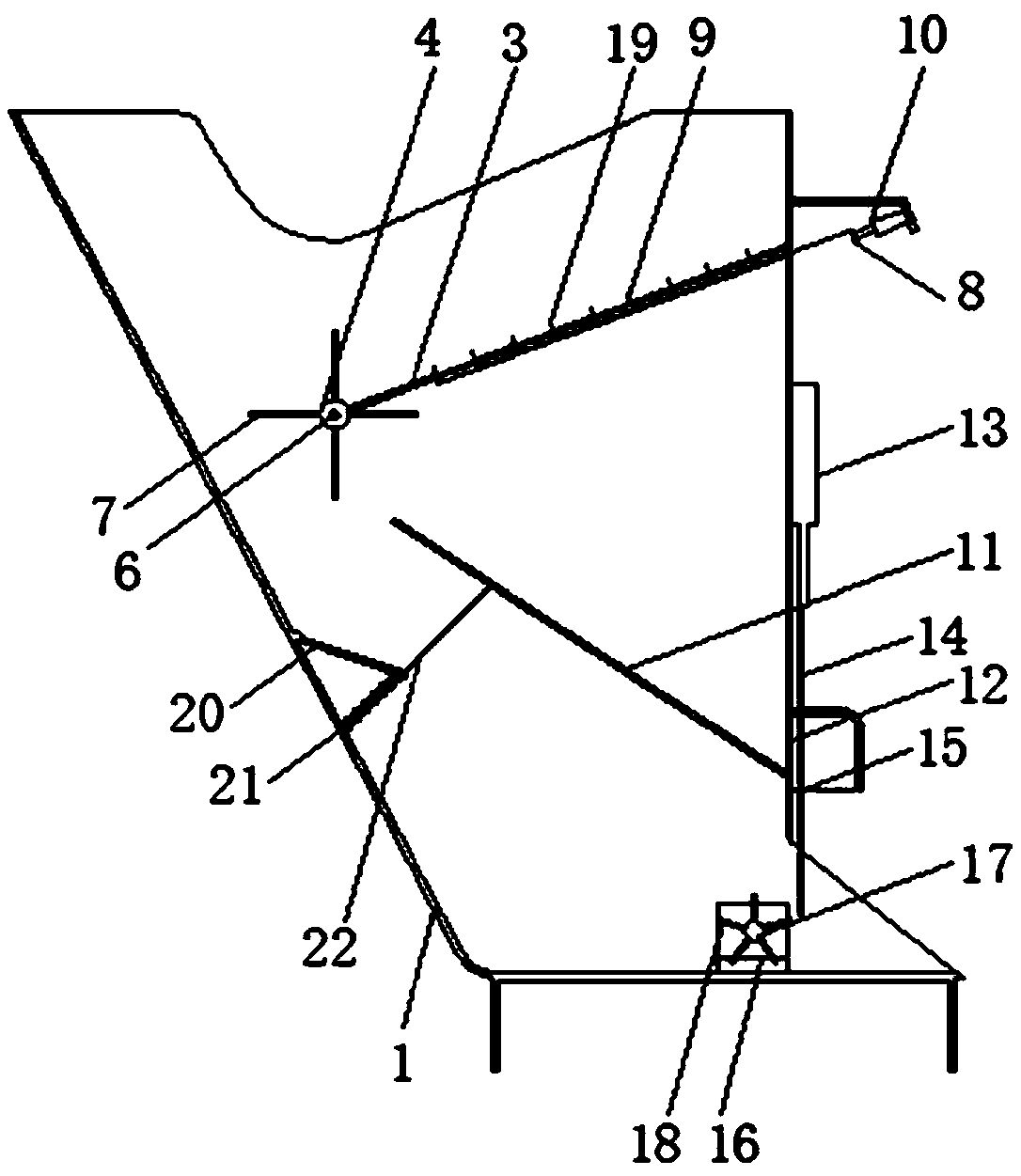

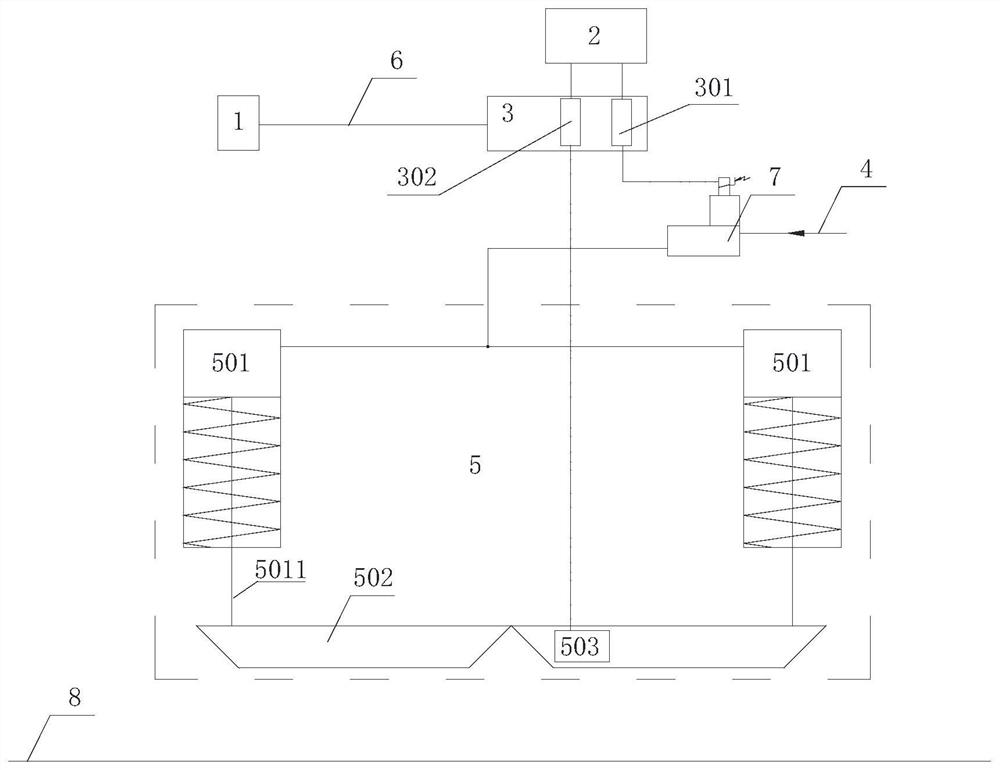

Experimental device and method for measuring liquid viscosity coefficient through U-shaped tube

InactiveCN105606491AControl the falling speedAccurate measurement of viscosity coefficientFlow propertiesLiquid densityExperimental methods

The invention discloses an experimental device and method for measuring a liquid viscosity coefficient through a U-shaped tube. The experimental device is composed of the U-shaped tube, a thin filament, a pulley block, a driving small ball, a driven small ball and experimental liquid. By analyzing the linkage movement of the two small balls connected to the two ends of the thin filament on the two sides of the U-shaped tube, and the liquid viscosity coefficient is obtained under the condition that the liquid density is not precisely measured and buoyancy is not calculated. According to the experimental method, by means of the stress of the small balls in the balanced state and the Stokes formula, the relation between the liquid viscosity coefficient and the terminal velocity of the small balls is acquired. The experimental method further includes the step that by changing the liquid level height, measuring the terminal velocity of the small balls and changing the average density of the driven small ball, the Reynolds number of the viscosity coefficient is corrected. The experimental device and method are clear in principle, equipment is simple, operation is fast, the falling speed of the driving small ball is effectively controlled by arranging the driven small ball, and the experimental device and method are suitable for measuring the liquid viscosity coefficient of small-viscosity liquid and are also suitable for physical experiment teaching.

Owner:QIQIHAR UNIVERSITY

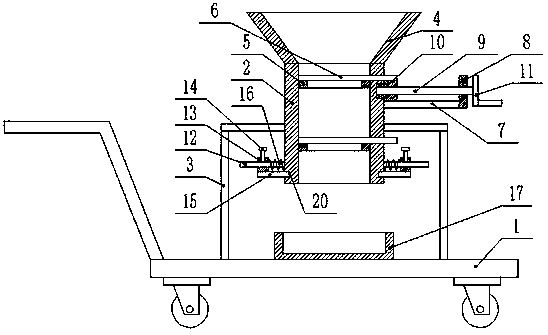

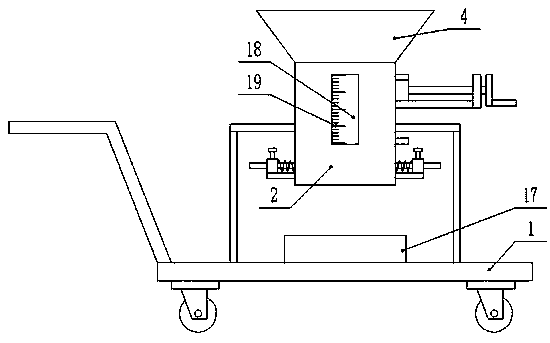

Rice bagging device

The invention discloses a rice bagging device which comprises a cart. A box body is arranged above the cart, the cross section of the box body is square, the box body and a cart plate of the cart arefixed through brackets on the two sides, the upper end of the box body is fixedly provided with a discharging hopper and communicates with the discharging hopper, the interior of the box body is provided with two square frames fixed to the inner wall of the box body, baffles are attached to the upper ends of the square frames, one end of each baffle passes through the side wall of the box body andis slidably connected with the side wall of the box body, the side end of the box body is fixedly provided with a horizontal plate, a vertical plate is fixed at the side end of the horizontal plate,a lead screw penetrates through the vertical plate, a hand wheel is fixed to one end of the lead screw, the other end of the lead screw is rotatably connected to the side wall of the box body througha bearing, the lead screw is sleeved with a lead screw nut and is in threaded connection with the lead screw nut, the upper end of the lead screw nut and the baffles above the inside of the box body are fixed, transverse bars are fixed below the two ends of the box body, the transverse bars are sleeved with sleeves and are in sliding connection with the sleeves, the sleeves are provided with boltsfor fastening the transverse bars, and the lower ends of the sleeves are fixedly provided with half clamps. By means of the rice bagging device, bag openings of rice bags are conveniently fixed, andrice bagging and weighing are facilitated.

Owner:宿迁市君来米业有限公司

Crusher convenient to load and unload

The invention discloses a crusher convenient to load and unload. The crusher comprises a machine body; a feeding place is arranged on one side of the machine body; a support ring plate is arranged onone side of the feeding place; a feed hopper is arranged on one side of the support ring plate; a rubber plate is fixed on the side, near the feed hopper, of the feeding place through bolts; an adjusting mechanism is arranged at one end of the feed hopper; a second clamping ring plate, a first clamping ring plate, a clamping spring, a pull handle and a clamping plate are arranged on the outer sideof a discharge place; through elastic force of the clamping spring, bag openings are conveniently fixed, and the operation is simple; the support ring plate, a rotating rod, an adjusting screw rod, afixed plate, a support plate and a rotating ball are arranged on the outer side of one end of the feed hopper; through cooperation between the rotating ball and a rotating groove, the support plate is preferably bonded with the feed hopper; and through the adjusting screw rod, the feed hopper and the support ring plate are rotated to conveniently adjust the inclined angle of the feed hopper so asto preferably control the falling speed of raw materials.

Owner:黄石利佳智能科技有限公司

Soil remediation device capable of accurately regulating blanking efficiency

ActiveCN108160695APrecise control of feeding efficiencySave storage spaceRotary stirring mixersTransportation and packagingSoil remediationDevices fixation

The invention discloses a soil remediation device capable of accurately regulating blanking efficiency. A slide is arranged at the bottom of a table body, and a first bearing is arranged on the slide;a first bearing seat is fixedly connected with a linear conveying device; the lower end of the linear conveying device is connected with a supporting piece; a storage silo is arranged on the table body, and a stirring shaft is arranged in the storage silo; a plurality of blades are evenly distributed on the stirring shaft; a dosing hopper is connected to the storage silo, and a discharge port isformed below the storage silo; a transfer frame is placed under the dosing hopper, and the upper and lower parts of the transfer frame is open; an elastic sheet is laid in the transfer frame, one endof the elastic sheet is fixed, the other end of the elastic sheet is connected to a rotating shaft, and the rotating shaft is driven by a variable frequency motor; and a partition plate, a baffle, anda partition plate are laid from top to bottom in the dosing hopper, first through holes are formed in the partition plates, the baffle is driven by a motor to rotate, and second through holes are formed in the baffle. According to the soil remediation device capable of accurately regulating the blanking efficiency, the problems that soil remediation equipment occupies a large amount of space andis difficult to transfer in the prior art are solved, and the purposes of reducing the space occupied by storage and facilitating the movement are achieved.

Owner:ANHUI HEKUANG MACHINERY

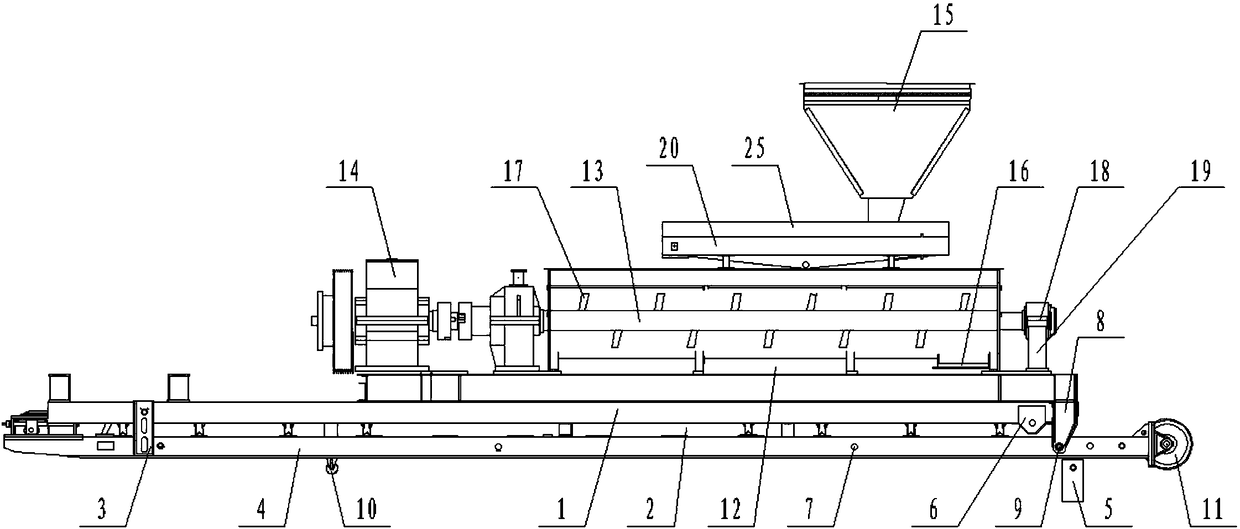

Smooth particle material rolling drying device

InactiveCN112503909AAchieve recyclingAvoid mixingGranular material dryingDrying solid materialsThermodynamicsElectric machinery

The invention belongs to the technical field of industrial and agricultural production tools, and particularly relates to a smooth particle material rolling drying device. The smooth particle materialrolling drying device comprises a bottom plate, first supporting legs, second supporting legs, a first rotating roller, a second rotating roller, a conveying belt, a supporting frame, a heat supply plate, a first hopper, a mounting frame, a connecting plate, a first motor, a discharging roller, a second motor and a material returning mechanism. According to the smooth particle material rolling drying device, by the obliquely-arranged conveying belt, when materials fall onto the conveying belt, the materials roll and move downwards under the action of the gravity of the materials; and throughrotation of the first motor, the conveying belt drives the materials to have an upward trend under the action of friction force; when the materials fall down, the materials are turned over under the combined action of the gravity of the materials and friction force provided by the conveying belt; and by adjusting the rotating speed of the first motor, the upward moving speed of the materials driven by the conveying belt is balanced with the downward rolling speed of the materials under the action of self weight, the materials stay on the conveying belt for a long time, and a heat supply platecan dry the materials more evenly.

