Patents

Literature

47 results about "Peripheral plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

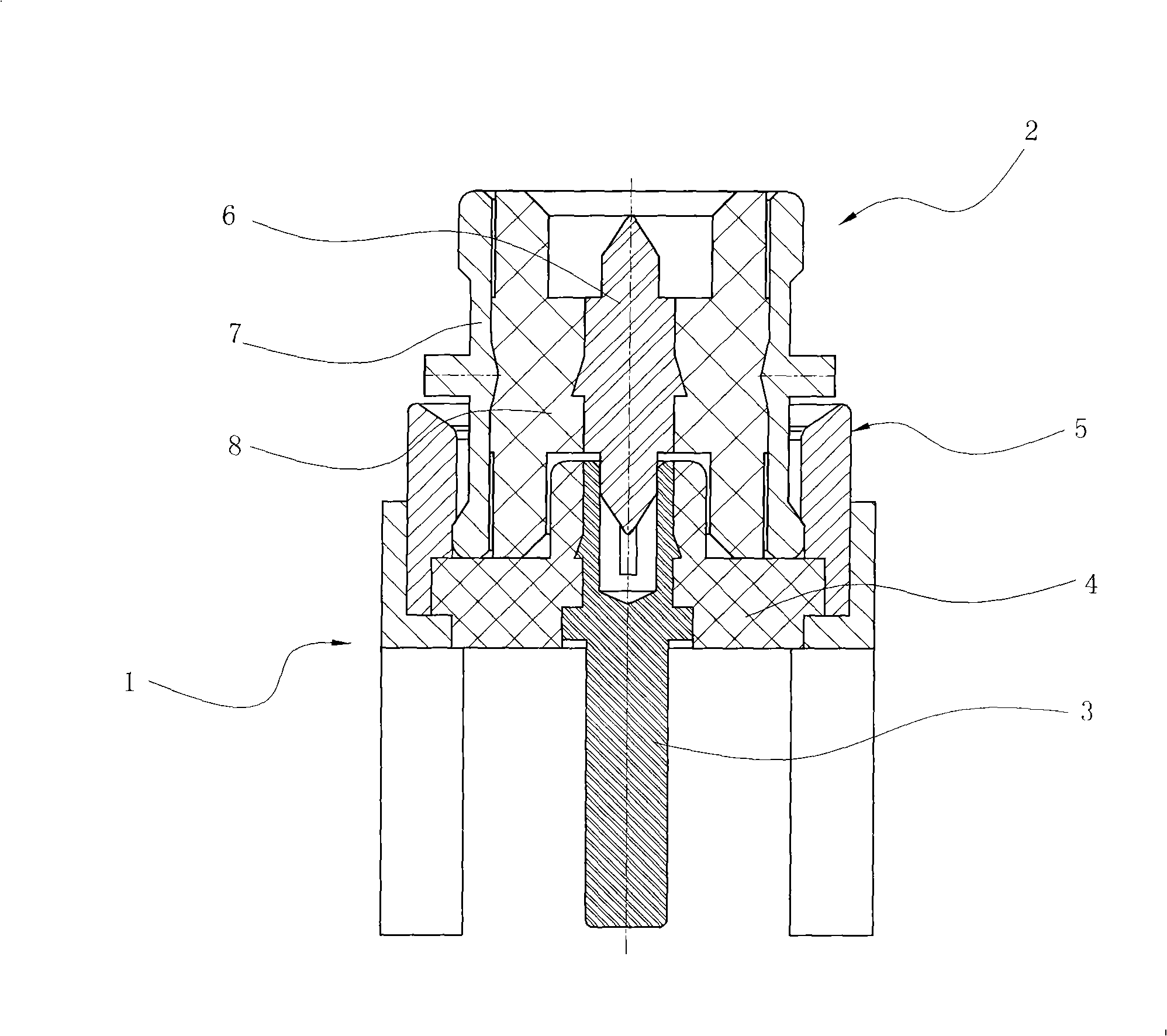

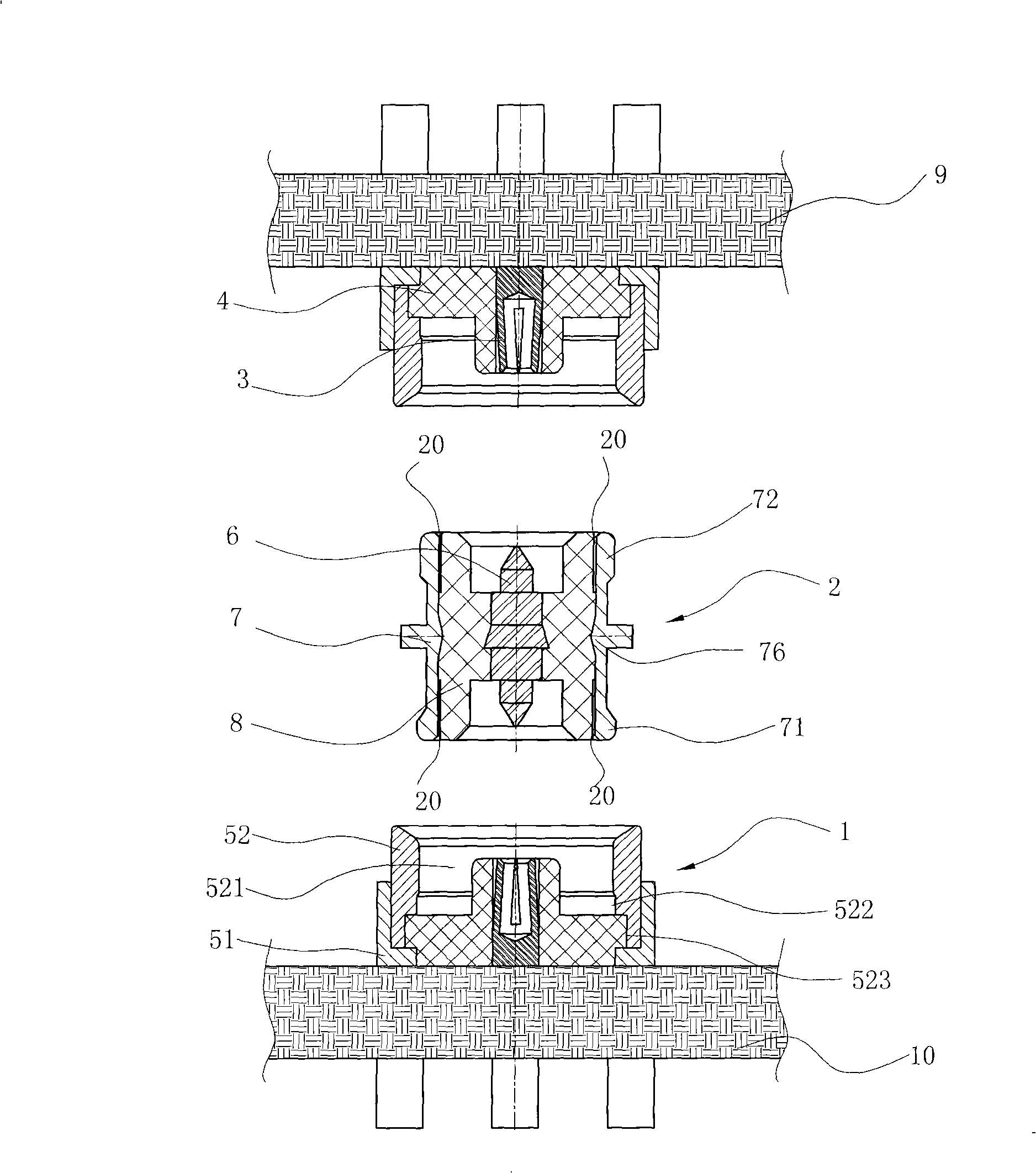

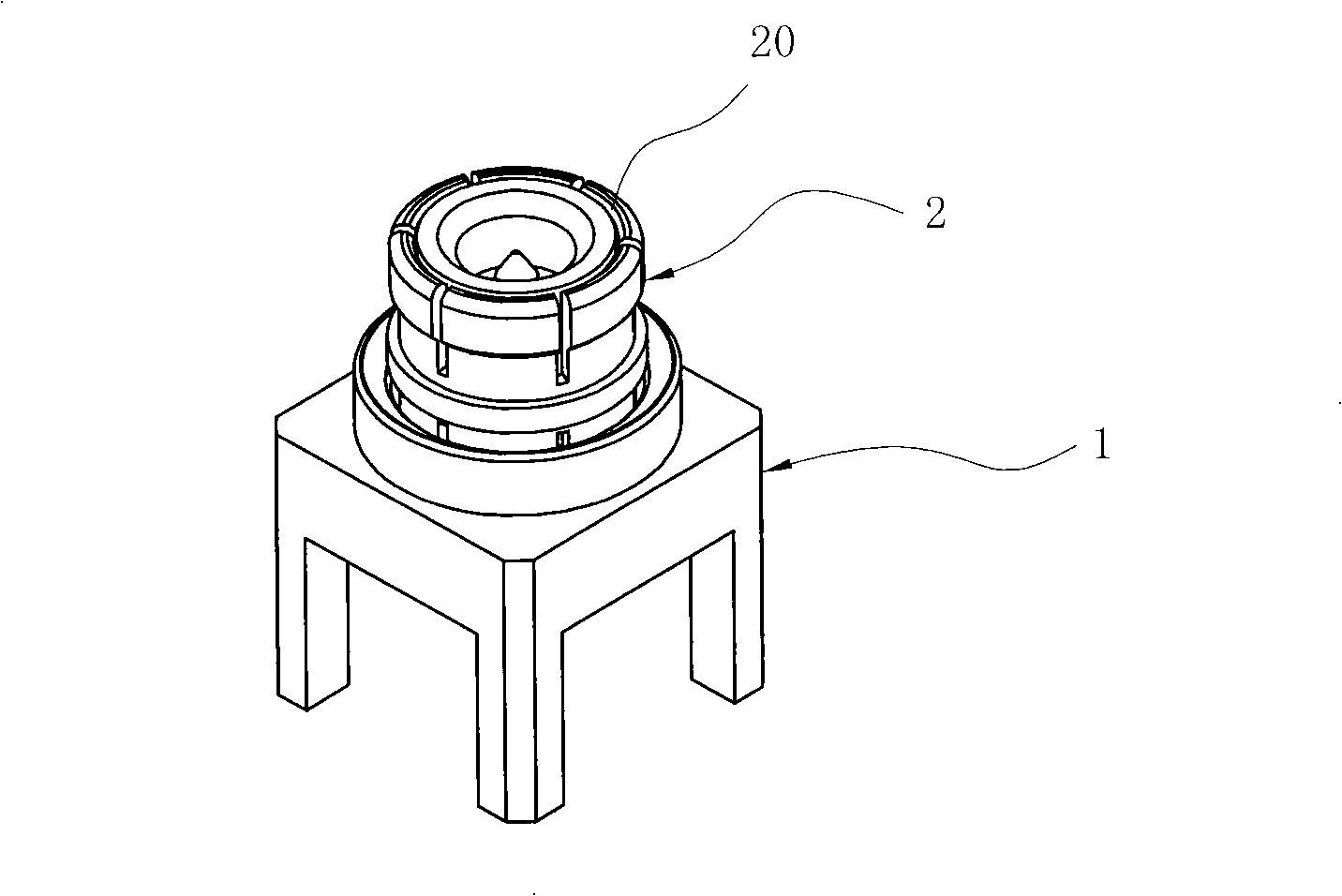

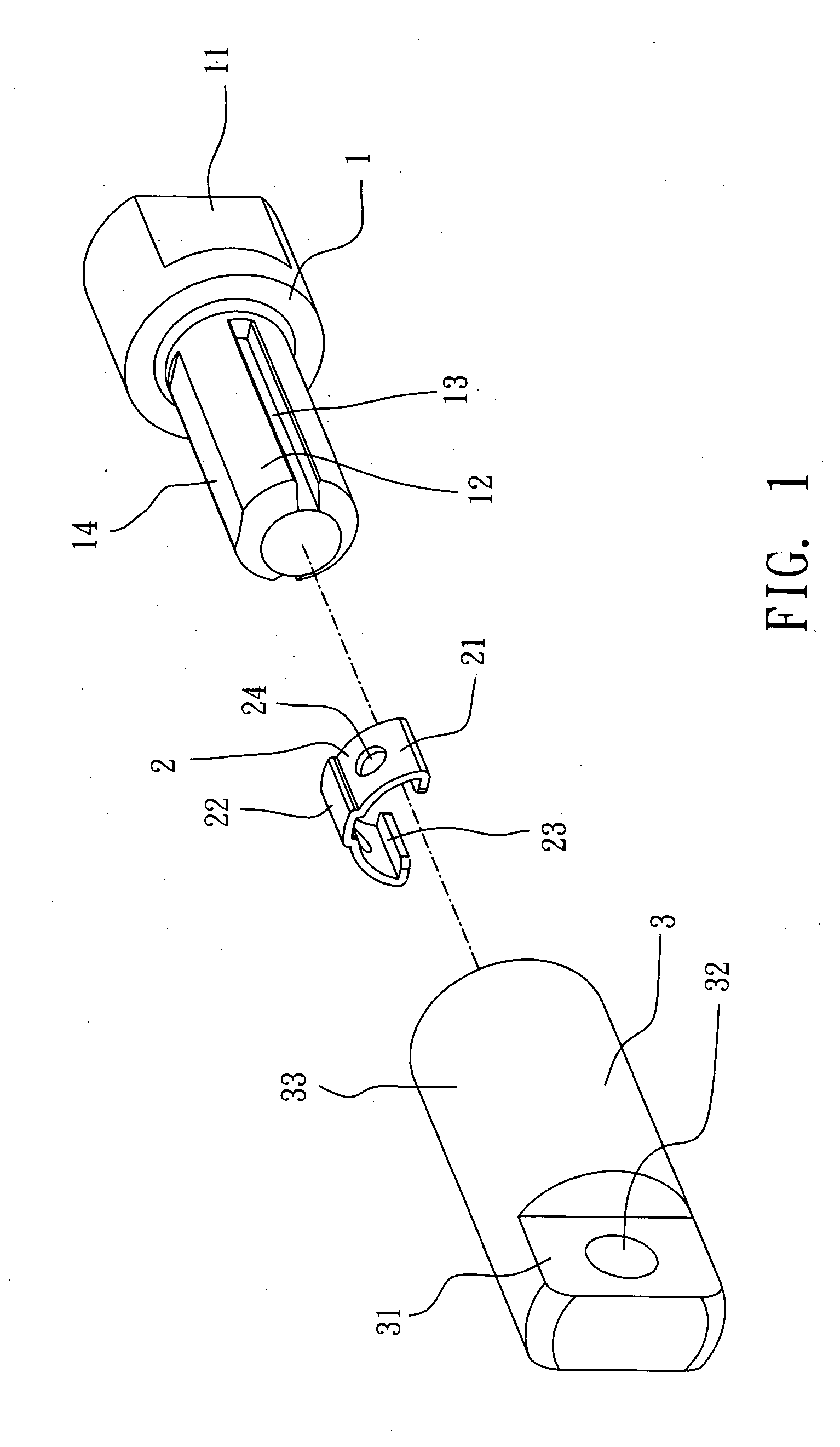

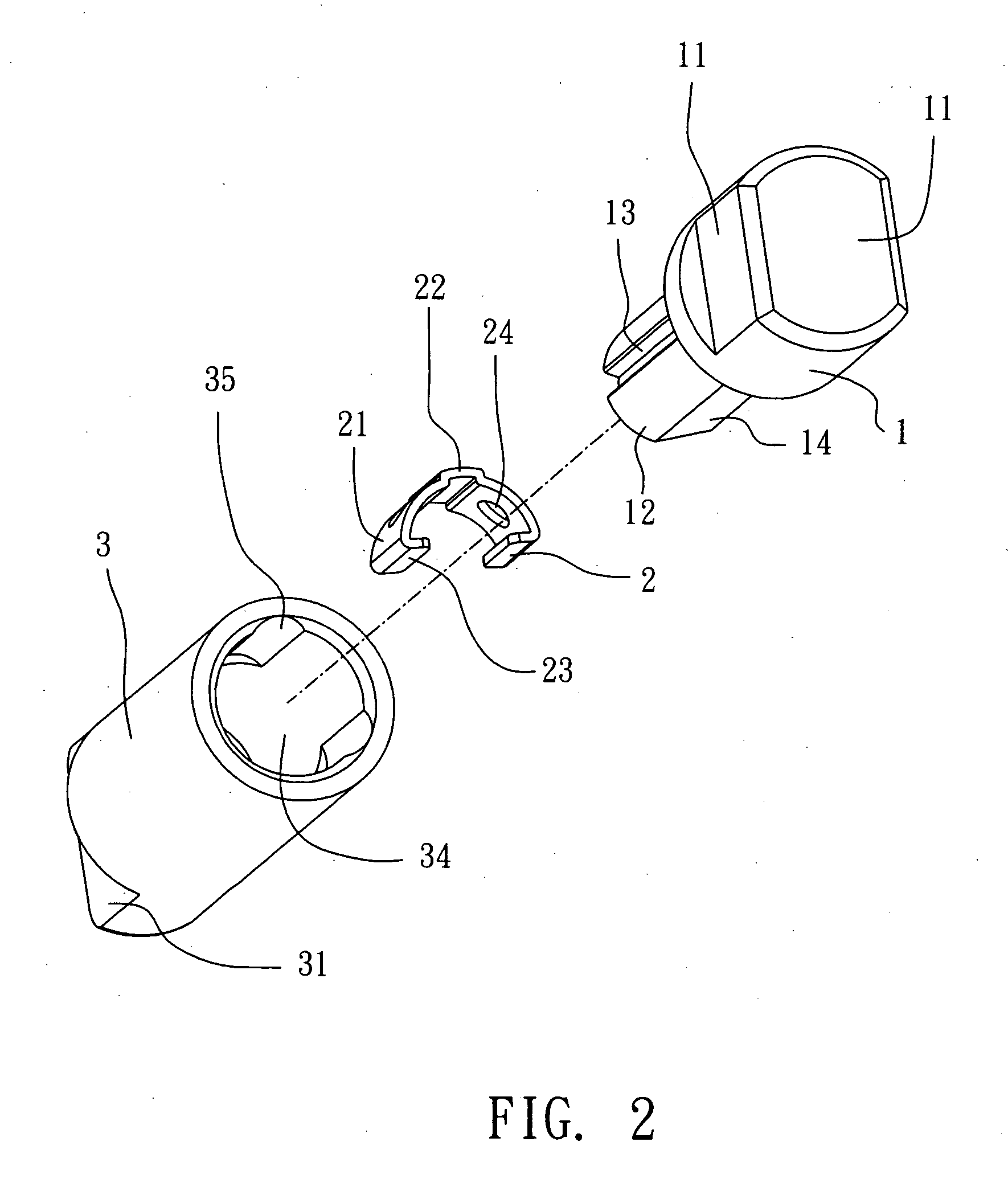

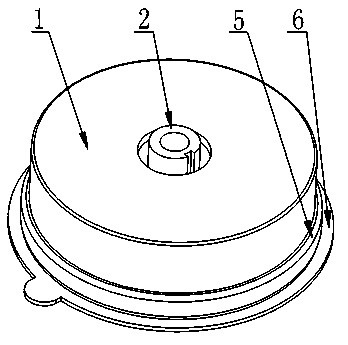

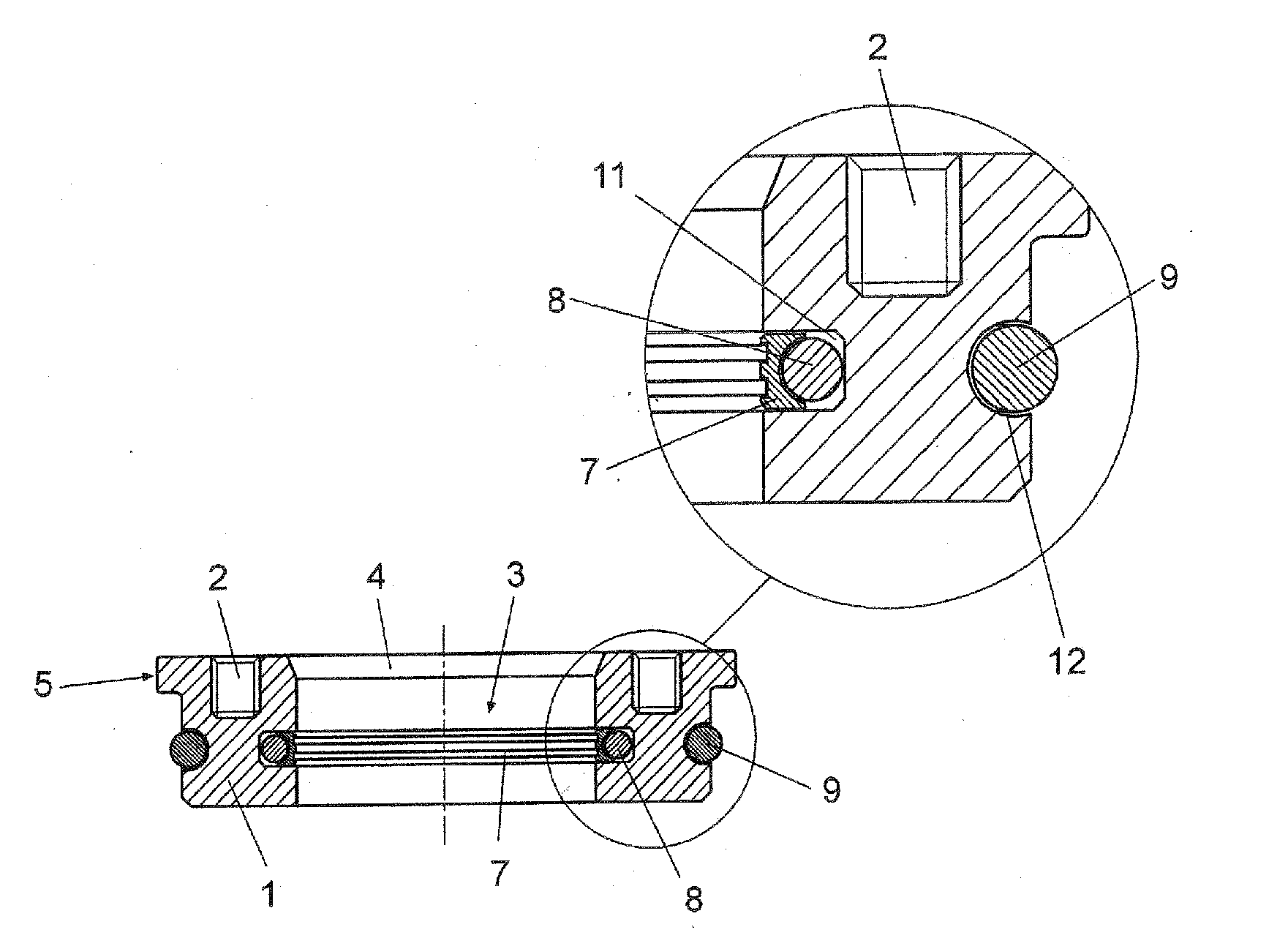

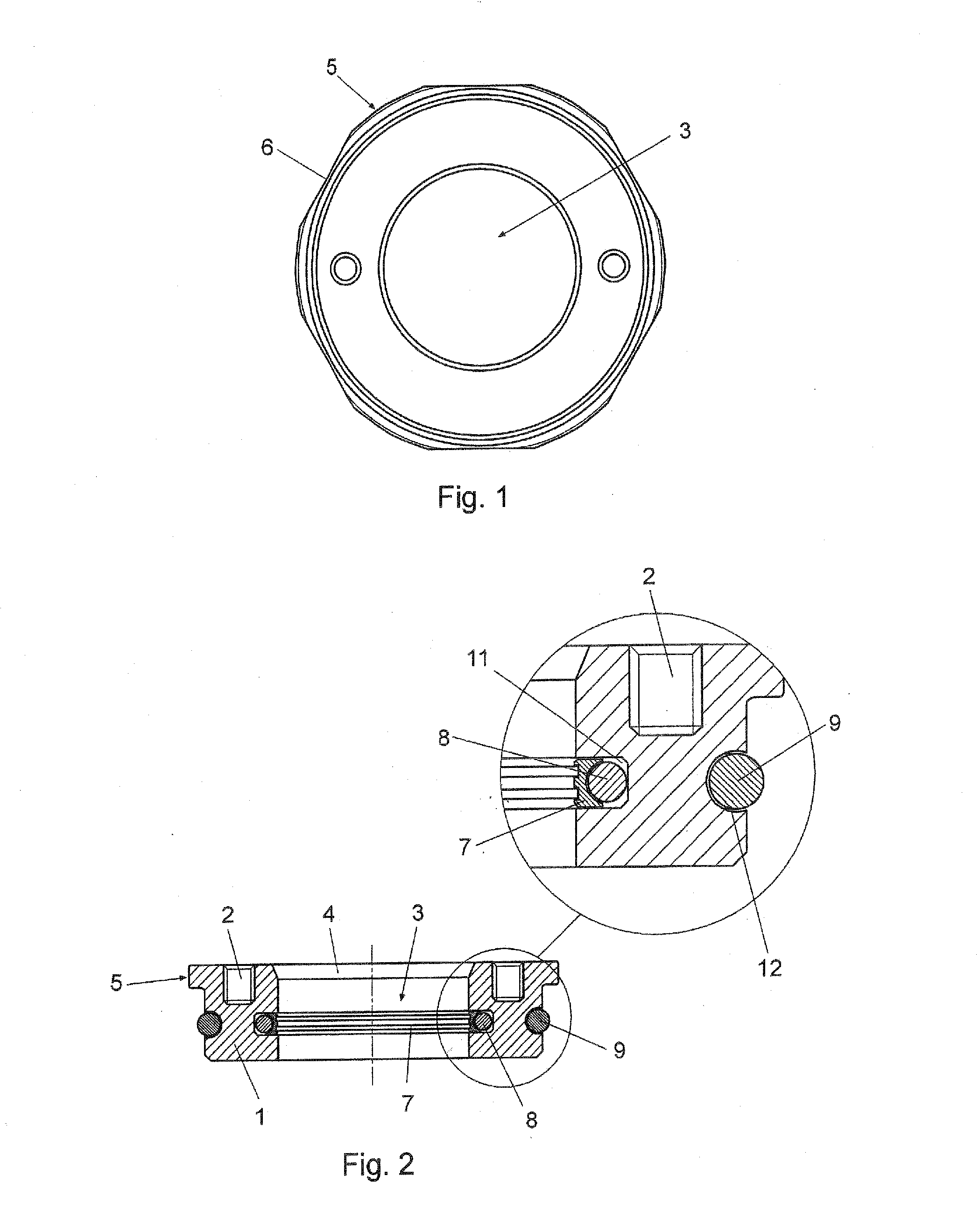

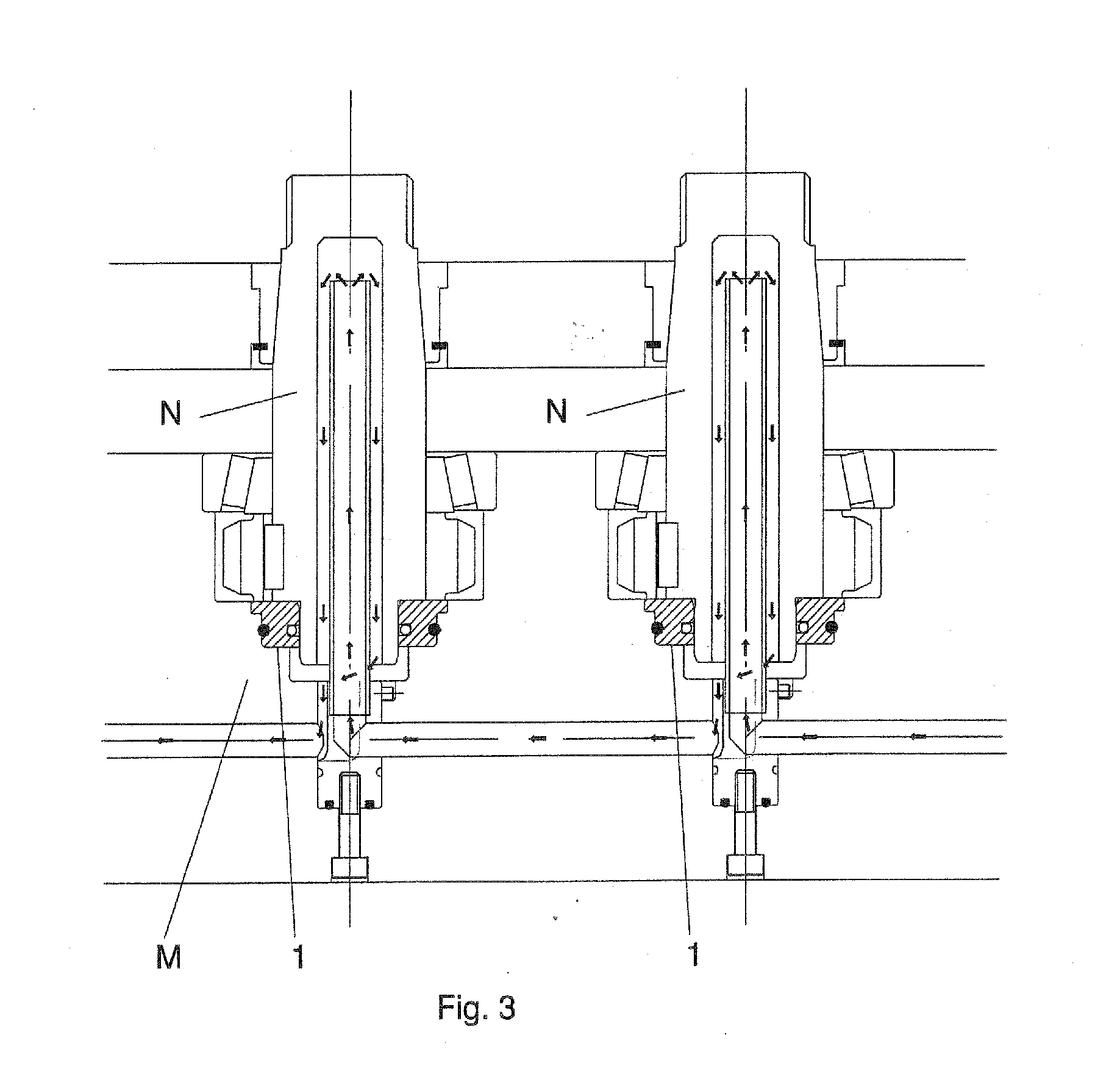

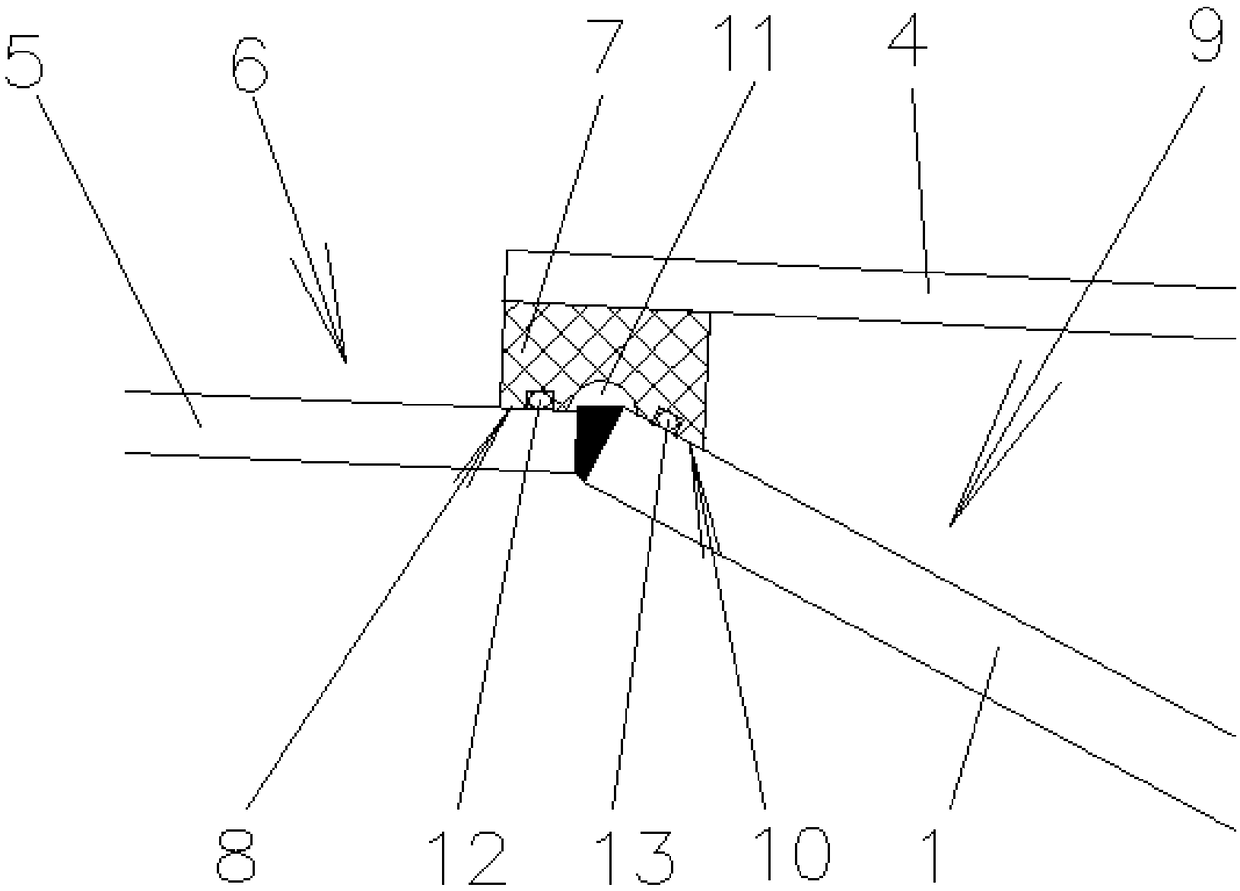

Plate-to-plate concentration mounting type RF coaxial connector

ActiveCN101350483AExtended service lifeOvercome the defect that cannot be installedTwo-part coupling devicesPull forcePeripheral plane

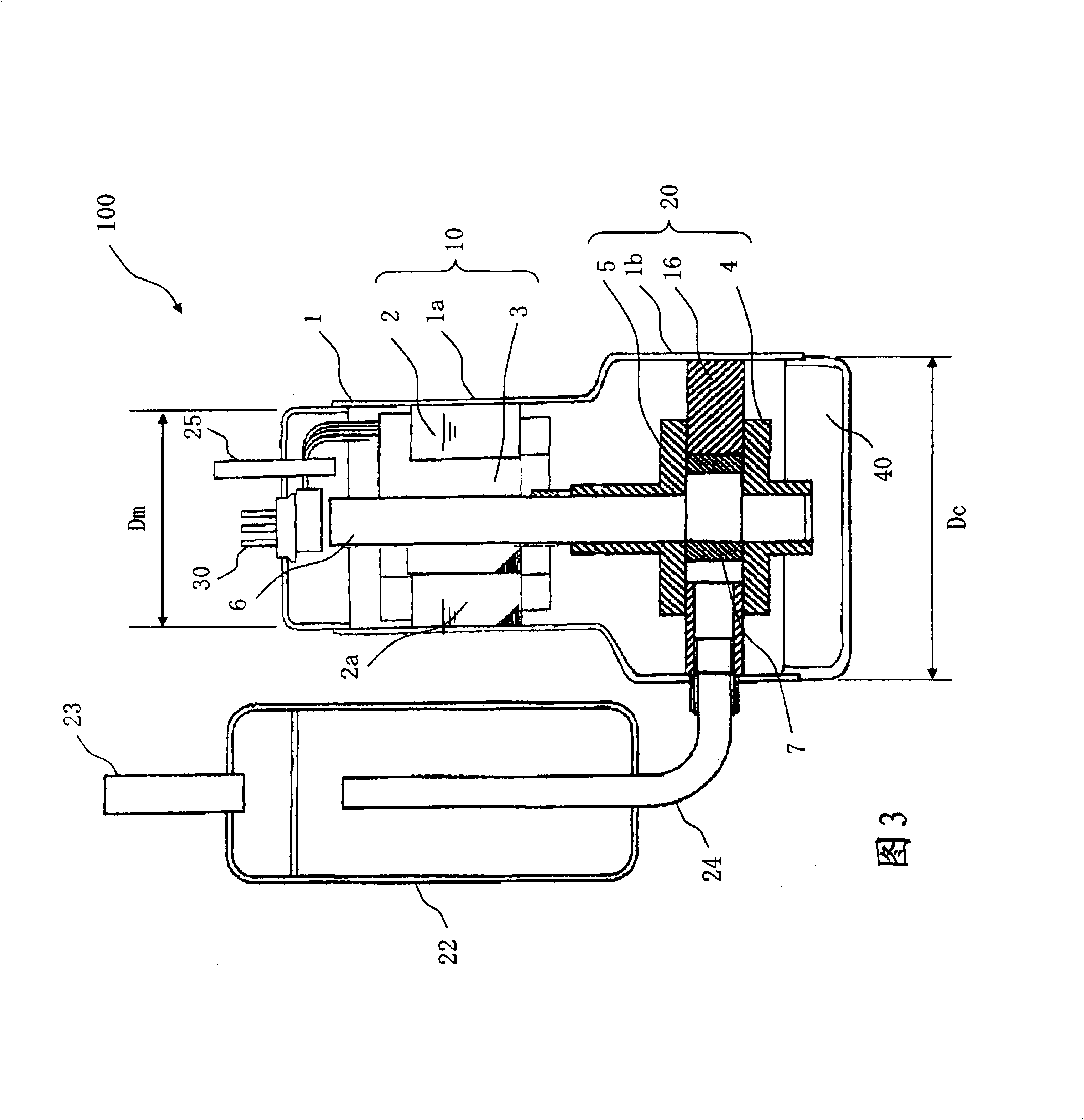

The invention discloses a plate-to-plate intensive assemblage coaxial connector, comprising two sockets and a commutator. A first flange and a second flange with different axial lengths are arranged on the peripheral planes of the two ends of the commutator; a groove is arranged on the side wall at the bottom of the opening of the socket; when the commutator is inserted into the socket, the first flange is located in the groove, the second flange clings to the inner side wall of the corresponding socket opening. Because the first flange, the second flange and the groove matching the first flange are provided, the plugging and pulling forces become varied, the commutator is left on one of the circuit boards when being pulled