Patents

Literature

154results about How to "High solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment of resins to lower levels of CPD-producing species and improve gelation stability

ActiveUS7081512B2Reduce removalCharacteristic viscosityNatural cellulose pulp/paperSpecial paperPolyaminePolyamine metabolism

A process for treating a composition containing a polyamine-epihalohydrin resin that has a low level of CPD-producing species and good gelation stability is disclosed. A polyamine-epihalohydrin resin is prepared with a ratio of epihalohydrin:amine of less than about 1.1:1.0; The resin is then subjected to a base treatment followed by an acid treatment resulting in a resin that has good gelation storage stability and produces low levels of CPD.

Owner:SOLENIS TECH CAYMAN

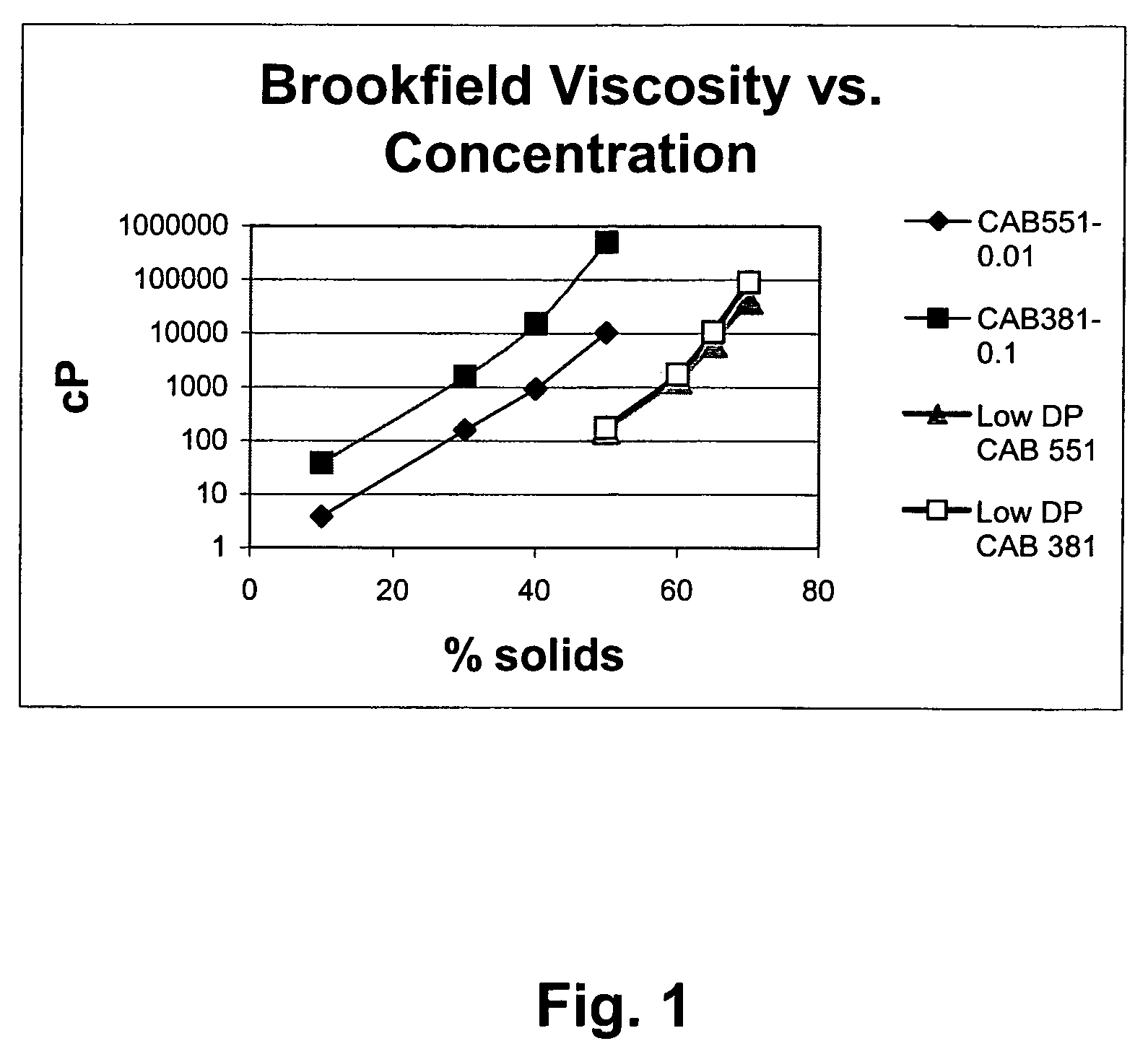

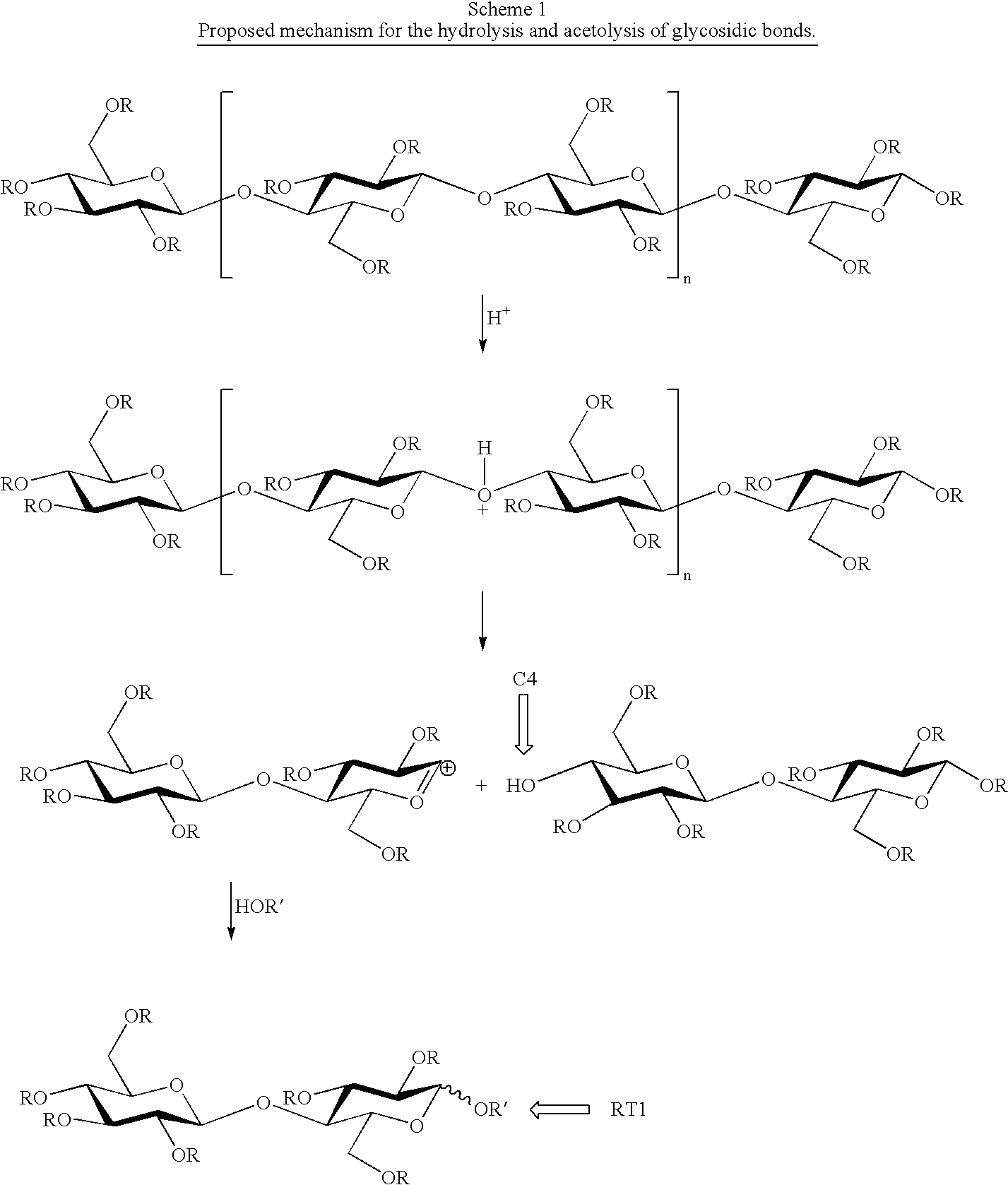

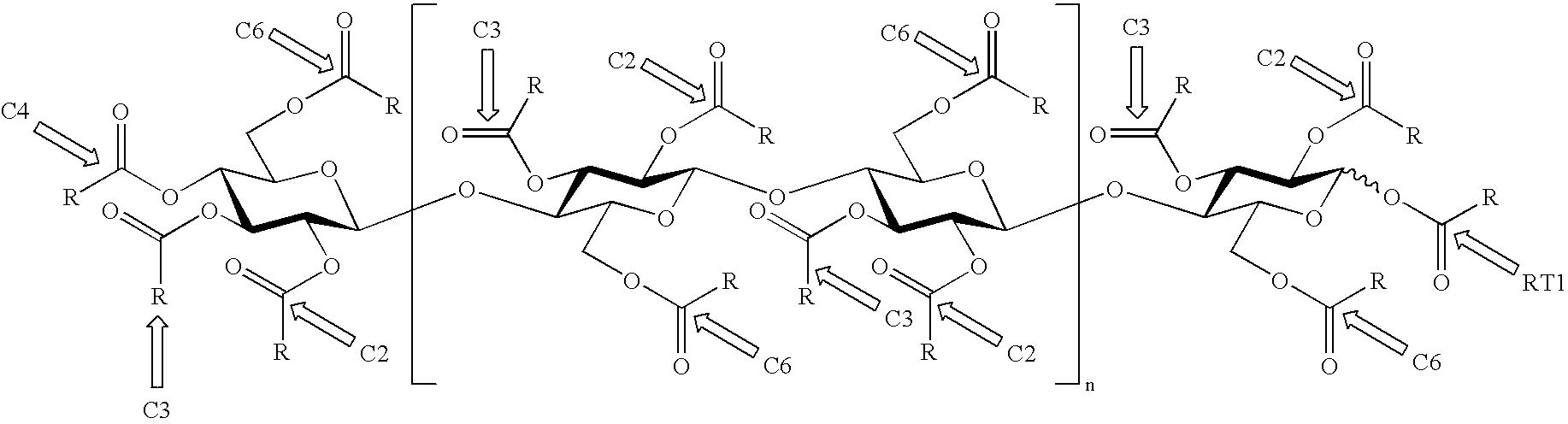

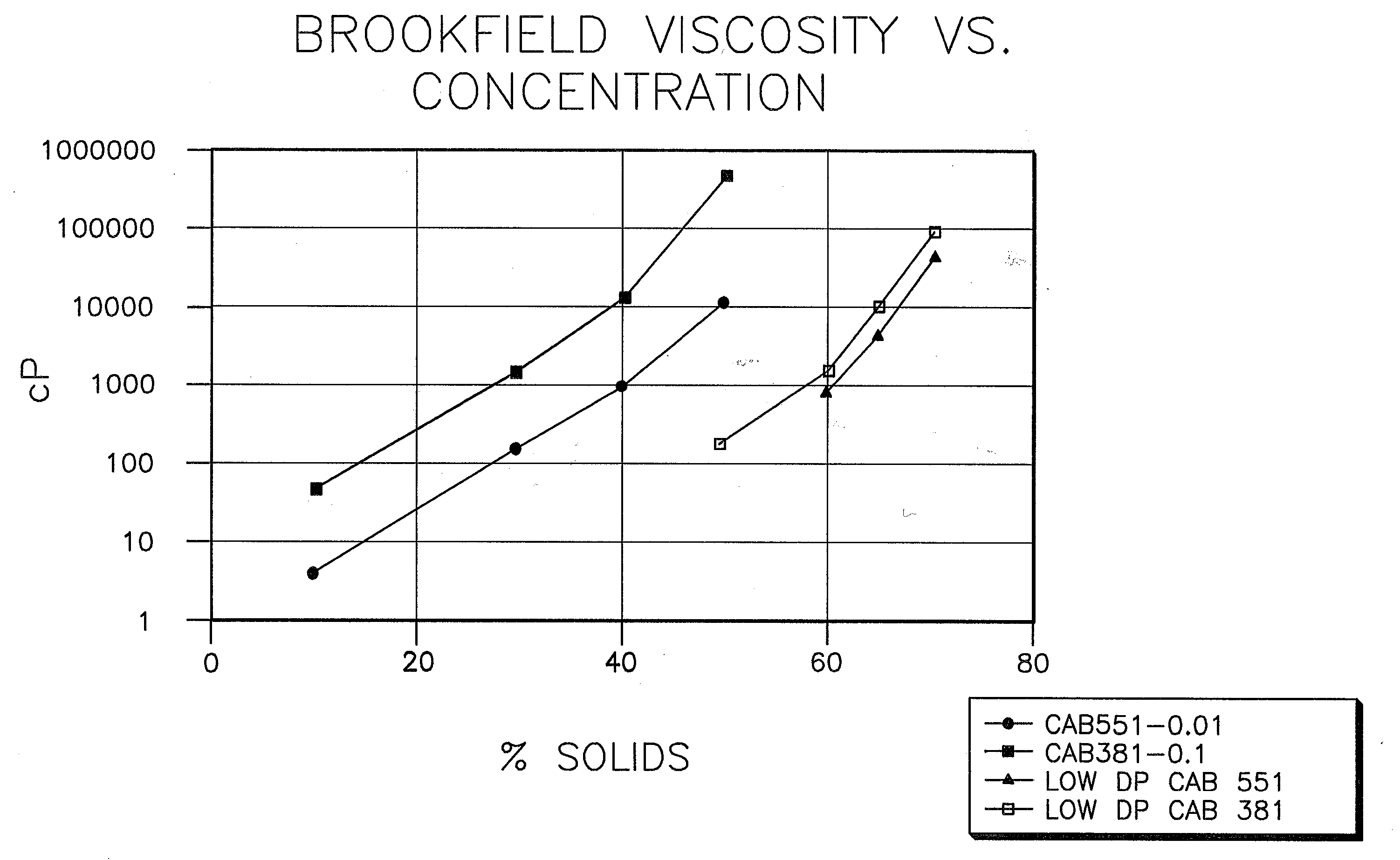

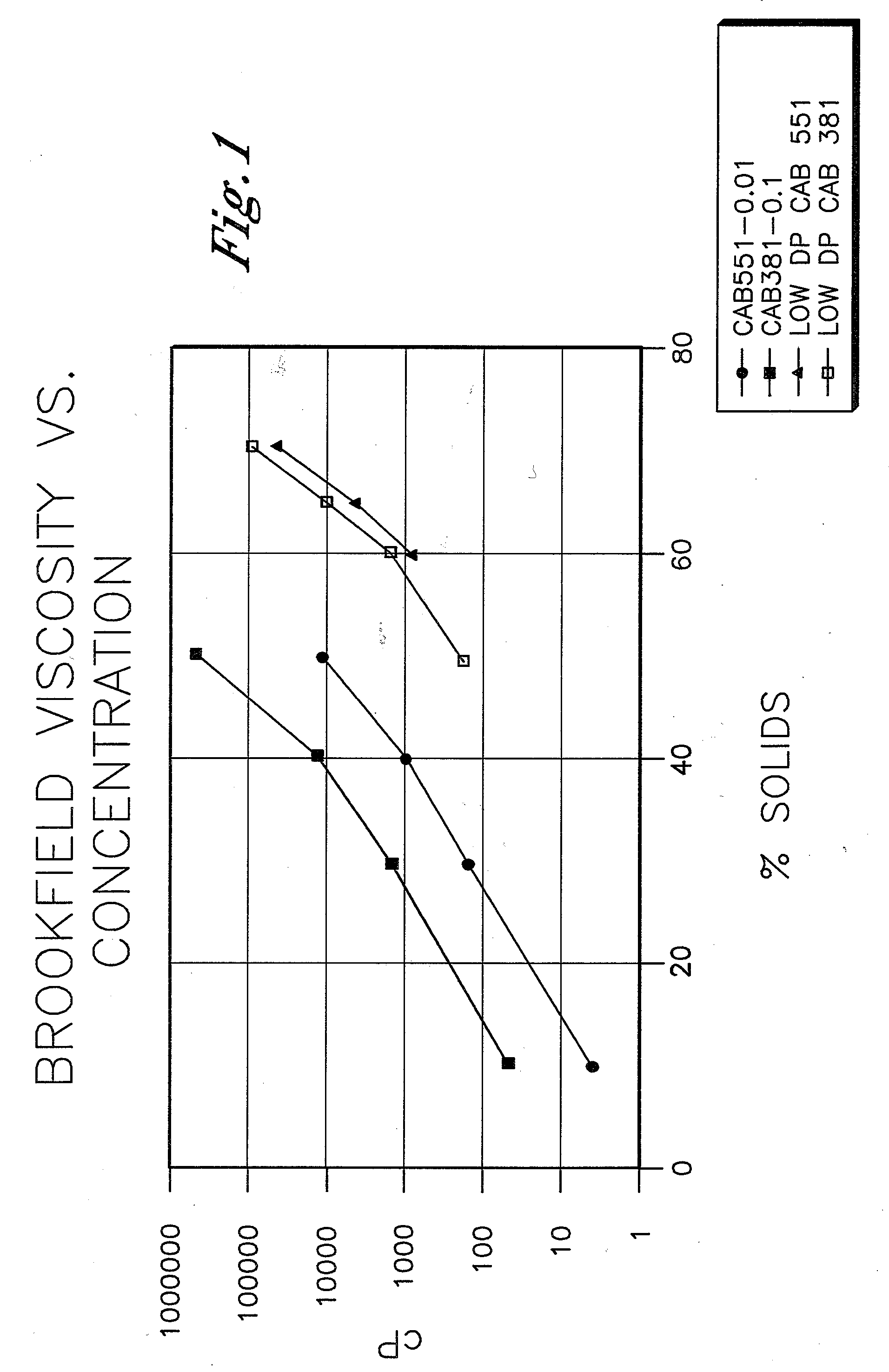

Low molecular weight cellulose mixed esters and their use as low viscosity binders and modifiers in coating compositions

ActiveUS7585905B2Reduce molecular weightHigh maximum degree of substitutionInksPolyurea/polyurethane coatingsSolubilityCellulose

Cellulose mixed esters are disclosed having low molecular weights and low degrees of polymerization. These new cellulose mixed esters include cellulose acetate propionate and cellulose acetate butyrate. The esters exhibit solubility in a wide range of organic solvents with minimal viscosity increase, are compatible with a wide variety of resins, and are useful in coatings and inks compositions as binder resins and rheology modifiers.

