Silver nanowire transparent conductive film and preparation method and application thereof

A technology of transparent conductive film and silver nanowire, which is applied in the direction of equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, conductive layer on insulating carrier, etc., can solve the chemical stability of silver nanowire transparent conductive film And poor thermal stability, affecting the photoelectric performance of silver nanowire transparent conductive film, silver nanowires are prone to agglomeration, etc., to achieve the effect of improving photoelectric performance, high reliability, and avoiding poor binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

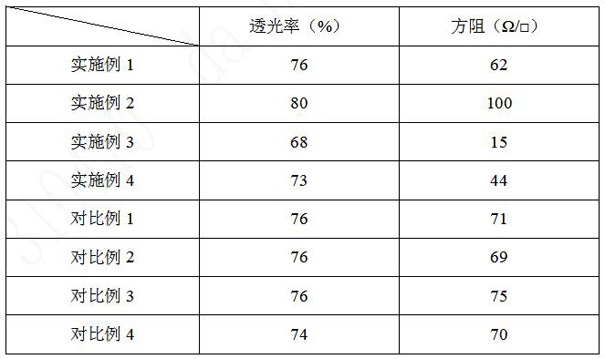

Examples

preparation example Construction

[0028] For this reason, the preparation method of the silver nanowire transparent conductive film provided by the invention comprises the following steps:

[0029] S1, mixing the first silver source, reducing agent, protective agent and polar solvent to obtain the first mixture, reacting the first mixture to prepare silver nano-crystal seed dispersion liquid, wherein the reducing agent is an aldehyde containing Anhydrides;

[0030] S2, mixing the silver nano-crystal seed dispersion, the second silver source and a thermosetting resin to obtain a second mixture, and irradiating the second mixture with ultraviolet light to obtain a first dispersion of silver nanowires, wherein , the viscosity of the second mixture is less than or equal to 200Pa.s;

[0031] S3, removing the polar solvent in the first dispersion, and then adding a curing accelerator to disperse to obtain a second dispersion of silver nanowires;

[0032] S4, activating the surface of the transparent substrate, and...

Embodiment 1

[0055] Add 0.01g of silver nitrate, 0.45g of 5-formyl-2-phenothioboronic acid, 0.31g of PVP and 10g of ethanol into a beaker to obtain the first mixture, and keep stirring the first mixture for 2h to obtain The silver nanowire seed crystal dispersion liquid, wherein, the grain size of the silver nanowire seed crystal is 2nm.

[0056] Then 0.09g of silver nitrate and 1g of bisphenol resin are added to the silver nanocrystal seed dispersion obtained above to obtain a second mixture with a viscosity of 80Pa.s. The second mixture is irradiated with ultraviolet light for 24h to obtain silver nanocrystals. The first dispersion liquid of wires, wherein the wire diameter of the silver nanowires is 30nm-65nm, and the wire length is 5μm-9μm.

[0057] Then, the ethanol was removed from the first dispersion liquid obtained above by thermal evaporation, and then 0.01 g of 2-ethyl-4-methylimidazole was added, stirred and dispersed by ultrasonic to obtain the second dispersion liquid of silv...

Embodiment 2

[0060] 0.01g of silver nitrate, 0.2g of 5-formyl-2-phenothioneic acid, 0.25g of PVP and 8g of ethanol were added to the beaker to obtain the first mixture, and the first mixture was continuously stirred for 2h to obtain The silver nanowire seed crystal dispersion liquid, wherein, the grain size of the silver nanowire seed crystal is 4nm.

[0061] Then 0.04g of silver nitrate and 1g of bisphenol resin are added to the silver nanocrystal seed dispersion obtained above to obtain a second mixture with a viscosity of 130Pa.s, and the second mixture is irradiated with ultraviolet light for 30h to obtain silver nanocrystals. The first dispersion liquid of wires, wherein the wire diameter of the silver nanowires is 35nm-60nm, and the wire length is 5μm-10μm.

[0062] Then, the ethanol was removed from the first dispersion liquid obtained above by thermal evaporation, and then 0.008 g of 2-ethyl-4-methylimidazole was added, stirred and dispersed by ultrasonic to obtain the second dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com