away, thereby, the operation time is saved and ineffective plugging and pulling actions reduced; in addition, the lockup between the shells is used to largely increase the plugging and adapting frequency. By taking advantage of the clearance between the commutator shell and the insulator thereof, the commutator deviates in the opening upon incorrect medium condition, as a result, the position is corrected automatically and the purpose of direct plugging and adapting is achieved.

Owner:宁波吉品科技有限公司

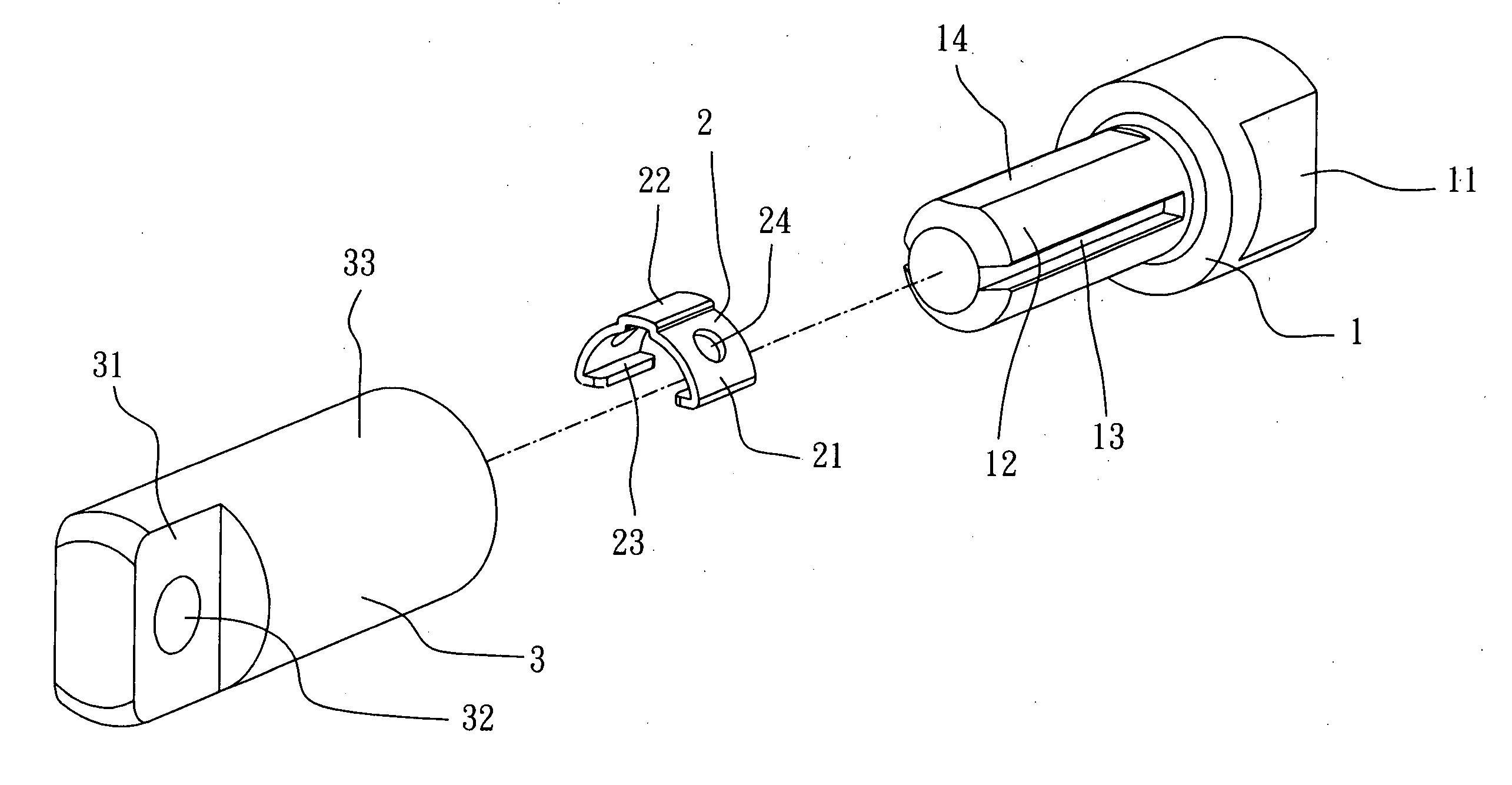

Sleeve joint type hinge

A sleeve joint type hinge includes a barrel, a pivot shaft, inserted into and rotatable relative to the barrel, and an arched resilient friction member, which has two hooked portions respectively extending from the two distal ends thereof and hooked on the periphery of the pivot shaft and a middle protruding portion kept spaced from a tangential peripheral plane of the pivot shaft and disposed in close contact with the inside wall of the barrel to produce a friction resistance and to hold the pivot shaft positively in positive after each rotary motion of the pivot shaft relative to the barrel by an external biasing force.

Owner:JARLLYTEC CO LTD

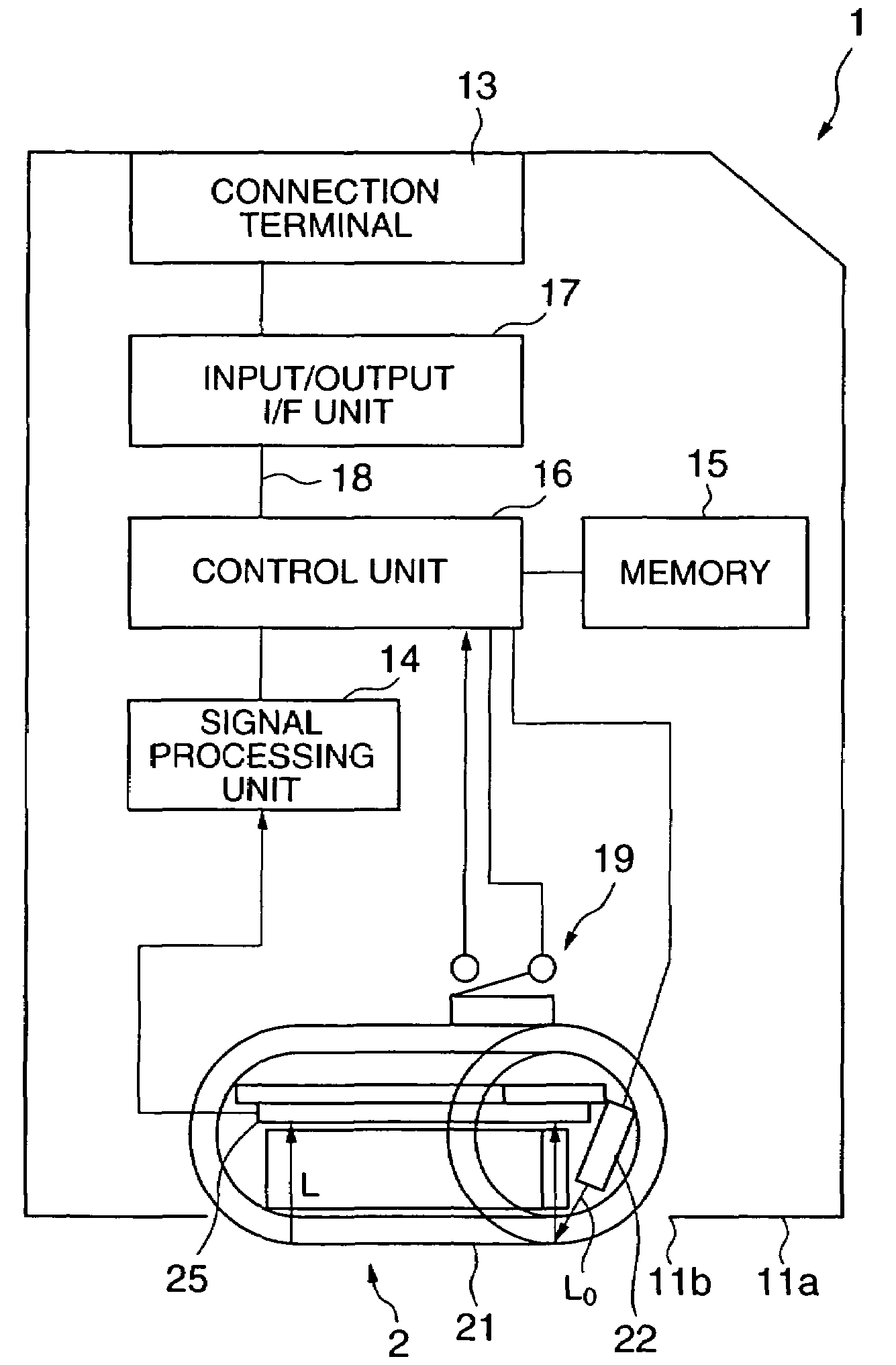

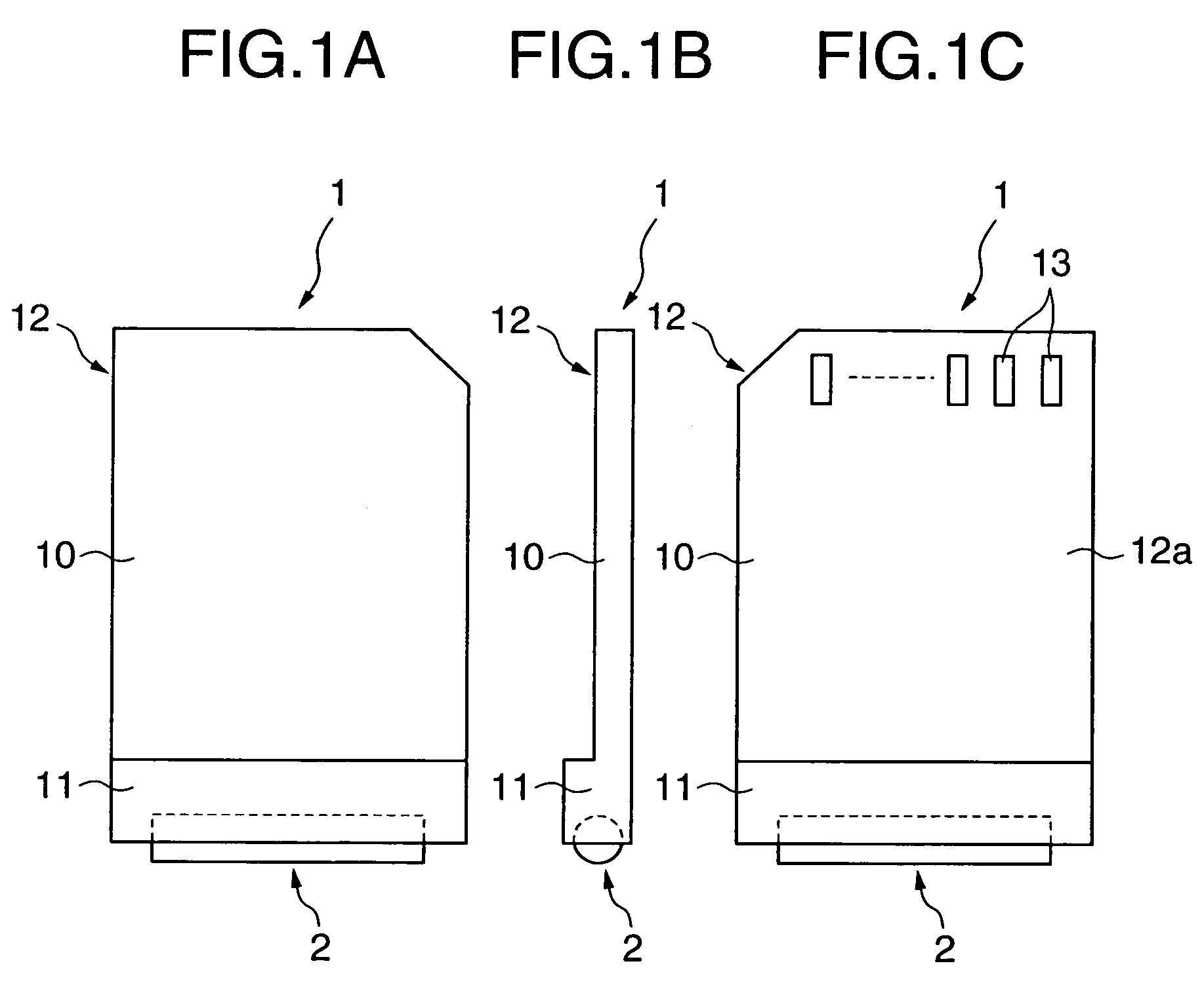

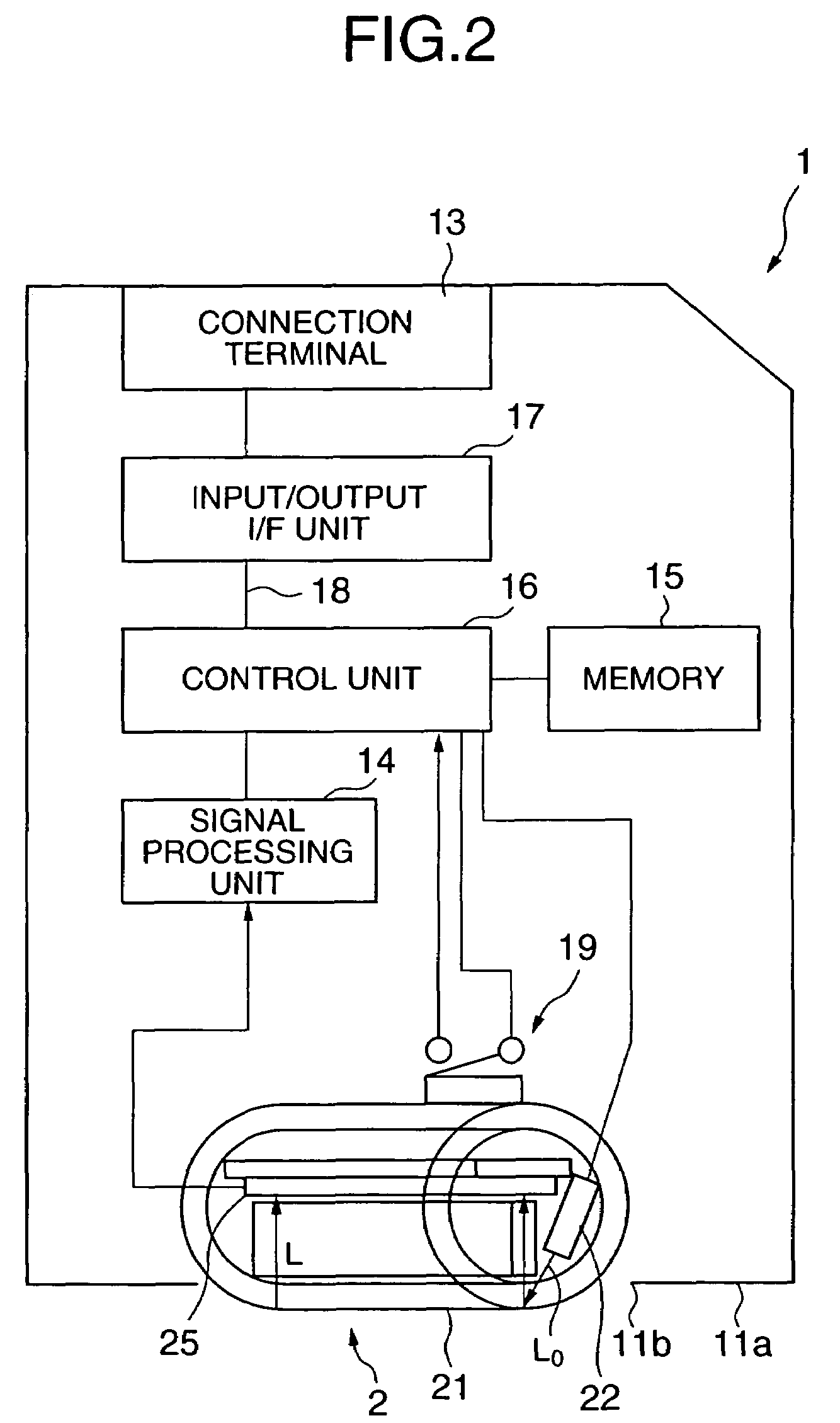

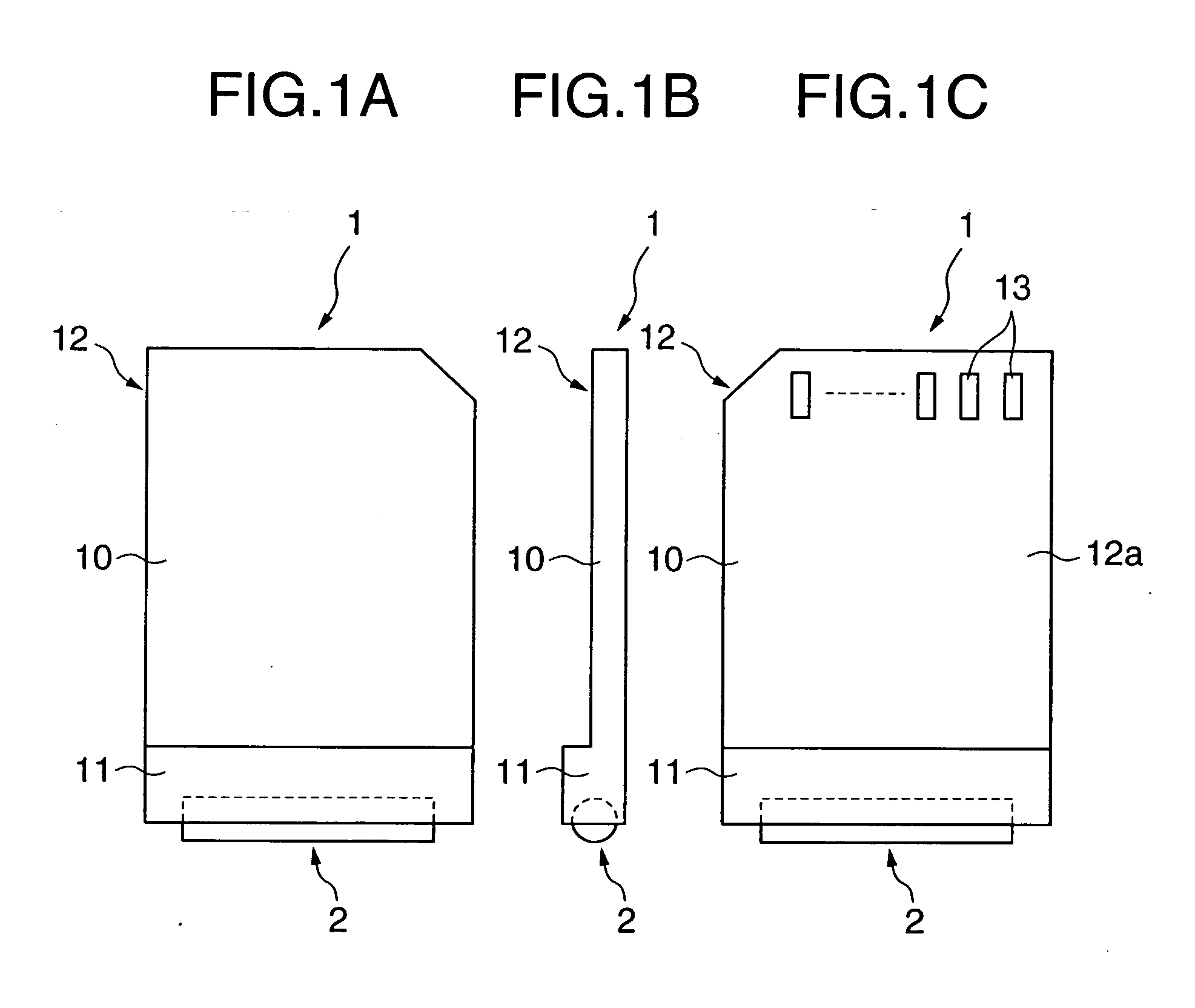

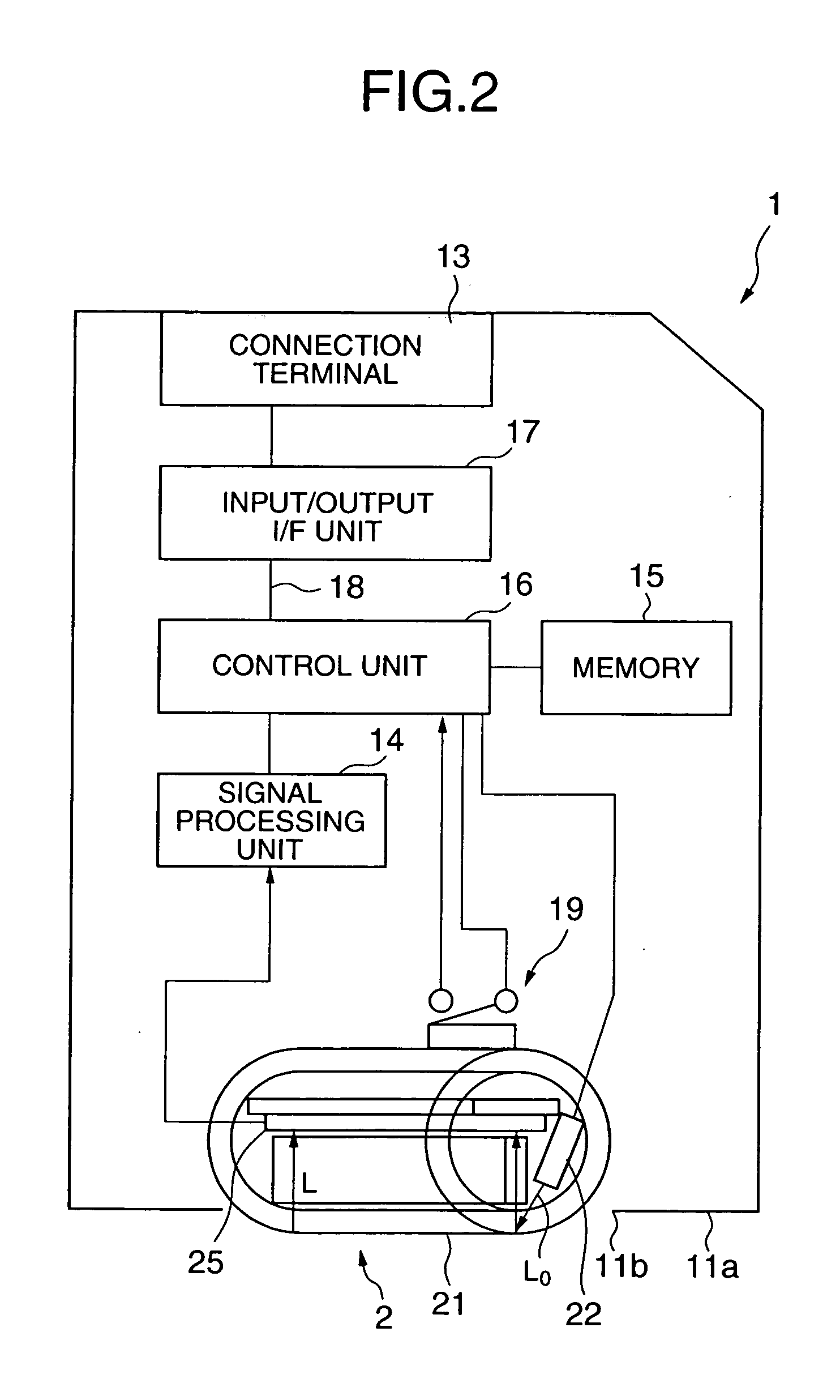

Card type device capable of reading fingerprint and fingerprint identification system