Owner:EASTMAN CHEM CO

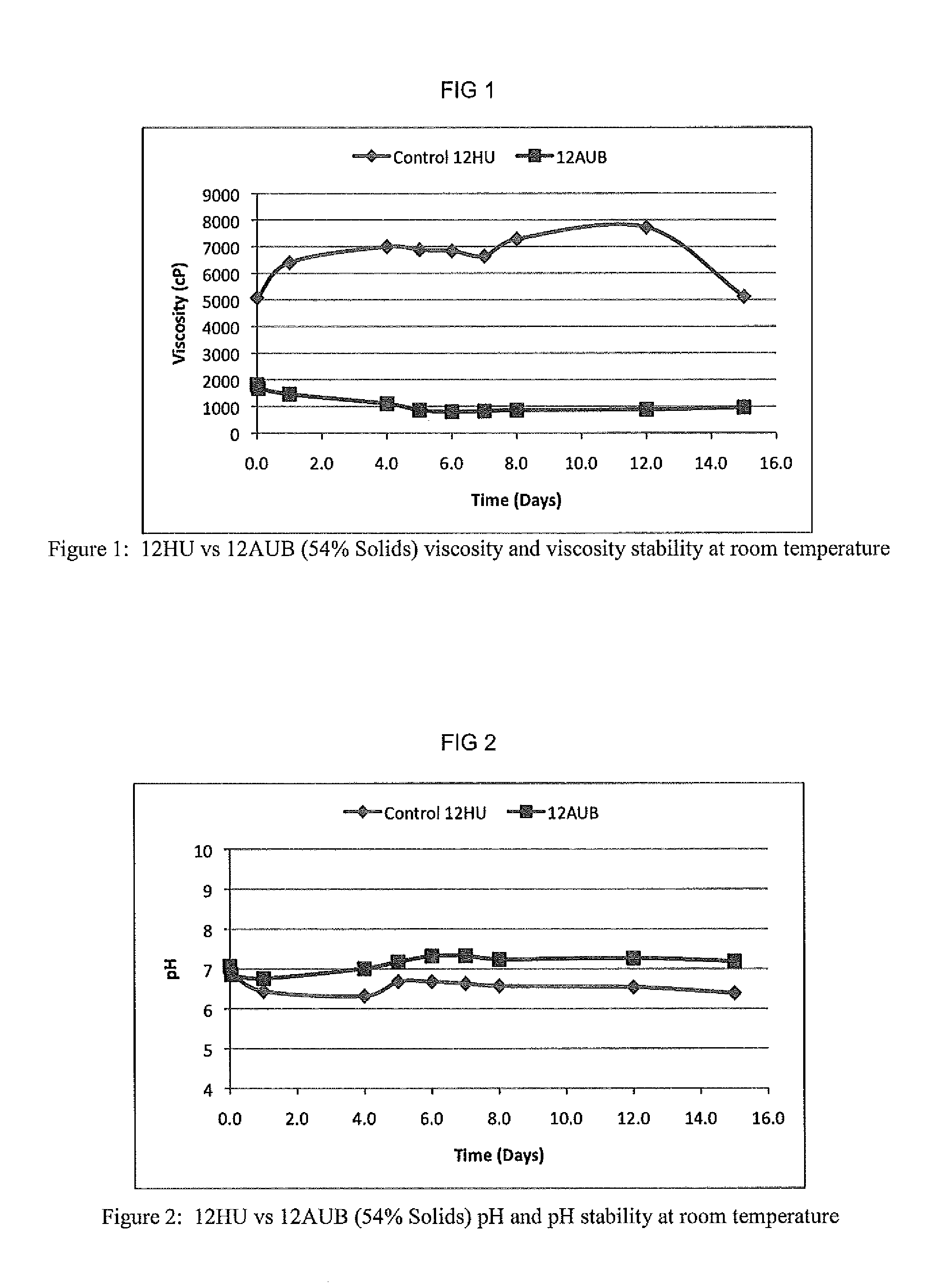

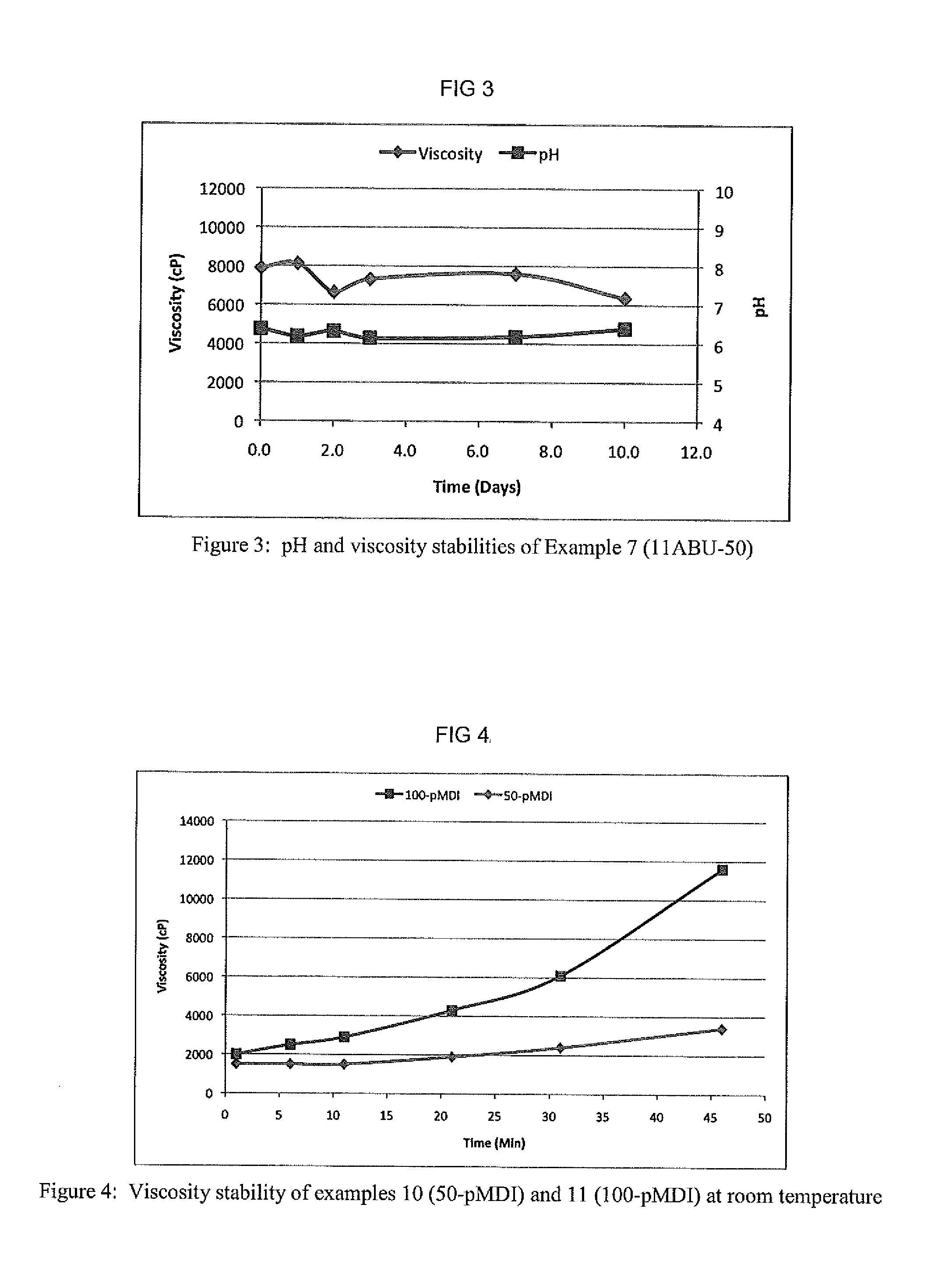

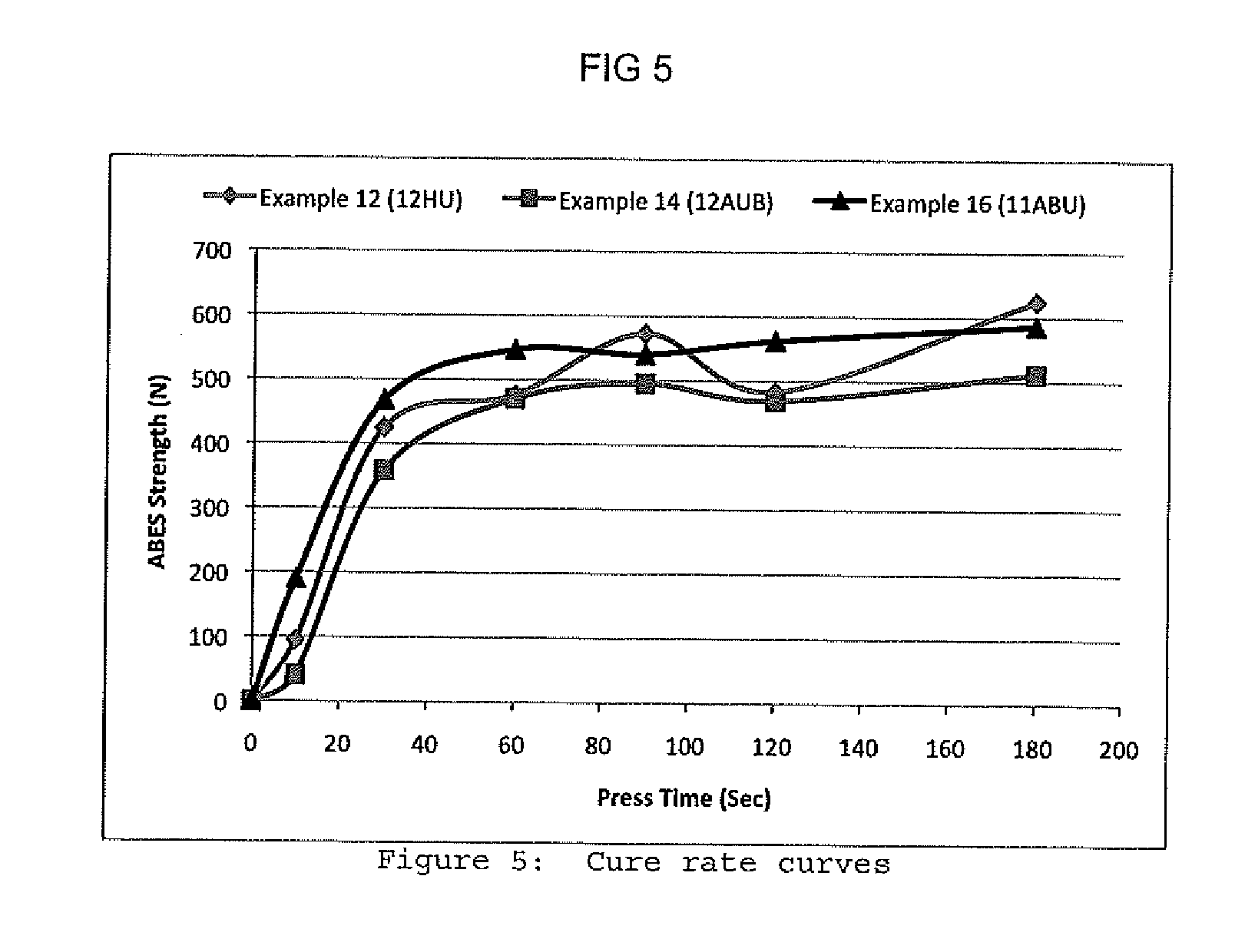

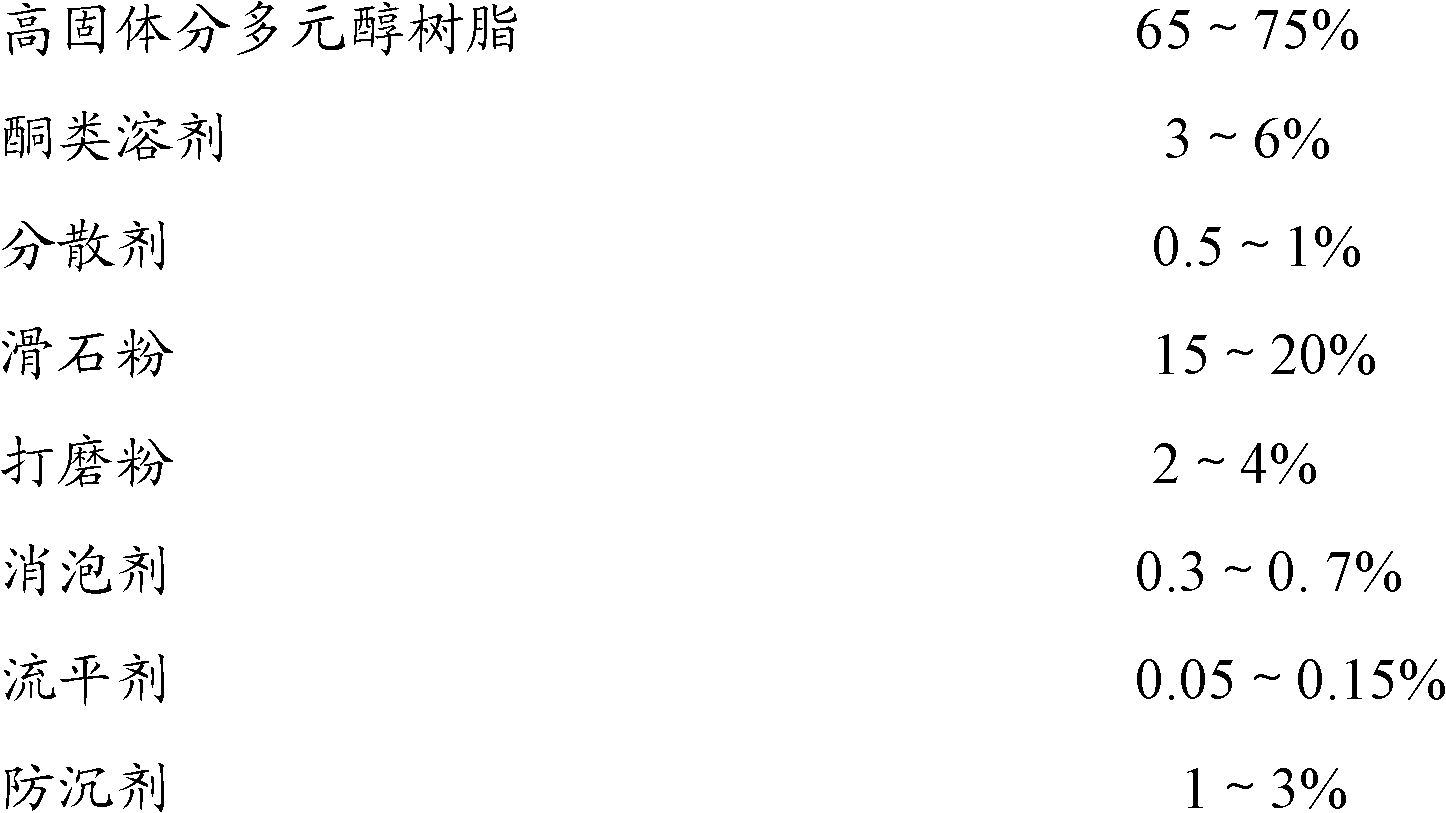

Stable Acid Denatured Soy/Urea Adhesives and Methods of Making Same

ActiveUS20110048280A1Good compatibilityImprove stabilityMonocarboxylic acid ester polymer adhesivesProtein adhesivesAdhesiveDiluent

The present invention provides an improved method of producing a stable acid denatured soy / urea adhesive having improved wet and dry strengths, with more efficient production and lower production costs. The method comprises combining urea with soy flour that has been acid treated until denatured and substantially free from urease activity. The soy flour is preferably lowered to a pH of 2.0 to 4.0 for at least 1 minute. Optionally, the method may also include adding a crosslinking agent, diluent or both to the soy flour / urea adhesive and / or adding an emulsified or dispersed polymer. Adhesives and dispersions prepared according to the methods of this invention offer increased stability and strength properties.

