High-performance nanofiber modified polymer cement-based repairing mortar and preparation method thereof

A nanofiber and polymer technology is applied in the field of high-performance nanofiber-modified polymer cement-based repair mortar and its preparation, which can solve the problems of long setting time, general crack resistance, mismatch of elastic modulus of base concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

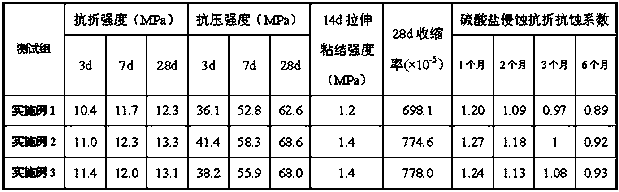

Examples

Embodiment 1

[0035] Example 1 A high-performance nanofiber modified polymer cement-based repair mortar, the repair mortar is composed of the following raw materials in mass percentage (kg): 29.5% cement, 52.7% quartz sand, 1.4% dispersible latex powder, nano SiO 2 0.4%, fly ash 3.5%, metakaolin 1.8%, fiber 0.07%, water reducing agent 0.18%, silicone defoamer 0.03%, cellulose ether 0.01%, and the balance is water.

[0036] The preparation method of the high-performance nanofiber modified polymer cement-based repair mortar comprises the following steps:

[0037] (1) Weighing according to the proportion;

[0038] (2) Add water reducer and silicone defoamer to 80% water, and then add nano-SiO 2 Add it, and stir rapidly in a cement mortar mixer for 1 to 2 minutes to obtain a mixed solution;

[0039] (3) Move the mixed solution to a digitally controlled ultrasonic cleaner, and disperse it with ultrasonic waves for 15 minutes to obtain a suspension;

[0040] (4) Pour cement, quartz sand, disper...

Embodiment 2

[0041] Example 2 A high-performance nanofiber modified polymer cement-based repair mortar, which is composed of the following raw materials in mass percentage (kg): 27.2% cement, 52.4% quartz sand, 1.7% dispersible latex powder, nano SiO 2 0.7%, fly ash 4.4%, metakaolin 2.6%, fiber 0.1%, water reducer 0.21%, silicone defoamer 0.035%, cellulose ether 0.017%, and the balance is water.

[0042] The preparation method of the high-performance nanofiber modified polymer cement-based repair mortar is the same as that in Example 1.

Embodiment 3

[0043] Example 3 A high-performance nanofiber modified polymer cement-based repair mortar, the repair mortar is composed of the following raw materials in mass percentage (kg): 25.0% cement, 52.2% quartz sand, 2.0% dispersible latex powder, nano SiO 2 1.0%, fly ash 5.2%, metakaolin 3.5%, fiber 0.14%, water reducer 0.24%, silicone defoamer 0.04%, cellulose ether 0.02%, and the balance is water.

[0044] The preparation method of the high-performance nanofiber modified polymer cement-based repair mortar is the same as that in Example 1.

[0045] In the above-mentioned Examples 1-3, the cement is 52.5 grade ordinary Portland cement.

[0046] Quartz sand refers to a mixture of 20-40 mesh quartz sand, 40-70 mesh quartz sand, and 70-140 mesh quartz sand in a mass ratio of 5:4:1.

[0047] Redispersible latex powder refers to an ethylene-vinyl acetate copolymer with a minimum film-forming temperature of 4°C, a particle size of 400 μm, and a sieve residue of no more than 4%.

[0048...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com