Owner:詹传喜

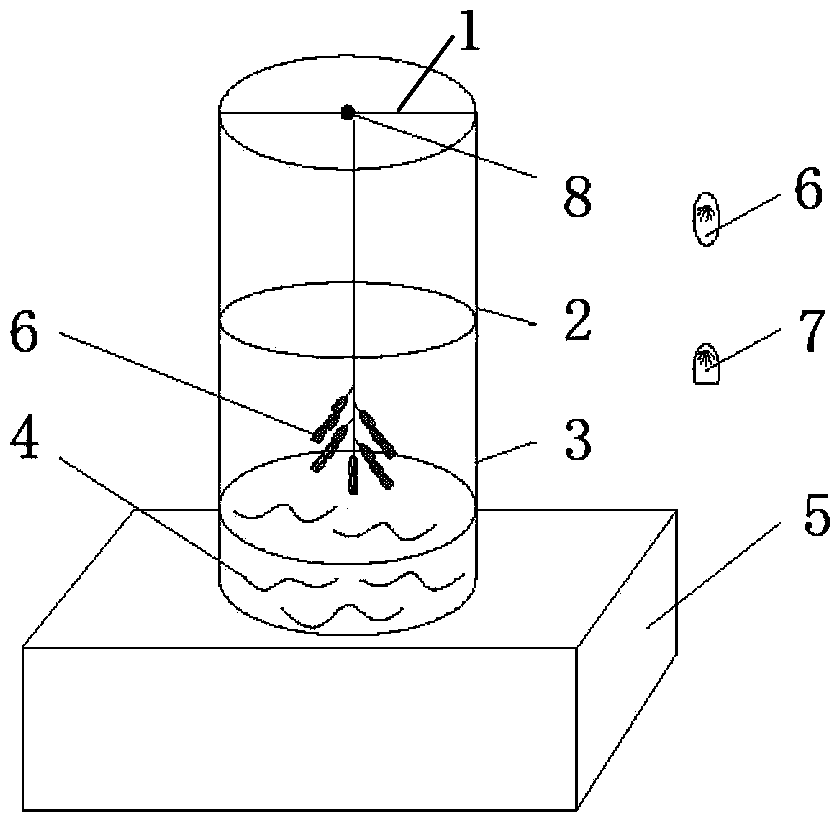

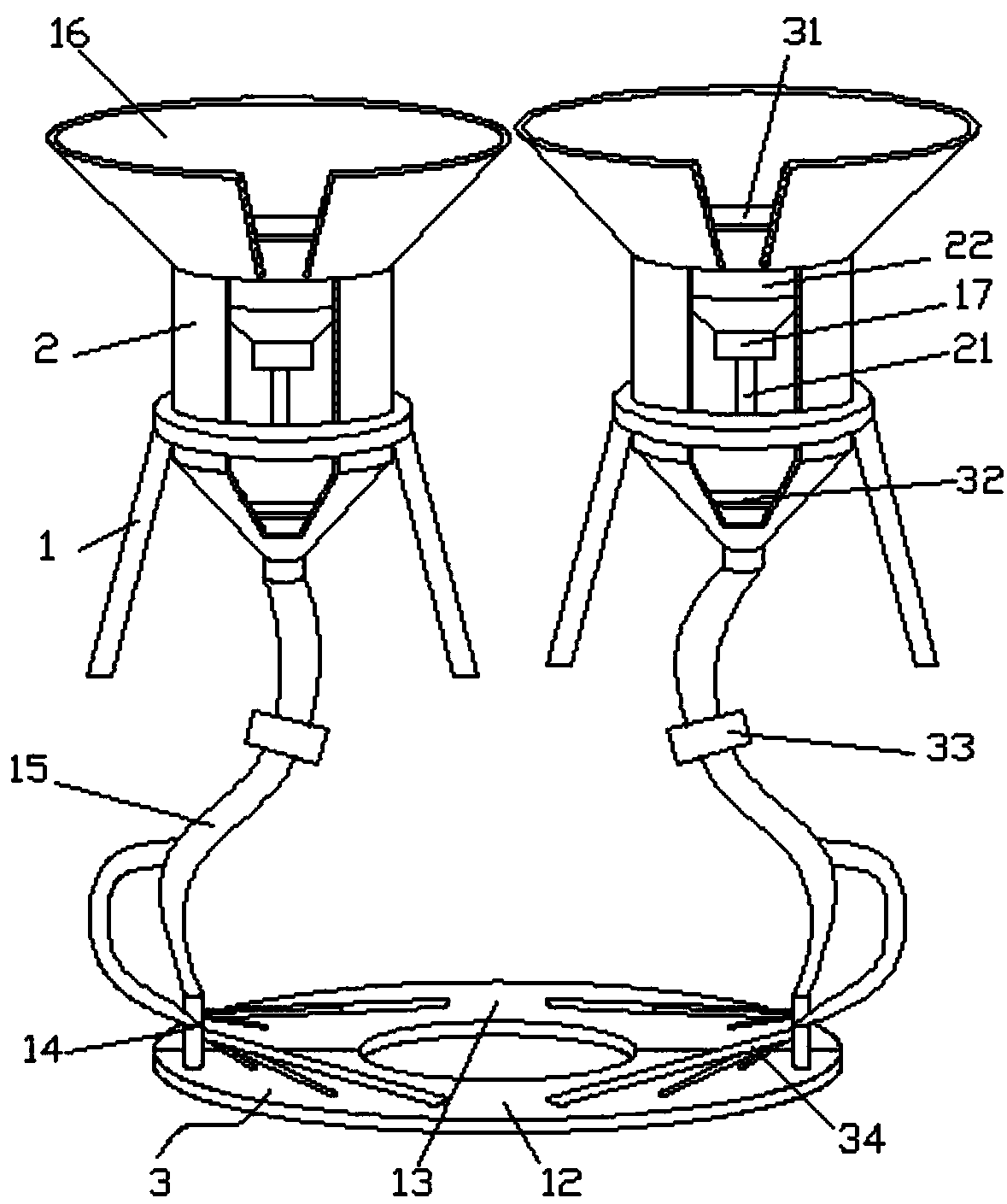

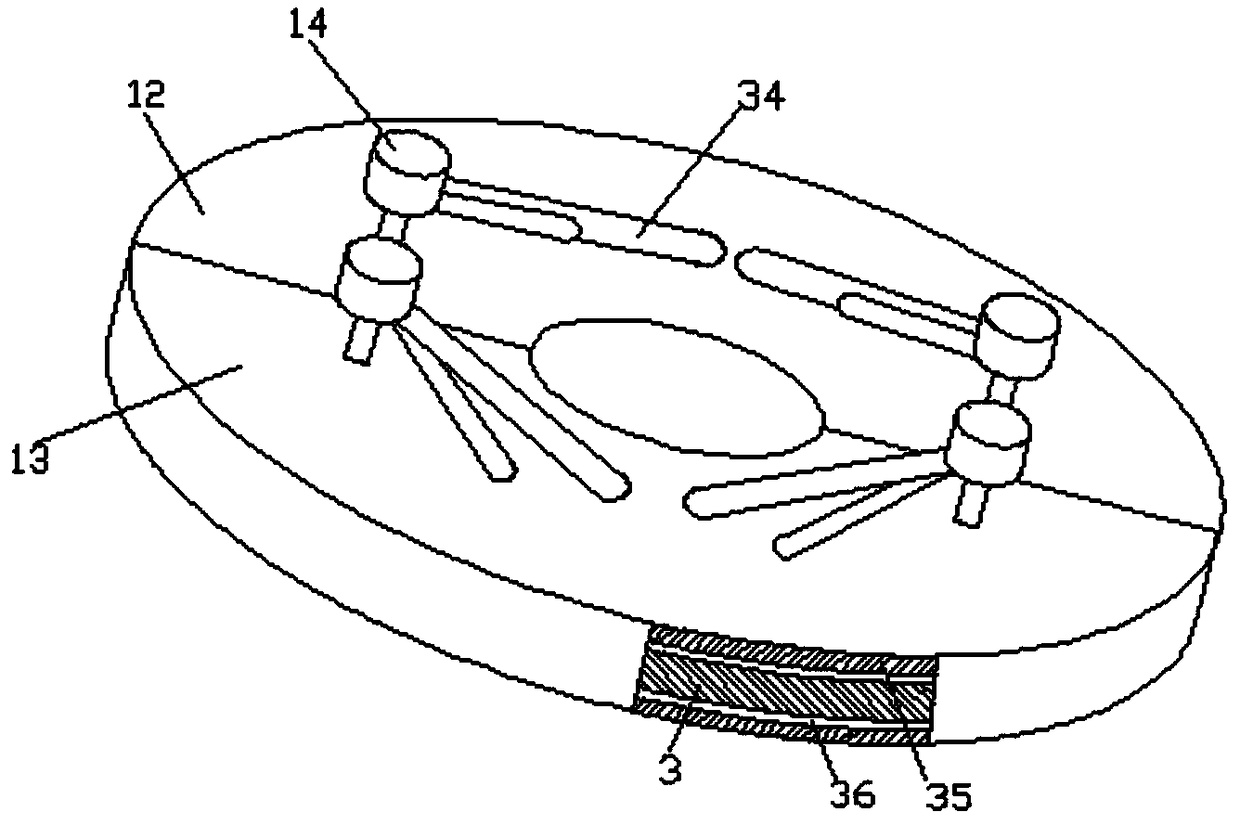

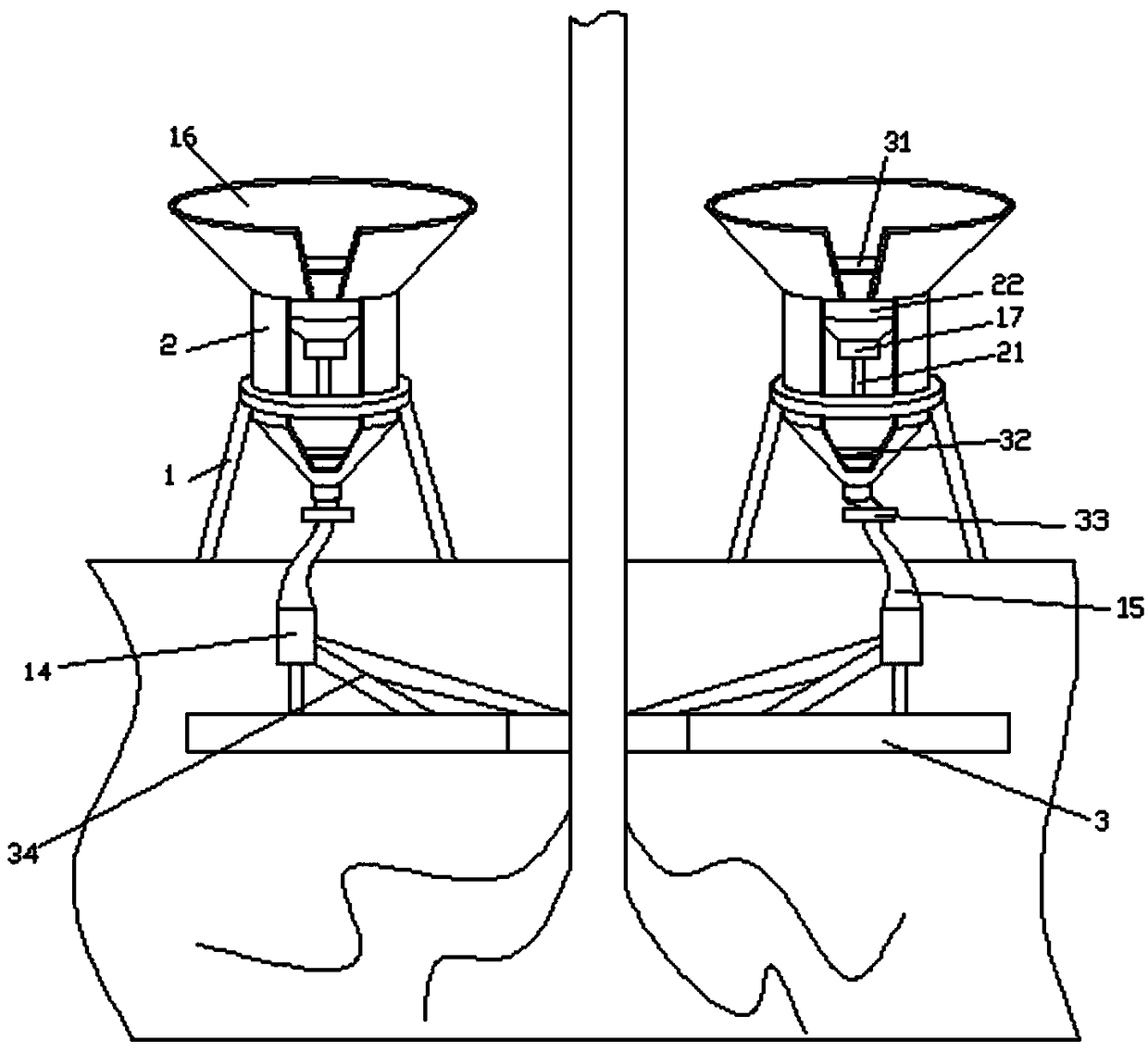

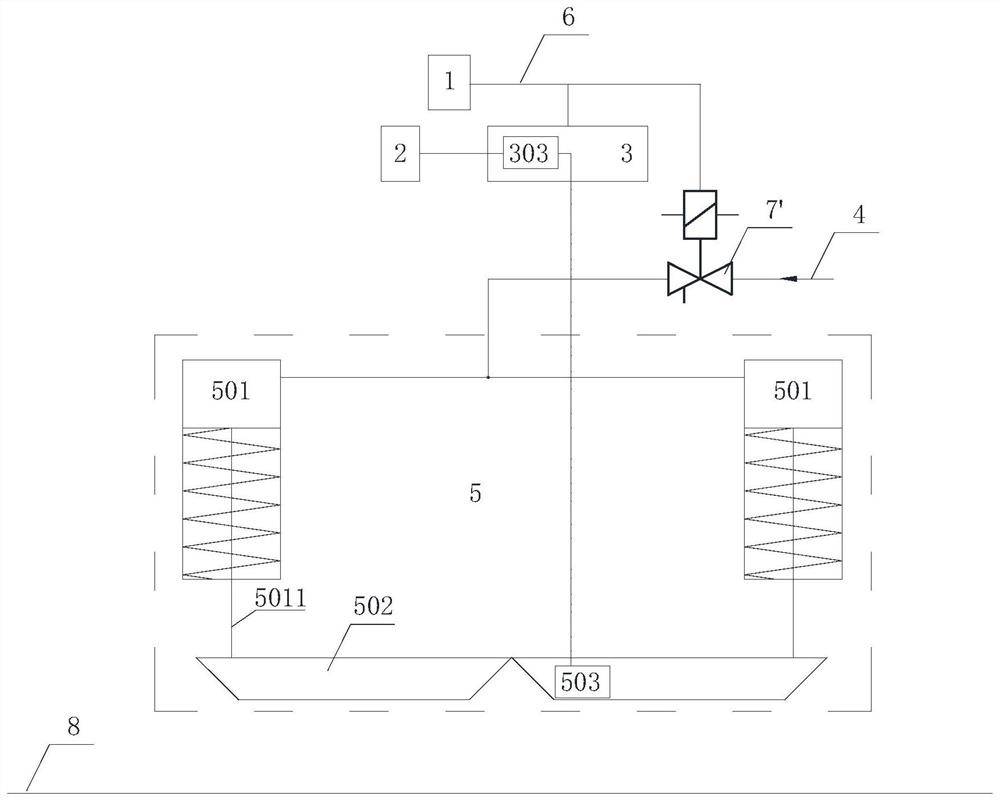

Drip irrigation device for field planting of pear trees

InactiveCN109122230AReduce evaporationSave waterGeneral water supply conservationWatering devicesRoot systemWater storage tank

The invention discloses a drip irrigation device for field planting of pear trees. The drip irrigation device comprises device support frames, water storage tanks and a capillary net plate; the capillary mesh plate is of an annular structure; a plurality of permeation holes are formed in the surface of the capillary mesh plate; the capillary net plate is divided into a left half ring and a right half ring along a middle axis; an end side of the left half ring and an end side of the right half ring are respectively provided with water inlets; each water inlet is respectively sleeved with a rubber hose; the other end of each rubber hose is connected to the bottom end of one water storage tank; each water storage tank is fixedly arranged on one device support frame; the opening at the upper end opening of each water storage is provided with a collecting funnel; and the bottom end of each collecting funnel is provided with a one-way valve. Through the device provided by the invention, moisture evaporation is reduced, and moisture absorption of root systems of pear trees is facilitated, so that the utilization of rainwater is facilitated, water resources are saved, and the irrigation effect is obvious.

