Patents

Literature

50results about How to "Shorten the fall distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

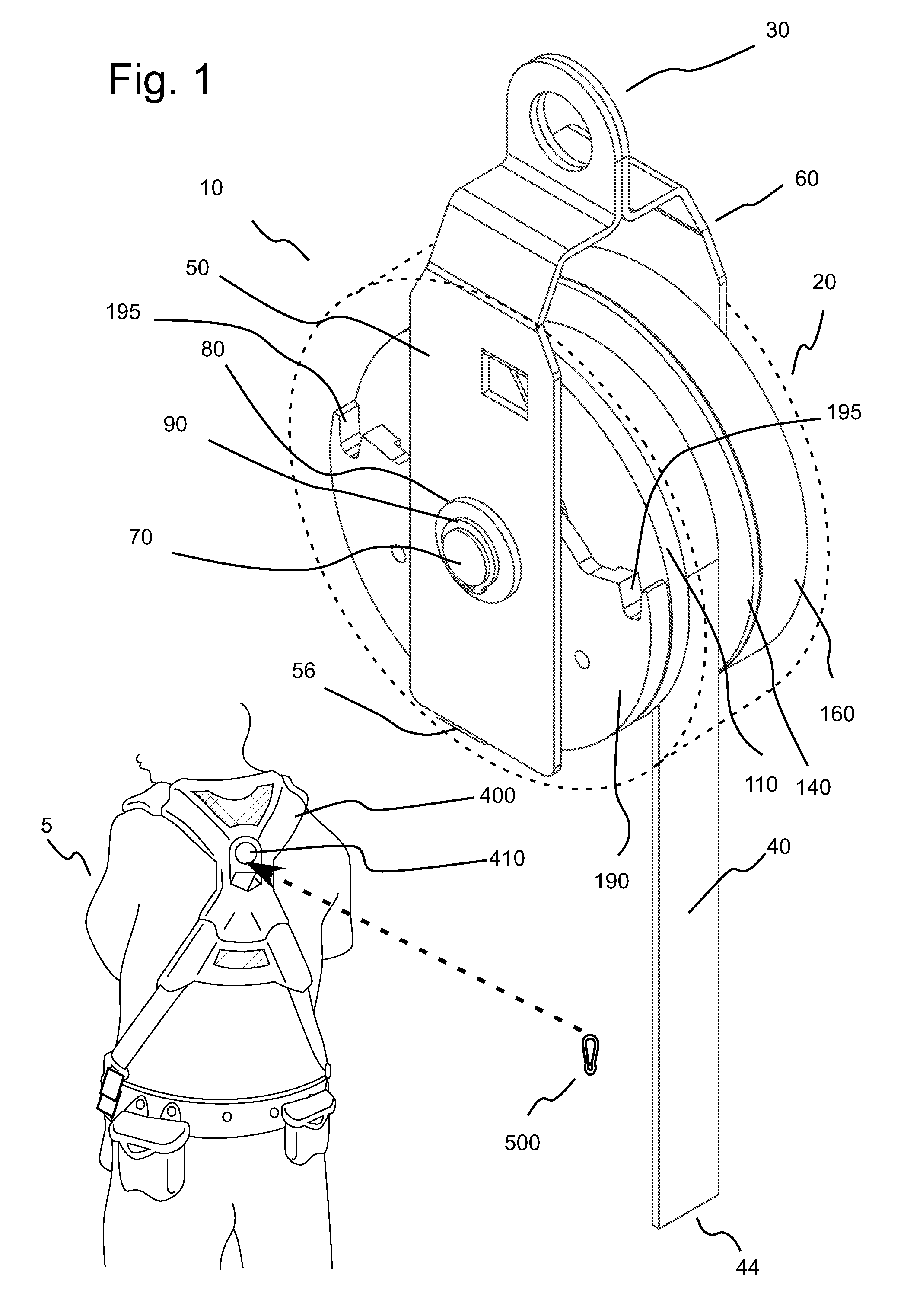

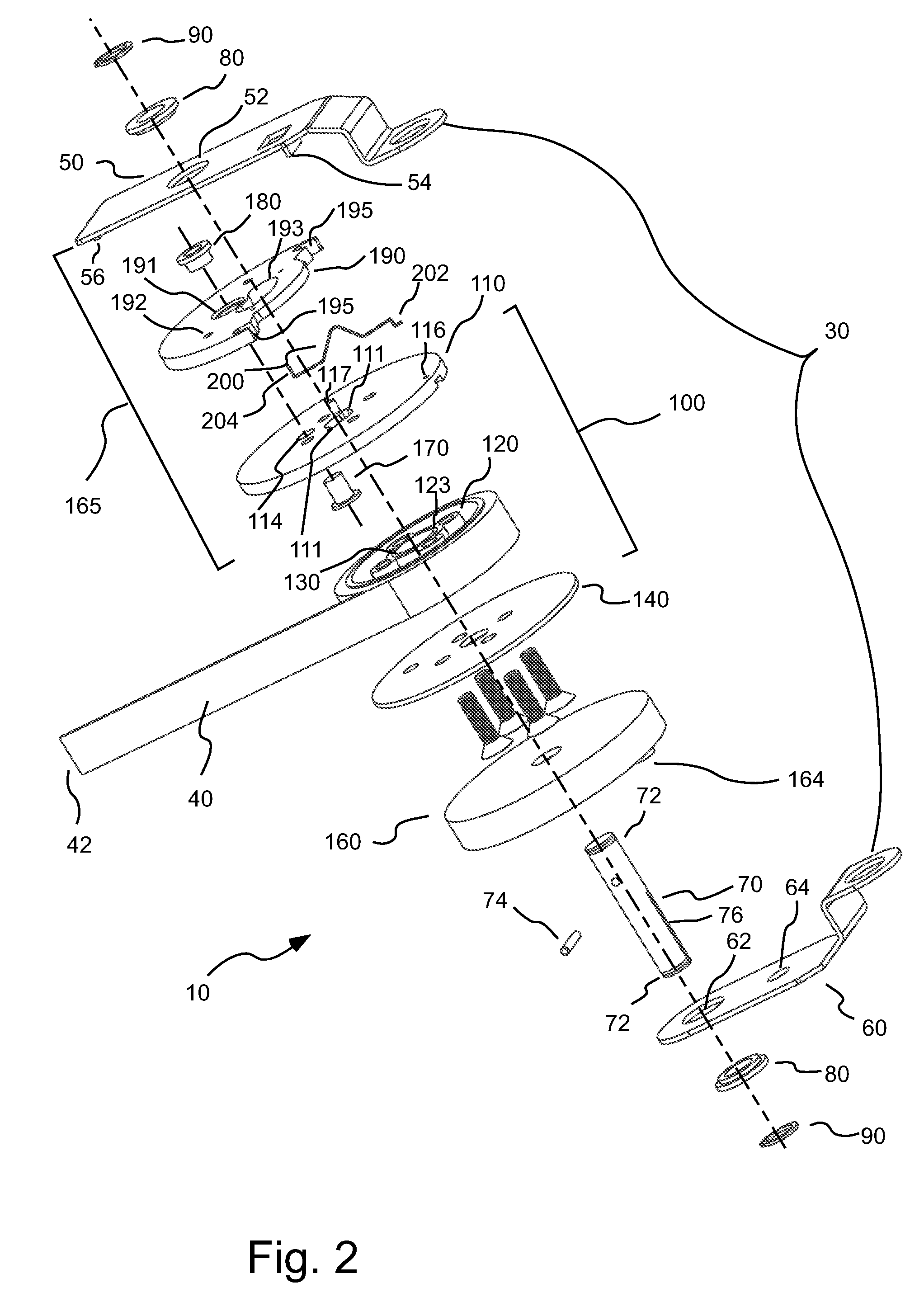

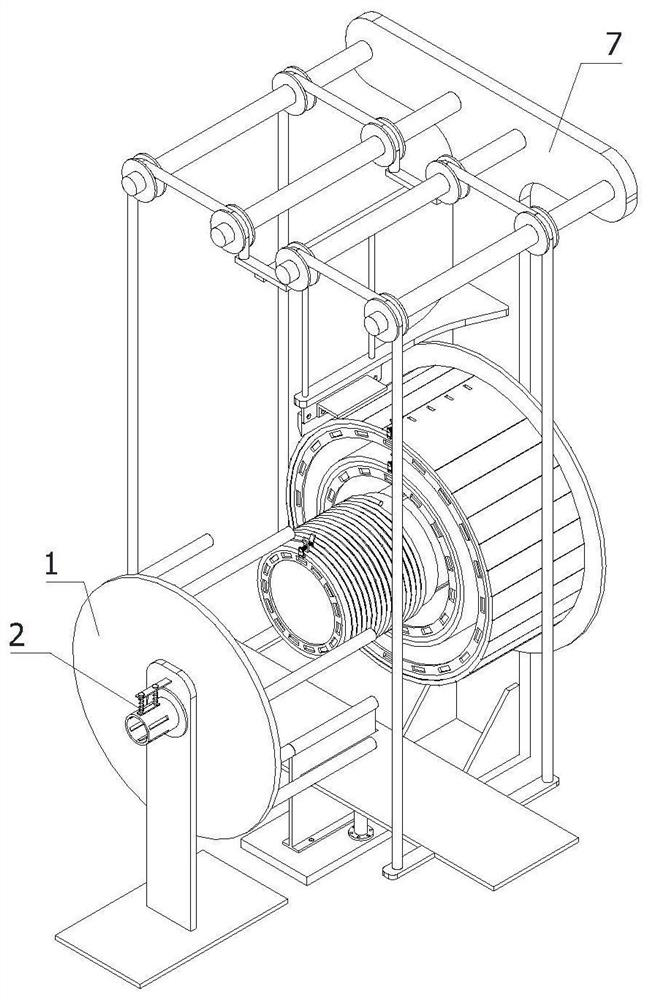

Self-retracting lifeline systems and braking systems therefor

ActiveUS8181744B2Shorten the fall distanceLess complexSafety beltsBelt retractorsEngineeringAngular acceleration

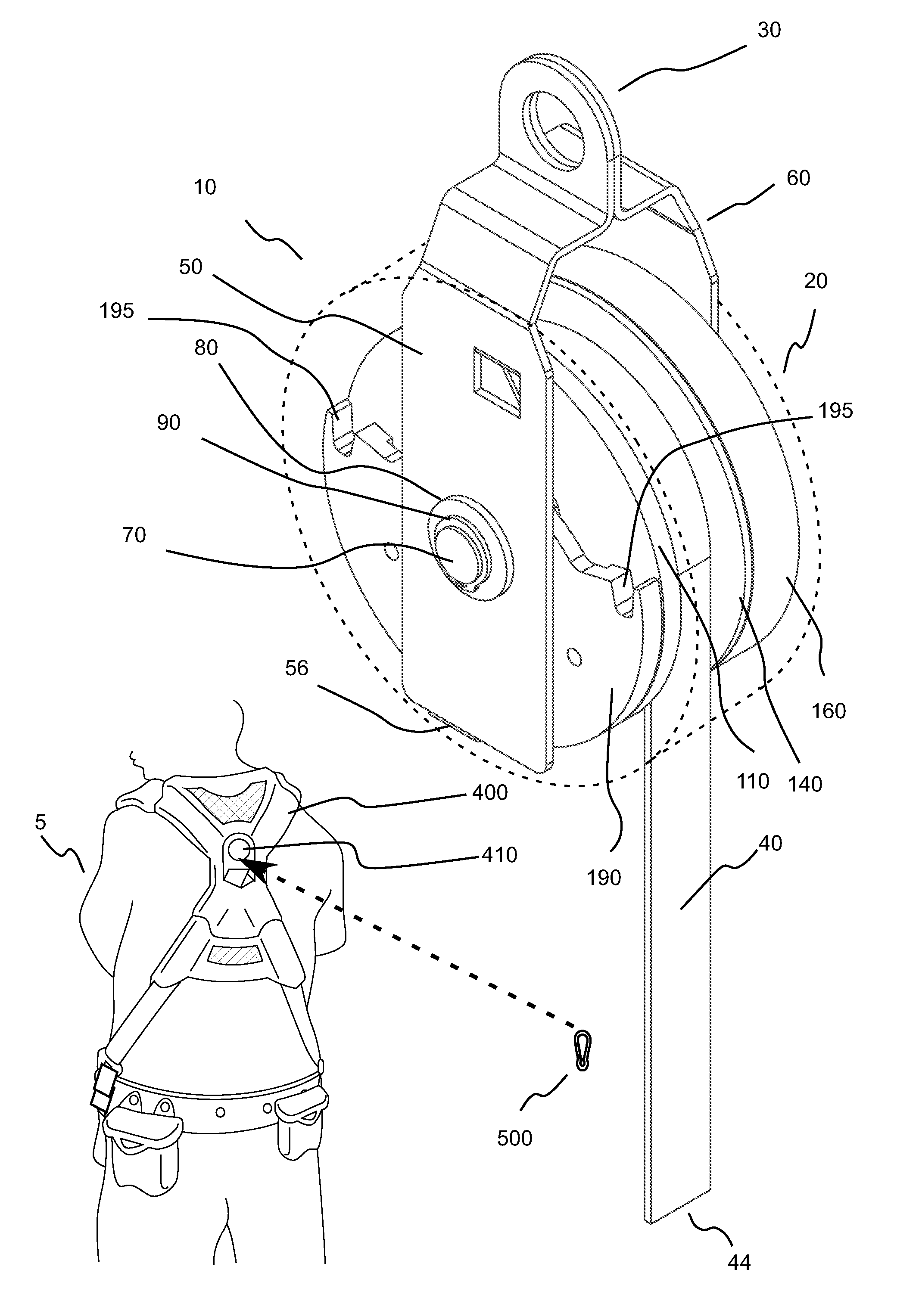

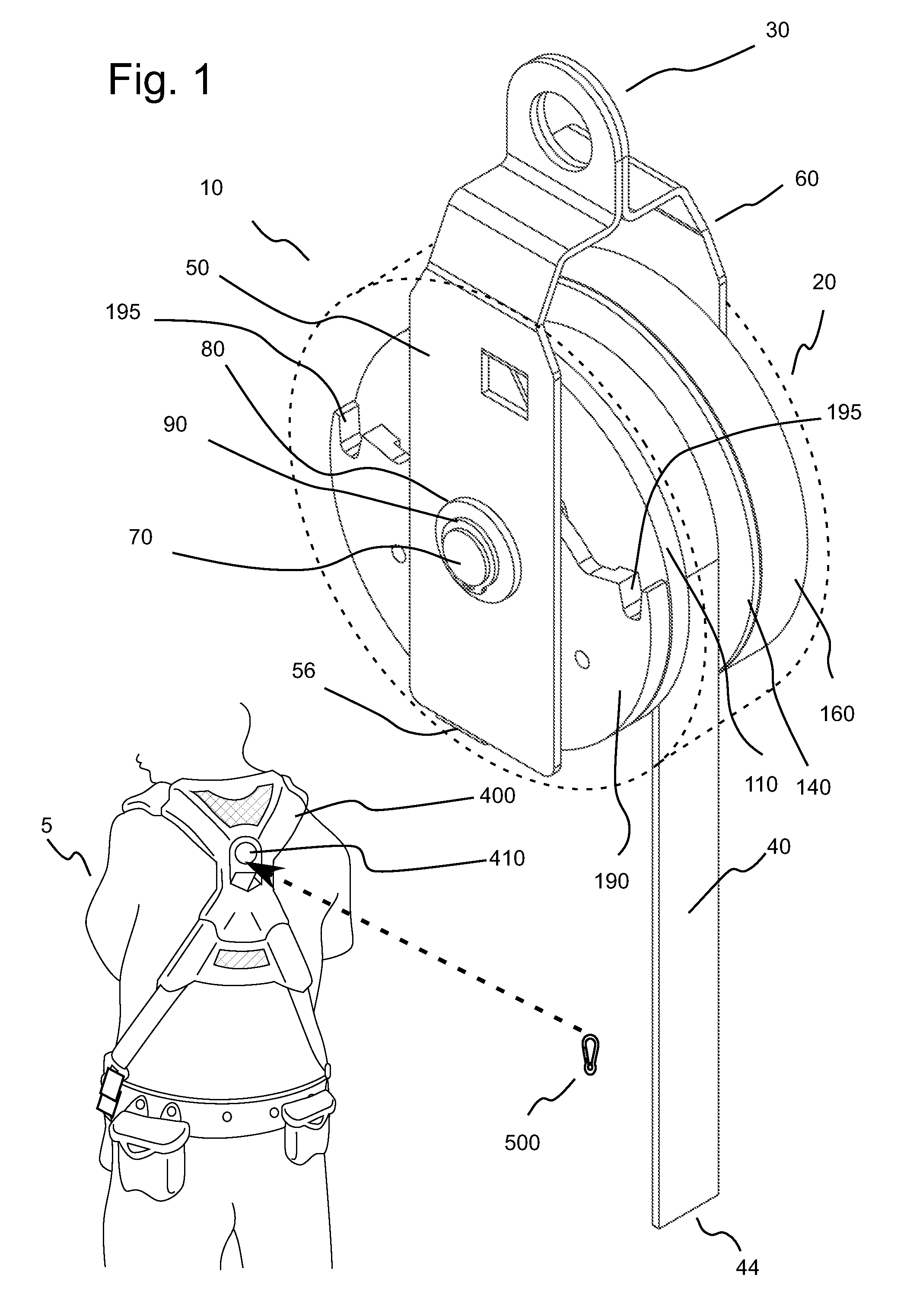

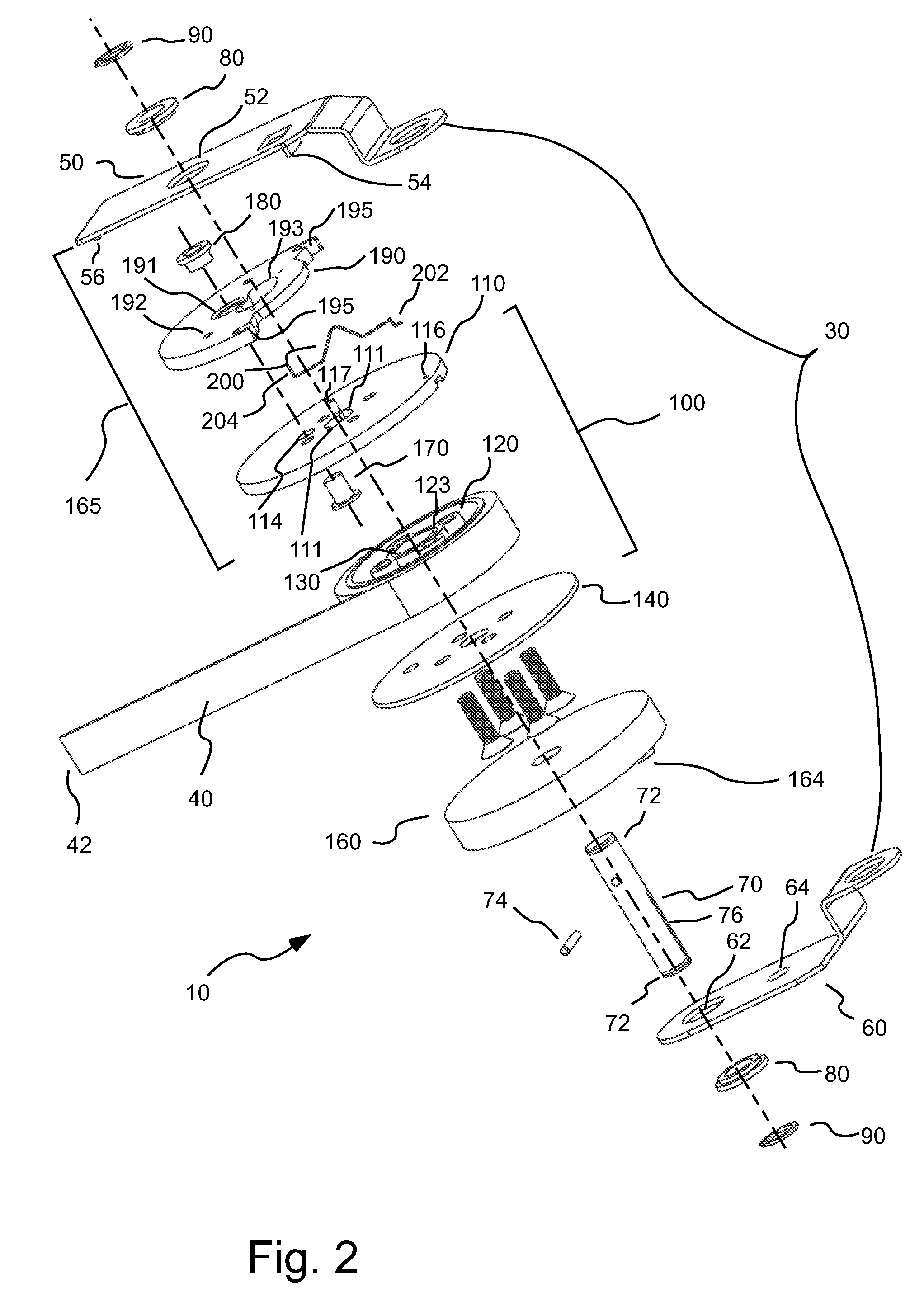

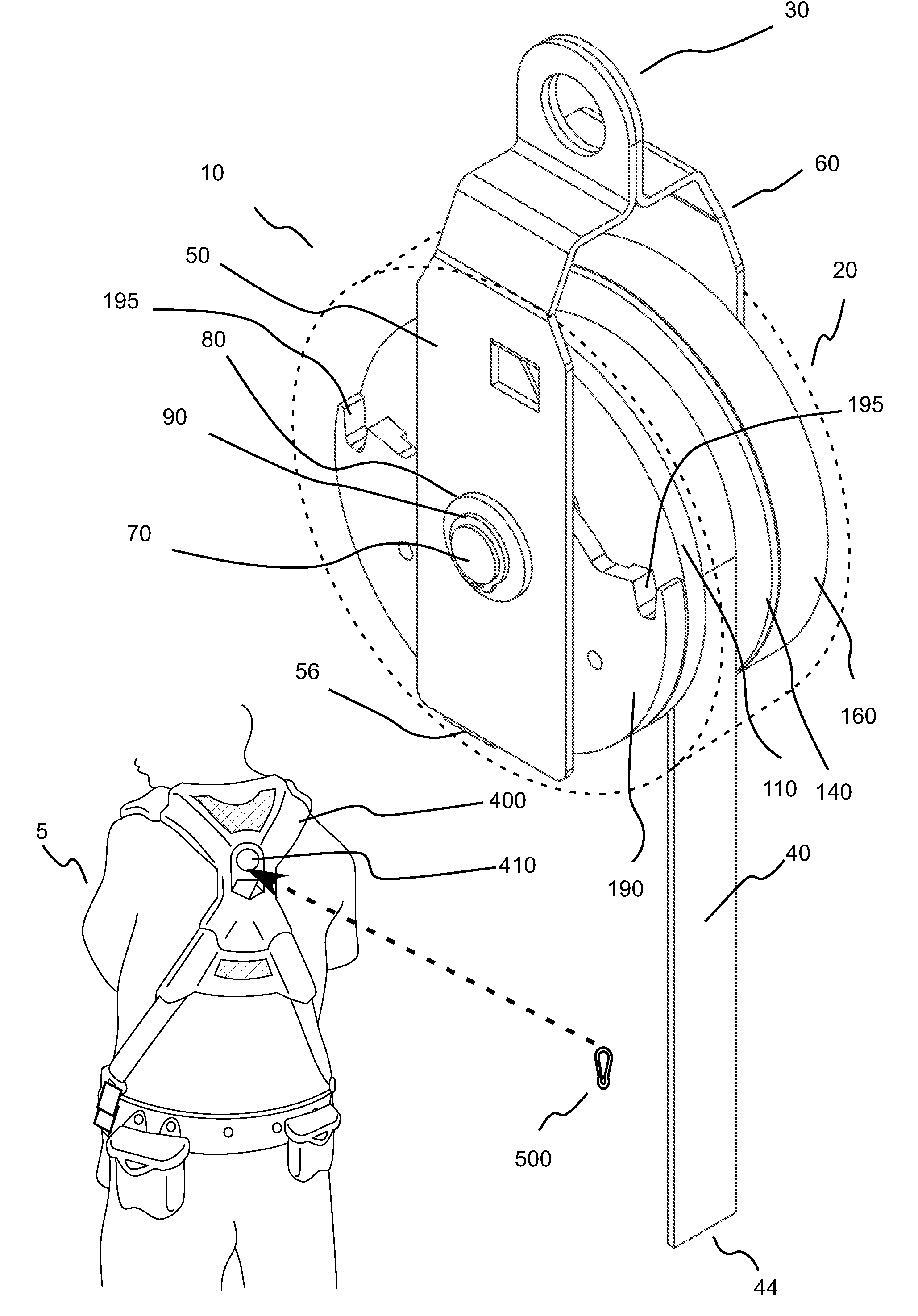

A lifeline system includes a lifeline and a drum assembly around which the lifeline is coiled. The drum assembly is rotatable about a first axis in a first direction during extension of the lifeline and in a second direction, opposite of the first direction, during retraction of the lifeline. The lifeline system further includes a tensioning mechanism in operative connection with the drum assembly to impart a biasing force on the drum assembly to bias the drum assembly to rotate about the first axis in the second direction. The lifeline system further comprises a braking mechanism in operative connection with the drum assembly. The braking mechanism includes a catch that is rotatable relative to the drum assembly about a second axis that is not concentric with the first axis. The second axis is operatively connected to the first axis so that the second axis rotates about the first axis in the same direction as the drum assembly when the drum assembly is rotating about the first axis. A center of mass of the catch is located in the vicinity of the second axis. The catch rotates about the second axis in the second direction when the drum assembly is rotated in the first direction at at least a determined angular acceleration to cause an abutment section of the catch to abut an abutment member of the lifeline system (for example, by moving radially outward a sufficient amount) and stop the rotation of the drum assembly.

