A Method for Asphalt Mixture Grading Prediction Based on Cold Material Monitoring

An asphalt mixture and grading technology, applied in image analysis, roads, buildings, etc., can solve the problems of uneven light, easy to contaminate the lens, blurred lens, etc., to overcome the uneven problem, ensure continuity, and reduce the falling distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions provided herein will be described in detail below with reference to the specific embodiments, and it is to be understood that the following specific embodiments are intended to illustrate the invention and are not intended to limit the scope of the invention.

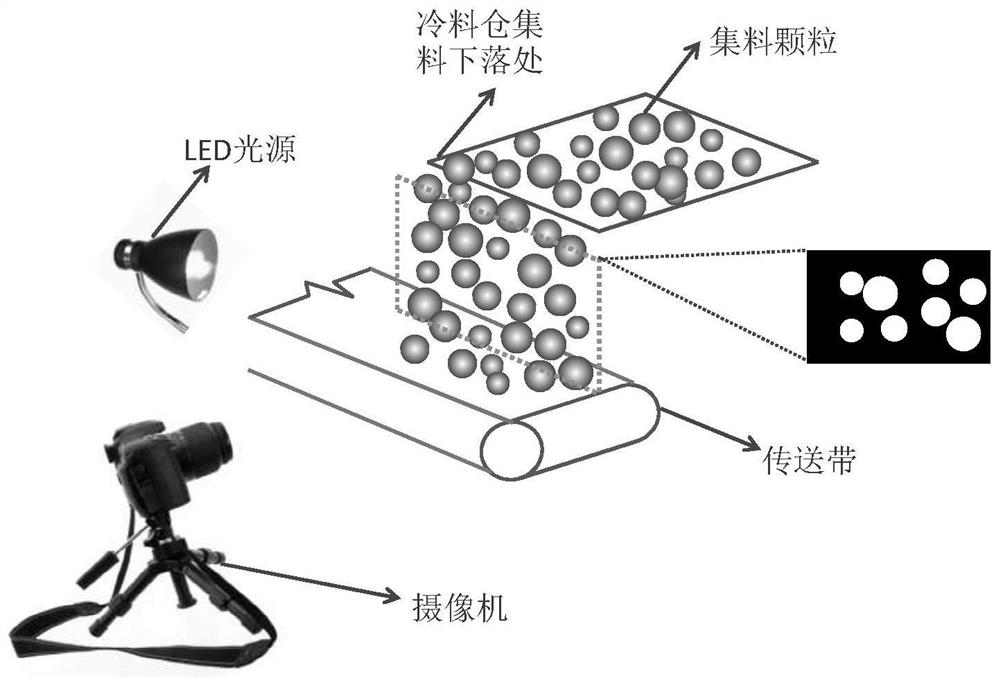

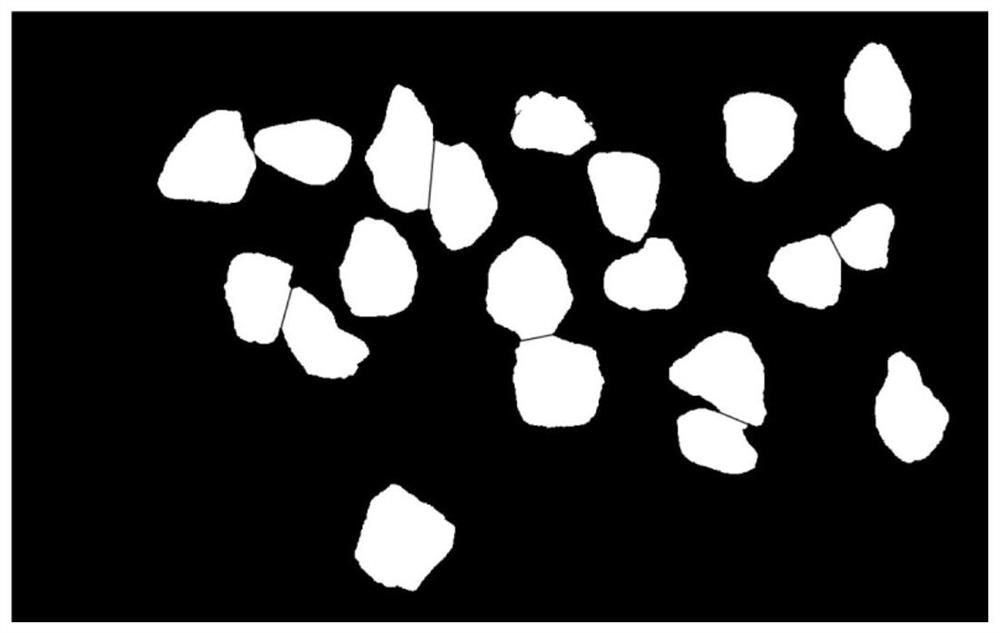

[0052] The present embodiment is directed to a batch-type asphalt mixing plant, high-speed cameras cold aggregate particles fall process, again using MATLAB cooling silo was calculated for each gradation, such as the implementation of environmental figure 1 Indicated. In asphalt mixing station, cold material on the conveyor belt by a mixture of cold aggregate silo from a plurality of, more commonly selected profile 9.5-16mm cold material of the present invention is an analysis target. DETAILED DESCRIPTION steps:

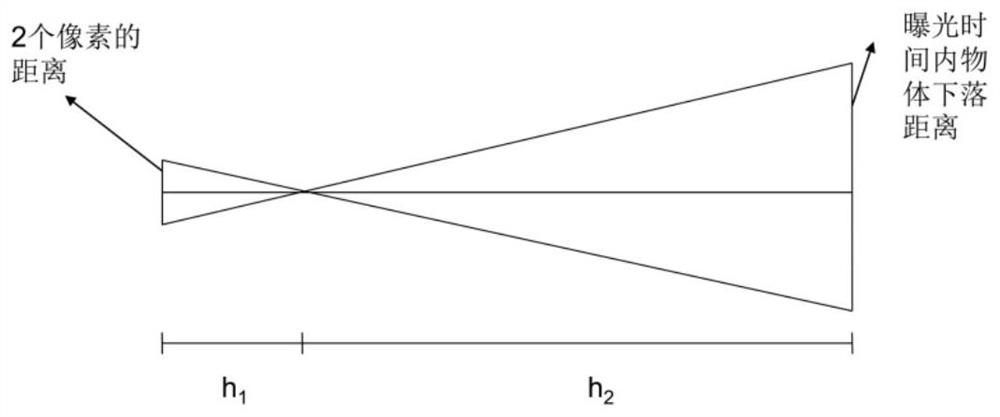

[0053] 1, select the frame rate and exposure time to meet the requirements of the camera. The actual operation of the cold material transfer device, the distance h from the camera fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com