Binary surface-to-surface adsorption type dispersing agent for slurry forming of low-rank coal and preparation method of dispersing agent

A binary surface-to-surface, adsorption-type technology, applied in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve problems such as inapplicable low-rank coal pulping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

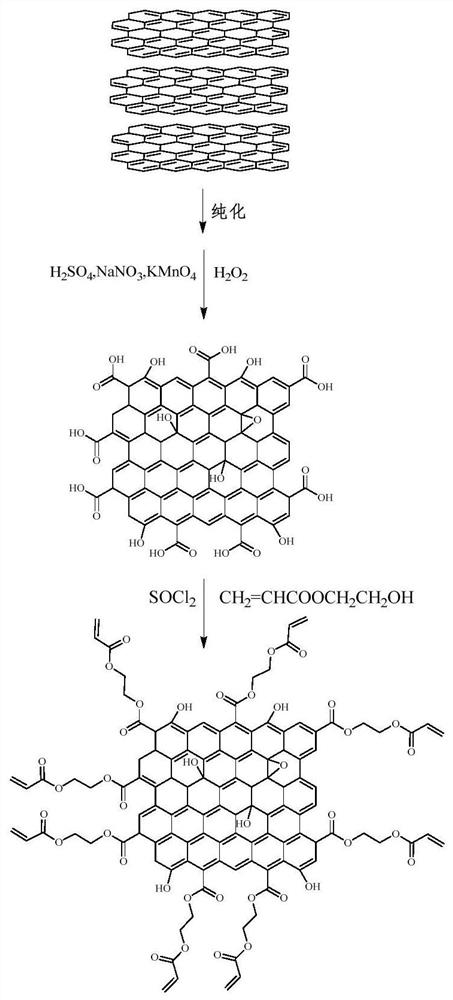

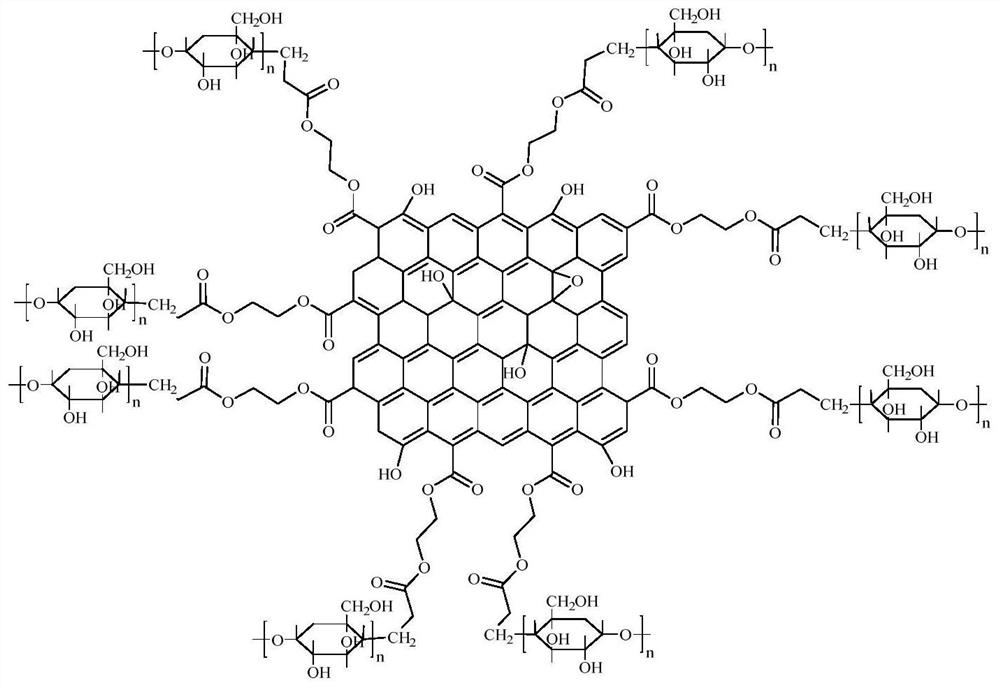

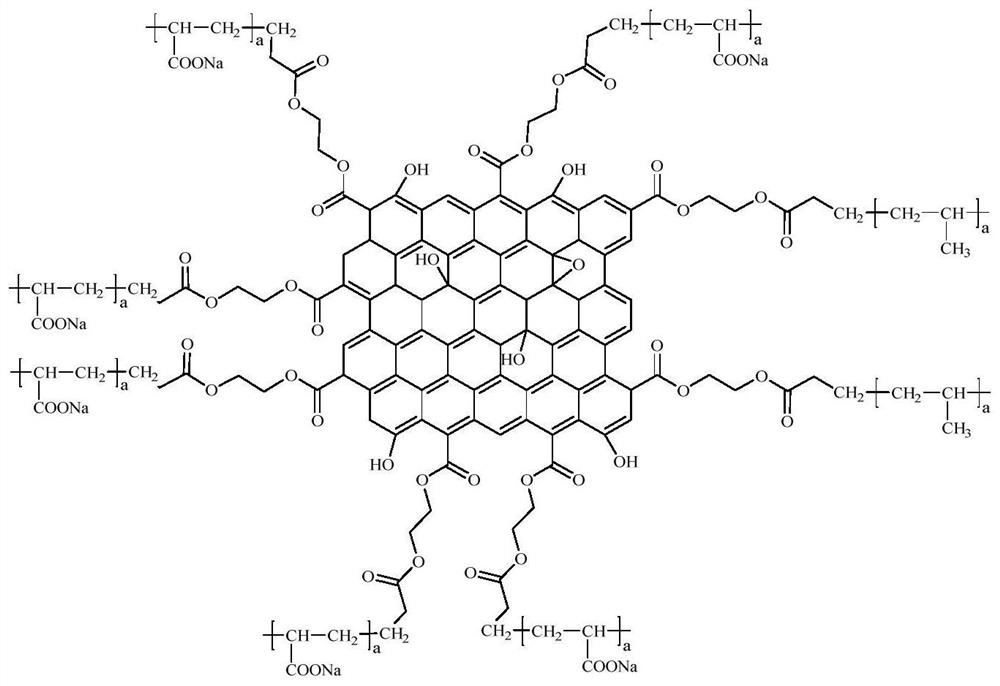

[0052] A preparation method of a binary surface adsorption type dispersant for non-stick coal slurrying, comprising the following steps:

[0053] Step 1), after acidifying 5g waste graphite with 25g concentrated HCl, washing with water and drying, get pretreated graphite, NaNO 3 and Concentrated H 2 SO 4 Mass ratio 1:1:40 was added to a dry three-necked flask, and stirred at 0°C for 0.5h. Slowly add KMnO with twice the mass of graphite several times while controlling the temperature of the reaction system below 5°C 4 , to be KMnO 4 After all the addition, react at a low temperature at 0°C for 2 hours, then raise the temperature to 35°C for a medium temperature reaction, react for 2 hours, and finally slowly add distilled water with a mass of 60wt% of the total mass of the current system into the system, and perform a high temperature reaction at 85°C. 1h. After the reaction is completed, add distilled water and H 2 o 2 (mass fraction is 30%), until the color of the solu...

Embodiment 2

[0057] Example 2 Preparation method of binary surface adsorption type dispersant for non-stick coal slurry