Owner:HONEYWELL INT INC

Self-retracting lifeline systems and braking systems therefor

ActiveUS20090211848A1Shorten the fall distanceLess complexBelt retractorsSafety beltsEngineeringAngular acceleration

A lifeline system includes a lifeline and a drum assembly around which the lifeline is coiled. The drum assembly is rotatable about a first axis in a first direction during extension of the lifeline and in a second direction, opposite of the first direction, during retraction of the lifeline. The lifeline system further includes a tensioning mechanism in operative connection with the drum assembly to impart a biasing force on the drum assembly to bias the drum assembly to rotate about the first axis in the second direction. The lifeline system further comprises a braking mechanism in operative connection with the drum assembly. The braking mechanism includes a catch that is rotatable relative to the drum assembly about a second axis that is not concentric with the first axis. The second axis is operatively connected to the first axis so that the second axis rotates about the first axis in the same direction as the drum assembly when the drum assembly is rotating about the first axis. A center of mass of the catch is located in the vicinity of the second axis. The catch rotates about the second axis in the second direction when the drum assembly is rotated in the first direction at at least a determined angular acceleration to cause an abutment section of the catch to abut an abutment member of the lifeline system (for example, by moving radially outward a sufficient amount) and stop the rotation of the drum assembly.

Owner:HONEYWELL INT INC

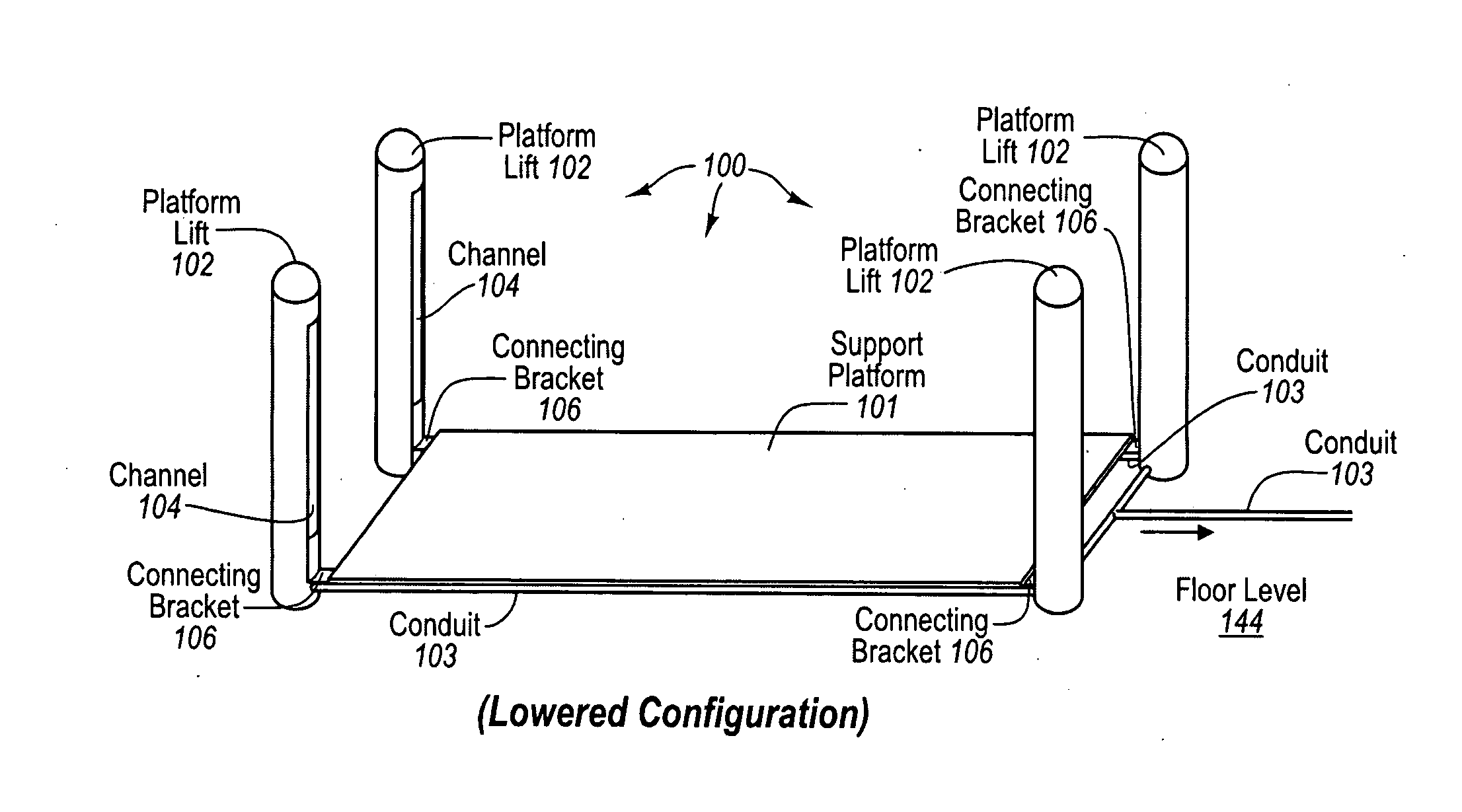

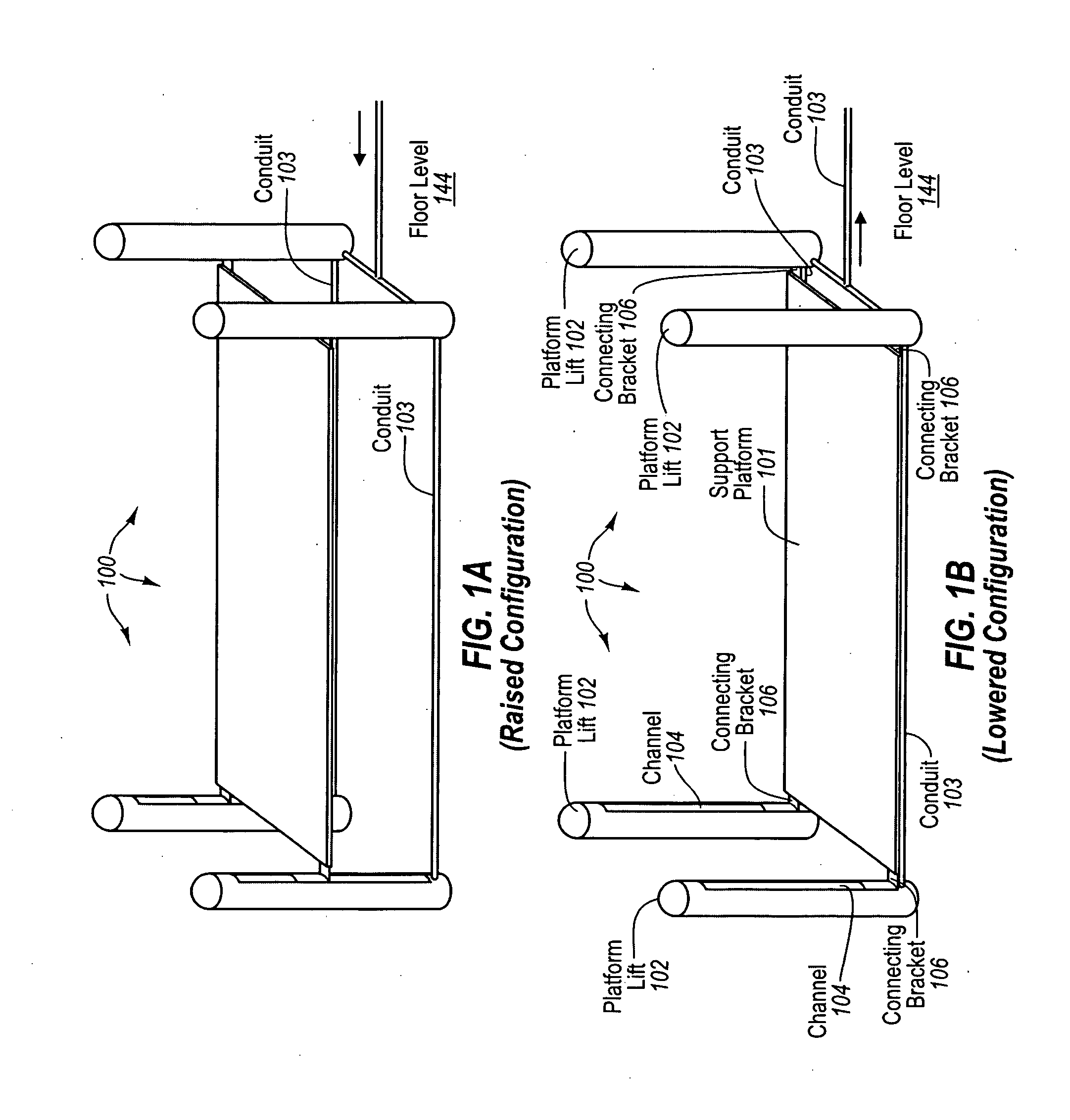

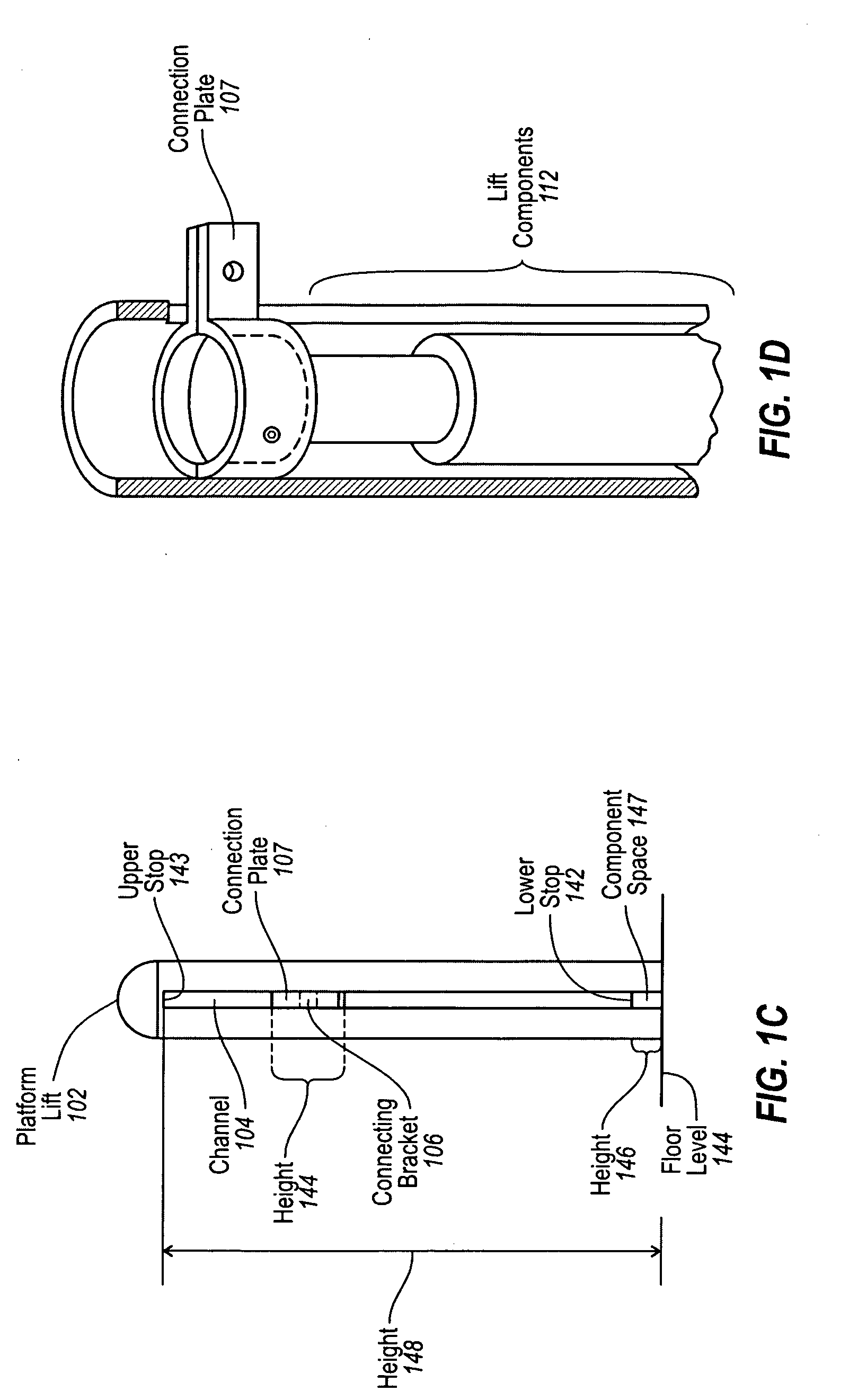

Height adjustable patient support platforms

InactiveUS20090044332A1Shorten the fall distanceReduced likelihoodNursing bedsDiagnostic recording/measuringEngineeringFloor level

The present invention relates to systems and methods for height adjusting patient support platforms, such as, for example, of a bed (e.g., the mattress support platform of a standard hospital bed with side rails), gurney, couch, chair, or recliner, to which a patient may be confined. The systems and methods are designed to lower the height of a patient support platform at least closer (and essentially all the way) to floor level in a relatively quick and controlled manner to reduce fall distances. Lowering the height of a patient support platform corresponding reduces the likelihood and significance of patient injuries resulting from falls when a patient attempts to exit the patient support platform.

Owner:BEE CAVE

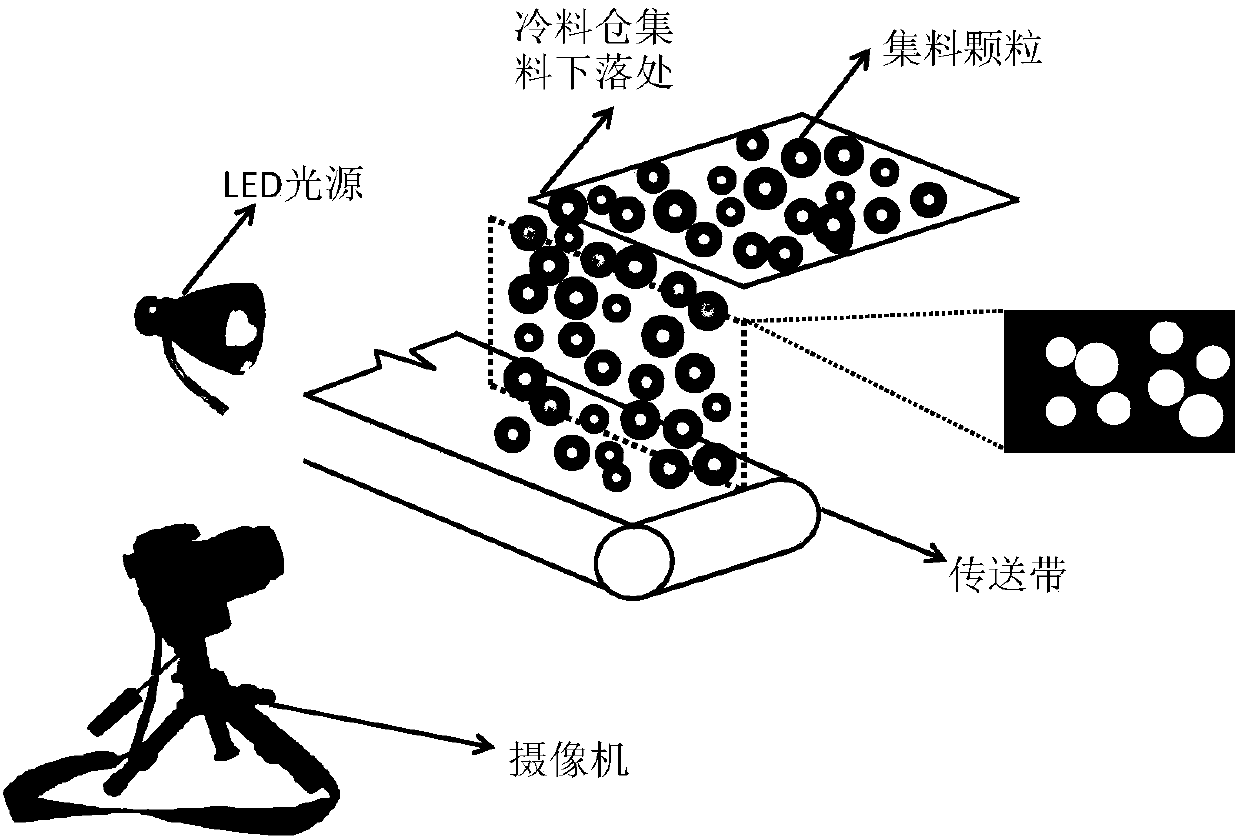

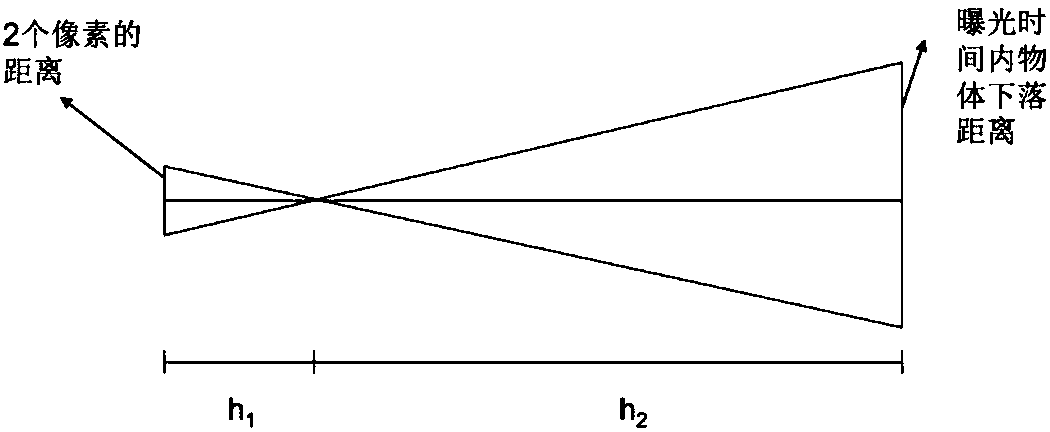

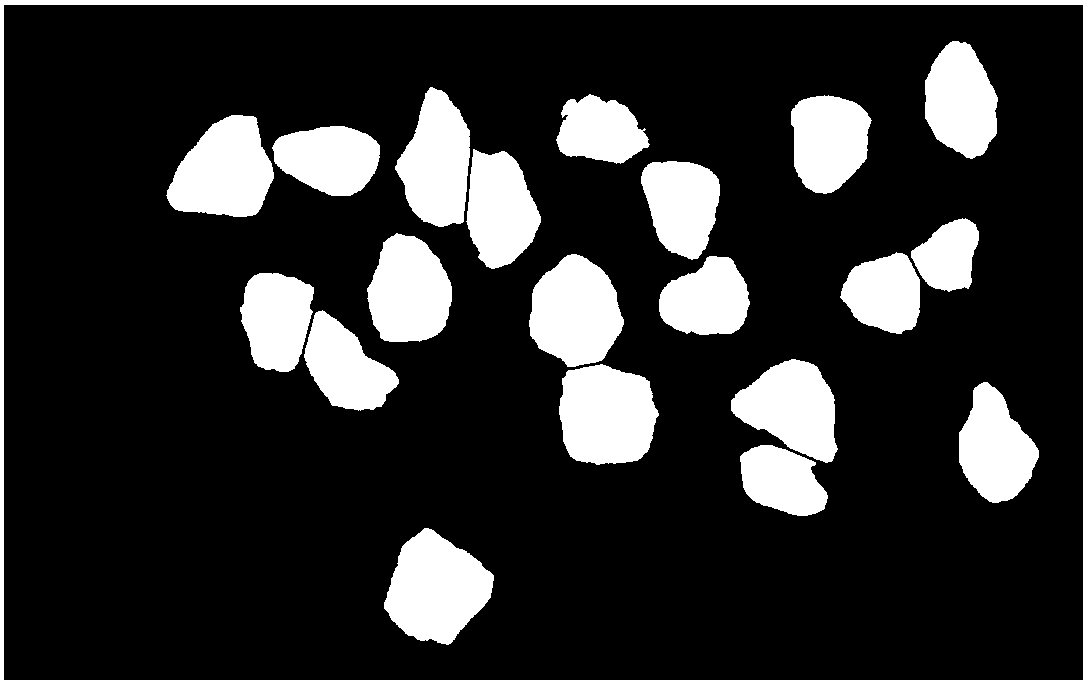

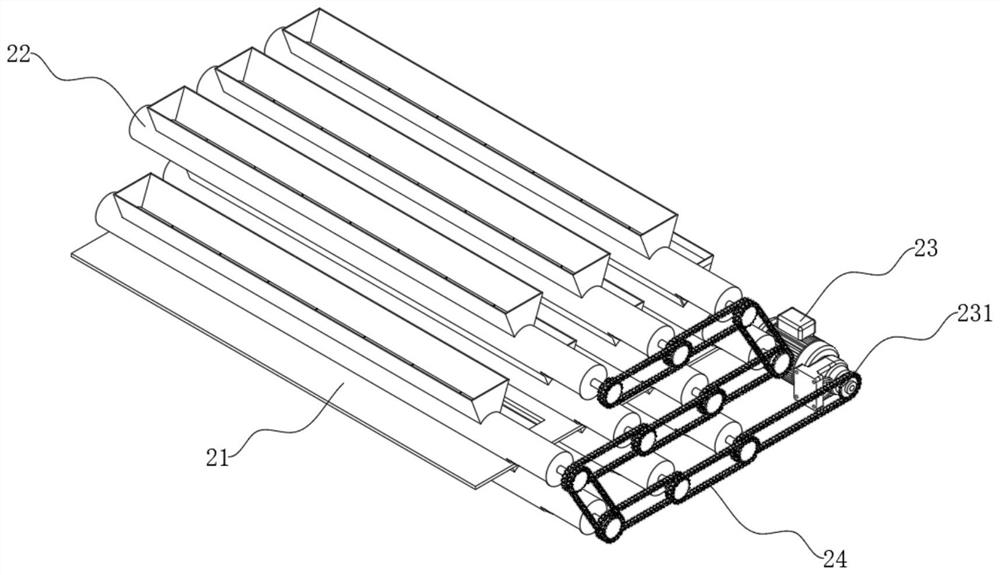

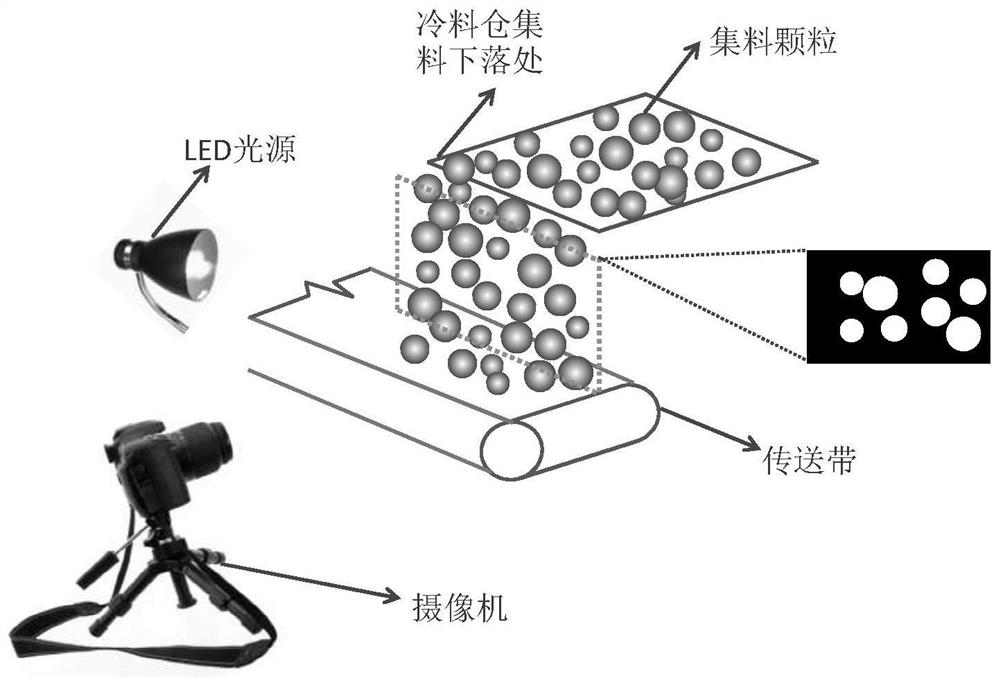

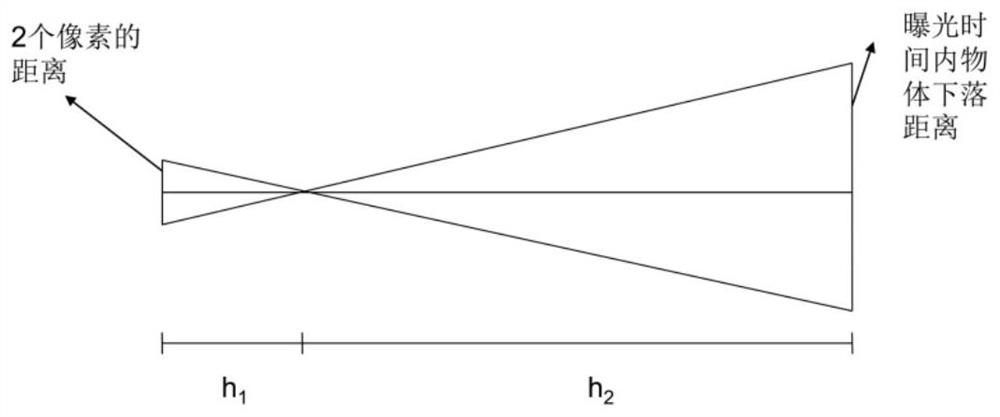

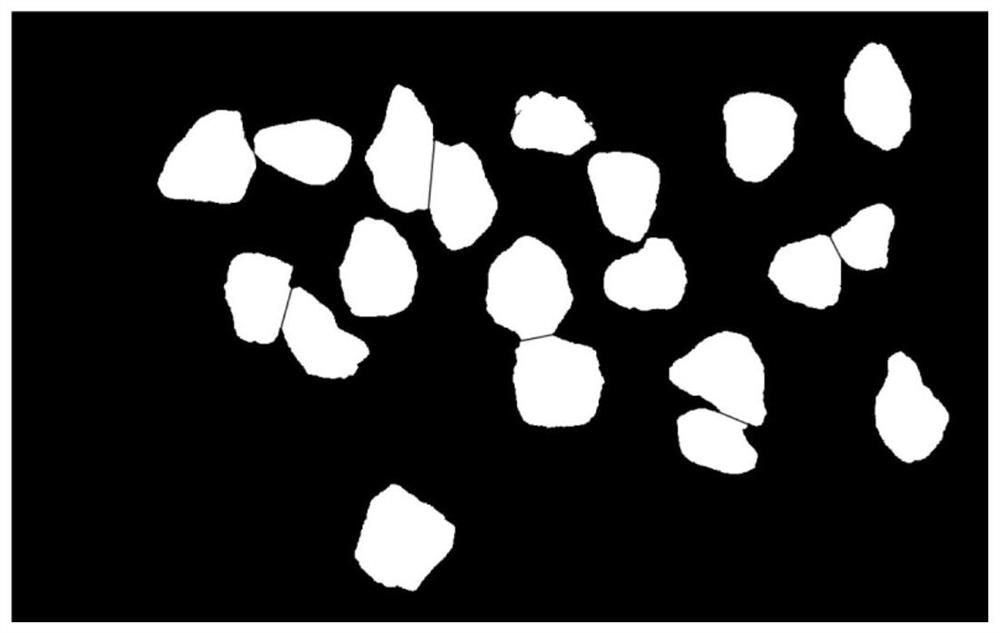

Bituminous mixture grading estimation method through cold charge monitoring

ActiveCN107909584AGradation Accurate MonitoringUneven solutionImage analysisRoads maintainenceColor imageEstimation methods

The invention discloses a bituminous mixture grading estimation method through cold charge monitoring. The method comprises the steps that an appropriate camera is selected; the position of the cameraand the intensity of an LED light source are adjusted; digital images used for analysis are determined; MATLAB is utilized to convert the color images into binary images; the distance between the binary images is calibrated; stone particles are virtually screened; the volume of aggregate particles is estimated; the aggregate passing rate is calculated; multiple levels of cold charge grading are determined; and the grading of a bituminous mixture in a stirring pot is estimated based on all levels of cold charge grading in combination with cold charge bin flow. Due to the fact that the fallingdistance of cold charge bin particles is small, the method cannot give rise to dust; the additionally installed LED light source can overcome the non-uniformity problem of natural light; the shot images are clear and continuous, and therefore cold charge grading can be accurately monitored; and meanwhile, on the basis of accurately monitoring the cold charge grading, the grading of the bituminousmixture can be estimated in combination with the flow of all cold charge bins, and the method can be applied to construction process control of the bituminous mixture.