A card type device is mounted on a card slot of an electronic appliance. A transparent cylindrical-shaped roller is provided at an edge portion of a housing such that an outer peripheral plane of the roller is projected from the edge portion. A one-dimensional image sensor is provided inside the roller, which acquires one-dimensional fingerprint data of a finger of a user, and this fingerabuts against the outer peripheral plane of the roller. Since the finger abutting against the outer peripheral plane of the roller is moved, the roller is rotated, so that one-dimensional fingerprint data which are continuously acquired by the one-dimensional image sensor are synthesized with each other to produce fingerprint data as a two-dimensional image. The synthesized fingerprint data is transmitted to the electronic appliance which carries out fingerprint identification.

Owner:CASIO COMPUTER CO LTD

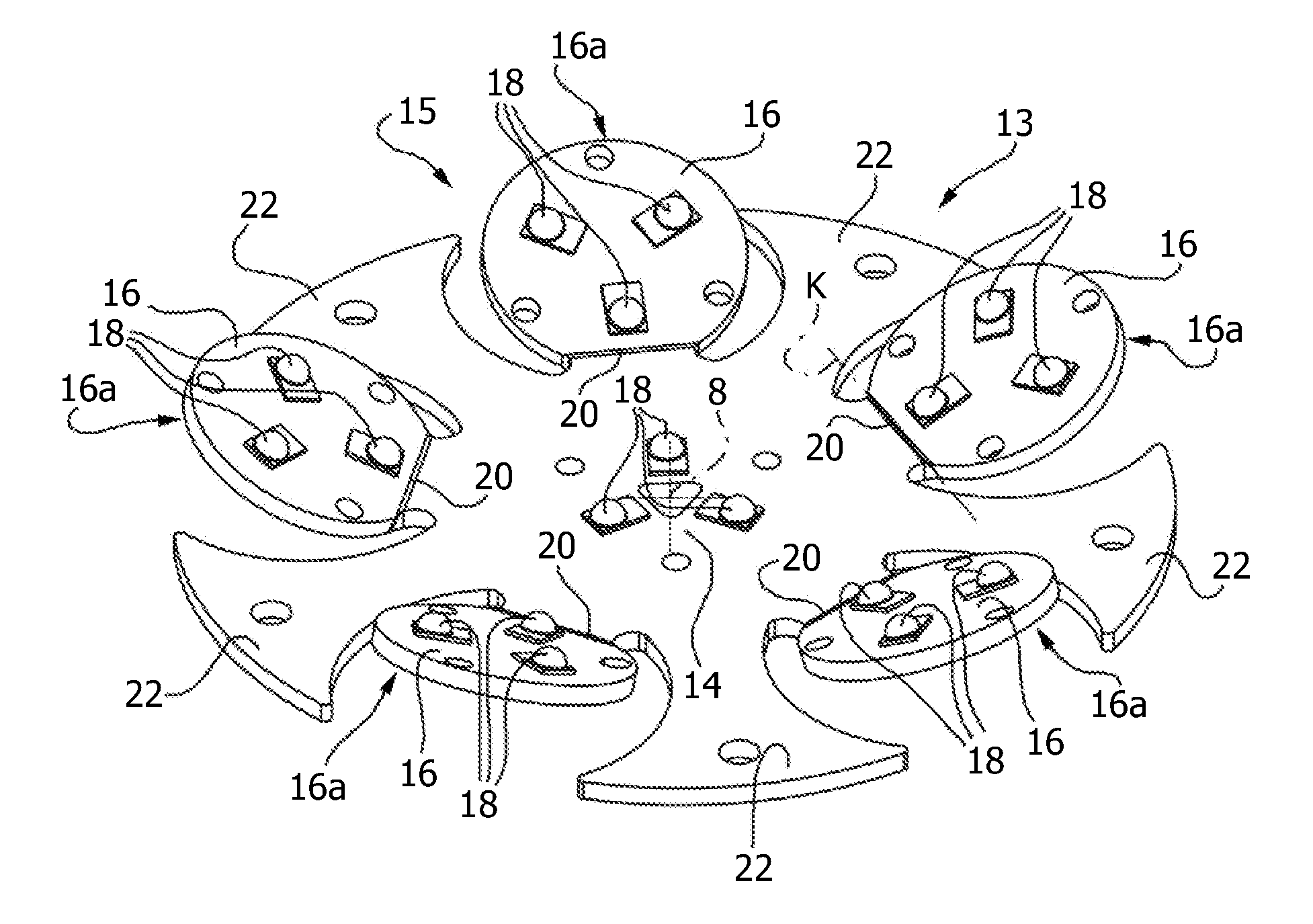

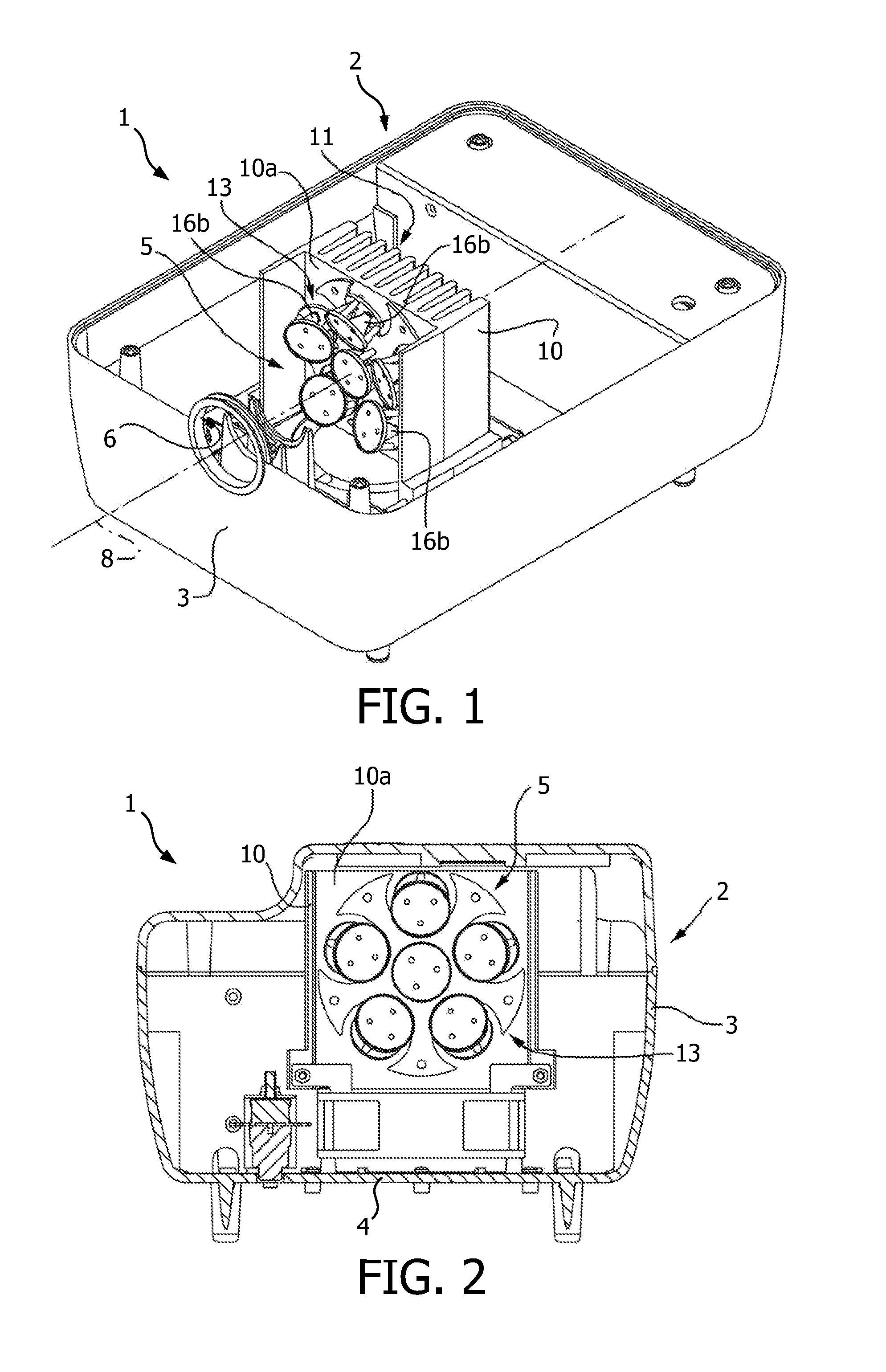

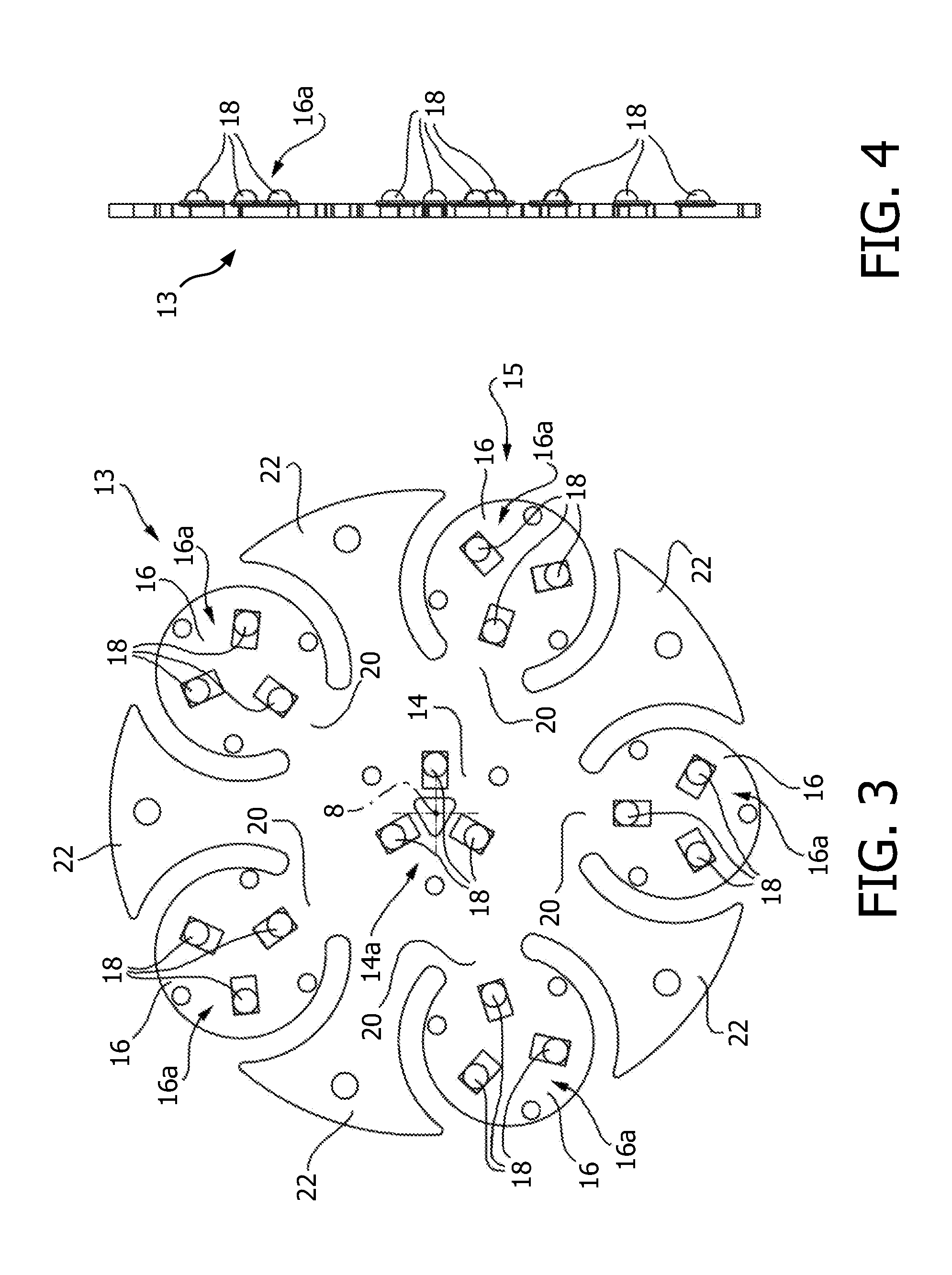

LED light emitting group

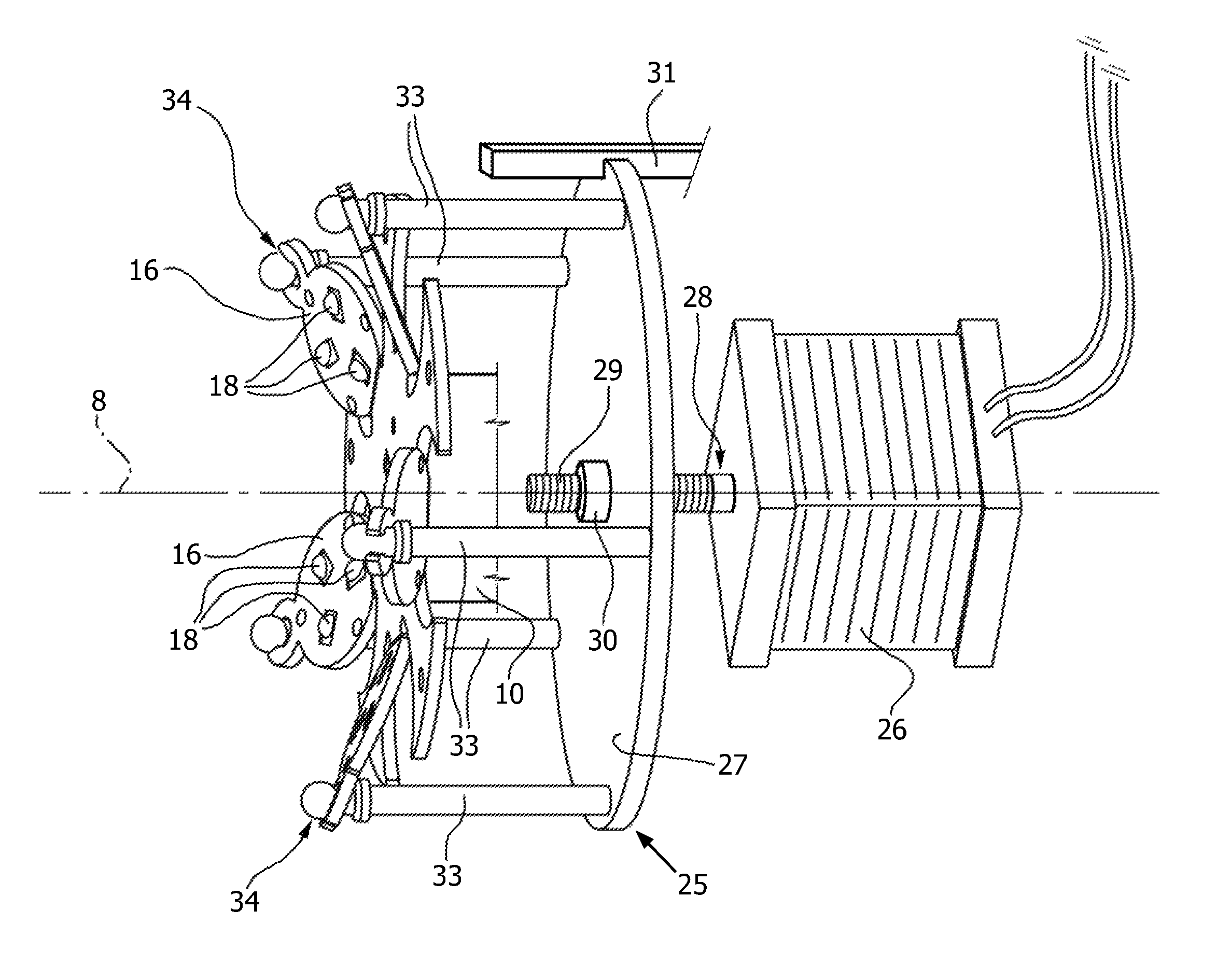

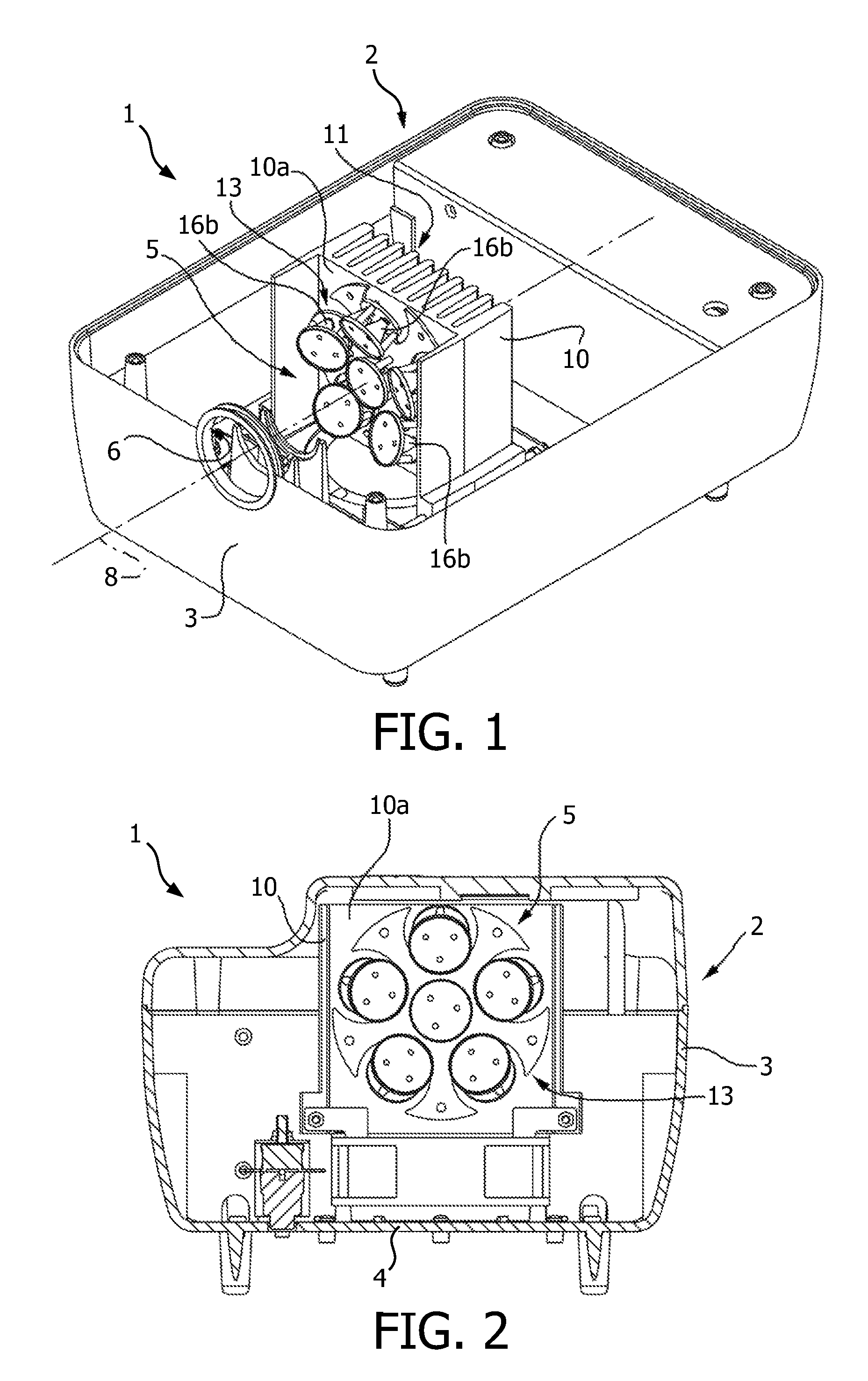

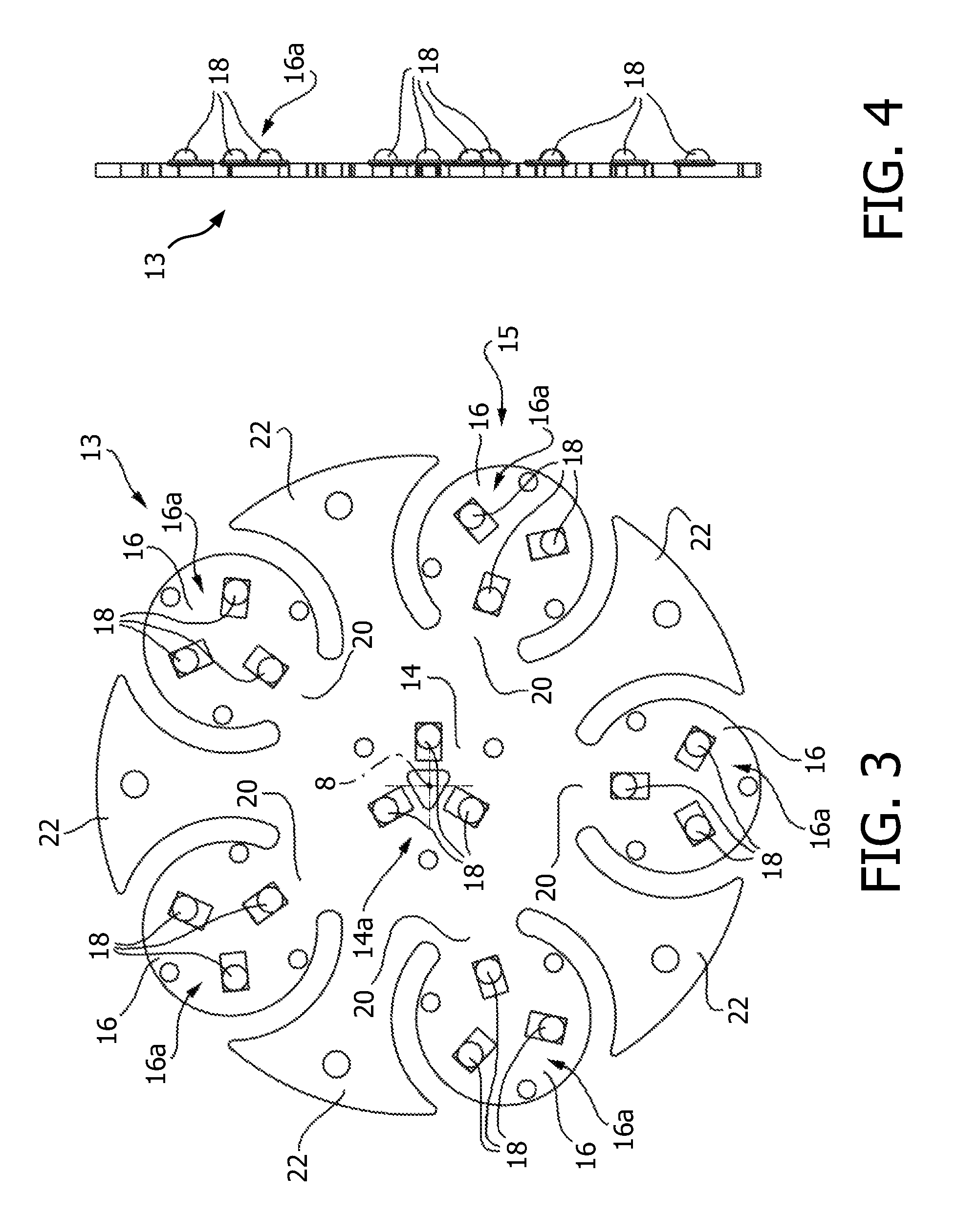

A LED light emitting group (1) apt to produce an outgoing light beam having its own optical axis (8) is equipped with a plurality of LEDs (18), distributed on a plate-shaped body (13) and having a fixed central plane portion (14) orthogonal to the optical axis (8) and a crown (13) of peripheral plane portions (16) tilted with respect to the central plane portion (14) and converging the one towards the other one and towards the central plane portion (14) and the optical axis (8); each one of said plane portions (14, 16) carrying a plurality of said LEDs (18).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