Owner:SOLENIS TECH CAYMAN

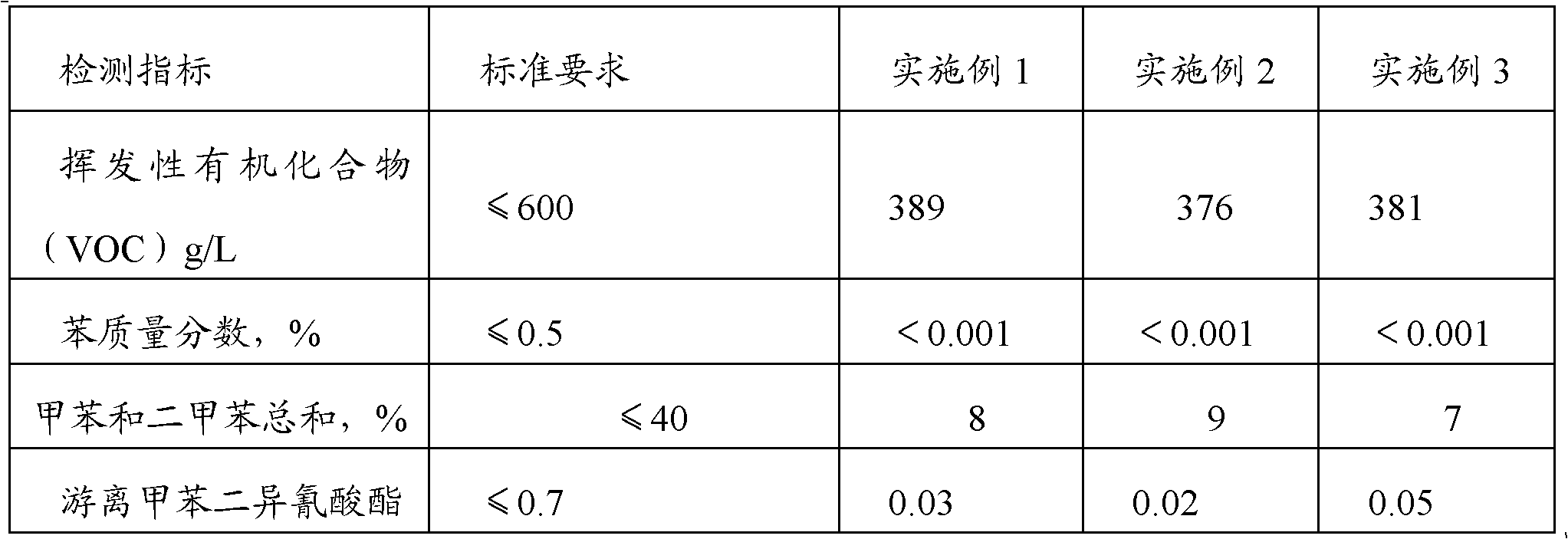

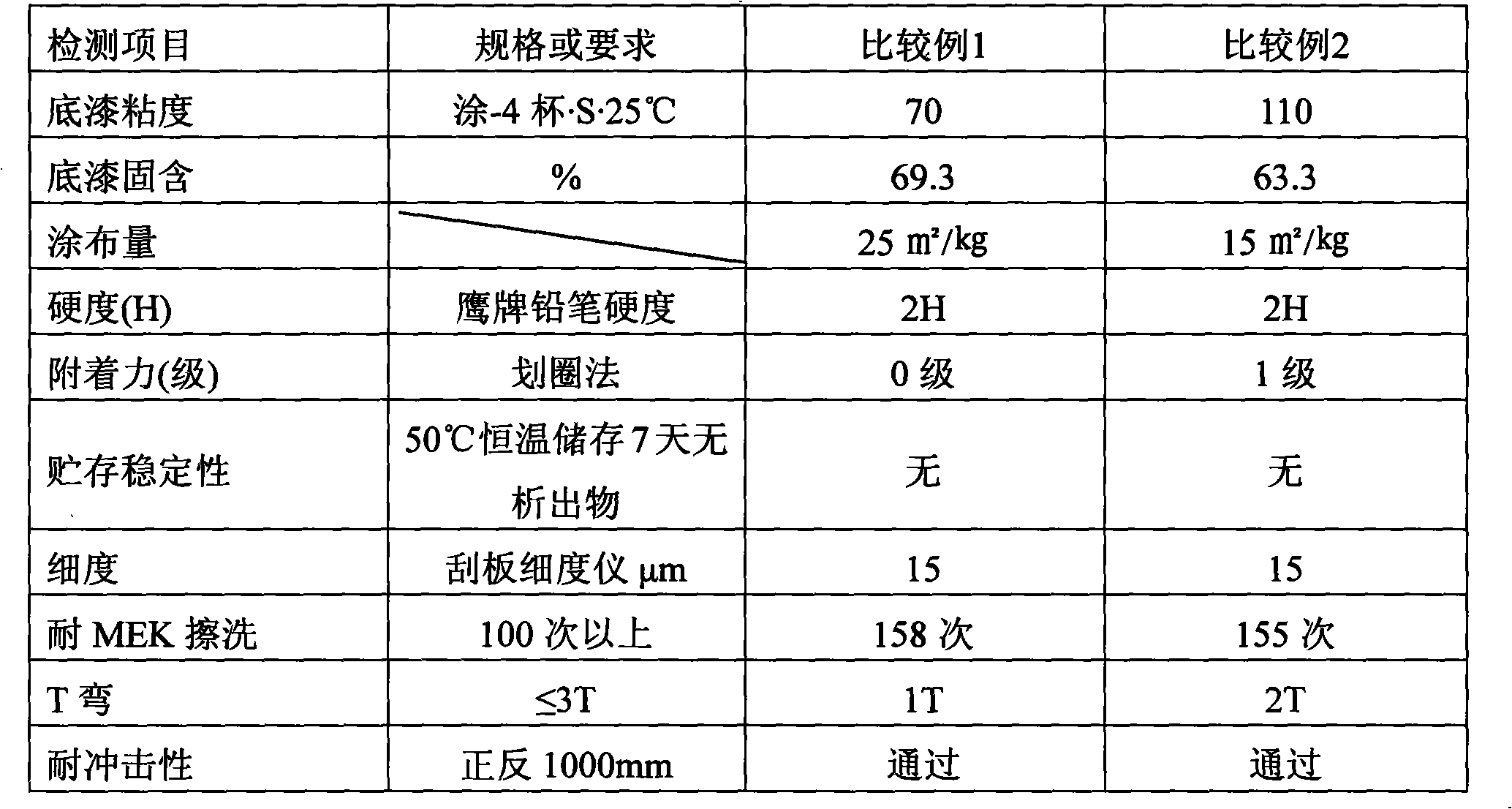

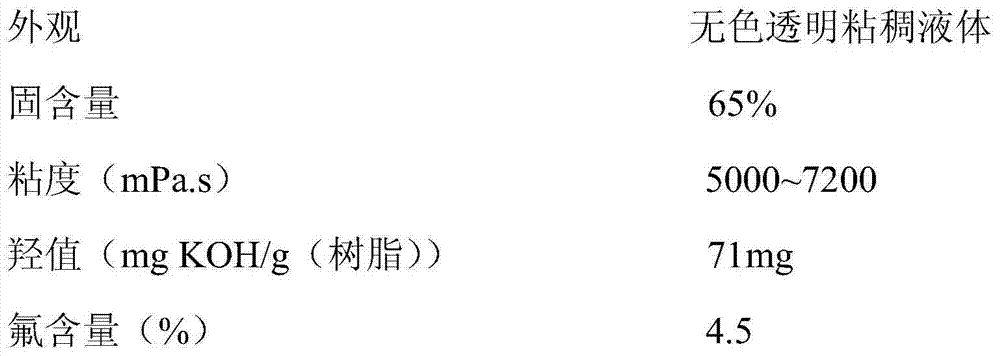

Bicomponent oily polyurethane primer with low VOC (volatile organic compounds)

The invention relates to the technical field of coatings, in particular to a bicomponent oily polyurethane primer with low VOC (Volatile Organic Compounds) and a preparation method thereof. The primer comprises a component A, a component B and a diluting agent, wherein the ratio in parts by weight of the component A to the component B is 2:1, wherein the component A comprises polyhydric alcohol resin with high solid content, an ester solvent, a dispersing agent, a matting powder, a defoaming agent and an anti-sediment agent; according to the preparation method, different molecular weights of the polyhydric alcohol resin in the component A and the polyisocyanates in the component B are respectively screened, the optimal molecular weight is intercepted so as to ensure the dissolubility of the polyhydric alcohol resin and the polyisocyanates in a ketone solvent, meanwhile, other auxiliaries are used for carrying out stem grafting improvement on a molecular structure to enhance the miscibility of the two components; and therefore, the bicomponent oily polyurethane primer not only has the characteristics of good application property, good water resisting property, high hardness and thelike owned by the traditional polyurethane paint, but also ensures that the content of the volatile organic compounds is greatly reduced and even is lower than 450g / L.

Owner:东莞大宝化工制品有限公司 +1

Hydroxyl acrylic acid emulsion with microgel nuclear structure and preparation process and application thereof

A hydroxyacrylic acid emulsion with micro gel core structure is prepared through copolymerization of vinylsilane coupling agent on acrylate monomer to obtain hydrophobic micro gel cores, copolymerization of hydroxyvinyl monomer on acrylate monomer on the surface of said core to become hydrophilic shell, and preparing emulsion. A process for preparing water-soluble dual-component polyurethane used for paint is also disclosed.

Owner:SOUTH CHINA UNIV OF TECH

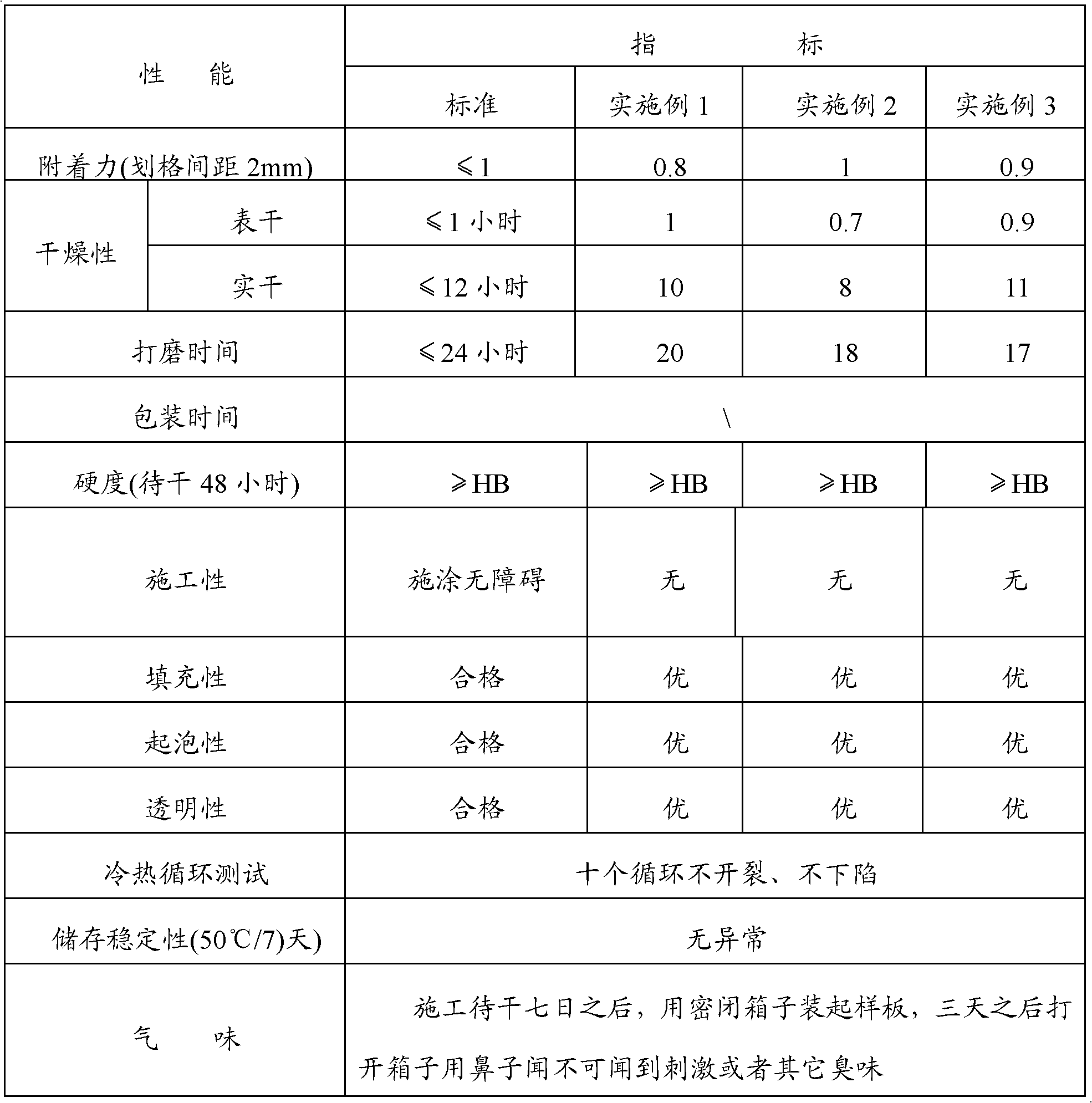

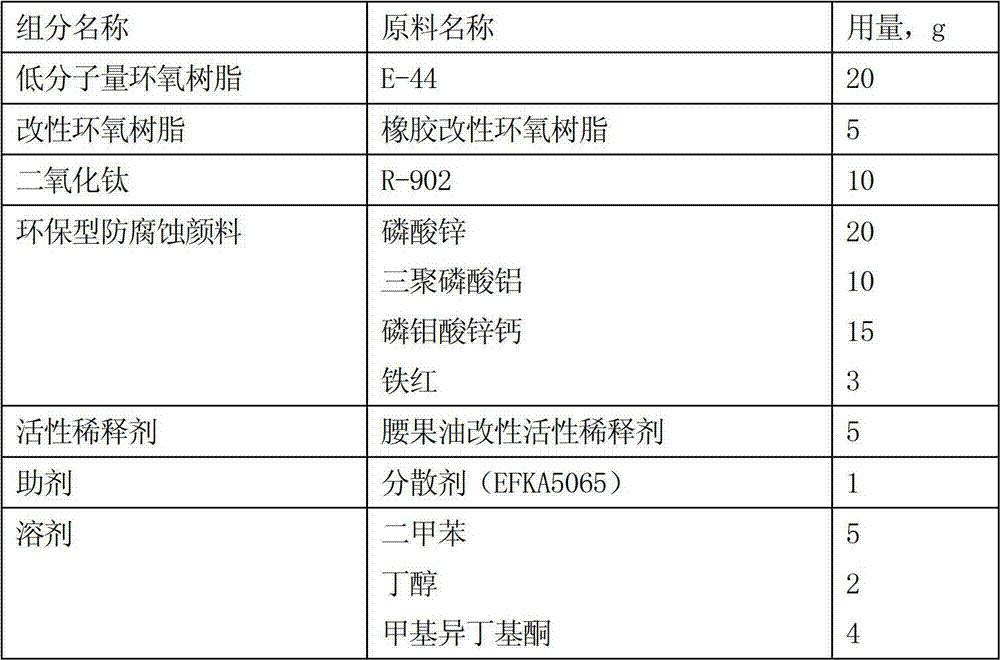

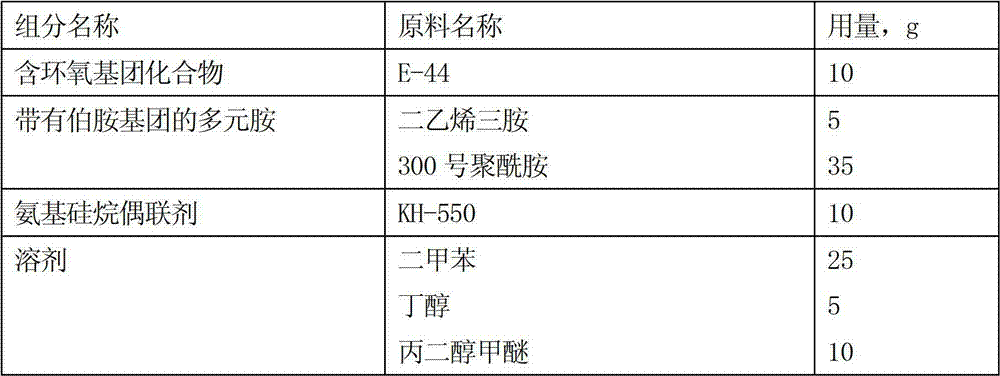

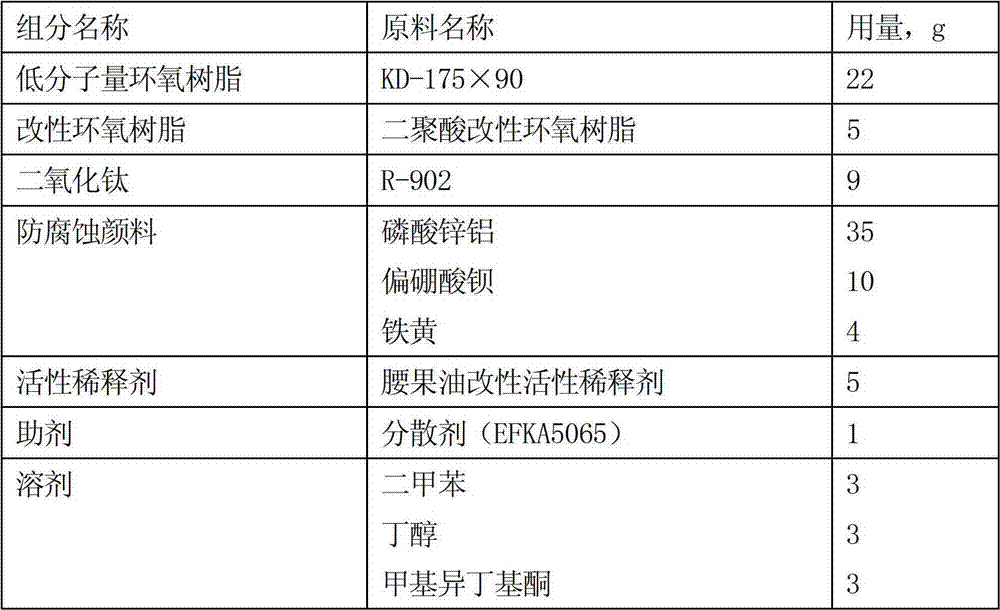

High solid anticorrosive paint and preparation method thereof

ActiveCN102732130AImprove adhesionLow viscosityAnti-corrosive paintsEpoxy resin coatingsReactive diluentSolvent

