Patents

Literature

35results about How to "Improve pulping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge petroleum charred slurry and preparing process and application thereof

ActiveCN101054541AHigh reactivityImprove utilization efficiencyBiofuelsSolid fuelsHigh concentrationHydrogen

The invention discloses a sludge petroleum coke slurry and its producing method and application. Said sludge petroleum coke slurry contains 100-200 shares of petroleum coke by weight, 5-100 shares of moisture sludge by weight, 5-200 shares of water by weight, 0.01-2 shares of dispersant by weight, 0.01-2 shares of sludge modification reagent by weight. The produced high concentration sludge petroleum coke slurry can be a burning fuel or producing synthetic gas and hydrogen by gasification. It not only fully utilize the caloric caloricity in the sludge and gets over the problems that the present moisture sludge has a high heat treatment energy consumption and the offgas and dregs are harmful and poisonous and has a big industrialization prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

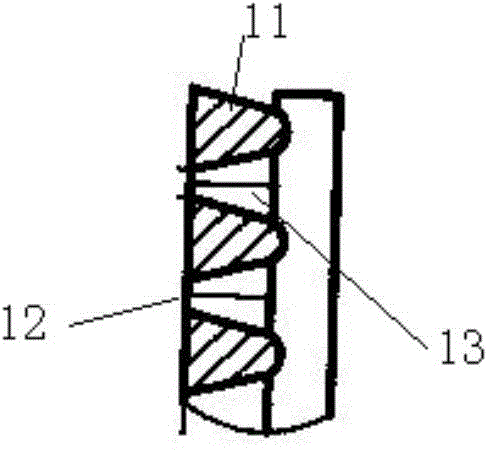

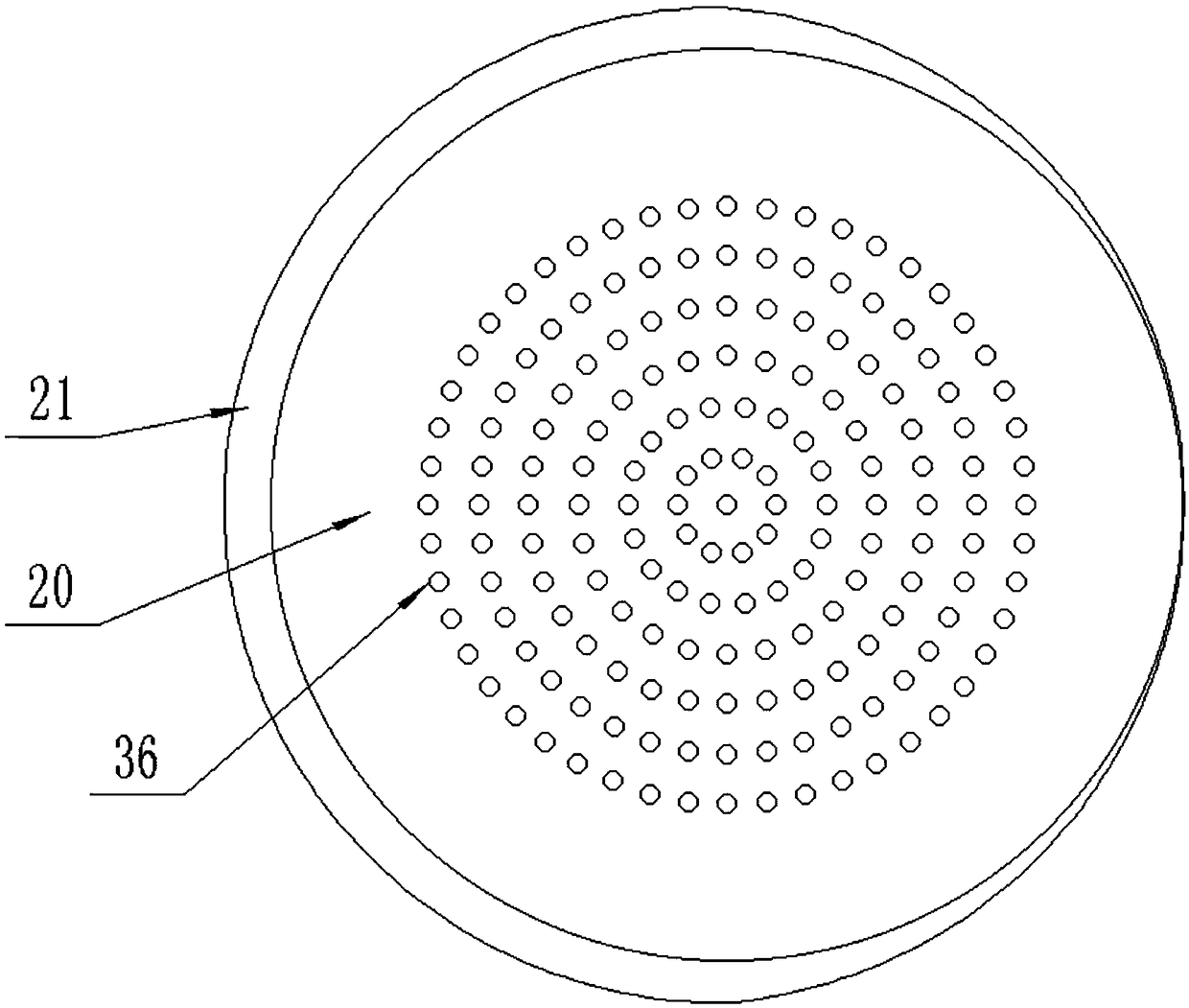

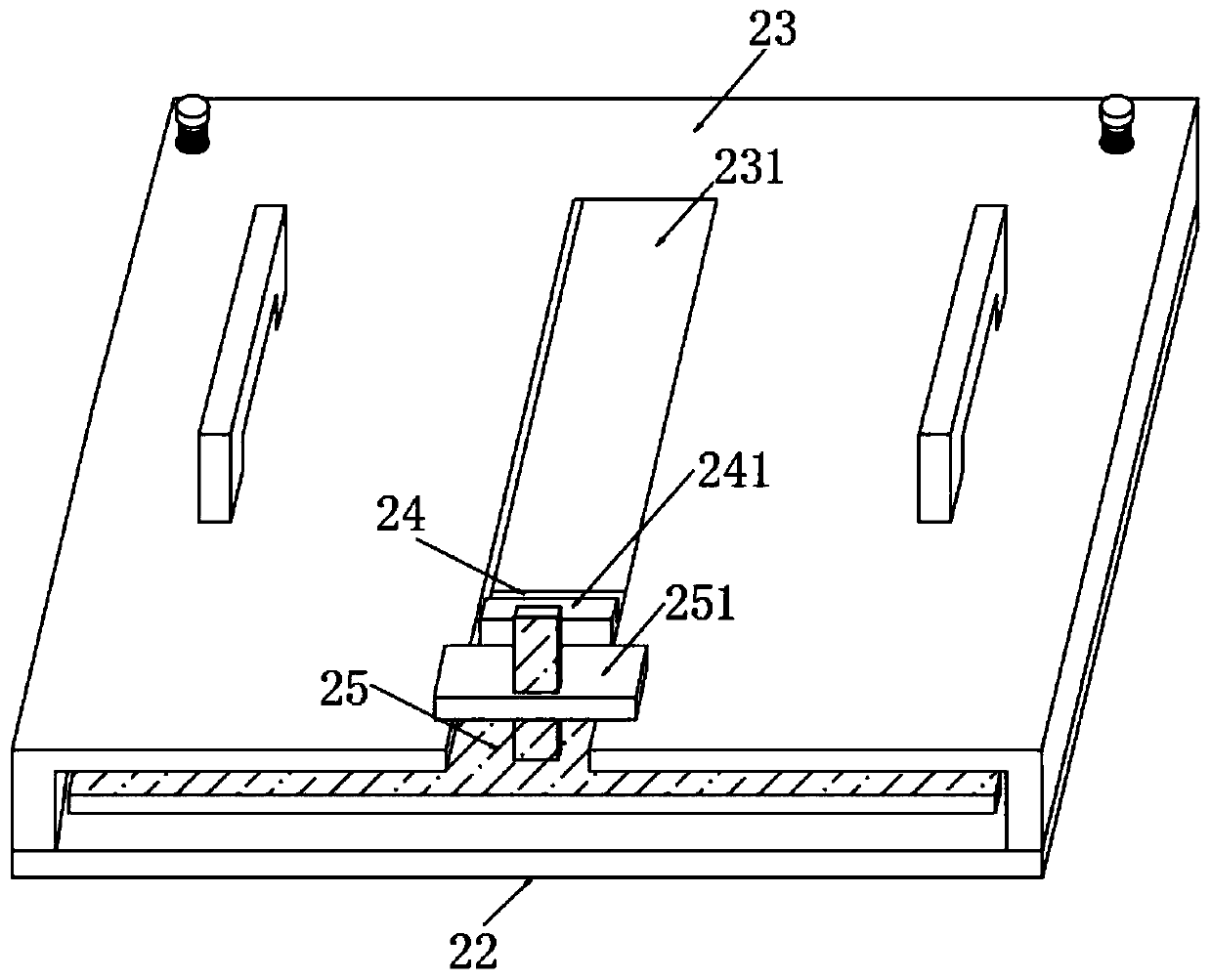

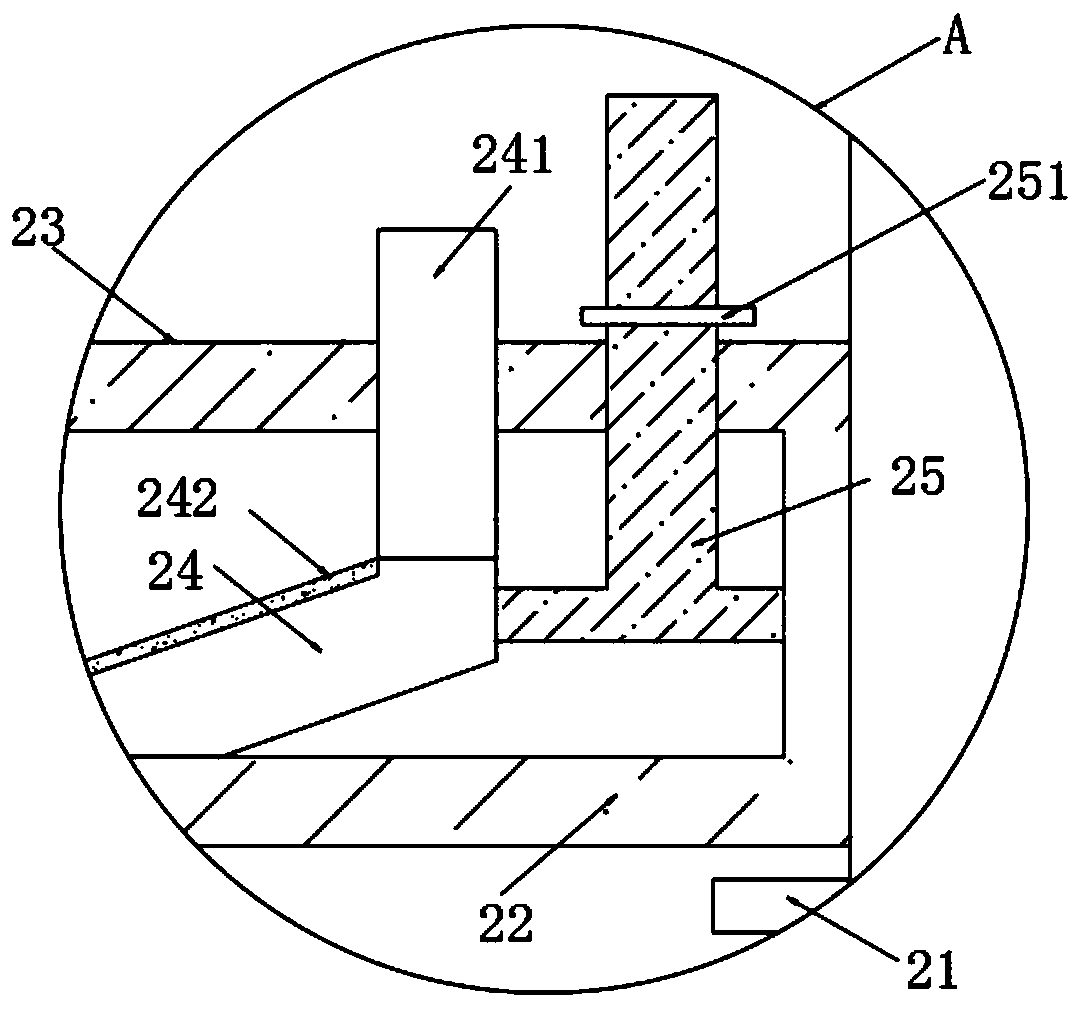

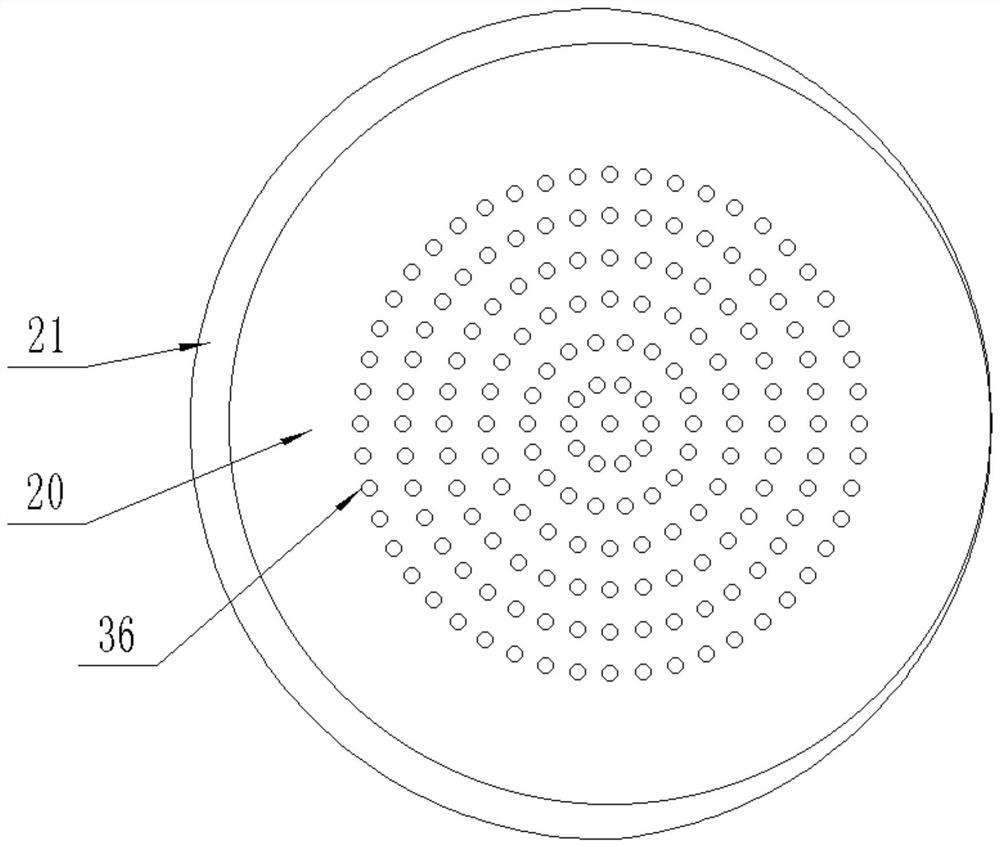

Rod milling method and device

The invention discloses a rod milling method. Two ends of a rod milling barrel are respectively connected with a hollow feeding shaft and a hollow discharge shaft by using bolts, and horizontally supported on two main shaft bushings; a lining plate is arranged inside the barrel body; a plurality of milling rods of which the lengths are a little shorter than the length of the barrel are arranged inside the barrel and mill together with materials when rotating inside the barrel; a plurality of holes are distributed in the surface of a discharge end cover of a rod mill; a cavity formed by a barrel end cover or a plate with the same shape is arranged between the discharge sides of the discharge end cover; the sizing agent at the discharge end of the rod milling barrel is discharged out from the holes in the discharge end cover of the rod mill; the discharged sizing agent is taken to the upper part of the hollow shafts of the barrel by the rotating cavity, and is forcibly discharged.