Owner:安徽省尚书生态农业科技有限公司

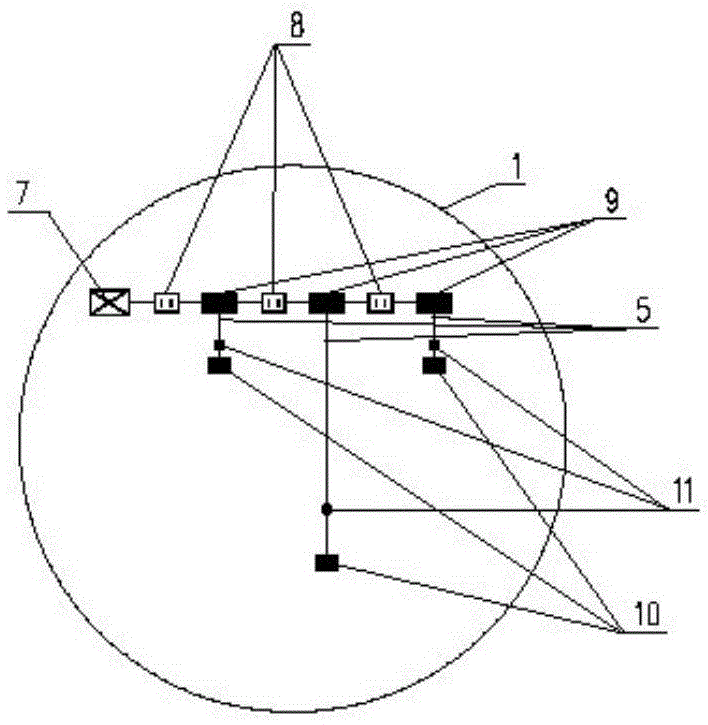

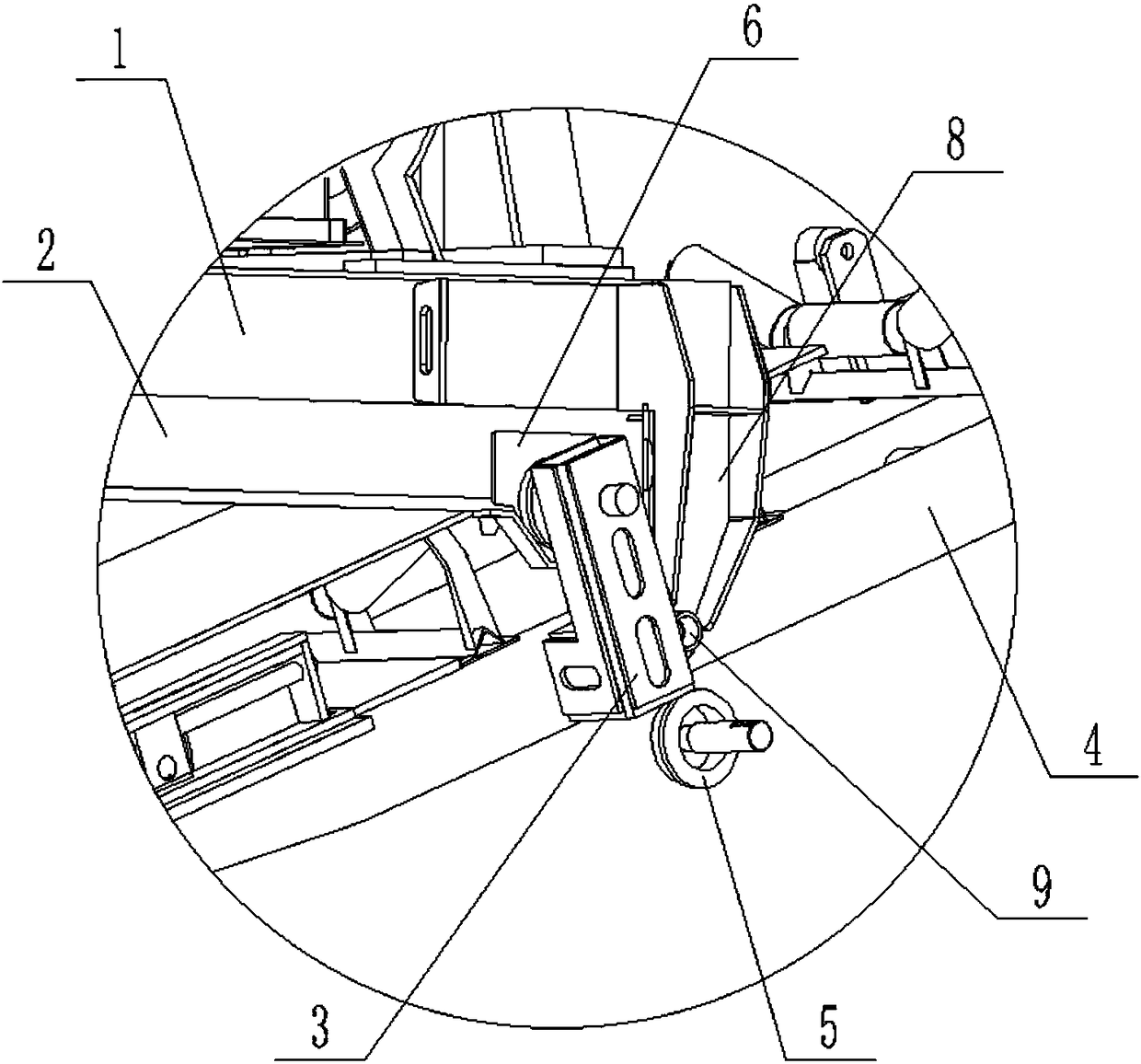

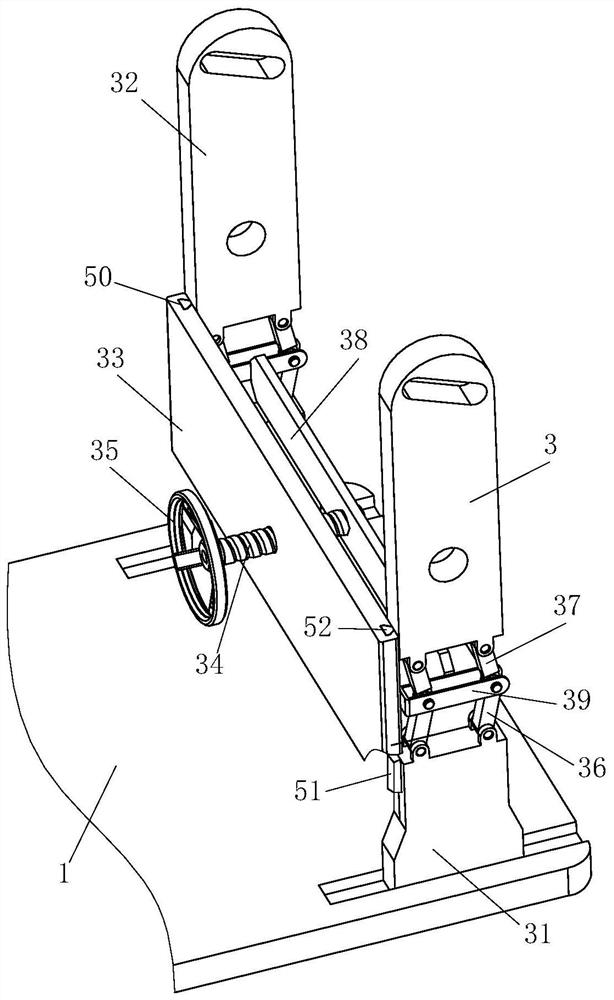

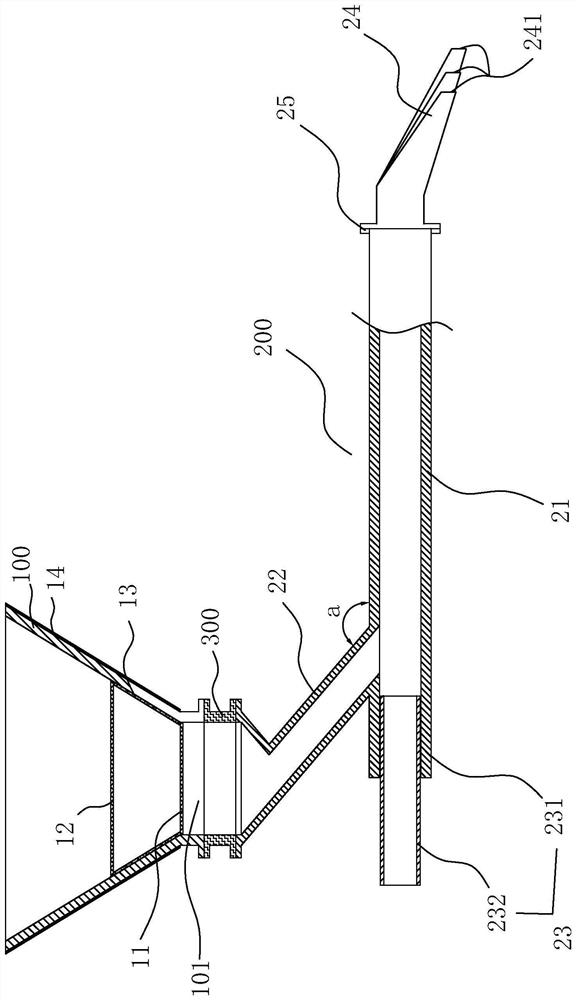

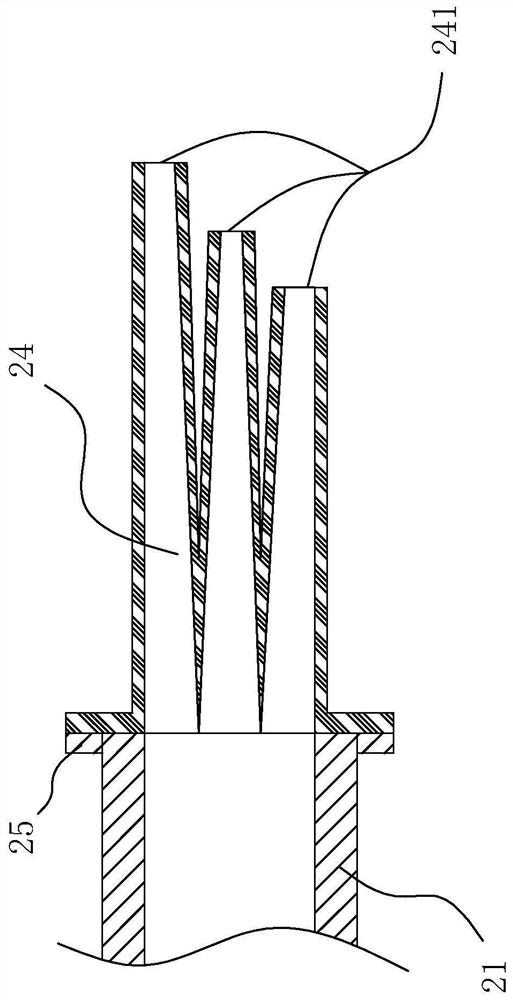

Fruit collecting device for auxiliary picking machine and adjusting method of fruit collecting device

ActiveCN113287418AEvenly distributedReduce falling speedVibration suppression adjustmentsPicking devicesAgricultural engineeringMechanical engineering

The invention discloses a fruit collecting device for an auxiliary picking machine and an adjusting method of the fruit collecting device. The device comprises a vertical conveying assembly, a buffering assembly, a supporting table assembly and a rotary adjusting assembly; the supporting table assembly is fixedly arranged on the auxiliary picking machine; the rotary adjusting assembly is rotationally mounted on the supporting table assembly and used for placing a fruit collecting box; the center line of the fruit collecting box in the vertical direction coincides with the rotation center of the rotary adjusting assembly; and the vertical conveying assembly is mounted on the auxiliary picking machine, an outlet of the vertical conveying assembly is located above the rotary adjusting assembly, and the center line of the outlet of the vertical conveying assembly does not coincide with the rotation center of the rotary adjusting assembly. The fruit collecting device can ensure that fruits uniformly fall into the fruit collecting box as much as possible, and the damage rate of the fruits in the collecting process is reduced.

Owner:SHANDONG JIAOTONG UNIV

Uniform coal feeding device of chain furnace

ActiveCN108930975ASimple structurePromote combustionLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationSlagCoal

The invention discloses a uniform coal feeding device of a chain furnace. The uniform coal feeding device comprises a coal hopper, wherein the upper end surface of the coal hopper is open, a strip-shaped slag outlet is formed in the lower end of the right side surface of the coal hopper, and a control switch is arranged on the front side surface of the coal hopper. The uniform coal feeding deviceof the chain furnace is simple in structure, the separation of the large coal briquettes and the pulverized coal is realized through the separating plates, the large coal briquettes are horizontally led out to the chain through the material guide plate, the coal foam flows out of the upper side of the large coal briquette through the powder outlet, and finally falls into a gap of a large coal briquette, the coal foam is easy to fully combust, so that the combustion of the coal briquettes is accelerated, and the conversion rate of the heat energy is improved; the shifting piece can poke a mixture of the large coal briquette and the coal foam on the separating plate, so that the coal foam can fall down from the strip-shaped through hole of the separating plate, and the separation of the pulverized coal can be accelerated; the falling speed of the large coal briquette can be controlled by the coal dividing plate, the coal foam can be prevented from tracking and slipping, so that the separation efficiency is improved, and finally, the large coal briquettes and the pulverized coal are mixed.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

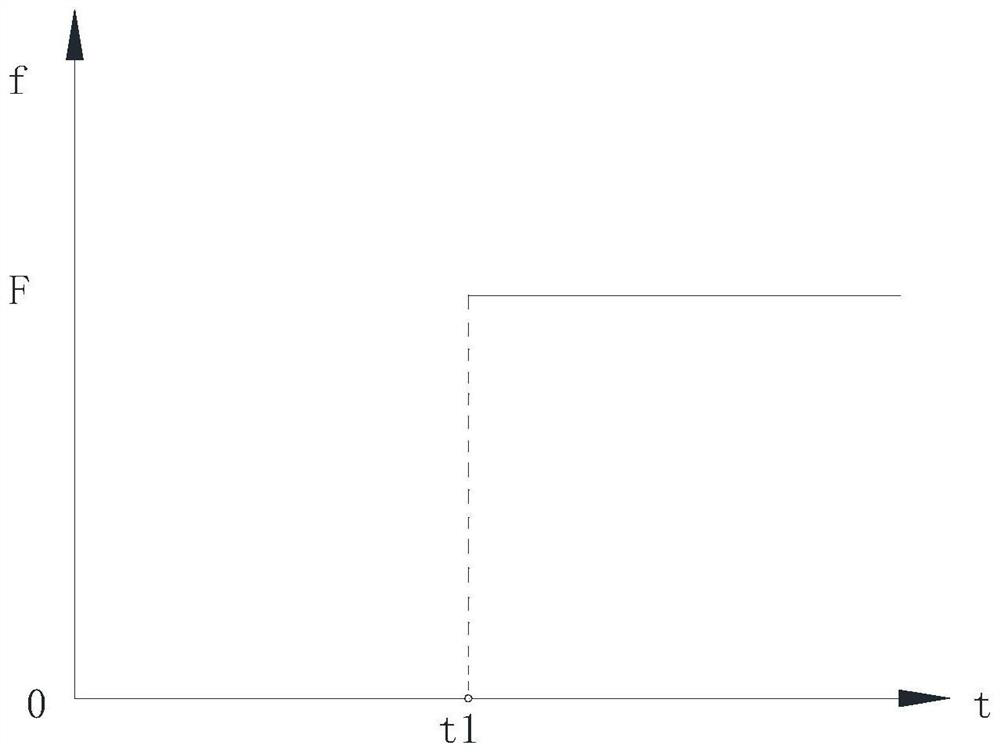

Magnetic track brake application control system and method

ActiveCN111775996AImprove impact performanceImprove ride comfort performanceTrack-braking member co-operationMicrocomputerControl system

The invention discloses a magnetic track brake application control system and method. The control system comprises a brake microcomputer unit, a brake power supply, a magnetic track brake control unit, a brake pipe and a magnetic track brake; the magnetic track brake comprises an air cylinder and a pole shoe; a piston rod of the air cylinder is fixedly connected with the pole shoe; and the controlsystem further comprises a normally-closed analog electric pneumatic valve. The magnetic track brake control unit is provided with a first current linear amplification unit and a second current linear amplification unit; the brake power supply is electrically connected with the control end of the analog electric pneumatic valve through the first current linear amplification unit; the brake pipe is connected with the air inlet end of the air cylinder through the analog electric pneumatic valve; and the brake power supply is electrically connected with a magnet exciting coil in the pole shoe through the second current linear amplification unit. When magnetic rail braking is applied, the air pressure of the air supply pipeline of the air cylinder is controlled to be linearly increased so asto control the falling speed of the pole shoe, meanwhile, linear current is output to the magnet exciting coil, it is guaranteed that a vehicle cannot generate large impact when magnetic rail brakingis switched on, and the riding comfort of passengers is improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

