Driving wheel of diamond bead rope sawing machine

A technology of bead wire saw machine and drive wheel, which is applied in the field of drive wheel, can solve problems such as inability to process, and achieve the effects of convenient adjustment, strong operability, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

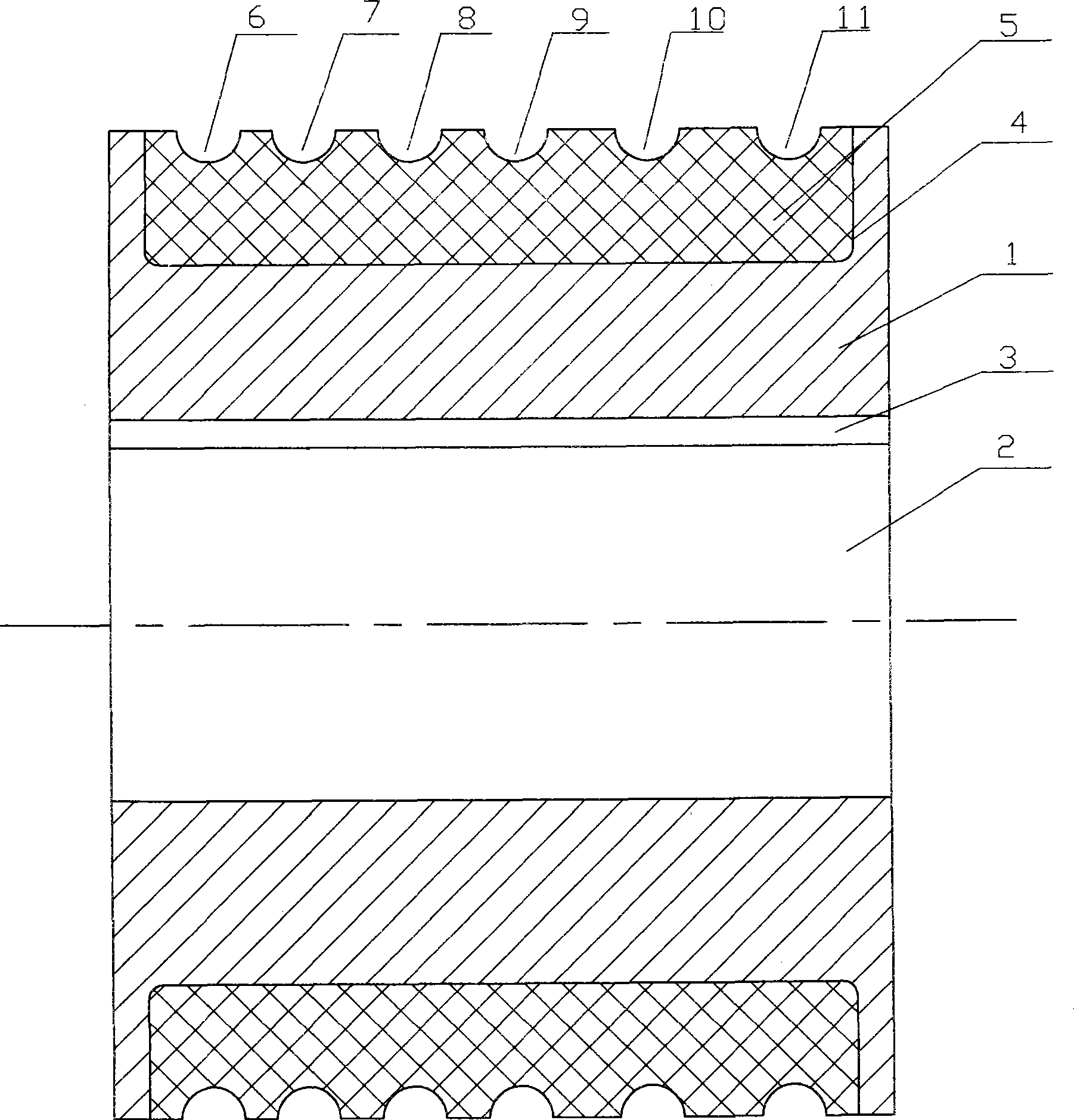

[0011] exist figure 1 Among them, a transmission wheel of a diamond beaded wire saw machine includes a transmission wheel body (1), and the transmission wheel body (1) is made of metal materials through precision casting.

[0012] A transmission shaft hole (2) is provided at the center line of the transmission wheel body (1), and a transmission keyway (3) is provided on the hole wall of the transmission shaft hole (2).

[0013] A wear-resistant overcoat (5) is embedded in the outer circular wheel groove (4) of the transmission wheel body (1). What this wear-resisting overcoat (5) adopts is polyurethane material, and one-time hot molding is embedded in the outer circular wheel groove (4) of transmission wheel body.