The invention discloses a high solid anticorrosive paint and a preparation method thereof. The paint is composed of a component A and a component B, the component A is composed of the following components in percentage by mass: 15-30% of low molecular weight epoxy resin, 5-10% of modified epoxy resin, 4-8% of a reactive diluent, 5-10% of titanium dioxide, 40-50% of environment-friendly anti-corrosion paint, 0.1-3% of an assistant and the balance of a solvent; and the component B is composed of the following components in percentage by mass: 8-15% of a compound with epoxy groups, 30-40% of aliphatic polyamine with primary amine groups, 8-15% of an amino silane coupling agent and the balance of a compound of solvents. The paint disclosed by the invention has high application solid, low viscosity, good suitability for spraying, good flexibility after film formation on multiple substrates such as aluminum alloy and the like, good performances to direct shock and backlash and excellent anticorrosive property.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Process for preparing high solid single component polyurethane elastor and its use

InactiveCN1587293APromote wettingGood dispersionPolyurea/polyurethane coatingsPolyurethane elastomerPolymer science

The polyurethane is prepared through the reaction between polyol and isocyanate and siloxane modification. The preparation process includes first synthesis of polyurethane prepolymer with end isocyanic radical and the subsequent modification with siloxane, or includes first synthesis of polyurethane prepolymer containing end isocyanic radical with siloxane containing isocyanate and the subsequent modification with siloxane containing active hydrogen. The modified polymer may be produced into paint film of 2-3 mm thickness, shore A hardness not lower than 60, elongation at rupture not smaller than 300 %, stretching strength not lower than 3 MPa and stable storage period of 3-6 months. The present invention is applied in making elastic polyurethane coating.

Owner:FUDAN UNIV

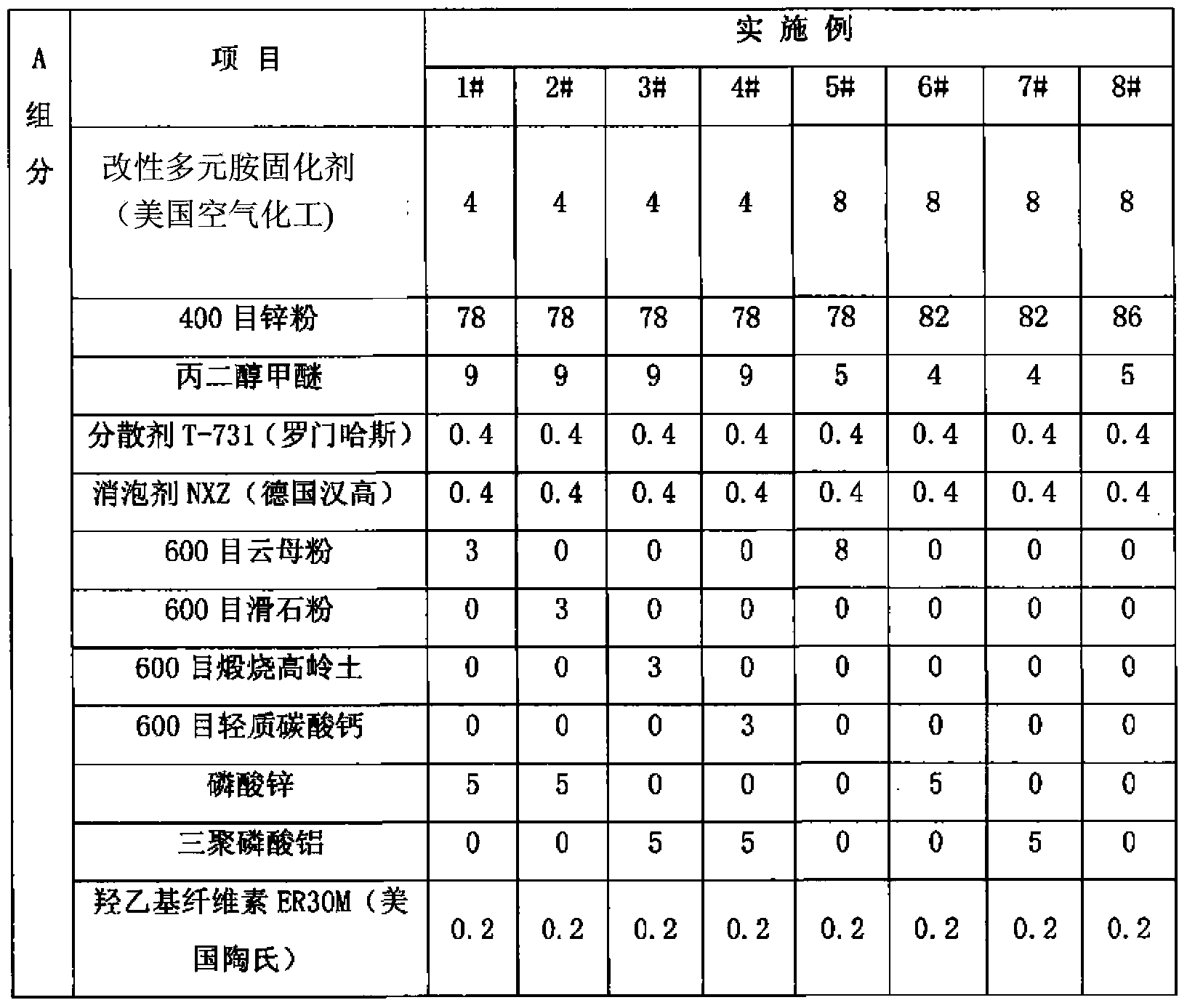

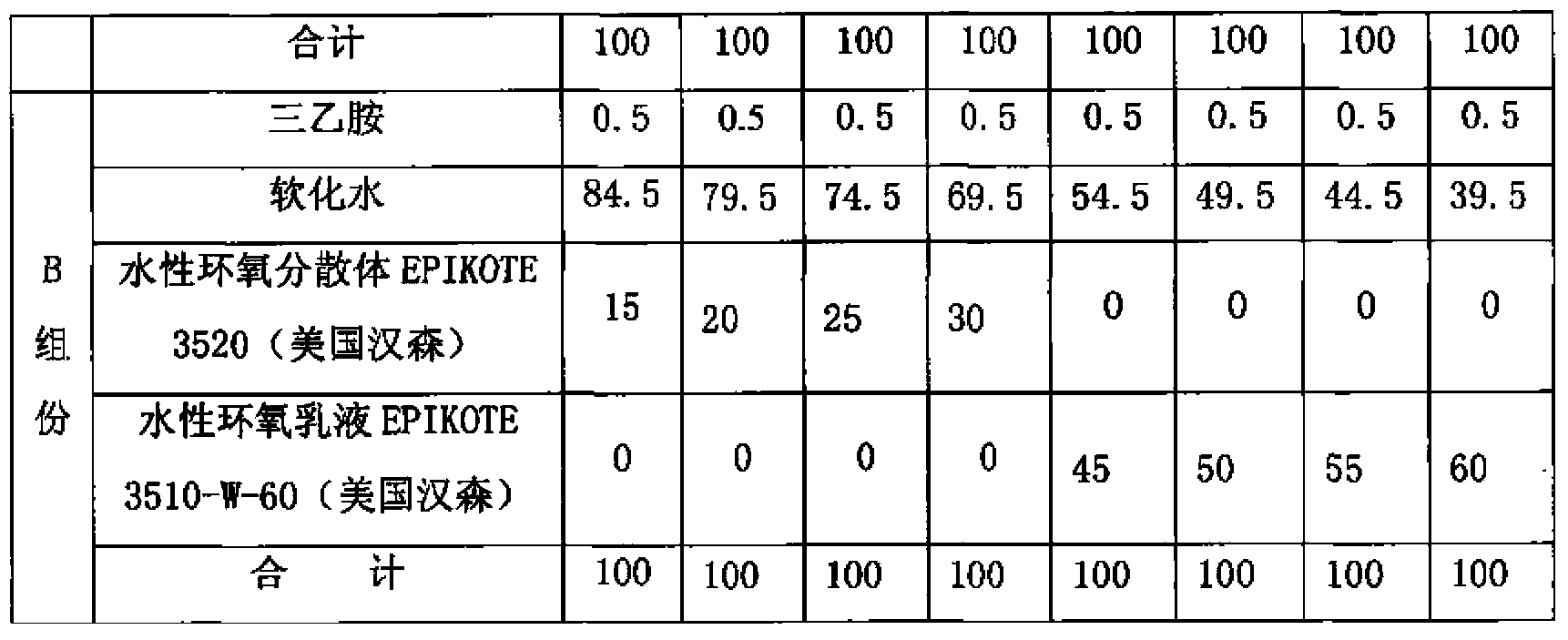

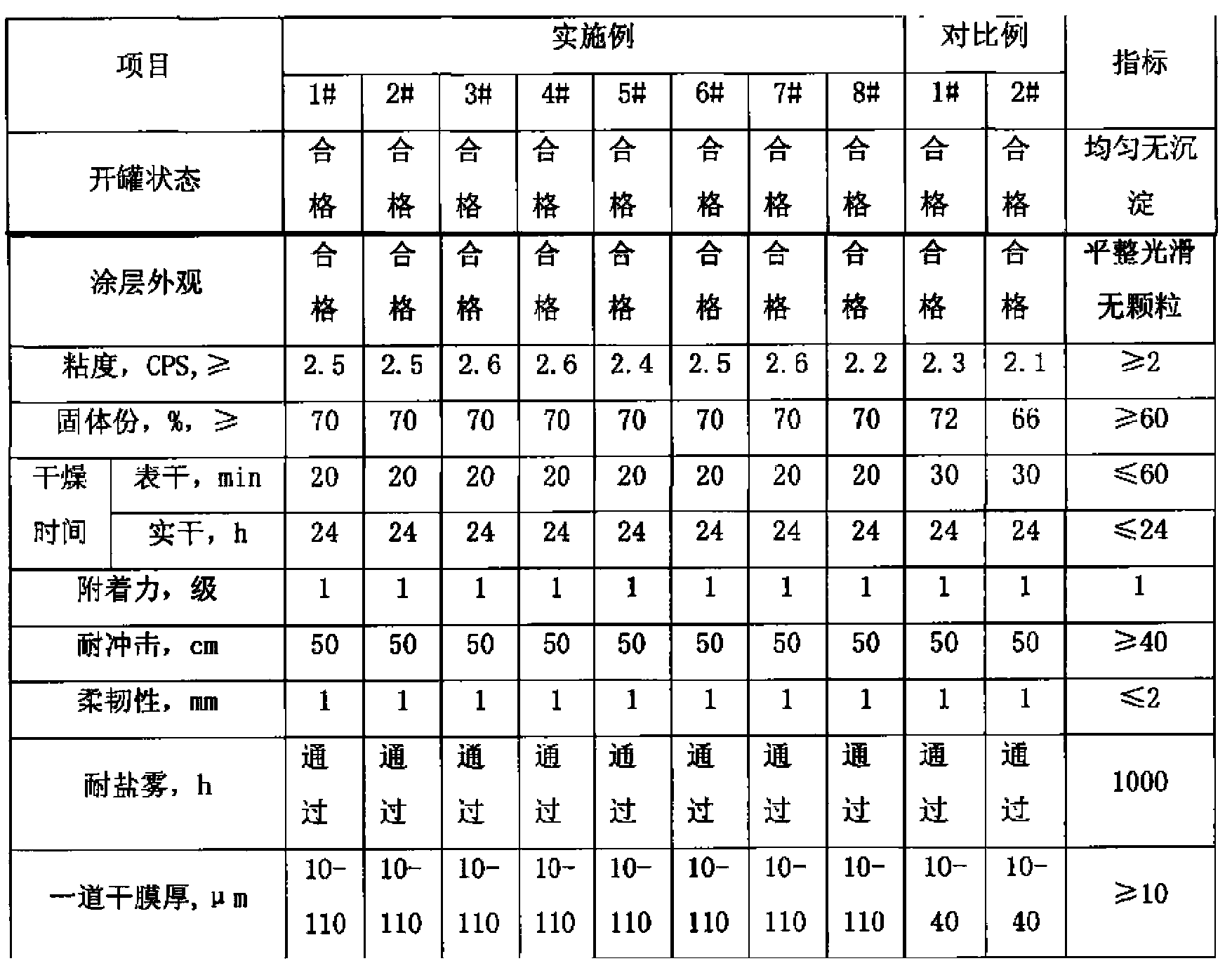

Waterborne epoxy zinc-rich primer

InactiveCN103409040AImprove rigidityHigh strengthAnti-corrosive paintsEpoxy resin coatingsEpoxySoftened water

The invention provides a waterborne epoxy zinc-rich primer. The waterborne epoxy zinc-rich primer is characterized by comprising component A and component B, wherein the component A comprises 3 to 10 wt% of a modified polyamine curing agent, 75 to 90 wt% of zinc dust, 2 to 10 wt% of a cosolvent, 0.1 to 2 wt% of an anti-settling thixotropic agent, 0.2 to 2 wt% of a dispersant and 0.2 to 20 wt% of an antifoaming agent, the zinc dust is nano-scale zinc dust, the component B comprises 14 to 60 wt% of a waterborne epoxy resin, 38 to 85 wt% of softened water and 0.2 to 2.0 wt% of a neutralizer, and a mass ratio of the component A to the component B is 100: 45.

Owner:张家港保税区金企鹅贸易有限公司

Acrylate polyurethane water-dispersed resin and its making method

This invention relates to a high solid acrylic polyurethane water-dispersible resin and method for making same. The solid content of this resin is up to 41-45%, and the resin does not contain free emulsifier and organic solvent. The procedures comprise: first it produces NCO capping polyurethane prepolymer with the ethenyl monomer part of which can be freely polymerized as medium, then obtain a water-dispersible polyurethane coated with ethenyl monomers after neutralization and water dispersion, add in the rest ethenyl monomer and initiator to perform free radical polymerization, to produce the acrylic polyurethane water-dispersible resin with a nuclear shell structure. This resin is characterized of high solid content, fast drying speed, stable storage, filming at room temperature, good adhesive force, flexility, hardness, and water resistance, low VOC content, and reasonable quality and cost ratio, and can be used in producing high-grade woodware coating material, water leather paint, and surface coating of plastic, metal, scrim and automobile.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

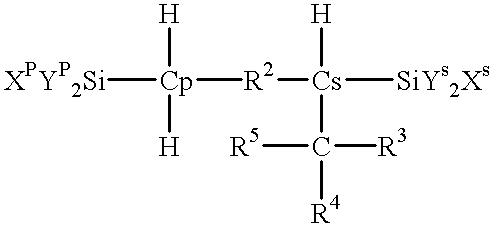

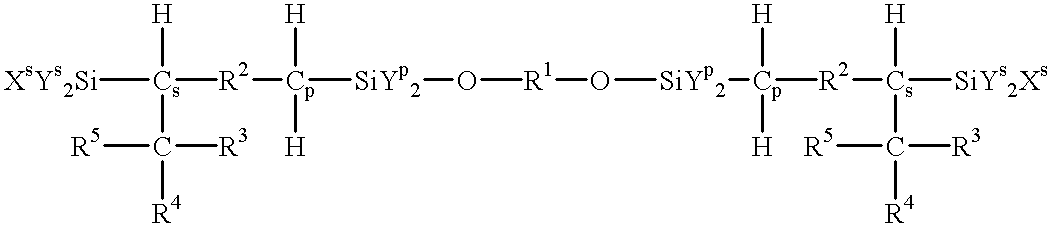

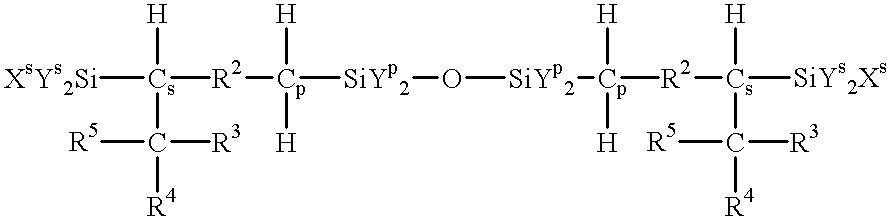

Process for producing reactive silane oligomers

InactiveUS6329489B1Low coatHigh solid contentGroup 4/14 element organic compoundsCoatingsOligomerPolymer science

The invention is directed to a process for making a reactive silane oligomer having low polydispersity, viscosity and volatility. The process utilizes reacting unsymmetrical difunctional silane monomers with water, diol monomers, or a combination thereof to make the reactive silane oligomer. The unsymmetrical difunctional silane monomers are with silane reactive groups having significantly different reactivities. Use of such reactive silane oligomers results in multi-component coating compositions having high miscibility, low VOC, low viscosity and high percentage of solids.