Owner:SOUTHEAST UNIV

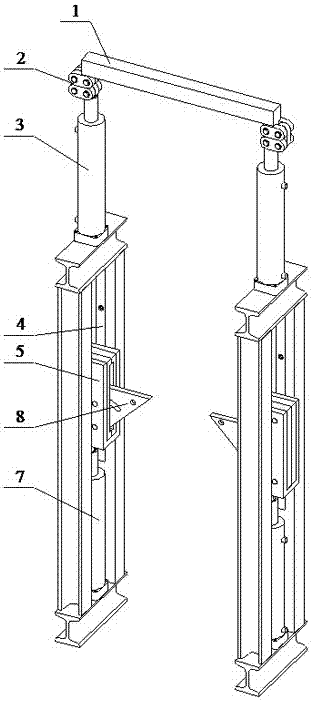

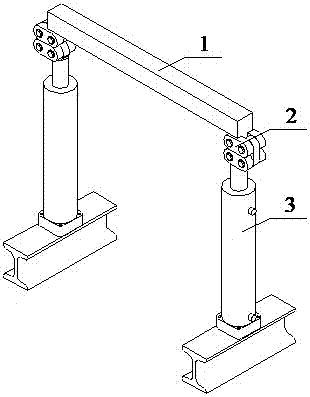

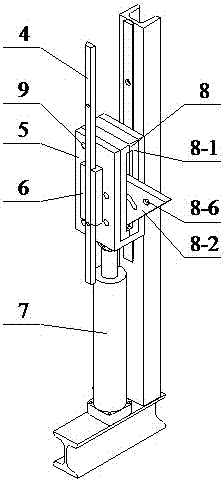

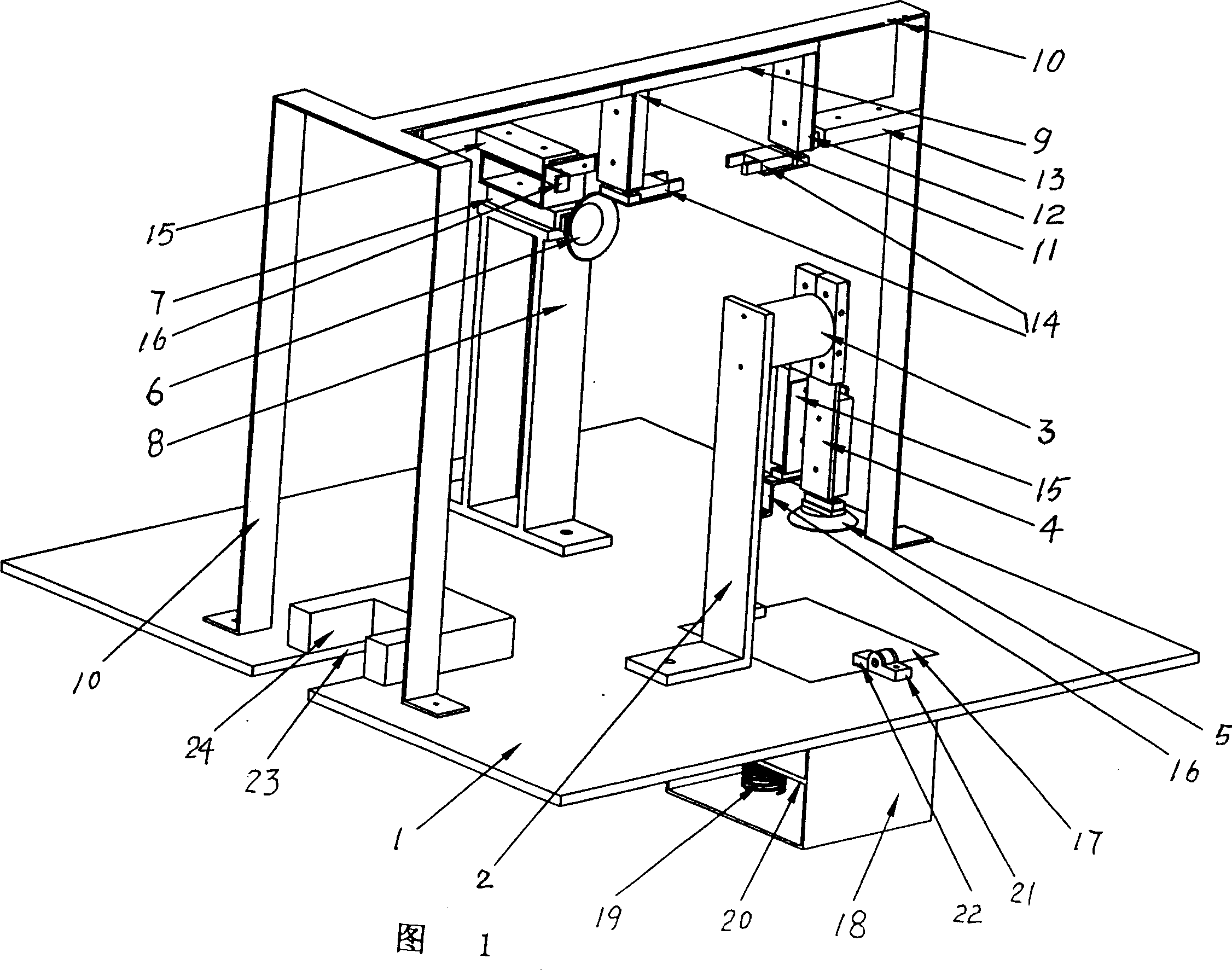

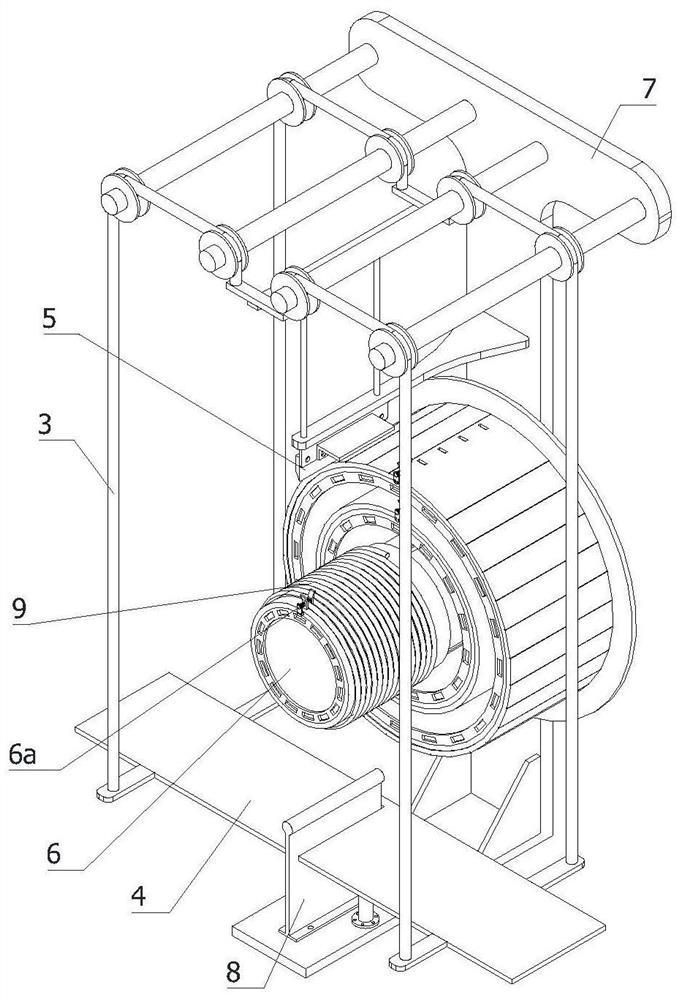

Overwinding buffer and tank supporting device for elevating systems of mine vertical shaft and hydraulic system

The invention relates to the technical field of mine transportation, in particular to an overwinding buffer and tank supporting device for elevating systems of a mine vertical shaft and a hydraulic system. The overwinding buffer and tank supporting device comprises a transverse beam buffer part and a hydraulic tank supporting part. The transverse beam buffer part comprises hydraulic buffer cylinders fixed to a derrick and a transverse beam located above the hydraulic buffer cylinders. The top of a piston rod of each hydraulic buffer cylinder is hinged to the corresponding end of the lower portion of the transverse beam through three buffer chain links. The invention further provides the hydraulic system matched with the overwinding buffer and tank supporting device. The overwinding buffer and tank supporting device has the advantages that the overwinding collision impact is small, the buffer braking power is stable, the falling distance is short, and tank supporting is reliable and recyclable, and the overwinding buffer and tank supporting device is suitable for overwinding protection for the various elevating systems of the mine vertical shaft.

Owner:唐山市赛娜机电设备有限责任公司

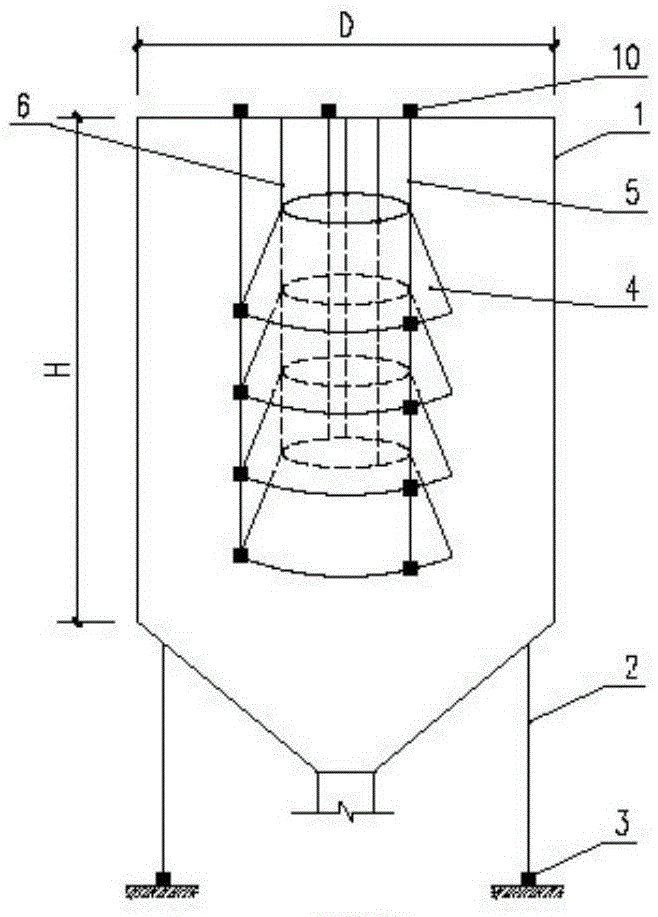

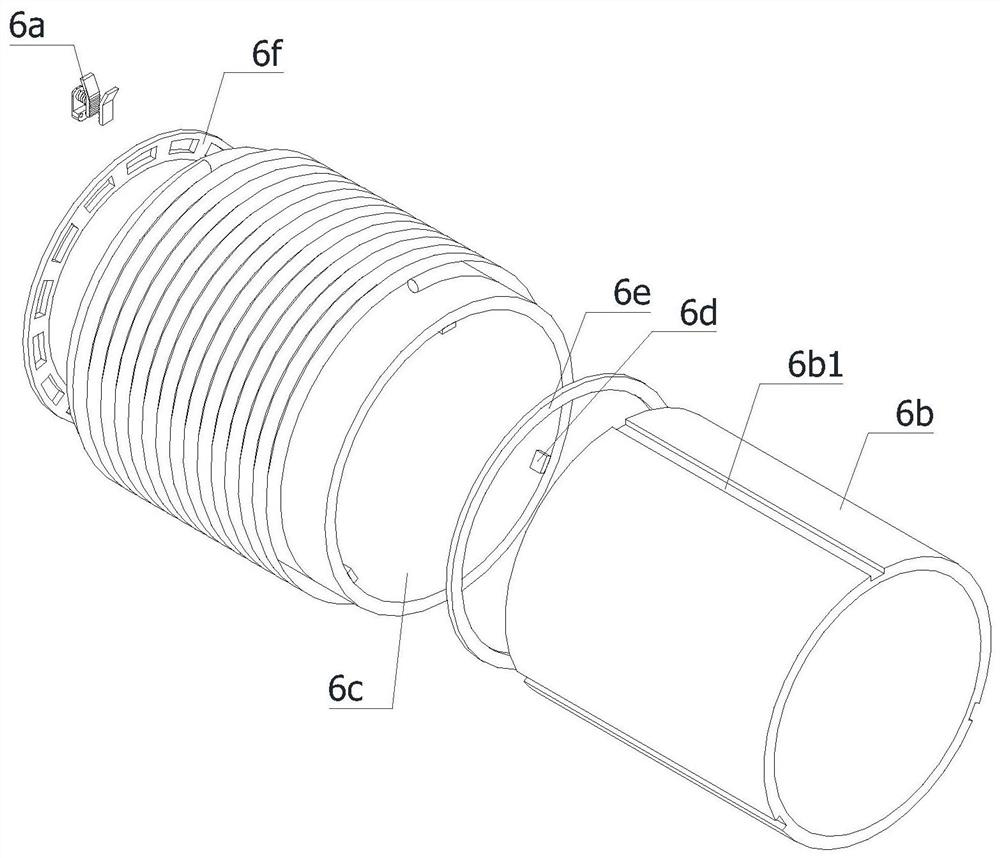

Anti-separation device for dry-mixed mortar bin

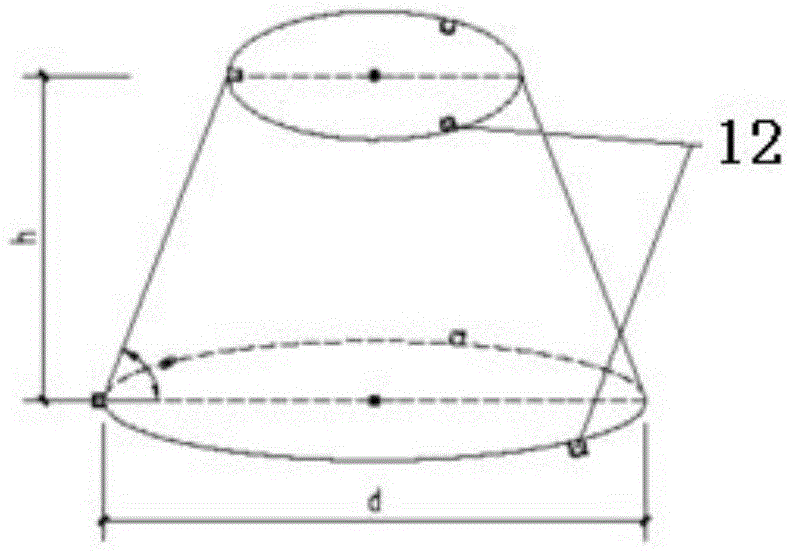

PendingCN105645138AShorten the fall distanceAchieve a second dropLoading/unloadingCouplingComputer module

The invention discloses an anti-separation device for a dry-mixed mortar bin. The anti-separation device for the dry-mixed mortar bin is composed of a plurality of sleeves, a lifting device and a connecting module, wherein the sleeves are arranged in the bin, the lifting device is arranged outside the bin, and the connecting module is located between the sleeves and the lifting device. Each sleeve is in the shape of a circular truncated cone, wherein the upper portion and the lower portion of the sleeve are open, and the area of the lower opening is larger than that of the upper opening. The sleeves are connected in a sleeved mode, connected through the connecting module and vertically hung in the bin. The connecting module is composed of steel wire ropes which are fixed to the outer circumference of the bottommost sleeve and fixed pulleys at the top of the bin and soft connecting ropes which are fixed to the inner circumferences of the sleeves and the inner wall of the top of the bin. The lifting device is arranged on the top surface of the bin and comprises a motor. A plurality of take-up and pay-off rollers are connected with the motor through couplings and spaced form the motor by a certain distance. One fixed pulley is correspondingly arranged in the position a certain distance away from each take-up and pay-off roller in the vertical direction. The fixed pulleys are evenly arranged along the circle center of the top surface of the bin, so that the effect that the connecting device and the sleeve are balanced is guaranteed. The anti-separation device for the dry-mixed mortar bin is exquisite in design, low in cost and outstanding in effect and has extremely high commercial promotional value.

Owner:广西建筑材料科学研究设计院有限公司

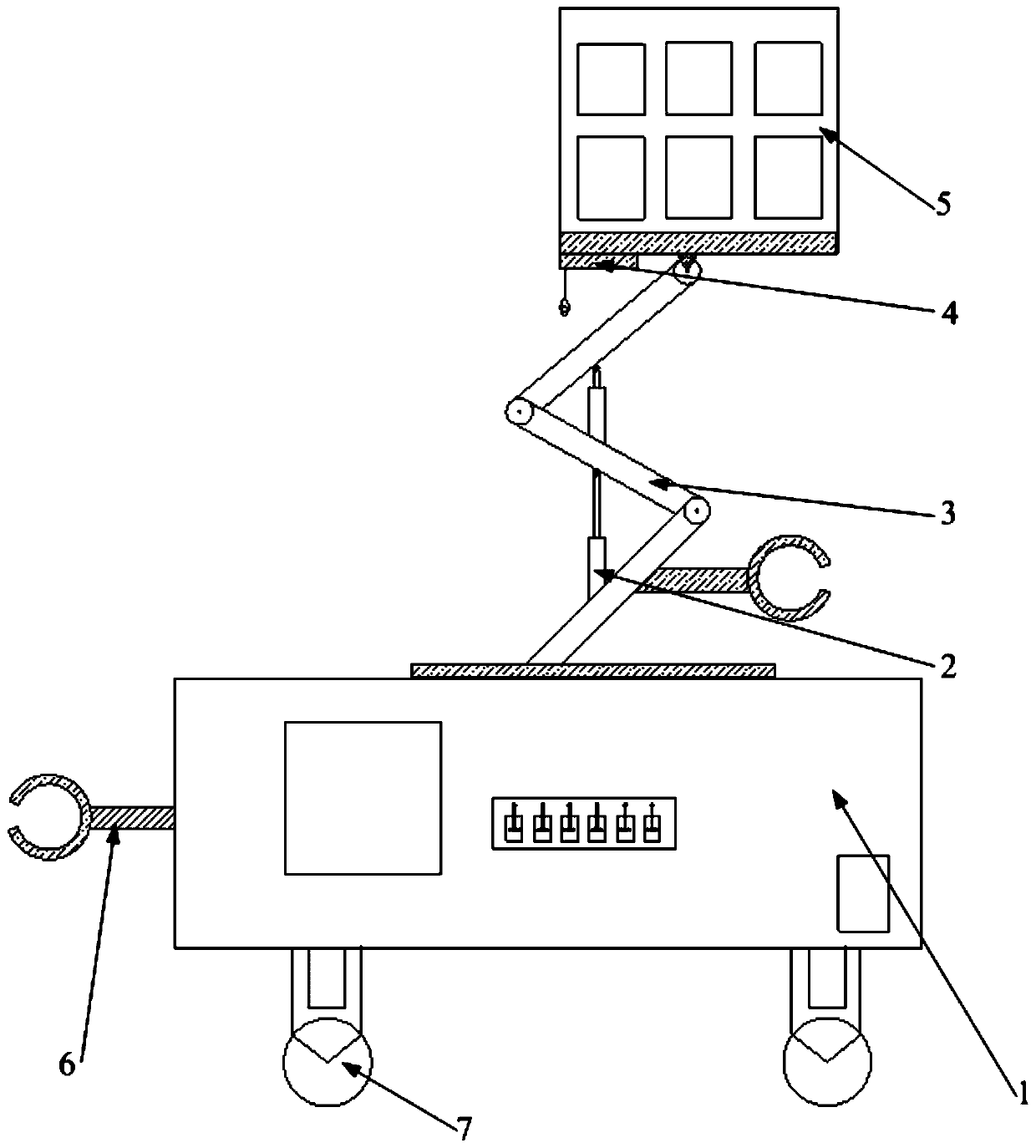

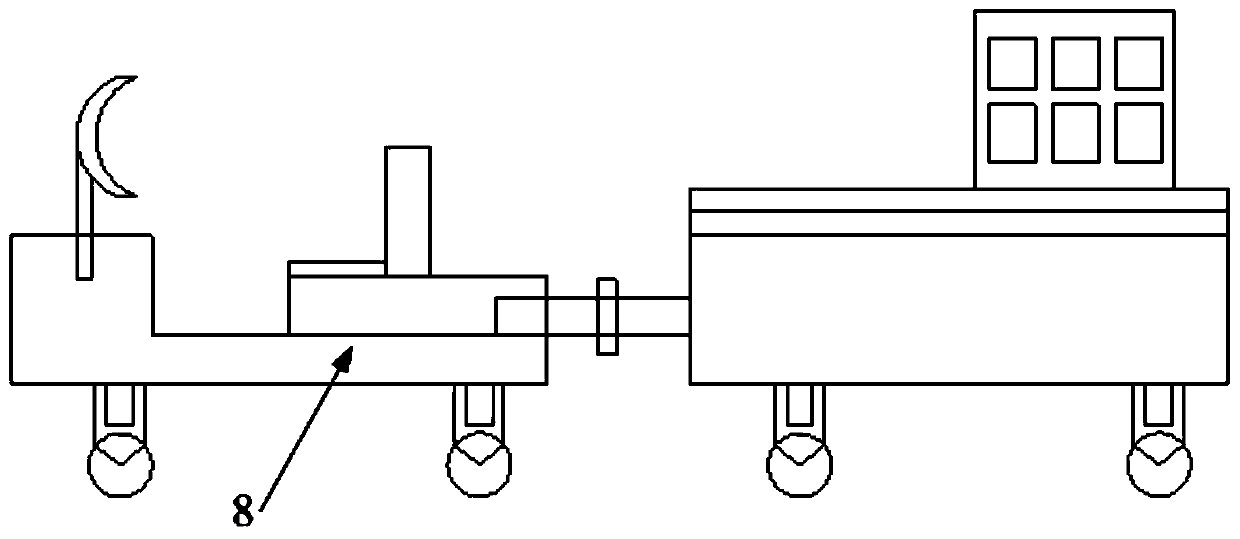

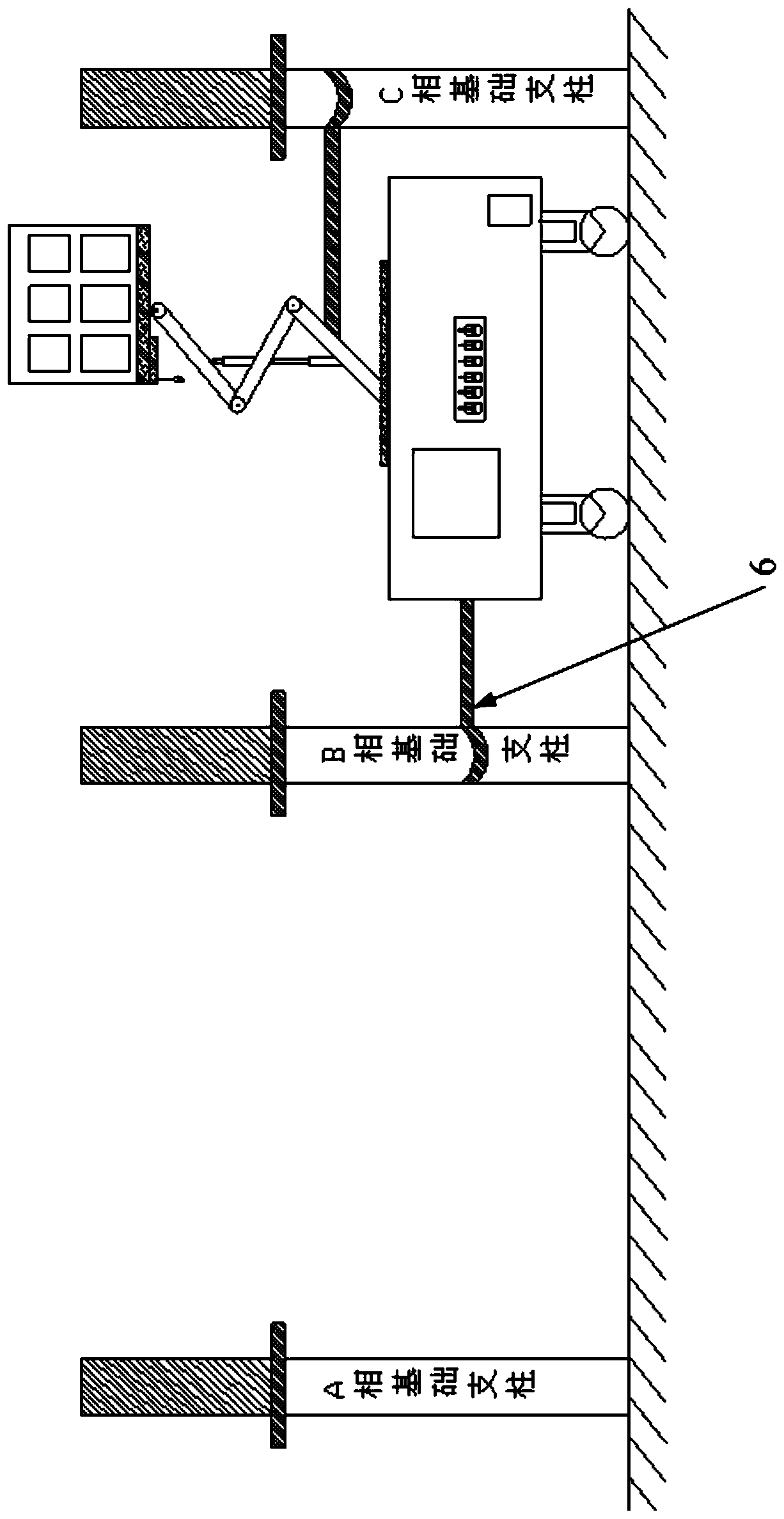

Auxiliary device for overhauling electric equipment

ActiveCN110034506AReduce shakingImprove construction qualitySwitchgearElectric equipmentElectric power

The invention provides an auxiliary device for overhauling electric equipment. The auxiliary device comprises an operation platform capable of being placed between two adjacent two-phase maintenance equipment of a substation and capable of moving, a work platform capable of supporting maintenance workers, and a lifting mechanism, wherein the work platform is provided with a safety belt high-hanging mechanism; the lifting mechanism is used for lifting the work platform; the lifting mechanism is arranged on the operation platform; and the work platform is arranged at the lifting end of the lifting mechanism. The work platform for supporting the overhauling workers is lifted by the lifting mechanism, and the work platform is supported by the lifting mechanism, so that the stability is relatively high, the shaking of workers in the working process is reduced, and the construction quality of overhauling operation is improved. Meanwhile, the safety belt high-hanging mechanism on the work platform is used as a safety belt high-hanging point of a worker when the working personnel is separated from the work platform and is operated by the maintenance equipment, so that the working personnelcan be guaranteed to have a relatively small falling distance once high-altitude falling occurs.