Owner:江苏东发重工科技有限公司

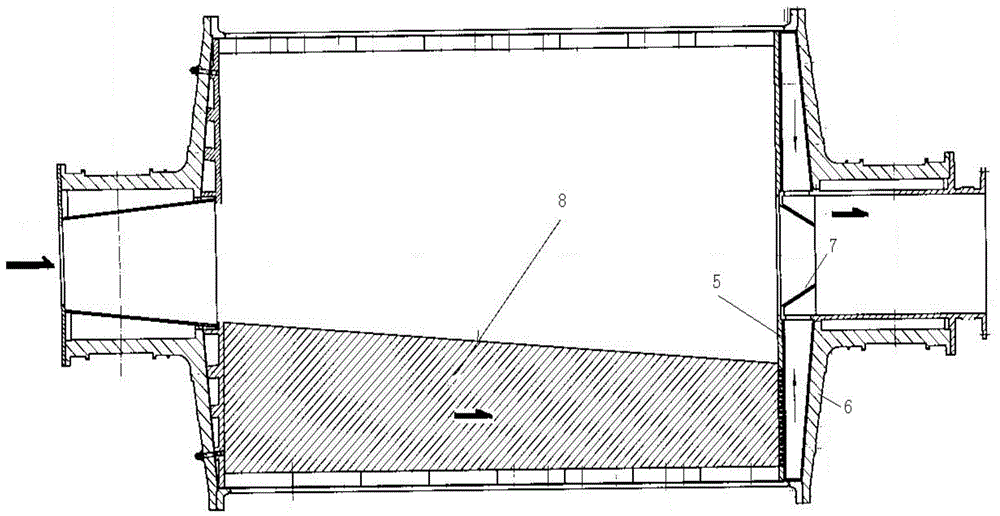

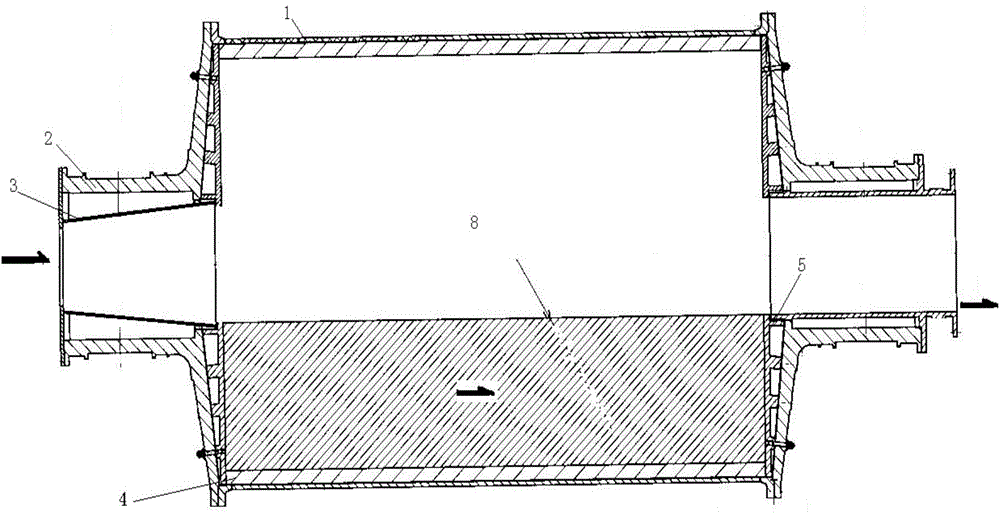

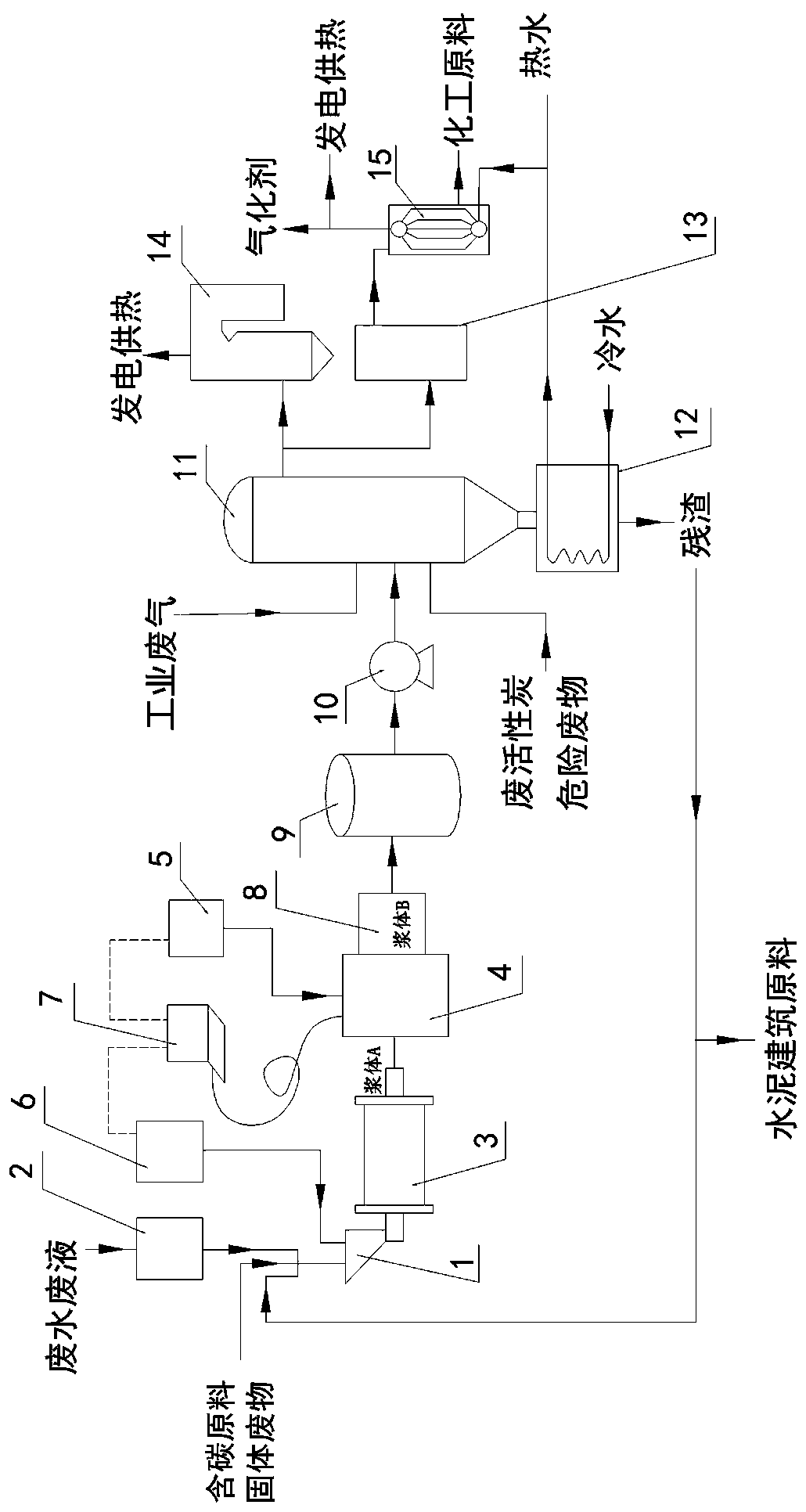

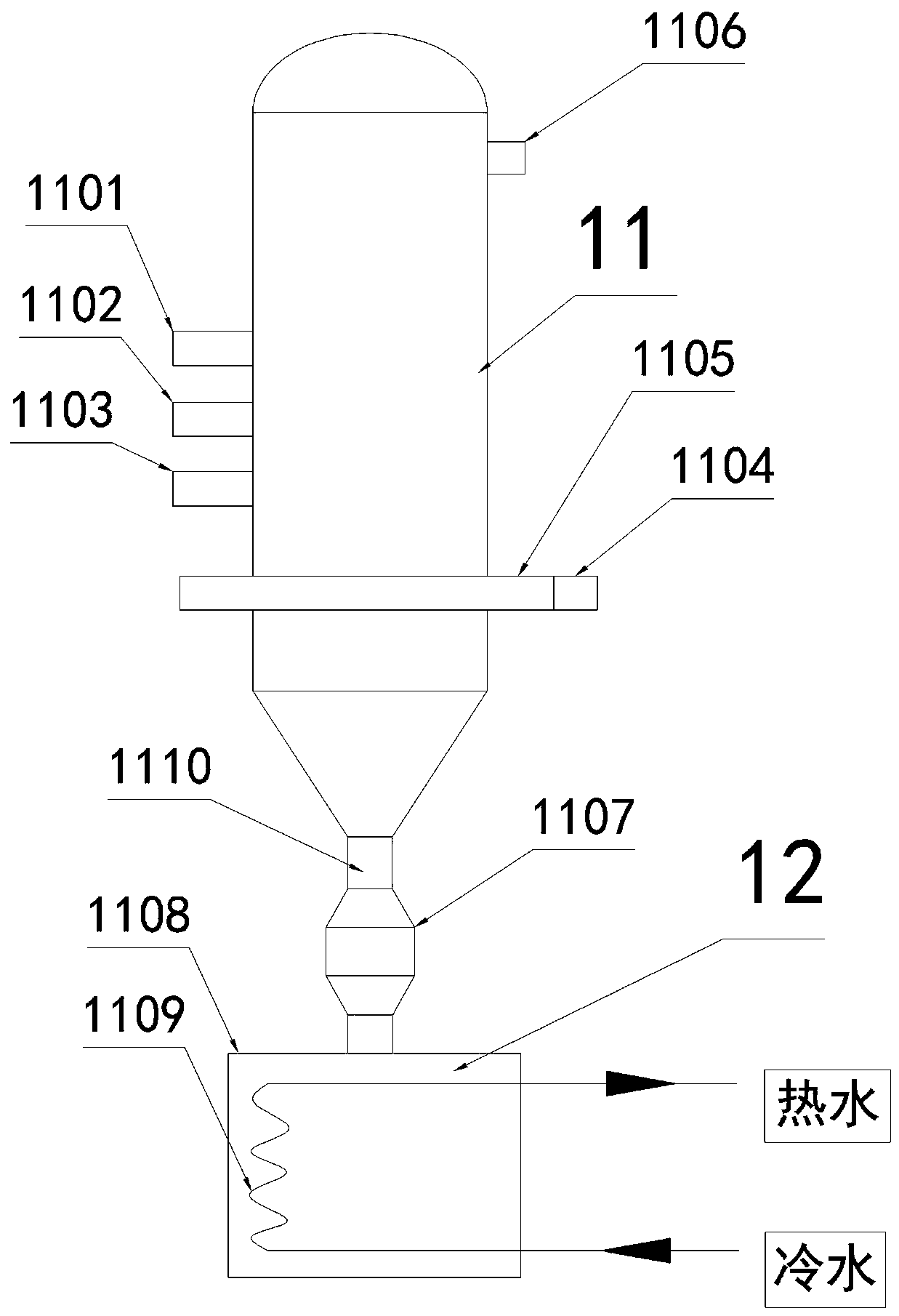

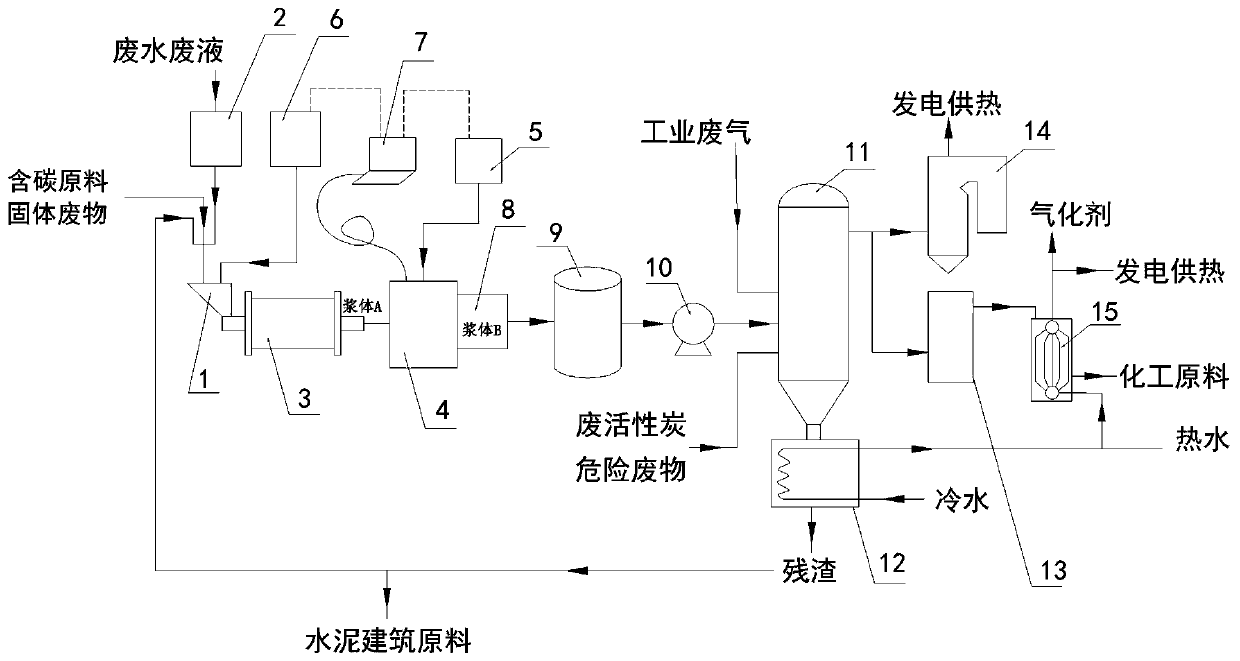

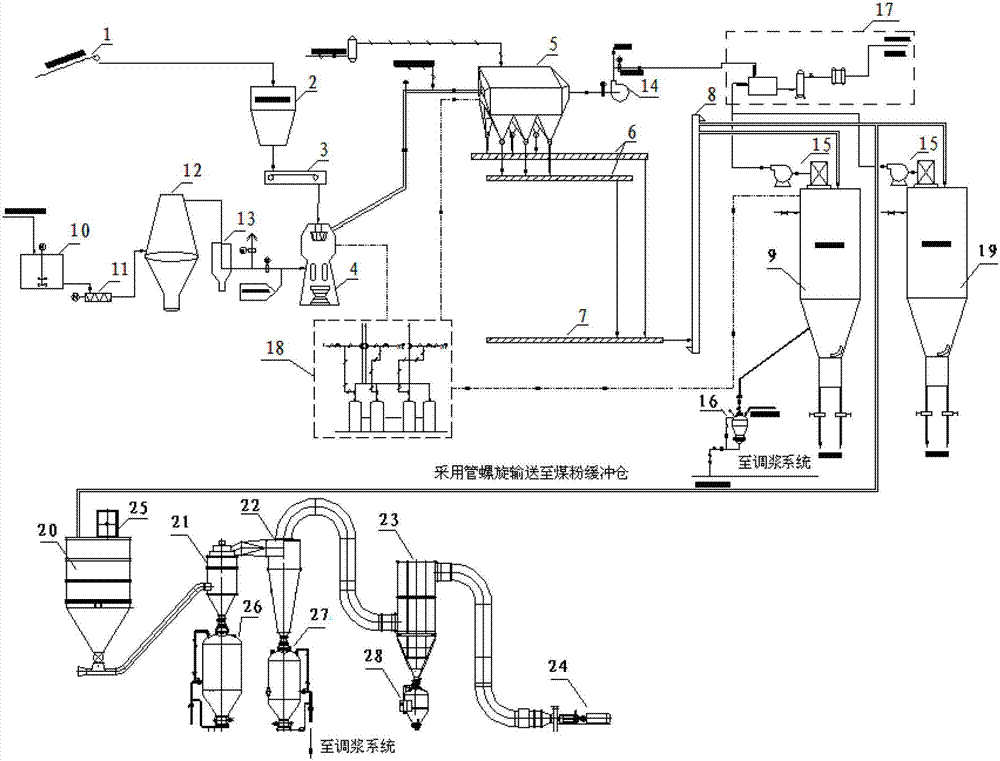

Gas-liquid-solid waste comprehensive treatment and resource utilization system

PendingCN110016368ARealize resource utilizationReduce high costGasification processes detailsCombustible gas productionLiquid wasteGuidance system

The invention relates to a gas-liquid-solid waste comprehensive treatment and resource utilization system, which comprises a grinding device, a pulping device and a gasification device. The grinding device comprises a feeding device and a mill. The feeding device is fed with carbon-containing raw material solid waste, waste water liquid and additives, and a formed mixture is sent to the mill for grinding to form a slurry A, and the slurry A is sent to the pulping device; the pulping device comprises a pulping body, a mixing pulping intelligent guidance system and a modifying conditioning device, wherein the mixing pulping intelligent guidance system guides the modifying conditioning device to perform conditioning treatment and ultrasonic treatment on the slurry A passing into the pulping body to generate a slurry B. The gasification device comprises a gasification furnace, wherein the gasification furnace is fed with the slurry B, which is prepared from the carbon-containing raw material solid waste and the waste water liquid by the front grinding device and pulping device, for pyrolysis and gasification to generate usable gas. The system provided by the invention is a system for comprehensive treatment of solid waste, waste liquid and waste gas.

