High-water-resistance carbonized consolidated fiber cement board and preparation method thereof

A technology of fiber cement board and fiber, which is applied in the field of high water-resistant carbonized consolidated fiber cement board and its preparation, can solve the problems of expansion damage, high water absorption, delamination of fiber cement board, etc., and achieve excellent mechanical properties and durability, Improve water resistance and mechanical properties, improve the effect of wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

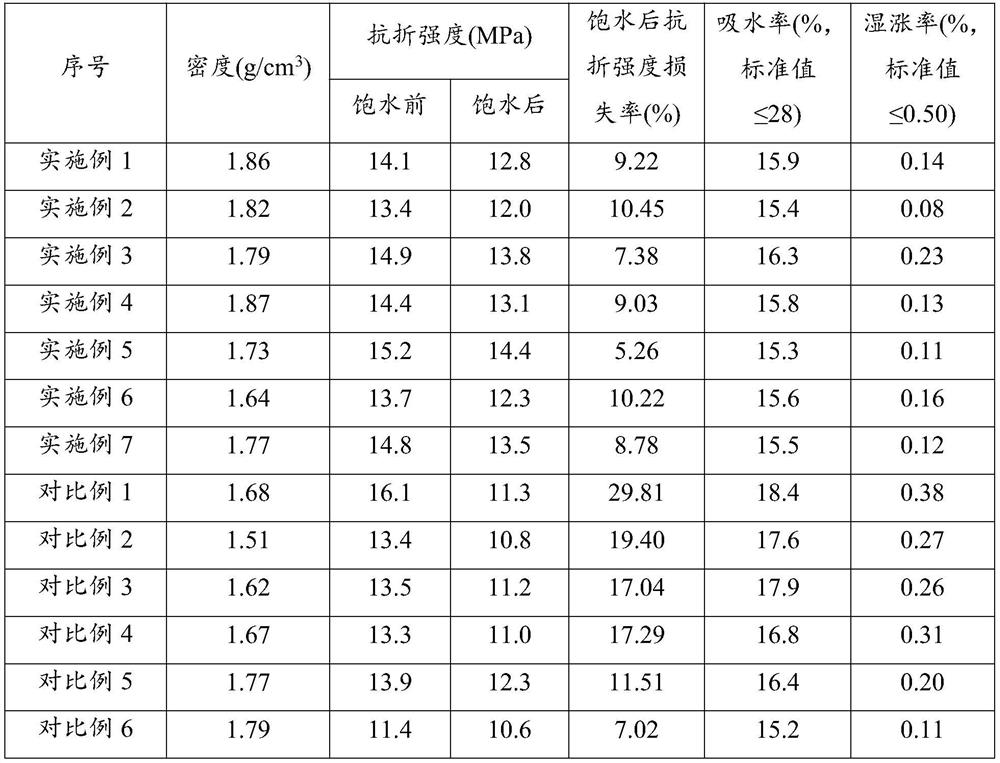

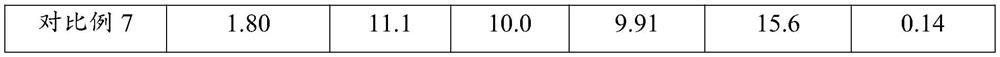

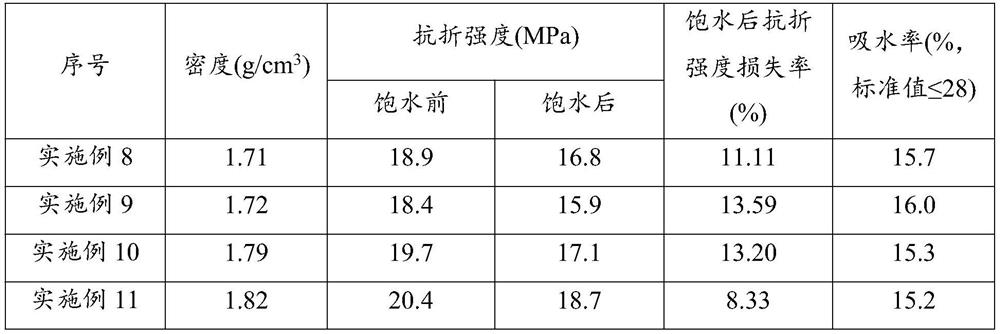

Examples

preparation example Construction

[0029] The present invention provides a kind of preparation method of high water resistance carbonization consolidation fiber cement board, comprises the following steps:

[0030] Mixing fibers, gelling components and water to obtain slurry; the fibers include wood fibers, glass fibers or polyvinyl alcohol fibers; the gelling components include calcium silicate mineral powder, calcium silicate-rich One or more of mineral phase steel slag powder and magnesium slag powder rich in calcium silicate mineral phase;

[0031] The slurry was sequentially dehydrated, squeezed, and rested in CO 2 Curing under the atmosphere to obtain the high water resistance carbonized consolidated fiber cement board.

[0032] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in this field.

[0033] In the present invention, the glass fibers preferably include glass wool and non-glass wool fibers, the non-glass wool fibers preferably h...

Embodiment 1

[0078] Embodiment 1 (γ-C 2 S)

[0079] The solid components are: γ-C 2 93 parts of S, 3 parts of non-glass wool fiber, 2 parts of glass wool, and 2 parts of wood fiber;

[0080] Preparation:

[0081] Add the weighed non-glass wool fiber, glass wool, wood fiber and 500 parts of water into the stirring device according to the proportion and stir to form a suspension;

[0082] According to the ratio, the weighed gelling component (γ-C 2 S) mixing with the suspension and placing it in a beater, adding water according to a slurry concentration of 12%, stirring for 15 minutes and fully mixing to form a slurry;

[0083] Pour the slurry into a vacuum filtration device, perform suction filtration and dehydration, move the formed slab to a grouting mold, and perform grouting with a pressure of 600kN and a holding time of 60s;

[0084] The slab after grouting is taken out, and placed in a curing box for resting, the resting condition is 40°C, the relative humidity is below 50%, the ...

Embodiment 2

[0087] Embodiment 2 (magnesium slag)

[0088] The solid components are: 93 parts of magnesium slag, 3 parts of non-glass wool fiber, 2 parts of glass wool, and 2 parts of wood fiber;

[0089]The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com