Owner:STATE GRID JIBEI ELECTRIC POWER COMPANY LIMITED CHENGDE POWER SUPPLY +1

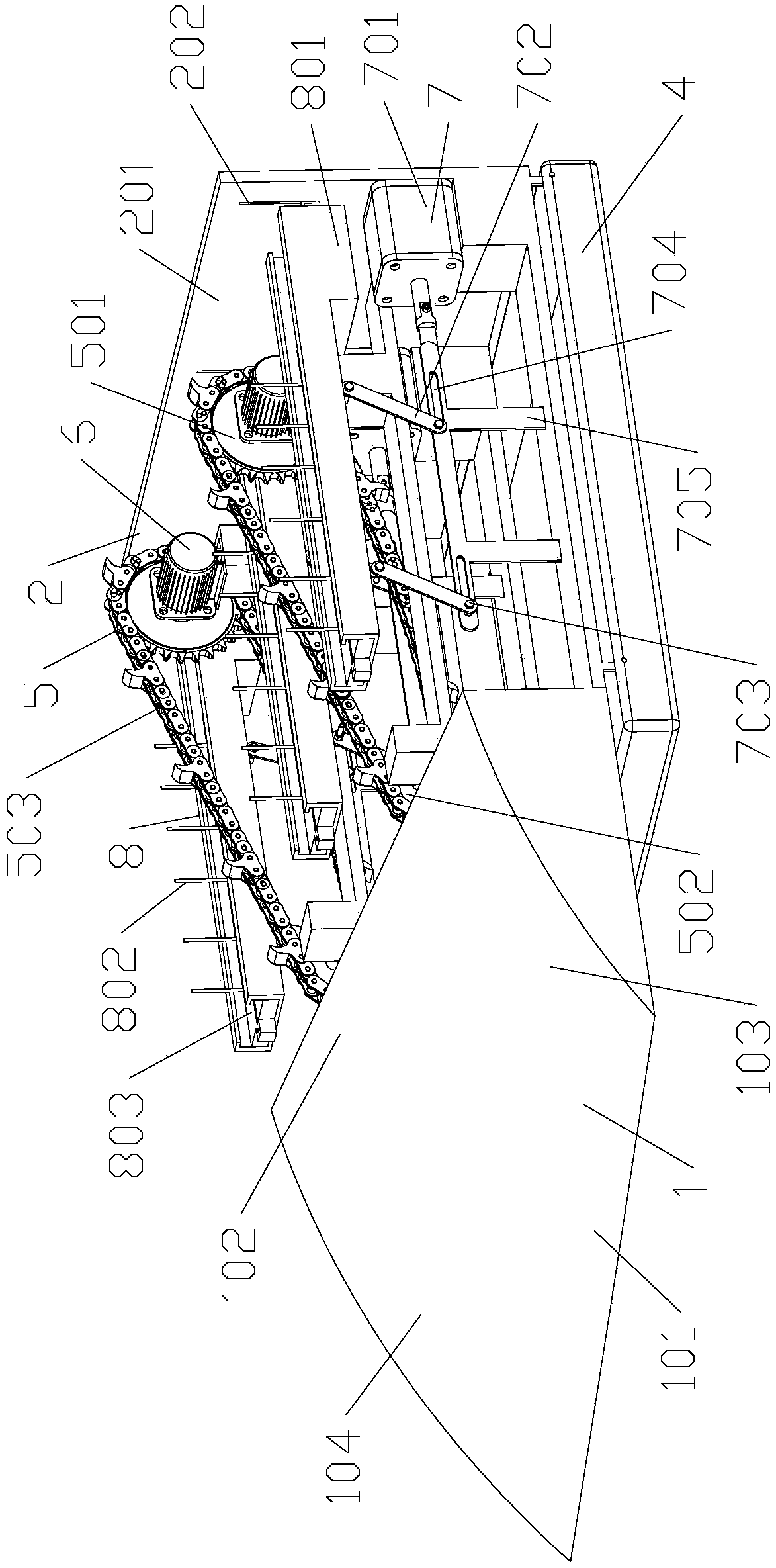

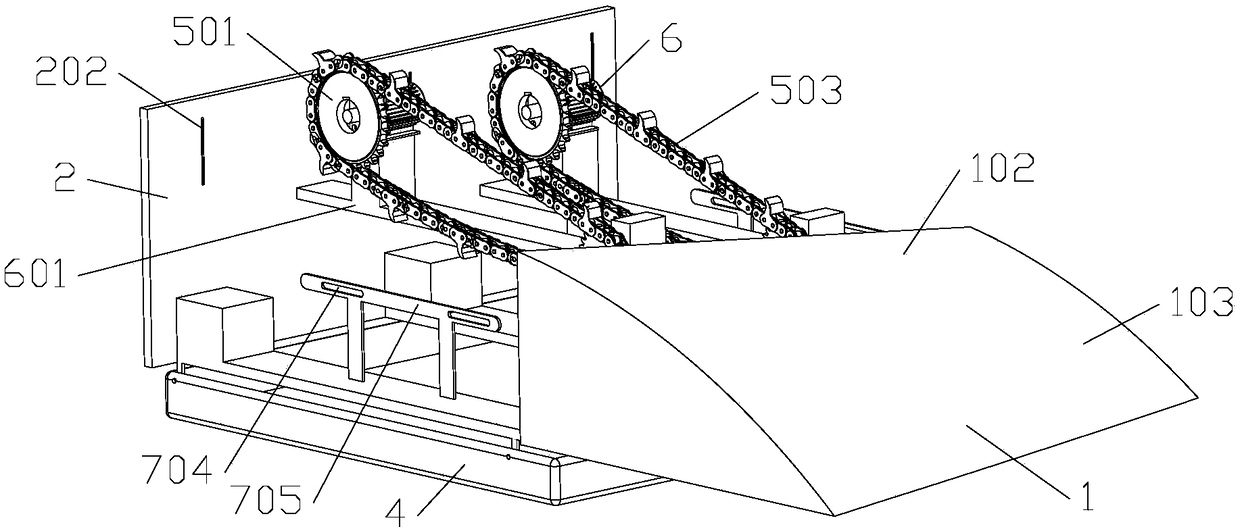

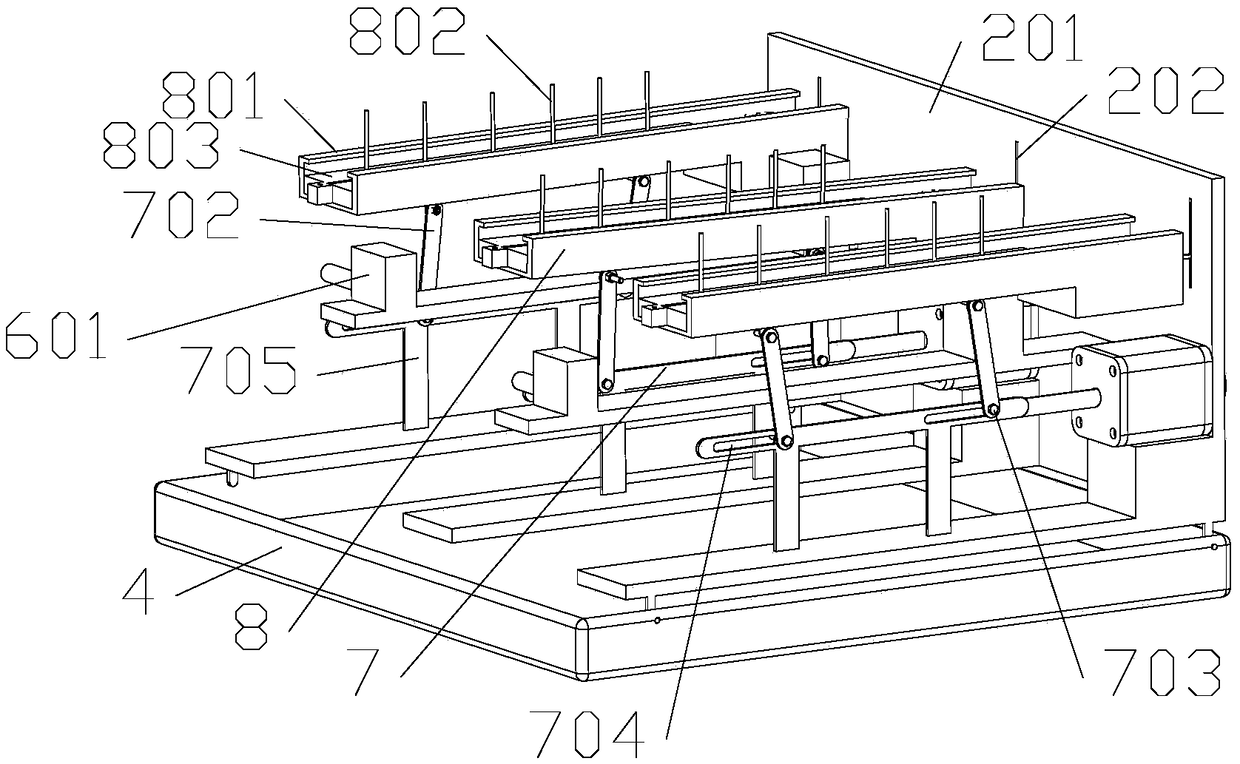

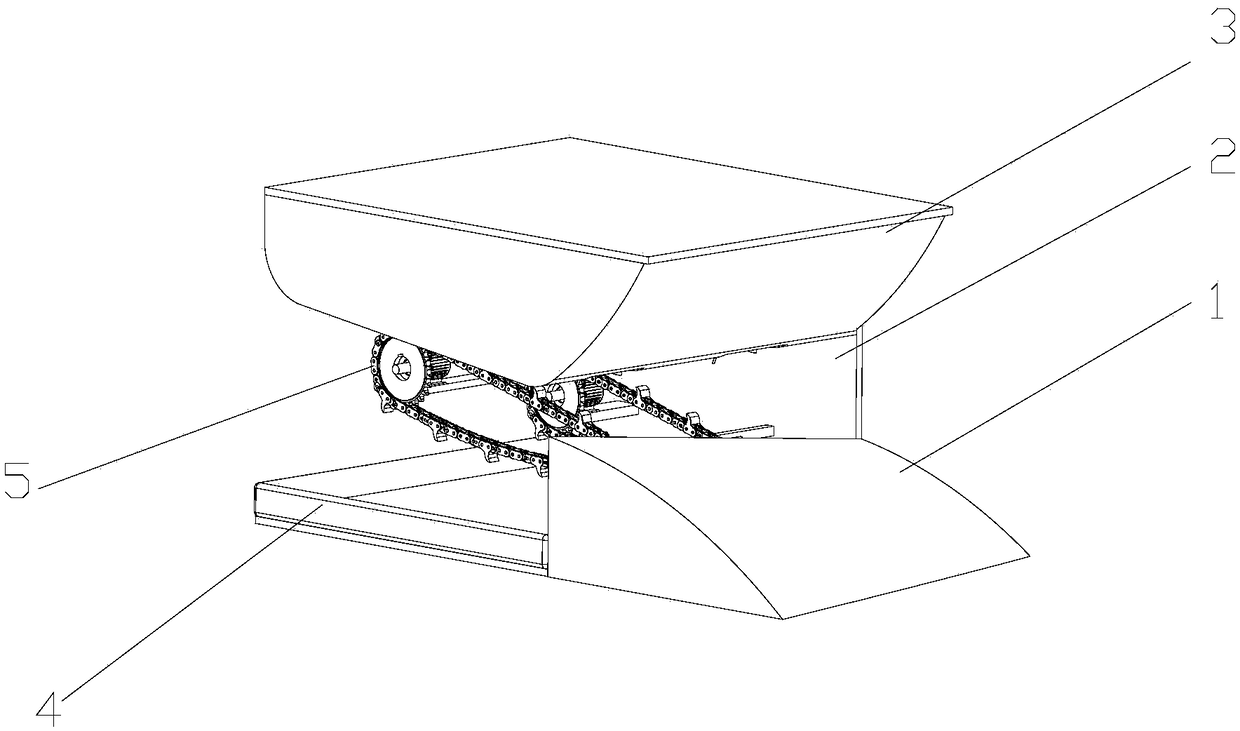

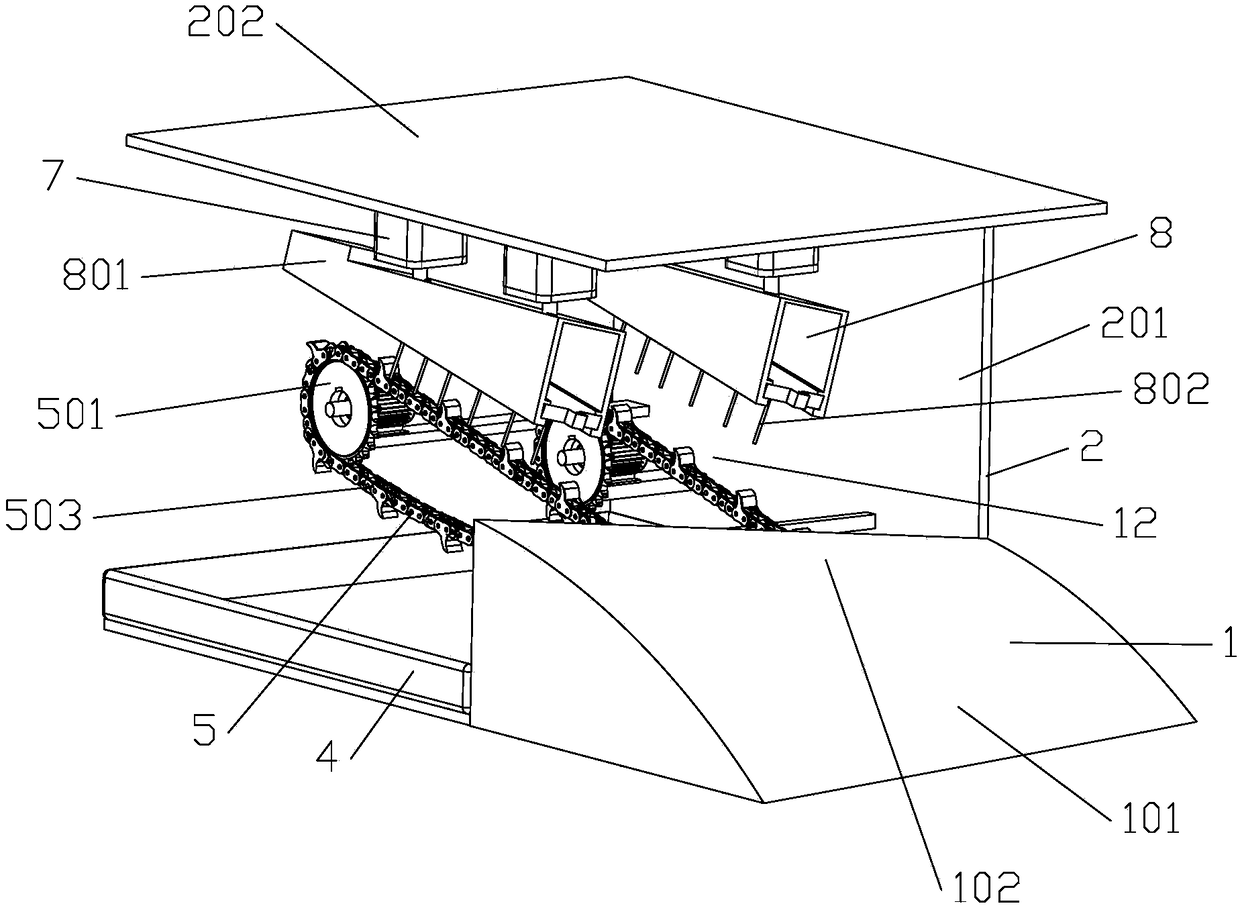

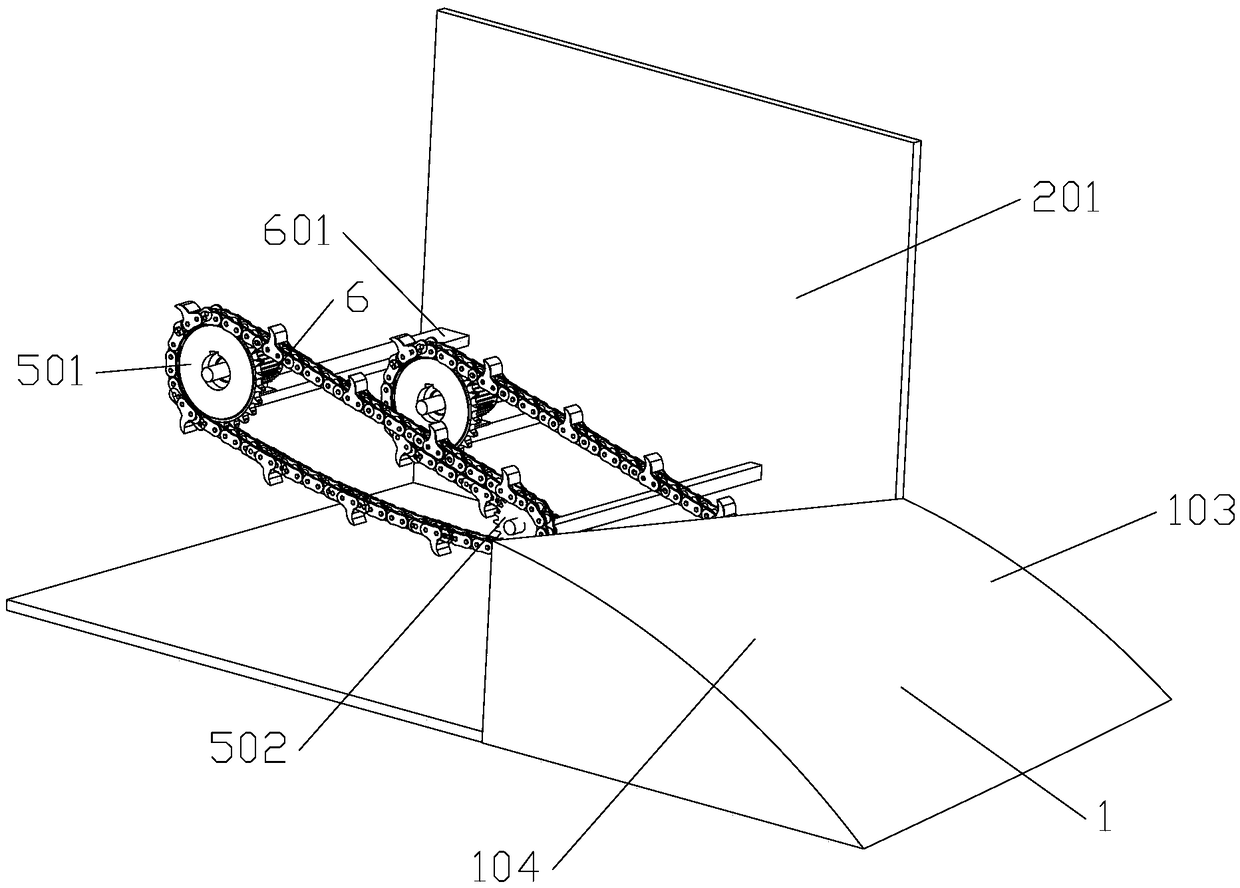

Compact vibration harvesting device for fruit harvesting

The invention provides a compact vibration harvesting device for fruit harvesting. The device lowers the fruit and branch damage rate and is suitable for harvesting of berries of fruit trees planted in a dwarfing close planting mode; a collecting box is arranged in the front of the bottom of a vertical plate, and a branch supporting device and an insertion tooth vibrating device are arranged abovethe collecting box; the branch supporting device comprises at least two front-back extending chains, and each chain surrounds a front chain wheel and a rear chain wheel; the insertion tooth vibratingdevice comprises a tooth insertion guide rail extending in the front-back direction, an insertion tooth fixing plate in sliding connection with the tooth insertion guide rail and a plurality of upward extending insertion teeth arranged on the insertion tooth fixing plate, and a vibrating mechanism for driving the insertion tooth fixing plate to reciprocate along the insertion tooth guide rail isarranged on the insertion tooth guide rail; the insertion tooth guide rail is in sliding connection with the vertical plate in the vertical direction, and the insertion tooth guide rail is connected with a vertical driving mechanism; the insertion tooth guide rail and the chains are arranged in a spaced mode.

Owner:NANJING FORESTRY UNIV

Automatic opening device for fruit bag

InactiveCN1274202CMeet bagging requirementsShorten the fall distancePlant protective coveringsFruit treeEngineering

The automatic fruit bag opening device features that it includes one work stage; one swinging motor supported on one side of the stage via support; two oppositely set sucker disk cylinders including one connected to the output end of the motor and the other one on the other side of the stage; two sucker disks connected to vacuum pump and to the piston rods of the sucker disk cylinders separately; one horizontal sliding way supported onto the stage via a frame; two vertical cylinders fixed relatively and set on the sliding way; one driving cylinder fixed horizontally onto the frame with piston rod connected to one vertical cylinder; and two pneumatic claws connected to the piston rods of the vertical cylinders. The present invention has simple structure and convenient operation, is pneumatically driven without environmental pollution and suitable for various fruit bagging operation.