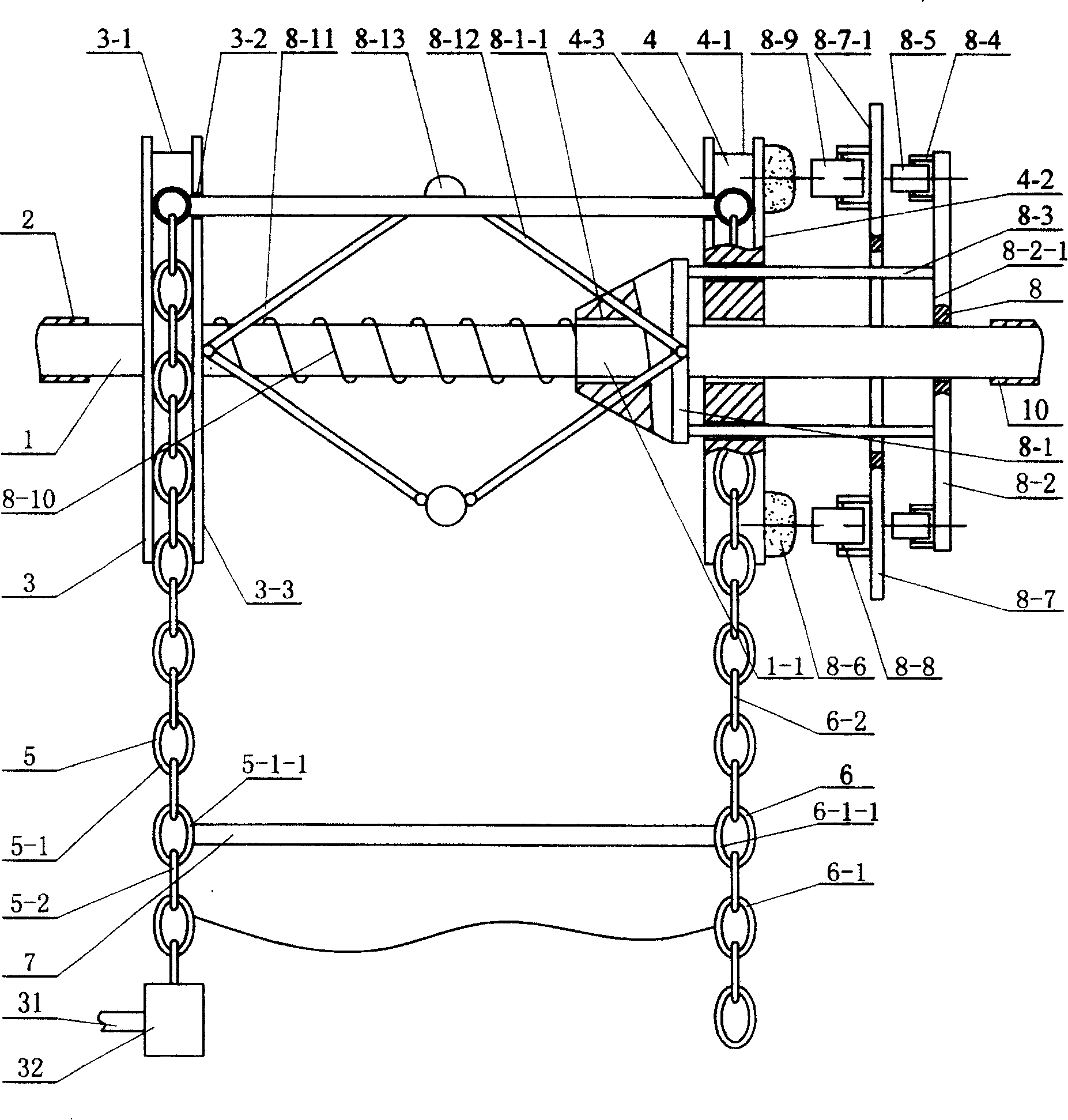

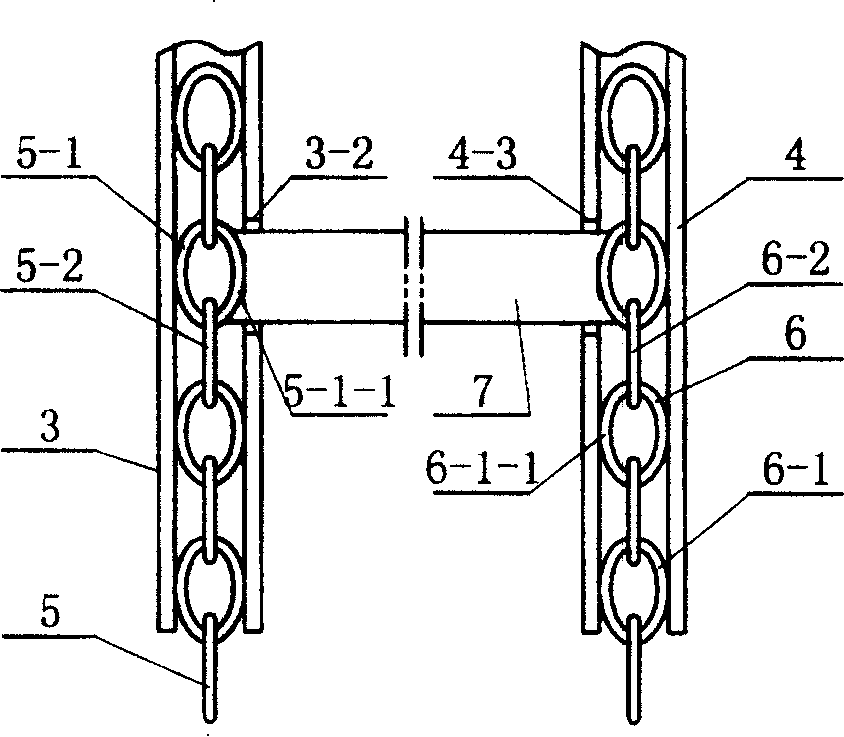

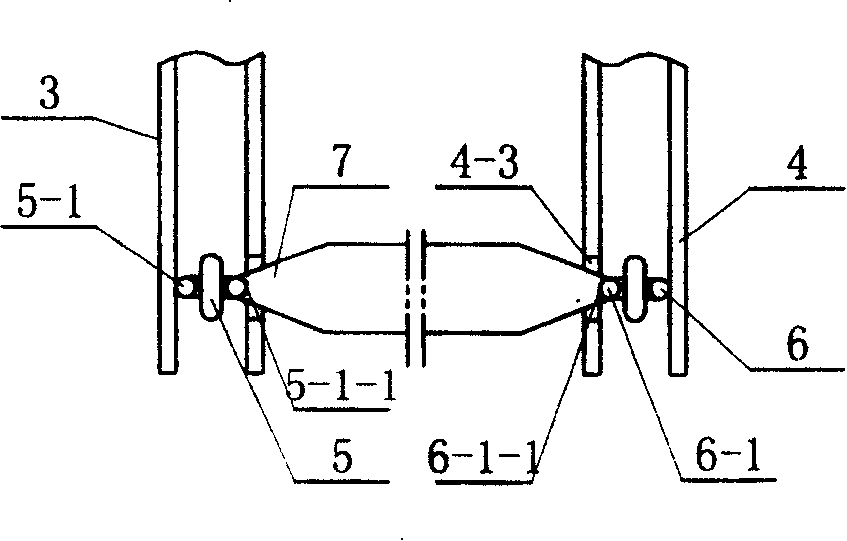

High building life saving device

Owner:高家榕

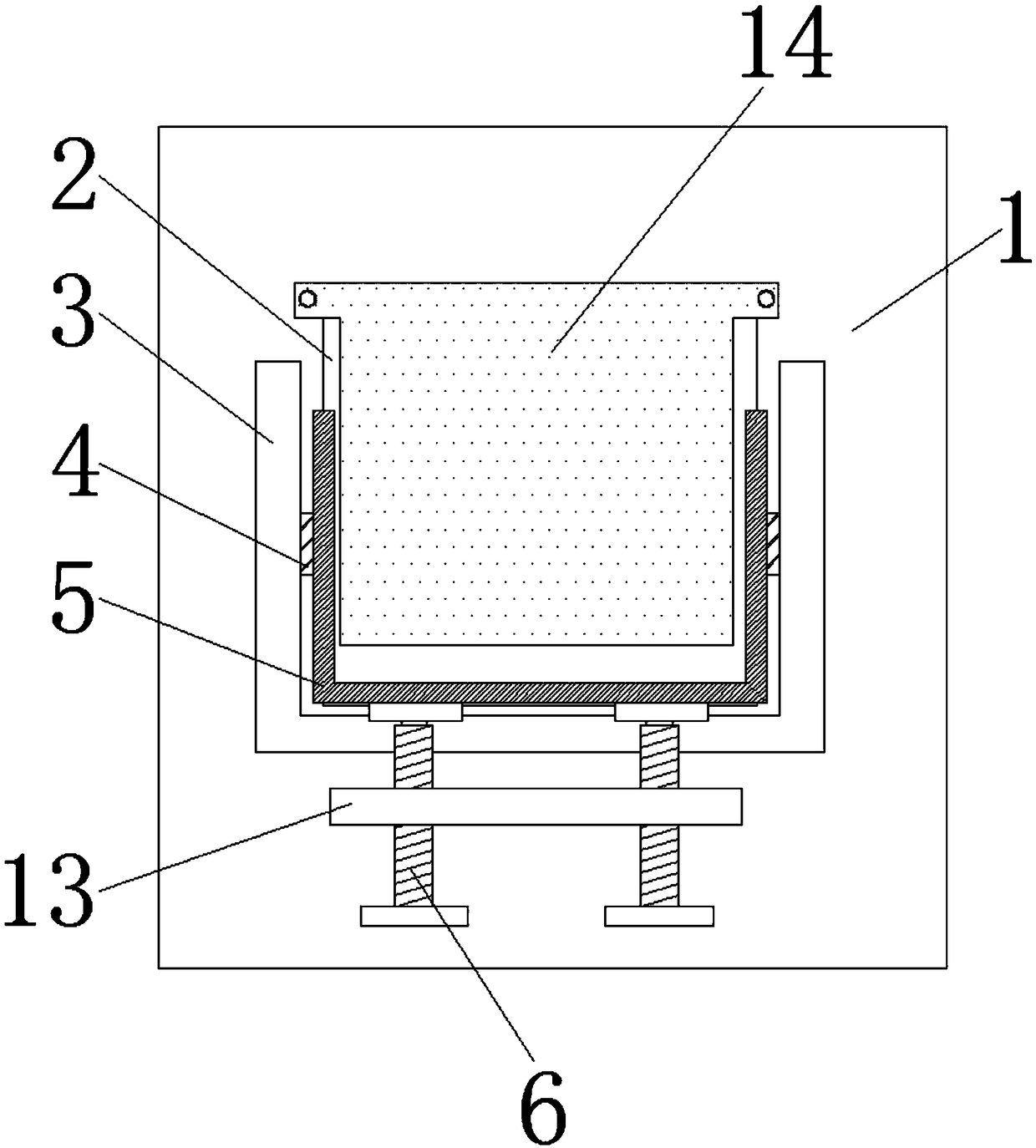

Stirring device

InactiveCN105435678AControl the falling speedAvoid cloggingFeeding-stuffTransportation and packagingEngineeringCam

The invention belongs to the field of feed production equipment, and specifically discloses a stirring device. The stirring device comprises a dry material cylinder, a material separating plate, a mixing cylinder, a nozzle for spraying liquid material, a stirrer, a motor, a driven bevel gear, a driving bevel gear, and a cam; the dry material cylinder is in a hopper shape, the lower end of the dry material cylinder is communicated with the mixing cylinder; the material separating plate is provided with a plurality of through holes, and is arranged in the lower end of the dry material cylinder; the lower end of the mixing cylinder is in a hopper shape and is provided with a material outlet; the stirrer and the output shaft of the motor are connected coaxially; the nozzle, stirrer, and motor are all arranged in the mixing cylinder; the driving bevel gear and the stirrer are connected through a same shaft; and the cam and the driven bevel gear form coaxial connection through a shaft rod. The stirring device solves the problem that the mixing device for mixing dry materials and liquid feed is easily stuck or obstructed during the application process. Compared with the prior art, the provided stirring device has the advantages that the provided stirring device cannot be stuck during the mixing process of dry material and liquid feed, the work procedure is fluent, and the work efficiency is high.