Owner:浙江百能科技有限公司 +1

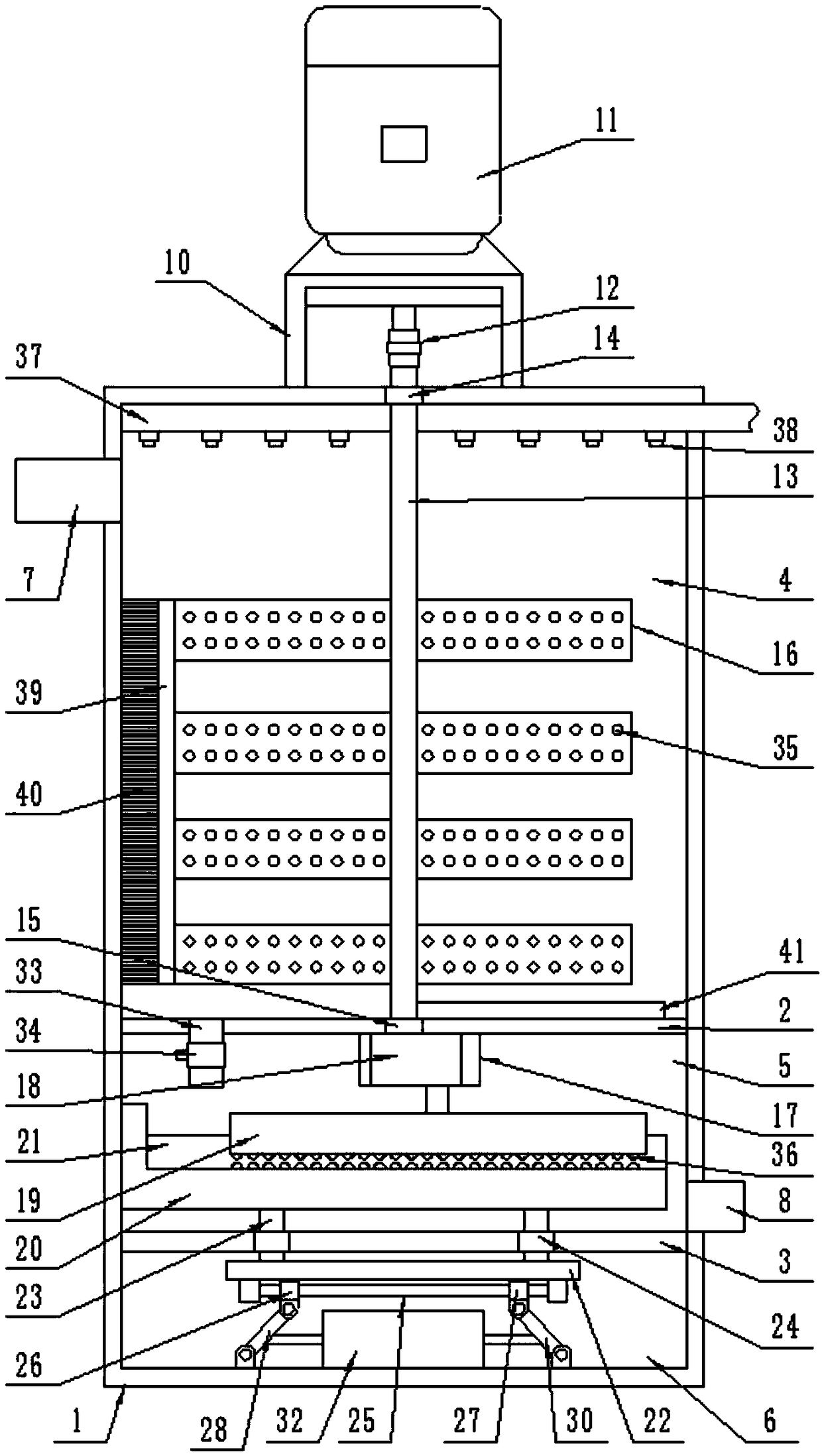

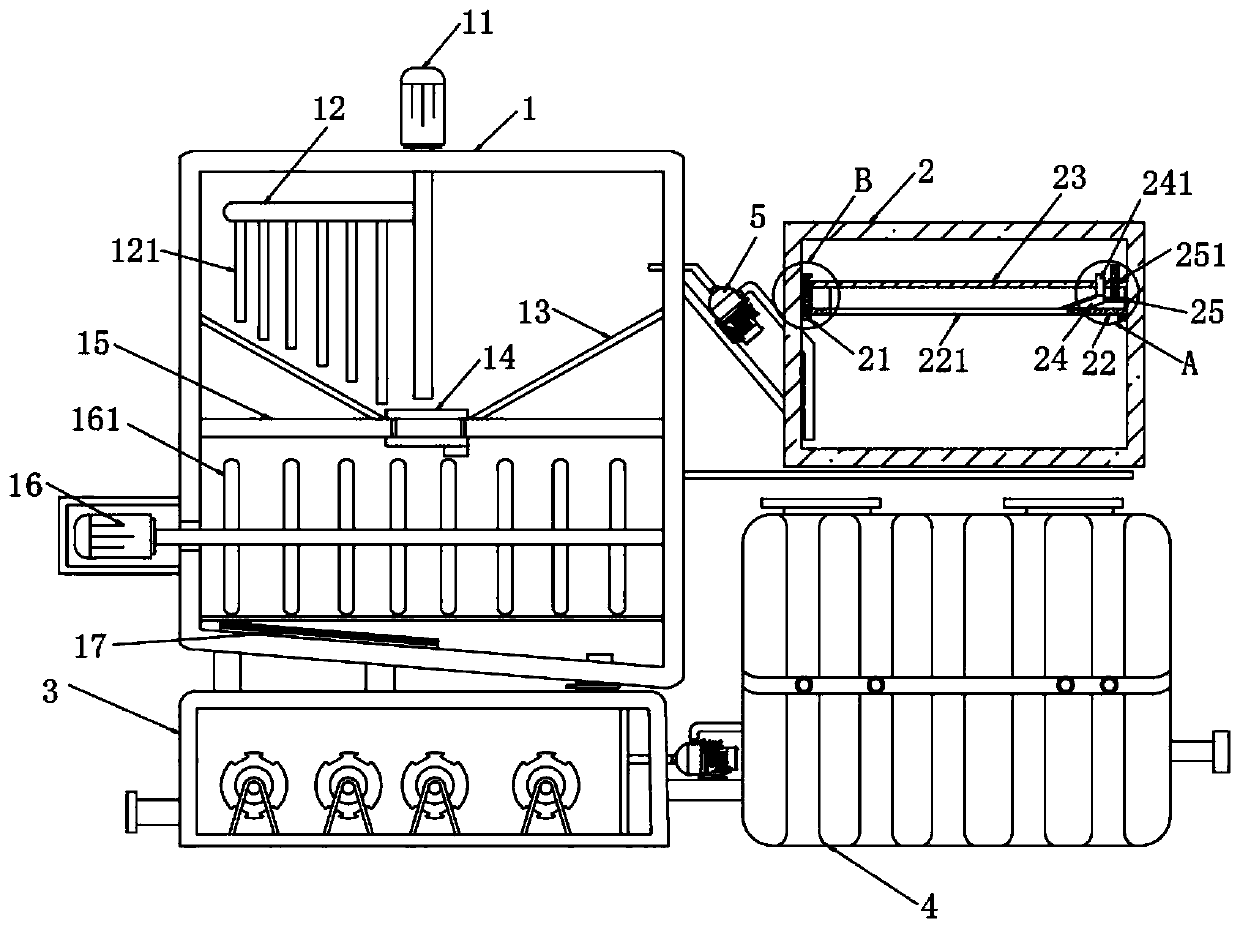

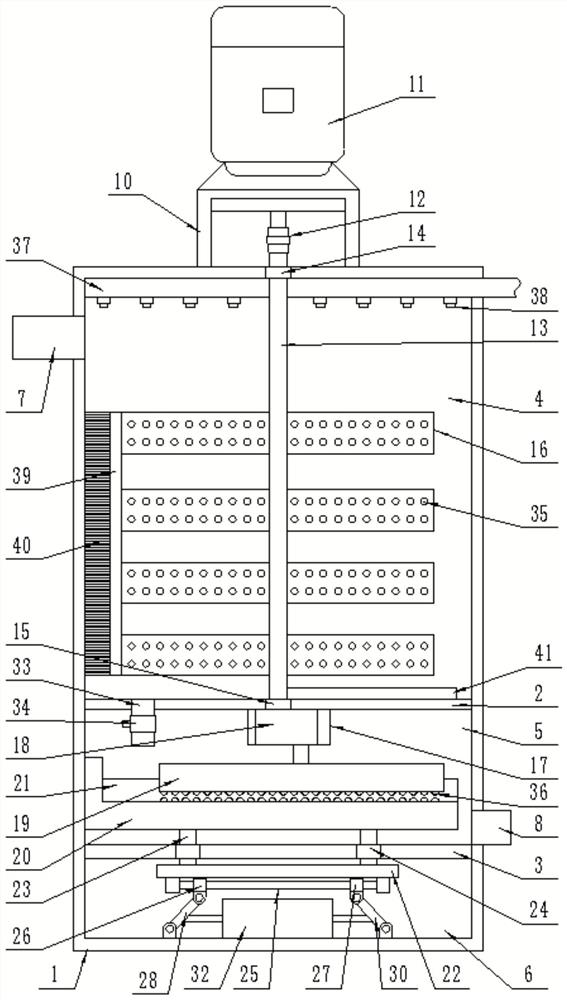

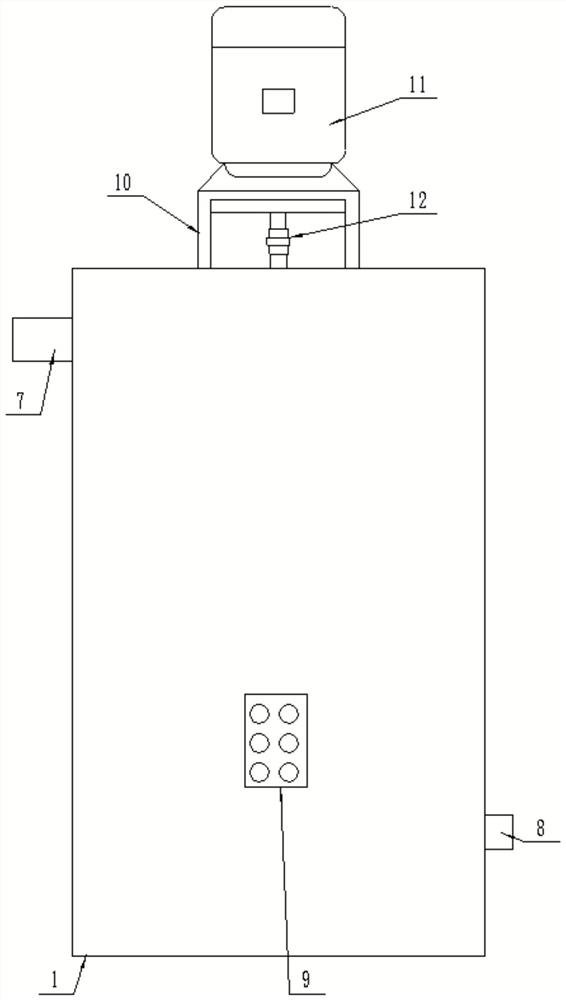

Pulp beating and refining device for papermaking production

ActiveCN109024043APrevent precipitationImprove pulpingPulp beating methodsSolenoid valvePulp and paper industry

The invention discloses a pulp beating and refining device for papermaking production, comprising a tank body, a pulp stirring mechanism and a pulp grinding mechanism, wherein the tank body is provided with a first partition plate and a second partition plate, the first partition plate and the second partition plate divide the inner cavity of the tank body into a stirring chamber, a grinding chamber and a functional chamber from top to bottom in sequence, and the tank body is provided with a feeding port, a discharging port and a controller. The pulp stirring mechanism comprises a motor bracket, a stirring motor, a stirring shaft and stirring blades. The pulp grinding mechanism comprises a protective shell, a reducer, an upper grinding disc, a lower grinding disc, and a grinding groove. Agrinding gap adjusting mechanism comprises a lifting push plate, a push rod, a sliding rod, a fixed seat, a first slider, a second slider, a first hinge rod, a first cross rod, a second hinge rod, a second cross rod and a bidirectional servo cylinder. The first partition plate is provided with a material discharging pipe communicating with the stirring chamber and the grinding chamber, the material discharging pipe is connected in series with a solenoid valve. The pulp beating and refining device has the advantages of simple structure and strong practicability.

Owner:SUZHOU DESIMIER SMART TECH CO LTD

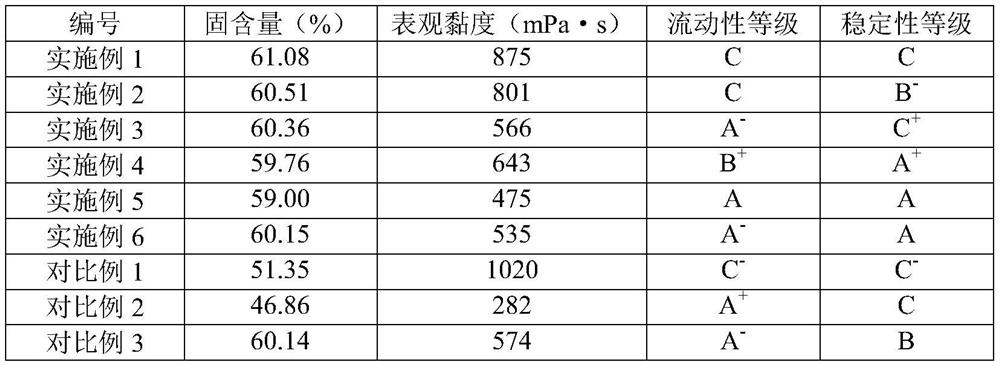

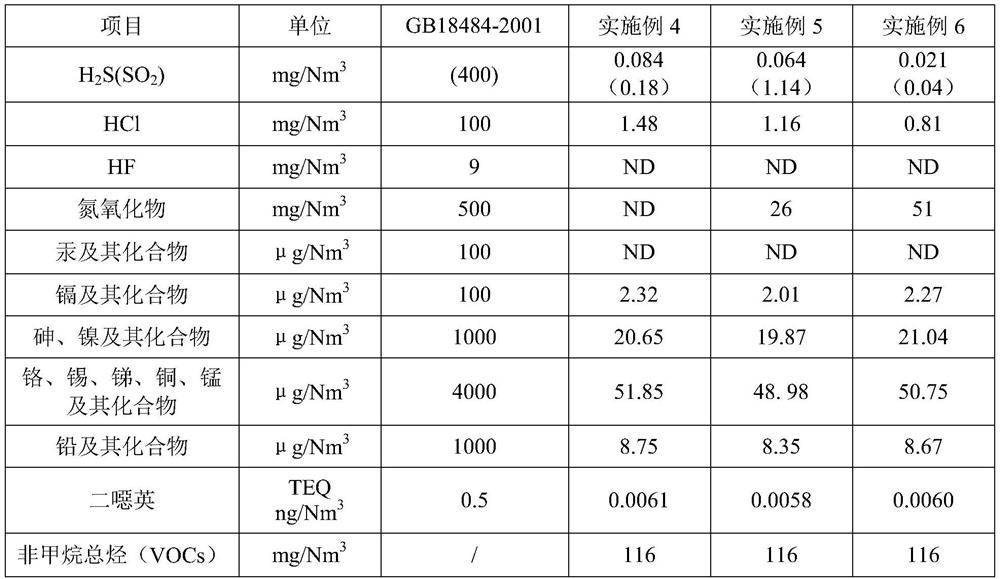

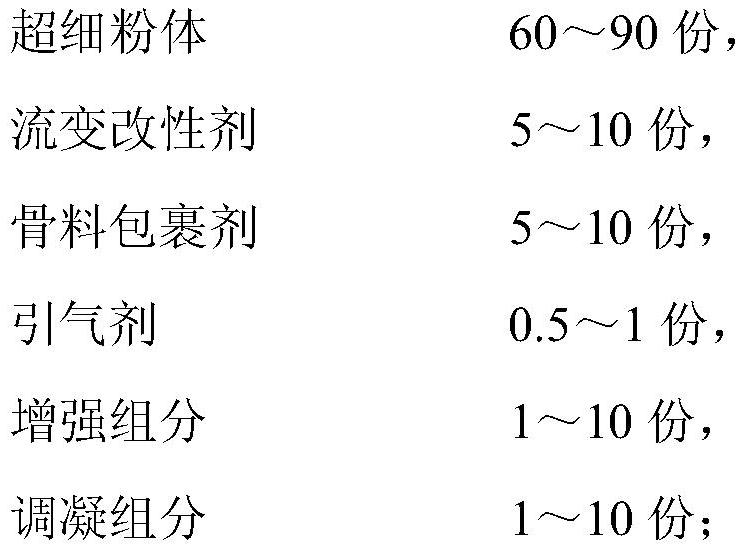

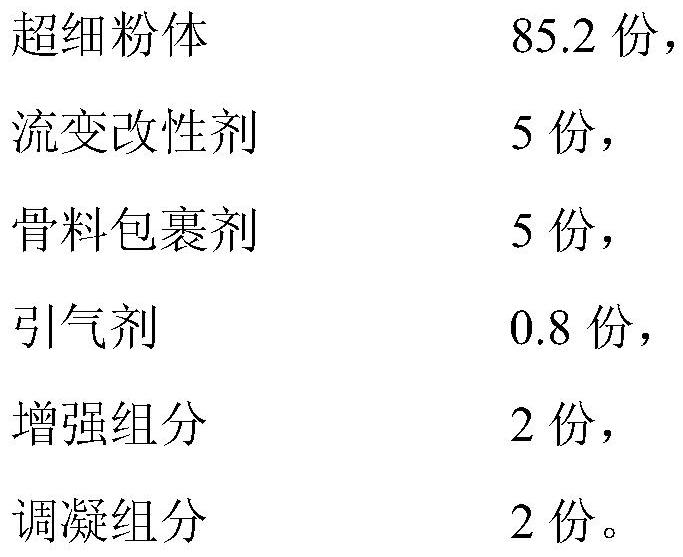

Viscosity adjusting admixture for spray construction and preparation method thereof

The invention discloses a viscosity adjusting admixture for spray construction and a preparation method thereof. The viscosity adjusting admixture is composed of following components in parts by weight: 60 to 90 parts of ultrafine powder, 5 to 10 parts of a rheology modifier, 5 to 10 parts of an aggregate wrapping agent; 0.5 to 1 part of an air entraining agent; 1 to 10 parts of a reinforcing component; and 1 to 10 parts of a setting control component; wherein the ultrafine powder is ultrafine limestone flour with a size of 600 to 1000 meshes, and the aggregate wrapping agent is a nano aggregate wrapping agent. The provided viscosity adjusting admixture can reduce the rebound rate, improves the construction efficiency, enhances the strength of all stages, and obviously improves the qualityof construction engineering that uses motor spraying and concrete spraying. The admixture can be used to adjust the viscosity of a spraying material. The pipe obstruction is inhibited. The construction efficiency is improved. The rebound rate of spraying construction, the strength of materials of all stages, and the bonding strength are all improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Method for preparing modified polyimide fiber paper