Owner:CHINA AGRI UNIV

Ladle filler sand feeding device

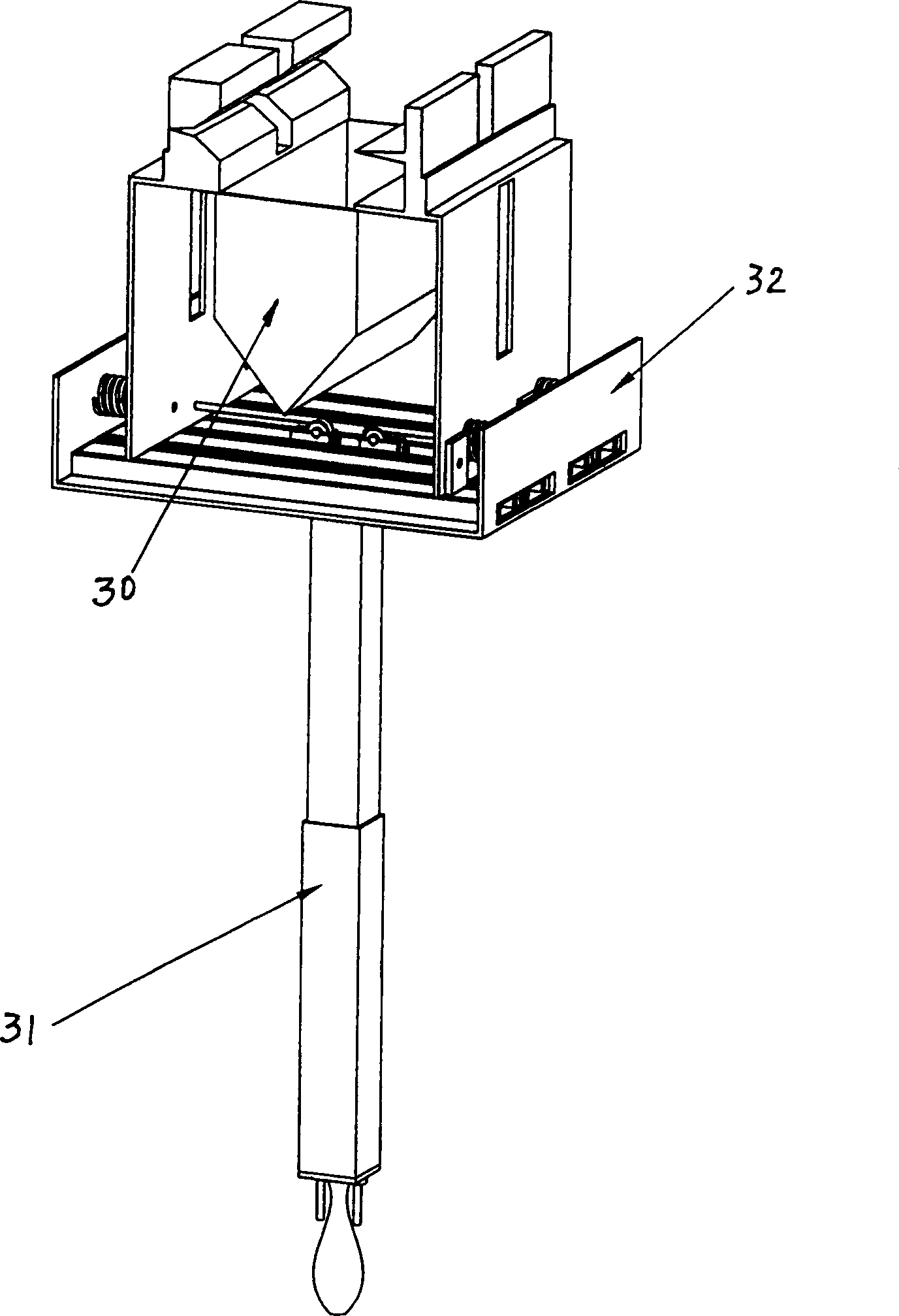

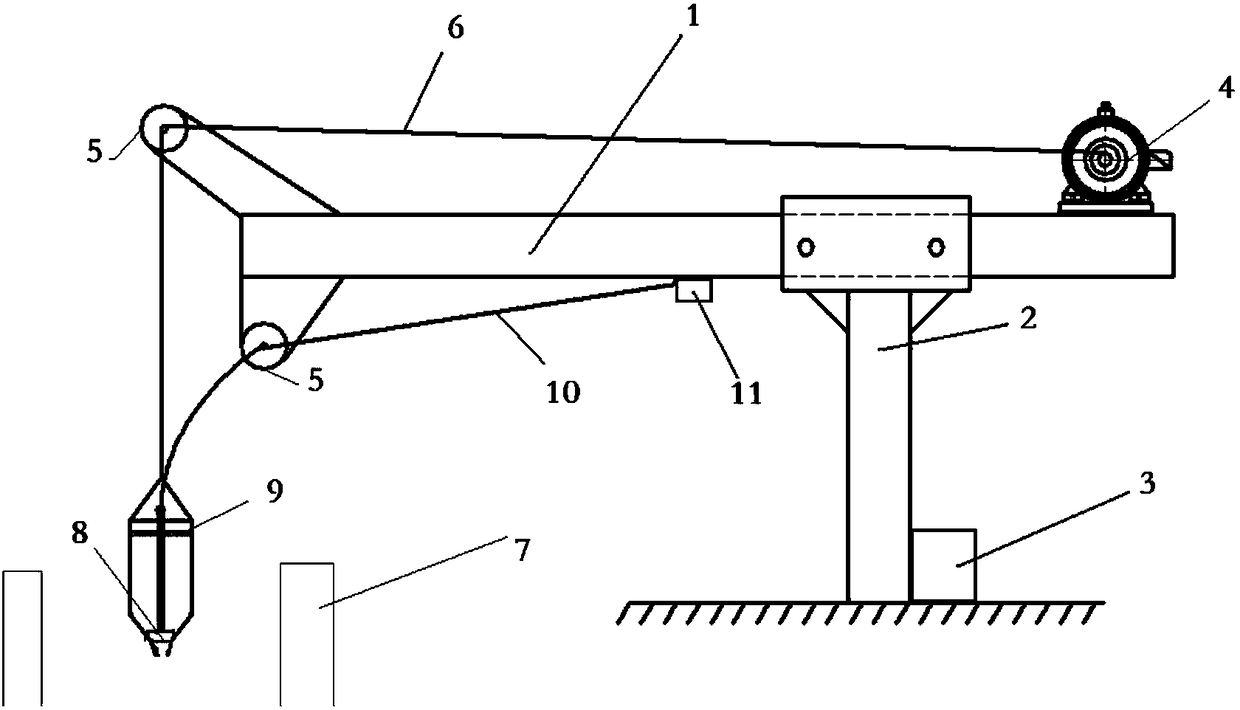

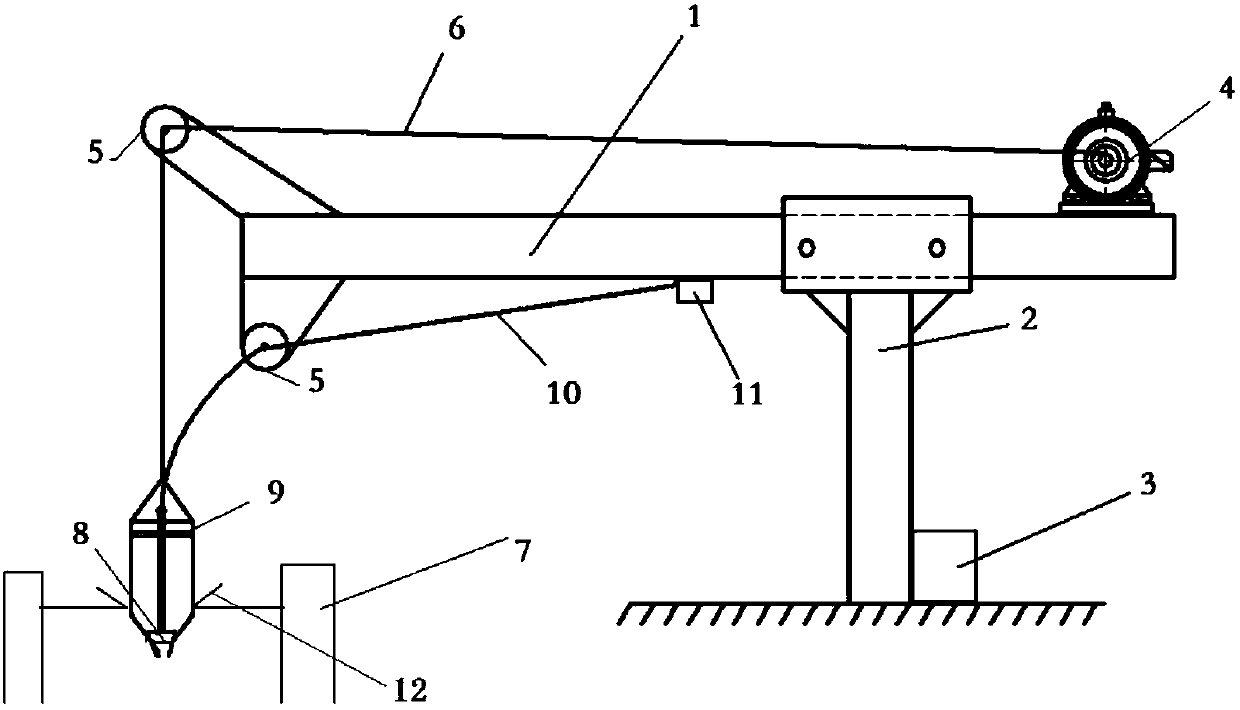

PendingCN108453249AShorten the fall distanceImprove joining accuracyMelt-holding vesselsPendulumEngineering

The invention discloses a ladle filler sand feeding device. The ladle filler sand feeding device comprises a swing arm and a pendulum shaft. The swing arm is fixed to the upper portion of the pendulumshaft, the pendulum shaft is fixed to the ground, and a rotating motor is arranged below the pendulum shaft and used for driving the pendulum shaft to rotate. The rear portion of the swing arm is provided with a motor reel, and the front end of the swing arm is provided with a guide wheel. A steel cable on the motor reel is connected with a charging barrel through the guide wheel. A switch is arranged below the charging barrel and controlled through an opening and closing steel cable. One end of the opening and closing steel cable is connected with the switch, and the other end of the openingand closing steel cable winds around the guide wheel below the swing arm and then is fixed to an electric shaft below the swing arm. The ladle filler sand feeding device has the beneficial effects that by adopting a charging barrel charging manner, the charging barrel can be further close to a water gap base, the falling distance of ladle filler sand is reduced, the ladle filler sand feeding accuracy is increased, scattering in the process is reduced, and the usage amount of the ladle filler sand is reduced.

Owner:BENGANG STEEL PLATES

Feeding device

InactiveCN109648069AShorten the fall distanceImprove joining accuracyMelt-holding vesselsBrickEngineering

The invention discloses a feeding device. The feeding device is characterized in that a swinging arm is fixed above a swinging shaft, the swinging haft is fixed on the ground, a rotating motor is arranged below the swinging shaft and is used for driving the swinging shaft to rotate, a motor reel is arranged at the rear part of the swinging arm, a guide wheel is arranged at the front end of the swinging arm, a steel rope on the motor reel is connected with a material cylinder through the guide wheel, a switch is arranged below the material cylinder, the switch is controlled by an opening and closing steel rope, one end of the opening and closing steel rope is connected with the switch, the other end of the opening and closing steel rope is fixed to an electric shaft below the swinging arm after being wound around another guide wheel below the swinging arm, centering devices are arranged right above a pocket brick, the centering devices comprise sealing covers, conical inlets are formedin the middles of the sealing covers, and the inner diameter of the conical inlets is larger than the outer diameter of the material cylinder. The feeding device has the advantages that the mode by which feeding is achieved through the material cylinder is adopted, and the material cylinder can be further close to a pocket, so that the falling distance of drainage sand is reduced, the adding accuracy of the drainage sand is improved, scattering in the process is reduced, and the use amount of the drainage sand is saved.

Owner:沈阳鑫颖超科技有限公司

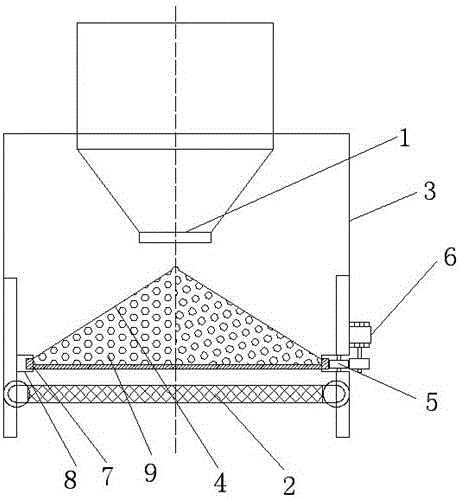

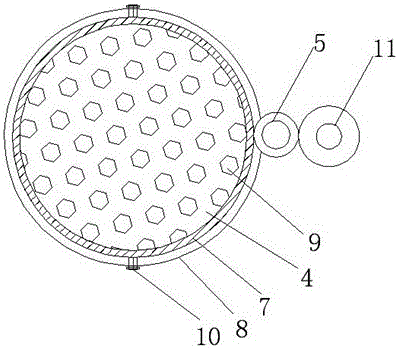

Discharging machine applicable to wheat berry production

The invention discloses a discharging machine applicable to wheat berry production. The discharging machine applicable to wheat berry production is installed between a discharging port of a wheat berry producing device and a material screening net and comprises a material blocking shell, a material distributing screen plate, a transmission wheel and a transmission motor; the material distributing screen plate is a conical material distributing screen plate protruding upwards; a plurality of wheat berry through holes are evenly distributed in the material distributing screen plate; a transmission layer is arranged on the outer side of the bottom of the material distributing screen plate; a circle of fixing ring track matched with the transmission layer is arranged on the inner side of the material blocking shell; the material distributing screen plate is movably installed in the fixing ring track through the transmission layer; the transmission wheel is installed on one side of the fixing ring track through a rotating shaft; the transmission wheel and the transmission layer make close contact; the transmission motor is installed on the outer side of the material blocking shell; and transmission is performed between the transmission wheel and the transmission motor through a gear. According to the discharging machine applicable to wheat berry production, by means of the combination effect of the material blocking shell and the material distributing screen plate, the wheat berry particle leakage in the discharging process is avoided, and uniform distribution of wheat berry particles on the material screening net is also facilitated.

Owner:南京东擎科技有限公司

Safety operation device used for elevator operation and operation process for safety operation device

InactiveCN106115411AProtection securityImprove buffering effectElevatorsKinetic energyOperations management

The invention belongs to the field of elevator protection, and specifically discloses a safety operation device used for elevator operation and an operation process for the safety operation device. The safety protection device comprises a safety brake and a buffer system; the safety brake comprises a safety base and a safety rod; the safety base comprises a horizontal limiting plate and a supporting plate which are integrally designed; one end of the safety rod is mounted at a joint of the horizontal limiting plate and the supporting plate in a manner of being capable of rotating in a perpendicular direction; and the buffer system comprises a bracket mounted on the inner wall of an elevator hoistway and a buffer unit mounted on the bracket. When an elevator suddenly drops, kinetic energy of an elevator car is converted into energy of other forms, so that an elevator structure and personnel are protected, and therefore, the safety operation device is simple in structure, is convenient to mount, is low in cost, and can be widely applied to safety operation of various elevators.

