Processing method of glass eyeglass of camera

A glass lens and processing method technology, applied in glass production, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of reduced glass lens processing efficiency, low glass processing efficiency, uneven glass chamfering, etc., and achieves a high degree of automation. , to avoid uneven problems, to simplify the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

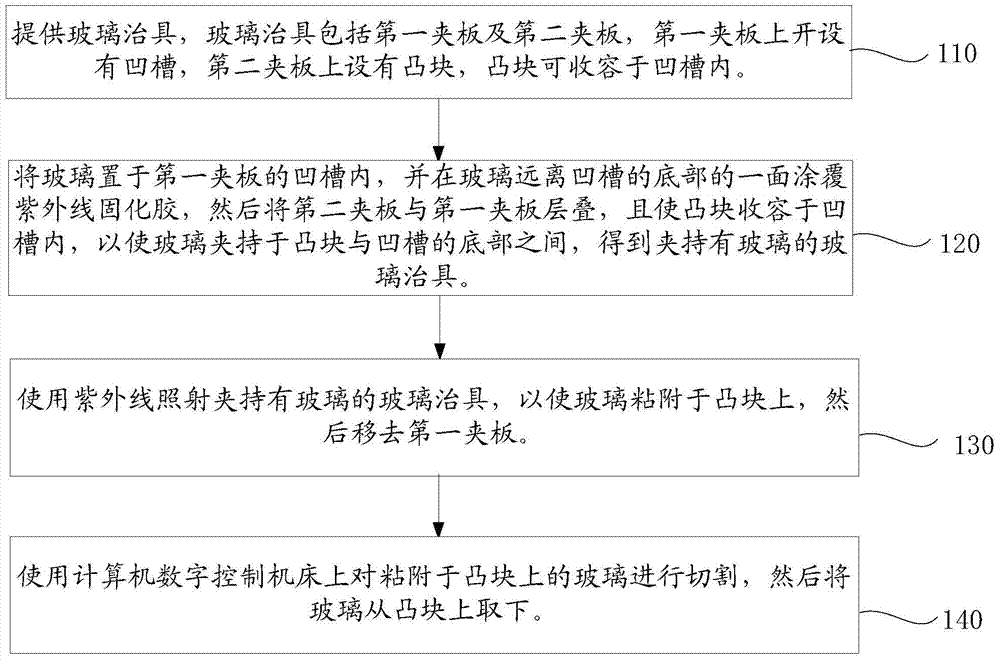

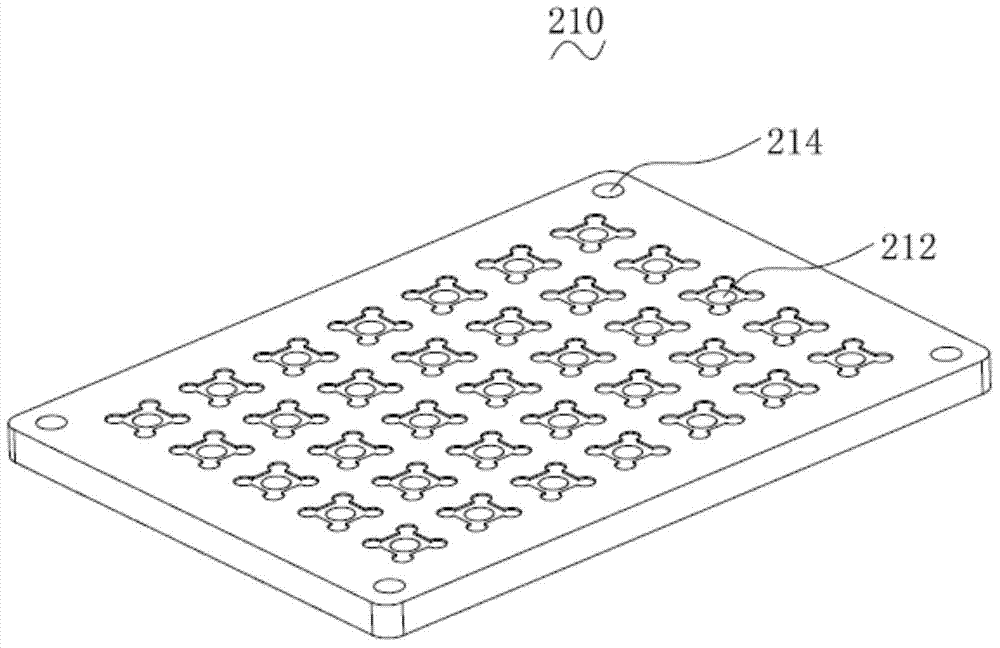

[0046] (1) Cut a large piece of raw glass into small pieces according to the product size, move the cut glass to the inserting workbench, the operator breaks the cut glass, and puts it flat into the empty tray; and then one by one Put the glass into the groove of the first splint, place a glass in each groove, fill the groove of the first splint with the glass, and visually check that there is no displacement when facing the light source.