Owner:EI DU PONT DE NEMOURS & CO

Highlight water-based automobile paint

InactiveCN101104768AGuaranteed stabilityMiscibility guaranteedLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedLacquer

The invention discloses a high-gloss water-based paint for car. The finishing varnish is prepared by mixing methacrylate resin(27-36%), ethyl acrylate resin(31-41%), water-soluble methyl-etherifying amino resin(9-14%), water-soluble polyurethane rheological agent(0.1-0.3%) , water-based polyurethane thickening rheology agent(3-5%) and deionized water(3-18.5%) in a container. A colored paint can be made by adding pigment concentrates into the finishing varnish. The stabilities of pigment dispersing into tiny particles and the miscibility of different pigments are guaranteed by using blended dispersants to wet and disperse the pigment. Good film fullness and glossiness can be obtained due to a higher solid content of the water-based paint by a mixture of more than two high-solid basic resin. The specification of this paint reaches and surpasses the standard level of common solvent car varnish by reducing the pollution of the harmful volatile organic solvent.

Owner:刘成金

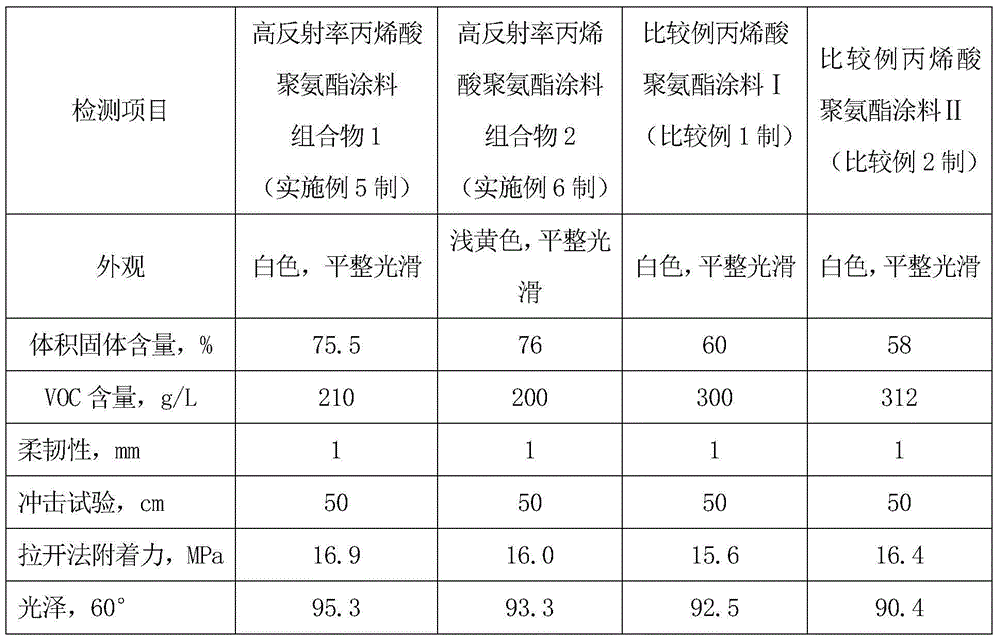

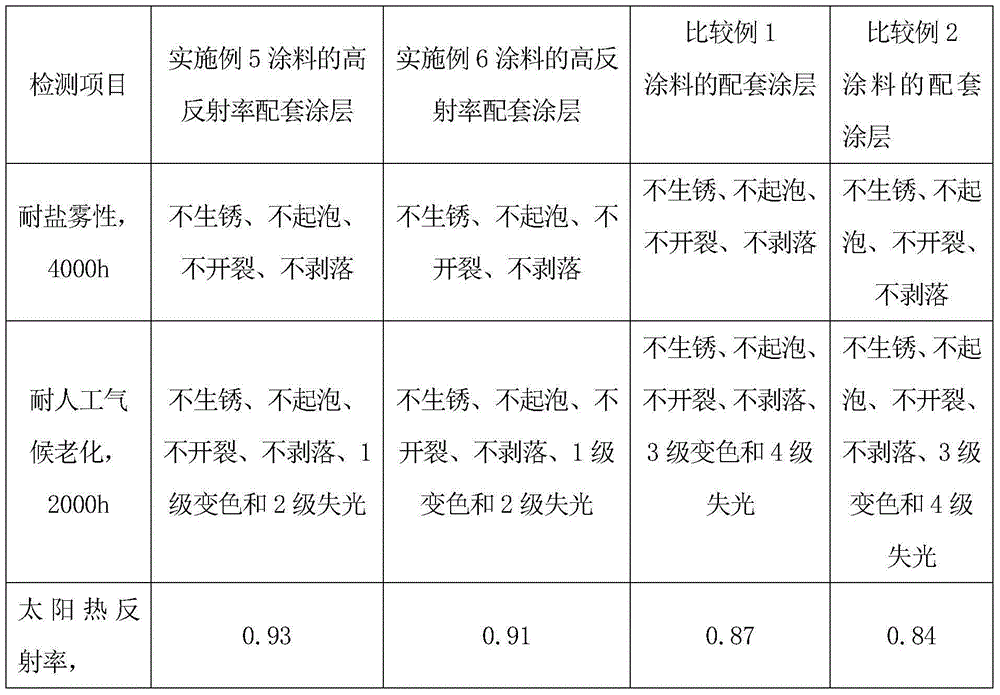

High-reflective acrylic polyurethane coating composition

ActiveCN104371531AHigh solid contentGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinIsophorone diisocyanate

The invention relates to a high-reflective acrylic polyurethane coating composition which comprises a component A and a component B in a mass part ratio of 20;3. The component A in 100 parts by mass comprises the following materials in part by mass: 30-50 parts of modified hydroxyl acrylic resin, 2-6 parts of auxiliaries, 35-45 parts of heat reflective pigments, 4-8 parts of aerogel and 10-15 parts of organic solvent. The component B in 100 parts by mass comprises the following materials in part by mass: 75-90 parts of polyisocyanate and 10-25 parts of organic solvent. The modified hydroxyl acrylic resin is obtained by cold-blending modified resin and hydroxyl acrylic resin in a mass part ratio of 1-3: 1; the solid content of the modified hydroxyl acrylic resin is greater than or equals to 75wt%; the particle size of heat reflective pigments ranges from 0.55 micron to 1.2 microns; the particle size of the aerogel ranges from 1 micron to 80 microns; the pore size of the aerogel ranges from 10 nanometers to 20 nanometers; and the heat conductivity coefficient of the aerogel is less than or equals to 0.015W / (m k). The polyisocyanate is one or more of HDI (hexamethylene diisocyanate) biuret, HDI trimer and IPDI (isophorone diisocyanate) trimer curing agents. The high-reflective acrylic polyurethane coating composition is high in reflective insulation quality; and the quantity of VOC (volatile organic compounds) of the high-reflective acrylic polyurethane coating component is low.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