Owner:HOHAI UNIV

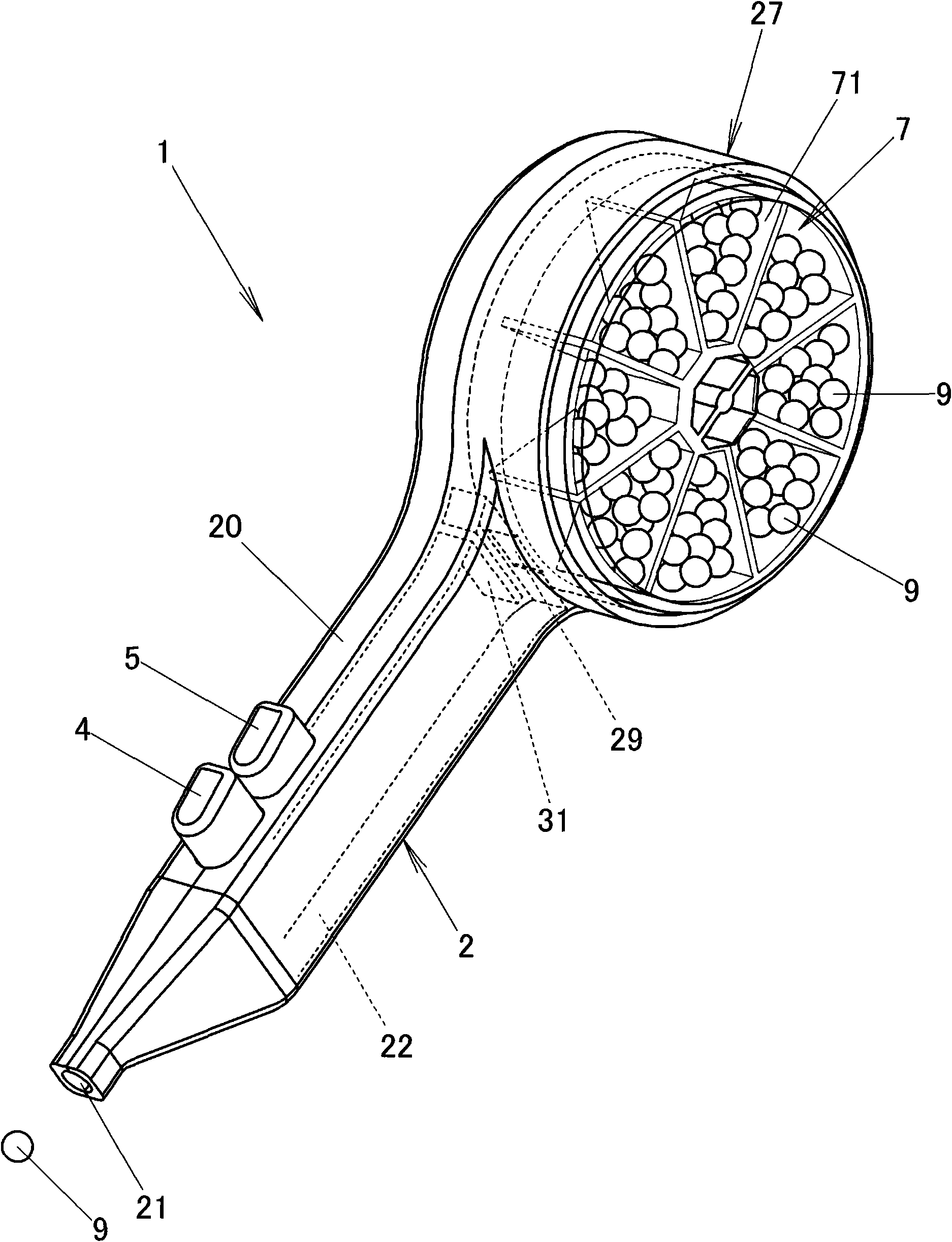

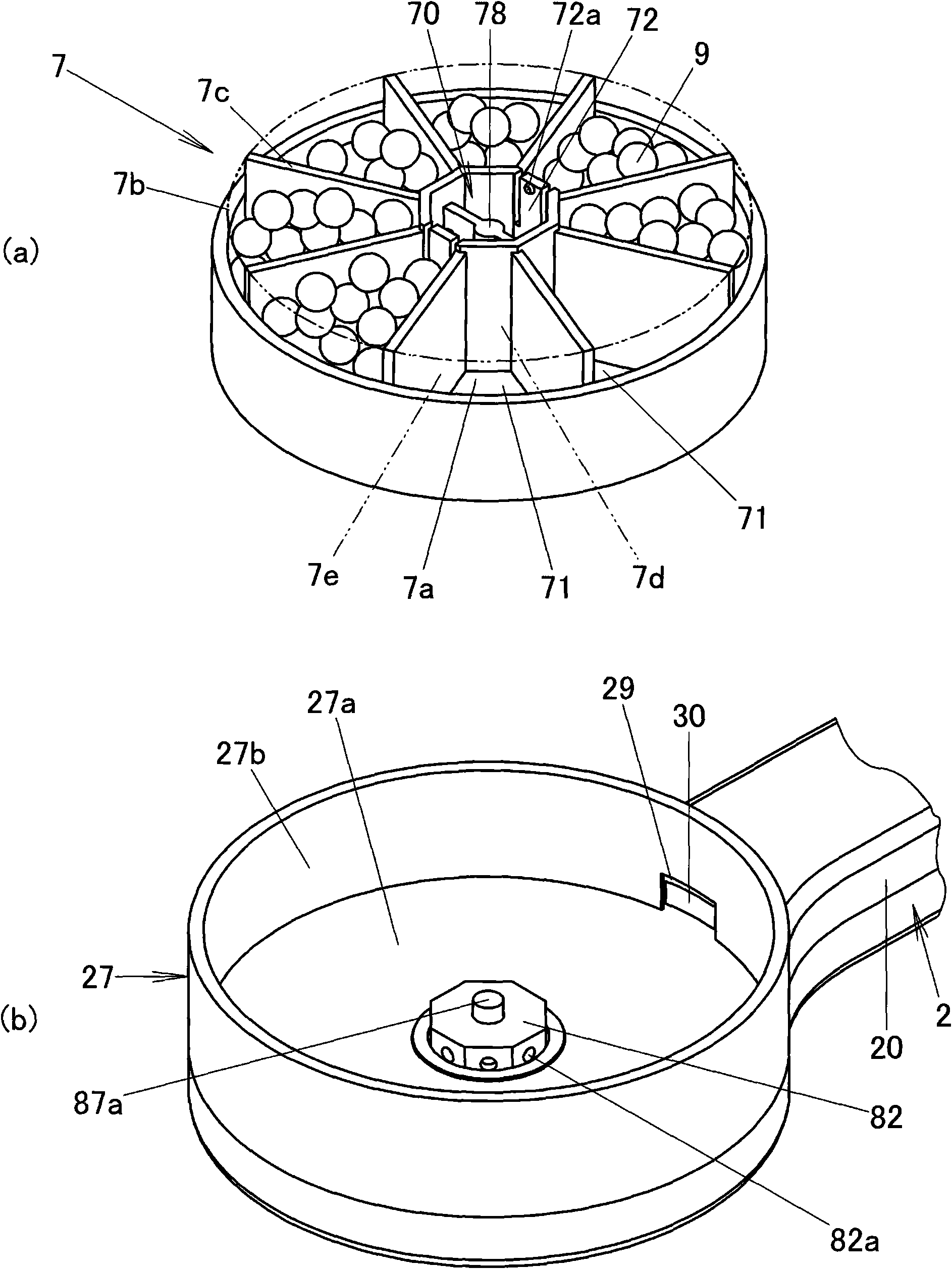

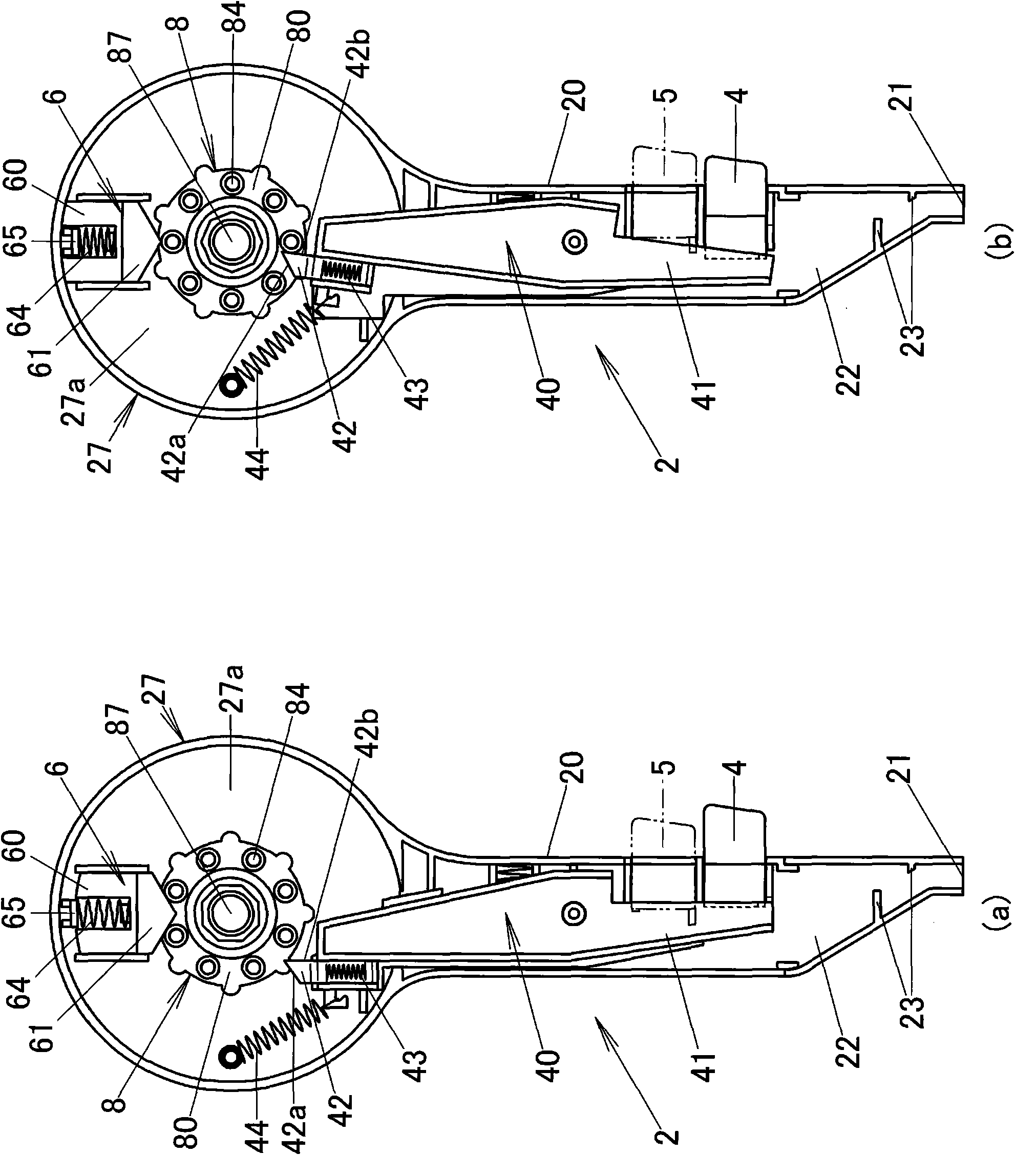

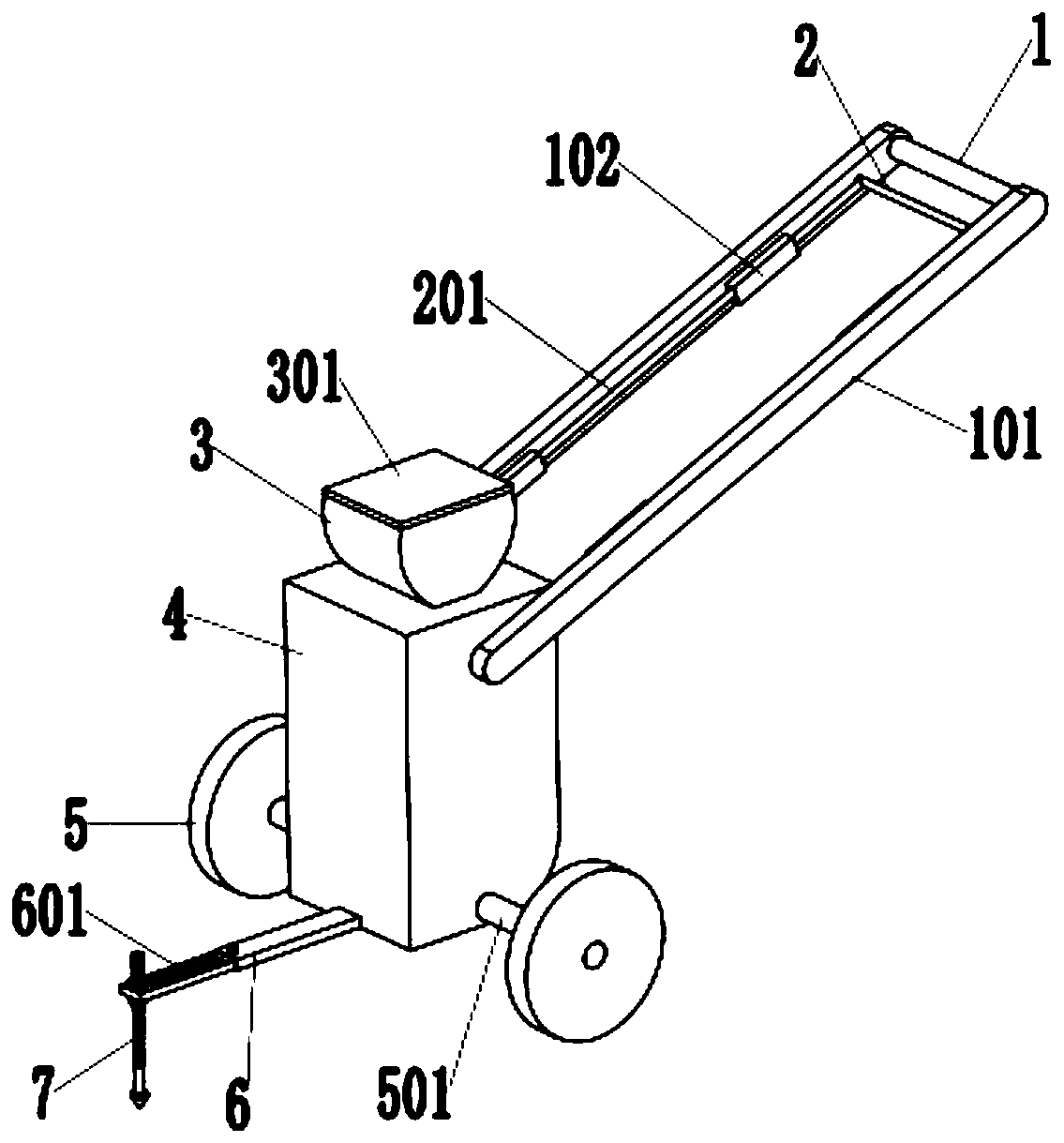

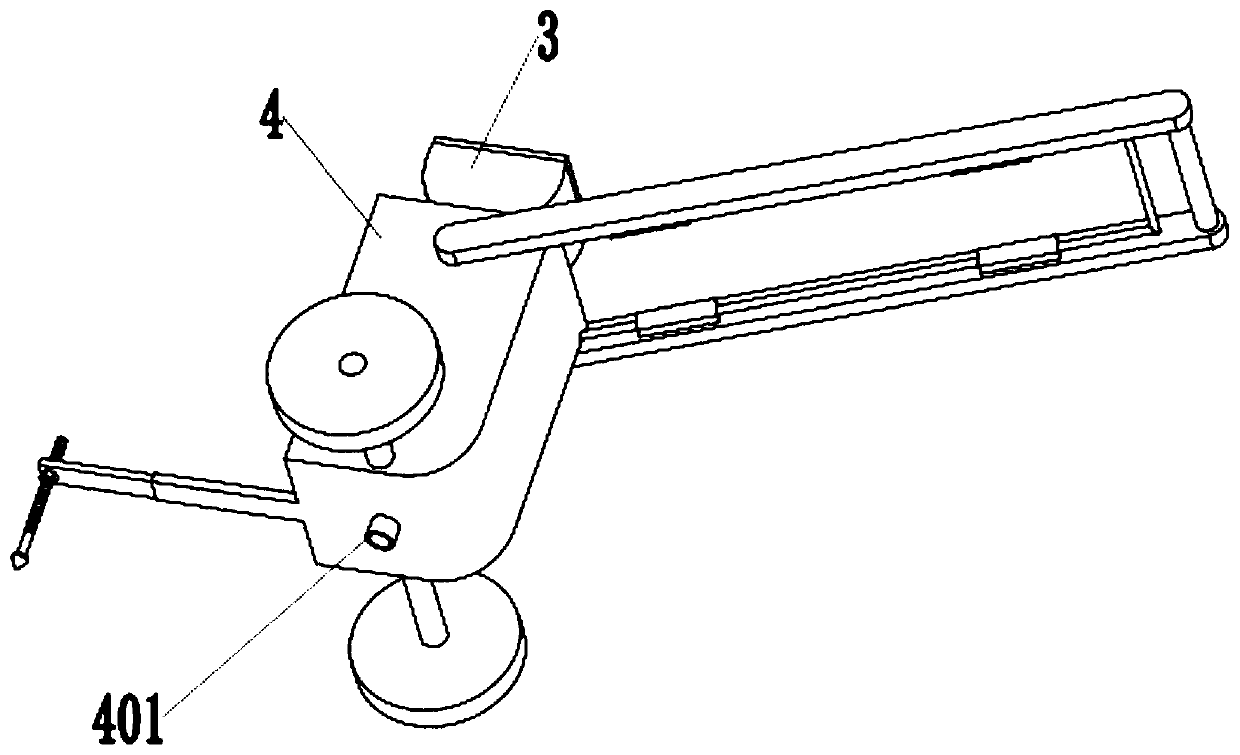

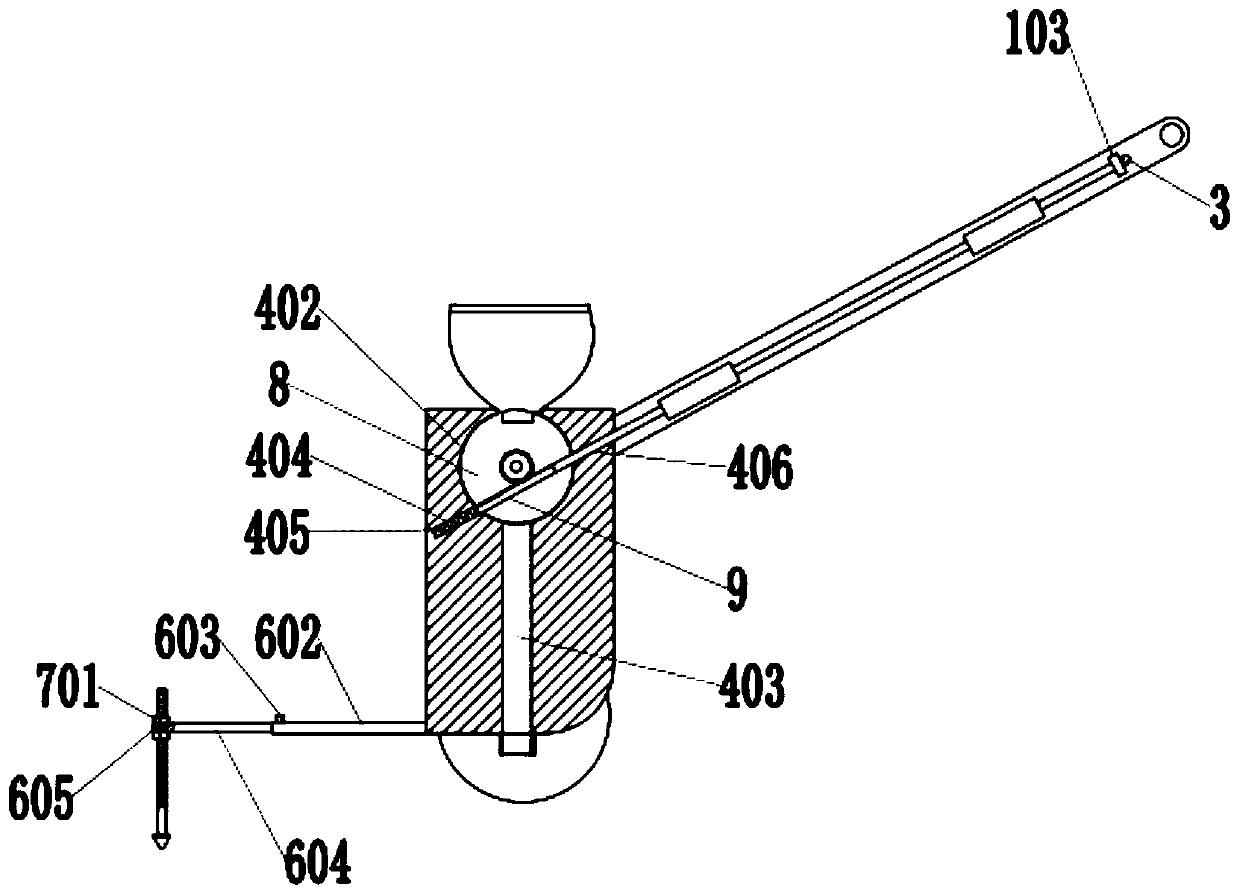

Ball feeder

The invention provides a ball feeder, wherein beads of various colors can be easily separated to be used.The ball feeder (1) is characterized by comprising a body part (2).The rear end of a tubular handle part (20) is equipped with a box housing part (27).A ball receiving box (7) equipped with a plurality of ball receiving spaces (71) in the circumferential direction thereof can be rotatably held on the box housing part (27).The front end of the handle part (20) is equipped with an opening part (21) of the body part (2).The rear end of the handle part (20) is equipped with a ball removal port (29).The handle part (20) is also equipped with a guide path (22) for communicating the opening part (21) with the ball removal port (29).A rotation mechanism and a ball handover mechanism are arranged inside the body part (2).The handle part (20) is also equipped with a rotation operation button (4) for rotating the rotation mechanism and a handover operation button (5) for operating the ball handover mechanism.

Owner:EPOCH CO

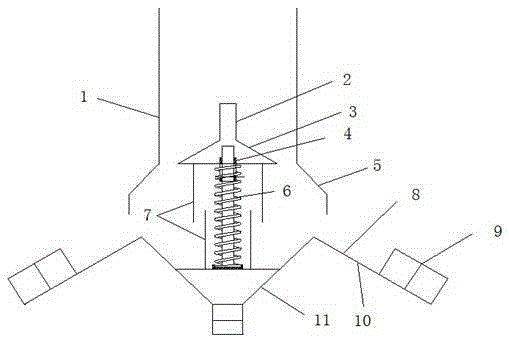

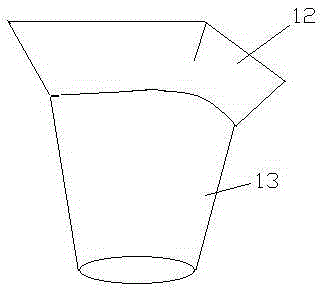

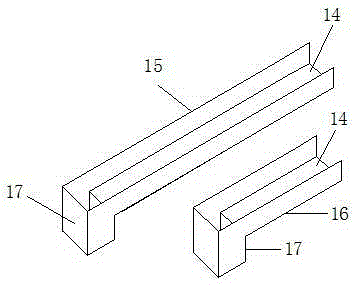

Squat silo grain feeding distributor

InactiveCN105383959AImprove breathabilityEasy to fill with nitrogenConveyorsLoading/unloadingNitrogenGrain storage

The invention discloses a squat silo grain feeding distributor, belongs to the technical field of squat silo grain feeding equipment, and is used for preventing the generation of automatic classification and grain crushing phenomenon in the grain feeding process. The squat silo grain feeding distributor is characterized in that an umbrella-shaped distributor is mounted below a grain inlet; the peripheral surface of the distributor is divided into multiple areas by separation plates; each area is respectively connected with the upper end of one chute; the lower ends of the chutes are respectively corresponding to grain dropping points in a squat silo; and the grain dropping points are uniformly distributed on the peripheral plane of the squat silo. A pressure door is mounted above the distributor; and when flows are different, the weights of soybeans on the pressure door are different, the downward moving distances of the pressure door are different, and blanking openings are different, so that the flows are controlled and the purpose of uniform distribution is achieved. The squat silo grain feeding distributor can preferably solve the automatic classification phenomenon in the silo feeding process, is convenient for the application of such advanced grain storage technologies as fumigation, nitrogen filling, mechanical ventilation and grain refrigerator cooling, reduces the loss, improves the grain storage stability, increases the grain storage benefit, reduces the labors, and reduces the grain storage cost.

Owner:中储粮油脂有限公司

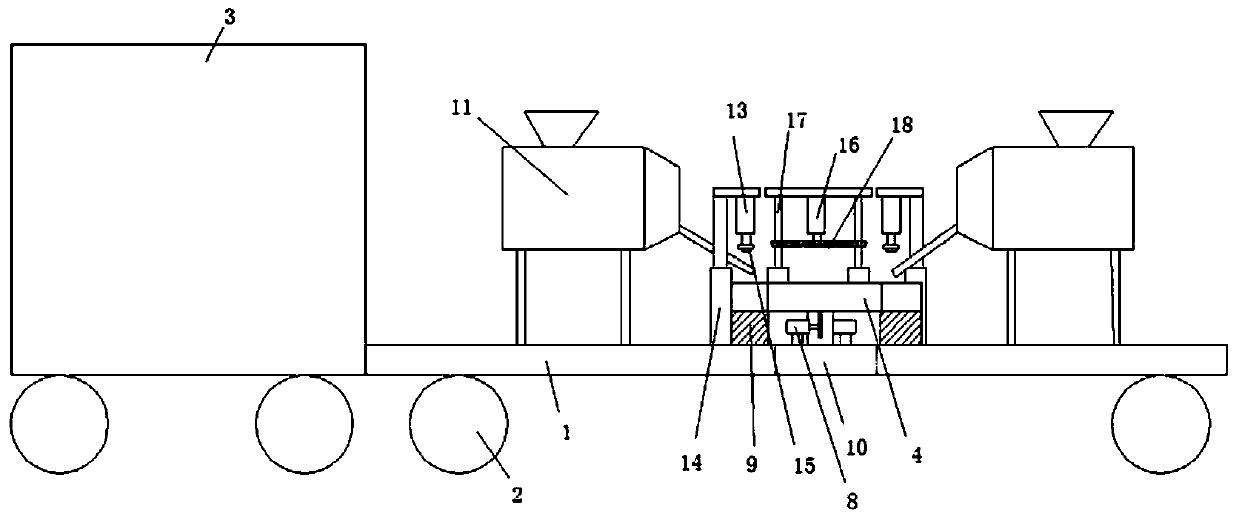

Movable cold-pressed brick production device and production system

ActiveCN111037712ASave shipping timeAvoid collision damageAuxillary shaping apparatusShaping press ramBrickVehicle frame

The invention relates to a movable cold-pressed brick production device and a production system. The movable cold-pressed brick production device comprises a transport vehicle, a brick making mechanism and a brick receiving mechanism, wherein the brick making mechanism is mounted on the transport vehicle and comprises a mold disc rotatably connected with the transport vehicle, the mold disc is provided with a plurality of mold cavities; the mold disc is connected with a driving mechanism; the driving mechanism can drive the mold disc to rotate so that switching of the mold cavities among a material receiving station, a material pressing station and a material discharging station is realized; a blocking seat in contact with a lower surface of the mold disc is arranged below the mold disc atthe material receiving station and the material pressing station, a discharging port is arranged in a position, corresponding to the material discharging station, of the transport vehicle, a materialpressing mechanism is arranged right above the material pressing station, a stirrer is installed on the transport vehicle, and stirred materials can be sent into the mold cavities of the material receiving station; and the brick receiving mechanism includes a frame, a first walking wheel is installed on the frame, a lifting mechanism is further installed on the frame, the lifting mechanism is connected with a supporting plate, and the supporting plate is used for placing a cold-pressed brick tray. The production device saves cold-pressed brick transportation time and accelerates a construction progress.