Owner:CHONGQING CHANGYUAN FEED CO LTD

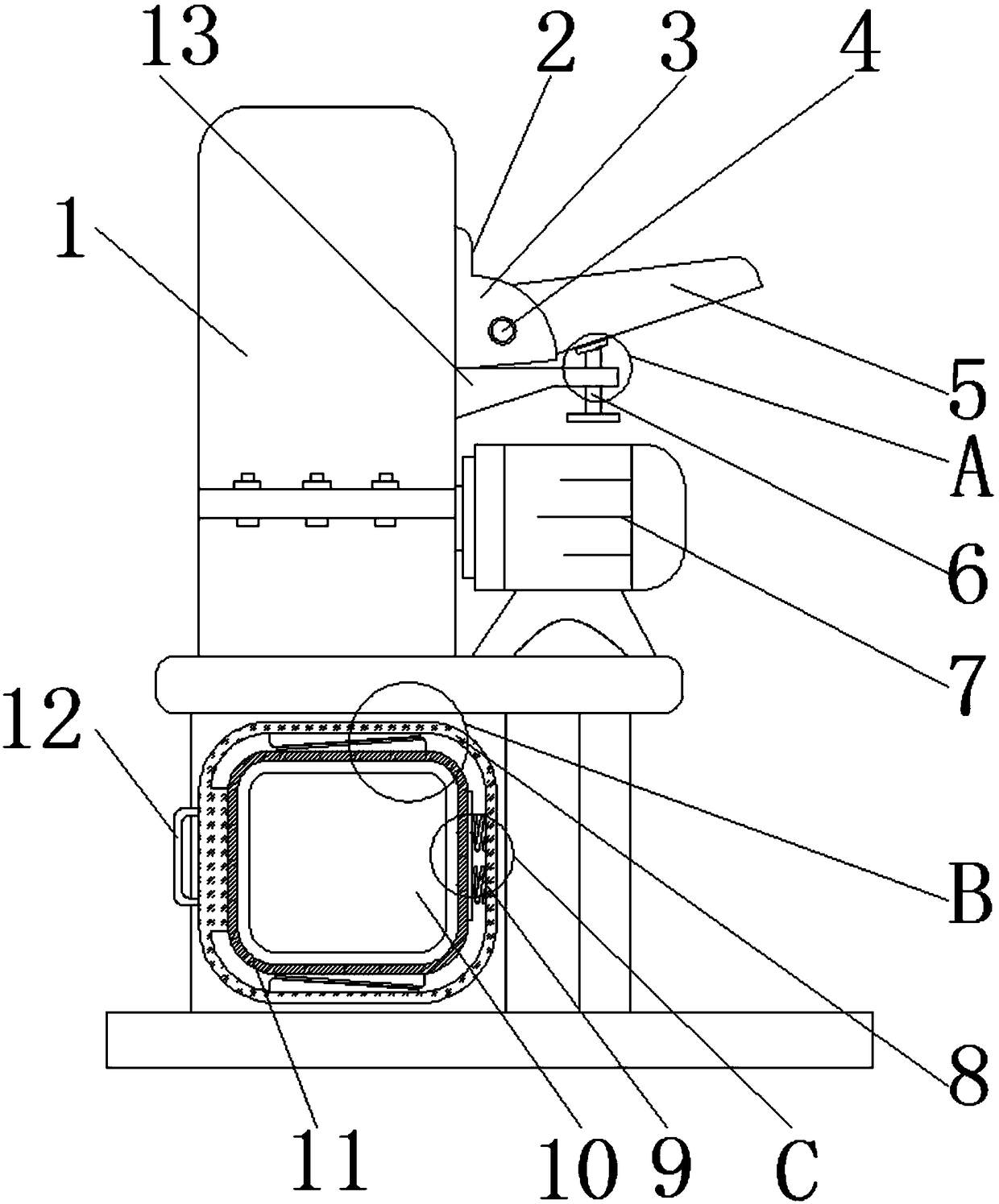

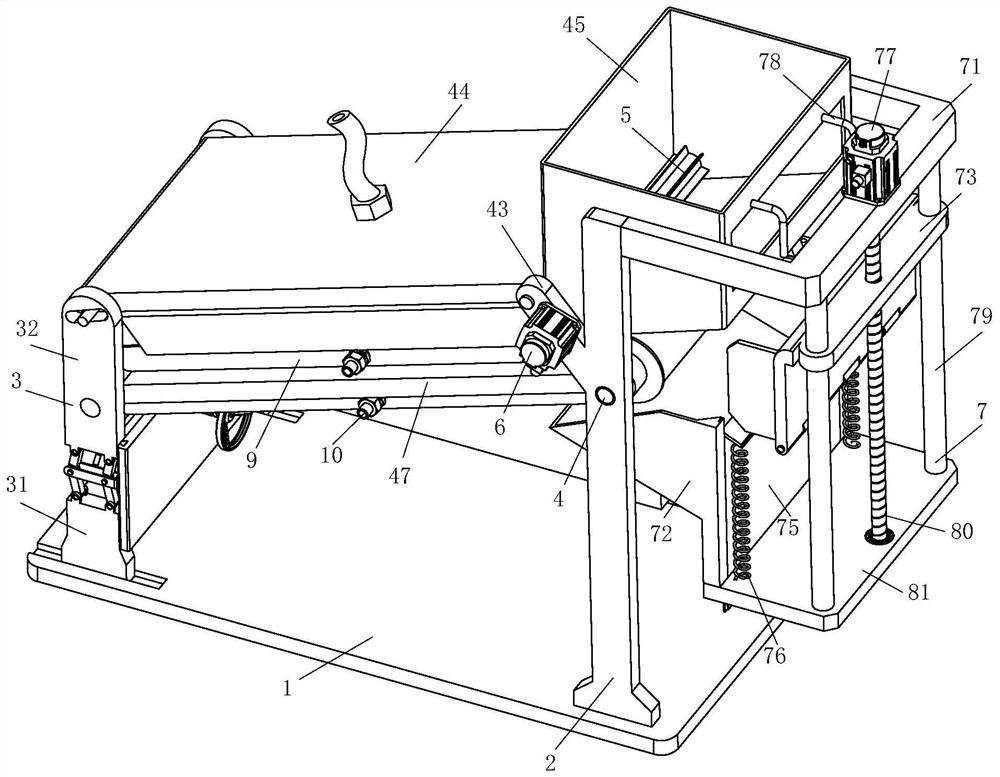

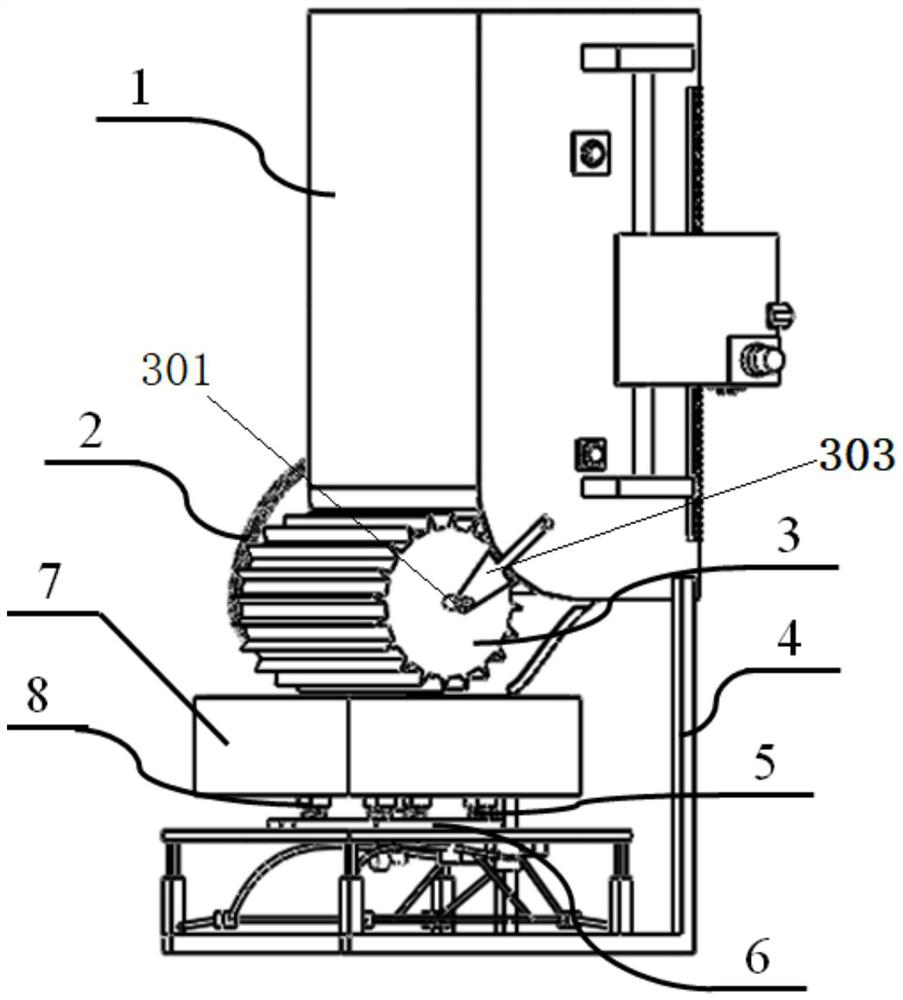

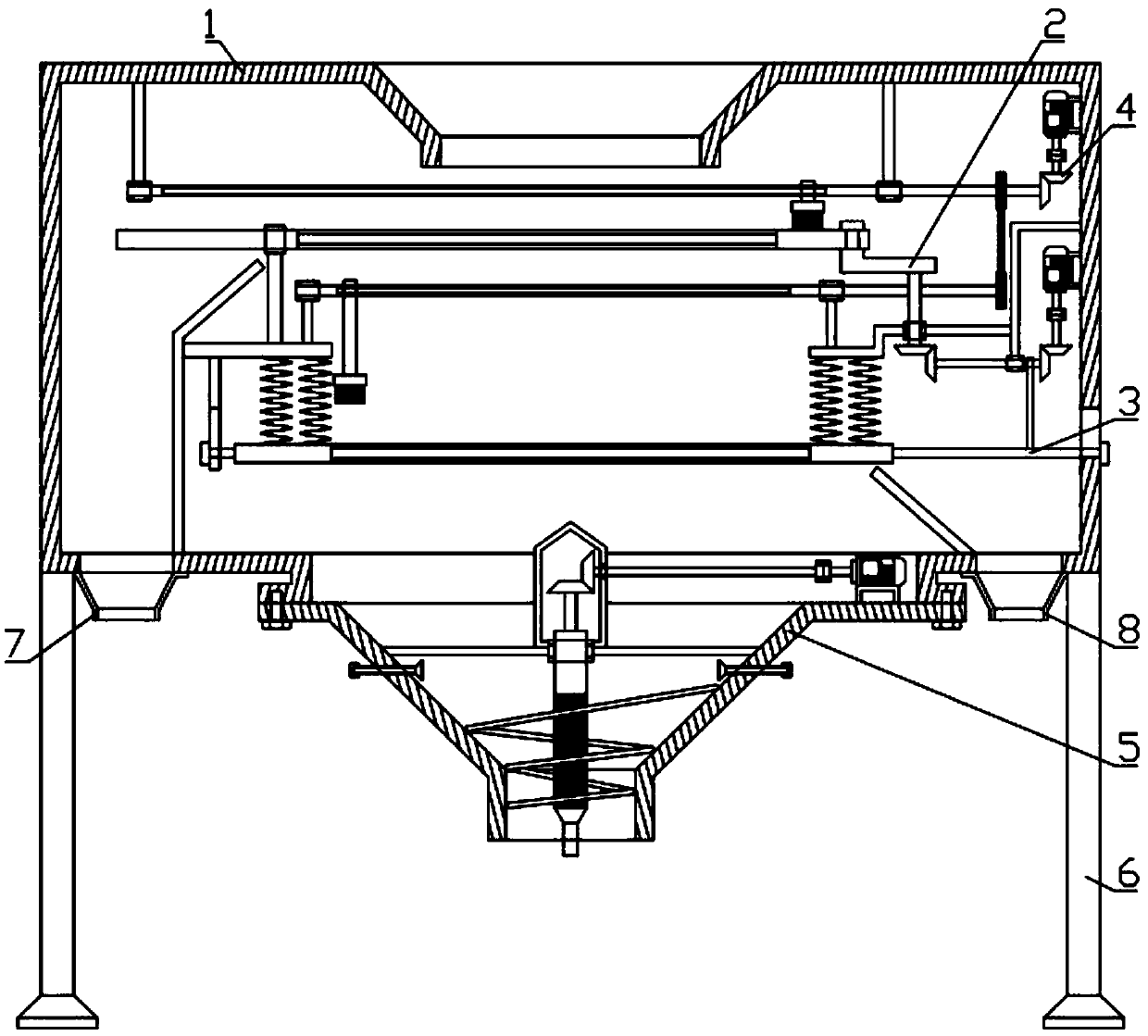

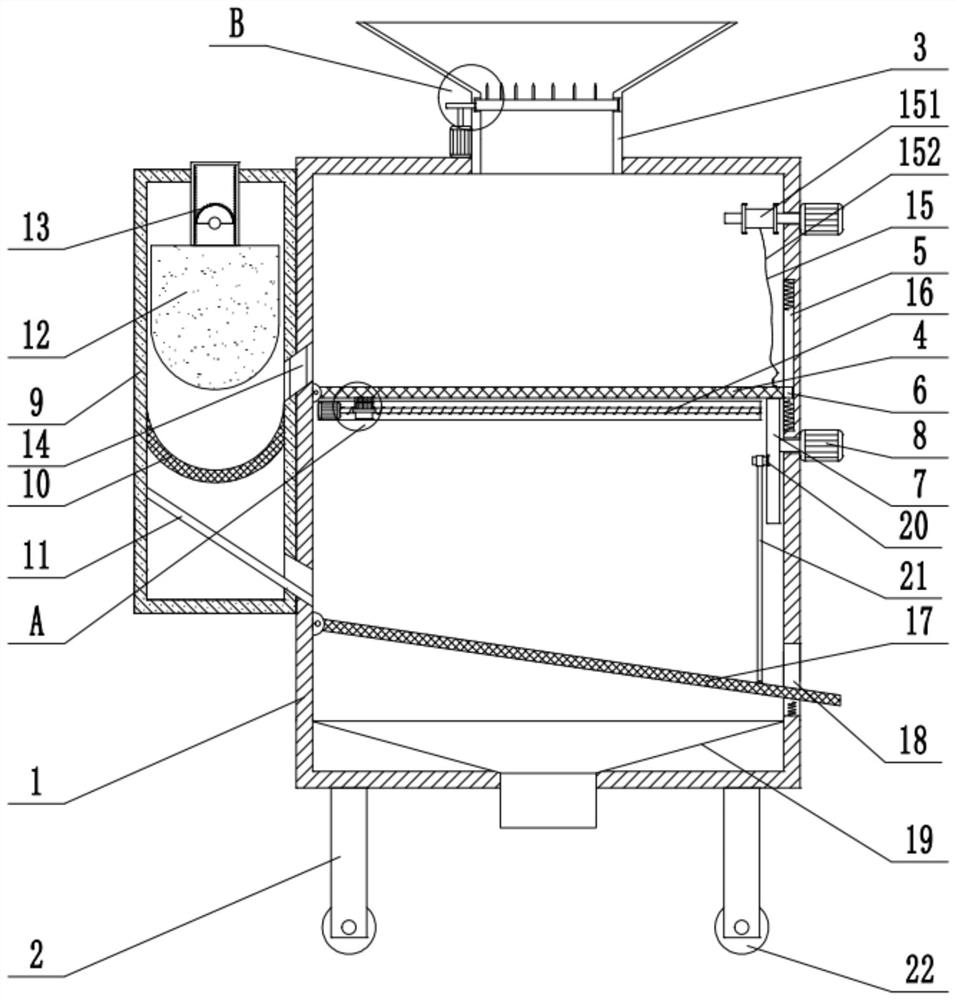

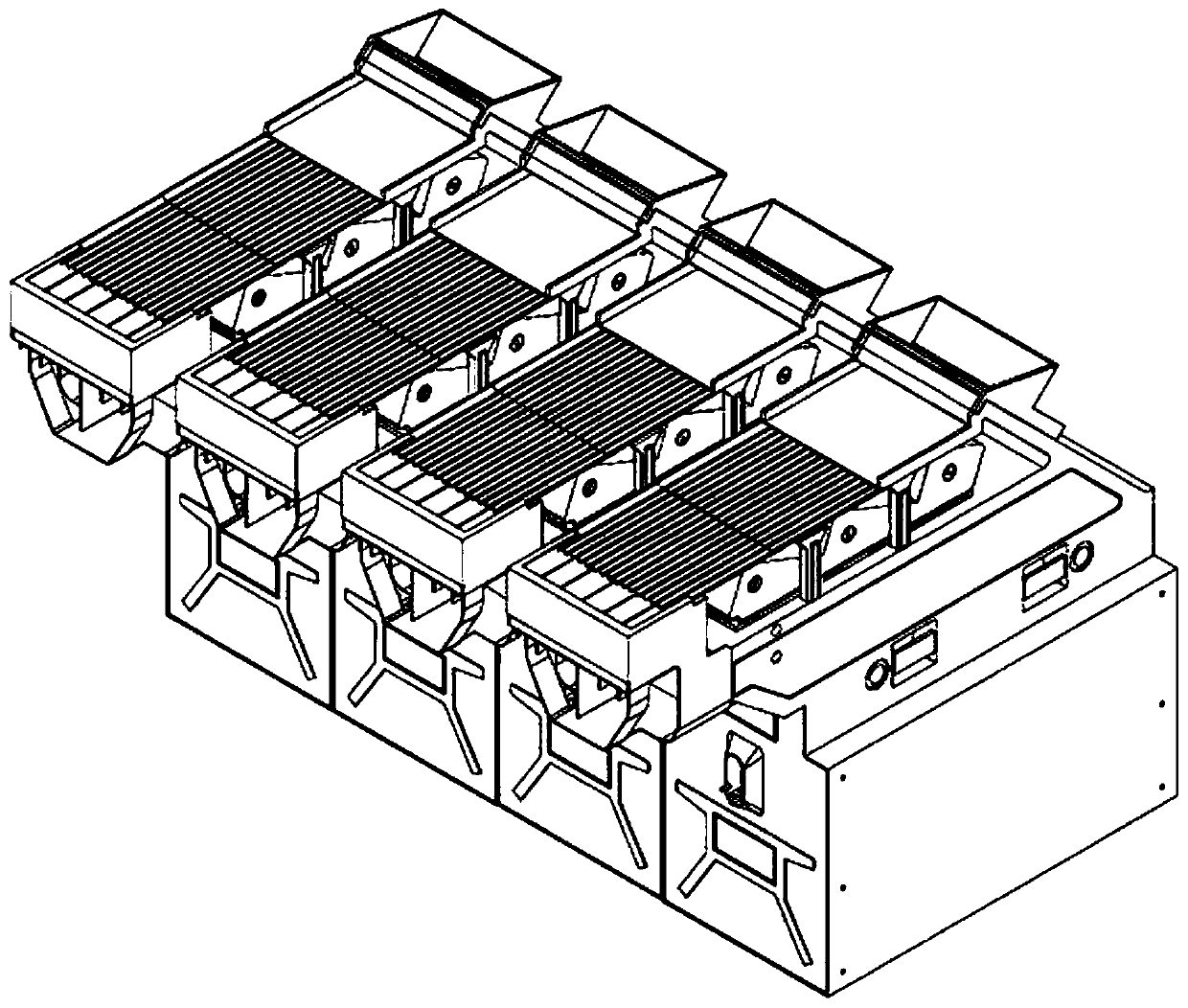

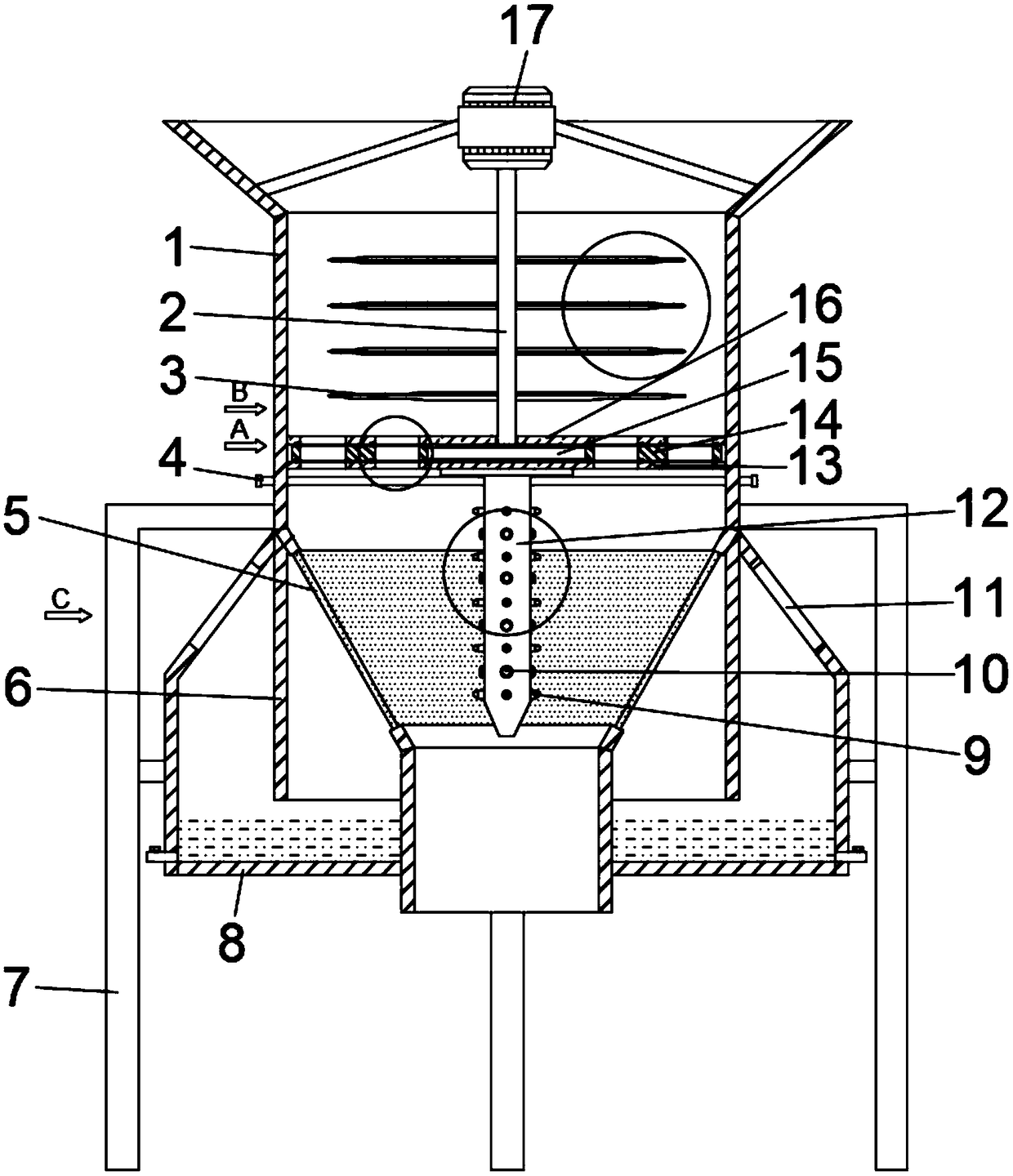

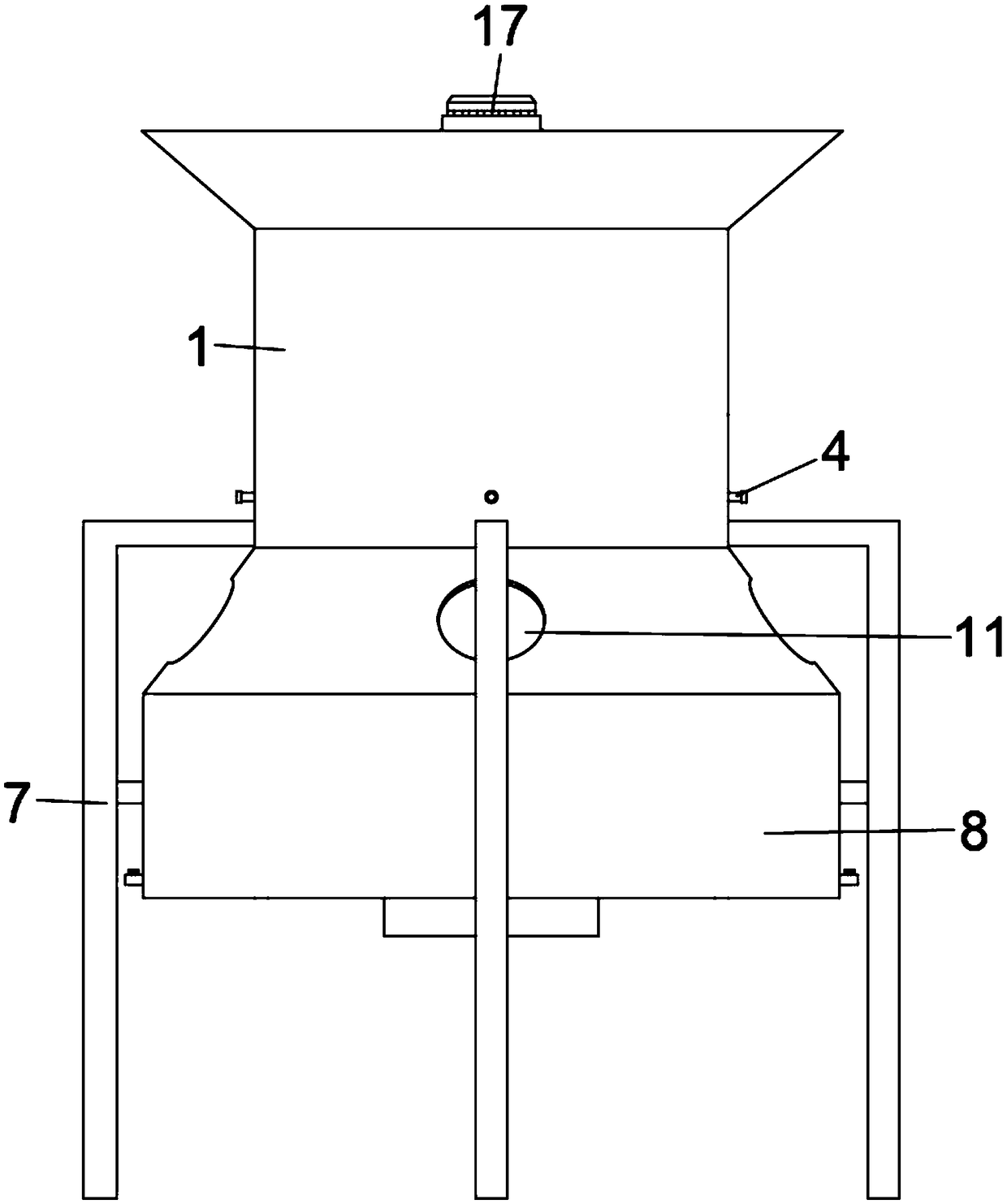

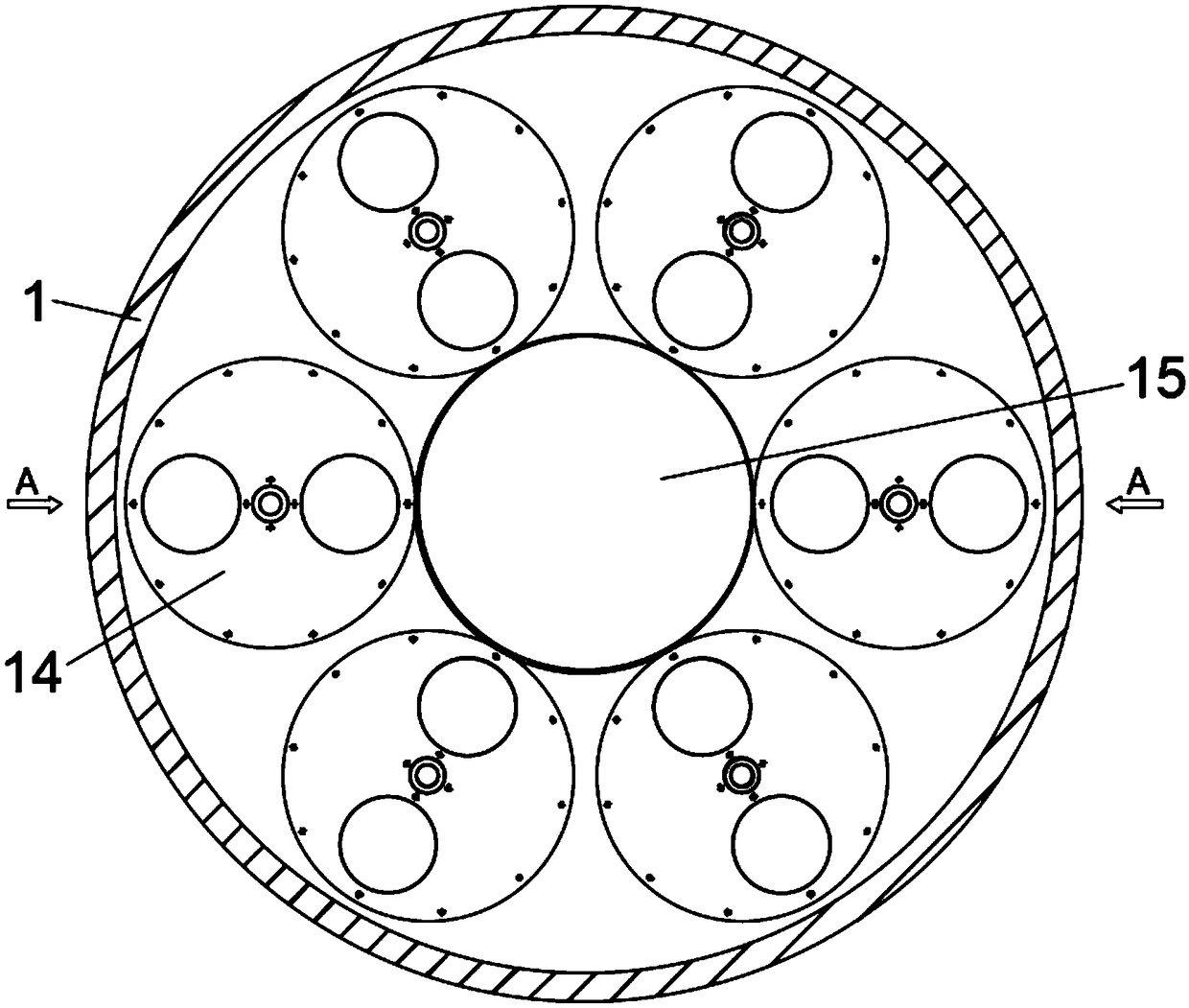

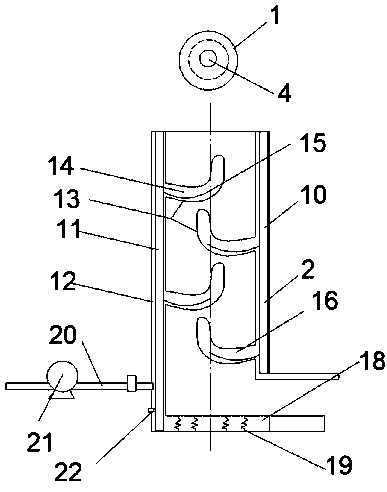

Multifunctional sand sieving device

ActiveCN109622378AControl the falling speedMeet the needs of useSievingGas current separationEngineeringWaste material

The invention relates to a sand sieving device, in particular to a multifunctional sand sieving device. The multifunctional sand sieving device comprises a machine box mechanism, a sand primary sieving mechanism, a sand secondary sieving mechanism, a sweeping device, a multifunctional secondary sieving sand discharging hopper mechanism, a supporting frame, a waste material discharging hopper and aprimary sieving sand discharging hopper. According to the multifunctional sand sieving device, sand can be subjected to primary sieving, the primarily sieved sand can be subjected to secondary sieving sequentially, and the sand of different thicknesses can be sieved out to meet use requirements; and the sand of different thicknesses can be correspondingly swept and collected, the sand can be transported, the falling speed of the sand from the discharging hoppers can be controlled, and the sand can be cleaned. The machine box mechanism is connected with the sand primary sieving mechanism, themachine box mechanism is connected with the sand secondary sieving mechanism, the sand primary sieving mechanism is connected with the sand secondary sieving mechanism, the left end of the machine boxmechanism is connected with the waste material discharging hopper, and the right end of the machine box mechanism is connected with the primary sieving sand discharging hopper.