ActiveCN107675549AHydrophilicImprove surface roughnessPaper coatingSynthetic cellulose/non-cellulose material pulp/paperFiberCrystallinity

The invention discloses a method for preparing modified polyimide fiber paper. The method comprises the following steps of: mixing polyimide fiber pulp which is modified by an amphiphilic block copolymer and polyimide chopped fiber which is modified through microwave radiation so as to obtain modified polyimide fiber base paper, wherein the polyimide fiber pulp and the polyimide chopped fiber havedifferent lengths; and then performing resin bonding and curing treatment to obtain the modified polyimide fiber paper. Since the polyimide fiber pulp has certain performance of hydrophilicity, and the surface of the polyimide fiber pulp comprises active groups, the dispersibility and slurryability of the system are improved, and the smoothness of the base paper is improved; since the roughness of the surface of the polyimide chopped fiber which is modified through the microwave irradiation is increased, the quantity of active groups is increased, the crystallinity is decreased, and hydrogenbonds is more easily generated among the fiber so that the fibre is combined; finally, the fiber paper with higher strength and stability is obtained, and can be applied to printed circuit board substrates as a reinforcing material with beneficially comprehensive-performance.

Owner:乐凯特科技铜陵有限公司

Preparation method of high-concentration gasified coal water slurry

InactiveCN110964580AImprove hydrophilicityImprove pulpingLiquid carbonaceous fuelsCoal waterIon exchange

Belonging to the field of coal chemical industry, the invention relates to a preparation method of high-concentration gasified coal water slurry. The method includes: mixing coal with ethanol, then carrying out reaction in a supercritical stirring reaction kettle, carrying out ion exchange on the separated solid in a Ca(OH)2 turbid liquid stirring kettle, and then adding an additive of CaO and sodium methylnaphthalene sulfonate to obtain a finished product coal water slurry; wherein the total amount of the additive is determined according to the mass of ash in the coal, the ash fusion point iscontrolled at 1300-1400DEG C, and the ash viscosity is smaller than or equal to 250Pa.s. The method is suitable for producing the gasified coal water slurry with a coal material with high coalification degree, poor gasification activity and high ash fusion point. The method provided by the invention can improve the gasification activity of the coal material and lower the ash fusion point, not only can expand the gasification utilization way of the coal material, improve the resource utilization efficiency, but also has good environmental benefits and social benefits at the same time.

