Vacuum sucker

A vacuum suction cup and height-adjusting technology, applied in suction cups, connecting components, household components, etc., can solve the problems of high adsorption force and easy falling off, high processing accuracy requirements, affecting the yield of finished products, etc., and achieves long service life and improved processing accuracy. , easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

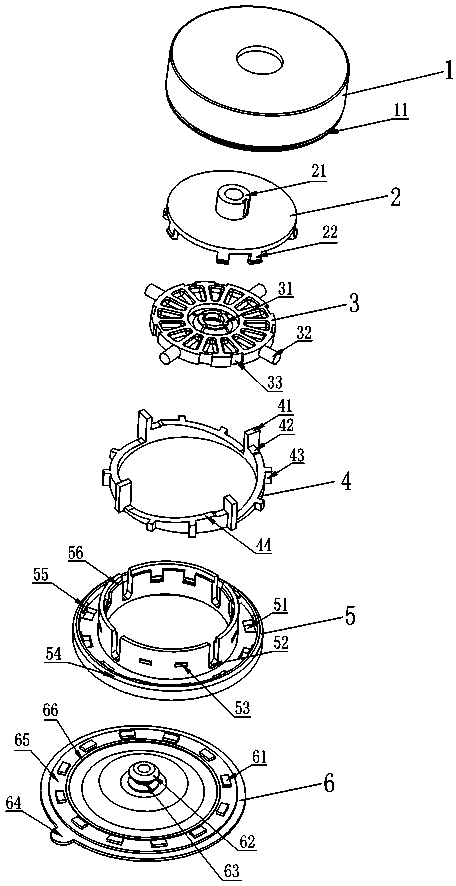

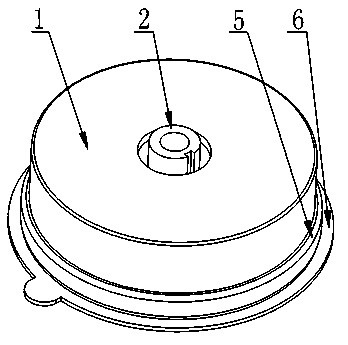

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

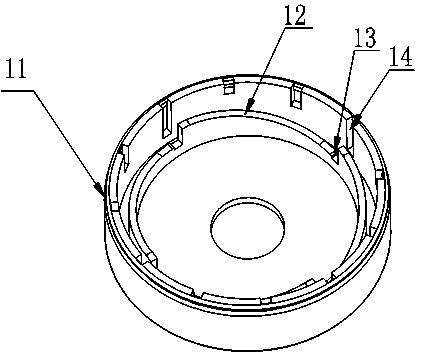

[0020] On the periphery of the inner wall of the cover 1, concave positioning ribs 14 uniformly distributed and of different heights are arranged, a ring groove 11 is arranged on the outer periphery of the lower edge, a through hole is arranged in the middle of the top surface, and there are more than two evenly distributed reverse ribs on the inner wall of the top surface. The annular circular wall formed by the slope 12 has a gap with the inner wall of the cover, and is matched with the forward slope 44 on the guide ring 4 directly below.

[0021] There is a connector 21 in the middle of the circular upper surface of the connecting seat 2, which is connected with the pendant (not shown in the figure), and there are hooks 22 extending out from the circular outer periphery and facing downwards, symmetrically distributed.

[0022] The upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com