Construction method of bridge pile foundation in mountainous area

A construction method and technology of pile foundation, applied in the direction of foundation structure engineering, construction, etc., to achieve the effect of improving the interface structure, enhancing the bearing capacity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

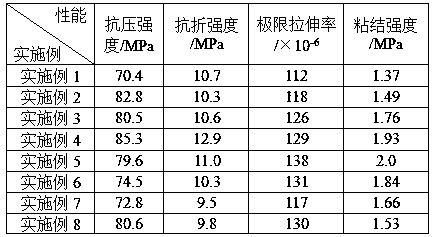

Embodiment 1

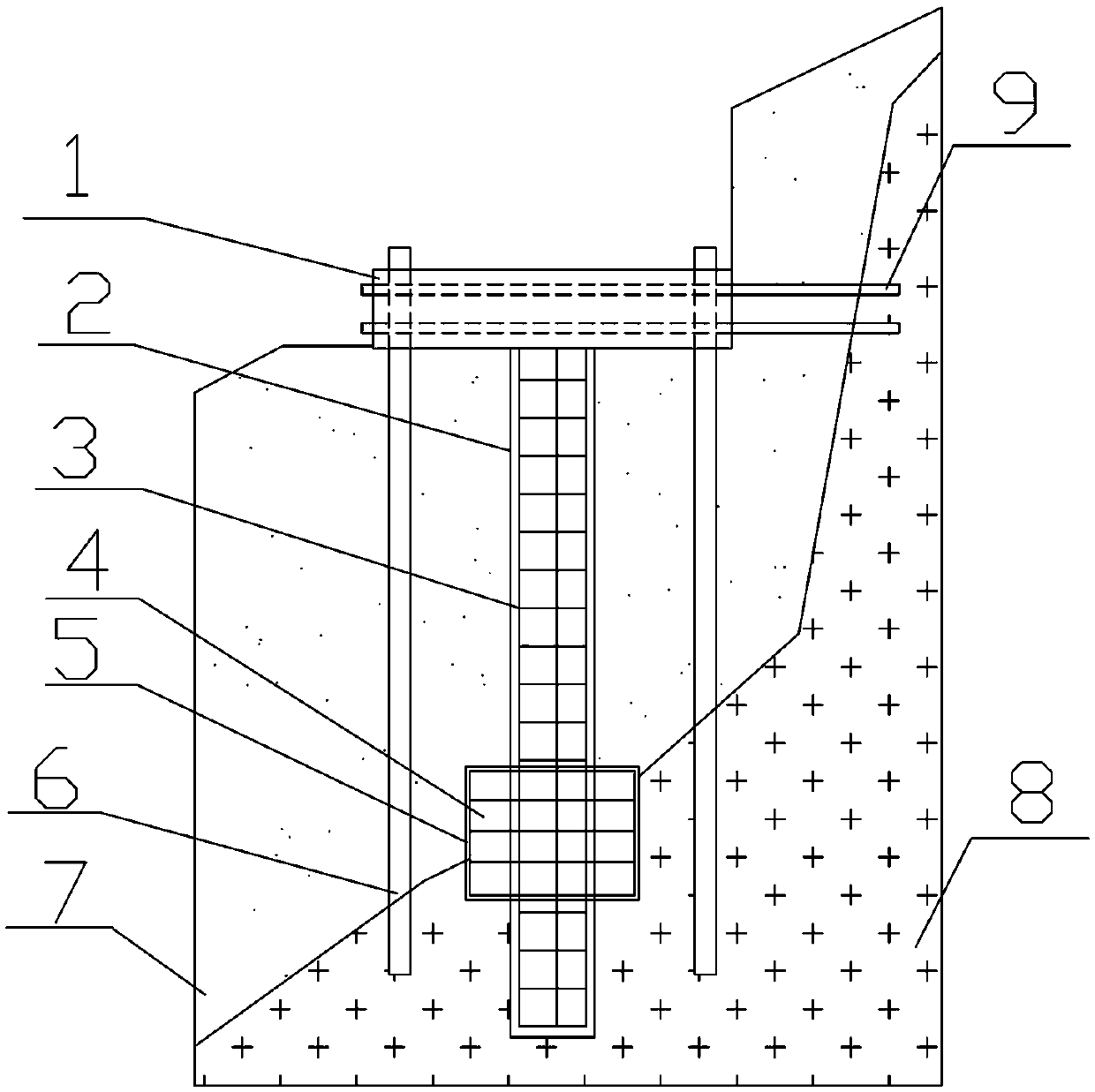

[0033] A construction method for bridge pile foundations in mountainous areas, combining figure 1 shown, including the following steps:

[0034] (1) Measurement and stakeout: Level the construction site, accurately locate the position of the pile foundation, and set up protective piles;

[0035] (2) Hole digging: In the process of digging the pile hole 2, in order to prevent the hole from collapsing, cast-in-place concrete retaining walls are used, one meter at a time, and the retaining wall concrete is C25 concrete, and a vibrating rod is used for tamping when pouring concrete , so that the concrete is dense and in close contact with the surrounding rock mass, the lower concrete should wrap the upper concrete retaining wall by 10cm to avoid water seepage; after the pile hole is completed, ream the hole to form the reaming cavity 5 above the rock mass 8 at the bottom of the pile hole;

[0036] (3) Place reinforcement cages and enlarged reinforcement cages: After hoisting the ...

Embodiment 2

[0048] Embodiment 2 is the same as the construction method of the mountain bridge pile foundation of embodiment 1, and the difference is:

[0049] Concrete includes the following raw materials in parts by weight: 282 parts of P.O42.5 Portland cement, 61 parts of coal ash powder, 28 parts of mineral powder, 18 parts of silica fume, 750 parts of fine aggregate, 1010 parts of coarse aggregate, water 170 parts, 6 parts of polycarboxylate superplasticizer, 7 parts of composite reinforcing fiber, 35 parts of polyvinyl acetate emulsion, 7 parts of dispersant sodium methylcellulose, 0.45 parts of silicone oil.

[0050] Among them, the fine aggregate is medium sand, the fineness modulus is 3.0, and the mud content is 1% to 1.5%.

[0051] Among them, the coarse aggregate is stone, with a mud content of ≤2% and a particle size of ≤35mm.

[0052] Wherein the preparation method of composite reinforcing fiber comprises:

[0053] Soak polypropylene fiber powder in NaOH solution with a volu...

Embodiment 3

[0058] Embodiment 3 is identical with the construction method of the bridge pile foundation in mountainous area of embodiment 1, and difference is:

[0059] Concrete includes the following raw materials in parts by weight: 285 parts of P.O42.5 Portland cement, 62 parts of coal ash powder, 26 parts of mineral powder, 16 parts of silica fume, 780 parts of fine aggregate, 1020 parts of coarse aggregate, water 160 parts, 7 parts of polycarboxylate superplasticizer, 8 parts of composite reinforcing fiber, 40 parts of polyvinyl acetate emulsion, 4 parts of dispersant methyl cellulose and sodium methyl cellulose, 0.5 part of silicone oil.

[0060] Among them, the fine aggregate is medium sand, the fineness modulus is 3.0, and the mud content is 1% to 1.5%.

[0061] Among them, the coarse aggregate is stone, with a mud content of ≤2% and a particle size of ≤35mm.

[0062] Wherein the preparation method of composite reinforcing fiber comprises:

[0063] Soak the polypropylene fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com