Owner:SHANXI LUAN COAL BASED SYNTHETIC OIL +1

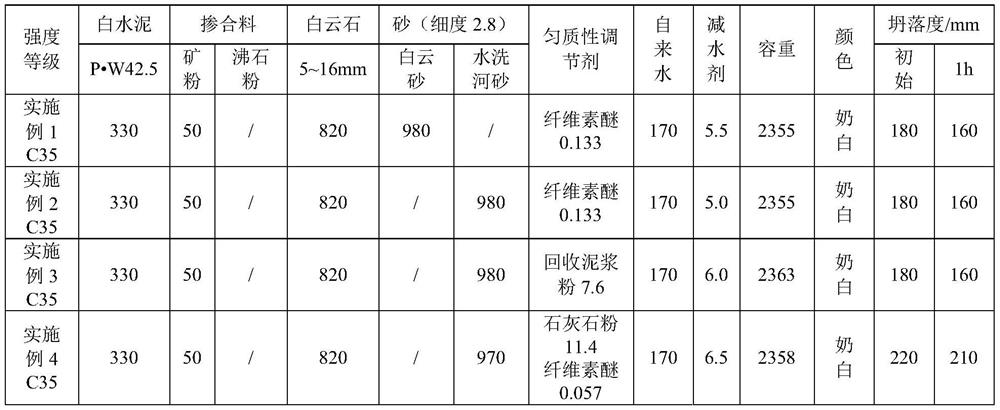

White fair-faced concrete for prefabricated part and preparation method of white fair-faced concrete

PendingCN113773022ASolve the overall grading gapSolve the difference in particle shapeSolid waste managementArchitectural engineeringStructural engineering

The invention discloses white fair-faced concrete for a prefabricated part and a preparation method of the white fair-faced concrete. Each cubic meter of the concrete comprises the following components by weight: 320-400kg of cement, 50-190kg of an admixture, 820-1010kg of coarse aggregate, 630-980kg of fine aggregate, 0-15kg of a homogeneity regulator, 5-16kg of a water reducing agent, 145-170kg of water and 0-35kg of titanium dioxide, and the total volume weight of the concrete is 2320-2430kg / m<3>. The C35-C80 grade white fair-faced concrete with high whiteness requirements such as light white and creamy white can be obtained, the requirements for high early strength and rapid demolding of components are met, the concrete is environmentally friendly, low in cost and flexible and adjustable in flowability, the concrete surface is flat, fine and smooth, the color is uniform and basically consistent, secondary decoration is not needed, production equipment does not need to be transformed or added, and the concrete can be applied to fabricated buildings or wind power concrete tower components, and has practical production operability and popularization value.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

High-strength mica paper and method for preparing same

InactiveCN106320060AImprove pulpingHigh mechanical strengthNon-fibrous pulp additionPaper/cardboardEthylene diamineApplication procedure

The invention discloses high-strength mica paper. A method for preparing the high-strength mica paper includes producing pulp from, by weight, 200-300 parts of mica sheets, 36-45 parts of polyethylene-based resin, 10-25 parts of asbestos, 5-10 parts of cationic starch, 4-10 parts of ethylene diamine tetraacetic acid and 100 parts of water and then manufacturing the high-strength mica paper with the pulp. The high-strength mica paper and the method have the advantages that the high-strength mica paper is extremely high in mechanical strength, and the shortcoming of poor mechanical strength of existing mica paper in application procedures can be overcome.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

High-strength mica paper and preparation method thereof

InactiveCN106400604AImprove pulpingHigh mechanical strengthPlastic/resin/waxes insulatorsSpecial paperGlass fiberHigh intensity

The invention discloses high-strength mica paper. The high-strength mica paper is prepared through pulping and papermaking from a mica plate, urea resin, glass fiber, polyacrylamide, ethylenediaminetetraacetic acid and water, wherein relative to 100 parts of water by weight, the using amount of the mica plate is 200 to 300 parts by weight, the using amount of the urea resin is 36 to 45 parts by weight, the using amount of the glass fiber is 10 to 25 parts by weight, the using amount of the polyacrylamide is 5 to 10 parts by weight, and the using amount of the ethylenediaminetetraacetic acid is 4 to 10 parts by weight. The high-strength mica paper has extremely high mechanical strength, and makes up the defect that the mica paper is low in mechanical strength in the application process.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

High-strength mica paper and preparation method thereof

InactiveCN106283843AImprove pulpingHigh mechanical strengthInorganic fibres/flakesReinforcing agents additionAcetic acidGlass fiber

The invention discloses high-strength mica paper. The high-strength mica paper is prepared from mica sheets, urea resin, glass fibers, polyacrylamide, ethylene diamine tetraacetic acid and water through pulping and papermaking, wherein in terms of 100 parts by weight of water, the high-strength mica paper is prepared from the components in parts by weight as follows: 200-300 parts of the mica sheets, 30-35 parts of urea resin, 10-25 parts of the glass fibers, 5-10 parts of polyacrylamide and 4-10 parts of ethylene diamine tetraacetic acid. The high-strength mica paper has quite high mechanical strength and overcomes the defect of low mechanical strength of the mica paper in an application process.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Resin composite mica paper and preparation method thereof

The invention discloses resin composite mica paper. A preparation method of the resin composite mica paper includes: preparing a mica layer; preparing a resin layer, to be more specific, mixing novolac epoxy resin, polyimide resin, glycol ether, Texanol and dibutyl phthalate with water, performing thermal treatment, and performing extrusion forming to obtain the resin layer; performing resin compositing on the mica layer and the resin layer, to be more specific, placing the mica layer on the resin layer, performing hot-pressing resin compositing, and naturally cooling to obtain the resin composite mica paper. The resin composite mica paper has the advantages of excellent insulating performance and excellent high temperature resistance of the mica paper and is quite high in mechanical strength and toughness.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

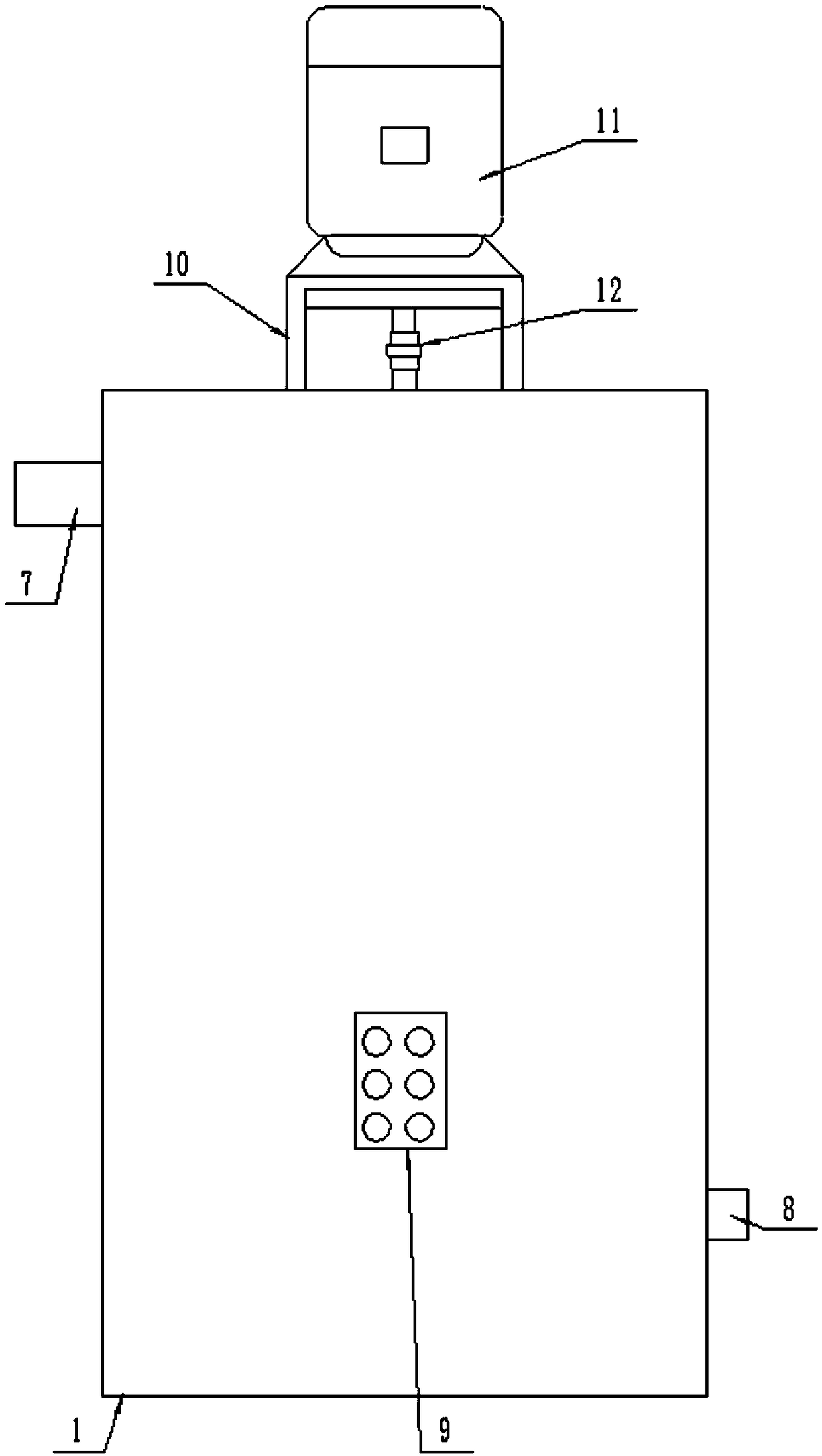

Purification equipment for waste paper pulping and with suspension tank device

PendingCN110863383AReduce entryImprove efficiencyPaper recyclingFiltration circuitsElectric machineFiltration

The invention discloses purification equipment for waste paper pulping and with a suspension tank device. The equipment comprises a box body, a dewatering and screening device and a suspension purification device, wherein the box body is communicated with the dewatering and screening device; the dewatering and screening device is communicated with the suspension purification device; the upper endof the box body is fixedly connected with a first motor; the output end of the first motor penetrates through the box body; the first motor is electrically connected with an external power supply; theoutput end of the first motor is fixedly connected with a connecting rod; and the lower end of the connecting rod is fixedly connected with a plurality of first stirring rods. According to a scheme in the invention, the possibility that floating impurities enter the box body can be reduced; therefore, during subsequent filtration and water treatment, the impurities are not mixed into discharged wastewater, so the time and purification burden of the suspension purification device for treating the wastewater are reduced, the purification operation of the suspension purification device on discharged wastewater is facilitated, and treatment efficiency and treatment quality during wastewater can be improved.