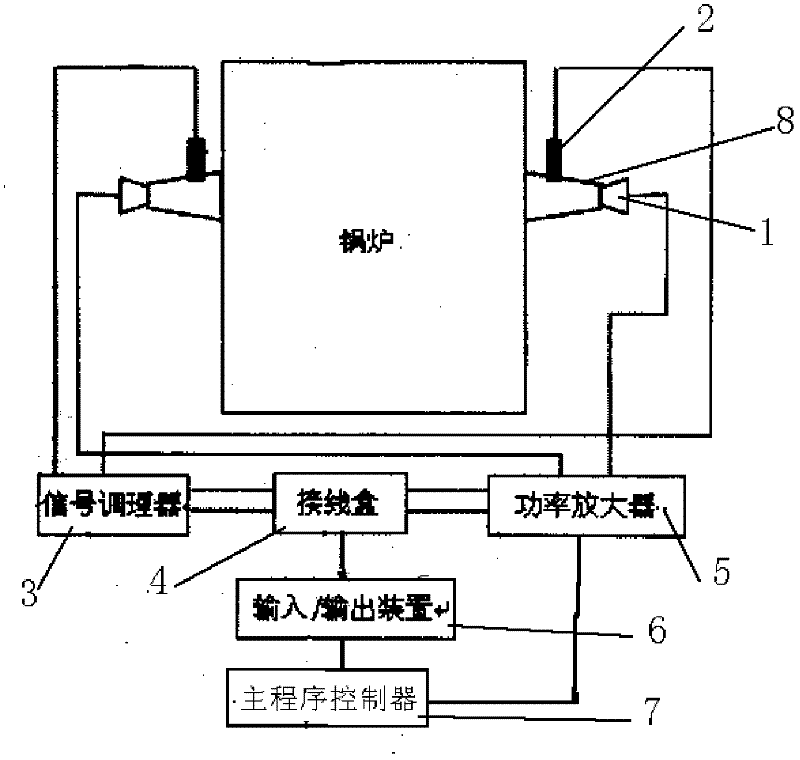

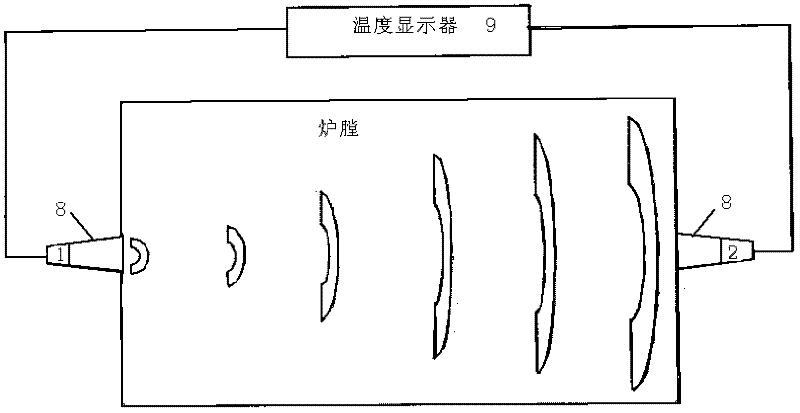

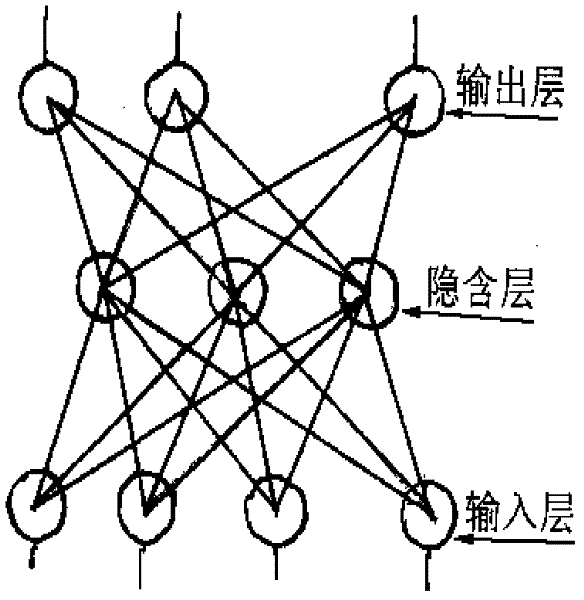

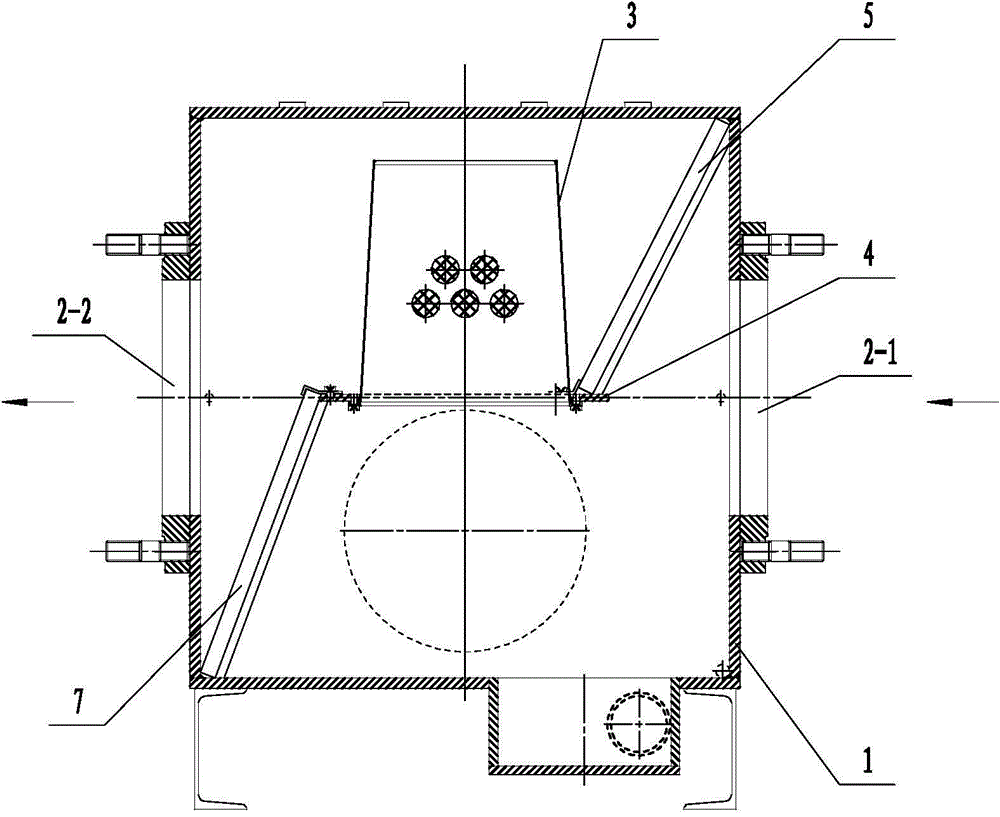

Monitoring system and monitoring method for soot on boiler convection heating surface

InactiveCN102588943AGuaranteed uptimeAvoid unplanned shutdownsBoiler indication operationsSlagData acquisition

The invention discloses a monitoring system and a monitoring method for soot on a boiler convection heating surface, which belong to the technical field of fuel burning on-line monitoring. A plurality of pairs of sound wave generators and sound wave receivers are installed on corresponding conduits on the peripheral plane of a boiler water-cooled wall, signal output of the sound wave receivers is connected with a signal regulator, the signal regulator is connected with a junction box through a data line, and the junction box is connected to a main machine programming controller through an input / output device. The monitoring system for the soot on the boiler convection heating surface is based on acoustical temperature measurement and a neural network. The monitoring system and the monitoring method for the soot on the boiler convection heating surface are respectively applied to the neural network and a data base, potential heat absorption capacity during cleaning of the boiler convection heating surface is predicted through the neural network, a data base system reads data in a data acquisition station (DAS) of a power station in fixed time, and finally a soot structure is conveyed to a main machine interface. The state of soot formation or slag build-up on the boiler heating surface can be timely learned, measures are taken in real time, normal running of a thermal generator set boiler is guaranteed, the running is safe, and accidental boiler shutdown accidents are avoided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

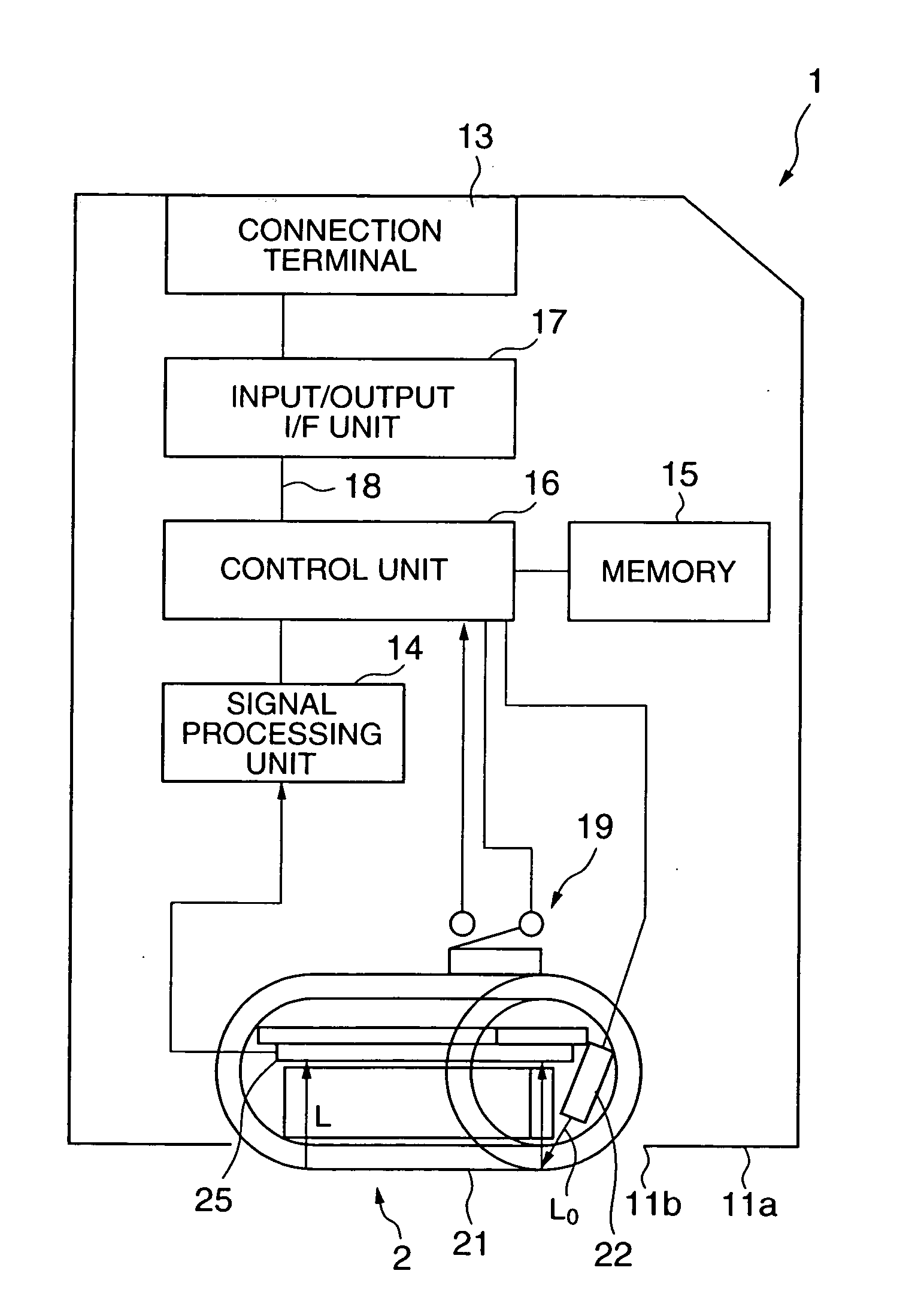

Card type device capable of reading fingerprint and fingerprint identification system

InactiveUS20050100197A1Limit its operationElectric signal transmission systemsImage analysisComputer hardwarePeripheral plane

A card type device is mounted on a card slot of an electronic appliance. In the card type device, a transparent cylindrical-shaped roller is provided at an edge portion of a housing in such a manner that an outer peripheral plane of this roller is projected from the edge portion. Also, a one-dimensional image sensor is provided inside the roller, while the one-dimensional image sensor acquires one-dimensional fingerprint data of a finger of a user, and this finger abuts against the outer peripheral plane of the roller. Since the finger a butting against the outer peripheral plane of the roller is moved, this roller is rotated, so that one-dimensional fingerprint data which are continuously acquired by the one-dimensional image sensor are synthesized with each other to produce fingerprint data as a two-dimensional image. The synthesized fingerprint data is transmitted to the electronic appliance, and then fingerprint identification is carried out by the electronic appliance.

Owner:CASIO COMPUTER CO LTD

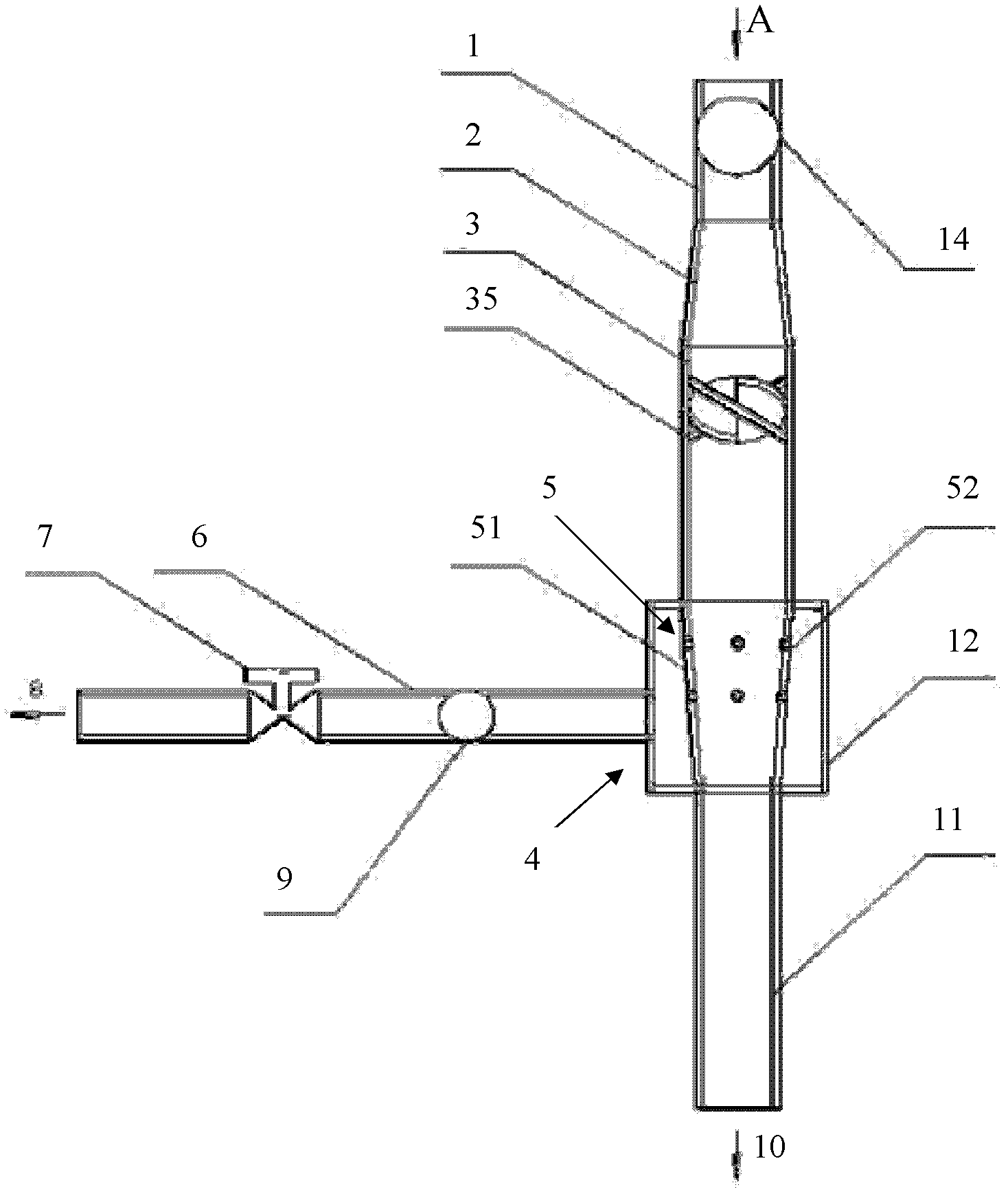

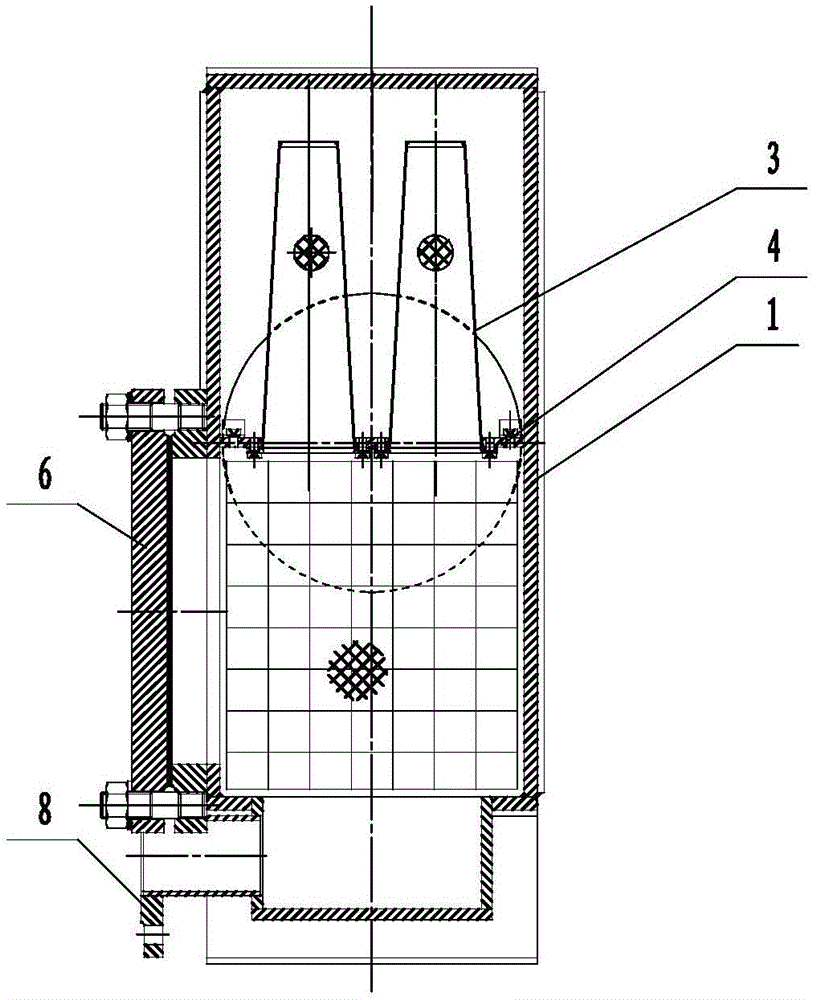

Dewatering apparatus and oil-water cyclone separator of pipe type distributor oil-water separator

ActiveCN102423549AImprove separation efficiencyImprove adaptabilityFluid removalSingle direction vortexCyclonePulp and paper industry

The invention discloses a dewatering apparatus of a pipe type distributor oil-water separator. The apparatus comprises a dewatering pipe with an oil-water inlet and an oil-water outlet. More than one set of dewatering holes are arranged on the dewatering pipe along an axial direction of the dewatering pipe. External peripheral planes of the dewatering holes are tangent with the inner wall of the dewatering pipe. The dewatering hole diameter d' is no larger than bD-calphaD, wherein b an c are constants, D is a diameter at the outlet, and alpha is an oil content at the inlet. The invention also discloses an oil-water cyclone separator. According to the invention, the external peripheral planes of the provided dewatering holes are tangent with the inner wall of the dewatering pipe, and the dewatering hole diameter d' is no larger than bD-calphaD, such that the diameters of the dewatering holes can be regulated according to the oil content, and an oil-water separating effect is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

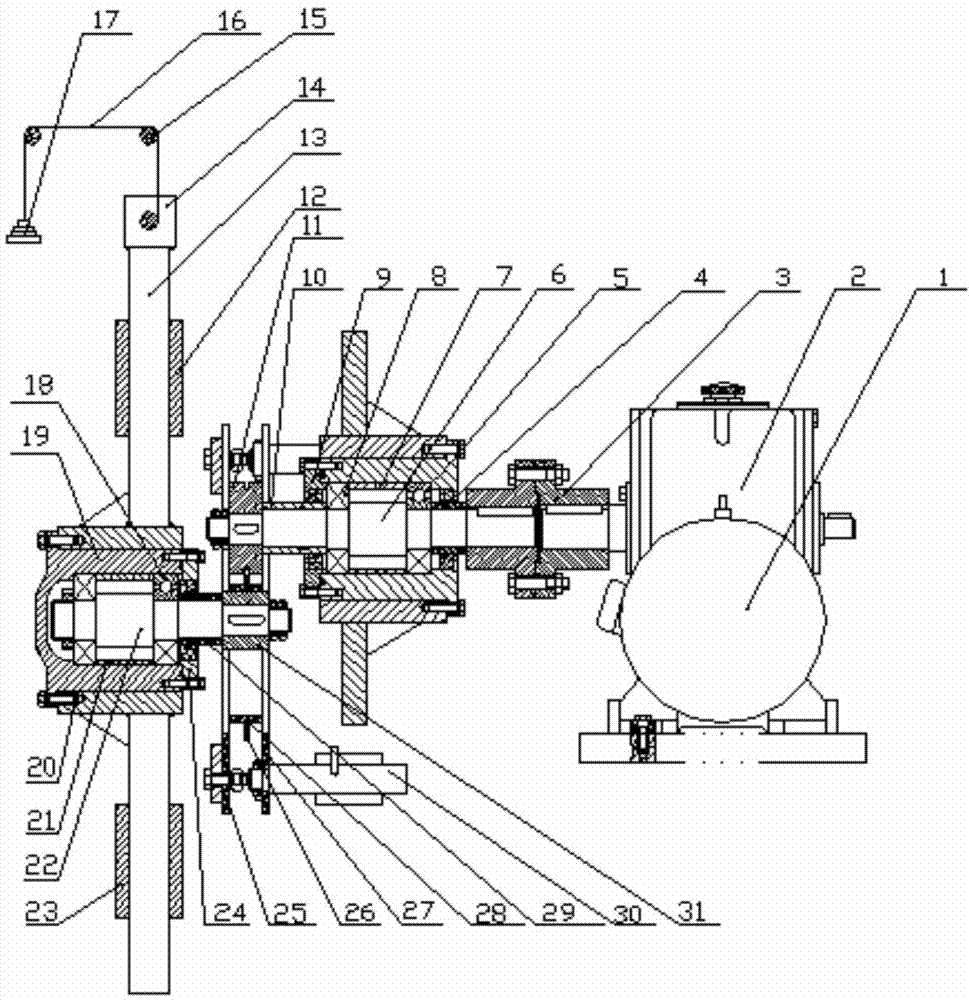

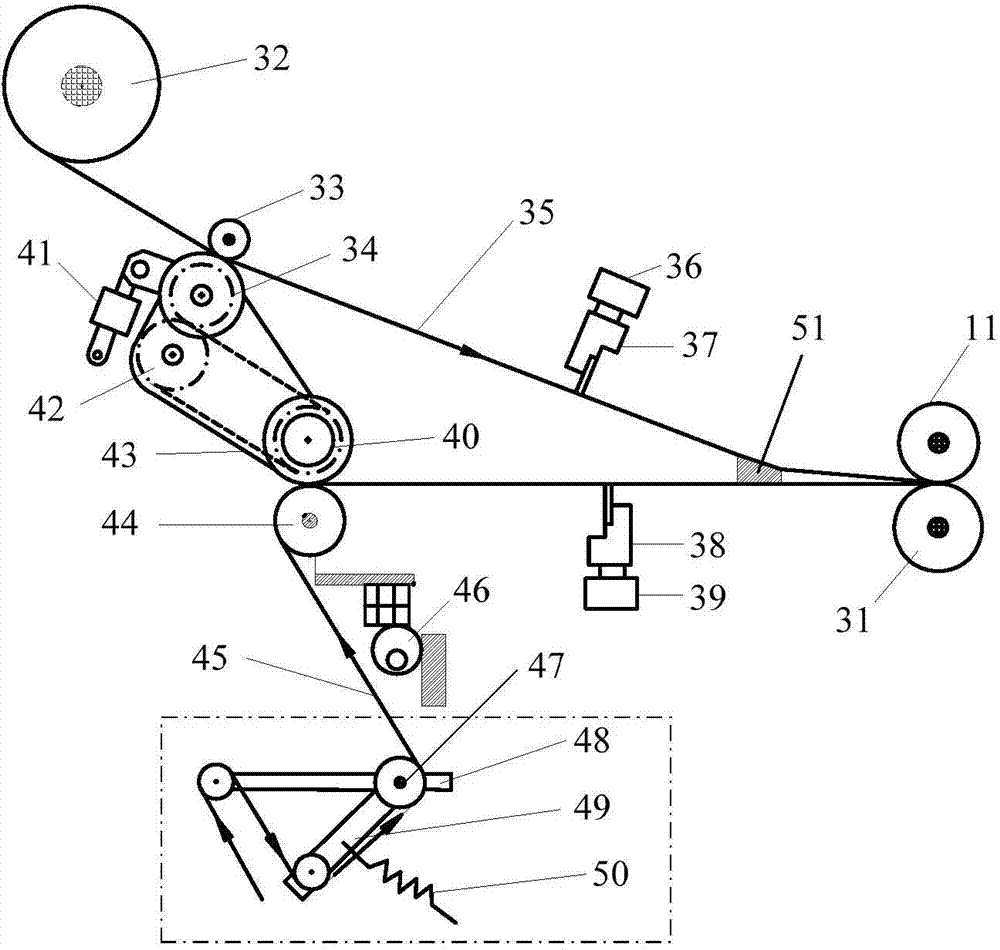

High-efficiency winding machine for flexible graphite metal spiral wound gasket

The invention relates to a high-efficiency winding machine for a flexible graphite metal spiral wound gasket, which mainly comprises a transmission mechanism and a winding feeding mechanism. In the transmission mechanism, an electric motor is connected with a speed reducer; an output shaft of the speed reducer is provided with a coupling and is connected with a compression wheel shaft; the compression wheel shaft is supported on a fixed support by adopting a bearing through a compression wheel shaft right end cover; a guide round rod is welded on the peripheral plane of an end cover support; the upper end of the guide round rod is welded with a welding block; a steel wire rope passes across a pulley on a fixing device; and the other end of the steel wire rope is connected with a counter weight. In the winding feeding mechanism, a graphite ribbon is connected between a compression wheel and a graphite ribbon reel; a guide block is arranged at the position between the graphite ribbon and a metal belt; the metal belt passes across an A wheel to be connected with a fixed arm arranged below the A wheel; and an eccentric mechanism is arranged between the A wheel and the fixed arm. According to the invention, quality of a domestic spiral wound gasket can be improved, so that the domestic spiral wound gasket meets more and more harsh working conditions in large-scale chemical production equipment; and the high-efficiency winding machine for the flexible graphite metal spiral wound gasket has more complete functions and a higher automation degree.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

