Gas-liquid-solid waste comprehensive treatment and resource utilization system

A comprehensive treatment and waste technology, applied in the field of gas-liquid-solid waste comprehensive treatment and resource utilization systems, can solve the problems of high energy consumption, high cost, difficult treatment, etc., to improve stability and pulp concentration, save money Expensive, widely adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

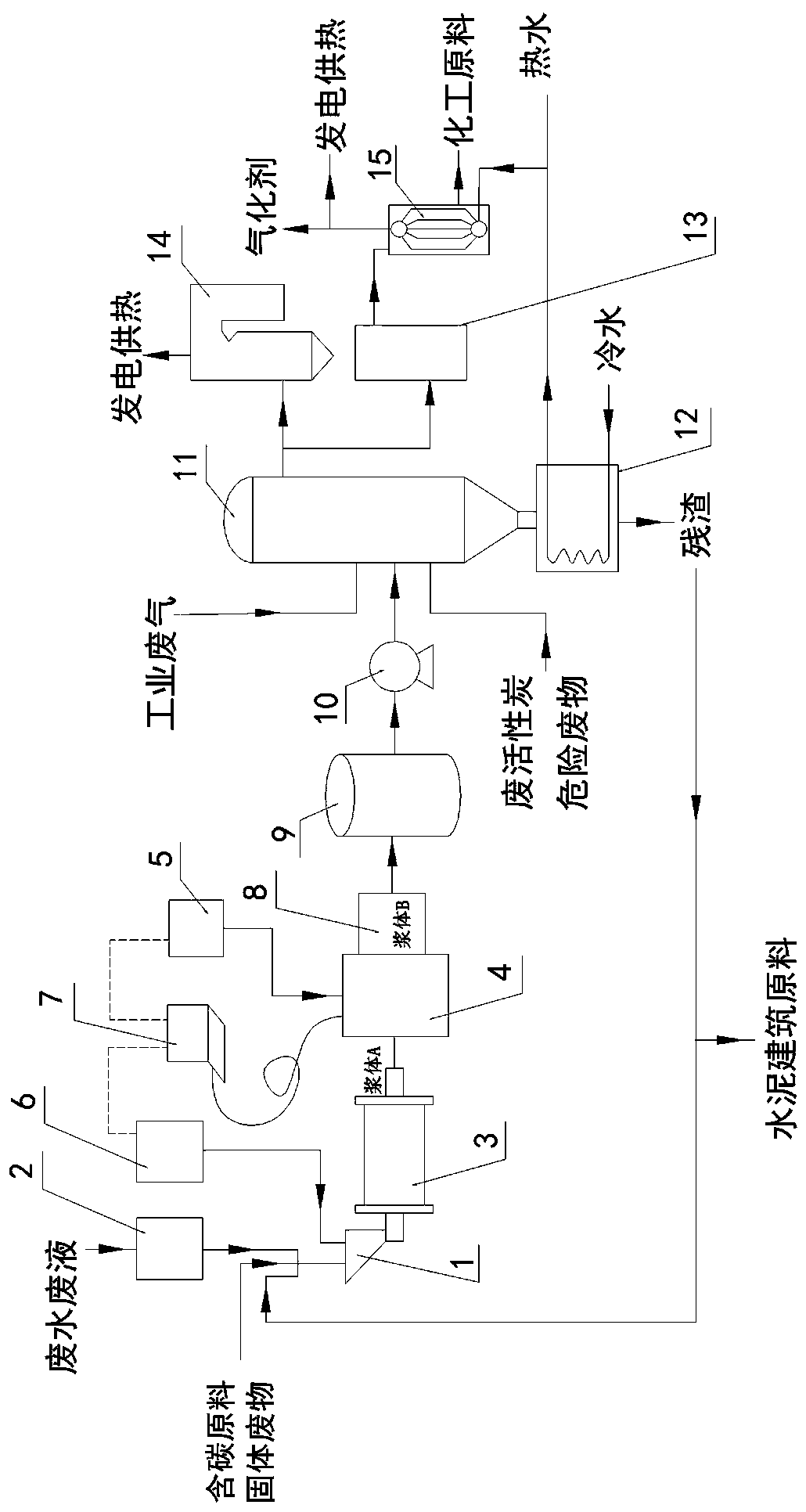

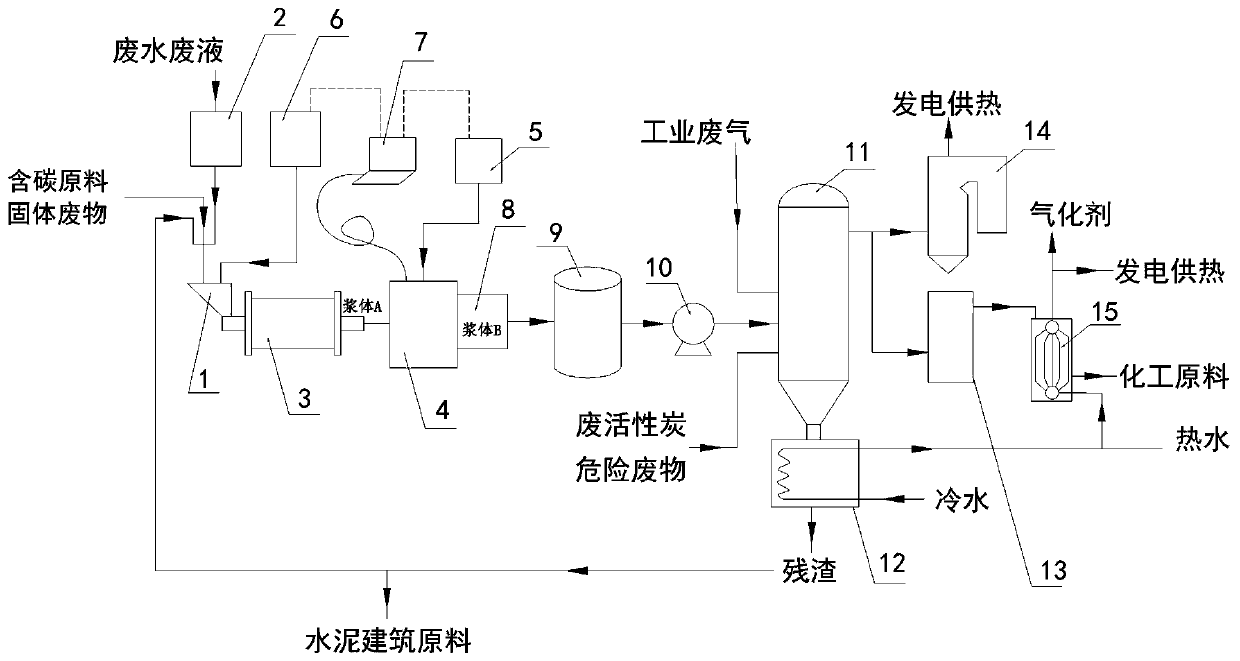

[0044] Such as Figure 1-2 As shown, a comprehensive gas-liquid-solid waste treatment and resource utilization system of the present invention includes an abrasive device, a pulping device and a gasification device.

[0045] The abrasive device includes a feeding device 1 and a mill 3, and the feeding device 1 is fed with carbon-containing raw material solid waste, waste water and waste liquid and additives, and sent to the mill 3 for grinding to form a slurry A, Slurry A is sent to the pulping unit;

[0046] The pulping device includes a pulping machine body 4, a mixed pulping intelligent guidance system 7 and a modified conditioning device 5, and the mixed pulping intelligent guidance system 7 guides the modified conditioning device 5 to pass into the pulping machine body 4 Slurry A undergoes tempering treatment and ultrasonic treatment to generate slurry B;