Owner:嘉兴市博莱特纸业股份有限公司

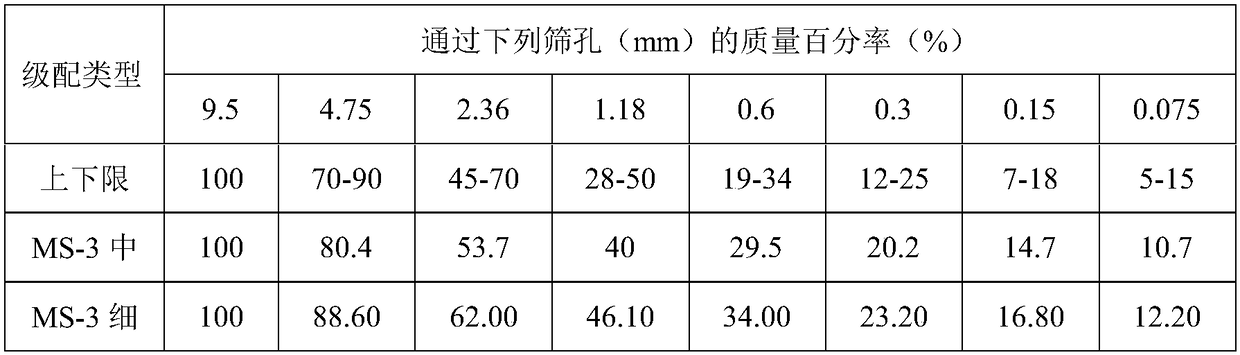

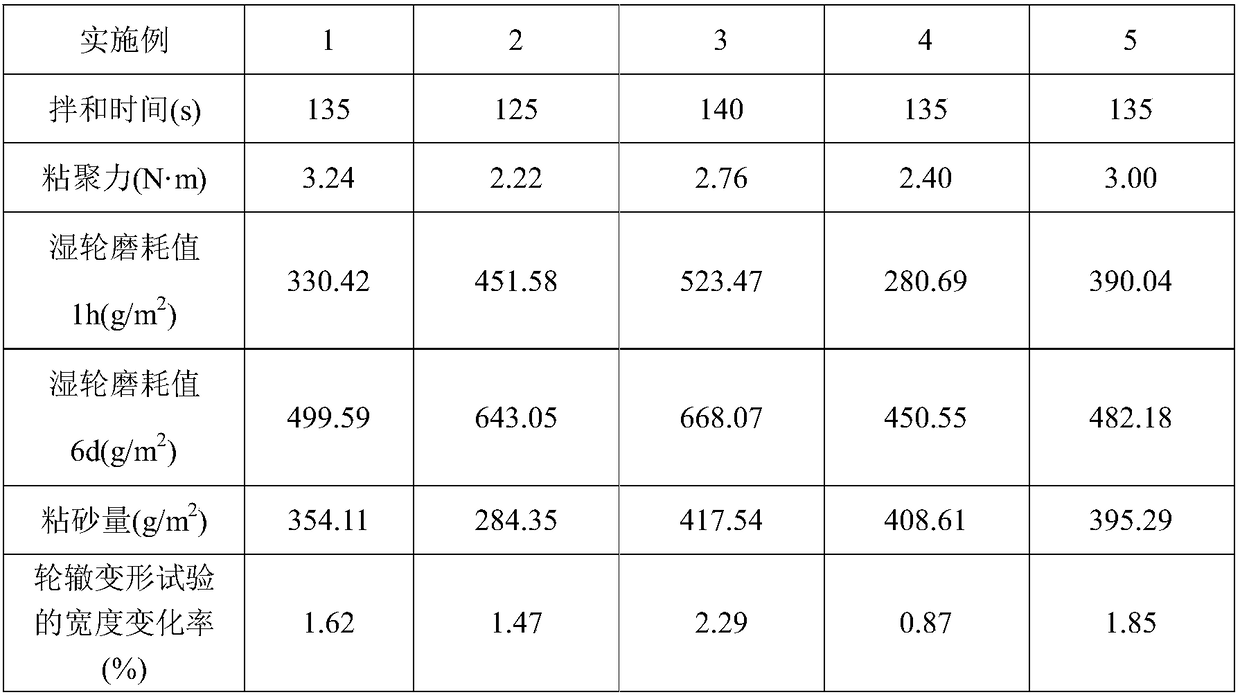

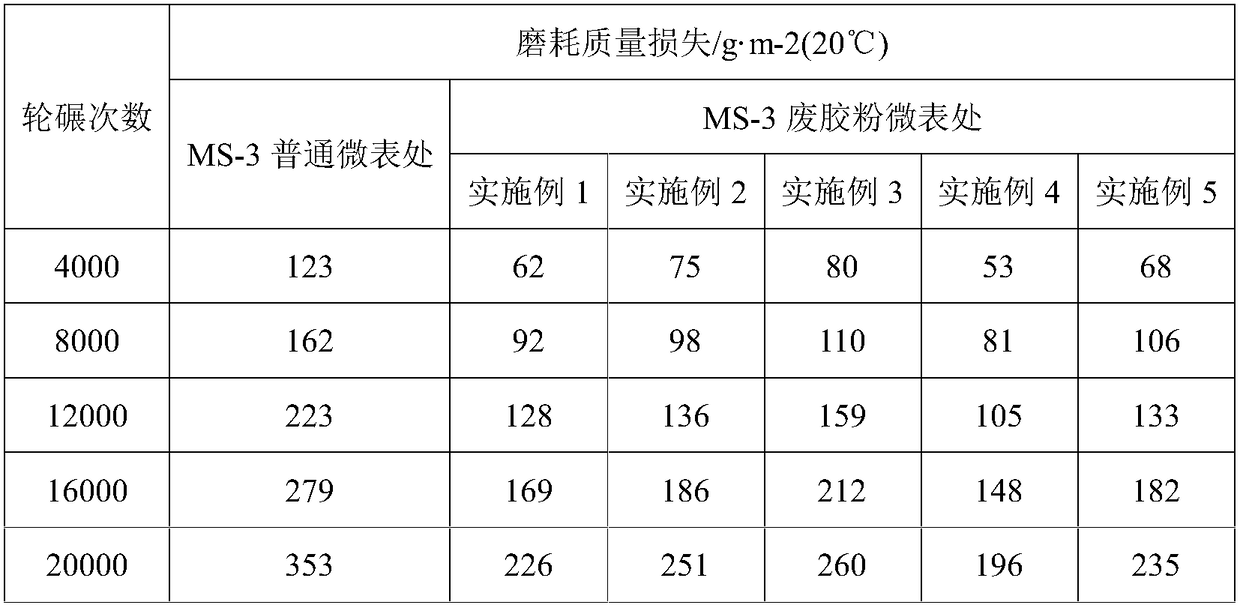

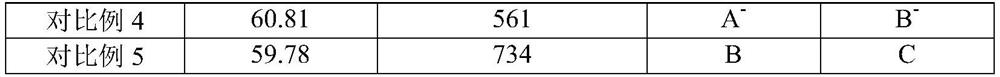

Waste rubber powder dry micro-surfacing mixed material and preparation method thereof

InactiveCN108147744AImprove the way of forceImproved particle gradation and particle size distributionSolid waste managementPortland cementWaste rubber

The invention discloses a waste rubber powder dry micro-surfacing mixed material and a preparation method thereof. The waste rubber powder dry micro-surfacing mixed material is prepared from, by masspercent, 100% of basalt aggregate, 12%-13% of SBR (styrene butadiene rubber) modified emulsified asphalt, 1%-2% of ordinary Portland cement, 1%-3% of waste rubber powder and water in a weight ratio of5%-7% to the aggregate; the waste rubber powder dry micro-surfacing mixed material is in an MS-3 medium grading; the ordinary Portland cement is P.O42.5 ordinary Portland cement. The preparation method of the waste rubber powder dry micro-surfacing mixed material includes steps of detecting raw materials according to the technical requirements in Micro-surfacing and Slurry Seal Technical Manual,according to the proportional ratio, weighing out the basalt aggregate, the cement and the waste rubber power which are qualified, and manually uniformly mixing the raw materials inside a mixing pot;pouring water of the specified weight into the mixing pot, uniformly mixing for about 15 seconds; then pouring the SBR modified emulsified asphalt of the specified weight into the mixing pot, and continuing to manually uniformly mixing for 15 seconds to obtain the waste rubber powder dry micro-surfacing mixed material.

Owner:SHANDONG JIAOTONG UNIV

High-strength mica paper and preparation method thereof

The invention discloses high-strength mica paper. The high-strength mica paper is prepared from mica sheets, polyvinyl resin, asbestos, polyacrylamide, ethylenediaminetetraacetic acid and water through pulping and papermaking; in terms of 100 parts by weight of the water, the high-strength mica paper is prepared from 200-300 parts by weight of the mica sheets, 36-45 parts by weight of polyvinyl resin, 10-25 parts by weight of asbestos, 5-10 parts by weight of polyacrylamide and 4-10 parts by weight of ethylenediaminetetraacetic acid. The high-strength mica paper has quite high mechanical strength and overcomes the defect of poor mechanical strength in an application process of the mica paper.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Sludge petroleum charred slurry and preparing process and application thereof

ActiveCN101054541BHigh reactivityImprove utilization efficiencyBiofuelsSolid fuelsHigh concentrationHydrogen

The invention discloses a sludge petroleum coke slurry and its producing method and application. Said sludge petroleum coke slurry contains 100-200 shares of petroleum coke by weight, 5-100 shares of moisture sludge by weight, 5-200 shares of water by weight, 0.01-2 shares of dispersant by weight, 0.01-2 shares of sludge modification reagent by weight. The produced high concentration sludge petroleum coke slurry can be a burning fuel or producing synthetic gas and hydrogen by gasification. It not only fully utilize the caloric caloricity in the sludge and gets over the problems that the present moisture sludge has a high heat treatment energy consumption and the offgas and dregs are harmful and poisonous and has a big industrialization prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing high-performance coal water slurry from kettle bottom residues and waste emulsion

ActiveCN112760144AImprove pulpingImprove gasification effectOther chemical processesLiquid carbonaceous fuelsCoal waterActivated carbon

The invention discloses a method for preparing high-performance coal water slurry from kettle bottom residues and waste emulsion. The method comprises the steps: (1) drying, crushing and screening raw material coal and kettle bottom residues to obtain coal powder and kettle bottom residue powder; (2) sequentially performing filtration and ultrafiltration pretreatment on the metal processing waste emulsion, adding activated carbon powder, and stirring and adsorbing to obtain pretreated waste emulsion; and (3) mixing 65-85 parts by weight of pulverized coal, 65-75 parts by weight of the pretreated waste emulsion, 15-28 parts by weight of kettle bottom residue powder and 1-2 parts by weight of an additive, carrying out ball milling, and uniformly stirring to obtain the high-performance coal water slurry. Through compatibility of the kettle bottom residues, the metal processing waste emulsion, the activated carbon and the pulverized coal, various properties of the coal water slurry are effectively improved by utilizing interaction among wastes, and the high-performance coal water slurry which is high in solid content, good in dispersity and stability and high in combustion efficiency is prepared.