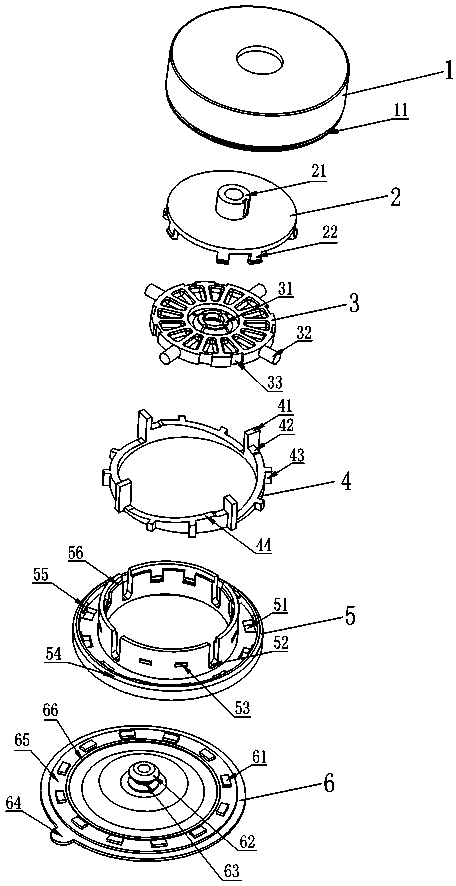

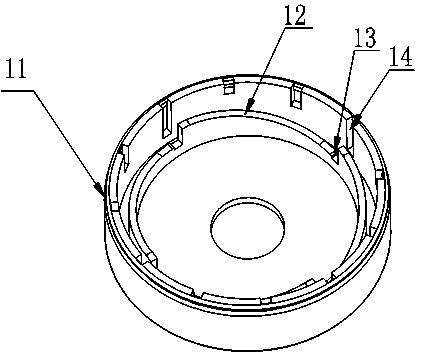

Vacuum sucker

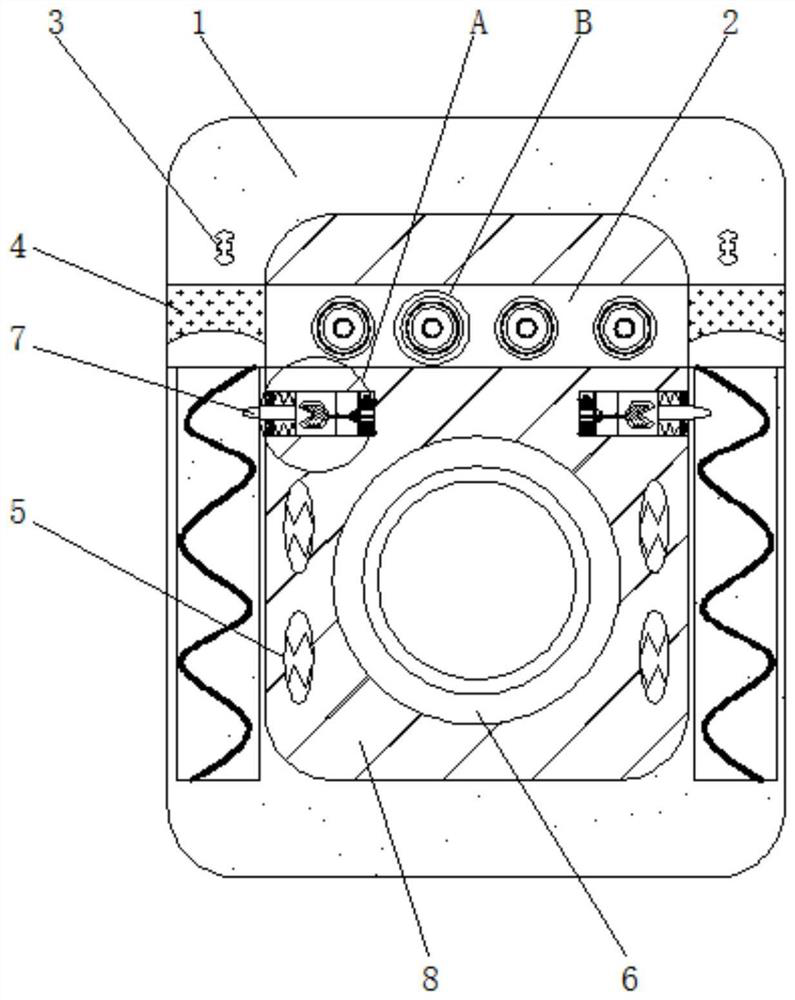

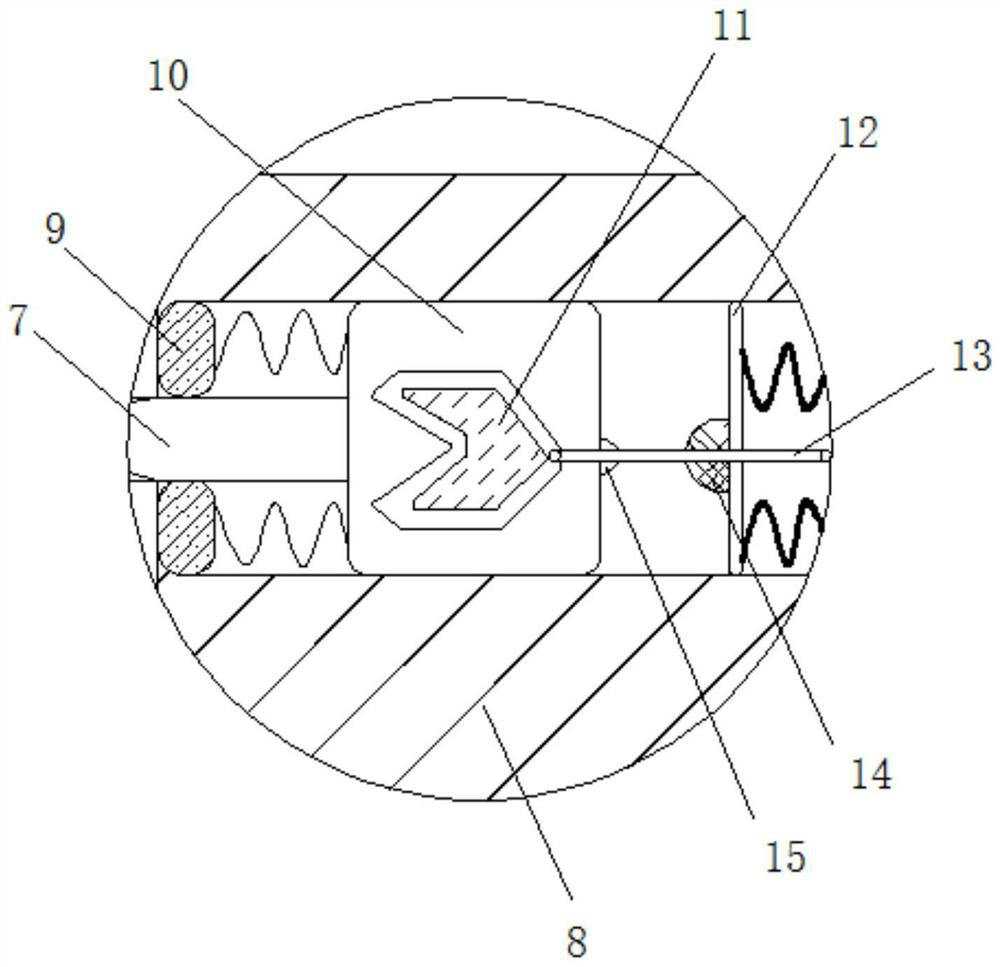

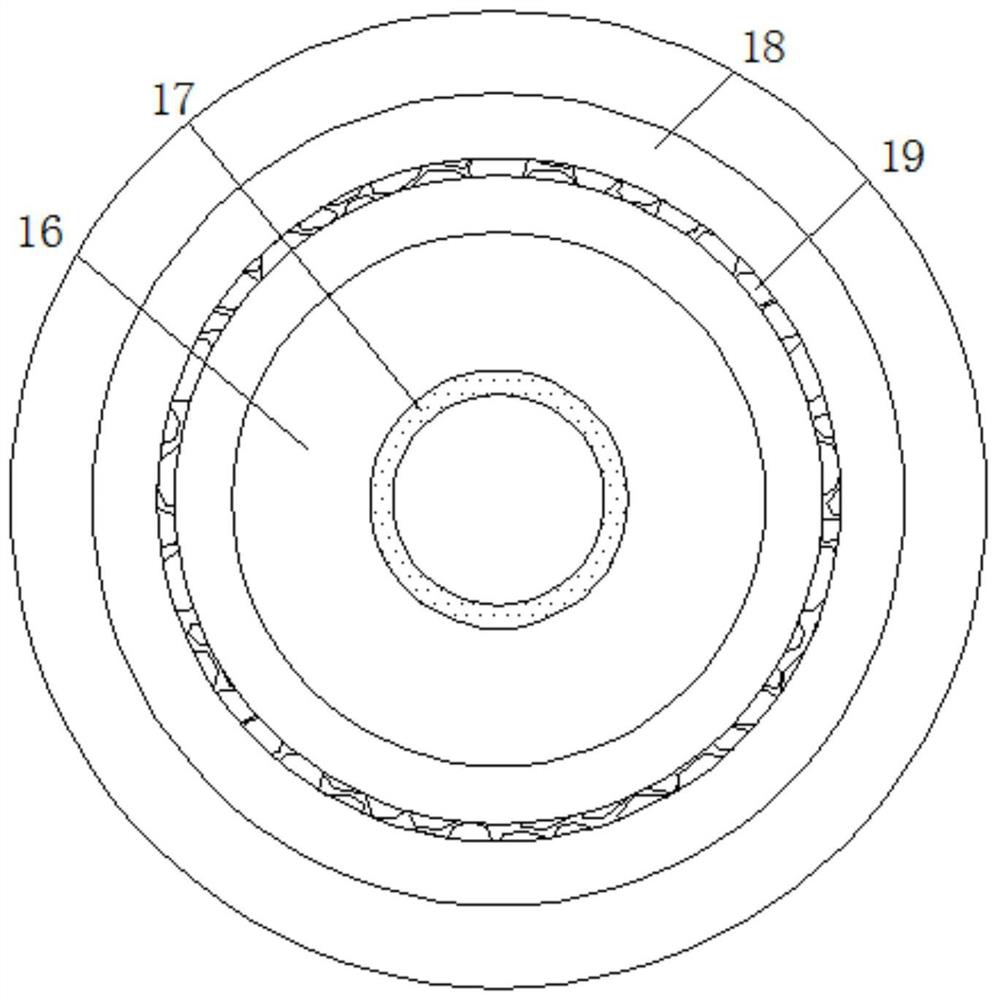

ActiveCN103953637ADoes not affect adsorptionIncrease the force rangeKitchen equipmentDomestic articlesPeripheral planeEngineering

A vacuum sucker comprises a cover, a compressing seat, a height adjustment piece and a suction wrapper which are connected into a whole, wherein the upper end and the lower end of the compressing seat are connected with a connecting seat and the suction wrapper; the inner side and the outer side of the compressing seat are connected with the height adjustment piece and a guide ring; the guide ring is matched with the height adjustment piece to allow the height adjustment piece to drive the suction wrapper to move upwards; a hanger is mounted on the connecting seat; a center pole on the suction wrapper is connected with the height adjustment piece into a whole; and the cover is connected with the compressing seat into a whole.The parts forming the sucker are concentric independent pieces; the sucker is simple in structure, easy to manufacture and high in precision; the compressing seat serves as a foundation; the parts are buckled and mounted on the compressing seat; stripping and air leakage affecting a use effect and an adsorption force do not happen; the outer side of the compressing seat is sleeved with the guide ring; the guide ring is matched with the height adjustment piece, so that a stress scope of the suction wrapper is moved to a peripheral plane from the middle; a vacuum space and the adsorption force are greatly extended and increased; and the sucker can be absorbed on an absorption surface without falling for a long time.The center pole connected with the hanger is divided into two independent parts, and the hanger is not directly fixed at the middle part of the suction wrapper, so that the sucker is good in use effect, long in service life and more practical, and the adsorption force can be increased by 20%.

Owner:浙江西塘实业有限公司

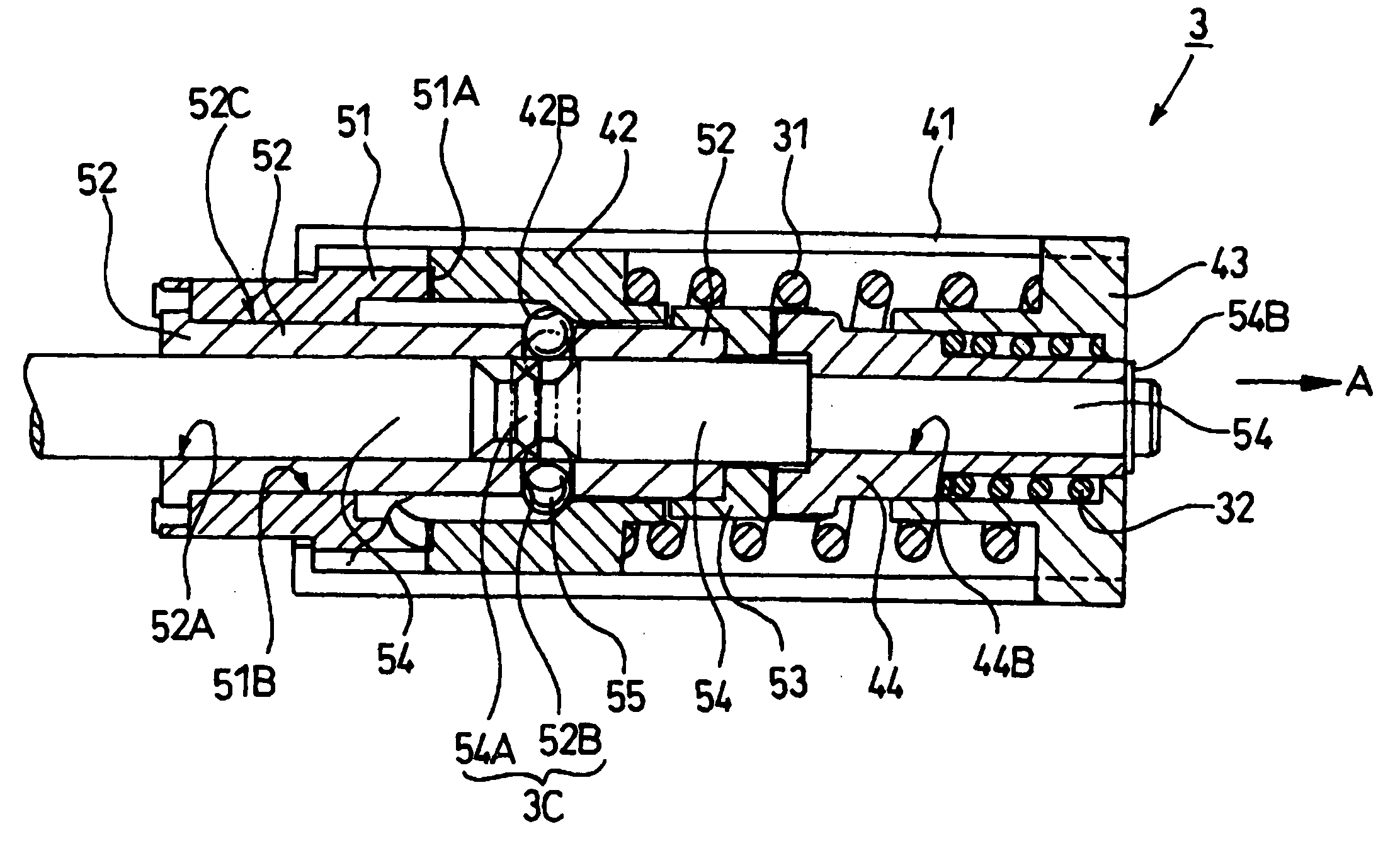

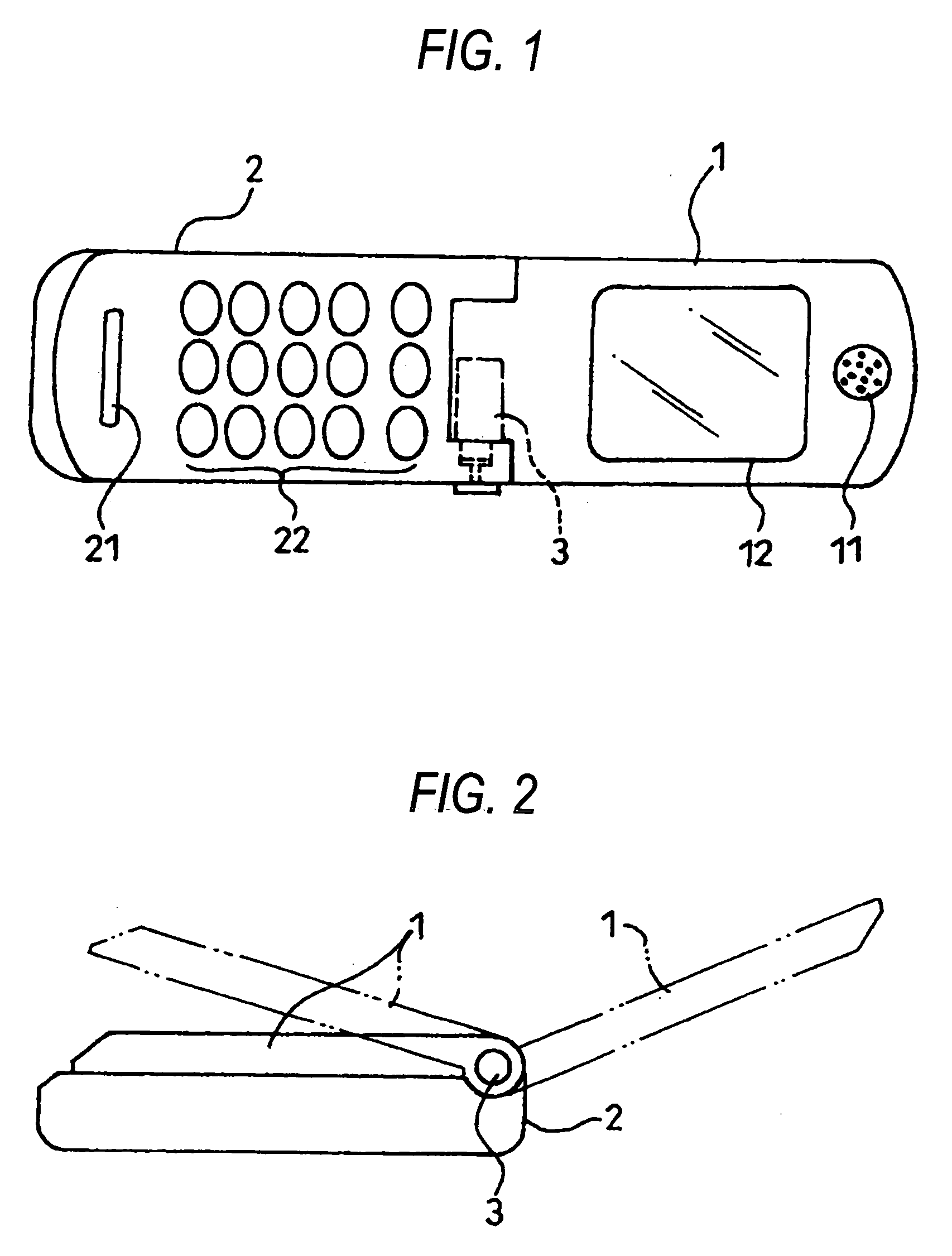

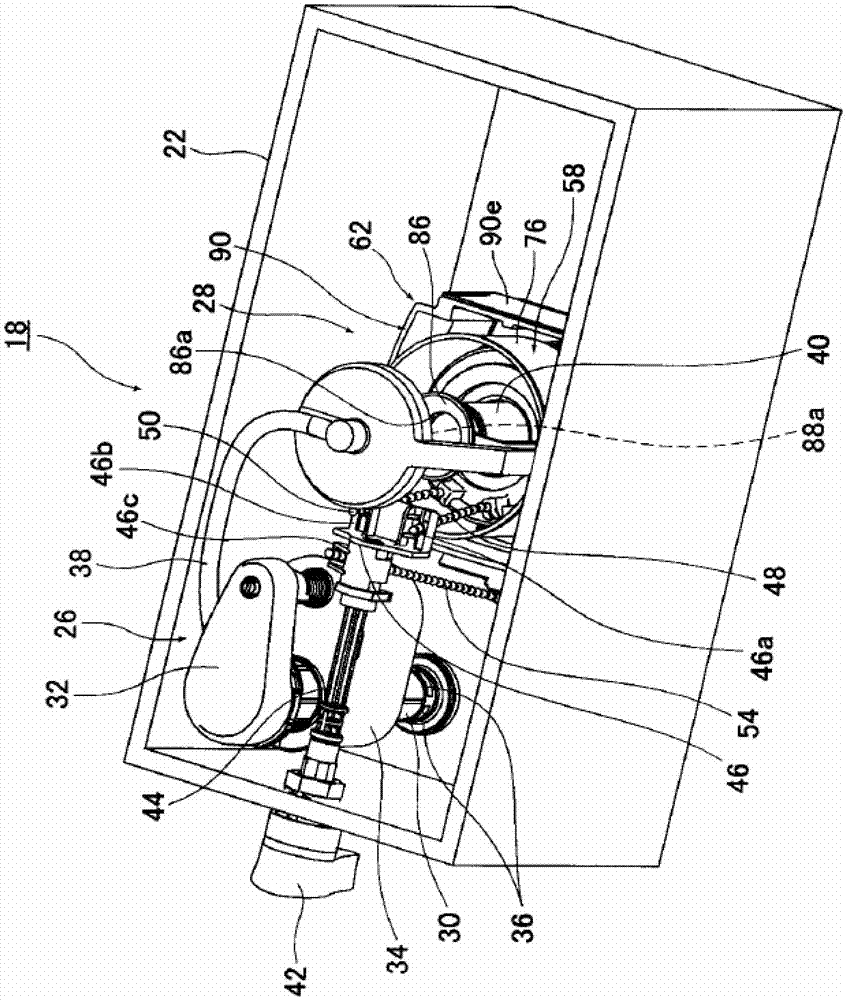

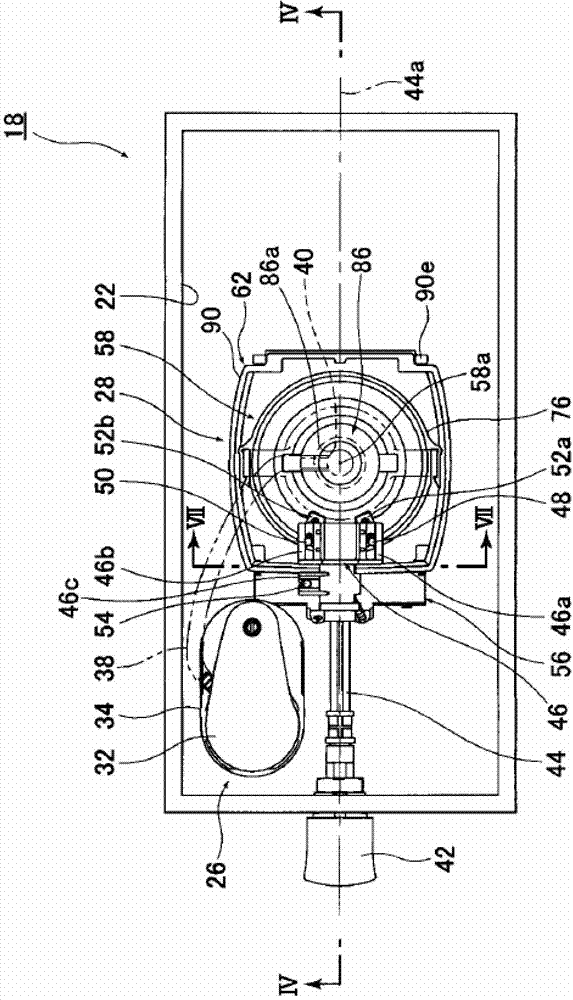

Opening/close device and mobile phone provided with the device

InactiveUS20060210059A1Manipulating force can be decreasedEasy to implementInterconnection arrangementsPivotal connectionsMiniaturizationEngineering

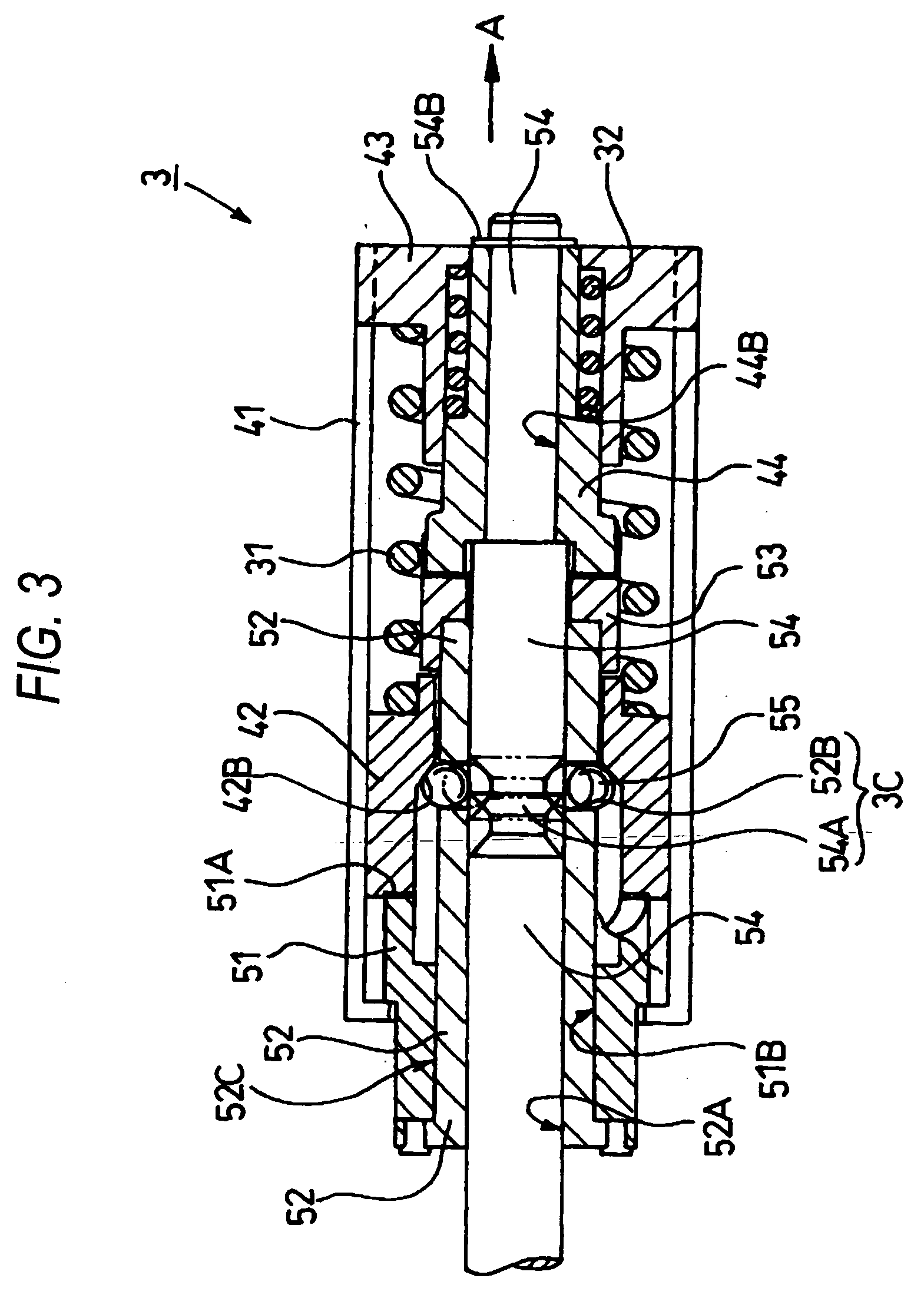

A purpose of the present invention is to provide an opening / closing apparatus and a portable telephone apparatus equipped with the opening / closing apparatus capable of reducing manipulation force used when housings are expanded, and at the same time, capable of making compact. The opening / closing apparatus for expanding the housings has: a base (43) which is fixed within a rotary member (41) having a substantially hollow tube shape; a fixing holder (52) which is allowed to be moved only along an inner peripheral plane direction of the rotary member (41); a driving cam portion (3A) having both a fixing cam member (51) and a first compression spring (31); a holding cam portion (3B) having a lift cam member (53) which is coupled to the fixing holder (52), a slide cam member (44) which is engaged with the base (43) and can be slid along a shaft direction, and a second compression spring (32) which is elastically provided between the slide cam member (44) and the base (43); and also, a clutch portion (3C) having a ball (55) which engages the rotary cam member (42), and a cam shaft (54) having a cam groove (54A) engaged with the ball (55), which is slid with the slide cam member (44) in an integral form along the shaft direction.

