A kind of viscosity adjusting admixture for spraying construction and preparation method thereof

A technology of viscosity adjustment and admixture, applied in the field of concrete spraying construction, can solve the problems of low strength and construction efficiency, high rebound rate, and achieve the effect of improving construction efficiency, increasing strength and reducing elastic collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

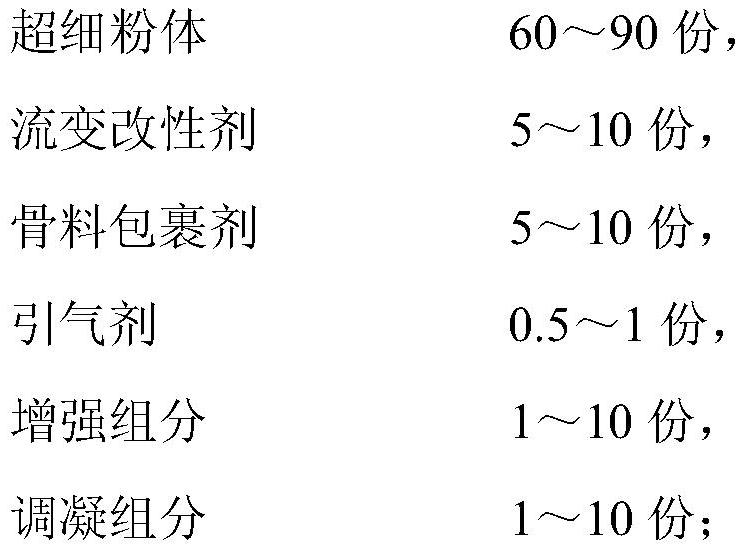

[0026] A viscosity-adjusting admixture for spray construction is prepared by mixing the following components by weight:

[0027]

[0028] Among them, the ultrafine powder is 600 mesh ultrafine limestone powder. The rheology modifier is a mixture of hydroxypropyl starch ether and acidified modified sodium bentonite in a mass ratio of 1:1; the aggregate encapsulating agent is magnesium aluminum silicate nanogel; the air-entraining agent is sodium lauryl sulfate; The strengthening component is a mixture of sodium sulfate and calcium formate in a weight ratio of 1:1; the coagulation-adjusting component is sodium sugar.

Embodiment 2

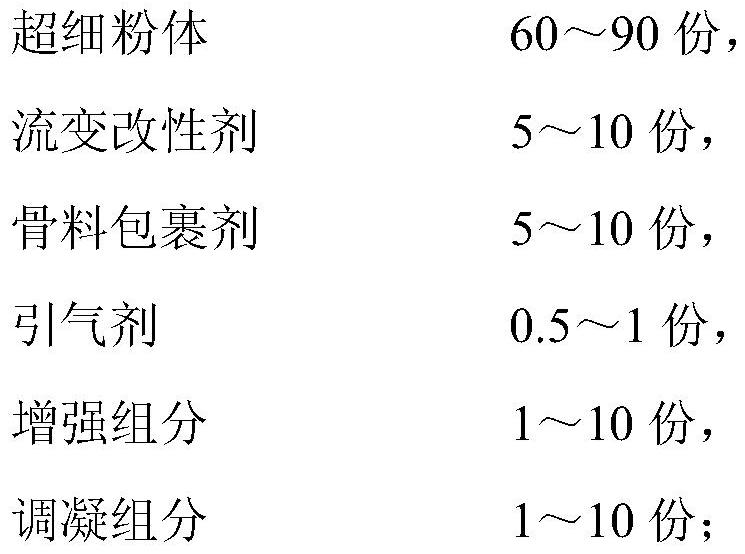

[0030] A viscosity-adjusting admixture for spray construction is prepared by mixing the following components by weight:

[0031]

[0032] Among them, the ultrafine powder is 800 mesh ultrafine limestone powder. The rheology modifier is a mixture of hydroxypropyl starch ether and acidified modified sodium bentonite in a mass ratio of 1:2; the aggregate encapsulating agent is magnesium aluminum silicate nanogel; the air-entraining agent is a triterpenoid saponin air-entraining agent; The strengthening component is a mixture of aluminum sulfate and calcium formate in a weight ratio of 1:2; the coagulation-adjusting component is sodium sugar.

Embodiment 3

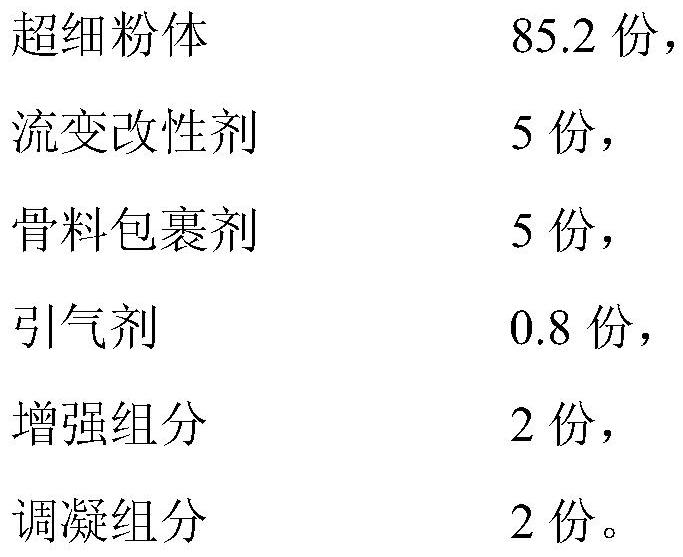

[0034] A viscosity-adjusting admixture for spray construction is prepared by mixing the following components by weight:

[0035]

[0036]

[0037] Among them, the ultrafine powder is 800 mesh ultrafine limestone powder; the rheology modifier is a mixture of hydroxypropyl starch ether and acidified modified sodium bentonite with a mass ratio of 1:2; the aggregate encapsulating agent is magnesium aluminum silicate nanometer Gel; the air-entraining agent is sodium lauryl sulfate; the reinforcing component is a mixture of sodium sulfate and calcium formate in a weight ratio of 1:1; the coagulation-adjusting component is glucose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com