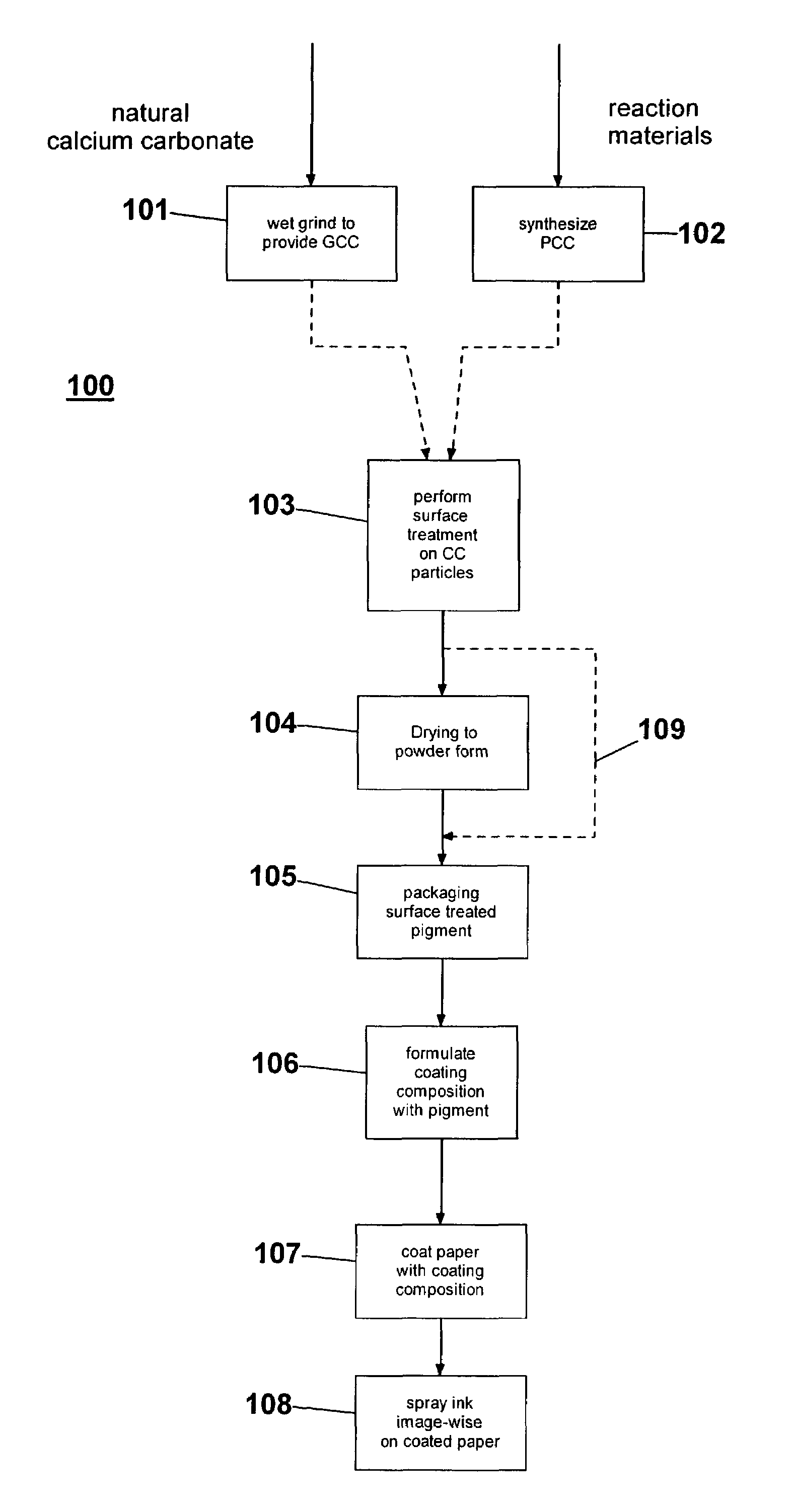

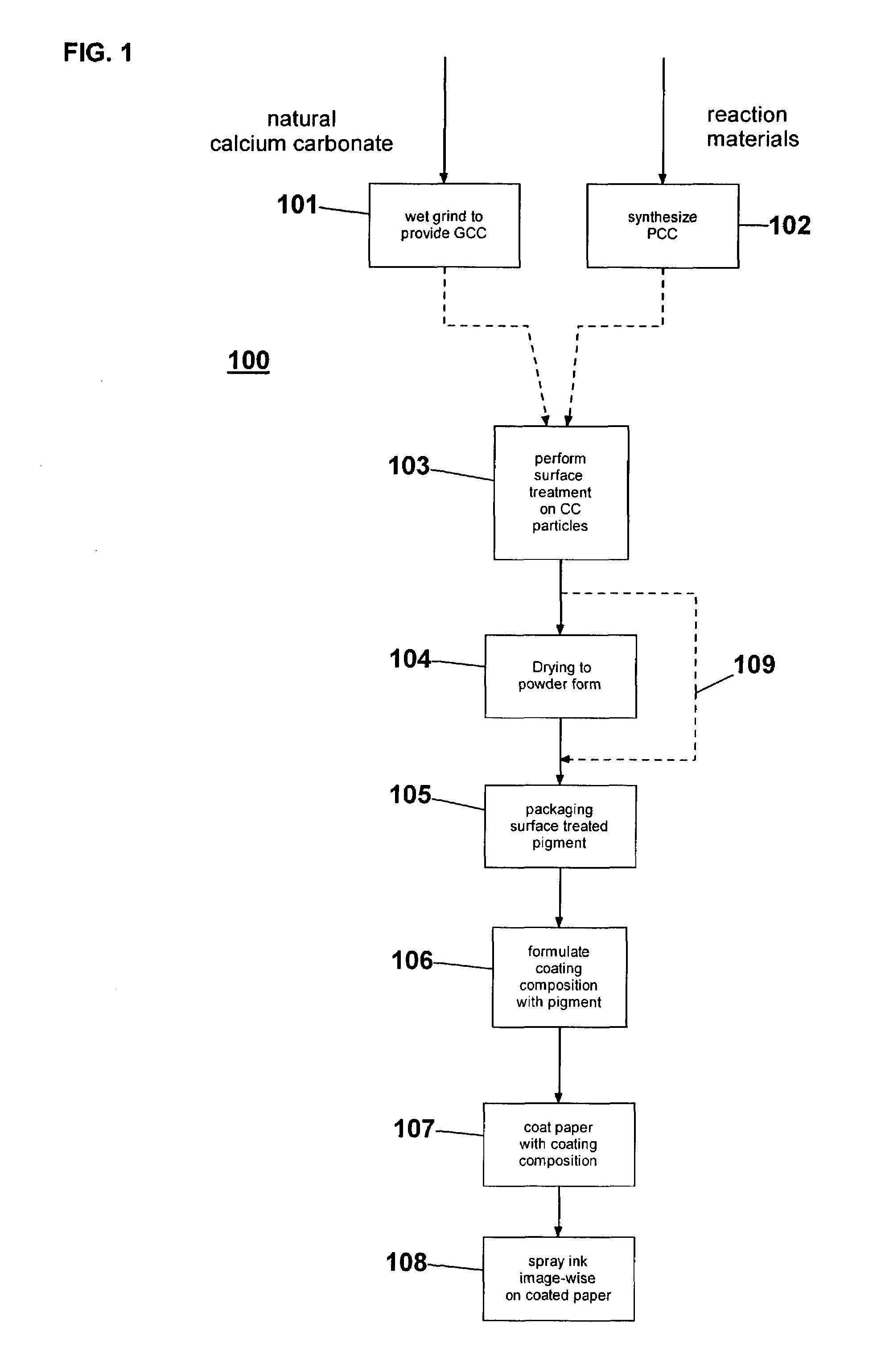

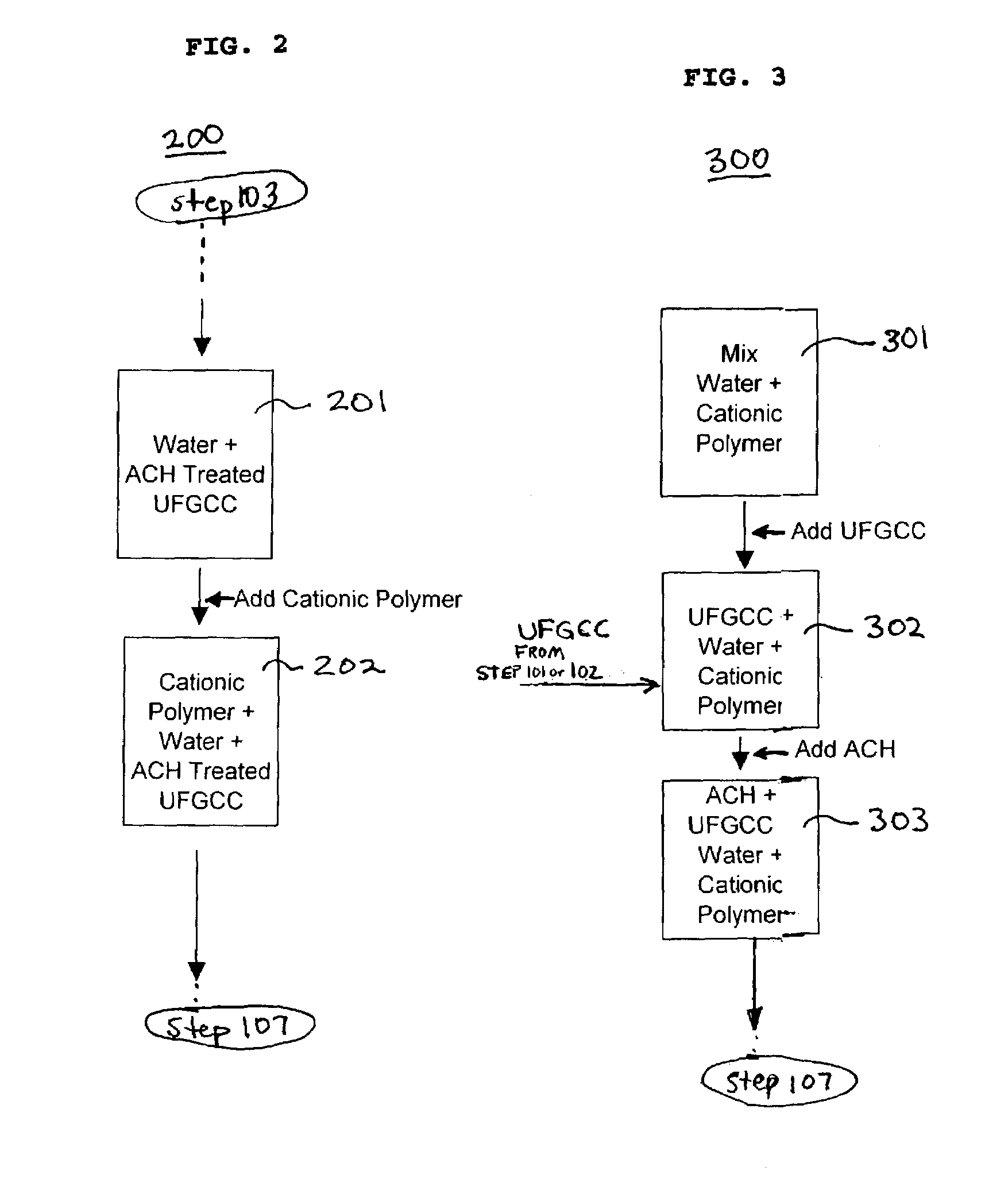

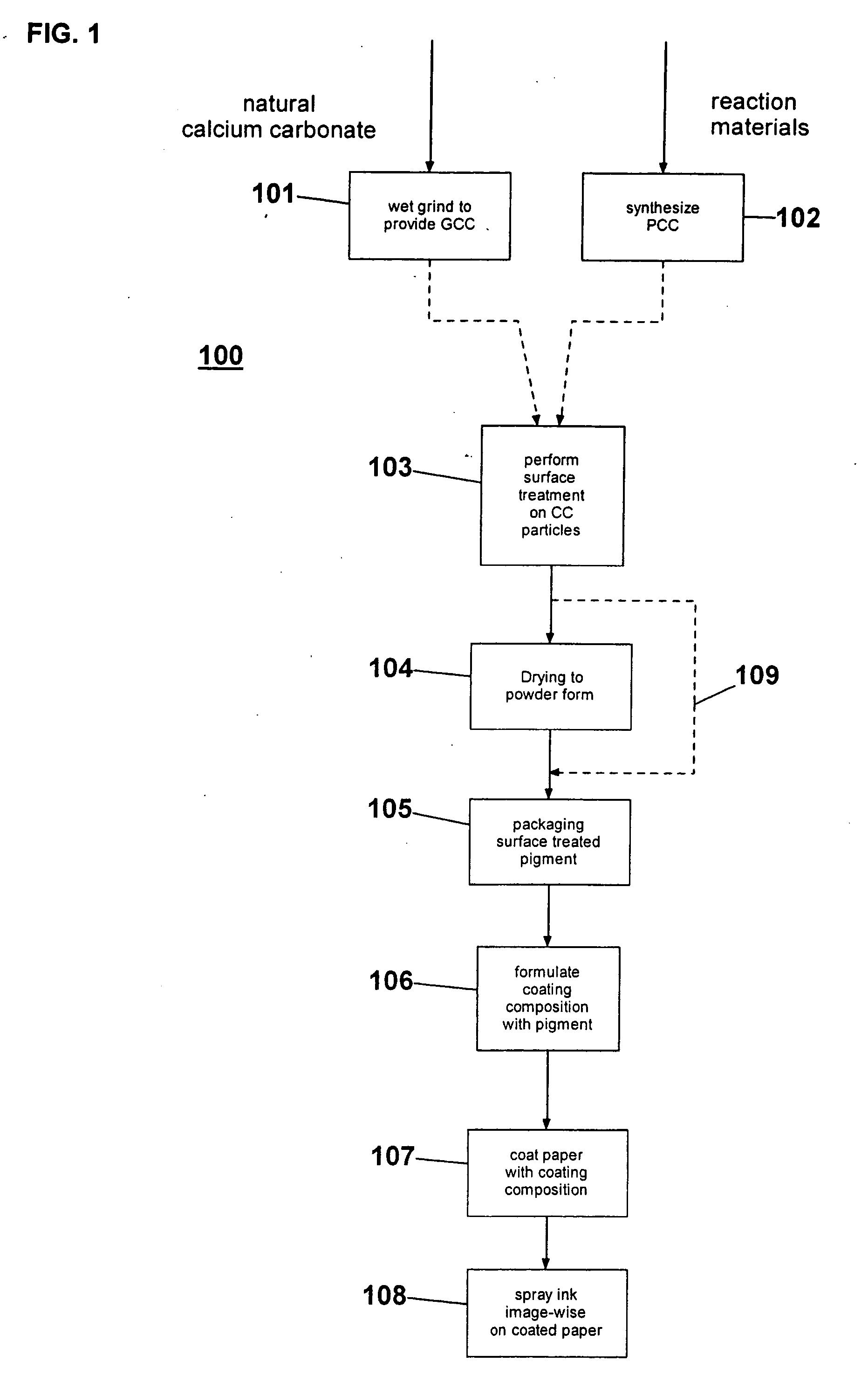

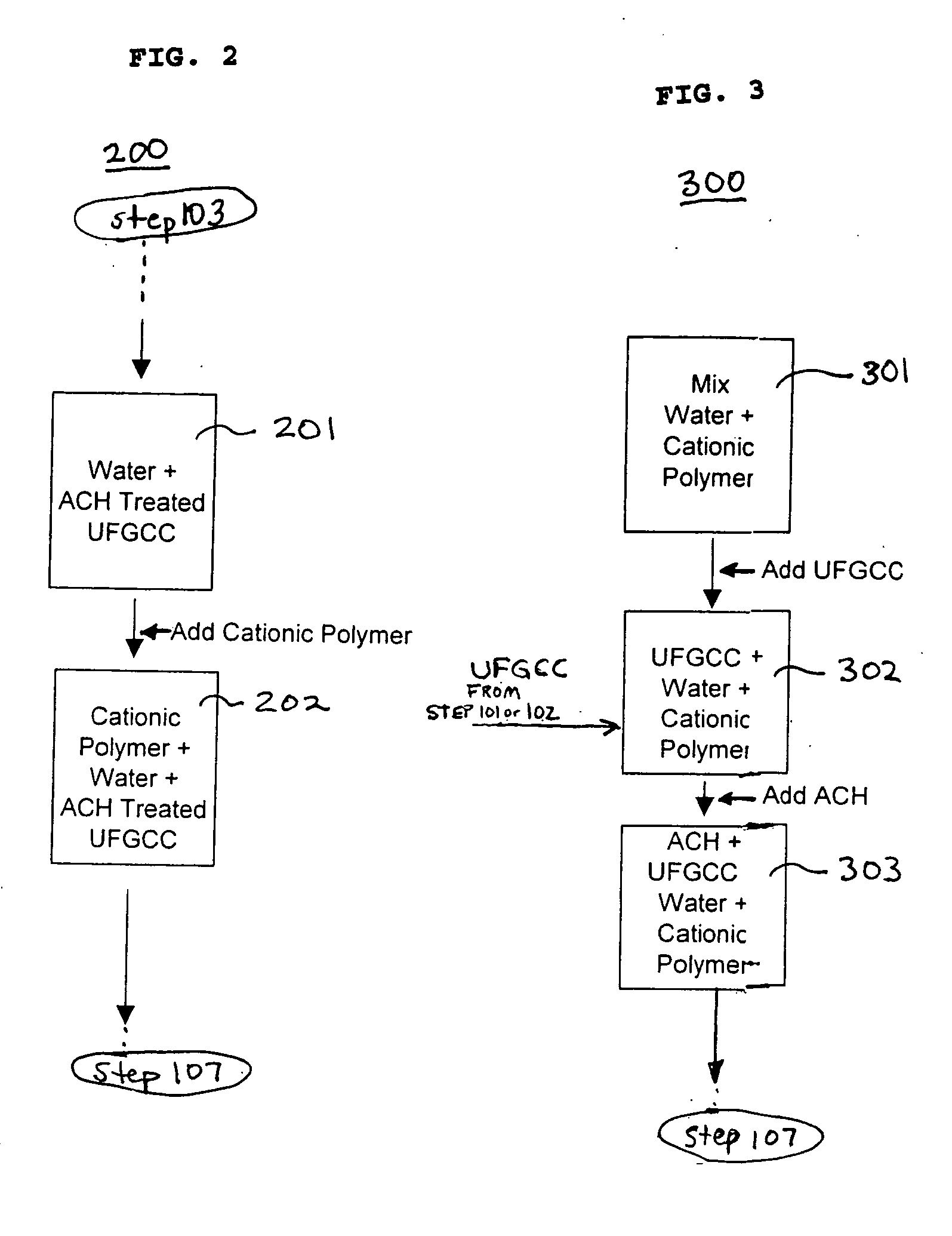

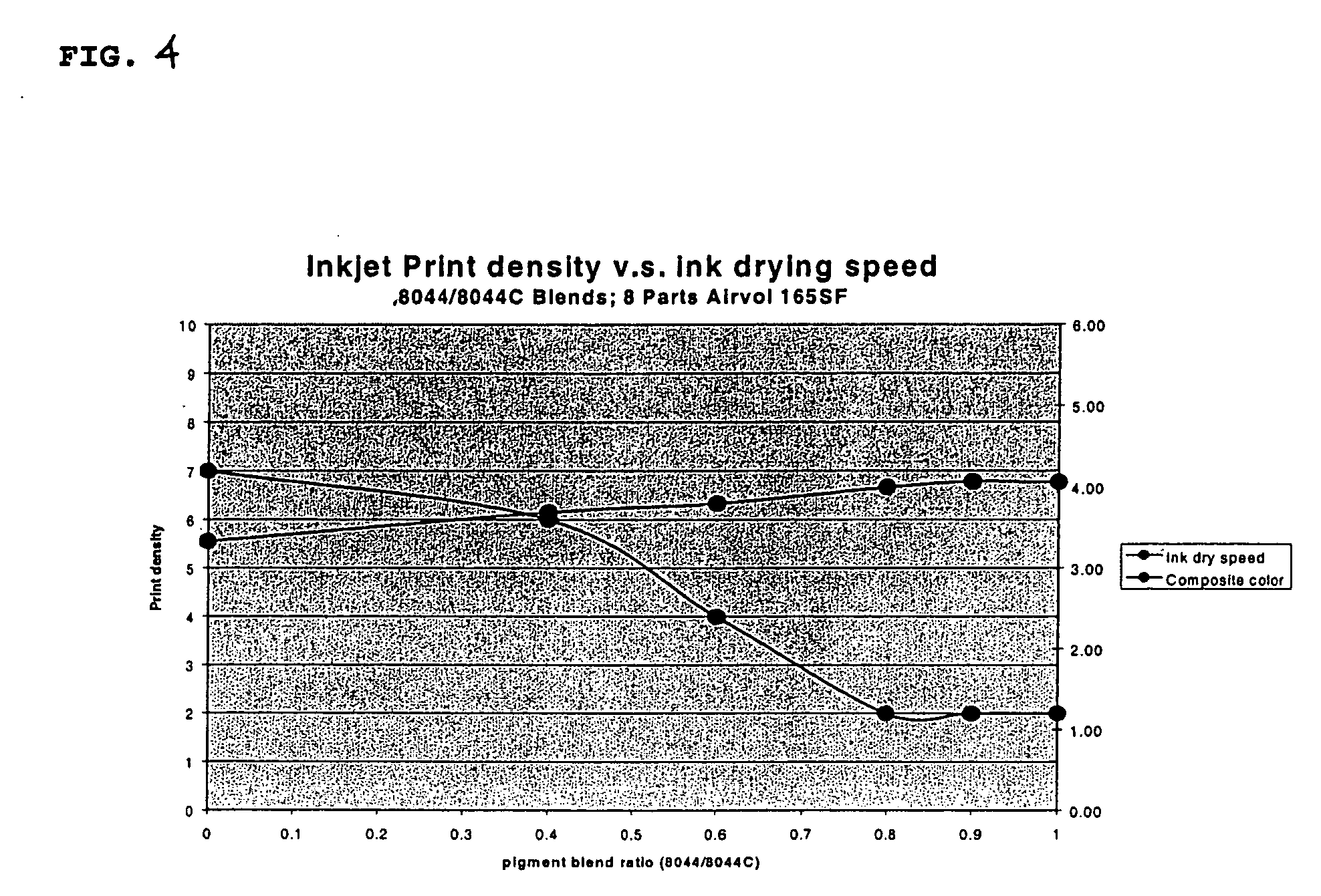

Pigment for use in inkjet recording medium coatings and methods

InactiveUS7172651B2Effective functional replacementHigh solidsPigmenting treatmentSpecial tyresParticulatesSilicon dioxide

Pigment suitable for use in coating compositions for inkjet recording media. Surfaces of an inorganic particulate are interacted with a water-soluble polyvalent metal salt in an aqueous medium. The treated particle surfaces have a significant cationic surface charge imparted to them. The salt is a salt of a metal of Group II or Group III of the Periodic Table. Inkjet recording media treated with a coating composition containing the above pigment provide high density, fast-drying, and non-feathering ink images with suitable water fastness, while the coating compositions also offer cost advantages and improved rheology at higher pigment levels over coatings based on silica pigments.

Owner:KAMIN

Monocomponent self-cross-linking epoxy acrylic acid composite emulsion , its preparation method and uses

The invention provides a monocomponent self-cross-linking epoxy acrylic acid composite emulsion , its preparation method and uses, wherein the emulsion comprises the constituents of epoxy resin, (methyl) acrylic ester, alkenyl carboxyl acid, ethenyl aromatic compound, silicane coupling agent, initiating agent, emulsifying agent, pH regulator, neutralization agent and water. The composite emulsion is prepared through the emulsion polymerization process and by using epoxy propylene acid composite emulsion as the base.

Owner:广东鸿昌化工有限公司

Polyester resin special for winding steel paint base and preparation thereof

InactiveCN101343353AHigh solidsLow viscosityLiquid surface applicatorsAnti-corrosive paintsSolventChemistry

The invention discloses a special polyester resin for priming paint in coil coating. According to the weight parts, the polyester resin comprises alcohol of 30 parts to 40 parts; acid of 30 parts to 40 parts; catalyzer of 0.1 parts; refluxing solvent of 3 parts and diluting solvent of 20 parts. The invention also discloses the preparation method for the special polyester resin for the priming paint in the coil coating. The special polyester resin for the priming paint in the coil coating of the invention has the advantages of good solid parts, low viscosity, quick dry speed, quick flow flat, excellent adhesive force, excellent pliability, excellent pigment wetting dispersilbility and high cloth coating amount, wherein, the advantages of good solid parts, low viscosity and high cloth coating amount are especially hard to be achieved by the ordinary polyester resin for the priming paint; simultaneously, the special polyester resin conforms to the energy conservation requirement advocated by the state. The preparation method for the special polyester resin for the priming paint in the coil coating is simple, and the requirements for the production facilities are not high, thus the special polyester resin is suitable for large-scale production.

Owner:WUXI HUHUANG PAINT

Process and reactor for synthesis of ultra-high molecular weight acrylic polymers

This invention relates to a process for producing high molecular weight (HMW) and ultra-high molecular weight (UHMW) acrylic polymers having unique polymer tacticity and exhibiting enhanced thermal and mechanical properties. This process comprises polymerizing ethylenically unsaturated monomer in the presence of a free radical initiator that results in a “living-like polymer” utilizing a multi-step approach. In conducting the process of this invention the “living-like polymer” is further dissolved in a liquid carrier, wherein the said liquid carrier is a reactive diluent that can be reacted subsequently by an addition polymerization process to create a block- or multi-block, copolymer or homopolymer. This process can be progressively repeated with the same or various different reactive diluents to generate desired architecture and molecular weight polymer(s) which can be used in further processing procedures to be manufactured directly into finished articles.