Owner:梵境新能源科技(浙江)有限公司

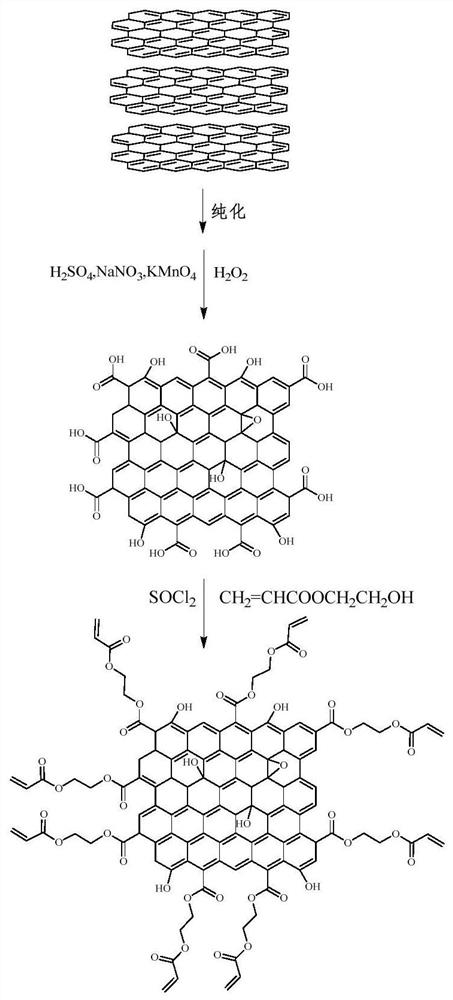

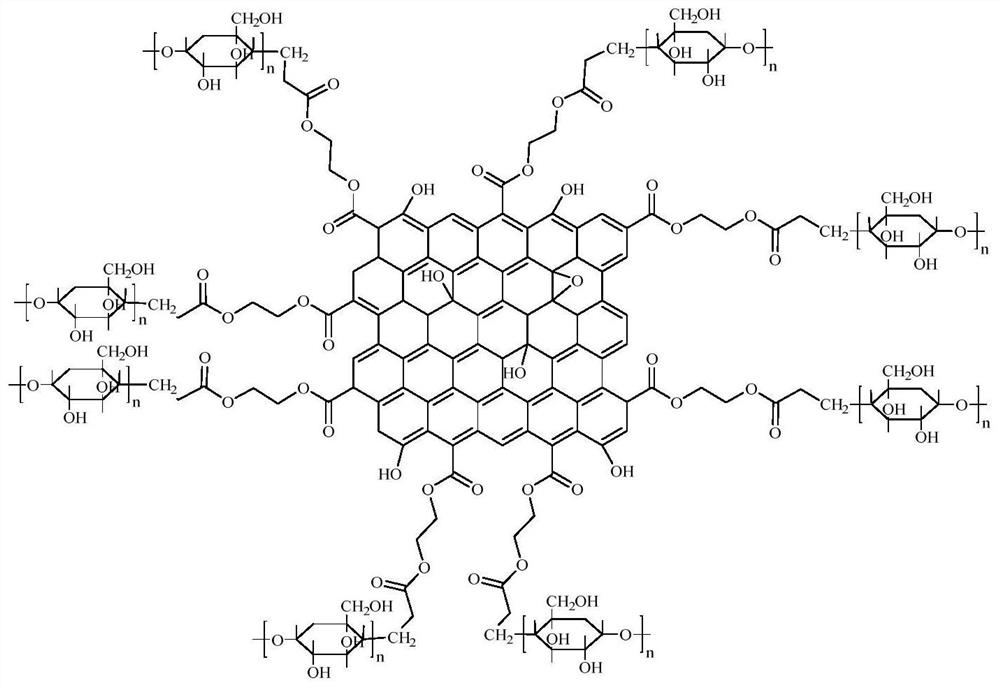

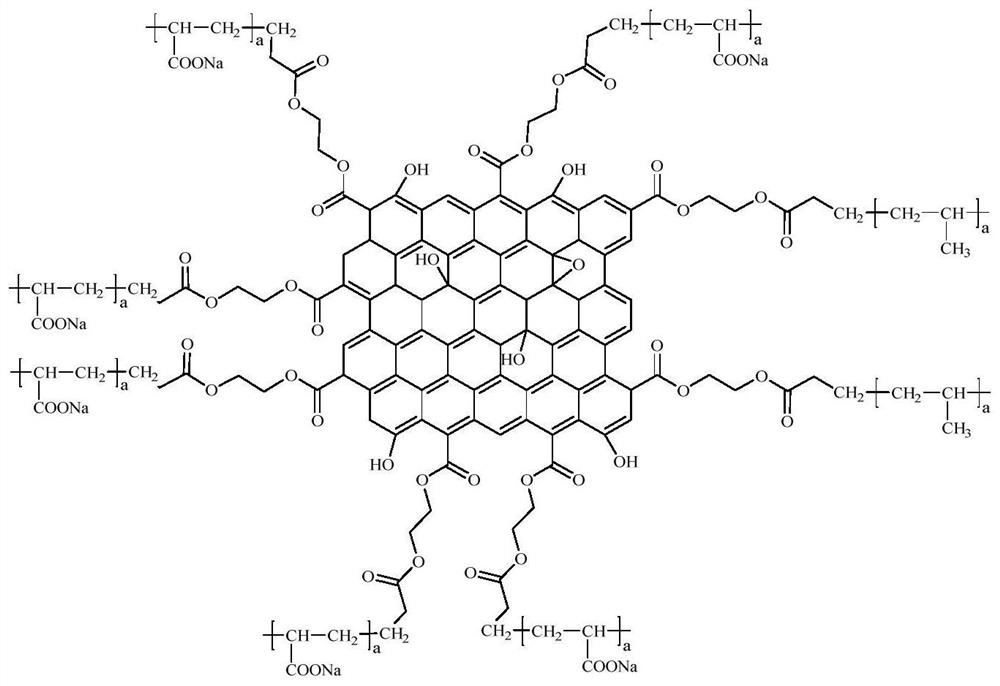

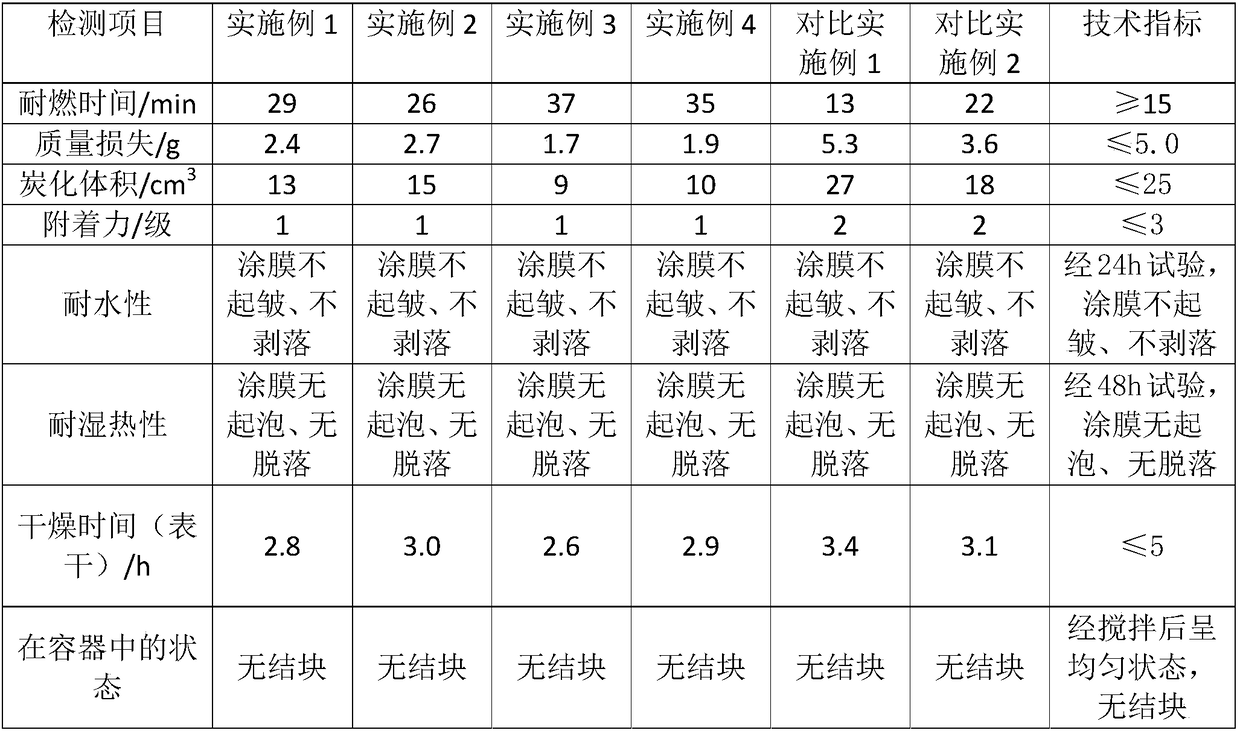

Binary surface-to-surface adsorption type dispersing agent for slurry forming of low-rank coal and preparation method of dispersing agent

ActiveCN113201106AImprove interface structureInhibit aggregationLiquid carbonaceous fuelsFuel additivesBrown coalHydrophobic effect

The invention discloses a binary surface-to-surface adsorption type dispersing agent for slurry forming of low-rank coal and preparation method of the dispersing agent, belonging to the field of dispersing agent. The preparation method comprises the steps that firstly, graphite is oxidized to obtain graphite oxide; then a carboxyl group on the edge of the graphite oxide is sequentially subjected to acylating chlorination and esterification; and then hydrophilic chains are grafted through an emulsion polymerization method so as to obtain the surface-to-surface adsorption type dispersing agent for slurry forming of low-rank coal. The dispersing agent has a central hydrophobic anchoring group similar to the surface structures of non-caking coal, sub-bituminous coal and lignite, so the dispersing agent can realize surface-to-surface adsorption with the surfaces of the non-caking coal, the sub-bituminous coal and the lignite through pi-pi effect, a hydrogen bond and a hydrophobic effect, and adsorption acting force and an adsorption area are relatively large. A hydrophilic chain is introduced into the structure of the dispersing agent, so the dispersing agent can effectively improve the interface structure of coal and water, reduce the polarity interaction energy of the interface, enhance the electrostatic repulsion and steric hindrance among coal particles and inhibit coal aggregation and moisture adsorption, thereby improving the slurrying performance of low-rank coal.

Owner:SHAANXI UNIV OF SCI & TECH

Flame-retardant antique color mud paint and preparation method thereof

InactiveCN109456018ASlow down the endothermic degradation processReduce the temperatureCalcium hydroxideSodium Bentonite

The invention discloses flame-retardant antique color mud paint and a preparation method thereof. The flame-retardant antique color mud paint is prepared from the following raw materials in parts by weight: 45 to 60 parts of nickel tailings powder, 5 to 20 parts of granite saw mud, 13 to 27 parts of a borate flame-retardant agent, 8 to 26 parts of pigment, 6 to 14 parts of diatomite, 3 to 9 partsof bentonite, 7 to 22 parts of quicklime, 8 to 19 parts of cement and 25 to 58 parts of water. By virtue of repeated test, the invention provides the flame-retardant antique color mud paint, the existing preparation method of the antique building paint is improved, the nickel tailings with good wear resistance and high hardness are converted into treasure, the diatomite with a porous structure isadopted to absorb the environment-friendly borate flame-retardant agent, the granite saw mud and the calcium hydroxide generate chemical reaction to generate a compound with water hard gel performance, and the flame-retardant and weather-resistant environment-friendly flame-retardant antique color mud paint is prepared.

Owner:林瑞云

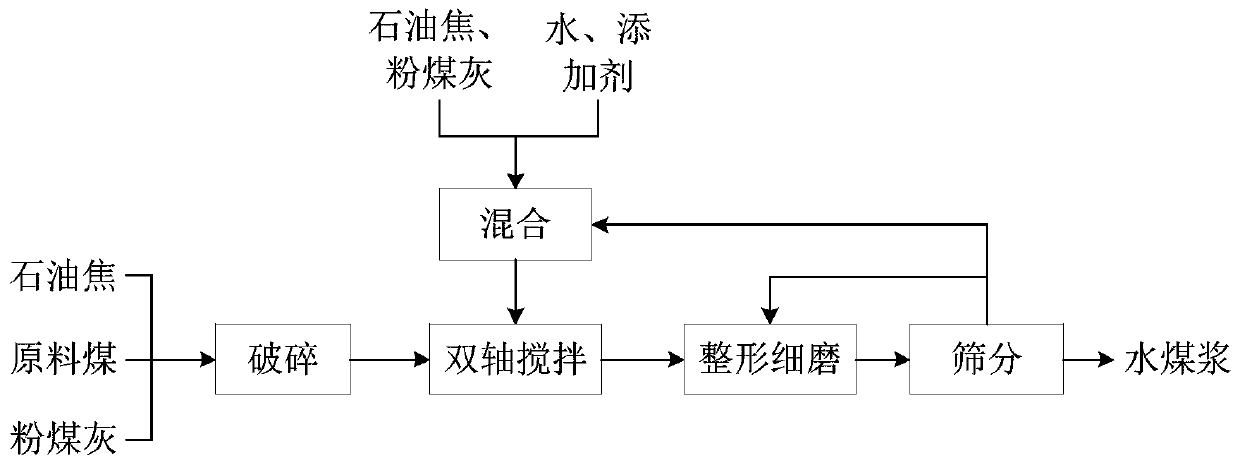

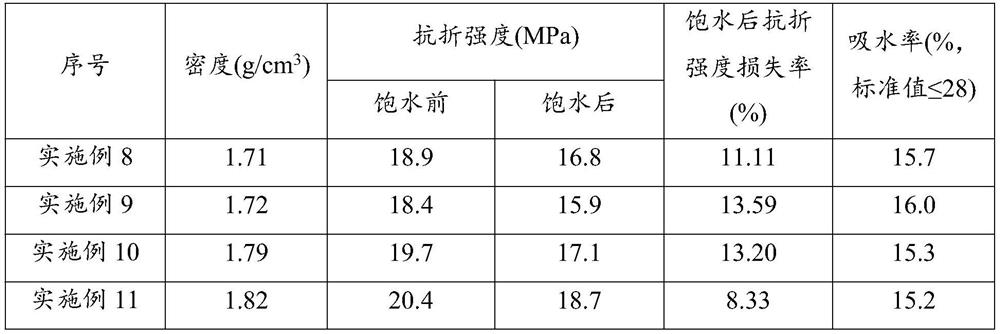

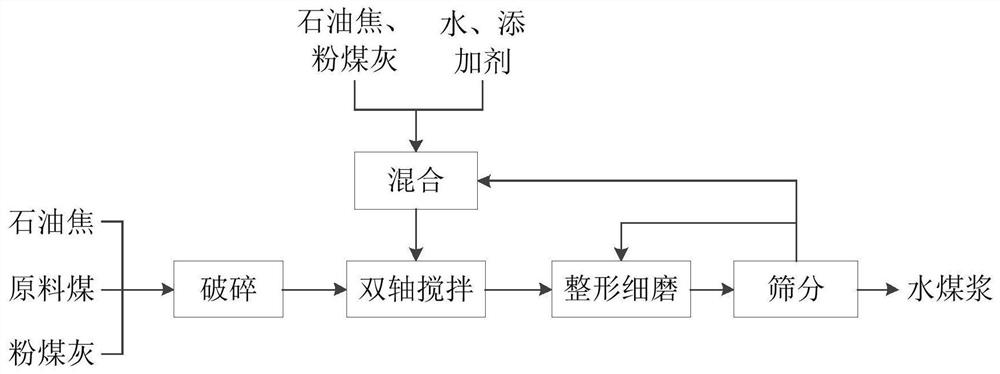

Preparation method of coal water slurry of blended coal

ActiveCN110699131AImprove pulpingIncrease concentrationLiquid carbonaceous fuelsCoal waterProcess engineering

The invention provides a preparation method of coal water slurry of blended coal. The preparation method comprises the following steps: blending feed coal, petroleum coke and fly ash, and carrying outcrushing to obtain first slurry; mixing petroleum coke and fly ash with water and an additive to obtain second slurry; mixing the first slurry and the second slurry under stirring to obtain third slurry; then performing shaping and fine grinding to obtain fourth slurry; carrying out screening, wherein screened slurry is fifth slurry, and residues on a sieve are sixth slurry; returning a part of the sixth slurry for mixing with the second slurry, and returning the rest of the sixth slurry for shaping and fine grinding; and outputting the fifth slurry to obtain the coal water slurry. Accordingto the method, a coal blending technology is adopted, petroleum coke and coal ash are added on the basis of feed coal to form blended coal, the blended coal improves the slurry forming performance ofcoal types and the concentration of coal water slurry; the stacking efficiency of the coal water slurry can be improved through cooperation of the particle sizes of blended coal components; and therefore, the heat value of the coal water slurry is increased, and the coal water slurry can be better used as gasified coal water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

High-strength mica paper and preparing method thereof

InactiveCN106436444AImprove pulpingHigh mechanical strengthNon-fibrous pulp additionPaper/cardboardPapermakingHigh intensity

The invention discloses high-strength mica paper. Relative to 100 by weight parts of water, the high-strength mica paper is prepared from, by weight, 200-300 parts of mica sheets, 30-35 parts of polyvinyl resin, 10-25 parts of asbestos, 5-10 parts of polyacrylamide and 4-10 parts of edetic acid, the materials are pulped and subjected to papermaking, and the high-strength mica paper is prepared. The high-strength mica paper has the quite-high mechanical strength, and the defect that the mica paper is poor in mechanical strength in the application process is overcome.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

A kind of viscosity adjusting admixture for spraying construction and preparation method thereof

The invention discloses a viscosity-adjusting admixture for spraying construction and a preparation method thereof. The viscosity-adjusting admixture for spraying construction of the present invention is composed of the following ingredients calculated by weight: 60-90 parts of ultrafine powder, 5-10 parts of rheology modifier, 5-10 parts of aggregate wrapping agent, 0.5-1 part of air-entraining agent, 1-10 parts of reinforcing component and 1-10 parts of coagulation-adjusting component; the ultrafine powder is 600-1000 mesh ultrafine limestone powder; the aggregate coating agent is nano-bone Material wrapping agent. The viscosity-adjusting admixture of the invention can reduce the rebound rate, improve the construction efficiency, and has the effect of increasing the strength of each age, and can significantly improve the overall quality of the sprayed mortar and sprayed concrete construction projects. The admixture is mainly used to adjust the viscosity of sprayed materials, and has the functions of reducing pumping pipe plugging, improving construction efficiency, improving resilience in spraying construction, and increasing the compressive strength and bonding strength of materials at various ages.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Resin composite mica paper and preparation method thereof

ActiveCN106400607BFast formingImprove pulpingNon-fibrous pulp additionSpecial paperEpoxyHeat treated

The invention discloses a resin composite mica paper. A preparation method of the resin composite mica paper comprises preparation of a mica layer, preparation of a resin layer and compounding of the mica layer and the resin layer. The preparation process of the resin layer comprises mixing phenolic epoxy resin, polyimide resin, ethylene glycol ether, 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, dibutyl phthalate and water, carrying out heat treatment, and carrying out extrusion molding to obtain the resin layer. The compounding process of the mica layer and the resin layer comprises placing the mica paper on the resin layer, carrying out hot-pressing compounding, and then carrying out natural cooling so that the resin composite mica paper is obtained. The resin composite mica paper has insulativity and high temperature resistance of the mica paper and has high mechanical strength and toughness.