Owner:嘉兴市恒泰化工科技有限公司

Sandstone screening equipment for building construction

InactiveCN112718060AFully mashIncrease profitSievingScreeningElectric machineArchitectural engineering

The invention belongs to the technical field of building construction, and discloses sandstone screening equipment for building construction. According to the technical key points, the sandstone screening equipment for the building construction comprises a box body, a first filter plate is rotatably mounted on the left wall in the box body, a vertical groove is formed in the right wall in the box body, and a slide block fixedly connected with the right side wall of the first filter plate is slidably mounted in the vertical groove; a motor is fixedly installed on the right side wall of the box body, an output shaft of the motor extends into the box body and is fixedly provided with a cam tightly attached to the right bottom wall of the first filter plate, a first discharging opening is formed in the side wall of the box body on the left side of the first filter plate, and a smashing box communicating with the box body through the first discharging opening is fixedly installed on the left side wall of the box body; and an arc-shaped mashing plate is fixedly installed in the smashing box, a vibrating column is slidably installed in the smashing box above the mashing plate, the top end of the vibrating column is connected with a vibrating component, a hole cleaning component is installed between the front inner wall and the rear inner wall of the box body below the first filter plate, and the right bottom of the first filter plate is upwards connected with a lifting component.

Owner:邹福全

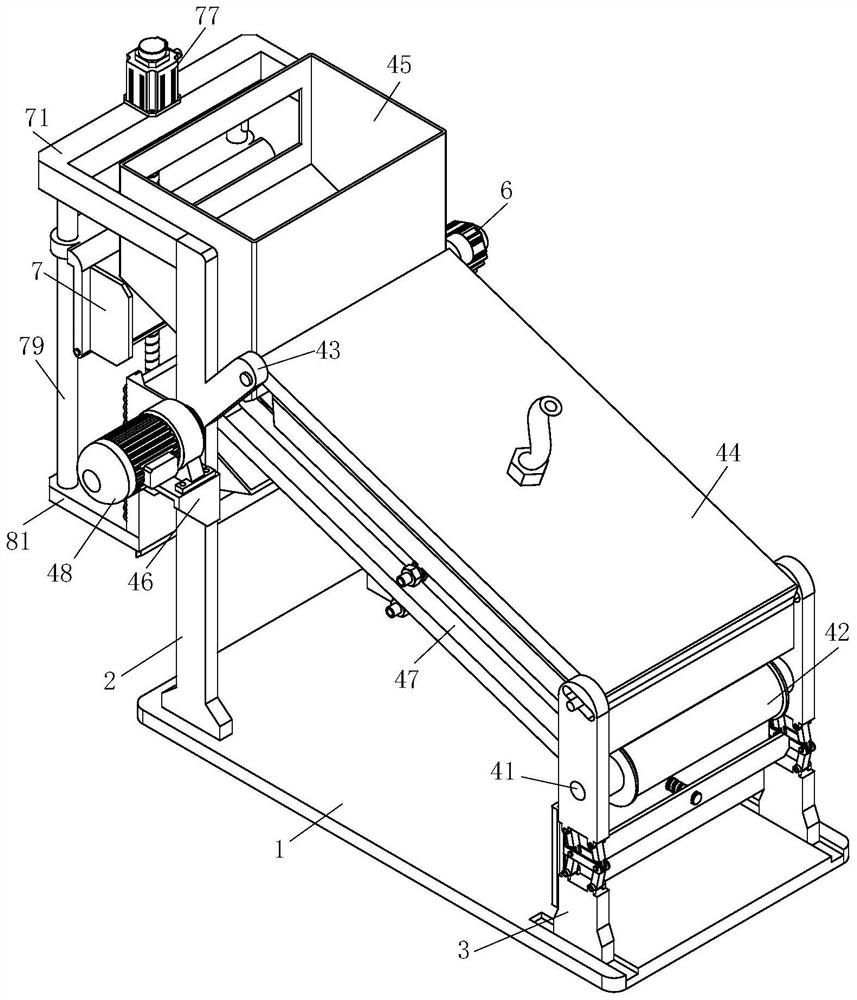

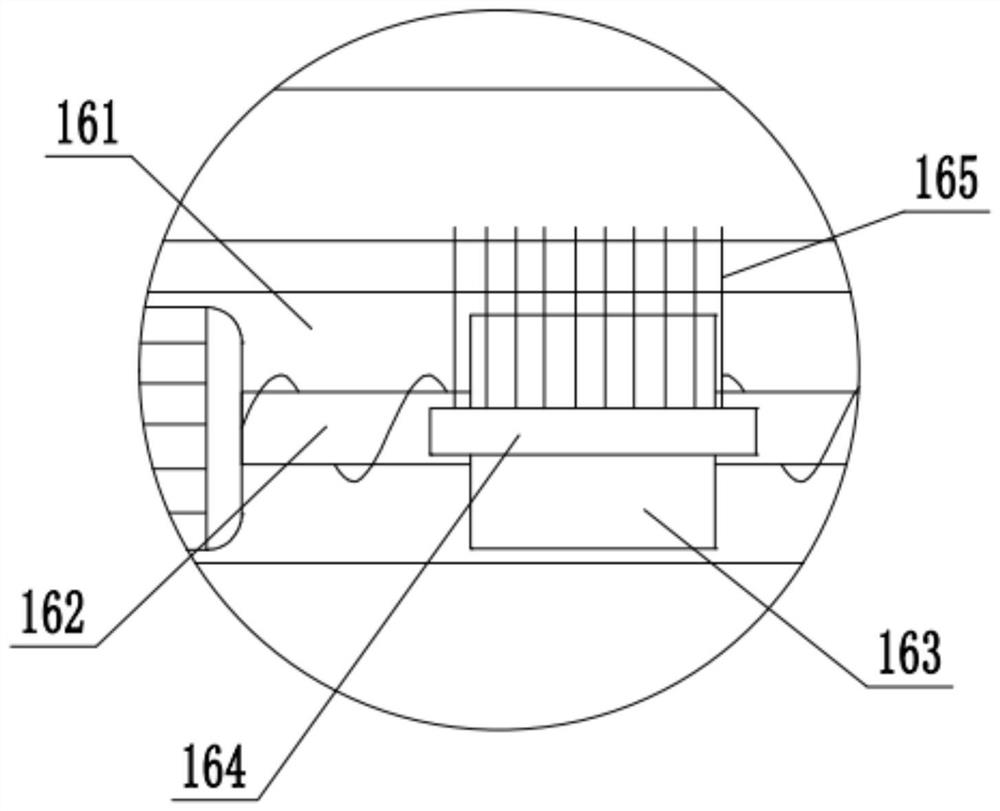

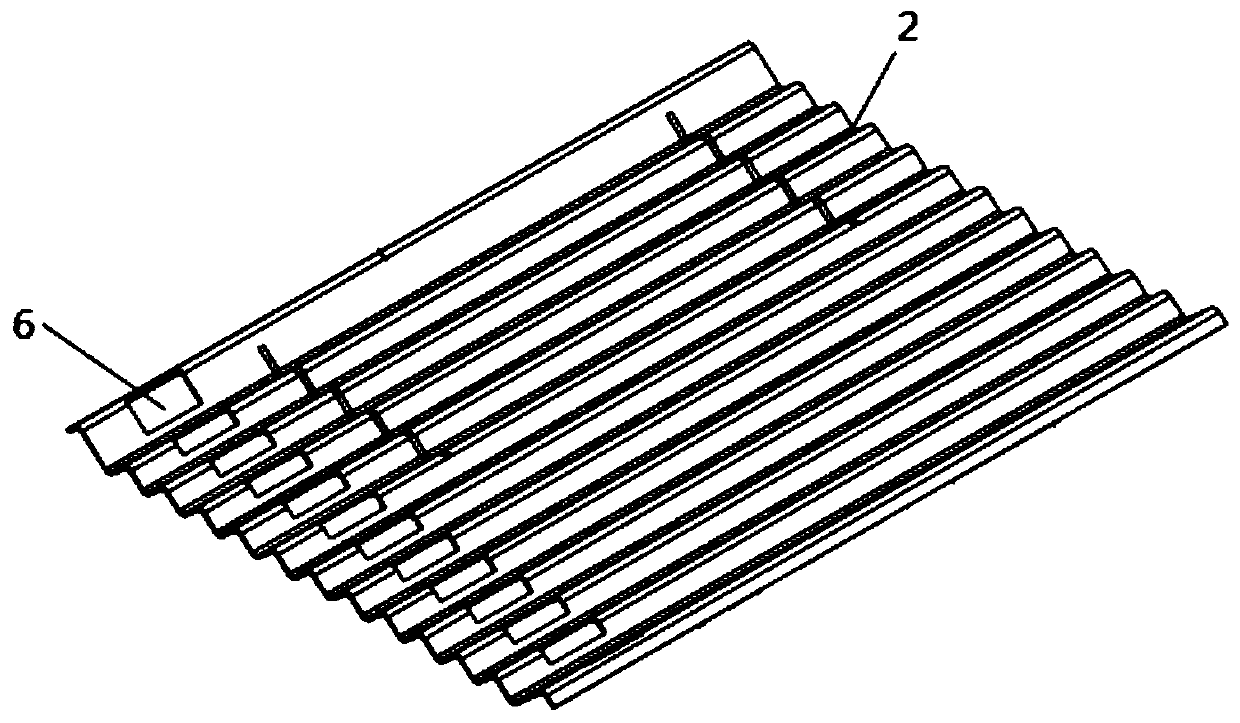

Modular grain counting machine

PendingCN110745311AControl the falling speedAdjust the tilt anglePackaging automatic controlProduction lineEngineering