Owner:OVATION POLYMER TECH & ENGINEERED MATERIALS

Preparation method of epoxy glass flake coating for oceanic tidal range/splash zone

ActiveCN104774527AHigh solidsReduce viscosityAnti-corrosive paintsEpoxy resin coatingsAntifoam agentFirming agent

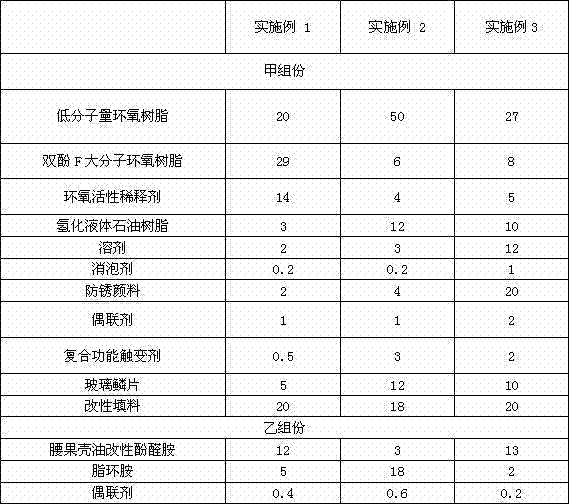

The invention relates to a preparation method of an epoxy glass flake coating for an oceanic tidal range / splash zone. The epoxy glass flake coating is composed of a component A and a component B, the component A contains low molecular weight epoxy resin, bisphenol F macromolecular epoxy resin, an epoxy active diluent, hydrogenated liquid petroleum resin, a solvent, an antifoaming agent, an antirust pigment, a coupling agent, a composite functional thixotropic agent, modified glass flakes and a modified filler, and the component B contains an amine composite curing agent and the coupling agent. The preparation method comprises the following steps: confirming the composition and weight part proportions of all raw materials, preparing the composite functional thixotropic agent, preparing the modified glass flakes, preparing the modified filler, preparing the amine composite curing agent, preparing the component A, preparing the component B, and blending the component A with the component B in proportion to prepare the epoxy glass flake coating. The epoxy glass flake coating has the advantages of high solid content, low viscosity, small use amount of the organic solvent, and great reduction of the volatilization of VOCs in the production, construction and curing process of the coating.

Owner:XIAMEN SUNRUI SHIP COATING

Method for extracting dietary fiber from leftovers of bamboo shoots

InactiveCN102132847ARich nutrition and health ingredientsUnique nutrition and health ingredientsFood preparationDietary fiberBamboo shoot

The invention discloses a method for extracting dietary fiber from leftovers of bamboo shoots, comprising the following steps: removing earth from the heads of aged bamboo shoots cut in the processing of the bamboo shoots, peeling the husks of the bamboo shoots, cleaning, squeezing and separating bamboo juice and bamboo shoot residuals; and processing the bamboo shoot residuals with steam explosion and ultrafine powder technology to obtain high-quality diet fiber. The method can be used for recovering and reutilizing the heads of the bamboo shoots to prepare and process the dietary fiber, thereby changing wastes into valuables, achieving good application prospect, finding a new way for the comprehensive utilization of the bamboo shoots. By the method, the additional value of the bamboo shoot product is increased, the resource waste is reduced, the environment is protected. Therefore the method has good social and economical benefits.

Owner:杨军

Stable acid denatured soy/urea adhesives and methods of making same

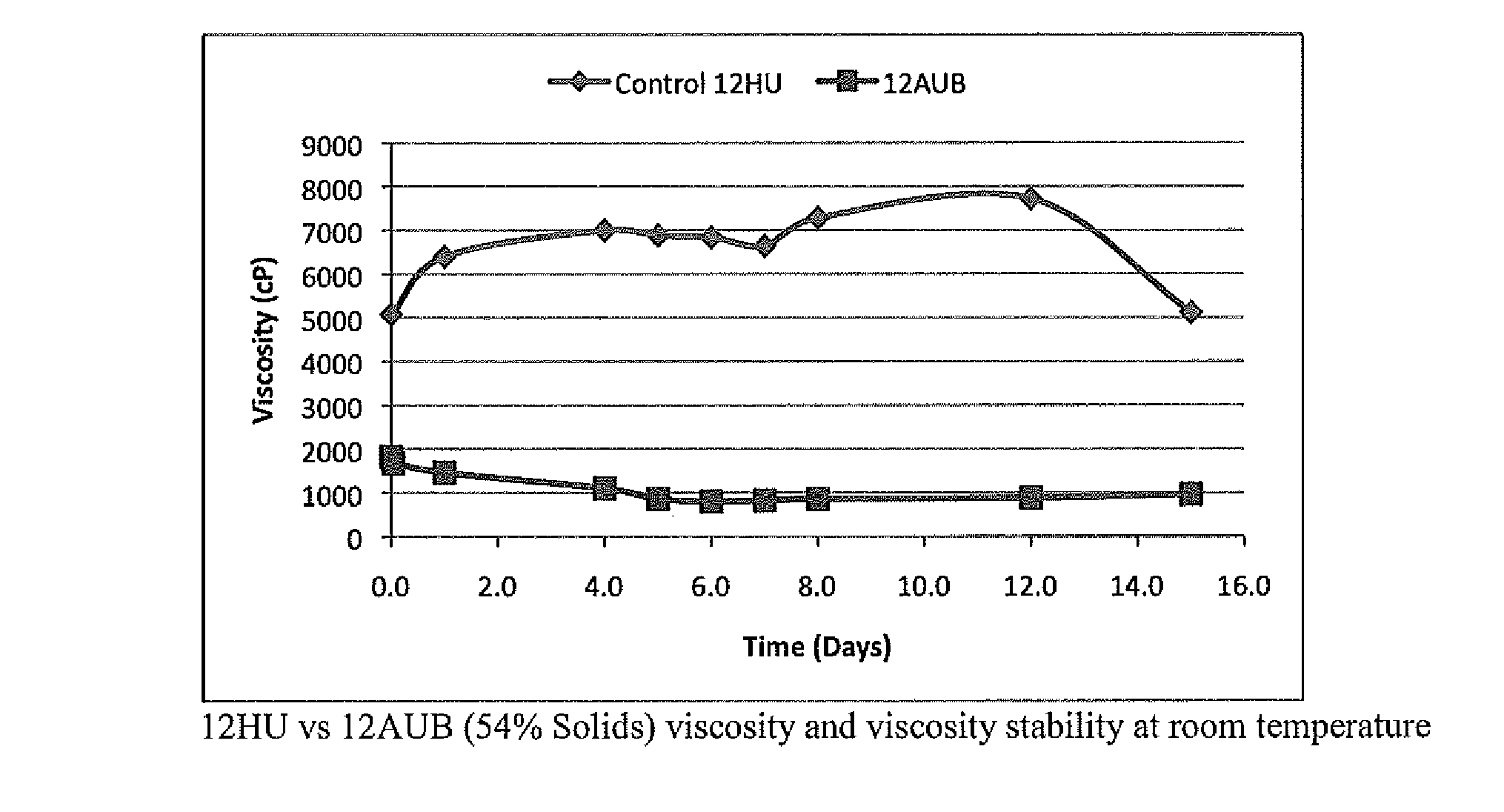

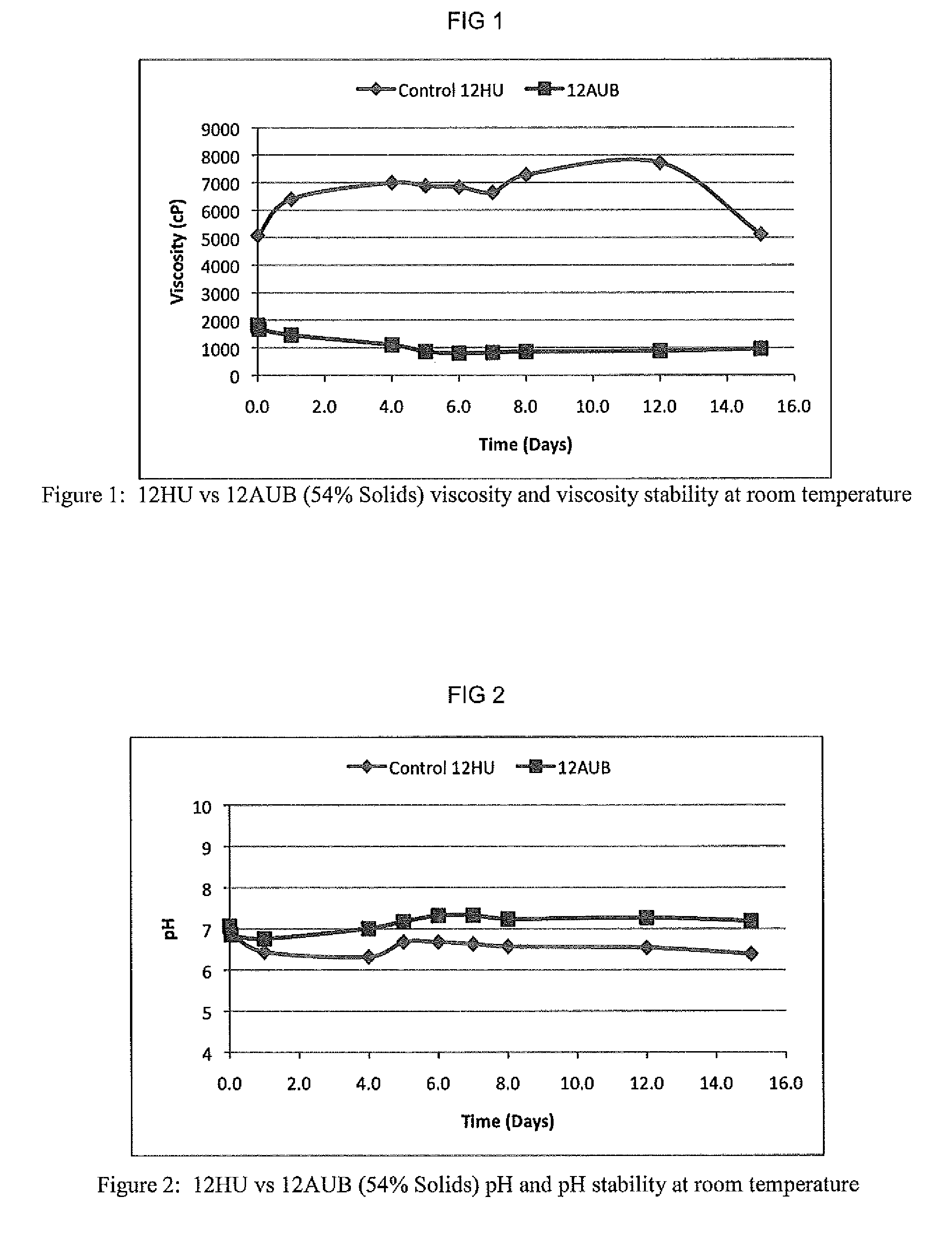

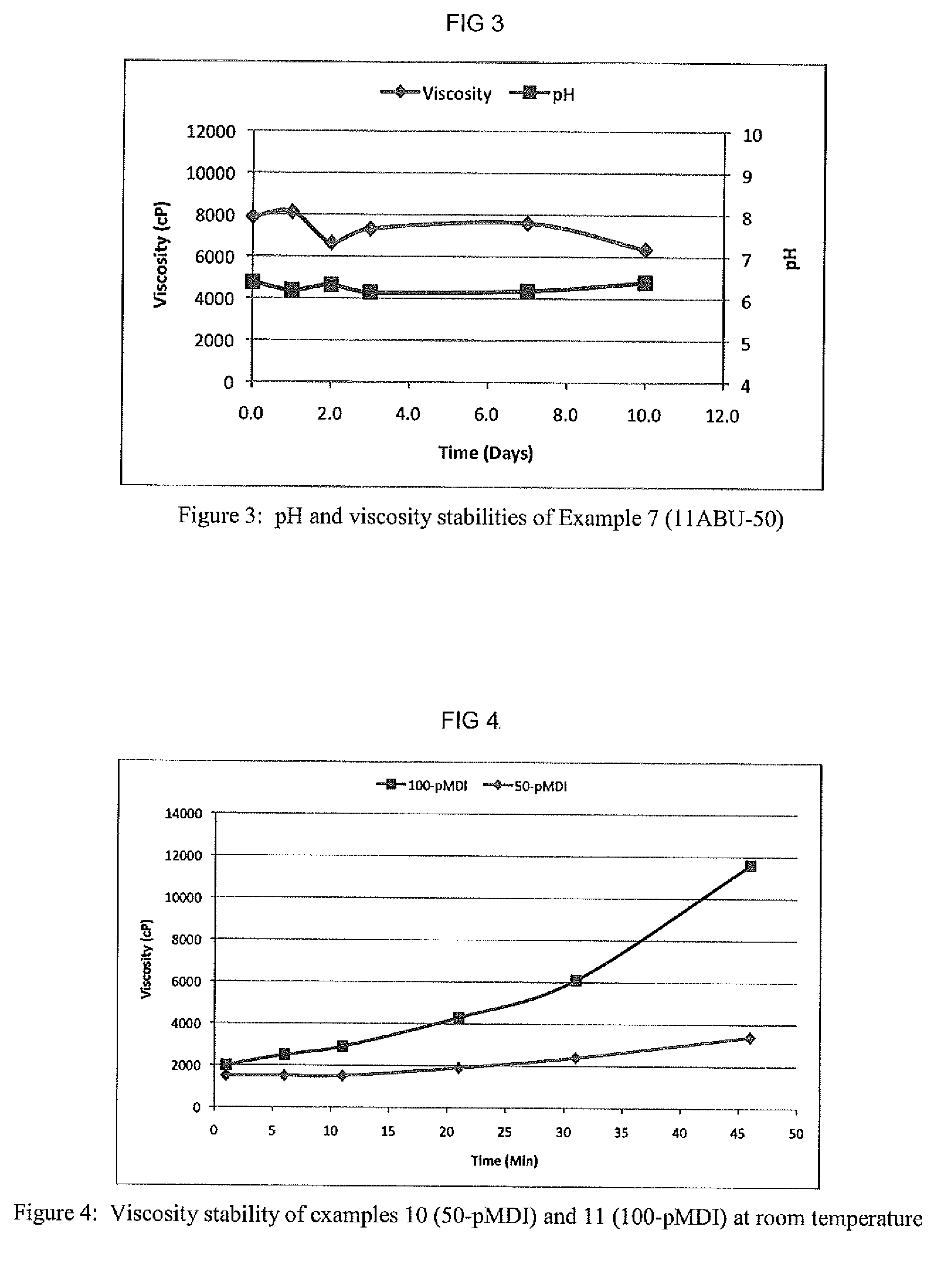

ActiveUS8465581B2Improve adhesionStable soy/urea adhesiveMonocarboxylic acid ester polymer adhesivesProtein adhesivesAdhesiveDiluent

The present invention provides an improved method of producing a stable acid denatured soy / urea adhesive having improved wet and dry strengths, with more efficient production and lower production costs. The method comprises combining urea with soy flour that has been acid treated until denatured and substantially free from urease activity. The soy flour is preferably lowered to a pH of 2.0 to 4.0 for at least 1 minute. Optionally, the method may also include adding a crosslinking agent, diluent or both to the soy flour / urea adhesive and / or adding an emulsified or dispersed polymer. Adhesives and dispersions prepared according to the methods of this invention offer increased stability and strength properties.

Owner:SOLENIS TECH CAYMAN

Low Gloss, High Solids Polyurea Coatings

ActiveUS20140221567A1Reduce glossHigh solidsPolyurea/polyurethane coatingsDiamineVolatile organic compound

A method of forming a low gloss, high solids polyurea coating containing very low volatile organic compounds (VOC) in the coating composition. The low volatile content not only makes the coating environmentally friendly but allows it to be applied at variable thickness levels and over a wide variety of environmental conditions. The coating composition is comprised of an isocyanate reactive agent containing a secondary diamine, a polyisocyanate, a gloss reducing agent and a viscosity modifier. The gloss reducing agent is generally pre-mixed into an isocyanate reactive agent containing a secondary diamine and / or polyisocyanate containing the viscosity modifier before mixing the two components together to form a low gloss polyurea coating.

Owner:EVONIK OPERATIONS GMBH

Two-component water-based hydroxyl acrylic coating

InactiveCN105368287AImprove adhesionStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a two-component water-based hydroxyl acrylic coating composed of a component A and a component B, wherein the weight ratio of the component A to the component B is 1 to (1-3). The component A comprises the raw materials in parts by weight: 40-80 parts of modified hydroxyl acrylic resin, 5-20 parts of water-based hydroxyl fluorosilicone acrylic resin, 5-15 parts of a water-based nano alumina dispersion body, 5-10 parts of a water-based nano silica dispersion body, 2-6 parts of ethylene glycol monoethyl ether acetate, 1-3 parts of a levelling agent BYK306, 0.2-0.8 part of a catalyst dibutyltin dilaurate, and 1-5 parts of xylene. The component B comprises the raw materials in parts by weight: 10-20 parts of a hexamethylene diisocyanate trimer, 1-5 parts of HDI biuret, and 20-30 parts of a diluent. The two-component water-based hydroxyl acrylic coating has good water resistance and excellent corrosion resistance.