Owner:马丽萍

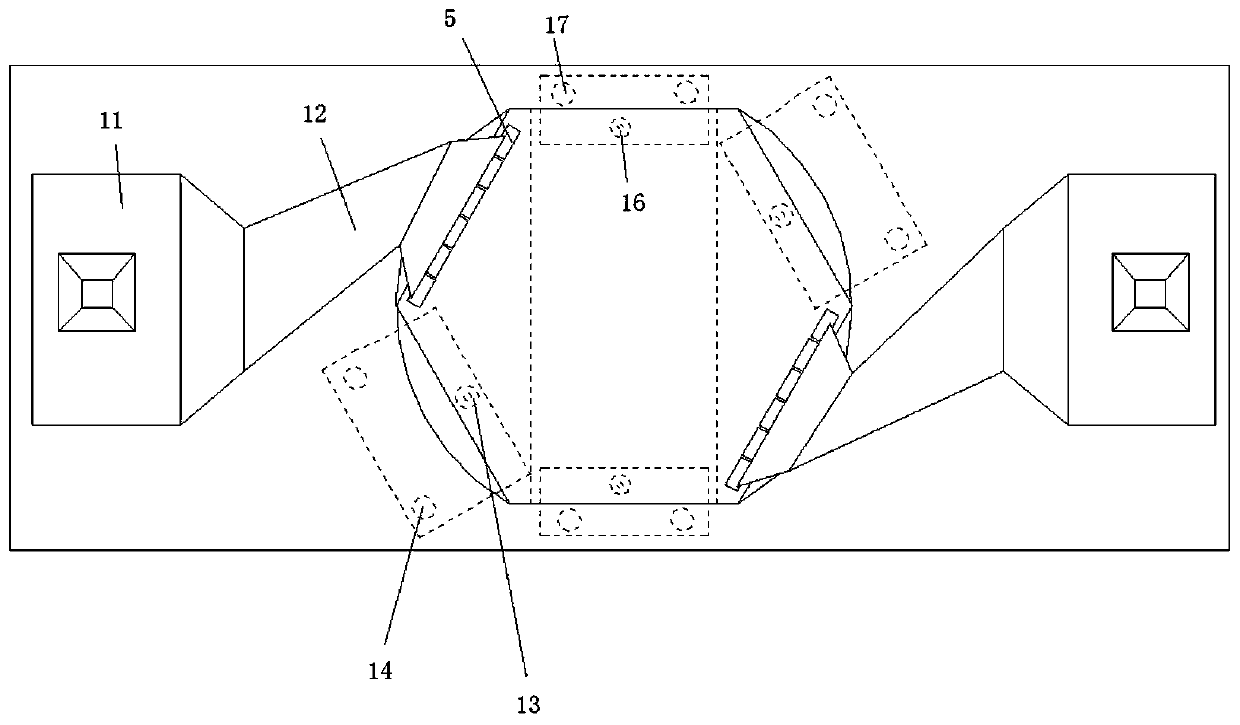

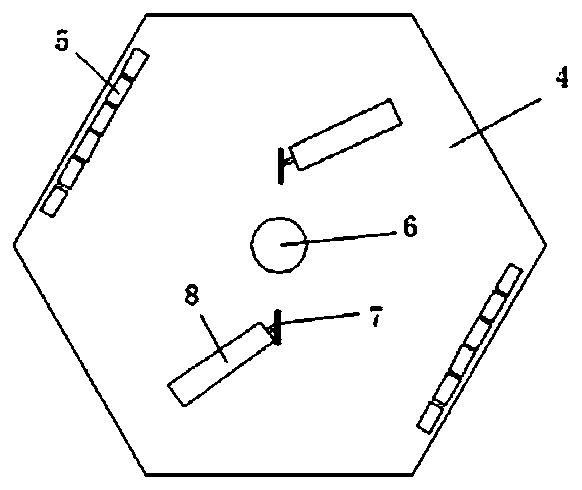

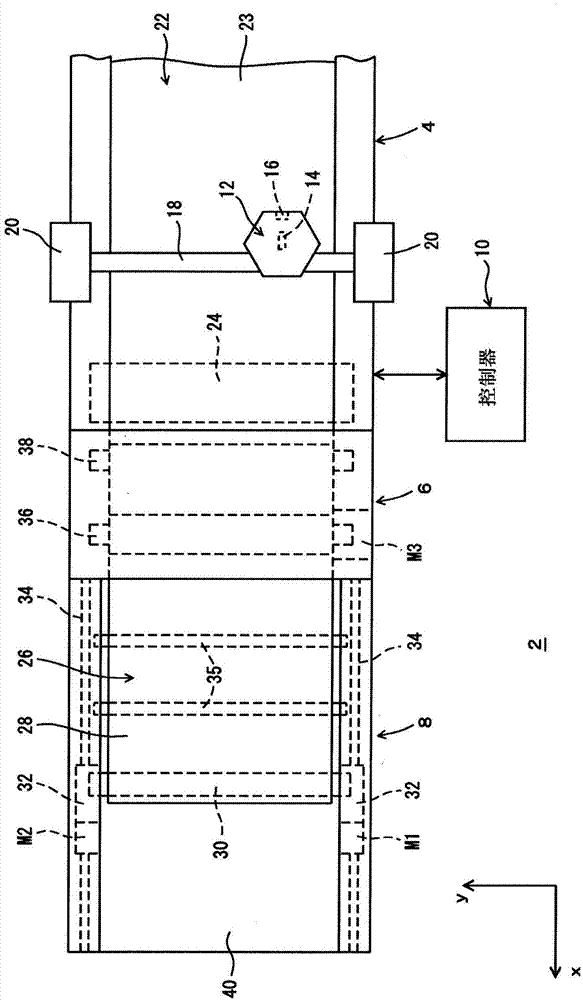

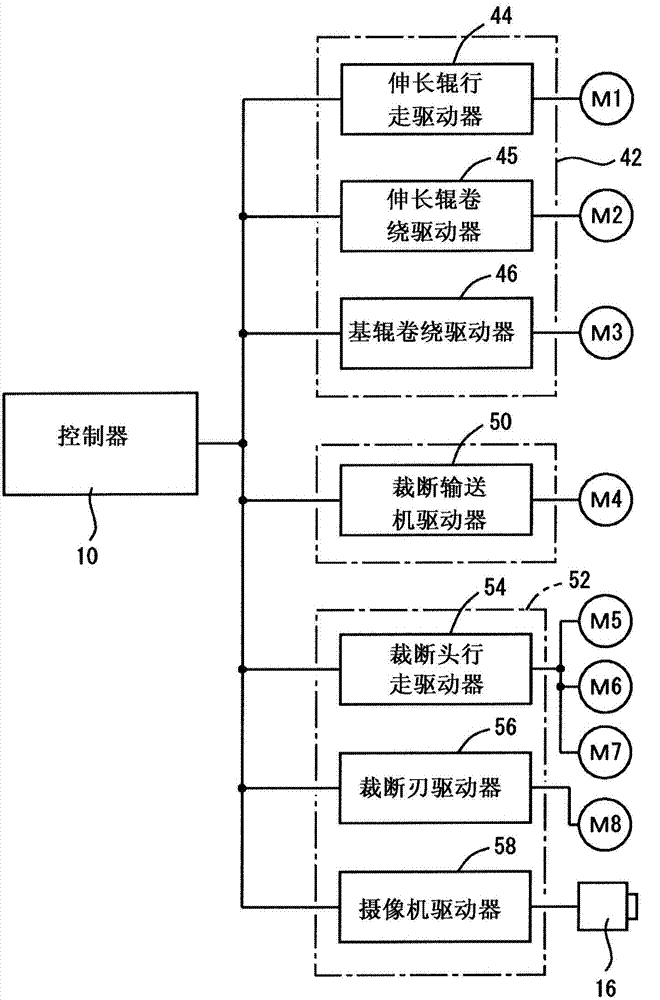

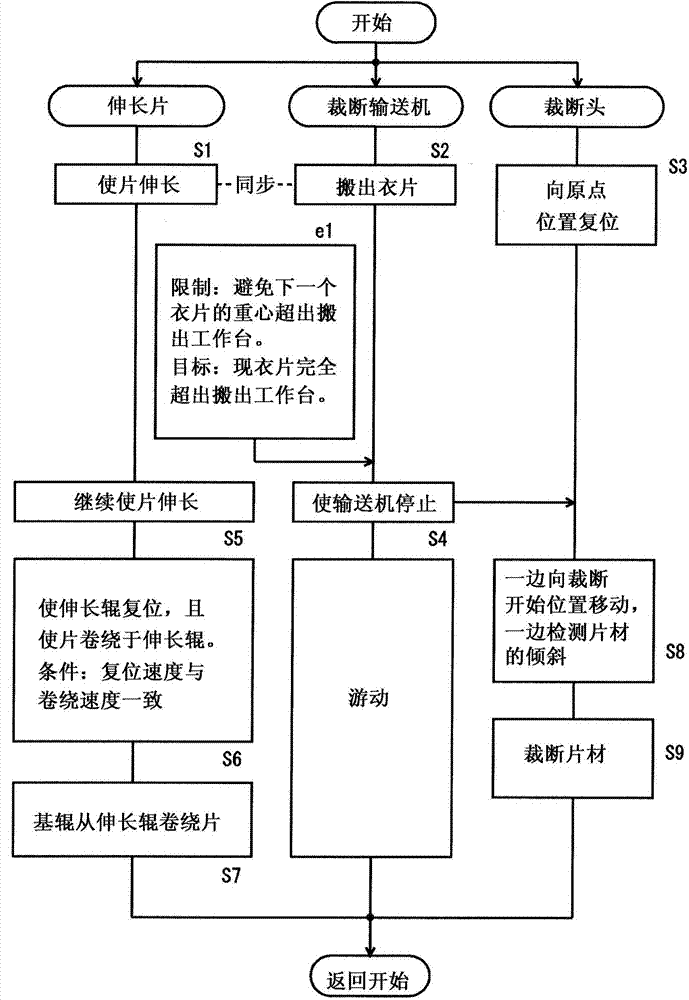

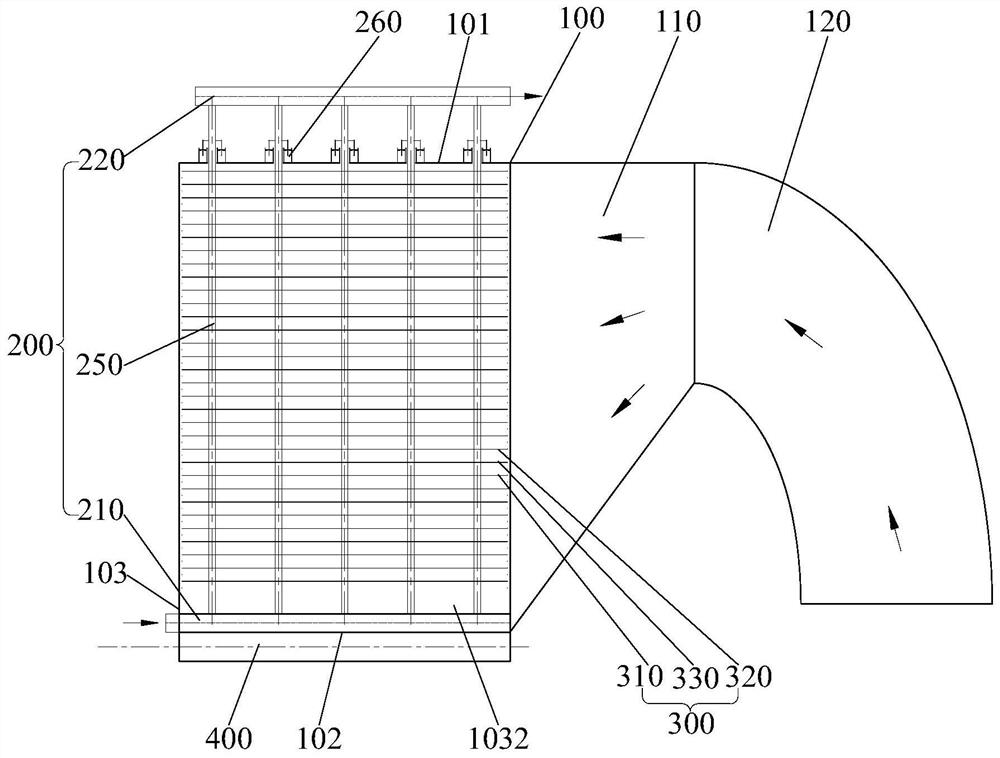

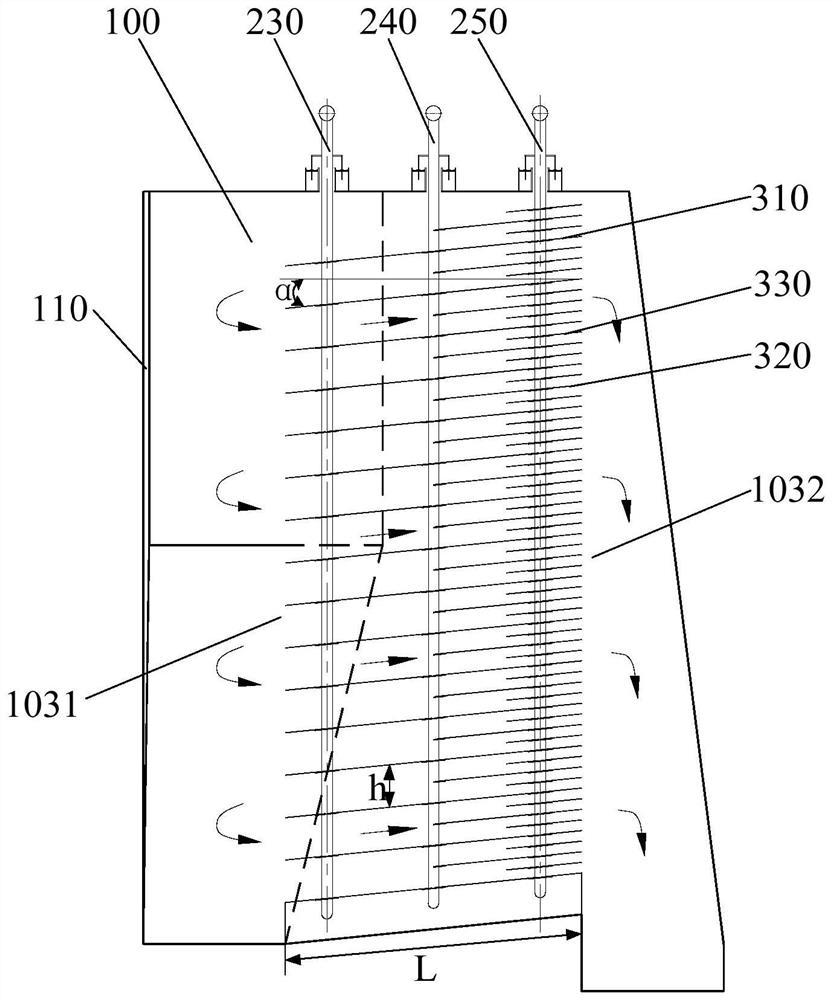

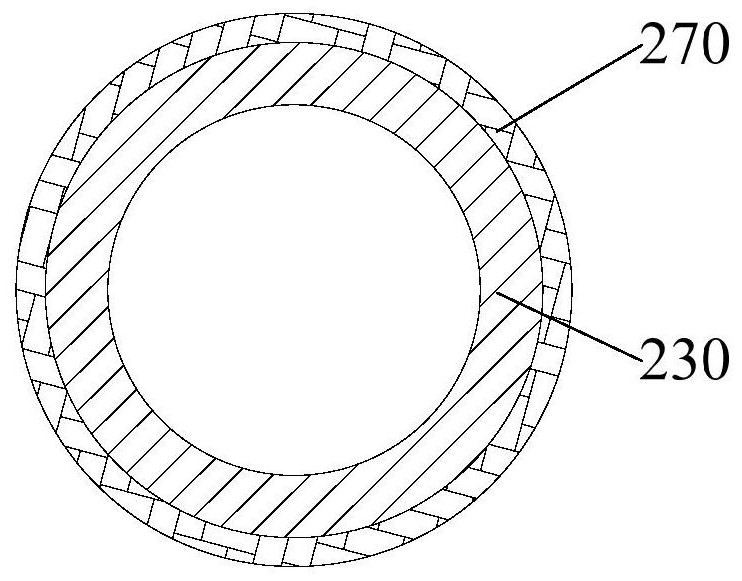

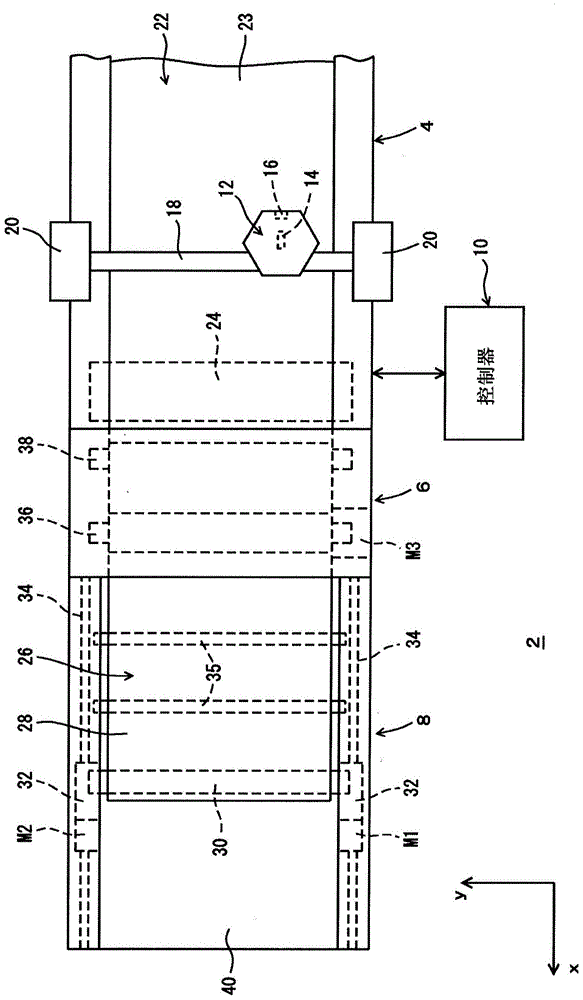

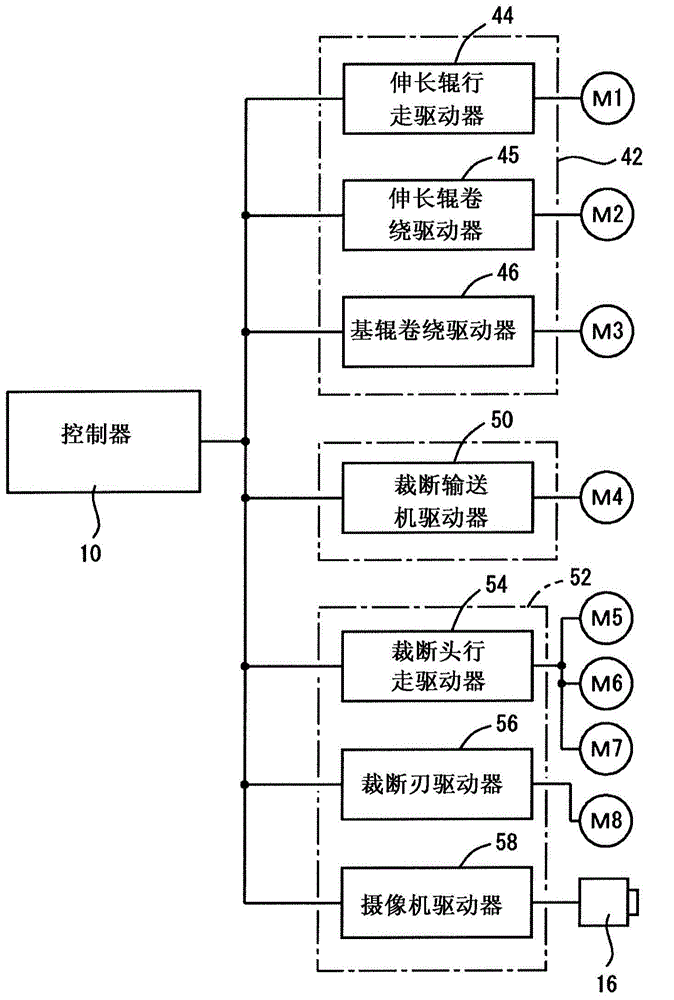

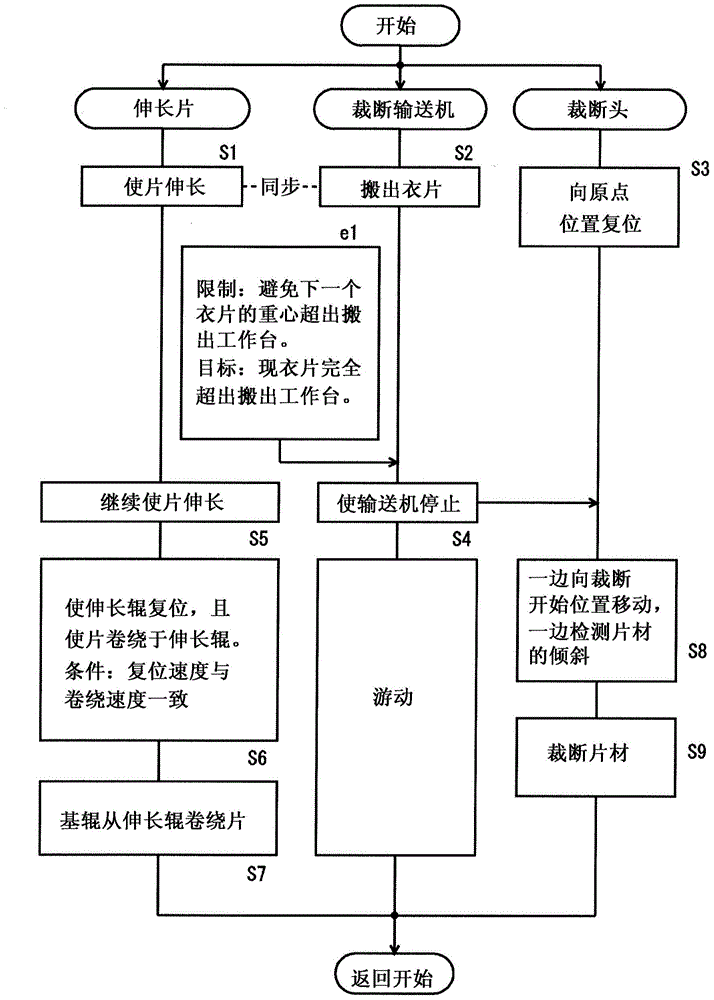

Sheet material cutting stacking apparatus and sheet material cutting stacking method

ActiveCN103704918AAvoid slackAvoid shakingSevering textilesClothes making applicancesSheet materialEngineering

The invention provides a sheet material cutting stacking apparatus and a sheet material cutting stacking method. The sheet material is cut off by a cutting head of a cutting conveyor, and the cut-off sheet material is moved out to a transportation workbench by the cutting conveyor. A stretching rod that supports a stretching sheet is feed in from a backward position close to the transportation workbench to a stacking table at the downstream side of the transportation workbench; cloth sheets are separated individually between the transportation workbench and the stretching sheet by a speed difference between the feed in speed of the stretching rod and the transportation speed of the cutting conveyor; the stretching rod is made to move backwards from the position where the distance to the rear end of the cloth sheets of the stretching sheet is longer than a prescript length of the front end of the transportation workbench, therefore, the cloth sheets can be stacked on the stacking table because of not getting into from under the transportation workbench.

Owner:SHIMA SEIKI MFG LTD

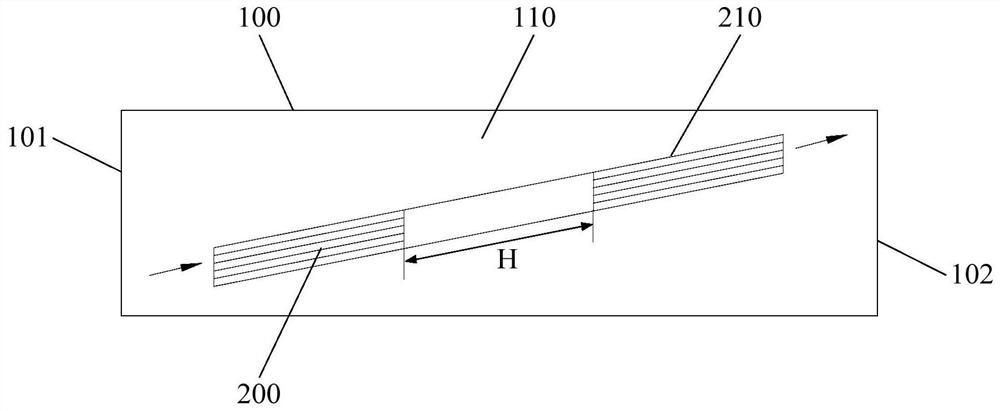

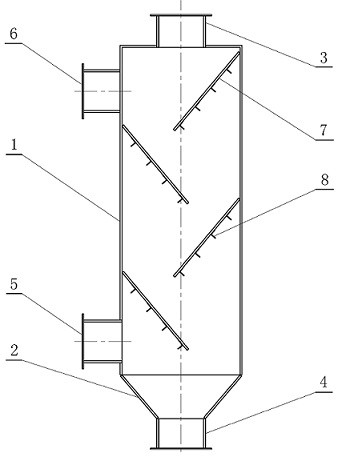

Multi-sedimentation high-temperature flue gas particle separation device

PendingCN112263878ASmall resistanceReduce energy consumptionDispersed particle separationFlue gasEngineering

The invention provides a multi-sedimentation high-temperature flue gas particle separation device which comprises a shell, a cooling assembly and a sedimentation assembly, an inlet and an outlet whichare opposite to each other are formed in the shell, and the inlet is connected with a steering bent pipe through a flared pipe; the cooling assembly comprises a water inlet header, a water outlet header and at least one first hanging rod communicating with the water inlet header and the water outlet header. The settling assembly is arranged in the shell and comprises at least two layers of firstinclined plates arranged at intervals, the first inclined plates are obliquely arranged towards the top wall of the shell in the smoke flowing direction, the included angle between each first inclinedplate and the top wall of the shell ranges from 5 degrees to 70 degrees, each first inclined plate is connected with the corresponding first hanging rod, and the upper ends of the first inclined plates extend to the outlet. According to the multi-sedimentation high-temperature flue gas particle separation device, the harm of local scouring and flue gas retention caused by non-uniform airflow is reduced, flue gas and particles are separated, the flue gas resistance loss is small, and the energy consumption is low.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

Intelligently-adjusted ganoderma lucidum planting frame

ActiveCN112740957AReduce fall distanceImprove collection efficiencyCultivating equipmentsMushroom cultivationHorticultureGanoderma lucidum

The invention provides an intelligently-adjusted ganoderma lucidum planting frame, and belongs to the technical field of medicinal material planting. The intelligently-adjusted ganoderma lucidum planting frame is used for solving the technical problem that an existing collecting device is low in ganoderma lucidum spore collecting efficiency. The intelligently-adjusted ganoderma lucidum planting frame comprises a supporting mechanism, wherein the supporting mechanism comprises a bottom plate, a liquid storage tank is fixed above the bottom plate, a supporting column is fixed above the liquid storage tank, the supporting column is hollow, a plurality of culture boxes are arranged on the side face of the supporting column, a sunshade mechanism is arranged above the supporting column, and a plurality of rotating grooves and a plurality of mounting grooves are formed in the side face of the supporting column at equal intervals; collecting mechanisms are arranged on the multiple rotating grooves, atomizers are fixed in the multiple mounting grooves and communicate with the supporting column, a water pump is arranged in the liquid storage box and communicates with the interior of the supporting column, and an opening and closing cover is arranged on the upper portion of the liquid storage box. According to the intelligently-adjusted ganoderma lucidum planting frame, the collecting mechanisms and the supporting mechanism are matched to humidify air around ganoderma lucidum, so that the falling distance of ganoderma lucidum spores is reduced, and the collecting efficiency of the ganoderma lucidum spores is improved.