Owner:安徽大松树脂有限公司

A method for preparing high-performance coal-water slurry by using bottom residue and waste emulsion

ActiveCN112760144BImprove pulpingImprove gasification effectOther chemical processesLiquid carbonaceous fuelsActivated carbonEmulsion

The invention discloses a method for preparing high-performance coal-water slurry by using bottom residue and waste emulsion, the steps are: (1) drying, pulverizing and sieving raw coal and bottom residue to obtain coal powder and bottom residue powder; (2) Add activated carbon powder to the metal processing waste emulsion after being pretreated by filtration and ultrafiltration, and stir and absorb to obtain the pretreated waste emulsion; (3) In parts by weight, 65~85 parts of coal Powder, 65~75 parts of pretreated waste emulsion, 15~28 parts of bottom residue powder and 1~2 parts of additives are mixed, and stirred evenly after ball milling to obtain high-performance coal water slurry. In the present invention, through the compatibility of the bottom residue, metal processing waste emulsion, activated carbon and coal powder, the interaction between wastes is used to effectively improve the various properties of the coal water slurry, and the prepared product has high solid content, good dispersibility and stability, High performance coal water slurry with high combustion efficiency.

Owner:梵境新能源科技(浙江)有限公司

System and method for improving slurry property of low order coal slurry

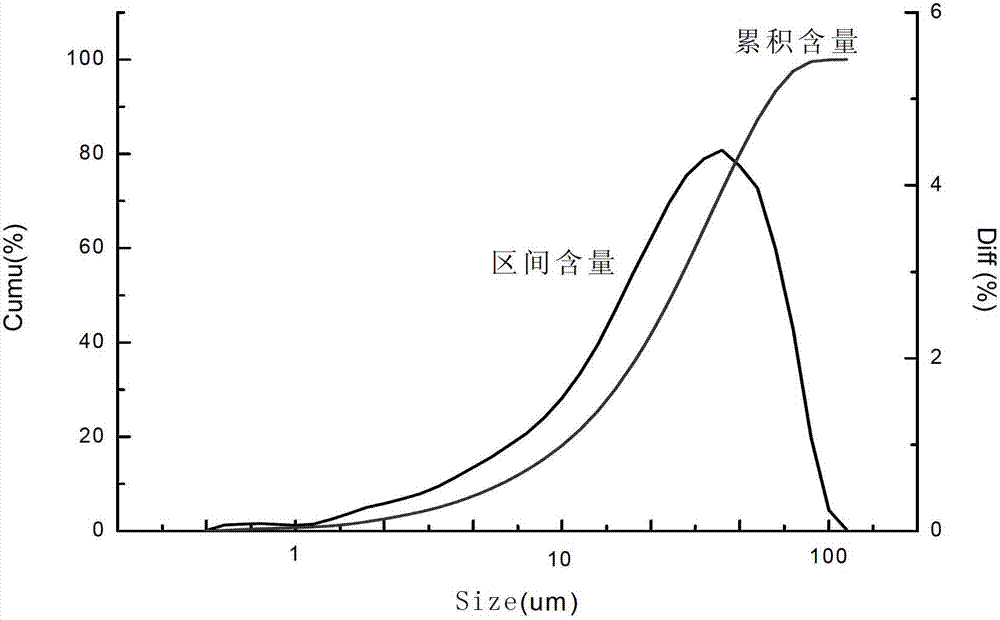

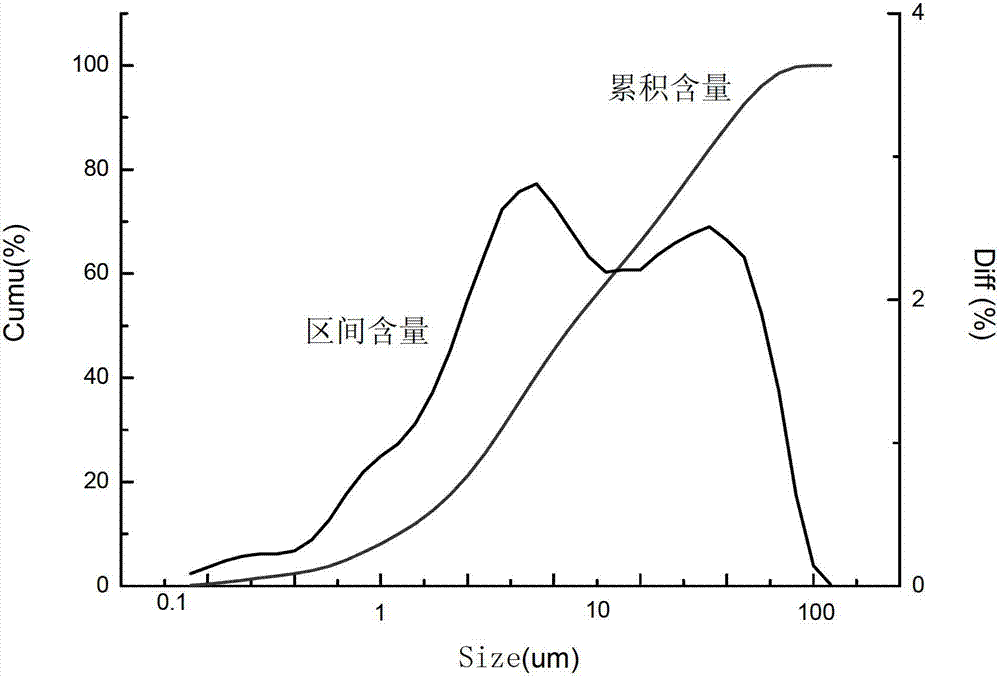

InactiveCN103206718BControl granularityStrong controllability of particle sizeLump/pulverulent fuel preparationCoal waterHigh density

The invention discloses a system and a method for improving slurry property of low order coal slurry. The system includes a powder making system and a fine powder separating system. The powder making system comprises two vertical mill mechanisms. The vertical mill mechanisms are connected with bucket elevators which are respectively connected with a coarse powder finished product cabin and a fine powder finished product cabin. The fine powder separating system comprises a buffering cabin connected with the fine powder finished product cabin. The buffering cabin is communicated with a first grader and a second grader in sequence. The first grader and the second grader are respectively communicated with a coarse powder collecting cabin and a super fine powder collecting cabin. The coarse powder finished product cabin is communicated with a slurry mixing system through a dense phase conveying device; and the fine buffering cabin is communicated with the slurry mixing system through a conveying belt. The method includes three parts of coarse powder preparation, fine powder separation and extraction, and high-density coal slurry preparation. By collocating proportion of coarse coal powder and fine coal powder, deposition efficiency of coal powder is improved, distribution of coal powder after being mixed is close to an Alfred model; and slurry property of low order coal slurry is improved through graduation.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP

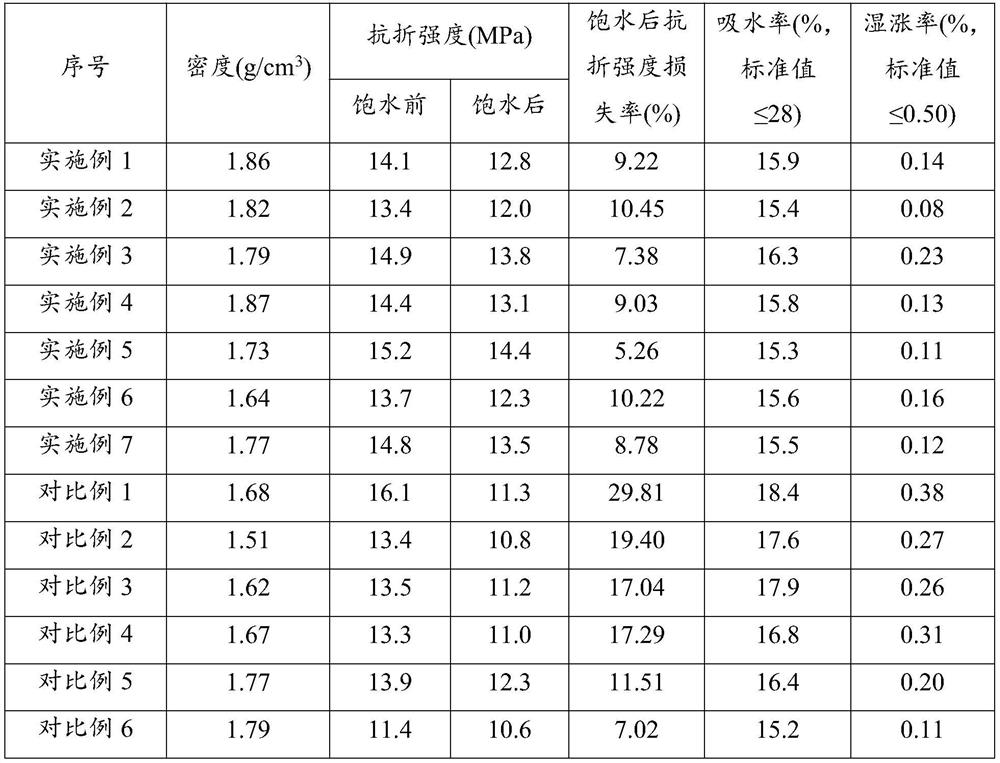

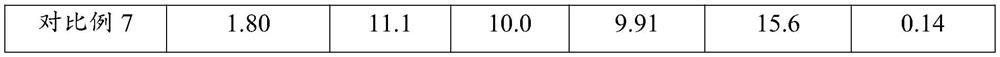

High-water-resistance carbonized consolidated fiber cement board and preparation method thereof

The invention provides a high-water-resistance carbonized and consolidated fiber cement board and a preparation method thereof, and belongs to the field of building materials. Mixing fibers, a gelling component and water to obtain slurry; the fibers are glass fibers and wood fibers or polyvinyl alcohol fibers and wood fibers; the gelling component comprises one or more of calcium silicate mineral powder, steel slag powder rich in calcium silicate mineral phase and magnesium slag powder rich in calcium silicate mineral phase; the slurry is sequentially subjected to dehydration, mud jacking and static curing, curing is conducted in the CO2 atmosphere, and the high-water-resistance carbonization consolidation fiber cement board is obtained. The glass fibers are doped to replace plant wood fibers, and hydrophobic groups on the surfaces of the glass fibers can effectively reduce the water absorption rate of the fiber cement board; the gelling component used in the invention has excellent CO2 reaction activity, can be subjected to mineralization reaction with CO2 to form a matrix structure composed of calcium carbonate, and is a main strength source of the fiber cement board.

Owner:WUHAN UNIV OF TECH

A kind of preparation method of coal water coal slurry

ActiveCN110699131BImprove pulpingIncrease concentrationLiquid carbonaceous fuelsCoal waterProcess engineering

The invention provides a preparation method of blended coal-water slurry. The method comprises: crushing raw coal, petroleum coke and fly ash after blending to obtain the first slurry; blending petroleum coke, fly ash with water, The additives are mixed to obtain the second slurry; the first slurry and the second slurry are mixed and stirred to obtain the third slurry, and then shaped and finely ground, and the obtained fourth slurry is sieved, and the sieved slurry It is the fifth slurry, and the sieve residue is the sixth slurry; return part of the sixth slurry to mix with the second slurry, and return the remaining sixth slurry for shaping and fine grinding; output the fifth slurry to obtain coal water slurry . The method of the present invention adopts coal blending technology, and on the basis of raw coal, petroleum coke and fly ash are added to form blended coal. The combination of particle size can improve the accumulation efficiency of coal-water slurry, thereby increasing the calorific value of coal-water slurry, and it can be better used as gasification coal-water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

A beating and refining device for papermaking

ActiveCN109024043BPrevent precipitationImprove pulpingPulp beating methodsSolenoid valveElectric machinery

Owner:SUZHOU DESIMIER SMART TECH CO LTD

Resin composite mica paper and preparation method thereof

The invention discloses resin composite mica paper. A preparation method of the resin composite mica paper includes: preparing a mica layer; preparing a resin layer, to be more specific, mixing novolac epoxy resin, polyimide resin, glycol ether, Texanol and dibutyl phthalate with water, performing thermal treatment, and performing extrusion forming to obtain the resin layer; performing resin compositing on the mica layer and the resin layer, to be more specific, placing the mica layer on the resin layer, performing hot-pressing resin compositing, and naturally cooling to obtain the resin composite mica paper. The resin composite mica paper has the advantages of excellent insulating performance and excellent high temperature resistance of the mica paper and is quite high in mechanical strength and toughness.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Resin composite mica paper and preparation method thereof

ActiveCN106400607AFast formingImprove pulpingNon-fibrous pulp additionSpecial paperEpoxyTemperature resistance

The invention discloses a resin composite mica paper. A preparation method of the resin composite mica paper comprises preparation of a mica layer, preparation of a resin layer and compounding of the mica layer and the resin layer. The preparation process of the resin layer comprises mixing phenolic epoxy resin, polyimide resin, ethylene glycol ether, 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, dibutyl phthalate and water, carrying out heat treatment, and carrying out extrusion molding to obtain the resin layer. The compounding process of the mica layer and the resin layer comprises placing the mica paper on the resin layer, carrying out hot-pressing compounding, and then carrying out natural cooling so that the resin composite mica paper is obtained. The resin composite mica paper has insulativity and high temperature resistance of the mica paper and has high mechanical strength and toughness.

Owner:安徽大松树脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com