Squat silo grain feeding distributor

A technology of distributors and round bins, applied in loading/unloading, conveyors, transportation and packaging, etc., can solve problems such as air permeability, poor thermal conductivity, affecting soybean storage safety, affecting application and effect, etc., to increase air permeability, The effect of improving the stability of grain storage and reducing the cost of grain storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

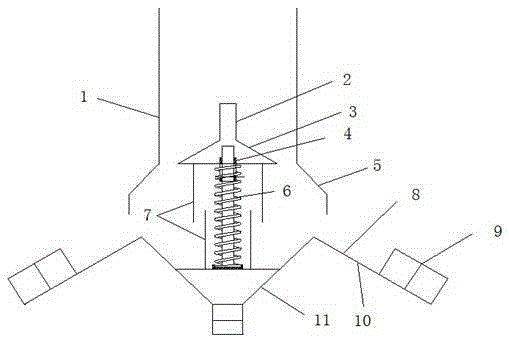

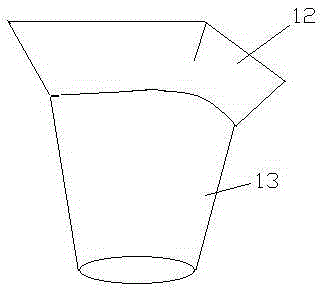

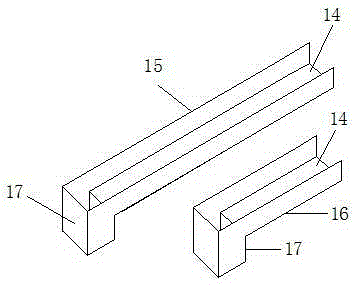

[0021] The present invention is composed of deflector 13, overflow barrel 1, pressure door 2, umbrella distributor 8 and a plurality of chutes. The deflector 13 and the overflow barrel 1 are installed in the discharge barrel of the shallow round silo, the pressure door 2 is installed under the grain inlet of the discharge barrel, the umbrella distributor 8 is installed under the pressure door 2, and multiple chutes are installed At the lower end of the umbrella-shaped distributor 8, the upper ends of a plurality of chutes are respectively connected with the outlets of the blanking area of the outer peripheral ring of the umbrella-shaped distributor 8, and the lower ends of the plurality of chutes are respectively connected with a plurality of falling grain points in the shallow round warehouse. Corresponding to 18, the grain falling point 18 of the shallow round bin is evenly distributed on the circumferential plane of the shallow round bin, and soybeans fall from the umbrell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com