Flame-retardant antique color mud paint and preparation method thereof

A coating and color mud technology, applied in the field of architectural coatings, can solve problems such as the accumulation of tailings pollution, the difficult protection of ancient buildings, and the hazards of construction personnel, which can reduce the temperature, improve wear resistance, and prevent pollution. good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

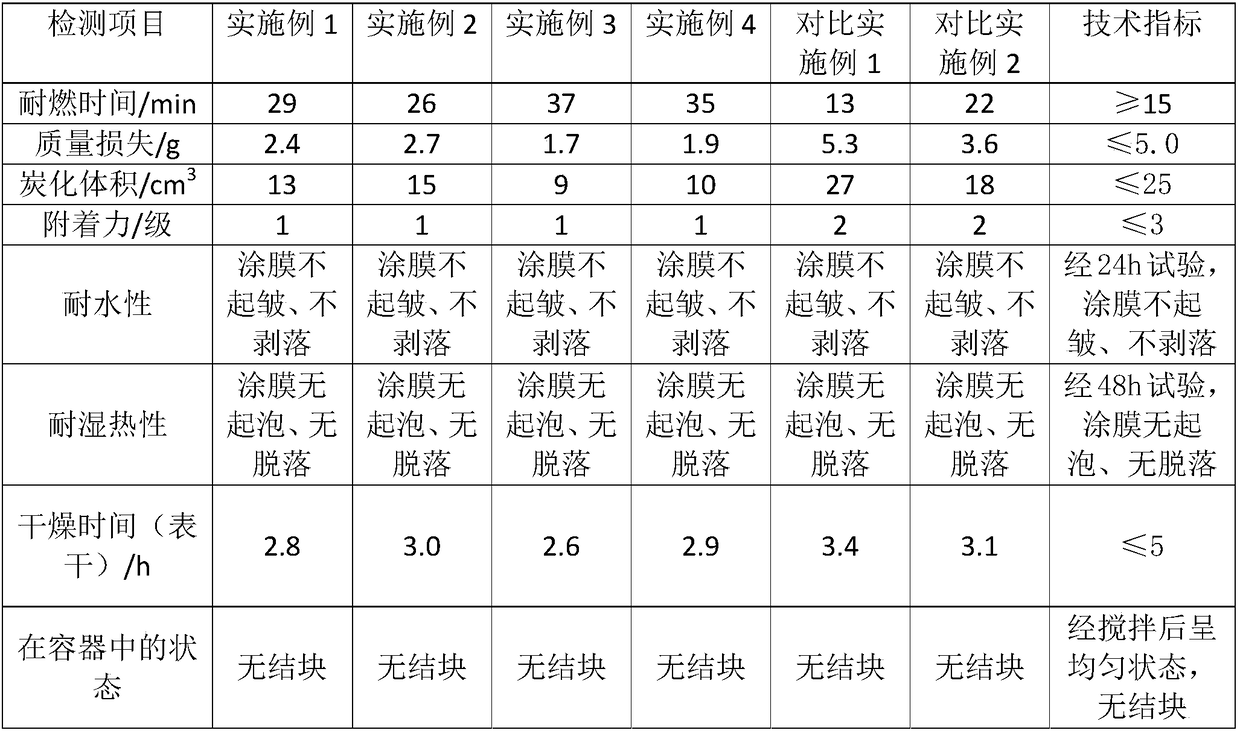

Examples

Embodiment 1

[0028] A flame-retardant antique colored mud paint, said flame-retardant antique colored mud paint is prepared from the following raw materials in parts by weight: 52 parts of nickel tailings powder, 16 parts of granite saw mud, 19 parts of borate flame retardant, 16 parts of pigment, 9 parts of diatomite, 5 parts of bentonite, 13 parts of quicklime, 11 parts of cement and 42 parts of water; the granite sawing mud is powdered granite particles.

[0029] Further, the borate flame retardant includes zinc borate and calcium borate, wherein the components are 11 parts by weight of zinc borate and 8 parts of calcium borate.

[0030] Further, the coloring material includes coloring powder and shell powder, wherein each component is in parts by weight: 5 parts of toner powder and 11 parts of shell powder.

[0031] A kind of preparation method of flame retardant antique color mud paint, specifically comprises the following steps:

[0032] S1. Add zinc borate, calcium borate, diatomac...

Embodiment 2

[0036] A flame-retardant antique colored mud paint, said flame-retardant antique colored mud paint is prepared from the following raw materials in parts by weight: 52 parts of nickel tailings powder, 16 parts of granite saw mud, 19 parts of borate flame retardant, 16 parts of pigment, 9 parts of diatomite, 5 parts of bentonite, 13 parts of quicklime, 11 parts of cement and 42 parts of water.

[0037] Further, the borate flame retardant includes zinc borate and calcium borate, wherein the components are 11 parts by weight of zinc borate and 8 parts of calcium borate.

[0038] Further, the coloring material includes coloring powder and shell powder, wherein each component is, in parts by weight, respectively: 5 parts of toner powder and 11 parts of crop straw particles.

[0039] A kind of preparation method of flame retardant antique color mud paint, specifically comprises the following steps:

[0040] S1. Add zinc borate, calcium borate, diatomaceous earth and water into the r...

Embodiment 3

[0044] A flame-retardant antique colored mud paint, said flame-retardant antique colored mud paint is prepared from the following raw materials in parts by weight: 56 parts of nickel tailings powder, 12 parts of granite saw mud, 23 parts of borate flame retardant, 13 parts of pigment, 11 parts of diatomite, 5 parts of bentonite, 16 parts of quicklime, 9 parts of cement and 45 parts of water.

[0045] Further, the borate flame retardant includes zinc borate and calcium borate, wherein the components are 13 parts by weight of zinc borate and 10 parts of calcium borate.

[0046] Further, the coloring material includes coloring powder and shell powder, wherein each component is in parts by weight: 5 parts of toner powder and 8 parts of shell powder.

[0047] A kind of preparation method of flame retardant antique color mud paint, specifically comprises the following steps:

[0048] S1. Add zinc borate, calcium borate, diatomaceous earth and water into the reaction kettle and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com