High-efficiency winding machine for flexible graphite metal spiral wound gasket

A technology of metal winding and flexible graphite, which is applied in the field of petrochemical sealing, can solve the problems of unstable quality, manual measurement, and low production efficiency, and achieve the effect of preventing uneven working surface, saving time and cost, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

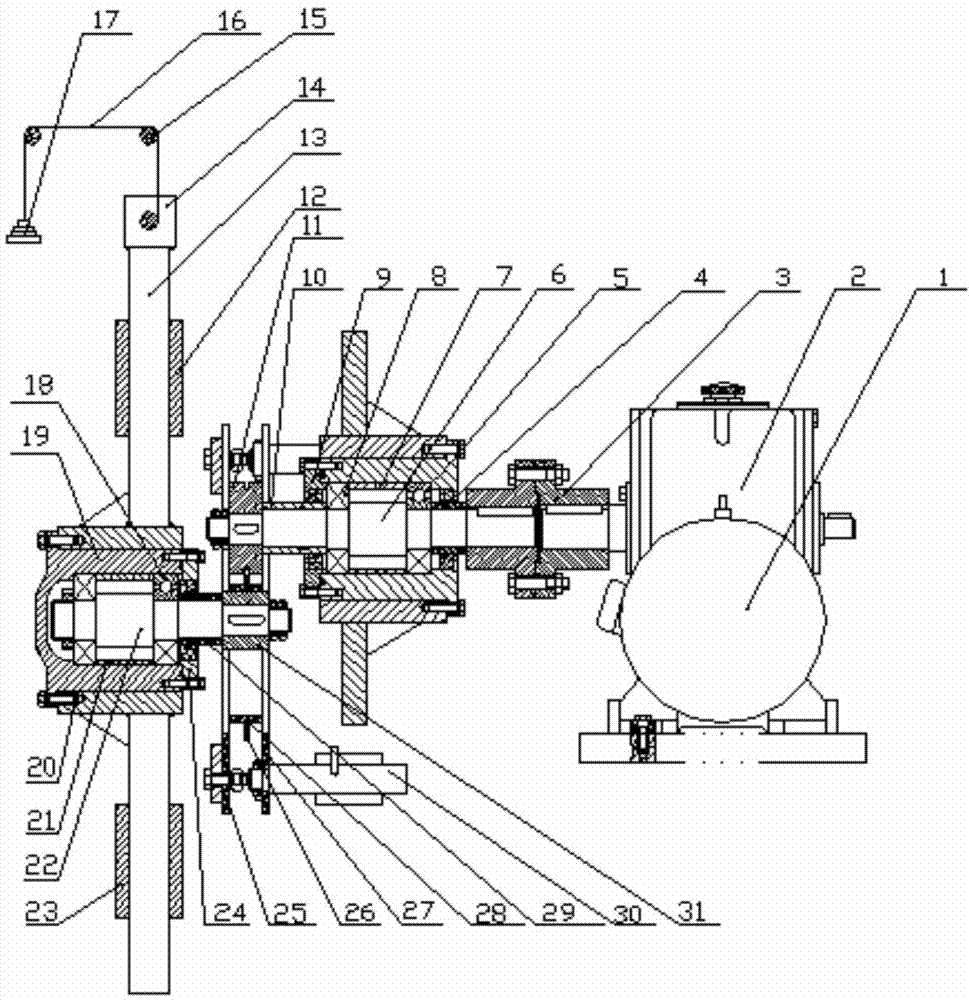

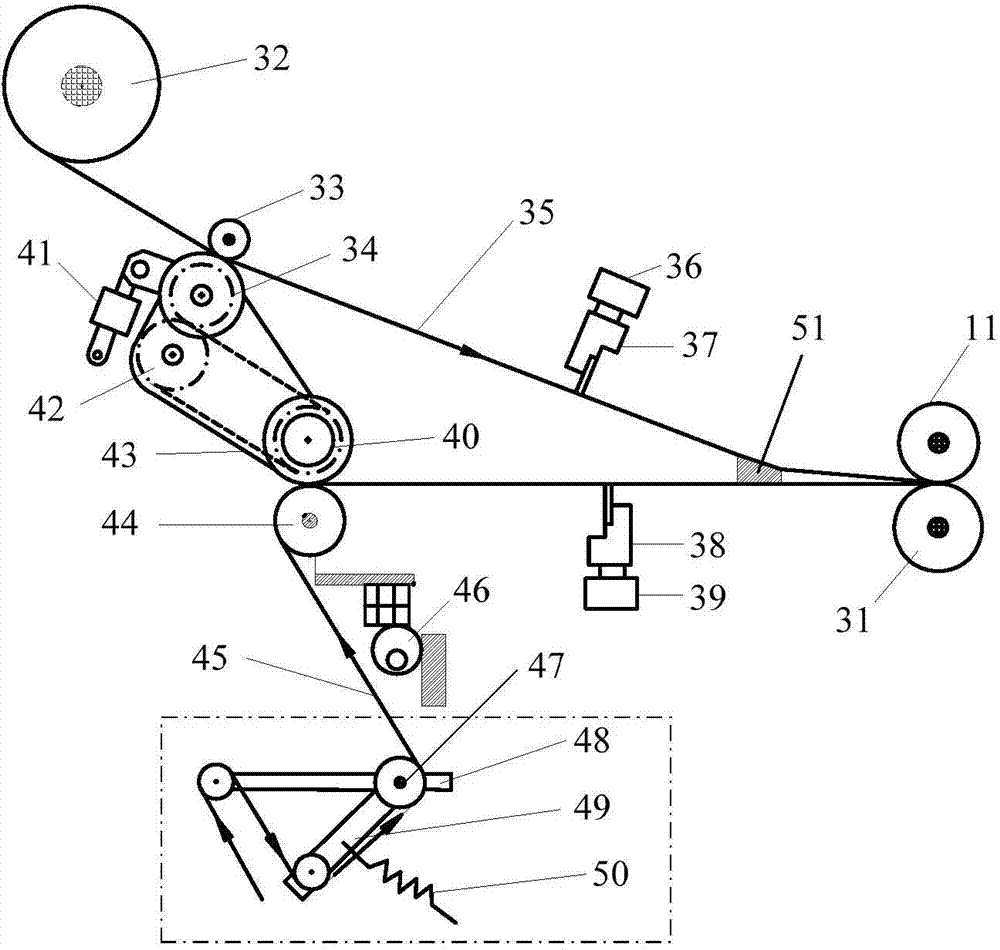

[0027] The flexible graphite metal wound gasket high-efficiency winding machine is mainly composed of a transmission mechanism and a winding and feeding mechanism.

[0028] (1) figure 1 It is a structural schematic diagram of the transmission mechanism in the winding machine in the embodiment of the present invention. Such as figure 1 The transmission mechanism shown includes a motor 1, a reducer 2 is connected to the motor 1, a coupling 3 is arranged on the output shaft of the reducer 2 and a pressing wheel shaft 6 is connected; the pressing wheel shaft 6 is separated by a shaft sleeve 7 The first bearing 8 is supported on the fixed support by the right end cover 5 of the compression wheel shaft. The outer ring side of the first bearing 8 is provided with the right end cover 5 of the compression wheel shaft, the shaft sleeve 7, and the shaft end cover 9 for fixed positioning. The first bearing The inner ring side of 8 is provided with the right bushing 4 of the pressing whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com