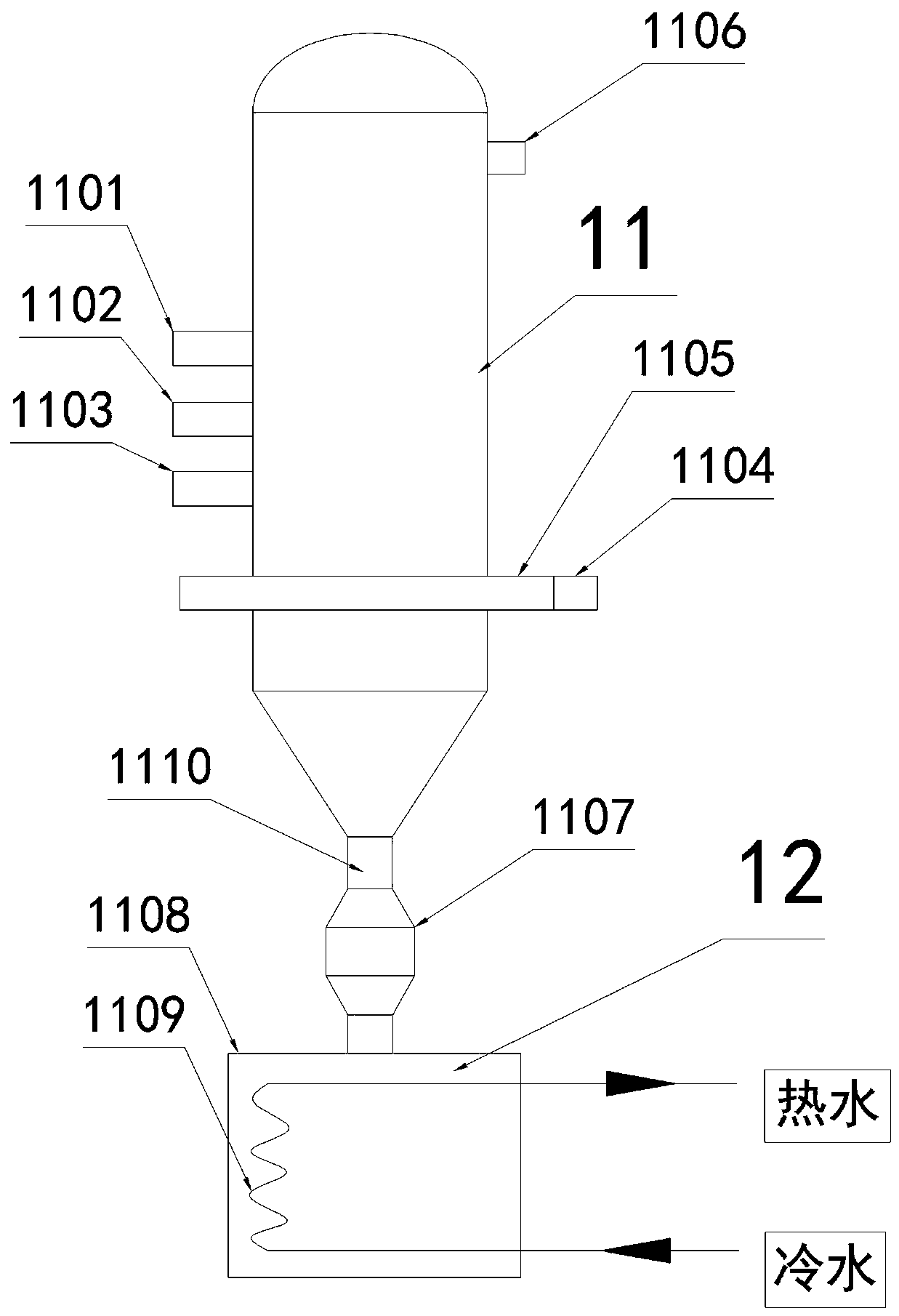

[0047] The gasification device includes a gasification furnace 11. The gasification furnace 11 comprehensively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com