Process protection structure of a stainless steel oil suction well of a ship

A technology for protecting structures and oil suction wells, applied in ship parts, ship construction, ship design, etc., can solve the problems affecting the inner surface quality of oil suction wells, uneven surface texture of oil suction wells, affecting the appearance quality of oil suction wells, etc. Good adaptability, good protection effect, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

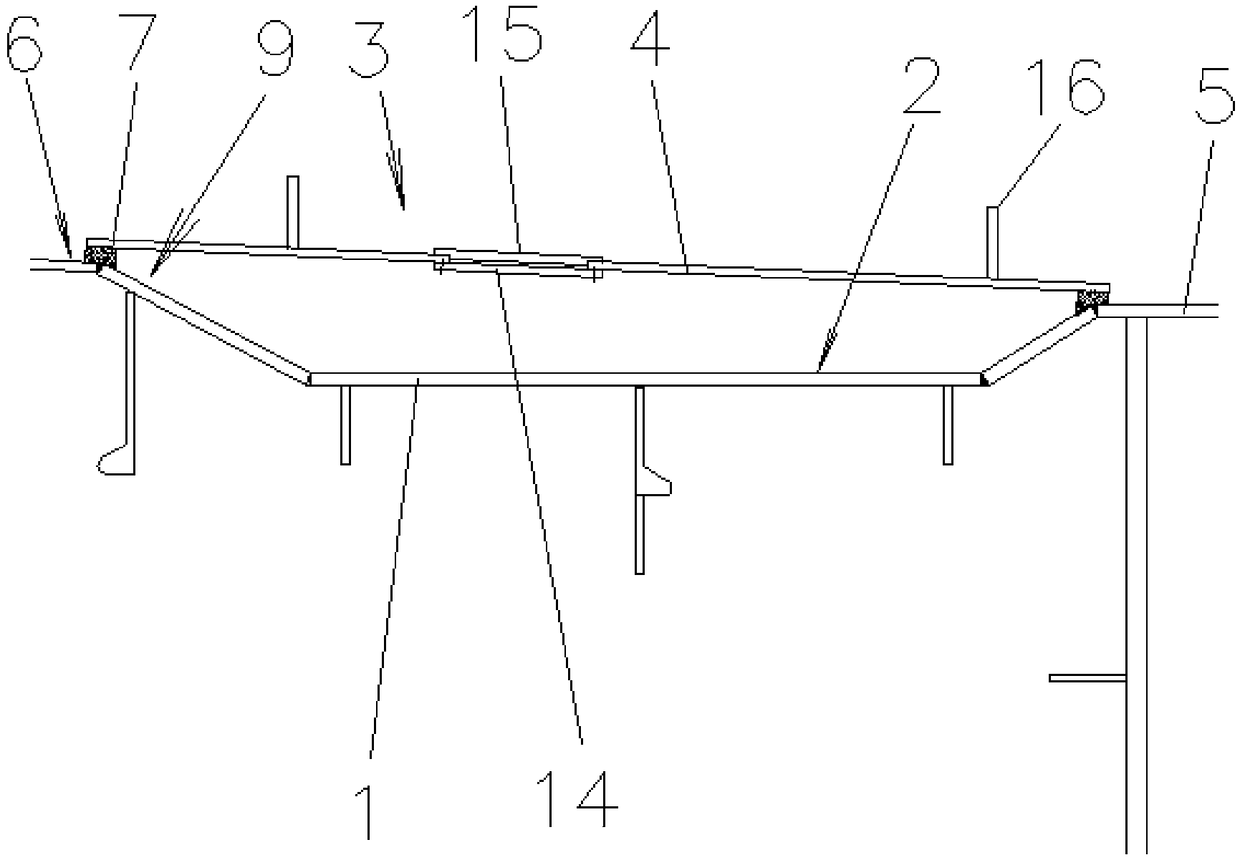

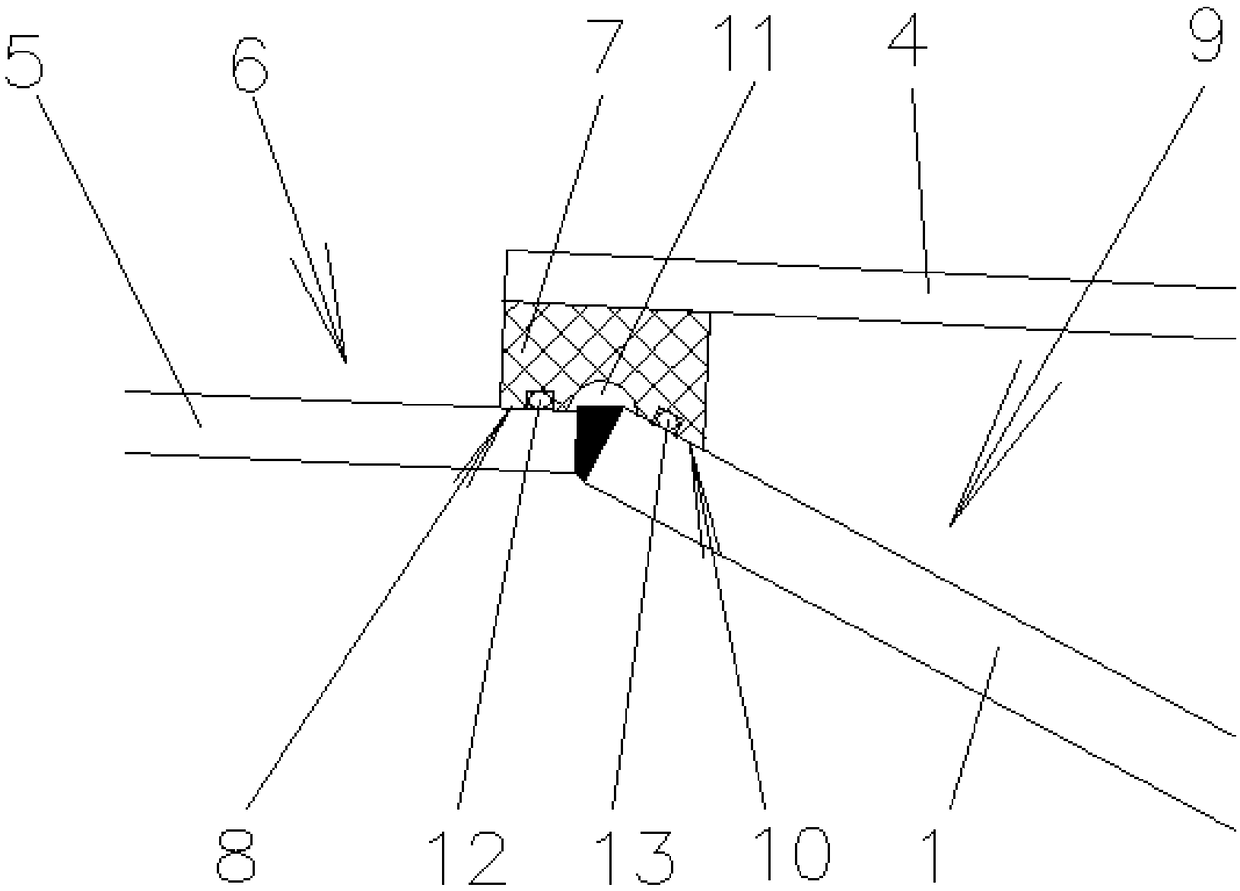

[0025] Such as Figures 1 to 2 Shown is an embodiment of the process protection structure of a stainless steel oil-absorbing well of a ship according to the present invention, including a stainless steel oil-absorbing well body 1, an erasable pre-welding protective layer 2 arranged on the surface of the oil-absorbing well body 1, and a On the hull section where the oil-absorbing well body is located and is a removable oil-absorbing well pre-coating protection device 3, the pre-weld protection layer 2 is a lime slurry layer painted on the surface of the oil-absorbing well body, the oil-absorbing well The protection device 3 before well coating includes a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com