Novel automatic screw feeding device

A screw feeding device and screw feeding device technology, applied in the field of new automatic screw feeding devices, can solve problems affecting production efficiency, errors, blocking, etc., and achieve the effects of reducing labor intensity, improving production efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

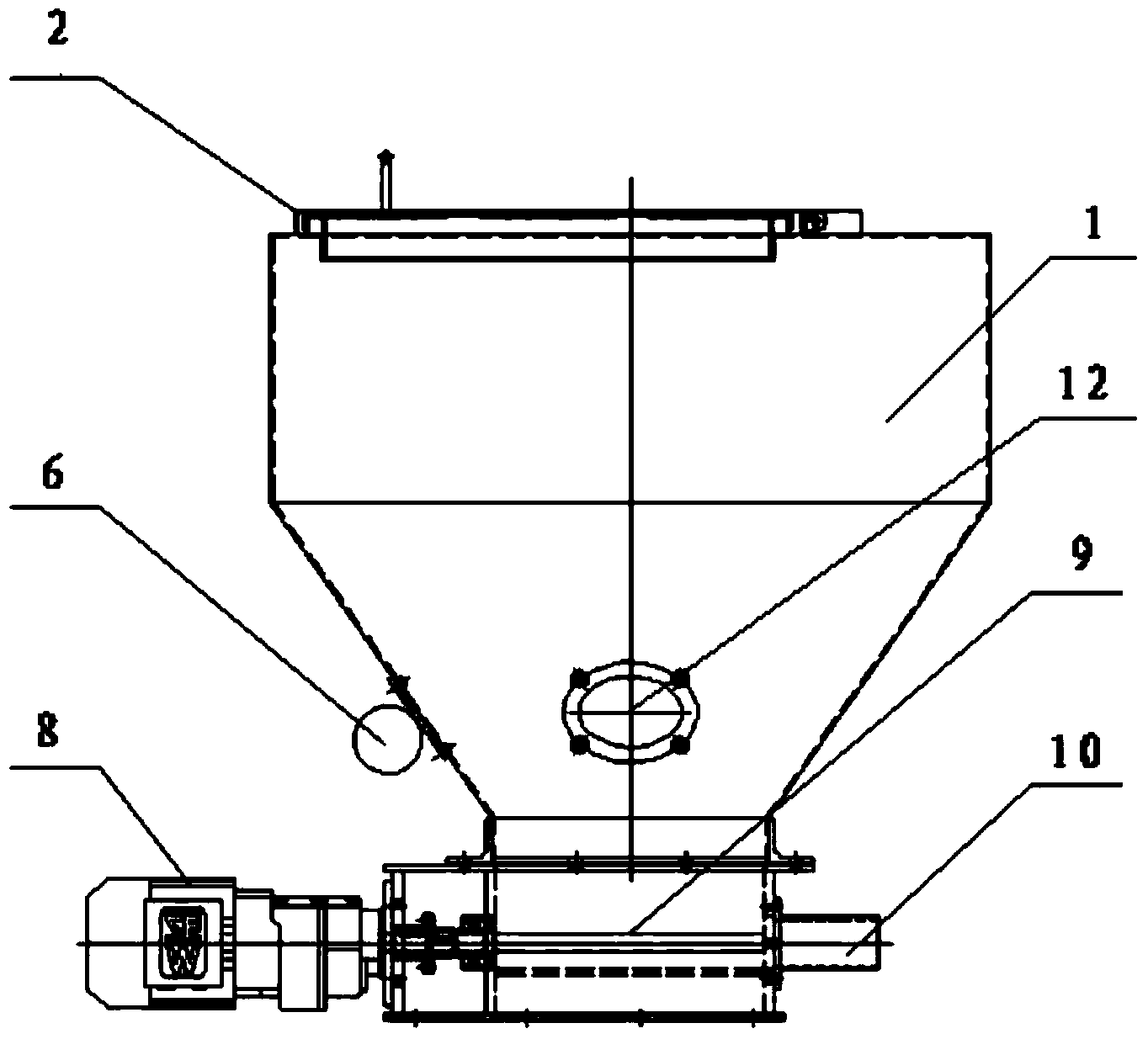

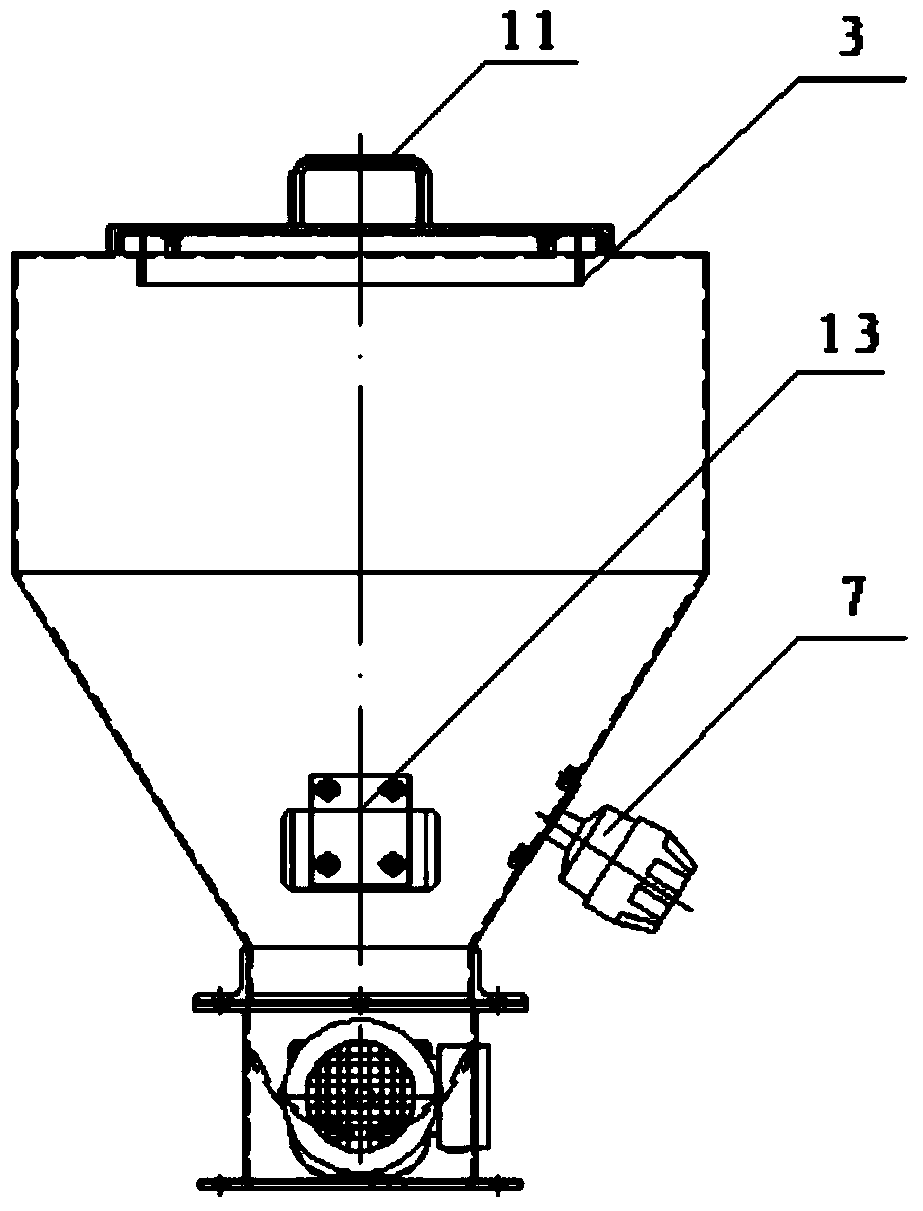

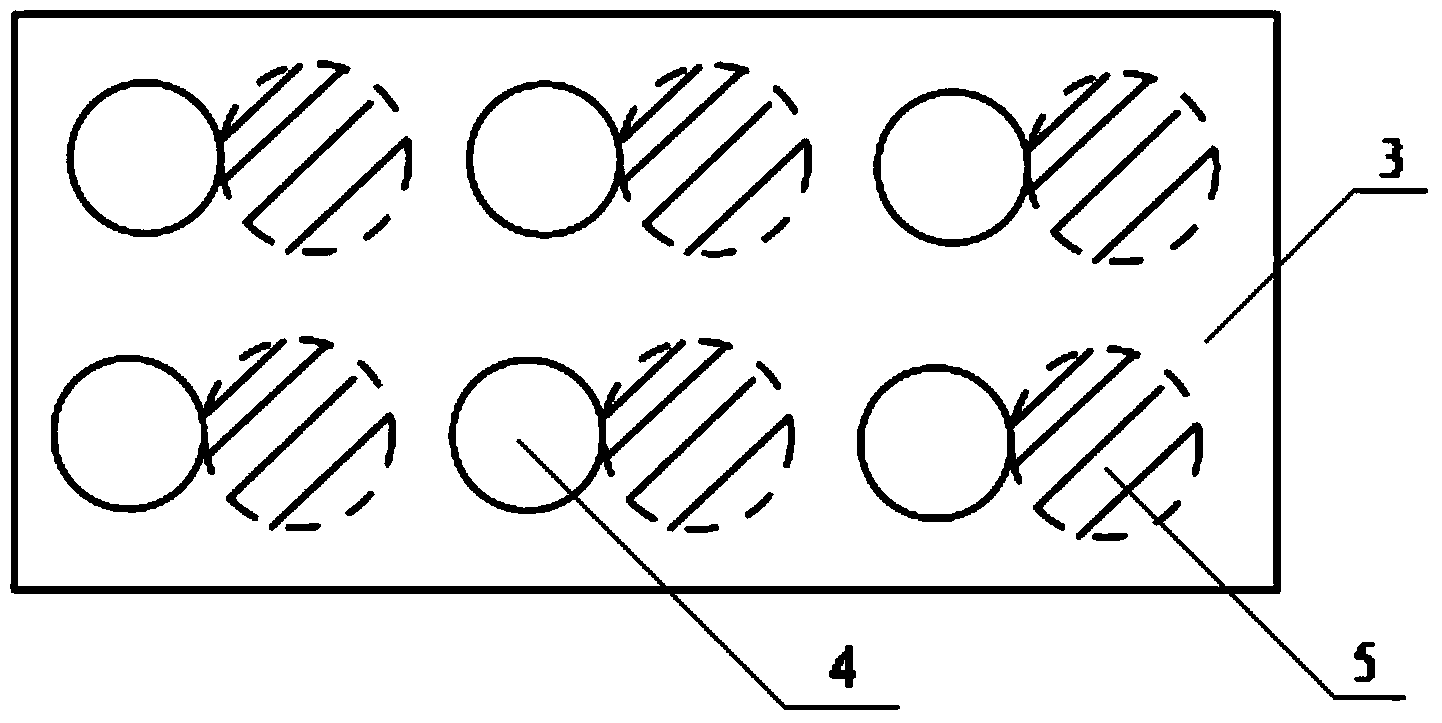

[0024] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , 2 , 3, the present invention provides a novel automatic screw feeding device, comprising a hopper 1 and a hopper upper cover 2 arranged on the top of the hopper 1, a rotatable filter plate 3 is provided at the upper opening of the hopper 1, and a rotatable filter plate 3 is arranged on the filter plate 3 A number of round holes 4 are provided. A rotatable circular baffle 5 is provided inside the filter plate 3. The inner diameter of the circular baffle 5 is larger than the inner diameter of the round hole 4. The bottom of the hopper 1 is respectively connected with a vibration motor 6 and a rotary-resistant material level. Meter 7, vibrating motor 6 is preferably Wittmann brand YZO series vibrating motor, anti-rotation level meter 7, screw feeding device connected to the lower opening of hopper 1, and said screw feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com