[0058] Step 1), after acidifying 5g waste graphite through 40g concentrated HCl, washing with water, drying, get pretreated graphite, NaNO 3 and Concentrated H 2 SO 4 Mass ratio 1:1:41 was added to a dry three-necked flask, and stirred at 3°C for 1h. Slowly add KMnO with a mass 2.5 times the mass of graphite multiple times while controlling the temperature of the reaction system below 5°C 4 , to be KMnO 4 After all the addition, stir at 5°C for low temperature reaction for 2.5h, then raise the temperature to 40°C for medium temperature reaction, react for 2.5h, and finally slowly add distilled water with a total mass of 70wt% of the system into the system, and perform high temperature reaction at 90°C for 1h . After the reaction is completed, add distilled water and H 2 o 2 (mass fraction is 30%), until the color of the solution turns bright yellow, filter whil...

Embodiment 3

[0061] Example 3 Preparation method of binary surface adsorption type dispersant for non-stick coal slurry

[0062] Step 1), after acidifying 5g waste graphite through 30g concentrated HCl, washing with water, drying, get pretreated graphite, NaNO 3 and Concentrated H 2 SO 4 Mass ratio 1:1.05:41 was added to a dry three-necked flask, and stirred at 0°C for 0.5h. Control the temperature of the reaction system below 5°C and slowly add KMnO with a mass 3 times that of graphite several times 4 , to be KMnO 4 After all the addition, stir at 0°C for low temperature reaction for 2.5h, then raise the temperature to 40°C for medium temperature reaction, react for 2h, and finally slowly add distilled water with a total mass of the system of 65wt% into the system, and perform high temperature reaction at 85°C for 1.5h . After the reaction is completed, add distilled water and H 2 o 2 (mass fraction is 30%), until the color of the solution turns bright yellow, filter while hot, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com