White fair-faced concrete for prefabricated part and preparation method of white fair-faced concrete

A technology for veneer concrete and prefabricated components, applied in the field of building materials, can solve the problems of difficult to achieve one-time molding of fair-faced concrete and high standard requirements for maintenance-free later, and achieve the effects of flexible and adjustable fluidity, less pores and small color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

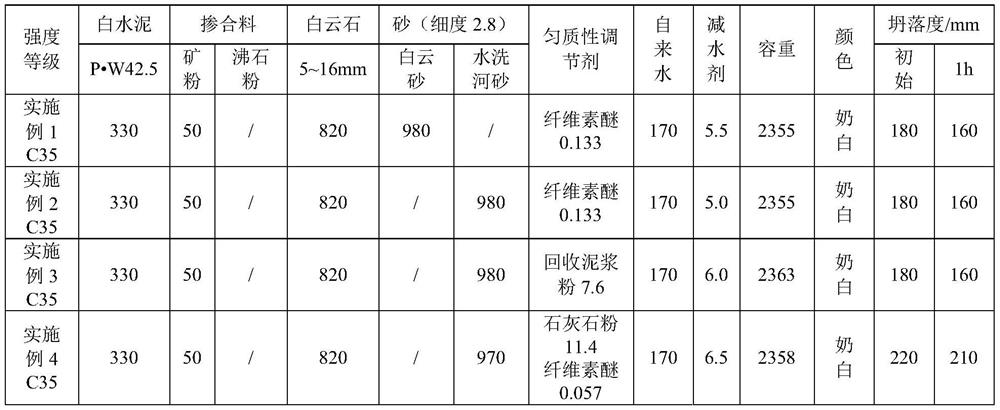

[0046] Examples 1 to 4 are C35 white fair-faced concrete with white P.W42.5 cement as the main cementitious material. The specific mix ratio is shown in Table 1, and the unit of each component is kg / m 3 , the water reducing agent used is the same.

[0047] Table 1

[0048]

Embodiment 5~7

[0049] Examples 5-7 are C40-C50 white fair-faced concrete with white P.W42.5 cement as the main cementitious material. The specific mix ratio is shown in Table 2, and the unit of each component is kg / m 3 , the water reducing agent used is the same.

[0050] Table 2

[0051]

Embodiment 8~12

[0052] Examples 8-12 are C35-C50 white fair-faced concrete with gray P.O42.5 cement as the main cementitious material. The specific mix ratio is shown in Table 3, and the unit of each component is kg / m 3 , the water reducing agent used is the same.

[0053] table 3

[0054]

[0055] Examples 13-15 are C60-C80 white fair-faced concrete with gray P.O42.5 cement as the main cementitious material. The specific mix ratio is shown in Table 4, and the unit of each component is kg / m 3 , the water reducing agent used is the same. The coarse aggregate used is 5-20mm light gray limestone crushed stone, with continuous gradation and mud content ≤ 1.0%, crushing index ≤ 9%, needle flake content ≤ 3%.

[0056] Table 4

[0057]

[0058] The appearance and strength of the above Examples 1-15 are shown in Table 5.

[0059] table 5

[0060]

[0061] As can be seen from Table 5, using the mix ratios provided by Examples 1 to 15, the white clear water facing concrete components with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com