Owner:WEST ANHUI UNIV

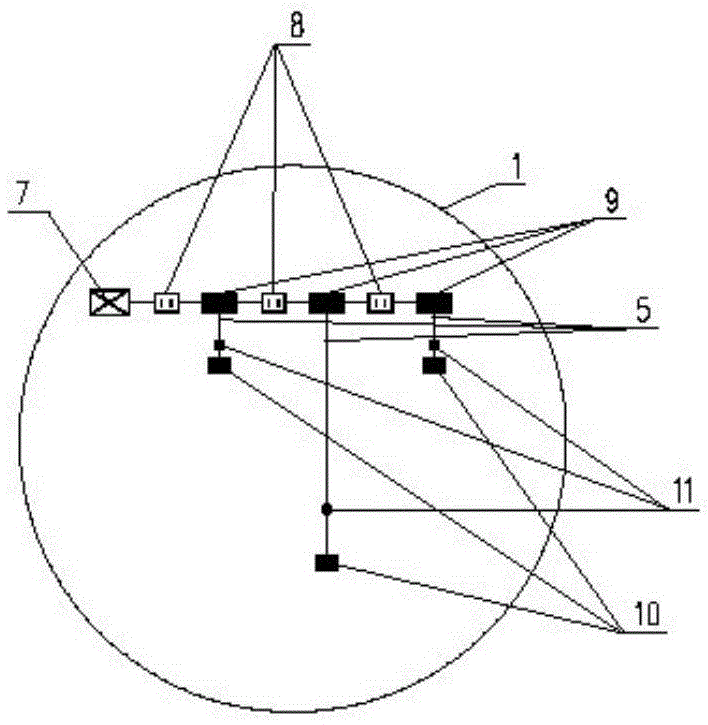

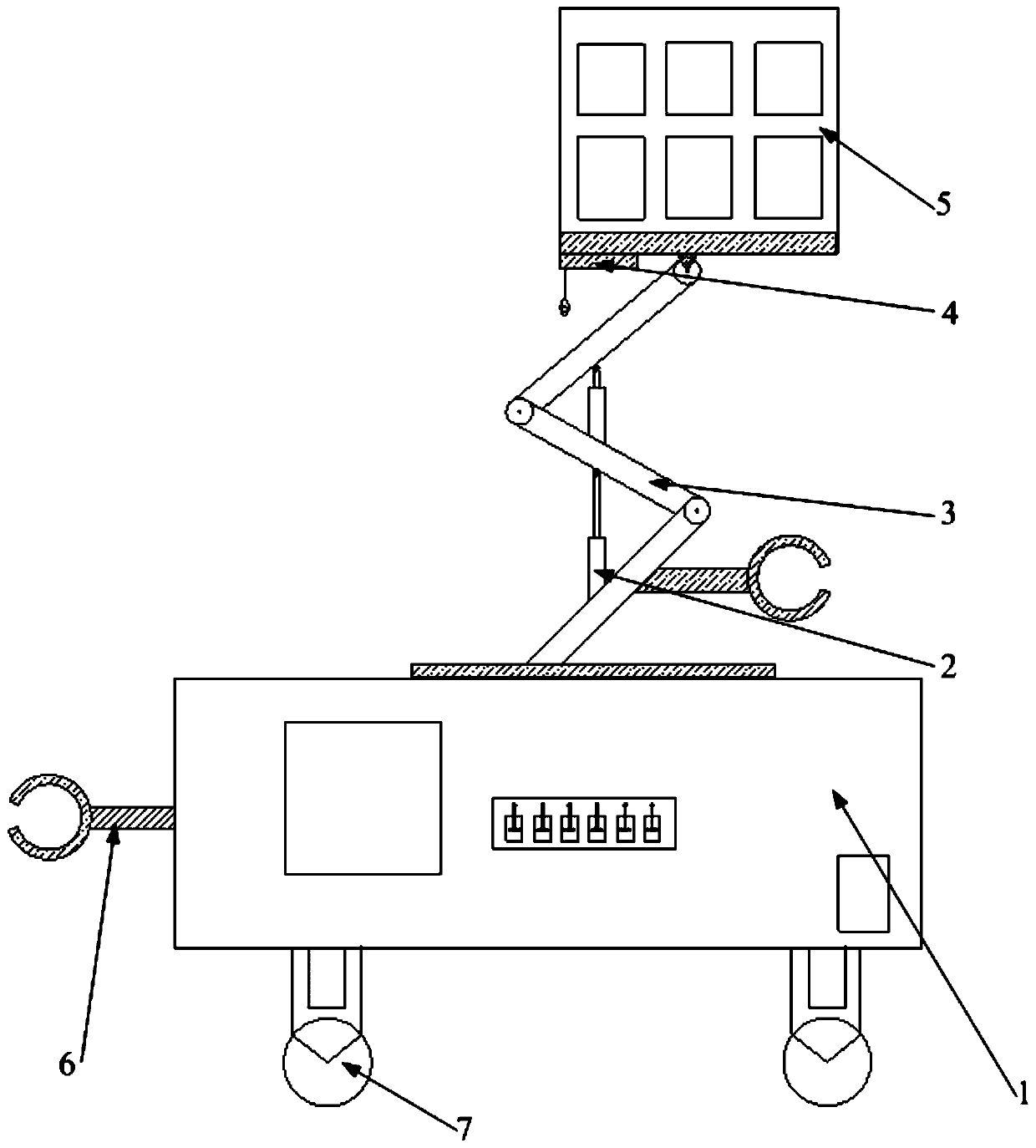

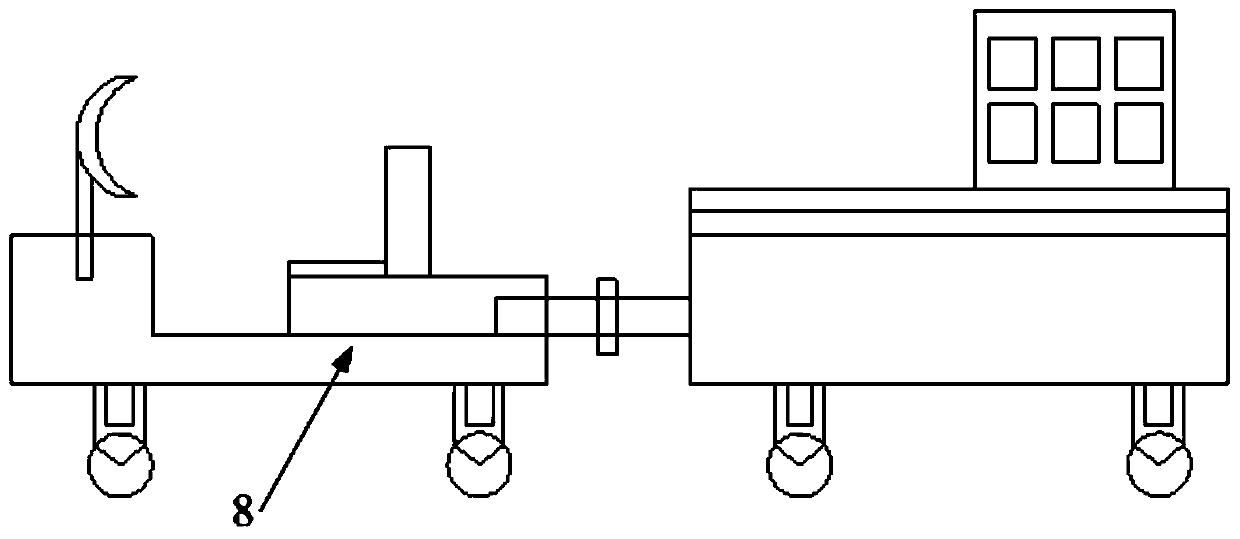

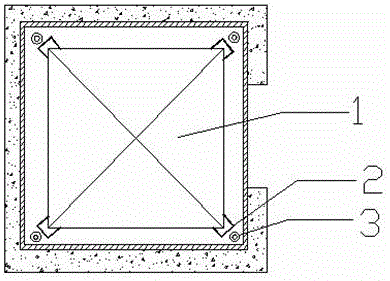

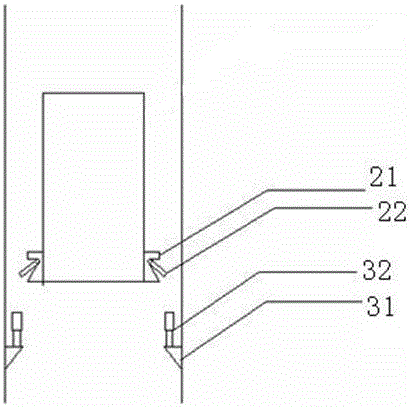

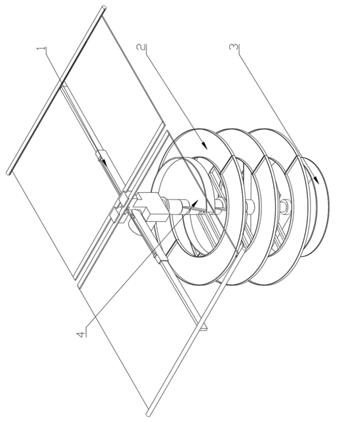

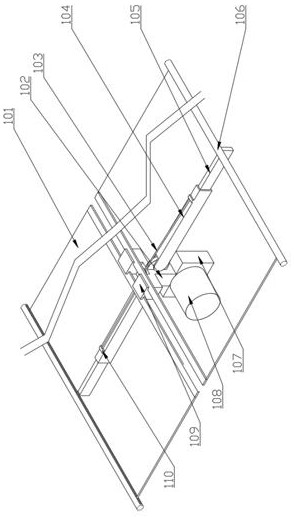

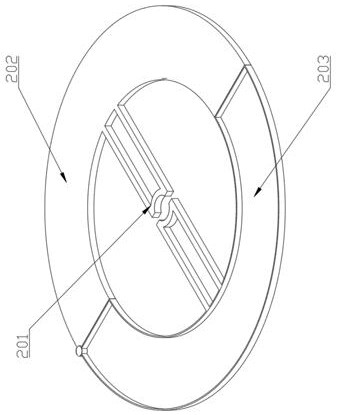

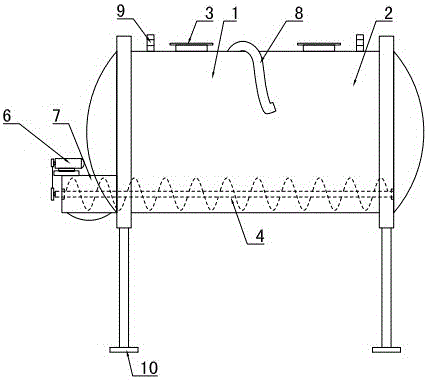

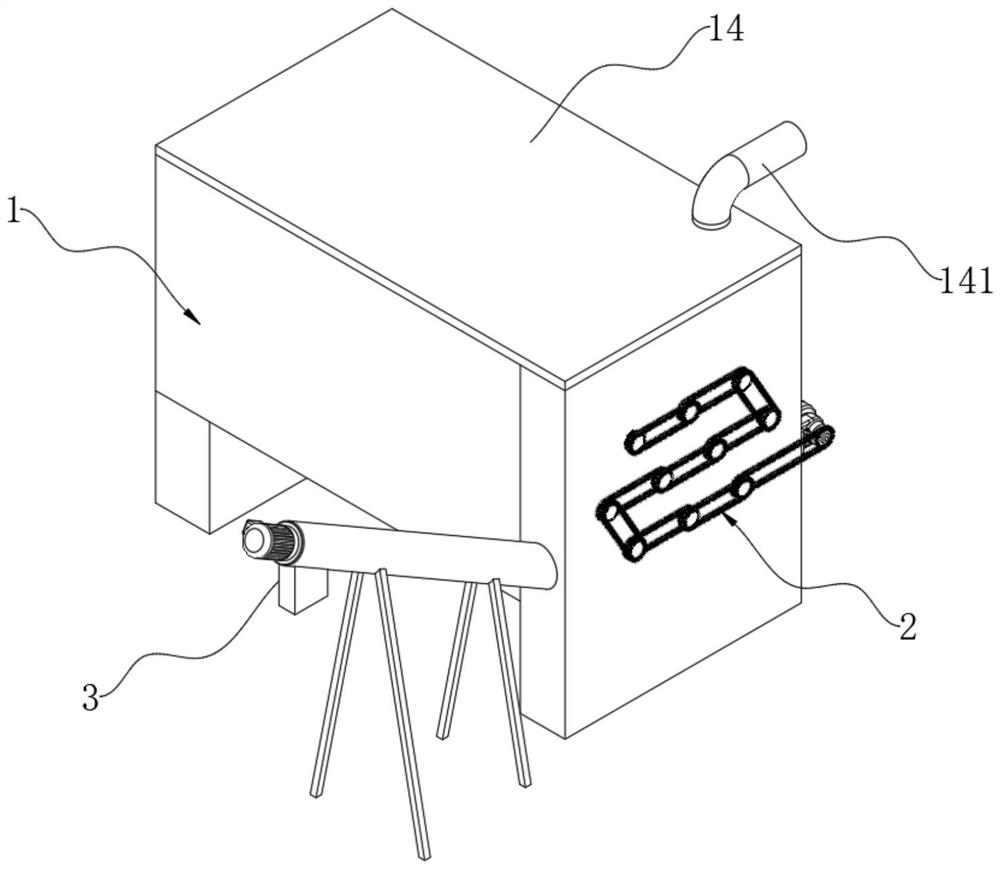

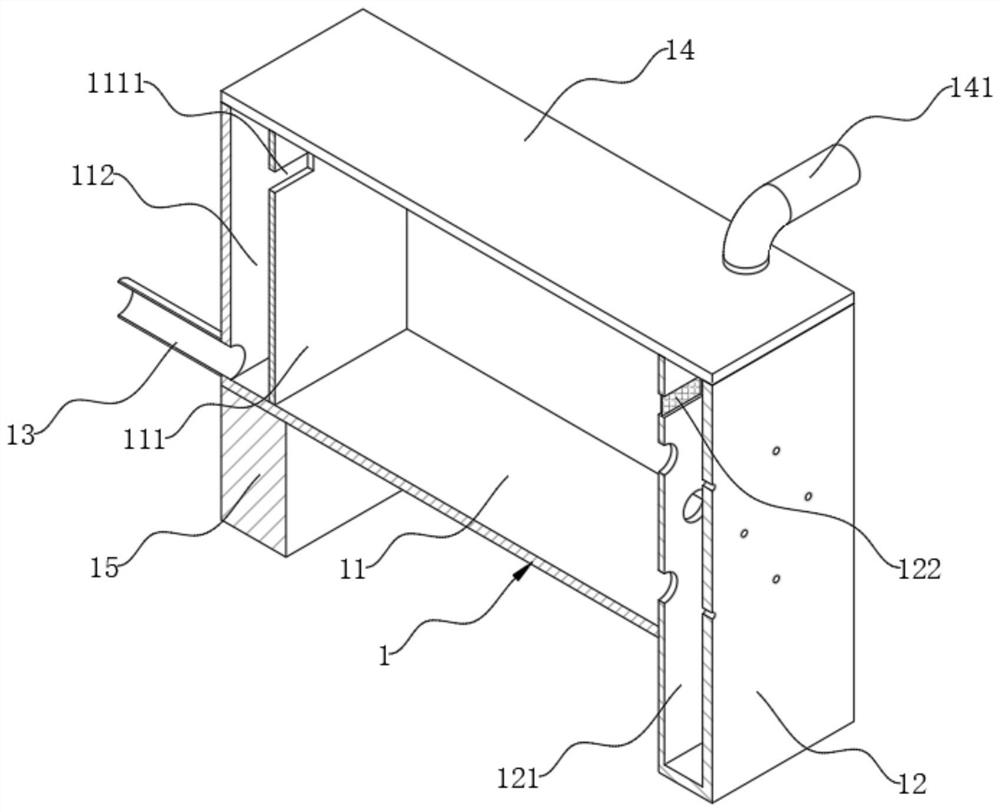

Horizontal mortar storage and transportation system

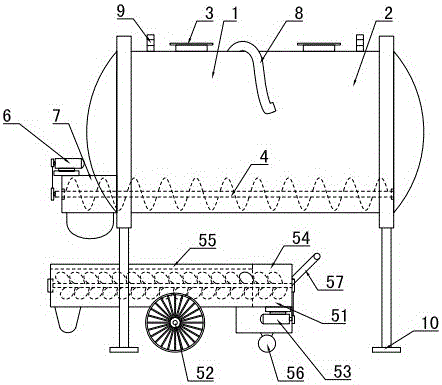

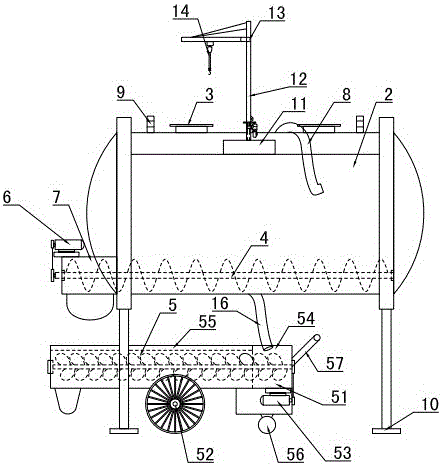

ActiveCN104528215BInhibition of segregationShorten the fall distanceLarge containersIngredients storageEngineeringMechanical engineering

The invention discloses a horizontal type mortar storage and transportation system and belongs to the field of mortar storing and stirring equipment for construction sites. The horizontal type mortar storage and transportation system is characterized in that a mortar tank comprises a tank body (1) which is transversely installed through a support (2) in a supported mode, a plurality of feed ports are formed in the upper end of the tank body (1), a stirring and conveying device (4) is transversely installed at the lower portion in the tank body (1), a first motor (6) and a discharge channel (7) are installed at the end of the tank body (1), the first motor (6) is used for driving the stirring and conveying device (4) to work, the end of the stirring and conveying device (4) extends out of the end of the tank body (1) and extends into the discharge channel (7), and a discharge port is formed in the lower portion of the discharge channel (7). The horizontal type mortar storage and transportation system can effectively prevent mortar from dissociating, feeding can be conducted through a plurality of modes, the horizontal type mortar storage and transportation system is used flexibly and conveniently in the construction sites, labor is saved, and the labor efficiency is improved.

Owner:谭云龙

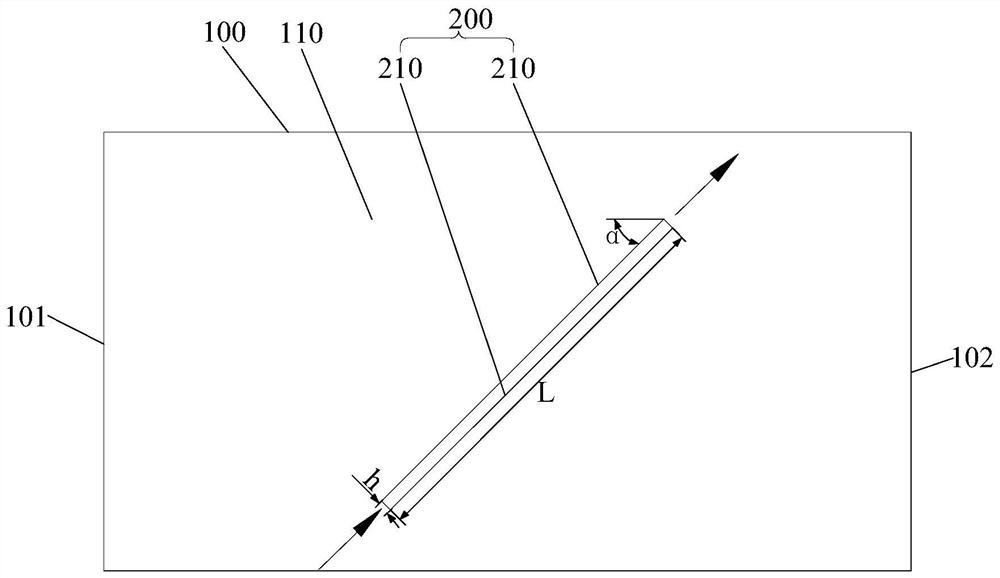

Separation device for centimillimeter particles in flue gas

PendingCN112267002AReduce energy consumptionEasy to reuseManufacturing convertersThermodynamicsFlue gas

The invention provides a separation device for centimillimeter particles in flue gas. The separation device is used for being arranged in a settlement area of a flue duct. The separation device for the centimillimeter particles in the flue gas comprises at least one settlement assembly; each settlement assembly comprises at least two layers of oblique plates which are parallelly arranged at intervals; the oblique plates incline towards the top wall of the flue duct in the flow direction of the flue gas; and the included angle between the oblique plates and the top wall of the flue duct is 5-70degrees. According to the separation device for the centimillimeter particles in the flue gas, the centimillimeter particles in the flue gas can settle down under the action of gravity, so that the aim of separating the particles from the glue gas is achieved.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

Mung bean seeding device

ActiveCN110352672ASave the trouble of manual rangingReduce cumbersomeMechanical clearance measurementsSeed depositing seeder partsAgricultural engineeringMung bean

The invention discloses a mung bean seeding device. The mung bean seeding device comprises a hopper, a vehicle body, a measuring mechanism and a position metering rod. The hopper is installed at the upper end of the vehicle body, and a wheel groove which communicates with the hopper is arranged in the vehicle body; a seed dropping hole is formed in the bottom of the wheel groove, and a seeding wheel is arranged in the wheel groove; a groove is formed in the side wall of the seeding wheel, and connecting shafts are arranged at two ends of the seeding wheel; the connecting shafts are rotatably connected with the side walls of the wheel groove, and the outer side wall of the vehicle body is connected with a push rod; an end of the push rod is provided with a holding rod, and one side of the holding rod is provided with a seeding rod; the seeding rod is connected with a pull rod, and one end of the pull rod is connected with the seeding rod; a rack plate is arranged at the other end of thepull rod, and a gear meshed with the rack plate is arranged on each connecting shaft; wheels are arranged on two sides of the vehicle body and connected with the vehicle body through wheel axles; andthe measuring mechanism is arranged at the front end of the vehicle body, and the position metering rod is arranged on the measuring mechanism.

Owner:SHANDONG CROP GERMPLASM CENT

An auxiliary device for maintenance of electrical equipment

ActiveCN110034506BReduce shakingImprove construction qualitySwitchgearElectric power equipmentEngineering

Owner:STATE GRID JIBEI ELECTRIC POWER COMPANY LIMITED CHENGDE POWER SUPPLY +1

Berry fruit vibration harvesting device with branch supporting function

The invention provides a berry fruit vibration harvesting device with a branch supporting function. The device causes small disturbance to branches, reduces the damage rate of fruits and branches, andis suitable for harvesting berry fruits of densely planted dwarf fruit trees. According to the device, a collecting box is arranged at the bottom of a vertical plate, a branch supporting device is arranged above the collecting box, and an insertion tooth vibration device is arranged above the branch supporting device; the branch supporting device comprises at least two chains, wherein each chainsurrounds a front chain wheel and a rear chain wheel; the insertion tooth vibration device comprises an insertion tooth guide rail, an insertion tooth fixing plate and a plurality of insertion teeth extending downwards, wherein the insertion tooth guide rail extends in the front-back direction, the insertion tooth fixing plate is slidably connected with the insertion tooth guide rail, the insertion teeth are arranged on the insertion tooth fixing plate, and a vibration mechanism used for driving the insertion tooth fixing plate to reciprocate is arranged on the insertion tooth guide rail. Theupper part of the insertion tooth guide rail is connected with a vertical driving mechanism; a traversing area for the fruit branches to pass through is formed among the right side of the vertical plate, the chains and the insertion teeth. When the fruit branches pass through the traversing area, the vertical driving mechanism and the vibration mechanism move so that the berry fruits on the fruitbranches are separated from the fruit branches and fall into the collecting box.

Owner:NANJING FORESTRY UNIV

Sewage treatment system for constructional engineering

PendingCN114130070ARapid precipitationShorten the fall distanceSettling tanks feed/dischargeSedimentation settling tanksElectric machineSewage

The invention discloses a sewage treatment system for constructional engineering, which comprises a treatment box body, a concentration bin is arranged at the front end of the treatment box body, a precipitation device is arranged in the treatment box body, a precipitate discharge structure is mounted on the concentration bin, and the precipitation device comprises a bottom plate, a plurality of precipitate conveying structures and a rotating motor. The sediment discharging structure comprises a fixing sleeve, a pocket plate and a long shaft. According to the sewage treatment device, the precipitation device is arranged, and a plurality of precipitation conveying structures are distributed in the precipitation cavity, so that silt in sewage can be more quickly precipitated into the precipitation conveying structures, the precipitation speed is increased, the precipitates can be directly discharged outwards through the precipitation discharging structure arranged on the concentration bin, and the precipitation efficiency is improved. Therefore, the purpose of cleaning sediments is achieved, and the sediments are prevented from being accumulated.

Owner:山东威如建设工程有限公司

A Method for Asphalt Mixture Grading Prediction Based on Cold Material Monitoring

ActiveCN107909584BGradation Accurate MonitoringUneven solutionImage analysisRoads maintainenceEngineeringMechanics

The invention discloses a method for estimating asphalt mixture gradation through cold material monitoring, which includes: selecting a suitable camera; debugging the position of the camera and the intensity of the LED light source; determining the digital image used for analysis; converting the color image by using MATLAB It is a binary image; distance calibration of binary image; virtual screening of stone particles; estimation of aggregate particle volume; calculation of aggregate passing rate; determination of multi-grade cold material grading; bin flow rate to estimate the gradation of asphalt mixture in the mixing tank. Due to the small falling distance of the particles in the cold material bin, the method of the present invention will not cause dust problems, and the problem of uneven natural light can be overcome by adding an LED light source; the captured images are clear and continuous, and the gradation of the cold material can be accurately monitored; at the same time, On the basis of accurately monitoring the cold material gradation, combined with the flow of each cold material silo, the asphalt mixture gradation can be estimated, and can be used for asphalt mixture construction process control.

Owner:SOUTHEAST UNIV

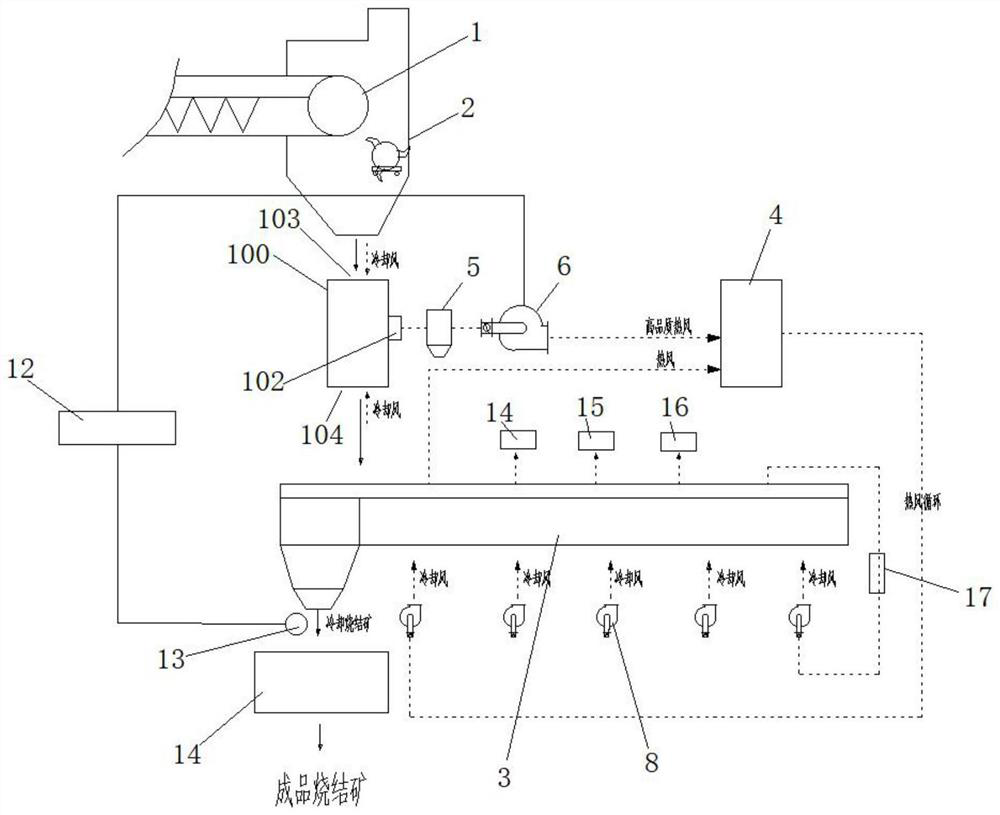

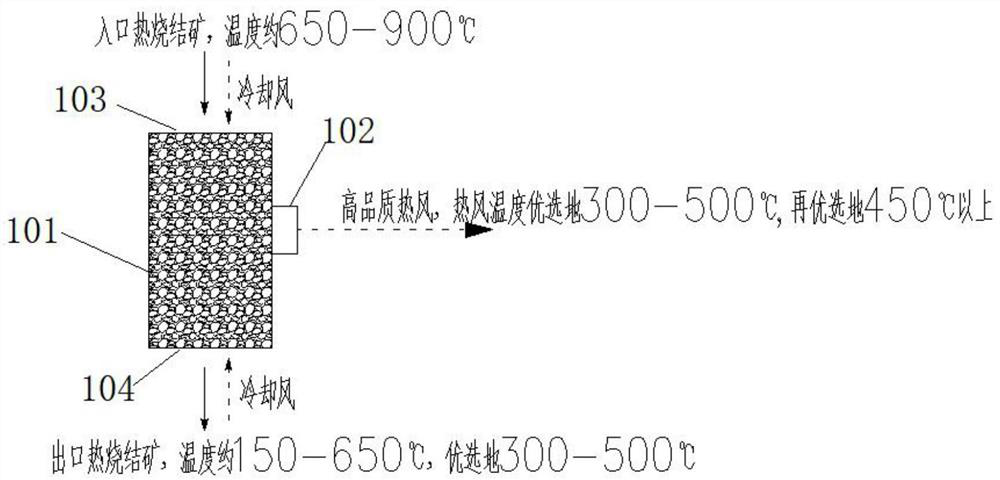

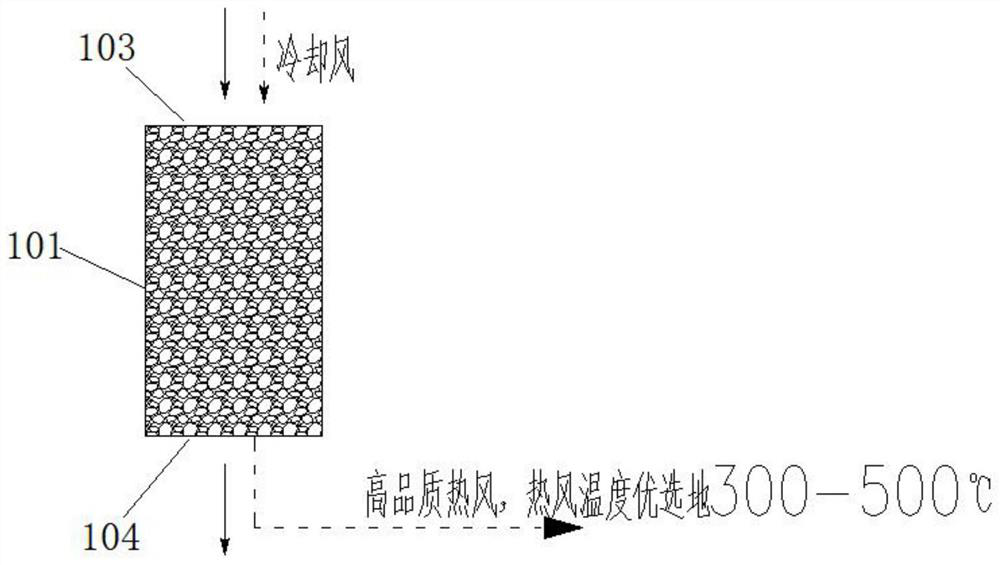

Sintering cooling waste gas zero emission system and sintering cooling process

PendingCN113295007AAchieving zero emissionsPromote circulationCharge treatment typeIncreasing energy efficiencyThermodynamicsExhaust gas emissions

The invention discloses a sintering cooling waste gas zero emission system and a sintering cooling process. The sintering cooling waste gas zero emission system comprises a pre-cooling device, an annular cooler, a dust removal device, an exhaust fan, a waste heat boiler, a control unit and a temperature detection unit, wherein the pre-cooling device is arranged on a hot sintered ore falling path between the discharging end of a crusher corresponding to a sintering machine and the feeding end of a circular cooler, a hot ore inlet is formed in the position, facing the discharging end of the crusher, of the upper end surface of the pre-cooling device, a hot ore outlet is formed in the position, facing the feeding end of the circular cooler, of the lower end face of the pre-cooling device, the pre-cooling device further comprises a hot air outlet, and the hot air outlet is led to the air inlet end of the waste heat boiler through the dust removal device and the exhaust fan in sequence. The sintering cooling waste gas zero emission system aims at solving the technical problem that in the sintering process in the prior art, more cooling waste gas is emitted.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Cable pre-cutting device

PendingCN113477838AReduced measurement timeShorten the timeFilament handlingMetal working apparatusControl theoryElectric cables

The invention relates to the field of cable pre-cutting, in particular to a cable pre-cutting device which comprises a take-up frame, a positioning clamping mechanism, an equidistant transmission mechanism, a supporting mechanism, a cutting mechanism, a cable positioning frame, a rotary supporting frame and three cable measuring mechanisms with the radiuses increasing in sequence. The cutting mechanism, the equidistant transmission mechanism and the supporting mechanism are combined; through the equidistant transmission mechanism, the supporting mechanism is driven to move in the working process of the cutting mechanism, so that the working time of the equipment is saved; through the equidistant transmission mechanism, the supporting mechanism can move as long as the distance that the cutting mechanism can move, and thus the supporting mechanism can adaptively act on the cable measuring mechanisms of various specifications; through the supporting mechanism, the falling distance of the cable is reduced, and shaking of the cable in the falling process is avoided, so that deviation of the center position of the cable is avoided, and the middle of the cable can be automatically reserved on the cable positioning frame in the falling process of a supporting plate.

Owner:芜湖市科特电线电缆有限公司

Sheet material cutting and laminating device and sheet material cutting and laminating method

ActiveCN103704918BAvoid slackAvoid shakingSevering textilesClothes making applicancesEngineeringSheet material

The invention provides a sheet material cutting stacking apparatus and a sheet material cutting stacking method. The sheet material is cut off by a cutting head of a cutting conveyor, and the cut-off sheet material is moved out to a transportation workbench by the cutting conveyor. A stretching rod that supports a stretching sheet is feed in from a backward position close to the transportation workbench to a stacking table at the downstream side of the transportation workbench; cloth sheets are separated individually between the transportation workbench and the stretching sheet by a speed difference between the feed in speed of the stretching rod and the transportation speed of the cutting conveyor; the stretching rod is made to move backwards from the position where the distance to the rear end of the cloth sheets of the stretching sheet is longer than a prescript length of the front end of the transportation workbench, therefore, the cloth sheets can be stacked on the stacking table because of not getting into from under the transportation workbench.

Owner:SHIMA SEIKI MFG LTD

Activated carbon static sorting device

PendingCN112916388AShorten the fall distanceIncrease spacingGas current separationActivated carbonStructural engineering

The invention discloses an activated carbon static sorting device which comprises a vertical sorting cylinder and multiple material guiding chutes. The top of the vertical sorting cylinder is provided with a feed port; the bottom of the vertical sorting cylinder is provided with a discharge port; one side of the lower end of the vertical sorting cylinder is provided with an air inlet; one side of the upper end of the vertical sorting cylinder is provided with an air outlet; the multiple material guiding chutes are located in the vertical sorting cylinder and arranged in the vertical direction; one end of each material guiding chute is fixedly connected with the inner wall of the vertical sorting cylinder; the other end of each material guiding chute inclines downwards; and the fixed ends of any two adjacent material guiding chutes are located on the two sides of the axis of the vertical sorting cylinder respectively. According to the activated carbon static sorting device provided by the invention, activated carbon entering the sorting cylinder slides down along the material guiding chutes which are arranged in an up-and-down staggered mode, meanwhile, dust and fine particles are blown out through reverse air, the falling distance of the activated carbon can be shortened, secondary fragmentation is avoided, coalescent activated carbon can be scattered, and the distance between the particles can be increased, so that the dust and the fine particles in the activated carbon can be effectively removed, and normal operation of a flue gas desulfurization and denitrification adsorption tower is guaranteed.

Owner:河北大河邯钢设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com