Owner:PANASONIC CORP

Steel reinforced concrete precast slab

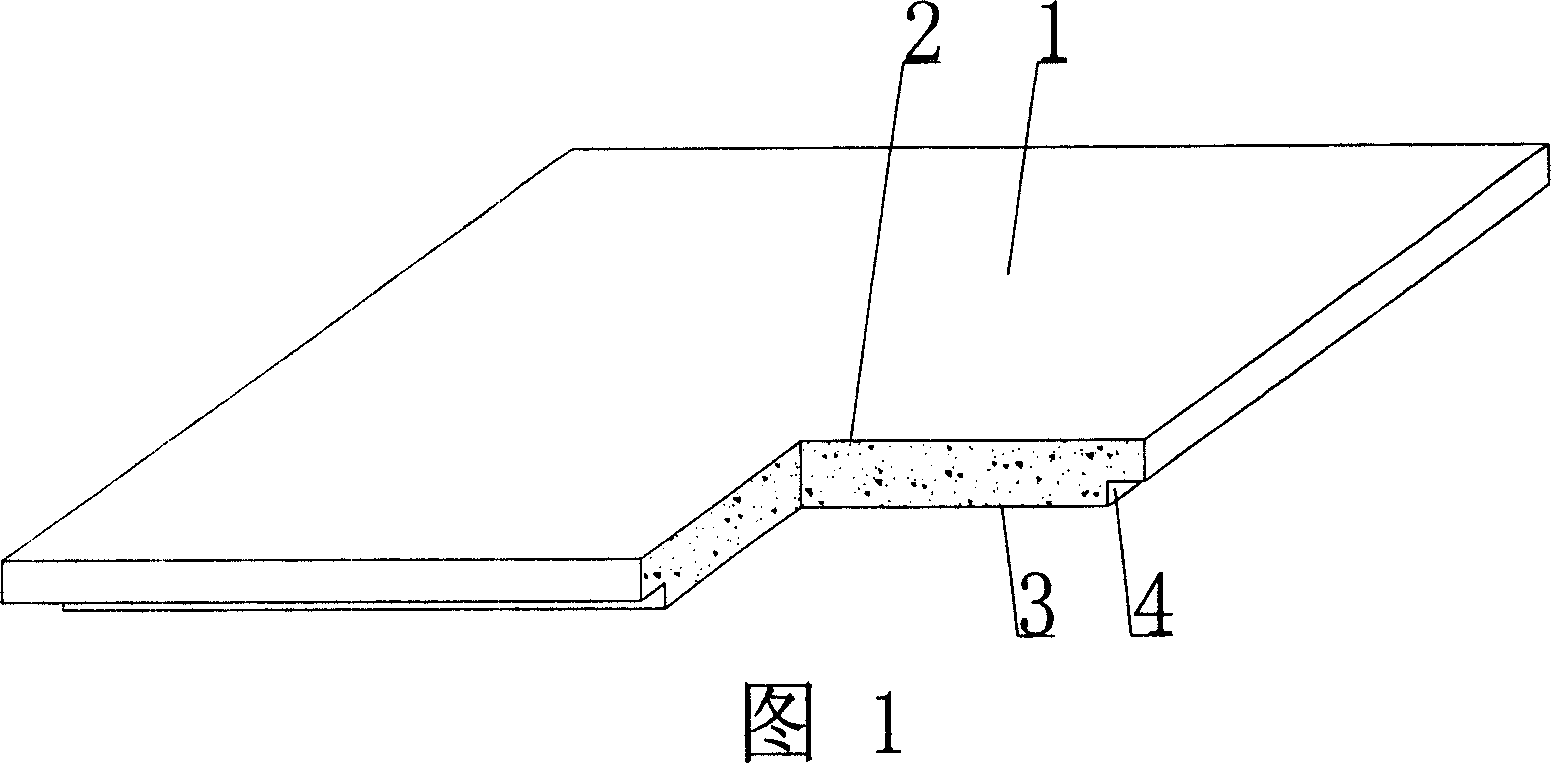

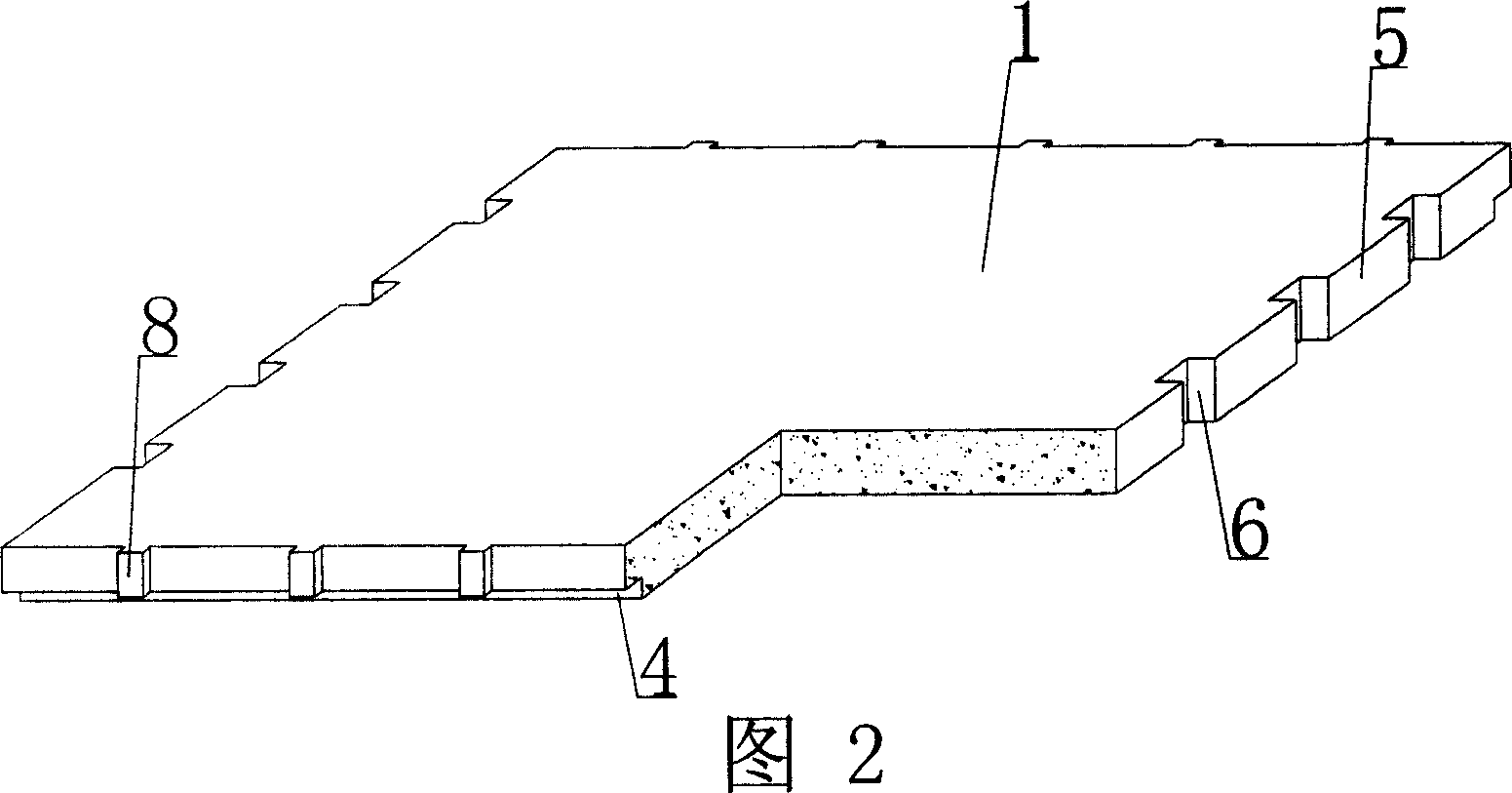

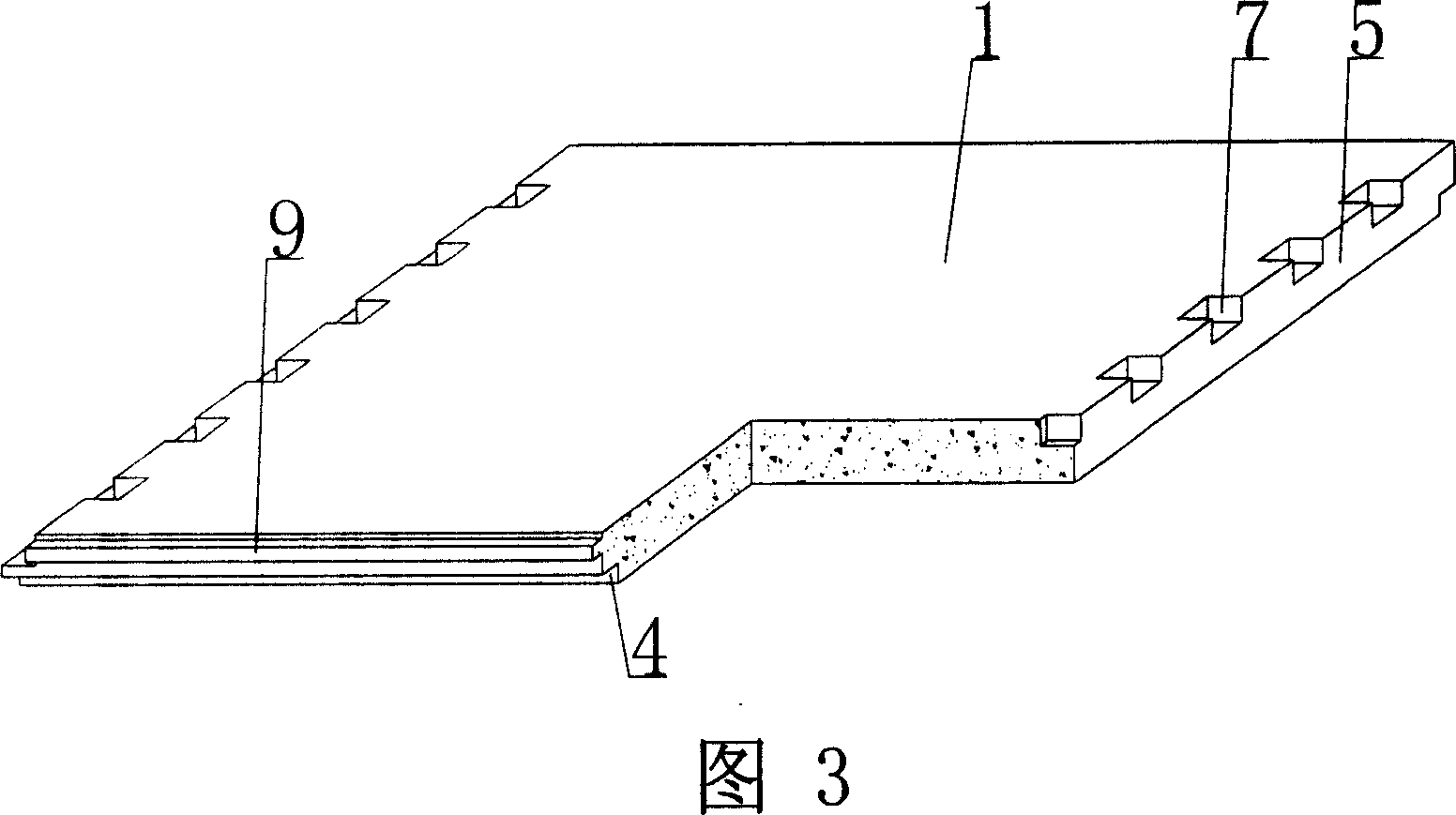

The reinforced concrete prefabricated slab includes one slab, and features that the slab has steps in the upper or the lower peripheral planes. The present invention is suitable for in-situ cast or pre-stressed reinforced concrete hollow floor slab, roof, wall, foundation slab and hollow bridge, especially hollow flat floor slab.

Owner:邱则有

Sealed bearing

InactiveUS20100322541A1Shrink the necessary spaceIncrease pressureEngine sealsBearing componentsDual effectPeripheral plane

The invention relates to a sealed bearing which comprises a body with a general cylindrical configuration for its assembly in the housing of a mold or support body, and has a cylindrical inner hole for the assembly and balancing of the tight movement of a rotary shaft or core pin provided with internal cooling. The body has: an inner channel for the assembly of a dual-effect rotary seal activated by a first O-ring seal; an outer channel for the assembly of a second O-ring seal for the static sealing of the bearing in the housing of a mold or support part; and, at one of its ends, a head with peripheral planes and threaded holes for its grip and extraction from the housing of the mold or support part.

Owner:COMML DE UTILES Y MOLDES

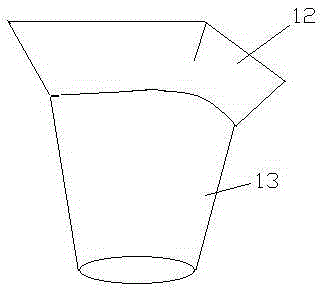

Combined water cleaner

ActiveCN104785004AQualified water filtration functionReduce energy costsStationary filtering element filtersWater filterEngineering

The invention relates to a combined water cleaner. The combined water cleaner is characterized by comprising a rectangular case, wherein a water inlet is arranged on the right side of the case, a water outlet is arranged on the left side of the case, and a middle supporting plate is arranged in the case and divides the inside of the case into upper-layer space and lower-layer space; the front side and the rear side of the middle supporting plate are connected with inner side walls of the case respectively, and the left side edge and the right side edge of the middle supporting plate are a certain distance away from the inner side walls of the case respectively; an upper filter plate is arranged between the right side edge of the middle supporting plate and the upper corner of the right side of the case, and a lower filter plate is arranged between the left side edge of the middle supporting plate and the lower corner of the left side of the case; one or more filter tanks are formed transversely in the middle supporting plate and extend into the upper-layer space of the case from the middle supporting plate, and the lower end of the one or more filter tanks is a tank opening. Each filter tank has five planes and the peripheral planes of each filter tank all incline towards the corresponding filter tank from the upper end. The combined water cleaner has a qualified water filter function, and the energy consumption and the water resistance are low.

Owner:薛铭

High-simulation digital mold ceramic tile and preparation method thereof

The invention discloses a high-simulation digital mold ceramic tile and a preparation method thereof, and relates to the technical field of architectural ceramic. Before color ink is applied, a ground glaze layer, a mold ink layer, a cover glaze layer and a color glaze layer are sequentially arranged on a ceramic tile green body, and by controlling main glaze components of the ground glaze layer, the mold ink layer and the cover glaze layer to be kept consistent, the concave part is enabled to be consistent with the peripheral plane or the convex part in glaze component after the ceramic tile is fired, so that the same influence is generated on the color development of color ink at the concave part and the peripheral plane or the convex part and the gloss of the upper protective glaze layer, the uniform and consistent color development and gloss of patterns at the concave part and the peripheral plane or the convex part are ensured, the pattern color and luster transition is natural, the surface texture of the digital mold ceramic tile is remarkably improved, and a ceramic tile product which is closer to the surface effect of real stone, wood, cloth, leather and other materials is obtained.

Owner:佛山科海意诺陶瓷科技有限公司

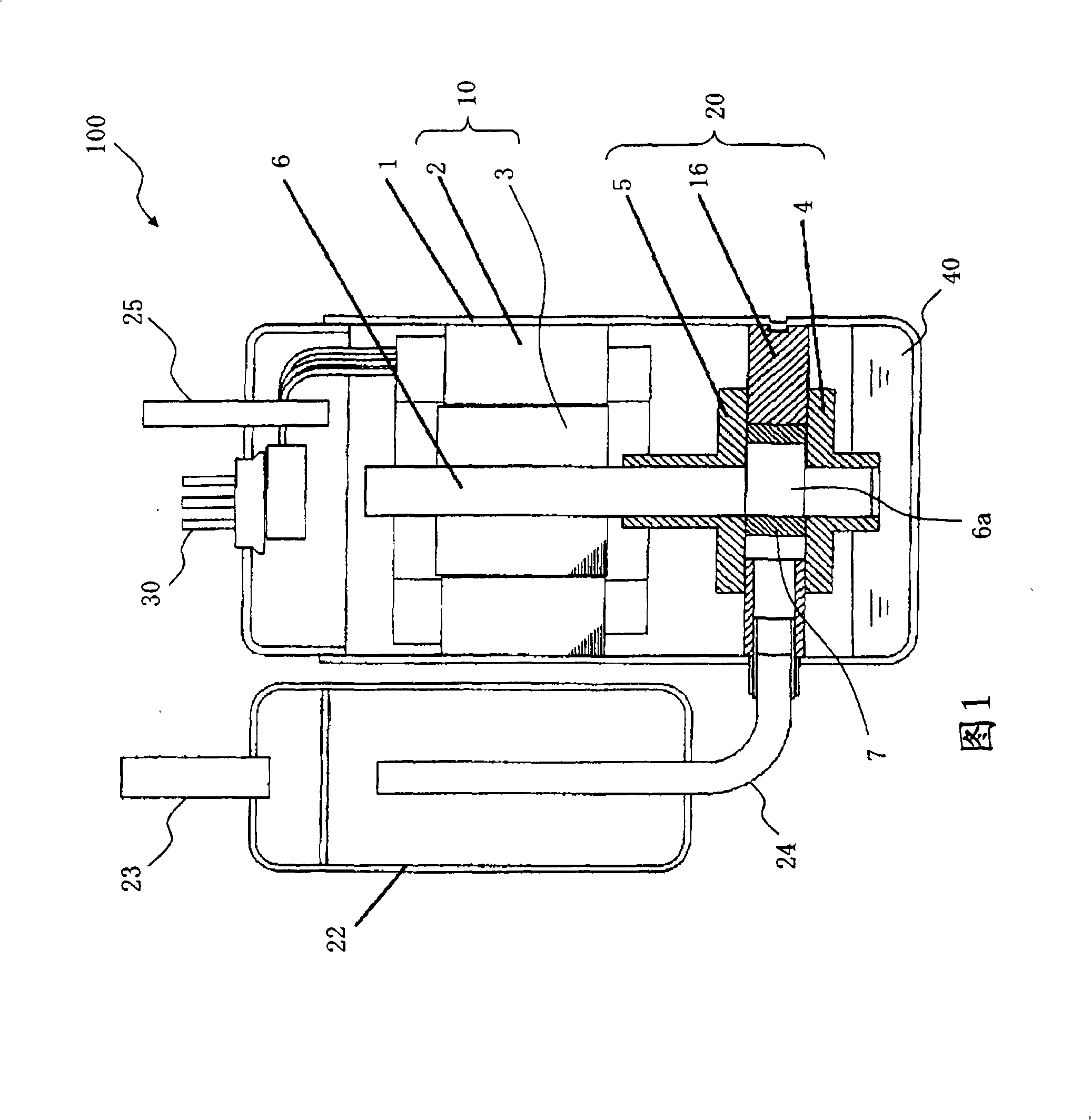

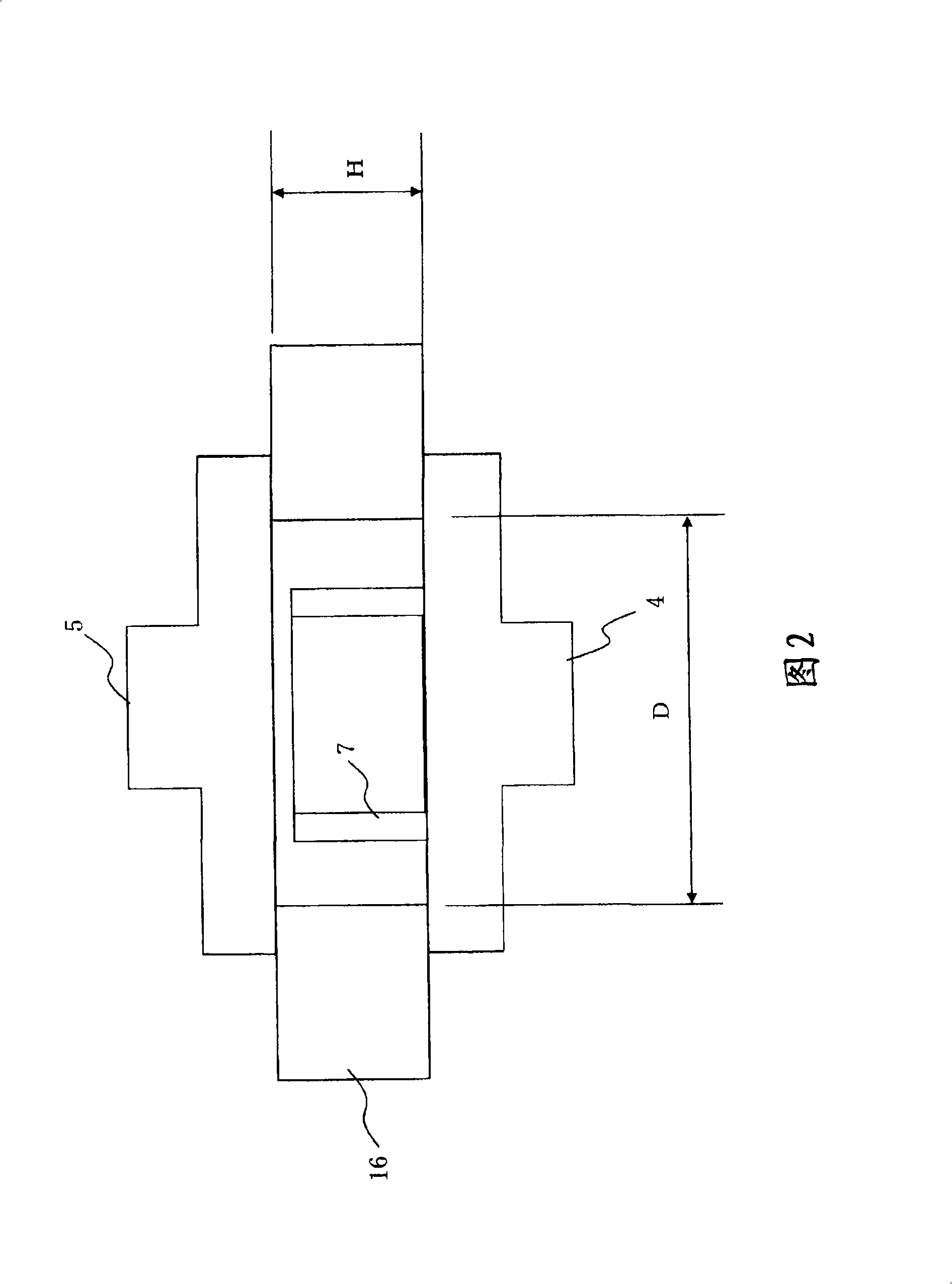

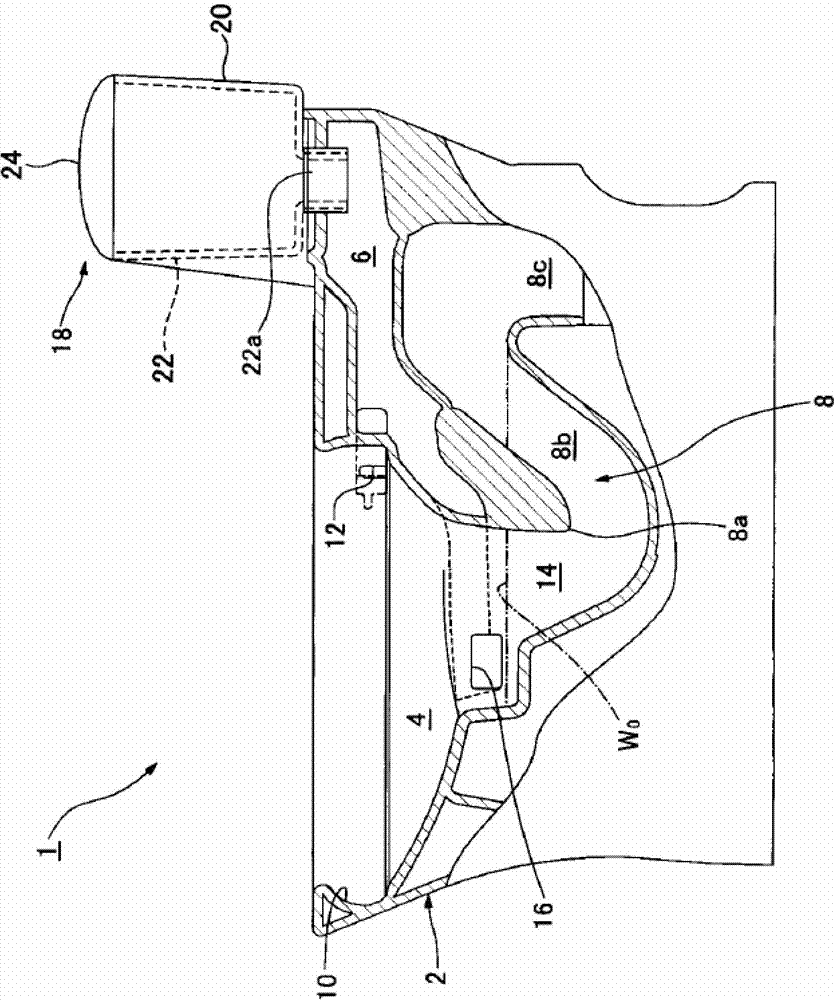

Hermetic type compressor

ActiveCN101514696AReduce the impactSmall outer diameterRotary/oscillating piston combinations for elastic fluidsCompressorCylinder headEngineering

The invention provides a device using HC refrigerant to cool a loop, namely a safe hermetic type compressor which can reduce danger of fire and explosion when the refrigerant is accidentally leaked. The hermetic type compressor 100 according to the invention comprises, inside a hermetic container 1, a compressing mechanism portion 20 and an electric motor 10 for driving the compressing mechanism portion 20, and performs compression of the refrigerant continuously by dividing a compression room with a vane into a high-pressure room and a low-pressure room. The compression room is composed of a cylinder 16 that disposes therein a rolling piston 7 fitted to an eccentric axis 6a of the crankshaft 6 rotated by the electric motor 10, and a cylinder head 4 and a frame 5 that block both ends of the cylinder 16 in an axial direction. According to the hermetic type compressor 100 using the HC refrigerant, the electric motor is fitted and fixed to an inner peripheral plane of the hermetic container. An outer diameter of the electric motor is less than an outer diameter of the compressing mechanism portion. For the cylinder having an inner diameter D and a height H, D / H is set to more than 0.5 and less than 0.6.

Owner:MITSUBISHI ELECTRIC CORP

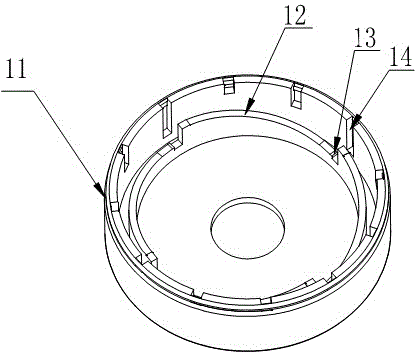

Inspection robot probe with self-cleaning function

InactiveCN112122191AWith self-cleaning functionReduce lossRegistering/indicating working of machinesClosed circuit television systemsRemote controlEngineering

The invention relates to the technical field of intelligent robots, and discloses an inspection robot probe with a self-cleaning function. The inspection robot probe comprises a shell, wherein an inner shell is fixedly connected to the inner wall of the shell, a camera is fixedly connected to the inner wall of the inner shell, a photoresistor is fixedly connected to the inner wall of the inner shell and is close to the outer side of the camera, an electromagnet is fixedly connected to the inner wall of the shell and is close to the outer side of the inner shell, and a connecting rod is elastically connected to the inner wall of the shell and is close to the bottom of the electromagnet. According to the inspection robot probe with the self-cleaning function, the connecting rod moves to passthrough a pressing rod, the electromagnet loses magnetism, so that after the connecting rod passes through the pressing rod, the connecting rod continues to descend, and meanwhile, a brush rotates toclean the camera and the peripheral plane; and based on the magnetic suspension principle, the loss of energy is reduced, wiping with tissues and remote control wiping are not needed, the damage to the environment is reduced, time and labor are saved, and energy conservation and environmental protection are achieved.

Owner:杭州能发科技有限公司

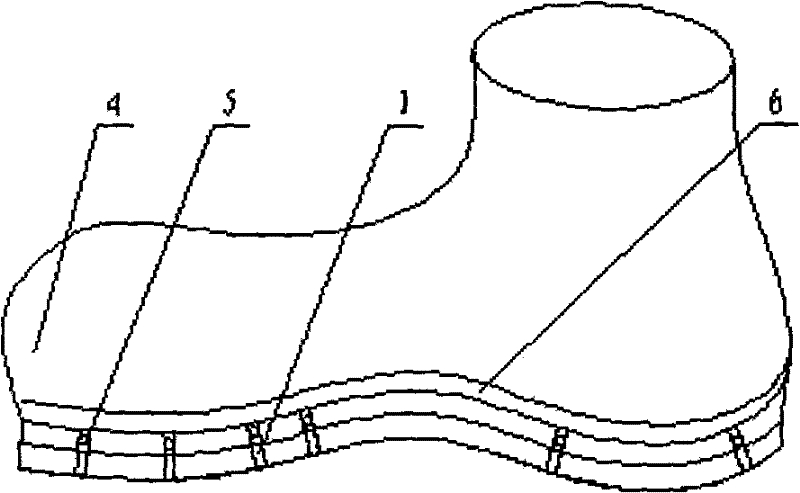

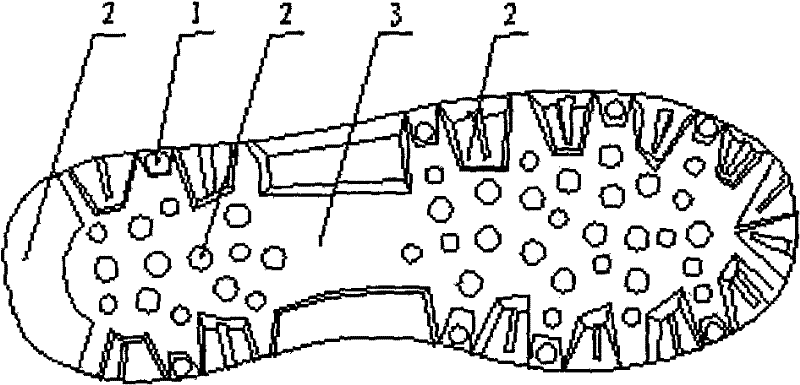

Water draining quick-drying shoes

InactiveCN102342621ARapid recovery of combat effectivenessFootwearRubber materialThermoplastic polyurethane

The invention relates to a pair of wild rapid water draining shoes capable of rapidly draining water in the shoes. According to the invention, the shoes comprise soles, uppers and vamps, wherein water permeable holes are formed on the soles; and one-way water permeable valves are arranged in the water permeable holes. According to the invention, the water permeable holes are lower than the peripheral planes of shoe cushions and water draining recesses are formed on the shoe cushions in contact with the soles. The soles are double-density soles formed by mixing TPU (Thermoplastic Polyurethane) and rubber materials. The shoe cushions are shoe cushions formed by polyurethane and aramid fabric composite materials. The wild rapid water draining shoes provided by the invention have the following advantage that: the water in the shoes can be drained within a shortest time during wild operation so that the fighting capacity of the operation personnel is rapidly recovered.