The invention provides a modular grain counting machine, and relates to the field of packaging equipment. The modular grain counting machine comprises a plurality of grain counting mechanisms, whereineach grain counting mechanism comprises a grain counting machine body and an electric appliance control box; each grain counting machine body comprises a feeding hopper, a material vibrating disc, adischarging hopper, a servo vibration mechanical module and a discharging opening; the upper part of each electric appliance control box is slidably connected with the corresponding grain counting machine body; each servo vibration mechanical module is arranged on the corresponding grain counting machine body; each material vibrating disc is fixedly arranged above the corresponding servo vibrationmechanical module; an electric telescopic rod is arranged on the right side of the bottom of each material vibrating disc; and each discharging opening is formed in the corresponding material vibrating disc. The modular grain counting machine can be separately combined with other equipment of a production line, the multiple grain counting mechanisms can also be freely combined and used on site according to requirements of users, when the modular grain counting machine needs to be maintained, another modular grain counting machine can be used for replacing the modular grain counting machine and then is maintained, thus, normal production is not affected, when the yield is high, the multiple modules can be freely combined, production requirements are met, and the production efficiency is improved.

Owner:李昱

Precise macromolecule adding device

InactiveCN112808151APlay the role of purgeEasy to transportTransportation and packagingMixer accessoriesEngineeringProcess engineering

The invention relates to the field of preparation of disposable hygienic products, in particular to an accurate macromolecule adding device which comprises a storage hopper and a blowing pipe barrel communicating with the storage hopper, the blowing pipe barrel comprises a blowing pipe, a feeding pipe and a compressed air pipe, the blowing pipe is horizontally arranged, the outlet end of the blowing pipe is connected with a plurality of discharging pipes which are horizontally arranged in parallel, the free ends of the discharging pipes are gradually reduced to form discharging ports, the discharging pipes incline downwards to enable the discharging ports to be arranged in a high-low staggered mode, and the feeding pipe is arranged at the inlet end of the blowing pipe and communicates with the storage hopper. The included angle between the feeding pipe and the blowing pipe is 110-160 degrees, and the compressed air pipe is arranged at the inlet end of the blowing pipe and is coaxial with the blowing pipe. The device is reasonable in structure, high polymer materials can be effectively and uniformly mixed with cotton pulp / wood pulp before a core body is formed, and the yield of disposable hygienic products is increased.

Owner:QUANZHOU HANWEI MACHINERY MFG

Jet-type disinfection and dust removal equipment for garbage treatment

ActiveCN109481721AEasy to collectNot easy to pile upUsing liquid separation agentMedical waste disposalEngineeringFall into water

The invention provides jet-type disinfection and dust removal equipment for garbage treatment. The jet-type disinfection and dust removal equipment comprises a main shell, a dust storage box and a gasjet cylinder; the bottom of the outer side of the main shell is also fixedly connected with the dust storage box, and the top of the dust storage box is fixedly and symmetrically provided with four vent holes in total; and the inner side of the dust storage box is also fixedly provided with a guide plate. The invention provides the jet-type disinfection and dust removal equipment for garbage treatment, an outer turnplate continuously rotates during treatment to enable through holes in the outer turnplate to be continuously superposed and staggered with through holes in a lower supporting plate and an upper supporting plate due to the arrangement of a shielding screen, garbage can fall off from the through holes when the through holes are superposed, at the moment, wind blown from an air nozzle can drive dust on the surface of the garbage to penetrate through the shielding screen to enter the inner side of the dust storage box, the wind can turn to flow downwards after being in contactwith the guide plate, most of dust can fall into water at the bottom of the dust storage box, and the rest air can be blown outwards through the vent holes, so that collection of the dust is more convenient, and the garbage cannot be blown outwards.

Owner:江苏巨邦环境工程集团股份有限公司

Building construction unloading device

InactiveCN108301626AReduce drop forceLand safelyBuilding material handlingArchitectural engineeringAirbag

The invention discloses a building construction unloading device. The building construction unloading device comprises a buffer capsule and a transport tube. The buffer capsule comprises an air bag and a pair of roller structures, wherein the air bag is a long-strip-shaped elliptical body, and a metal zipper is arranged on the middle portion of the air bag. The roller structures are separately arranged at both ends of the air bag, and the roller structures comprises fixed shafts and rollers mounted on the fixed shafts. The transfer tube includes a rectangular tube body, the inner layer of thetube body is provided with a steel plate, and the outer layer of the tube body is covered with a first airbag. The tube body is internally provided with a plurality of sets of buffer structures, and each of the buffer structures comprises a pair of long-strip-shaped buffer petal bodies; and the outer layers of the baffle petal bodies are provided with second air bags, and the first air bag communicates with the second air bags. The building construction unloading device adopts the buffer capsule and the transport tube which are matched with each other, the physical transportation can be completed without the need of an additional lifting device, and the operation is easy.

Owner:CCCC SHEC FOURTH ENG

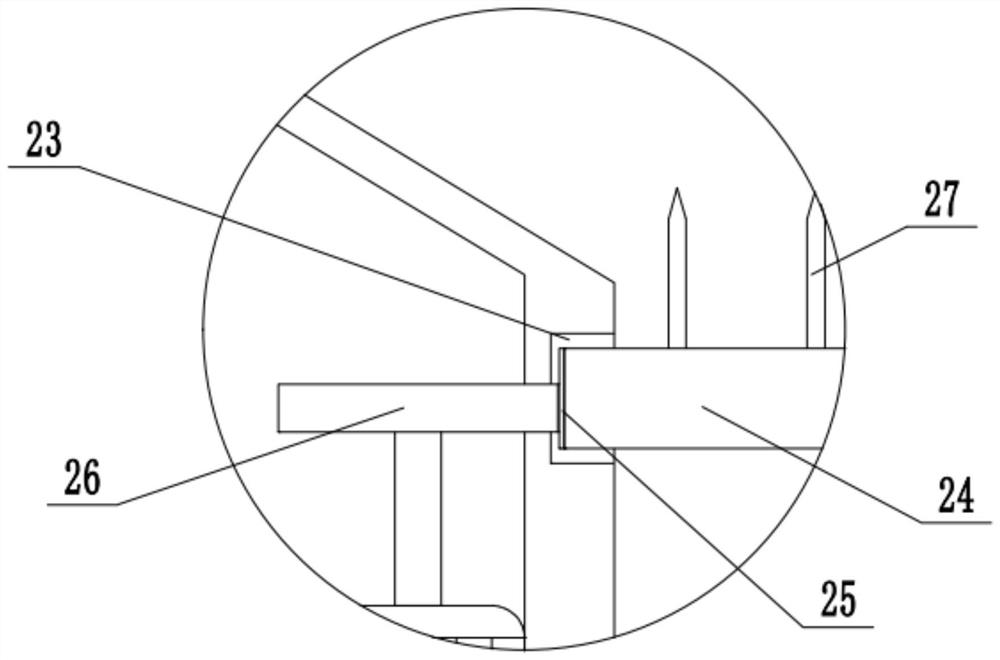

Automatic gasification and dosing device for fumigation storehouse

ActiveCN108244086AControl the falling speedAvoid insufficient fumigationWood treatment detailsFumigatorsPest controlSurface structure

The invention discloses an automatic gasification and dosing device for a fumigation storehouse. The device comprises a dosing device body, the dosing device body is of a rectangular cylinder structure inside which a placement slot is formed, a material storage tank is arranged at the top of the dosing device body, the material storage tank penetrates through the outer wall of the dosing device body, a feeding pipe is fixedly connected with the bottom of the material storage tank, the feeding pipe is of a circular cylinder structure of which the inside is hollow, the bottom of the feeding pipeis provided with a ball, the ball matches with a sliding rail arranged on the outer wall of a material conveying roller, the material conveying roller is of an I-shaped circular cylinder hollow structure, the bottom surface of the feeding pipe is of a curved surface structure, the curved surface matches with the surface of the material conveying roller, the inner portion of the dosing device bodyis provided with the material conveying roller, and the material conveying roller matches with the feeding pipe to effectively control the falling speed of materials and avoid the inadequate fumigation caused by putting into medicines together, which cannot achieve the desired effects of pest control.

Owner:RIZHAO QUARANTINE TREATMENT CO LTD

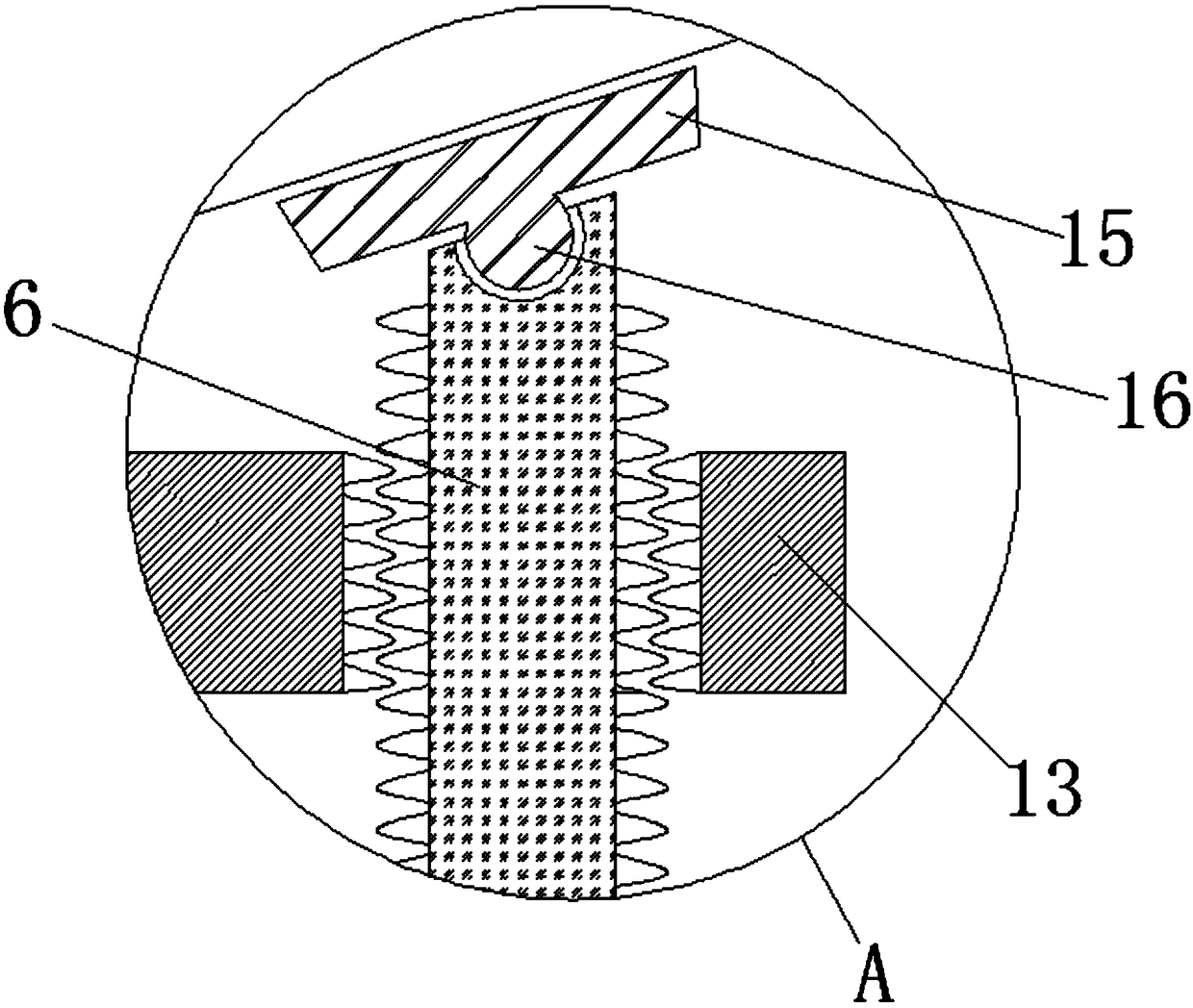

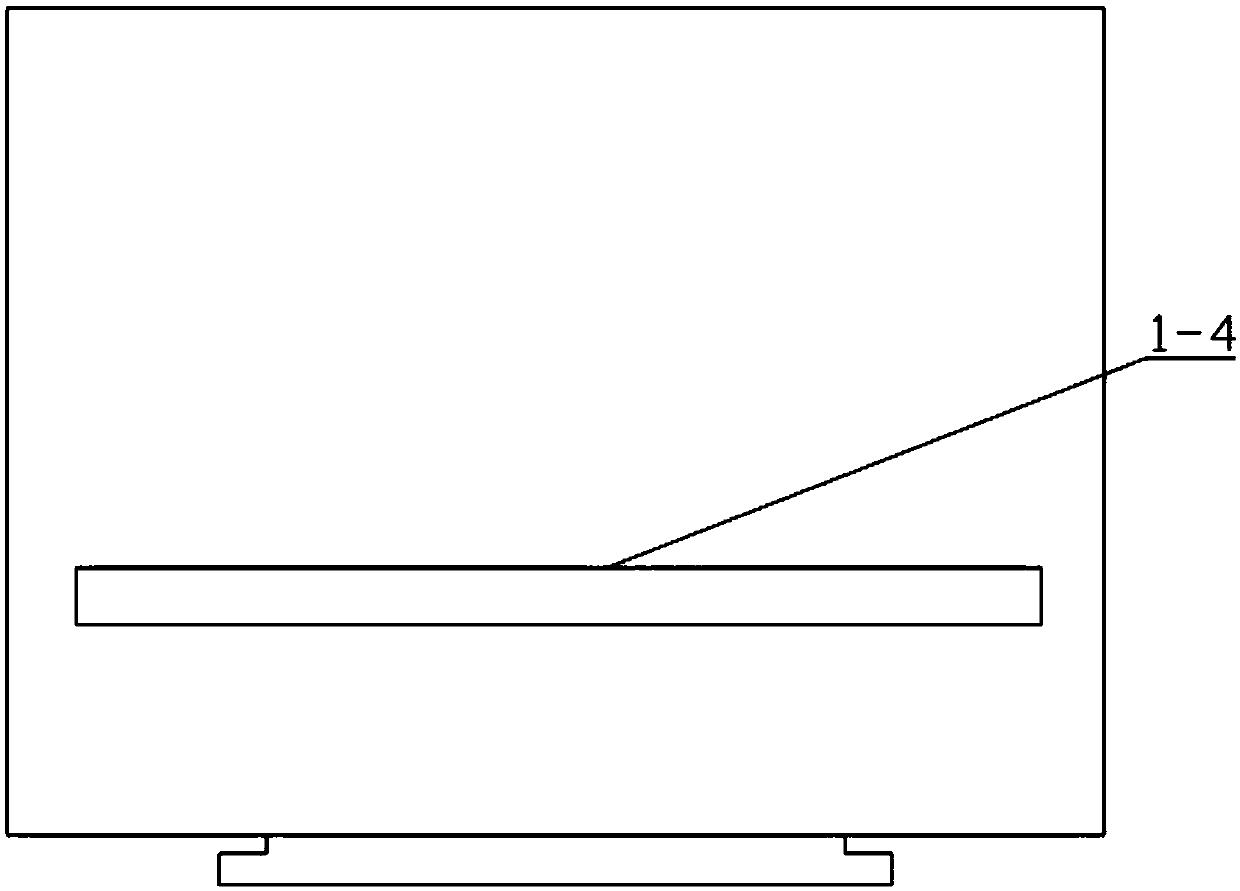

Feeding funnel with excellent screening effect

The invention discloses a feeding funnel with excellent screening effect, and relates to the technical field of feeding equipment. The feeding funnel with excellent screening effect comprises a funnel, wherein a screening box is fixed on the outer wall of the conical part of the funnel and the outer wall of the straight pipe part, a funnel penetrates through the screening box, a motor is fixed atthe bottom of the screening box, a cam is fixed at one end of an output shaft of the motor, a base plate is arranged on one side of the cam, a guide rod is fixed on one surface of the base plate, anda vibration frame is movably matched with one end of the guide rod, a spring is arranged on the outer surface of the guide rod in a surrounding mode. The feeding funnel with excellent screening effectcomprises a funnel, a screening box, a motor, a cam, a base plate, a guide rod, a vibration frame and a spring, the first screen plate and the second screen plate are matched and used, so that materials entering into the feeding funnel can be screened, the materials which meet the requirements enter the working machine, the materials which do not meet the requirements are discharged by the discharging groove in a classified mode, the screening machine is prevented from being screened by using the screening machine, and meanwhile, the processing efficiency and quality are improved by uniformlyprocessing the materials, and the service life of the working machine is prolonged.