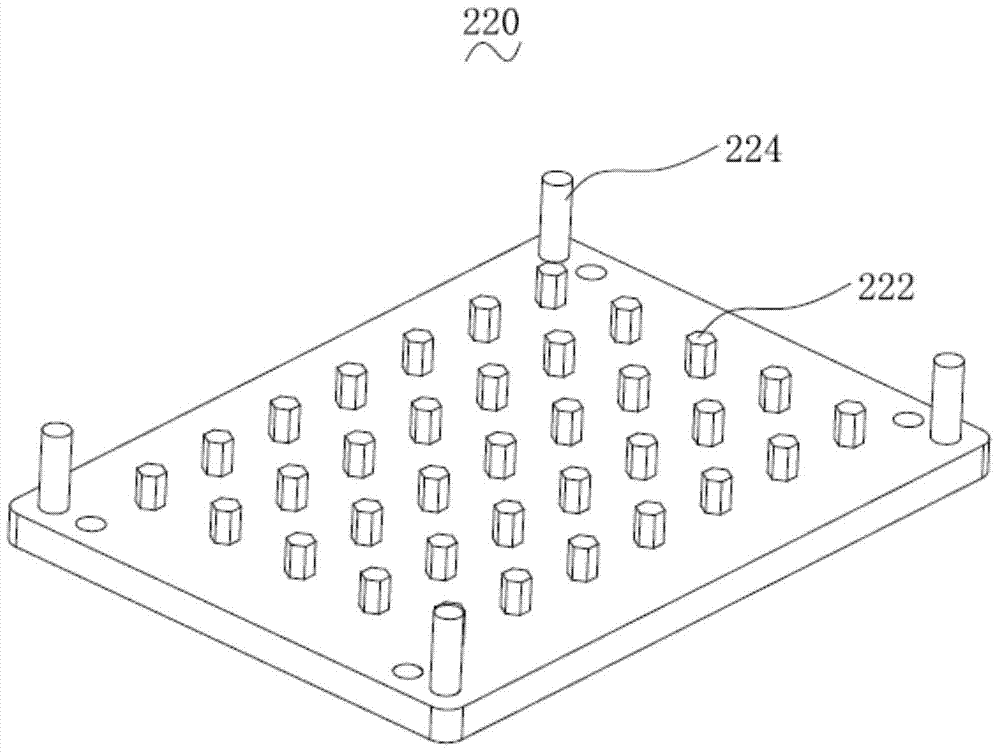

[0047] (2) Use a glue dispenser to apply UV-curable glue on the side of the glass away from the bottom of the groove, then place the second splint on the first splint, and accommodate the bumps in the groove so that the glass is clamped on the Between the end surface of the free end of the projection and the bottom of the groove, a glass fixture holding the glass is obtained.

[0048] (3) Then turn over the glass jig holding the glass so that the second splint is on top of the first splint. After standing for 5 minutes, use ultraviolet ligh...

Embodiment 2

[0052] (1) Cut a large piece of raw glass into small pieces according to the product size, move the cut glass to the inserting workbench, the operator breaks the cut glass, and puts it flat into the empty tray; and then one by one Put the glass into the groove of the first splint, place a glass in each groove, fill the groove of the first splint with the glass, and visually check that there is no displacement when facing the light source.

[0053] (2) Use a glue dispenser to apply UV-curable glue on the side of the glass away from the bottom of the groove, then place the second splint on the first splint, and accommodate the bumps in the groove so that the glass is clamped on the Between the end surface of the free end of the projection and the bottom of the groove, a glass fixture holding the glass is obtained.

[0054] (3) Then turn over the glass fixture holding the glass so that the second splint is on top of the first splint. After standing for 10 minutes, use ultraviolet...

Embodiment 3

[0058] (1) Cut a large piece of raw glass into small pieces according to the product size, move the cut glass to the inserting workbench, the operator breaks the cut glass, and puts it flat into the empty tray; and then one by one Put the glass into the groove of the first splint, place a glass in each groove, fill the groove of the first splint with the glass, and visually check that there is no displacement when facing the light source.

[0059] (2) Use a glue dispenser to apply UV-curable glue on the side of the glass away from the bottom of the groove, then place the second splint on the first splint, and accommodate the bumps in the groove so that the glass is clamped on the Between the end surface of the free end of the projection and the bottom of the groove, a glass fixture holding the glass is obtained.

[0060] (3) Then turn over the glass jig holding the glass so that the second splint is on top of the first splint. After standing for 8 minutes, use ultraviolet rays...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com