Owner:JIHUA 3515 LEATHER & SHOES

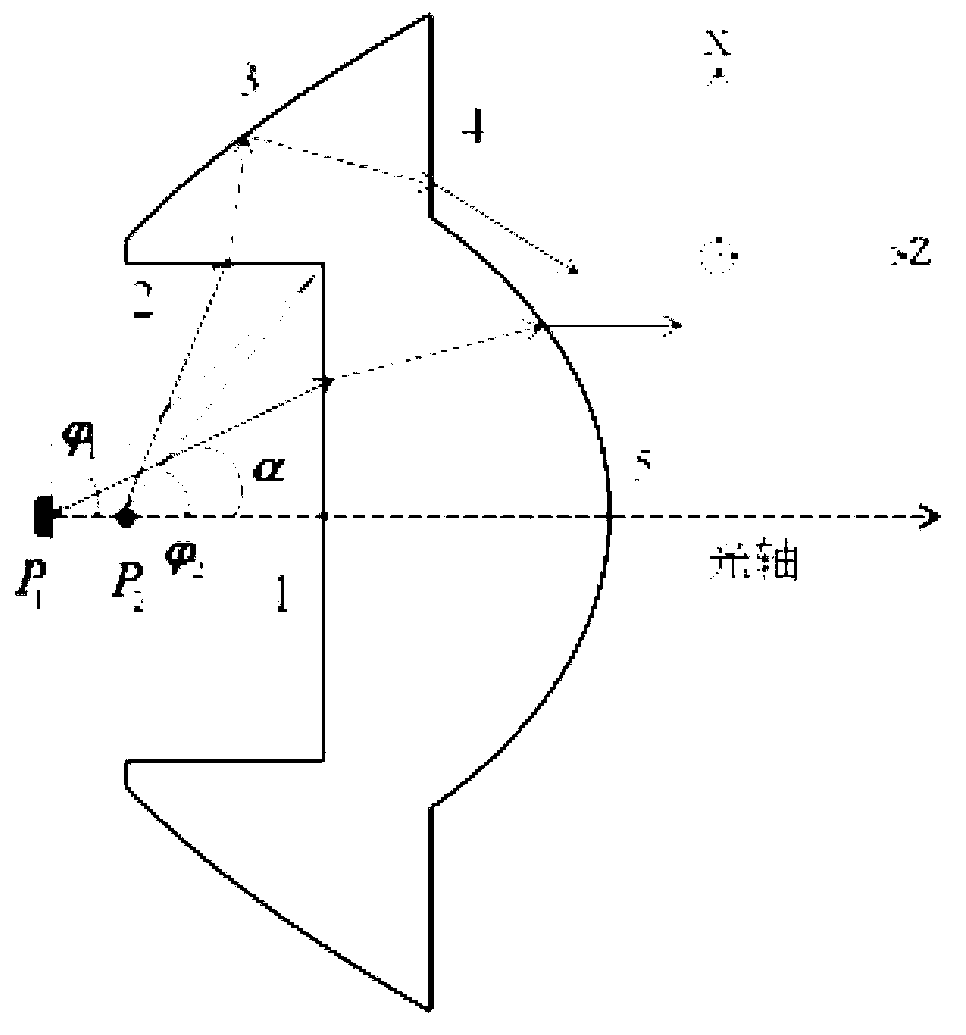

Novel LED total reflection lens capable of realizing continuous zooming and design method of novel LED total reflection lens

InactiveCN102829432AImprove uniformity of illuminationReduce volumePoint-like light sourceRefractorsTarget surfaceIlluminance

The invention discloses a novel LED total reflection lens capable of realizing continuous zooming and a design method of the novel LED total reflection lens, and belongs to the field of semiconductor illumination. The lens comprises a bottom containing cavity, a total reflection surface, a peripheral plane and a central transmission surface, the total reflection surface and the bottom containing cavity are connected with the peripheral plane, the peripheral plane is connected with the central transmission surface, the bottom containing cavity, the total reflection surface, the peripheral plane and the central transmission surface are symmetric around an optical axis, and both the total reflection surface and the central transmission surface are free-form surfaces. The novel LED total reflection lens realizes continuous zooming by a single total reflection lens, and is convenient to mount and adjust, and a system is small in size and. By the design method, light energy is distributed in a free-form surface manner, so that light energy utilization rate of the system and illuminance uniformity degree of a target surface are increased.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

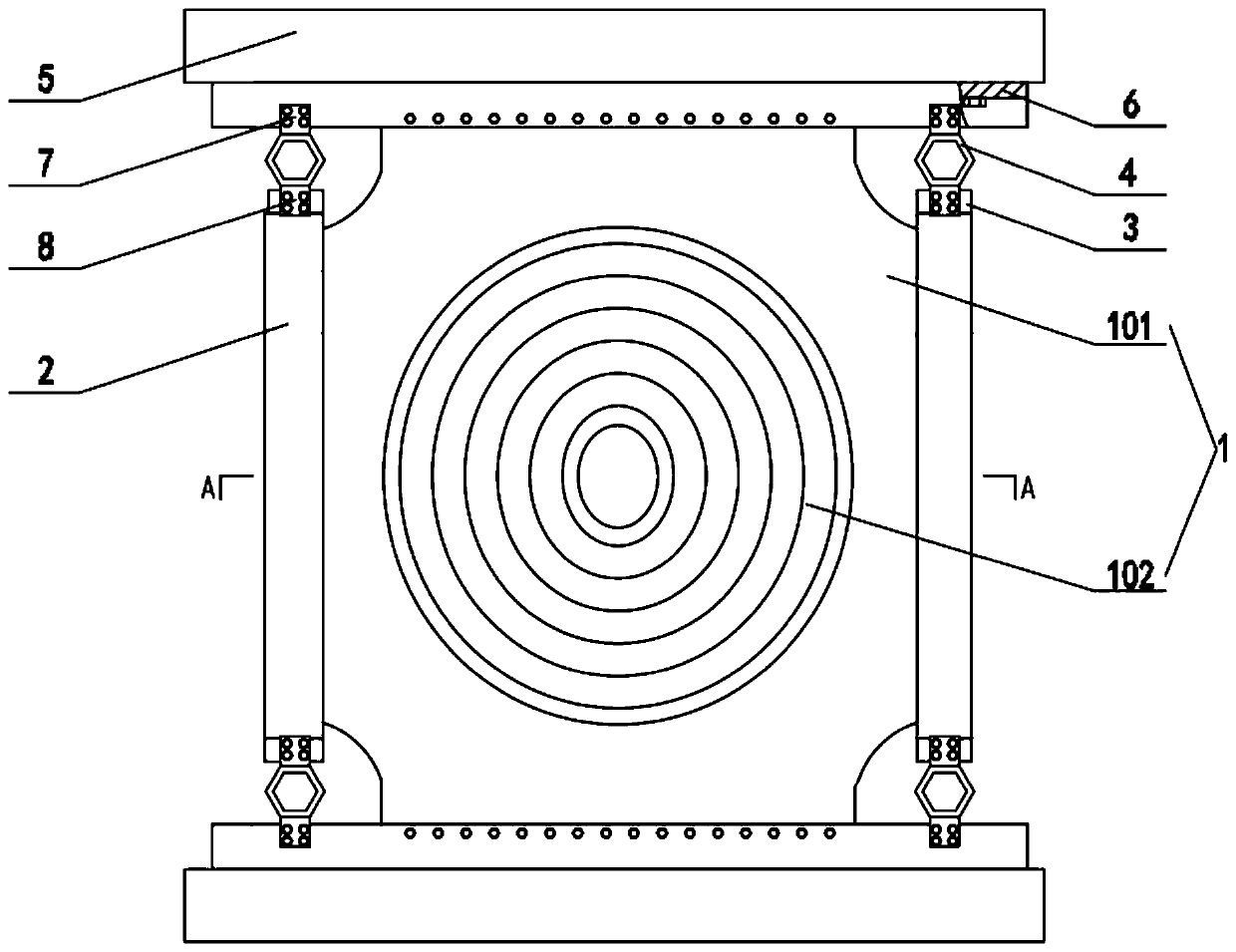

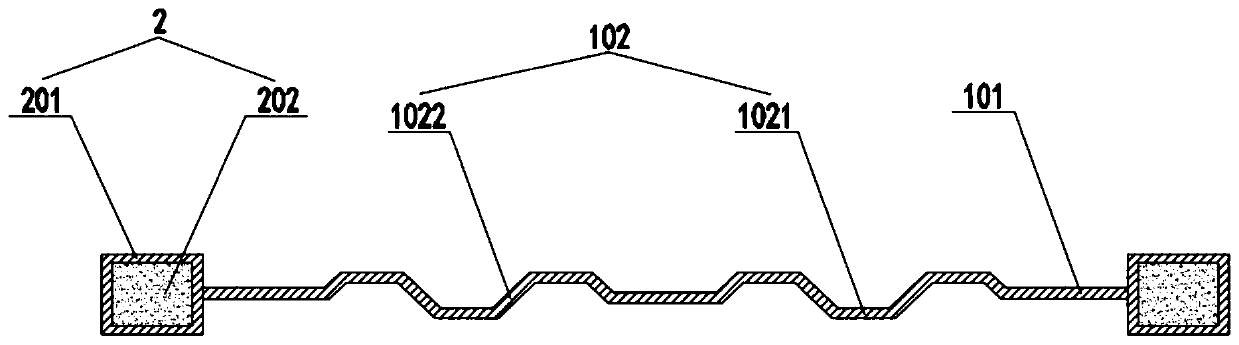

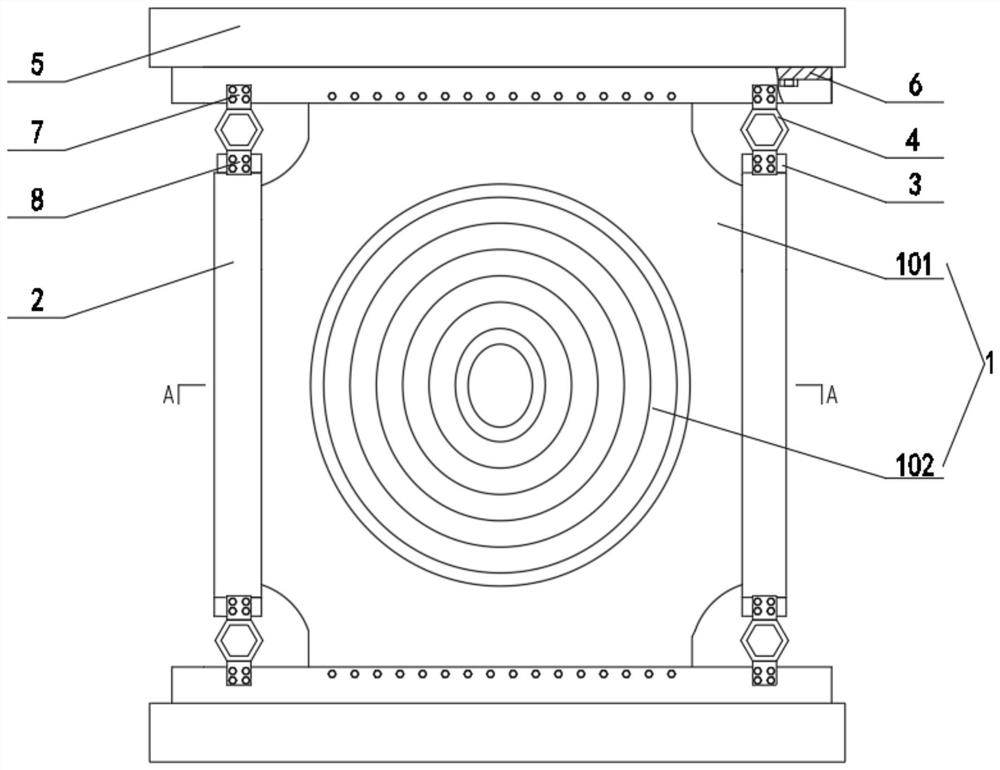

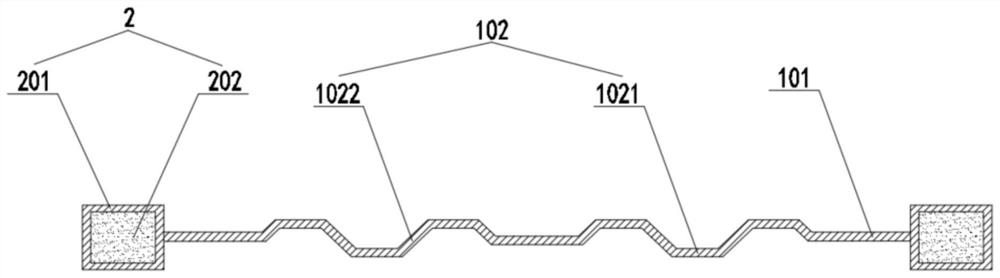

Corrugated steel plate wall with power-wasting corner

ActiveCN111075052AImprove anti-deformation abilityImprove vertical supportConstruction materialWallsClassical mechanicsPeripheral plane

The invention relates to a corrugated steel plate wall with a power-wasting corner. The corrugated steel plate wall with the power-wasting corner comprises a corrugated steel plate wall body, the corrugated steel plate wall body is composed of a peripheral plane steel plate and a central corrugated steel plate which are integrally formed, corrugated tracks of the central corrugated steel plate isin a regular oval shape, corresponding edge columns are fixedly connected to the two sides of the peripheral plane steel plate correspondingly and are concrete-filled square steel tubular column components, the concrete-filled square steel tubular column components are formed by rectangular cold-formed hollow profile steel filling with concrete, the left side and the right side of the peripheral plane steel plate are welded to the inner side faces of the corresponding rectangular cold-formed hollow profile steel correspondingly, the upper end and the lower end of the rectangular cold-formed hollow profile steel are integrally provided with a set of corresponding end plates, and the end plates are fixedly connected to connecting plates fixedly connected to a frame beam through correspondingenergy wasting keys correspondingly. According to the corrugated steel plate wall, vertical stress and transverse stress can be effectively coped with at the same time without generating excessive deformation, and corner connection tearing can be effectively prevented.

Owner:上海市建工设计研究总院有限公司

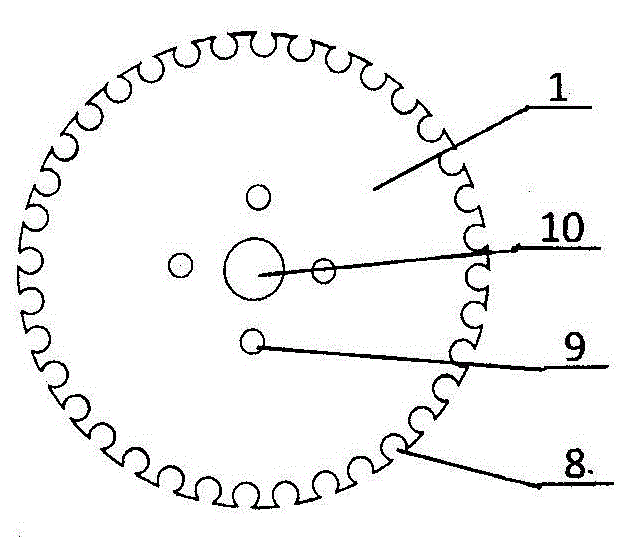

Driving wheel of diamond bead rope sawing machine

InactiveCN101451604AEasy to adjustReasonable structurePortable liftingWorking accessoriesDrive wheelDrive shaft

The invention relates to a transmission wheel of a diamond wire saw, which is used in a stone cutting machine. The transmission wheel comprises a transmission wheel body, the center line of which is open with a transmission shaft hole and a transmission key groove or a bearing room, the outer ring wheel groove of the transmission wheel body is embedded and provided with a wear resistant casing, the outer peripheral plane of the wear resistant casing is open with semicircle transmission grooves of the diameter of 8.5mm, the transmission grooves are characterized in that the transmission grooves have six and are arranged from left to right, the center distance between the first transmission groove and the second transmission groove is 13.5mm, the center distance between the second transmission groove and the third transmission groove is 15mm, the center distance between the third transmission groove and the fourth transmission groove is 15mm, the center distance between the fourth transmission groove and the fifth transmission groove is 18.5mm, and the center distance between the fifth transmission groove and the sixth transmission groove is 20mm. The transmission wheel has the advantages of simple and reasonable structure, convenient use, easy regulation of the wire saw distance and high processing efficiency, and large scale of plates of different thicknesses which are multiples of 5 can be processed at the same time.

Owner:荣成中磊科技发展有限公司

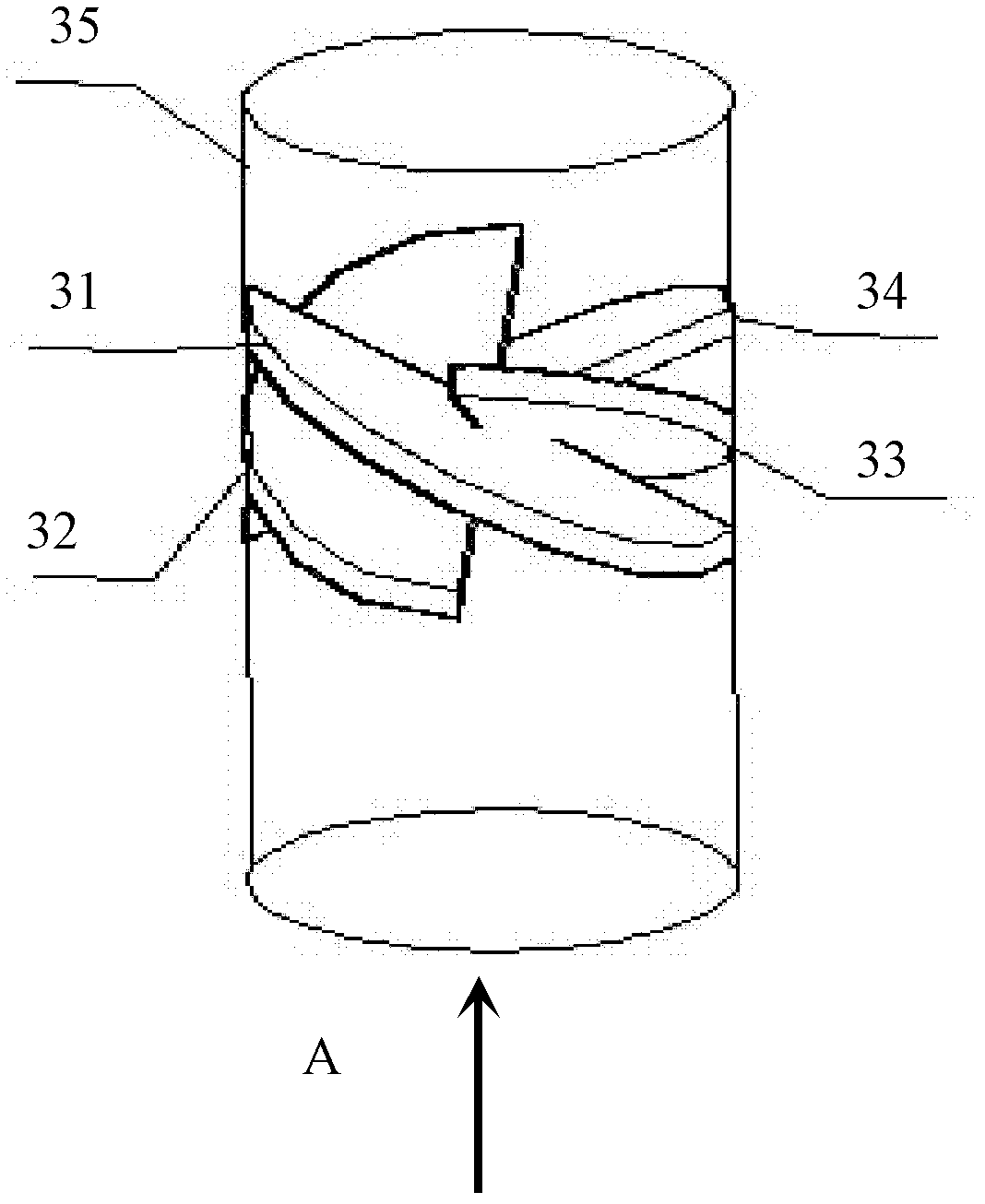

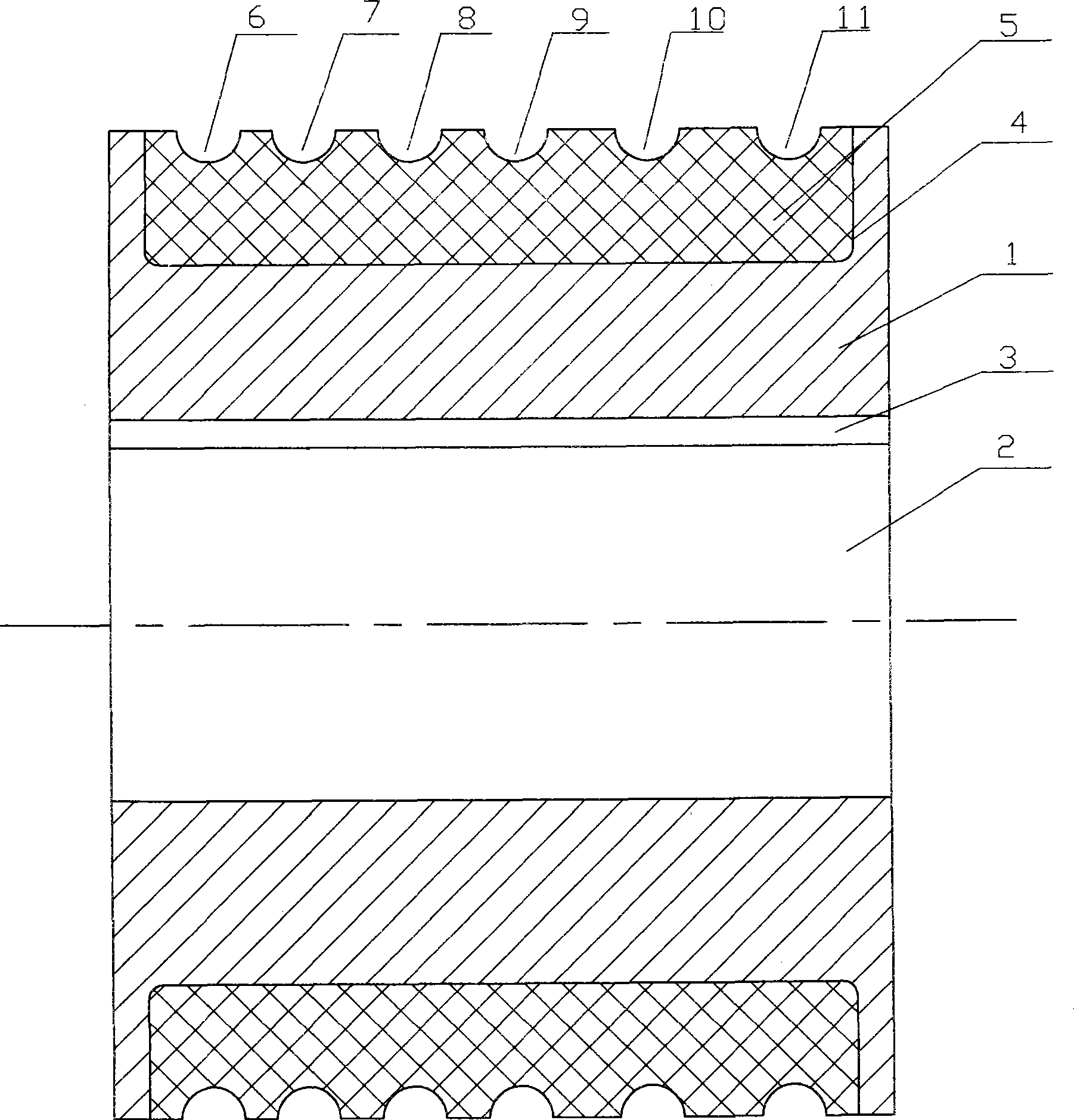

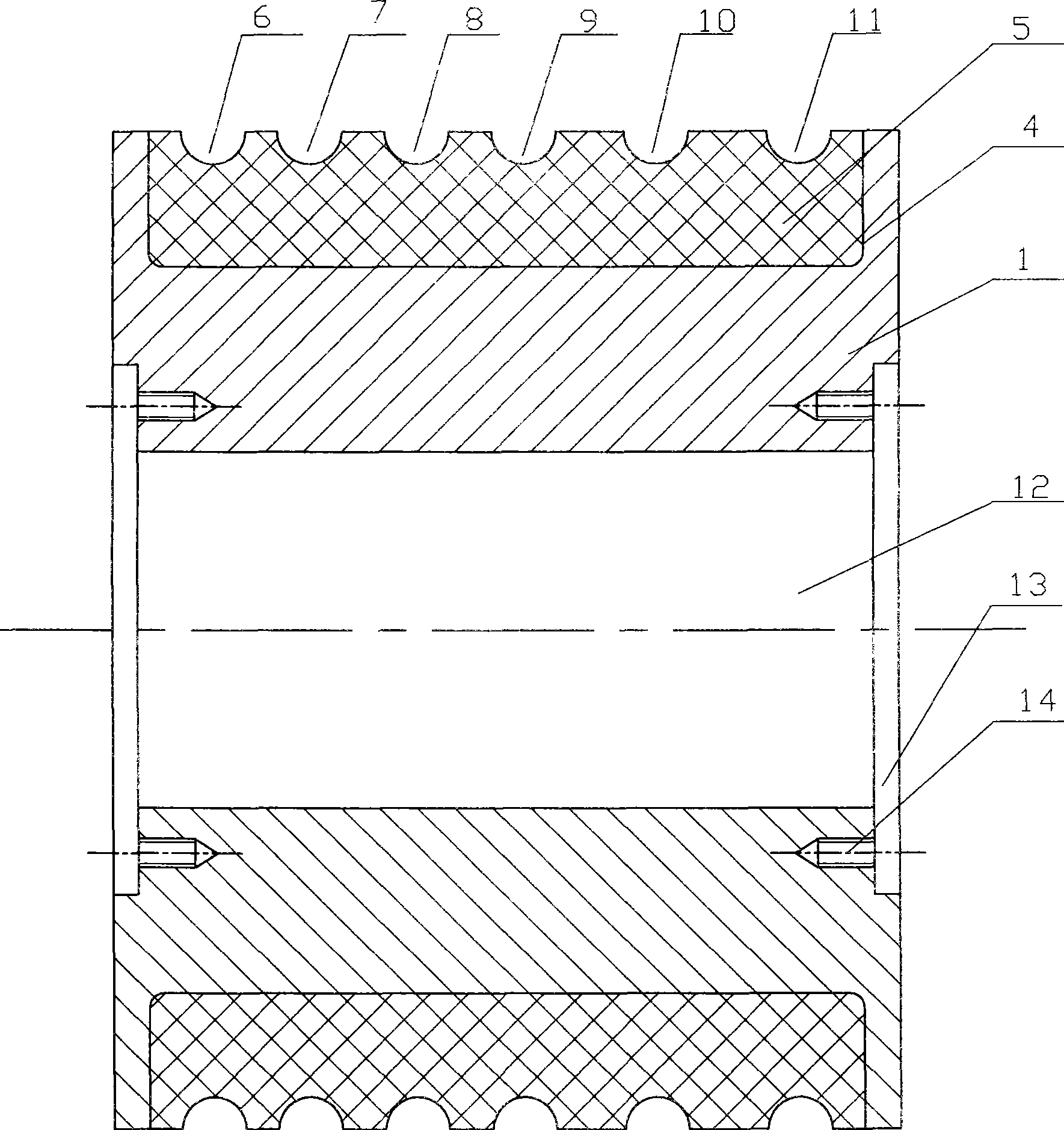

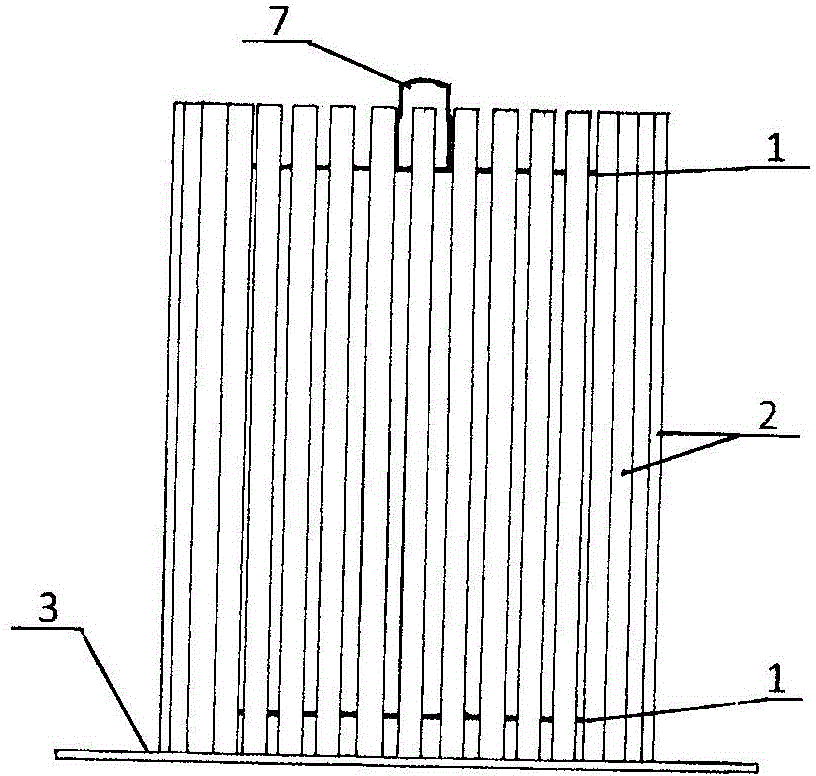

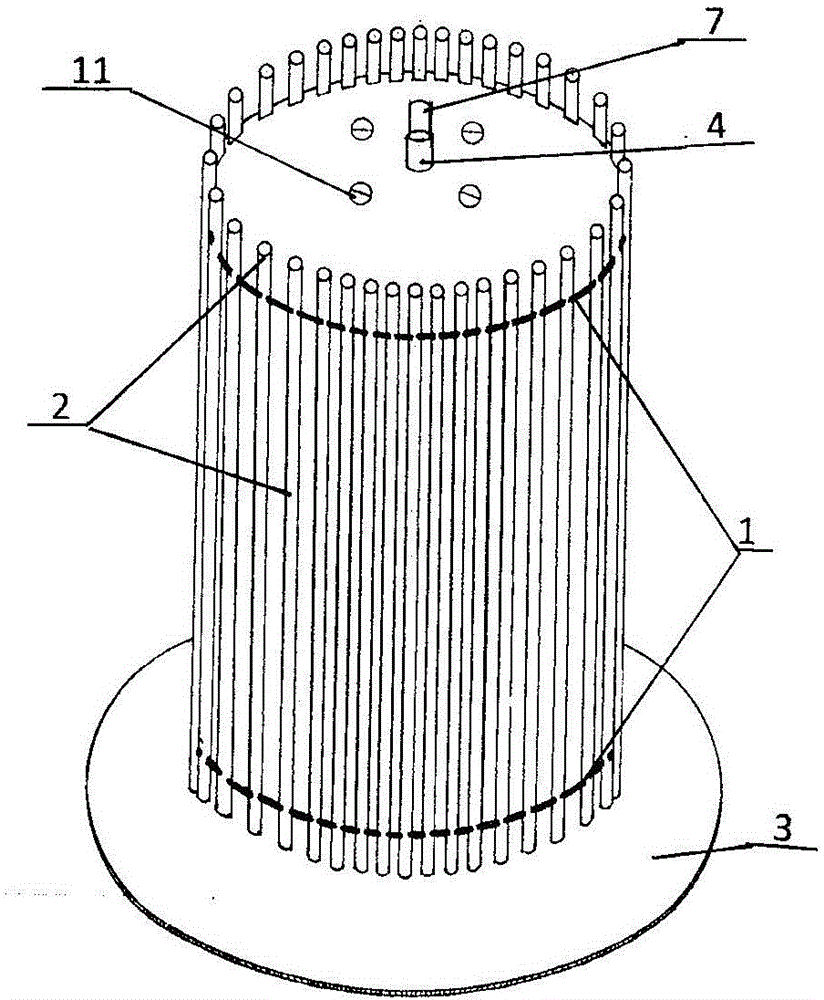

Combination molded tube capable of nesting spiral blades

InactiveCN104567571ALow costReduce weightMechanical measuring arrangementsSpiral bladePeripheral plane

The invention discloses a combination molded tube capable of nesting spiral blades and aims to provide a combination molded tube which is low in weight and cost, adjustable in size, multifunctional and capable of nesting spiral blades. The technical scheme of the combination molded tube is characterized in that at least two round plates with multiple slightly unedged holes drilled in peripheral planes are flatly arranged on an upper part and a lower part of a stand column in the center through screws respectively, multiple small round bars are vertically inserted into the unedged holes in peripheries of the upper round plate and the lower round plate respectively to form a cylindrical sleeve, the central stand column is vertically installed on a lower base, and a plane of the base is larger than planes of the two round plates so as to prevent the combination molded tube from toppling. The combination molded tube capable of nesting the spiral blades can be multipurpose as long as the round plates of corresponding sizes are replaced according to a process requirement.