Owner:合肥通快钣金科技有限公司

Gate hoist

The invention relates to a gate control device that could quick show down the gate, comprising a base, a controlling device, a drive motor, a driving device and a box body, the driving axis of the driving device is connected arranged inside the screw of the box body via a driving gear, the screw is provided with an internal feed screw, the bottom of the feed screw is connected with the gate, comprising a retaining clutch, a speed-limiting device and a cushion cylinder, the motor axis is connected with the driving axis via the retaining clutch, the central part of the rotation axis is providedwith a speed-limiting device fixed connected with the box body, the top end of the feed screw is connected with a cushion cylinder. When The invention is power off, the magnetic brake is released, andthe gate drops and shuts down by the weight. When the gate automatically drops, the drive motor will be reversely drove by the driving device, to prevent the magnetic electricity generated by the reverse rotation of the motor from damaging the drive motor, to control the rotation speed of the driving axis, to prevent the direct burst of the weight, to effectively protect the gate and the base, and to mutually prolong the durability of the cushion cylinder.

Owner:JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD

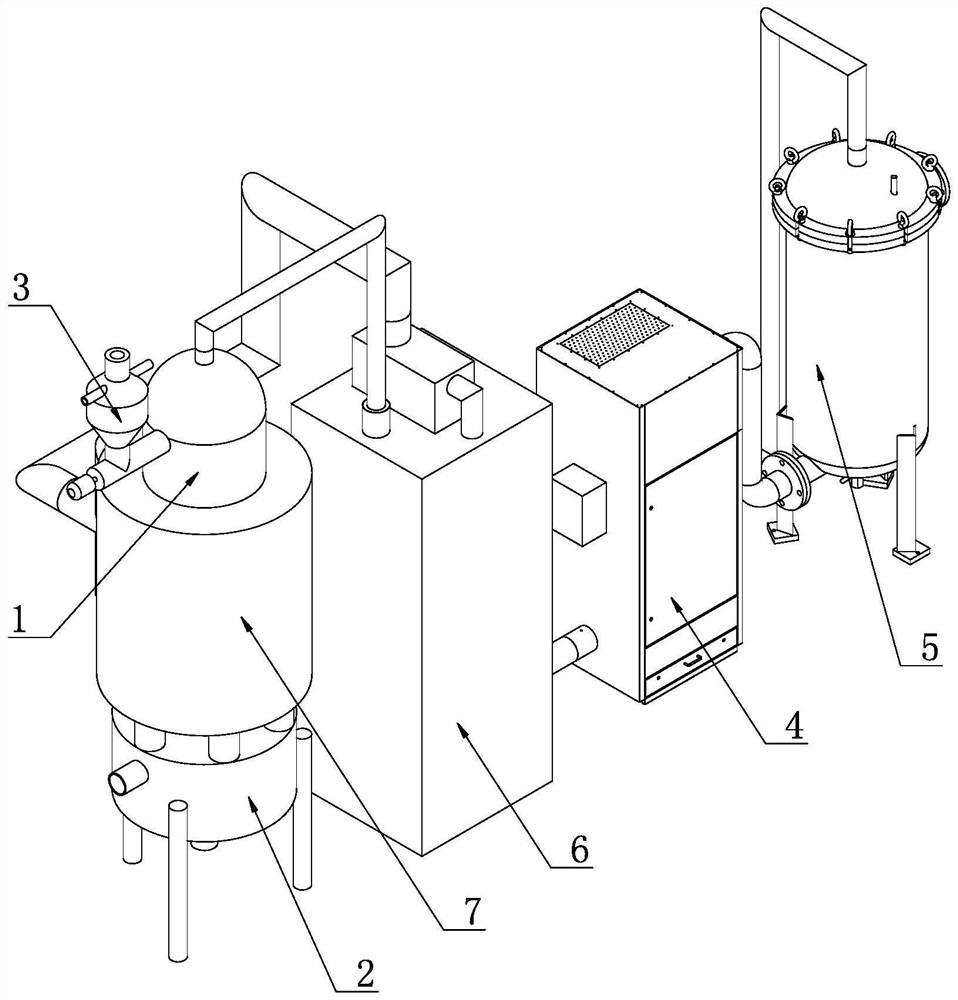

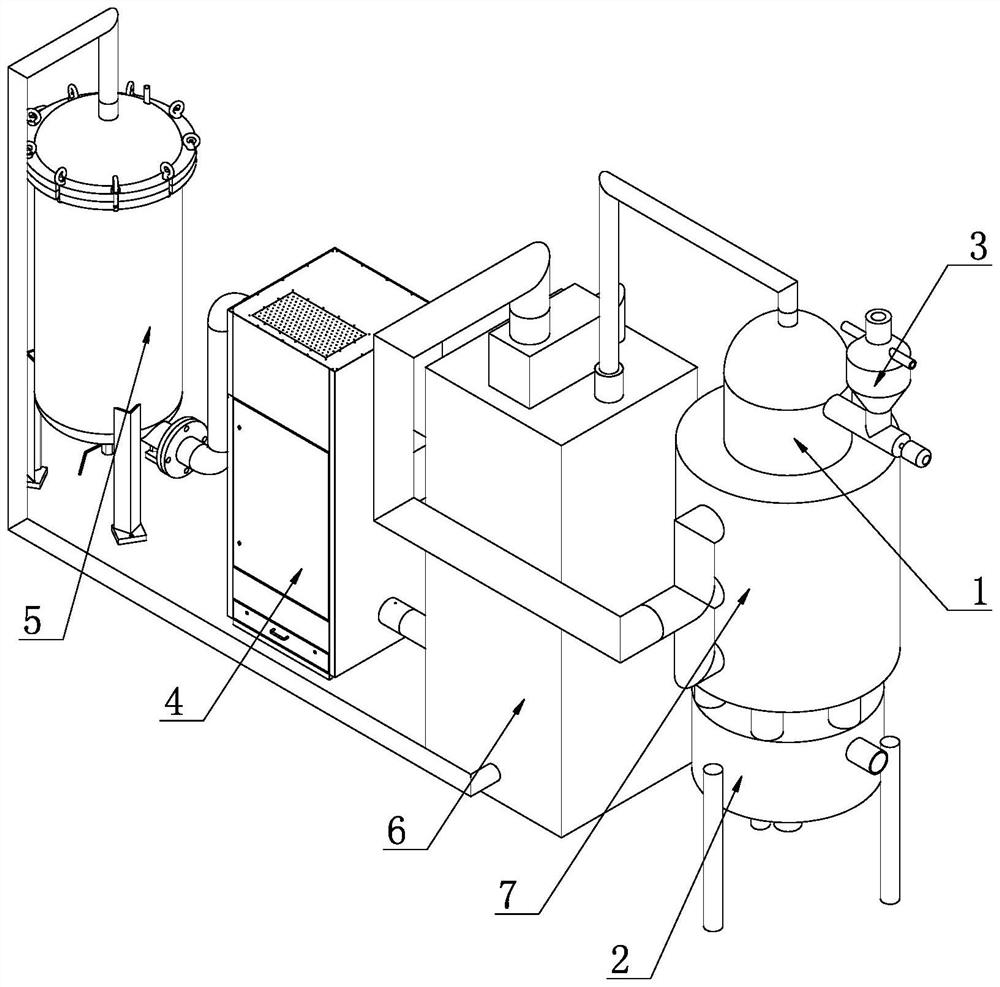

High-purity graphite purification system

PendingCN114291815AControl the falling speedLong enough to heatCarbon compoundsHigh energyEngineering

The invention relates to a high-purity graphite purification system, the high-purity graphite purification system comprises a purification furnace, the purification furnace is in a vertically arranged cylindrical shape, the purification furnace comprises a furnace body, an air guide ring, an air inlet ring and a heating column, the furnace body is a cylindrical shell, the upper end and the lower end of the furnace body are respectively provided with an air outlet and a discharge port, the upper part of the furnace body is provided with a feed port, and the upper part of the furnace body is provided with a discharge port; the air guide ring and the air inlet ring are correspondingly arranged on the inner side and the outer side of the circumference of the furnace body respectively, the lower end of the air guide ring is fixedly connected with the furnace body in a sealed mode, a gap is reserved between the upper end of the air guide ring and the inner wall of the circumference of the furnace body, and an opening of the section of the air inlet ring is fixedly connected with the outer side of the circumference of the furnace body in a sealed mode. The air inlet ring communicates with the air outlet end of an inert gas source, and the heating column is coaxially and fixedly arranged in the furnace body. The invention aims to solve or at least alleviate the problems of high energy consumption and non-uniform heating during purification of the existing graphite high-temperature purification equipment, and provides the high-purity graphite purification system.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

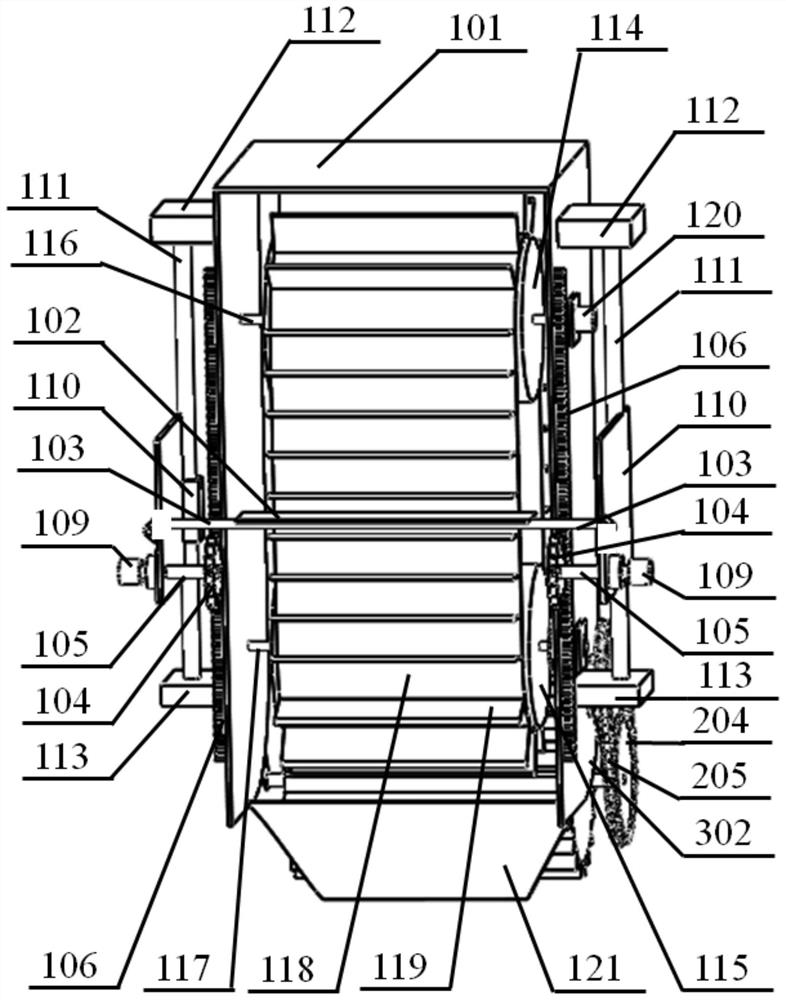

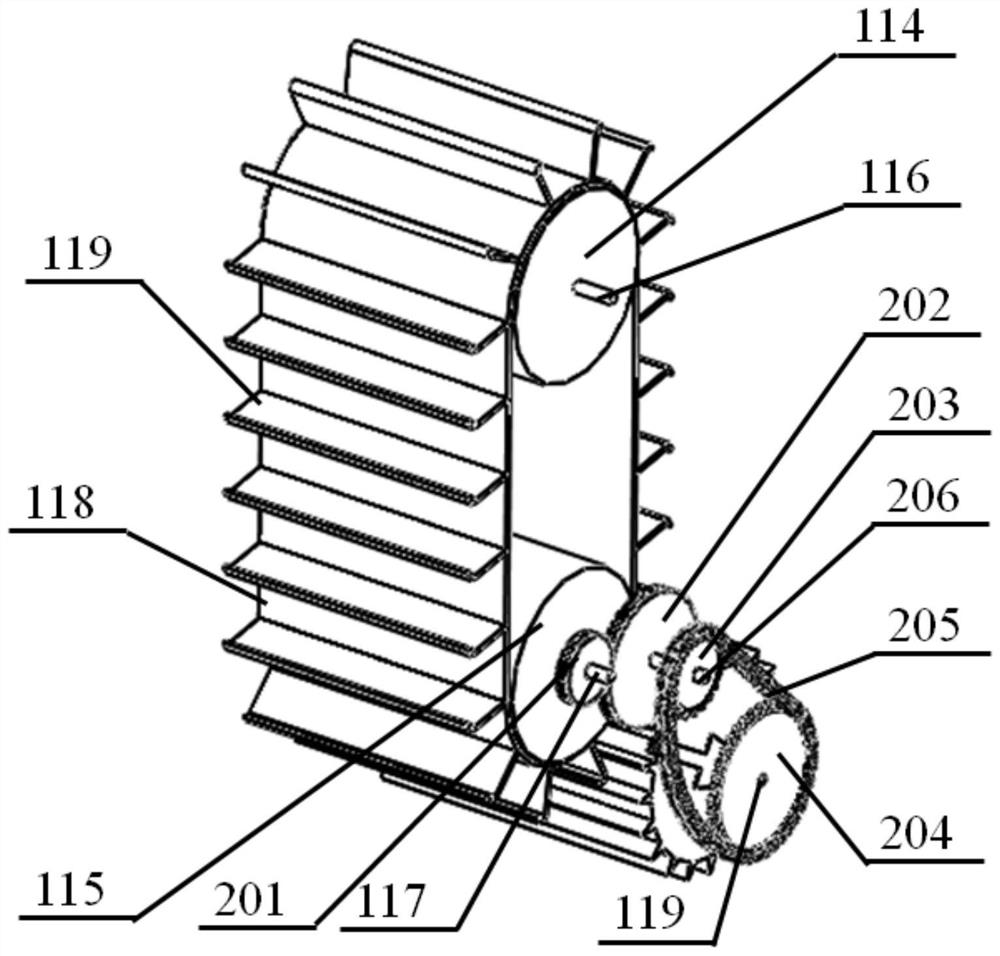

Intelligent silkworm breeding equipment

ActiveCN113925027AAutomatically control the uniformity of blankingRealize the sterilization functionBio-organic fraction processingLoading/unloadingControl theoryMechanical engineering

The invention relates to the technical field of lime powder disinfection of silkworm nests, in particular to intelligent silkworm breeding equipment. The equipment comprises a machine frame, an electromagnetic vibration discharging machine, a discharging channel, an intelligent detection system, a mounting frame, silkworm nests and a displacement driving system, the electromagnetic vibration discharging machine is arranged beside the machine frame, the intelligent detection system is arranged in the discharging channel, and the mounting frame can be arranged on the machine frame in a sliding mode in the direction parallel to the conveying direction of the machine frame. The intelligent detection system comprises a controller and a pressure sensing mechanism, the displacement driving system comprises a horizontal displacement device, a vertical displacement device and a rotary driving device, and the controller is electrically connected with the pressure sensing mechanism, the horizontal displacement device, the vertical displacement device and the rotary driving device. The intelligent detection system in the equipment automatically controls the overall discharging speed and the lime powder discharging uniformity degree, the lime powder scattering amount in each silkworm nest is kept within a certain range, the intelligent degree of the equipment is improved, and the sterilization effect on the silkworm nests is improved.

Owner:那坡同益新丝绸科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com