[0014] Offer 6 semicircular transmission grooves on wear-resisting overcoat (5) outer peripheral surface, because what generally adopt abroad at present is that diameter is 8.5mm diamond bead wire saw, so the diameter of transmission groove is 8.5mm. Such as fig...

Embodiment 2

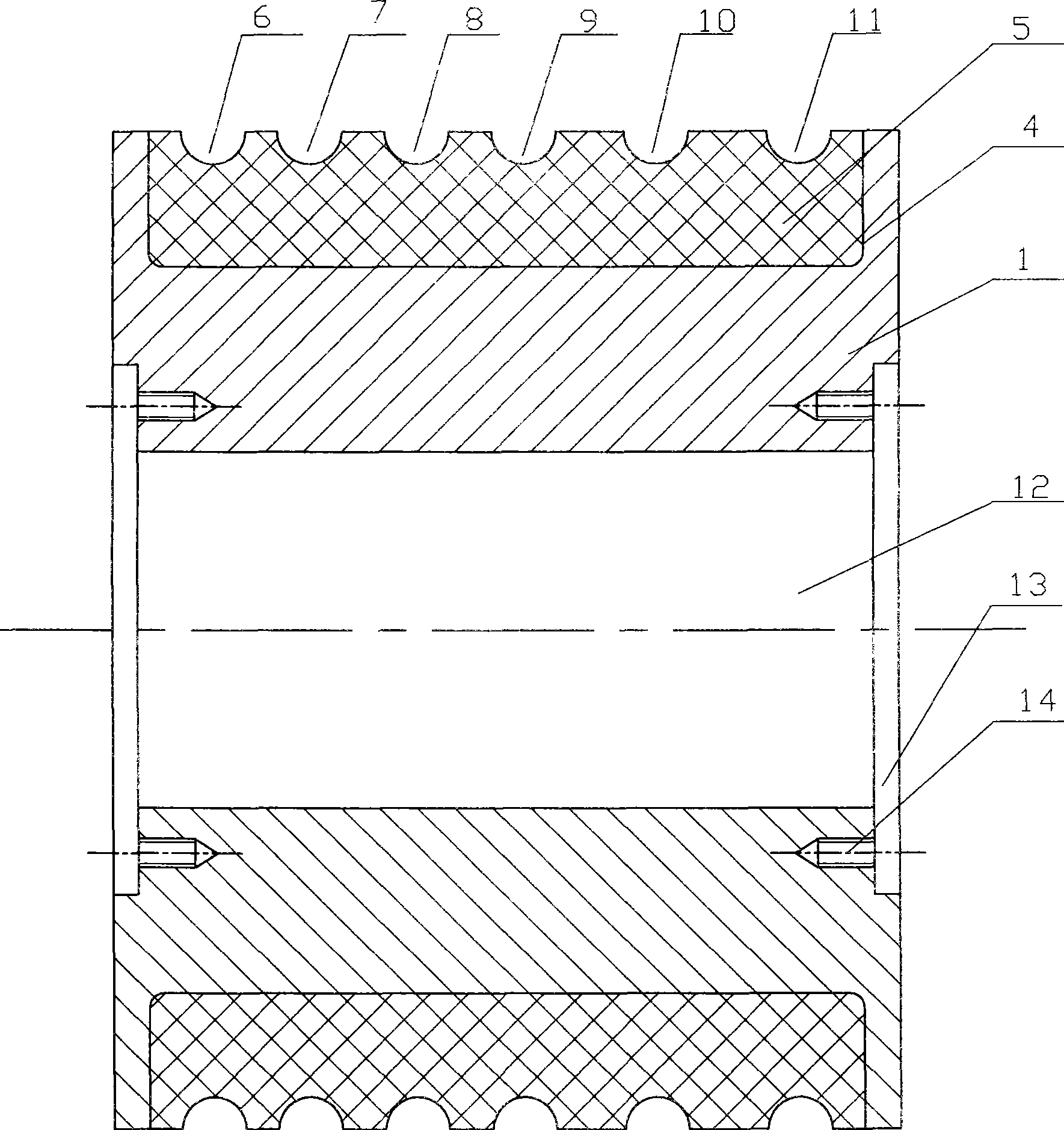

[0017] figure 2 A main cross-sectional view of the structure of another example of the present invention is given. In the figure, there is only a bearing chamber (12) at the center line of the transmission wheel body (1), and a cover plate groove ( 13) and the threaded hole (14) that is matched with the fixing screw that the fixed cover plate is used.

[0018] It should be noted that the other components and the structure of the components provided on the transmission wheel body (1) are the same as those in Embodiment 1, and will not be repeated here.

[0019] The driving wheel in this embodiment can rotate around a positioning shaft and is used as a driven driving wheel.

[0020] When the present invention is in use, as figure 1 , figure 2 As shown, diamond beaded wire saws are installed in the first transmission groove (6), the third transmission groove (8) and the fifth transmission groove (10) on the outer circumferential surface of the wear-resistant jacket (5), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com