Owner:刘运武

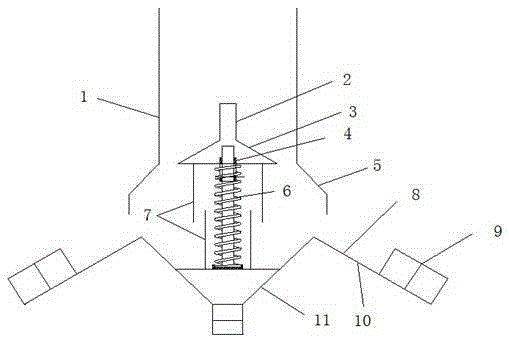

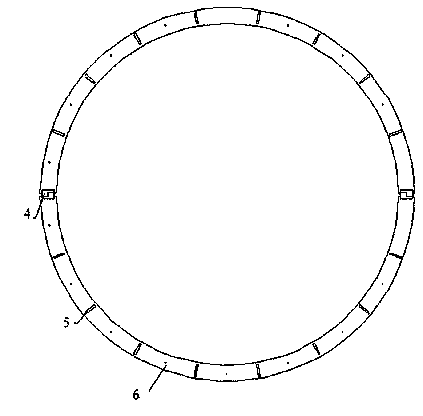

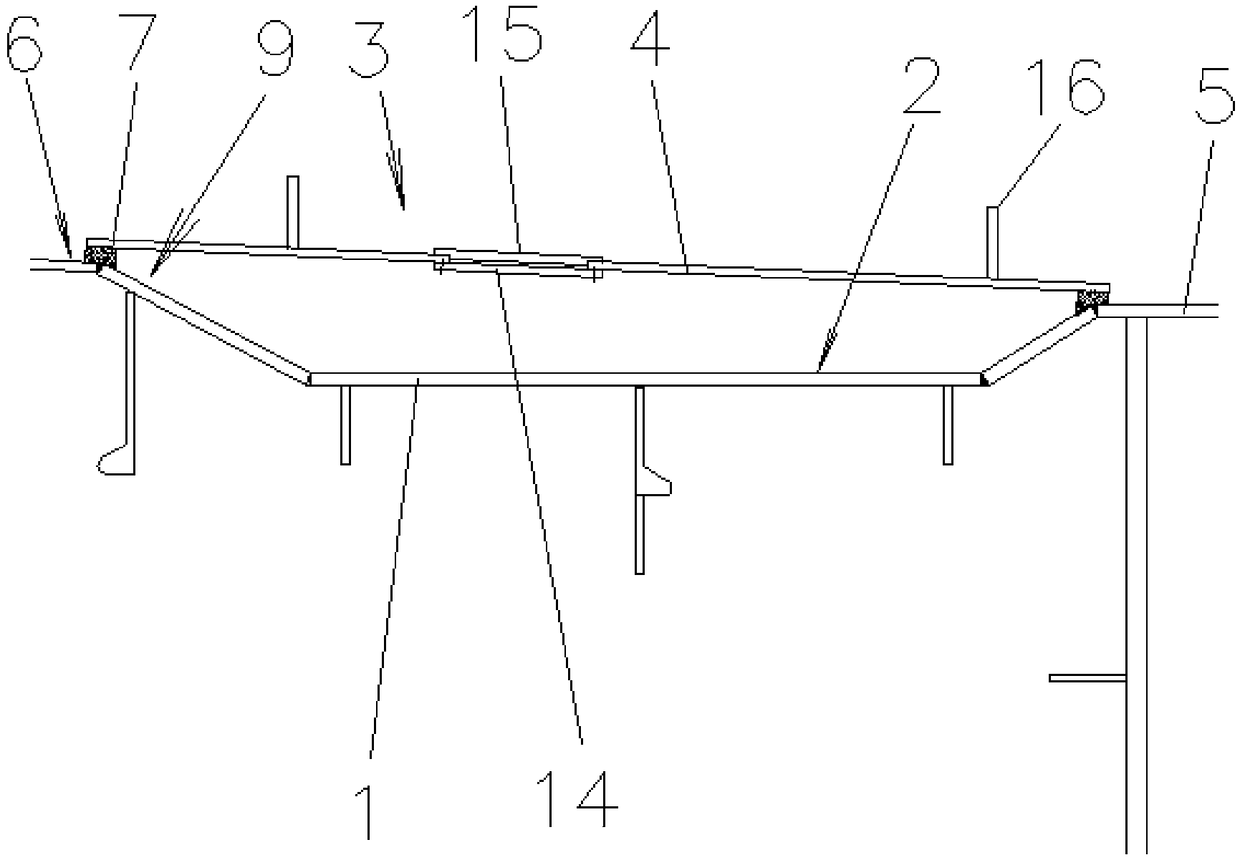

Squat silo grain feeding distributor

InactiveCN105383959AImprove breathabilityEasy to fill with nitrogenConveyorsLoading/unloadingNitrogenGrain storage

The invention discloses a squat silo grain feeding distributor, belongs to the technical field of squat silo grain feeding equipment, and is used for preventing the generation of automatic classification and grain crushing phenomenon in the grain feeding process. The squat silo grain feeding distributor is characterized in that an umbrella-shaped distributor is mounted below a grain inlet; the peripheral surface of the distributor is divided into multiple areas by separation plates; each area is respectively connected with the upper end of one chute; the lower ends of the chutes are respectively corresponding to grain dropping points in a squat silo; and the grain dropping points are uniformly distributed on the peripheral plane of the squat silo. A pressure door is mounted above the distributor; and when flows are different, the weights of soybeans on the pressure door are different, the downward moving distances of the pressure door are different, and blanking openings are different, so that the flows are controlled and the purpose of uniform distribution is achieved. The squat silo grain feeding distributor can preferably solve the automatic classification phenomenon in the silo feeding process, is convenient for the application of such advanced grain storage technologies as fumigation, nitrogen filling, mechanical ventilation and grain refrigerator cooling, reduces the loss, improves the grain storage stability, increases the grain storage benefit, reduces the labors, and reduces the grain storage cost.

Owner:中储粮油脂有限公司

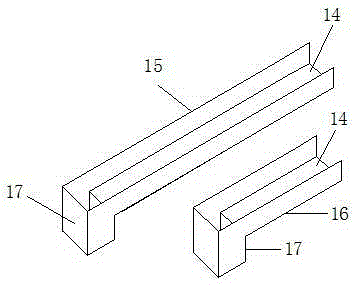

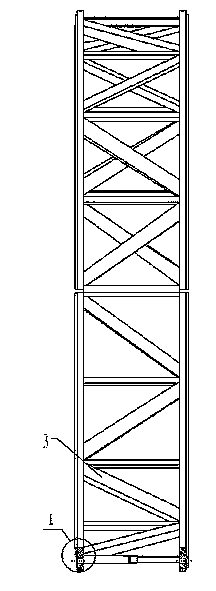

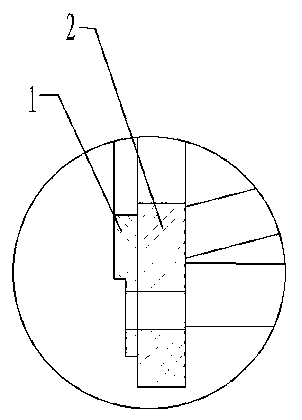

Tool for butt joint between tanks of mixer truck

InactiveCN103624471ARealize dockingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention discloses a tool for butt joint between tanks of a mixer truck. The tool for butt joint between the tanks of the mixer truck comprises connecting rings arranged on the two tanks of the mixer truck, and connecting plates, wherein the two connecting rings are axially connected along the peripheries of the connecting rings through the connecting plates, a spigot ring is arranged along the peripheral plane of each connecting ring, square reinforcing tubes are arranged between the two connecting rings, rib plates are evenly arranged at the outermost end of each spigot ring, and connecting holes are further formed in each connecting ring. The two tools which are completely matched with the tanks are used, the connecting holes are formed in the tools, two barrels arranged in the tools are adjusted to be at the appropriate positions so as to carry out butt joint, connection and locating are carried out through connecting bolts, and butt joint between the tanks is achieved; operation of the butt joint mode is easy, equipment manufacturing accuracy is high, the working procedures are centralized, manpower consumption is low, and production efficiency is improved. The tool for butt joint between the tanks of the mixer truck is simple in structure, and convenient to manufacture and operate.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

Process protection structure of a stainless steel oil suction well of a ship

The invention relates to the technical field of shipbuilding, the invention discloses a process protection structure of a stainless steel oil suction well of a ship, includes a stainless steel suctionwell body, an erasable pre-weld protective layer is arranged on the surface of the oil suction well body, and a removable oil suction well pre-coating protective device arranged on the hull section where the oil suction well body is located, the protective layer before welding is a lime slurry layer painted on the surface of the oil absorption well body, the protective device for oil suction wellbefore coating comprises a protective plate covered on the oil suction well body, and magnetic rubber strips are arranged on the peripheral plane of the protective plate which is in contact with theoil suction well mounting connection plane of the hull section, and the magnetic rubber strips are glued and connected with the protective plate. The invention improves the manufacturing quality of the stainless steel oil suction well by setting the process structure of the stainless steel oil suction well.

Owner:CHENGXI SHIPYARD

Water discharge valve device and flush water tank device with same

InactiveCN103140636BImprove supply capacityImprove reliabilityFlushing devicesWater storage tankPeripheral plane

A water discharge valve device includes: a water discharge valve unit which has a valve element for opening and closing a discharge port and a control casing for controlling an up-down movement of the valve element; a casing module which includes a peripheral wall extending upwardly from a bottom wall of a water storage tank while surrounding peripheries of the discharge port and the control casing of the water discharge valve unit, to define an upwardly open space therebetween, an opening formed to penetrate through the peripheral wall, and a switching valve attached to the peripheral wall and adapted to open and close the opening; and a communication port formed in a peripheral plane extending from the control casing of the water discharge valve unit to the discharge port, to provide fluid communication between the casing module and the discharge port.

Owner:TOTO LTD

LED light emitting group

Owner:KONINK PHILIPS ELECTRONICS NV +1

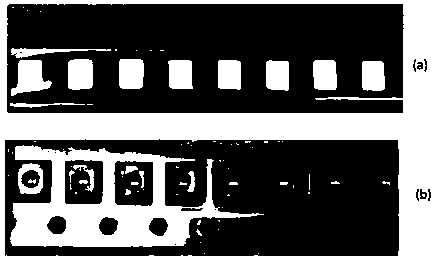

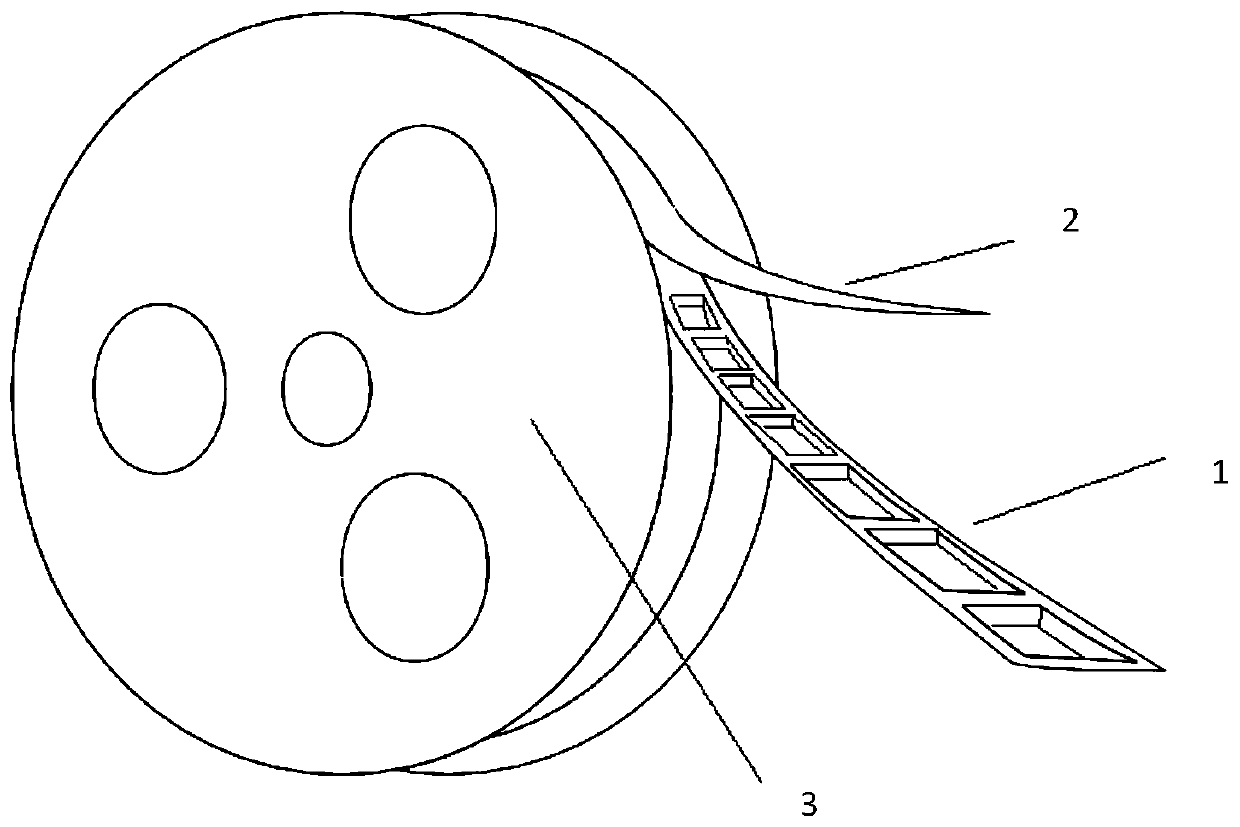

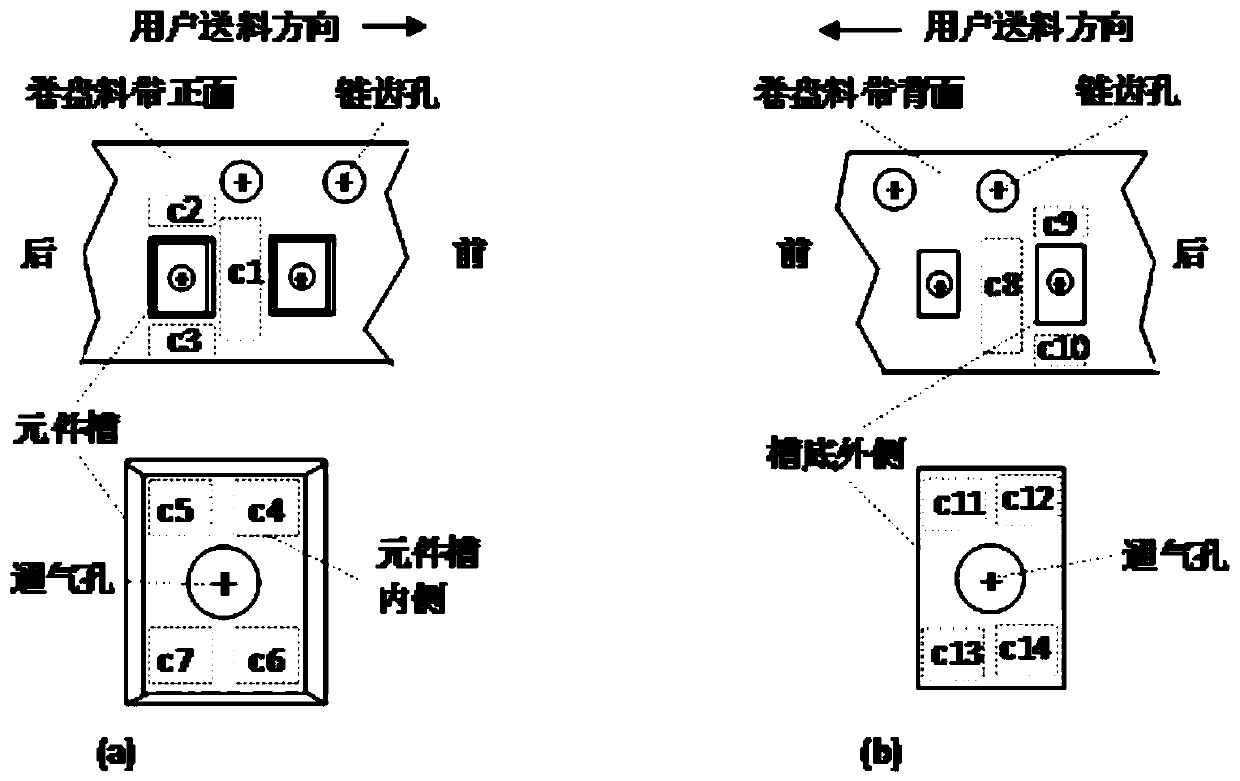

Reel material strip marking method

ActiveCN109784455AAccurate labelingConvenient labelingRecord carriers used with machinesPeripheral planeFixed position

The invention provides a reel material strip labeling method. Uniqueness identification of each device on a reel is realized by adding a graphic code on a carrier tape. When one component is placed ata component fixing position, the serial number of the fixing position becomes the serial number of the component, one serial number occupies one or more adjacent component fixing positions and peripheral planes, and the unique serial number of each component groove in the reel is realized by reading the serial number codes. According to the invention, the parameters of each component can be moreaccurately marked, and the parameters can be conveniently marked on the components.

Owner:青岛柯锐思德电子科技有限公司

A corrugated steel wall with dissipative corners

ActiveCN111075052BImprove anti-deformation abilityImprove vertical supportConstruction materialWallsClassical mechanicsEngineering

The invention relates to a corrugated steel plate wall with energy-dissipating corners, including a corrugated steel plate wall. The corrugated steel plate wall is composed of an integrated peripheral flat steel plate and a central corrugated steel plate. The two sides of the peripheral planar steel plate are respectively fixed with corresponding edge columns, the edge columns are square steel tube concrete column components, and the square steel tube concrete column components are formed by filling concrete inside rectangular cold-formed hollow steel sections , the left and right sides of the peripheral planar steel plate are respectively welded to the inner side of the corresponding rectangular cold-formed hollow section steel, and the upper and lower ends of the rectangular cold-formed hollow section steel are respectively integrally provided with a set of corresponding end plates, and the end plates The plates are respectively fixedly connected to the connection plates affixed to the frame beams through corresponding energy dissipation keys. The present invention can effectively deal with vertical force and transverse force simultaneously without excessive deformation, and can effectively prevent tearing of corner joints.

Owner:上海市建工设计研究总院有限公司

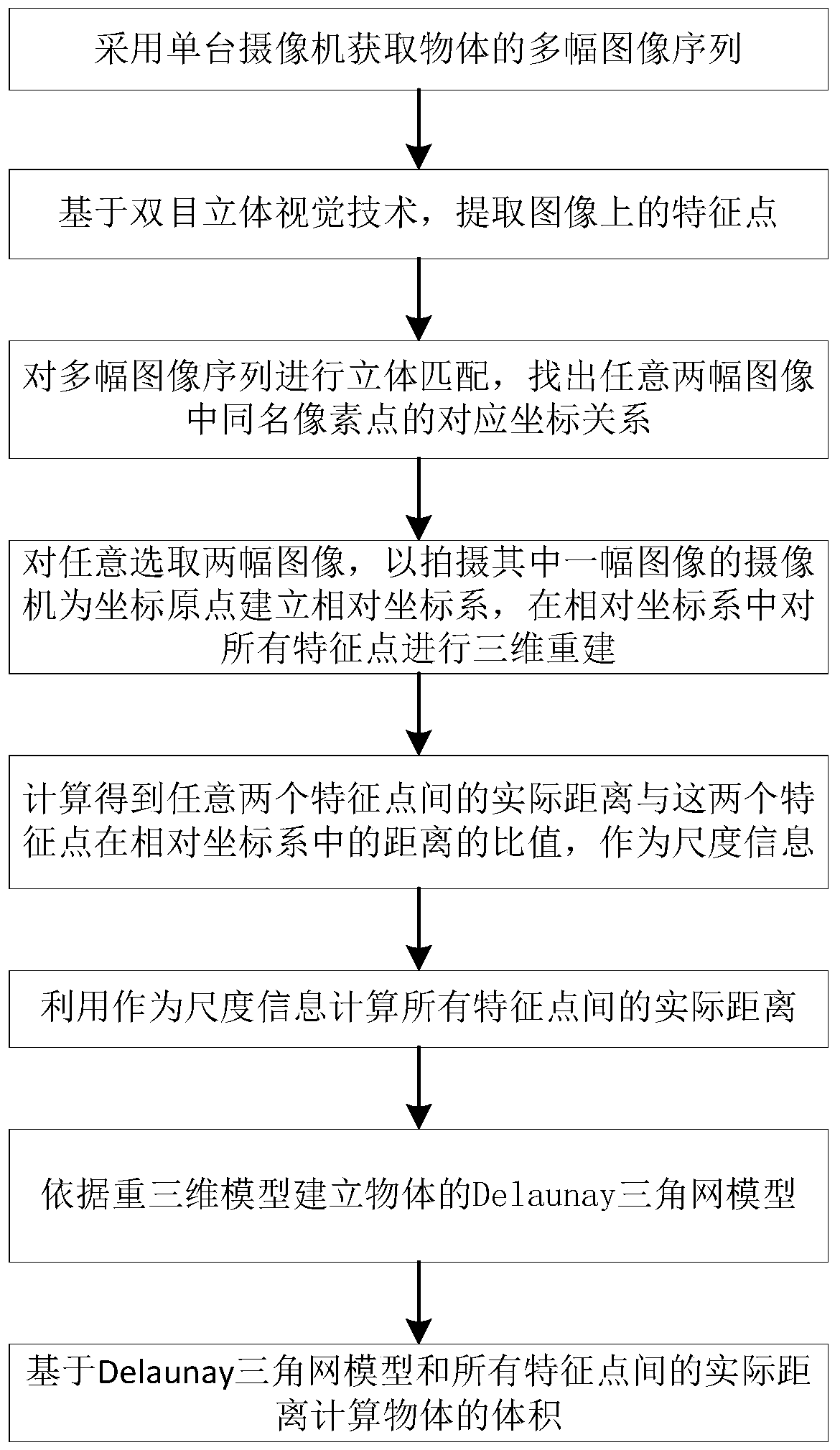

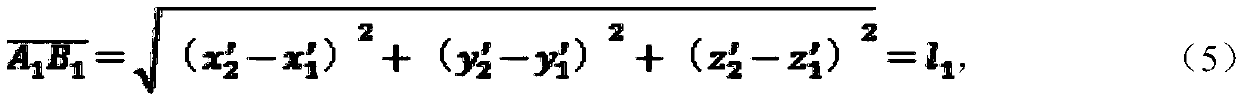

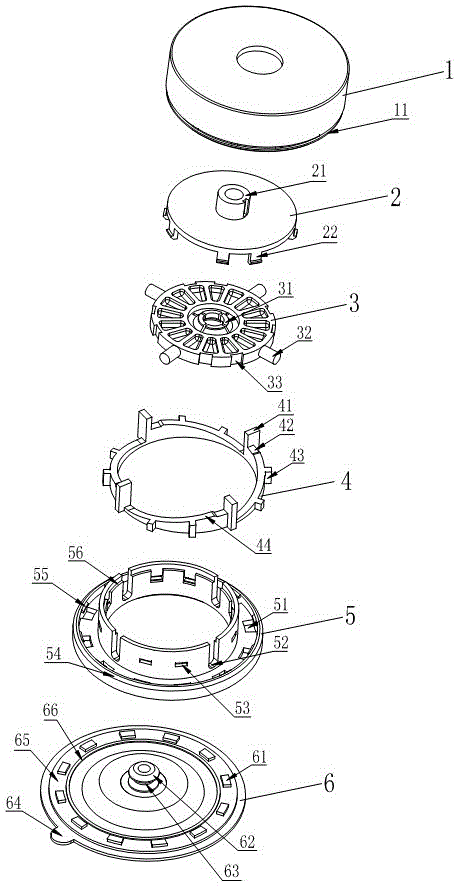

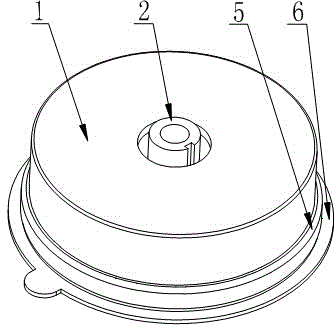

A Fast Volume Measurement Method Based on Space Invariant Property

ActiveCN104778720BQuick measurementTo achieve the purpose of photogrammetryImage analysisTriangulationObject point

The present invention provides a fast volume measurement method based on space-invariant characteristics. The method includes: extracting and matching feature points and three-dimensional reconstruction of the acquired image; adding the actual distance between feature points and the The distance ratio between the relative coordinate system and the real world is used as the scale information; the three-dimensional coordinates of the feature points are used to construct the Delaunay triangular mesh, and the boundary edge detection elements are added to fit the optimal reference plane; according to the idea of discrete integrals, the triangular mesh Projected onto the datum plane, find the volume of the irregular object surrounded by the triangular network. You can use "one camera, one ruler" to complete the measurement of the actual distance between all the feature points of the object, which saves the trouble of field measurement; at the same time, when constructing the Delaunay triangular mesh, a data structure for detecting boundary edges is added, which can effectively The peripheral datum plane of the formed boundary surface is obtained, which is further used for volume calculation.

Owner:SOUTHEAST UNIV

Vacuum suction cup

ActiveCN103953637BDoes not affect adsorptionIncrease the force rangeKitchen equipmentDomestic articlesPeripheral planeEngineering

Owner:浙江西塘实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com