Owner:ANHUI JINDUN PAINT

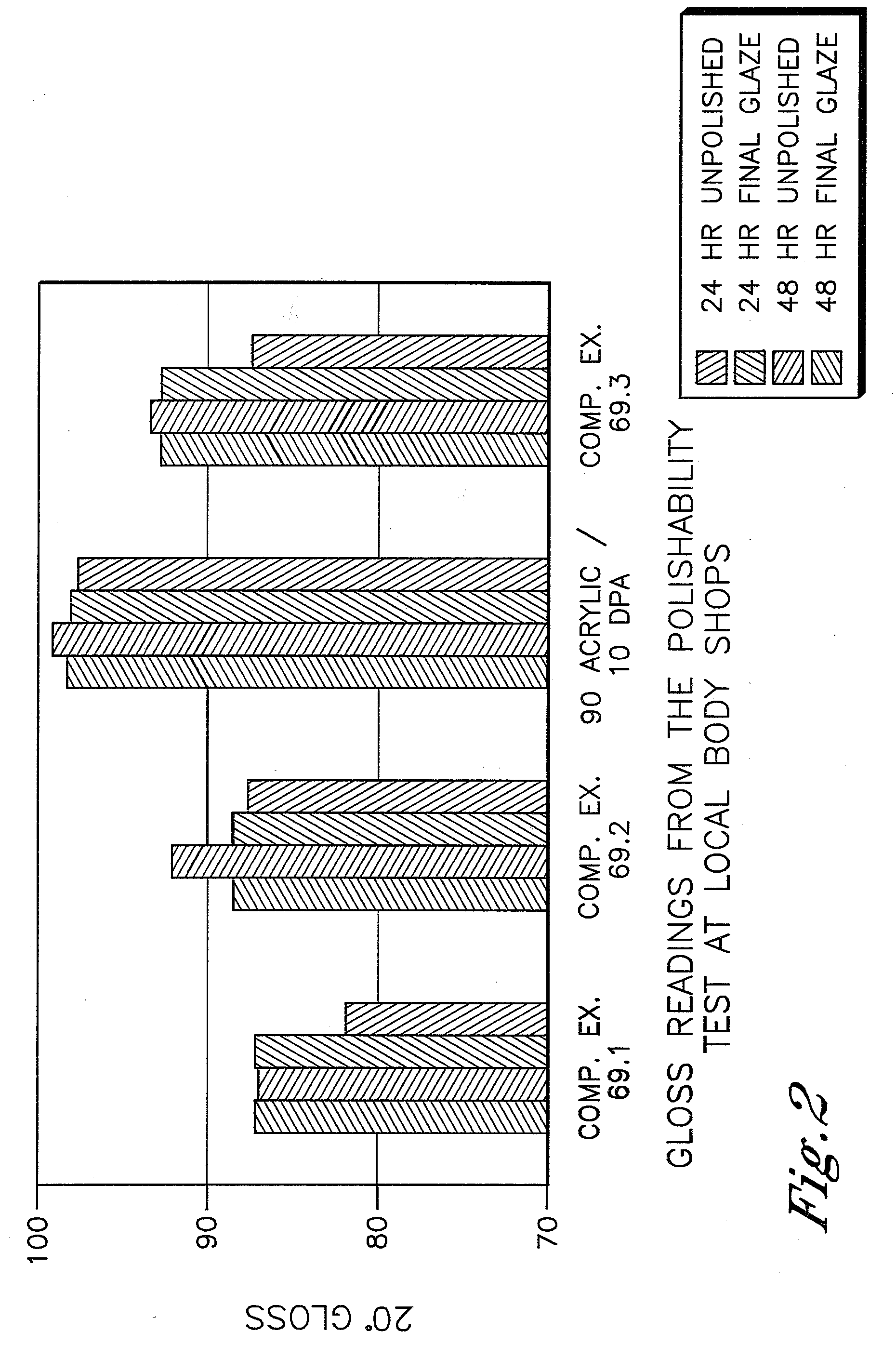

Low VOC coating compositions comprising low molecular weight cellulose mixed esters and low molecular weight hydroxyl-containing polymers

InactiveUS20080090960A1Reduce molecular weightHigh maximum degree of substitutionInksPolyester coatingsCellulosePolymer chemistry

A coating composition is provided comprising: a) at least one hydroxyl-containing polymer; b) at least one low molecular weight hydroxyl-containing polymer; c) at least one crosslinking agent; d) at least one curing catalyst; and e) a cellulose mixed ester. In addition, articles comprising the coating composition are also provided.

Owner:EASTMAN CHEM CO

Solvent sprayable contact adhesive formulations from functionalized/controlled distribution block copolymers

InactiveUS20080153970A1Maintain good propertiesImprove performanceFilm/foil adhesivesGraft polymer adhesivesPolymer sciencePlasticizer

The invention relates to a solvent sprayable contact adhesive composition comprising (i) one or more styrenic block copolymer compositions, (ii) a tackifying resin, (iii) a solvent and (iv) optionally one or more plasticizers, wherein said styrenic block copolymer composition comprises a selectively hydrogenated and functionalized controlled distribution block copolymer having monoalkenyl arene end blocks and hydrogenated controlled distribution mid blocks containing certain mixtures of monoalkenyl arene and conjugated diene.

Owner:KRATON POLYMERS US LLC

Method for producing watersoluble floating coat paint suitable for original factory of vehicle and repair

InactiveCN101294045AMeet the use requirementsLow drying temperatureLiquid surface applicatorsPolyurea/polyurethane coatingsCoated surfaceWater dispersible

The invention provides the preparation method of a water intermediate coating suitable for automobile factories and repair. The coating prepared by the method is universally suitable for automobile factories and repair. The preparation method comprises the following steps and process conditions: (1) synthesizing water-dispersible resin; (2) modifying hydrophilic polyisocyanate; (3) preparing the intermediate coating for automobile factories and repair; and (4) mixing the intermediate coating prepared in step (3) with the hydrophilic end-terminated polyisocyanate synthesized in step (2) to obtain the final product. The prepared intermediate coating has high applicability and is suitable for factory manufacturing and for repair. The intermediate coating is very friendly to the environment and greatly reduces the use of and the dependence on organic solvent, thus effectively conserving the energy resources. Additionally, the coating has the advantages of excellent flexibility, particularly high chip resistance and water resistance, smooth and fine coating surface and excellent interlayer adhesive force with the prime coat and the top coat.

Owner:朱斌 +4

Polyester modified hydroxyl type fluorinated acrylate resin and preparation method thereof

InactiveCN103483503ALow costMaintain propertiesPolyurea/polyurethane coatingsMethacrylatePolymer science

The invention discloses polyester modified hydroxyl type fluorinated acrylate resin and a preparation method thereof. On the basis of double-bond hydroxyl type polyester, (methyl) acrylics, (methyl) fluorinated acrylics, (methyl) acrylic acid and hydroxyl (methyl) acrylate monomers are subjected to graft copolymerization through solution polymerization, and hybridization of fluorinated acrylate resin and polyester resin is realized; and during preparation of fluorine resin, the polyester resin is introduced creatively to perform hybridizing modification on the fluorine resin, features of the fluorine resin are kept while the cost of the fluorine resin is reduced, meanwhile, the solid content is higher, and the resin has the better environmental protection performance. Used synthetic raw materials are common raw materials, the requirements for a production technology are not high, the synthesis cost of the fluorine resin is low, the performance of 2KPU (two-component polyurethane) varnish prepared with the fluorine resin is excellent, and prepared coatings are applicable to various base materials such as wood products, metals, plastics, concrete and the like.

Owner:JIANGSU BLUESTAR GREEN TECH

Method for extracting bamboo juice from bamboo shoot leftovers

InactiveCN102160665ARich nutrition and health ingredientsUnique fragranceFood preparationSeparation technologyEconomic benefits

The invention discloses a method for extracting bamboo juice from bamboo shoot leftovers, which comprises the following steps of: removing soil from aged bamboo shoots which are cut in bamboo shoot processing, and stripping bamboo shells; cleaning, squeezing and separating out the bamboo juice and bamboo shoot dregs; and extracting clear bamboo juice through enzymolysis and a membrane separation technology. The bamboo juice extracted from the bamboo shoot leftovers has richer nutrition, sweet taste and low cost and saves fuel compared with that extracted from bamboo, forest resources can be reasonably utilized, the green homeland of people is protected, waste is reduced, environment is protected, and the method has good social and economic benefits.

Owner:杨军

Pigment for use in inkjet recording medium coatings and methods

InactiveUS20070014941A1Absorb evenlyMore color reproductionPigmenting treatmentSpecial tyresParticulatesSilicon dioxide

Pigment suitable for use in coating compositions for inkjet recording media. Surfaces of an inorganic particulate are interacted with a water-soluble polyvalent metal salt in an aqueous medium. The treated particle surfaces have a significant cationic surface charge imparted to them. The salt is a salt of a metal of Group II or Group III of the Periodic Table. Inkjet recording media treated with a coating composition containing the above pigment provide high density, fast-drying, and non-feathering ink images with suitable water fastness, while the coating compositions also offer cost advantages and improved rheology at higher pigment levels over coatings based on silica pigments.

Owner:J M HUBER CORP

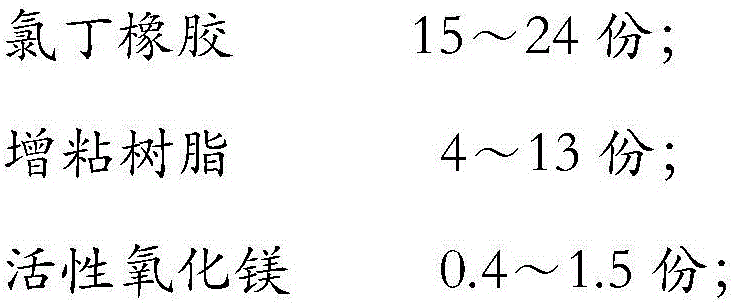

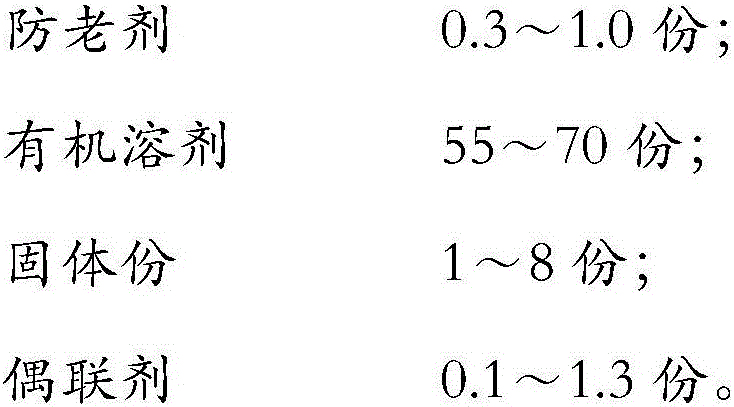

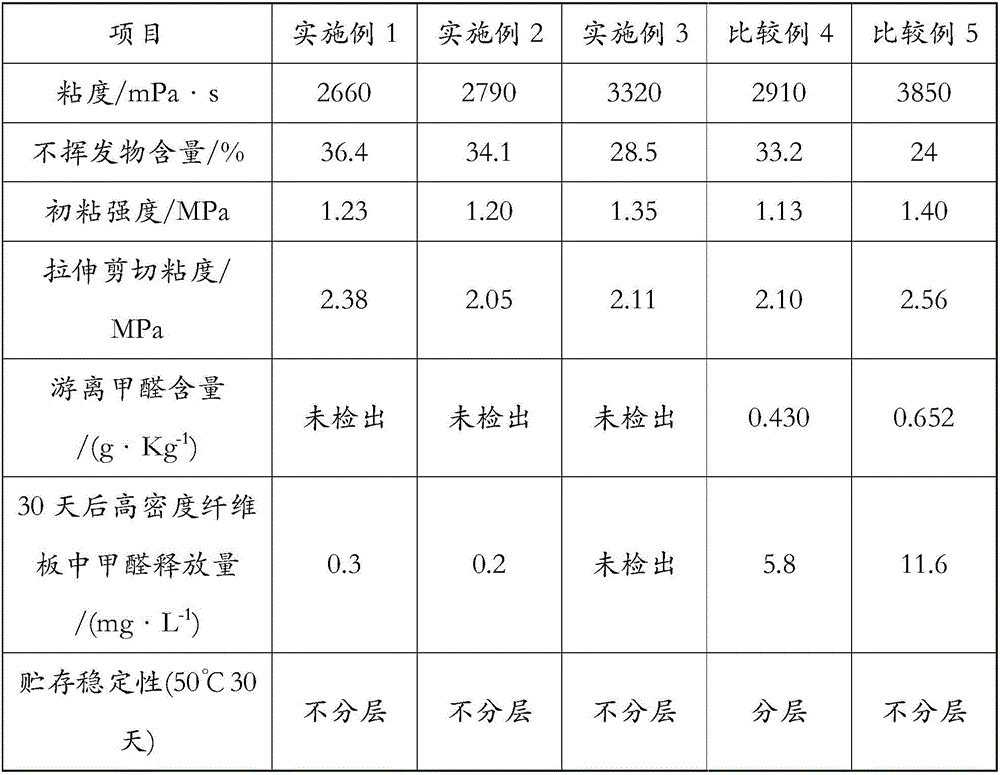

Neoprene adhesive and preparation method thereof

InactiveCN106221614AGood weather resistanceHigh solidsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesChemistryMagnesium

The invention discloses a neoprene adhesive. The neoprene adhesive is prepared from, by weight, 15-24 parts of neoprene rubber, 4-13 parts of tackifying resin, 0.4-1.5 parts of active magnesium oxide, 0.3-1.0 part of antiager, 55-70 parts of organic solvent, 1-8 parts of solids and 0.1-1.3 parts of coupling agent. By the adoption of the technical scheme, the neoprene adhesive has the following advantages that the neoprene rubber, the tackifying resin, the solids, the antiager and other additives are combined, and the neoprene adhesive is good in weatherability, high in solid content, low in VOC content, more environmentally friendly, stable in viscosity, non-layering and excellent in bonding performance. The invention further discloses a preparation method of the neoprene adhesive.

Owner:AMRICAN SANVO HONG KONG CHEM TECH HLDG LTD

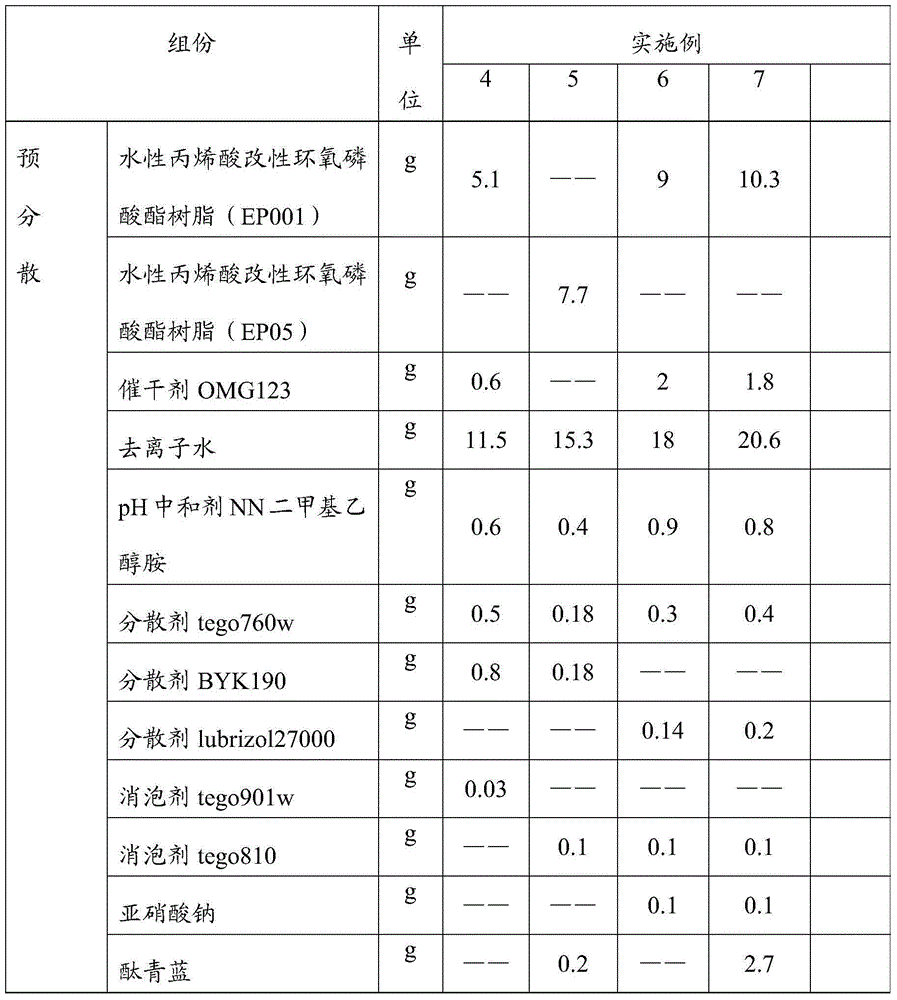

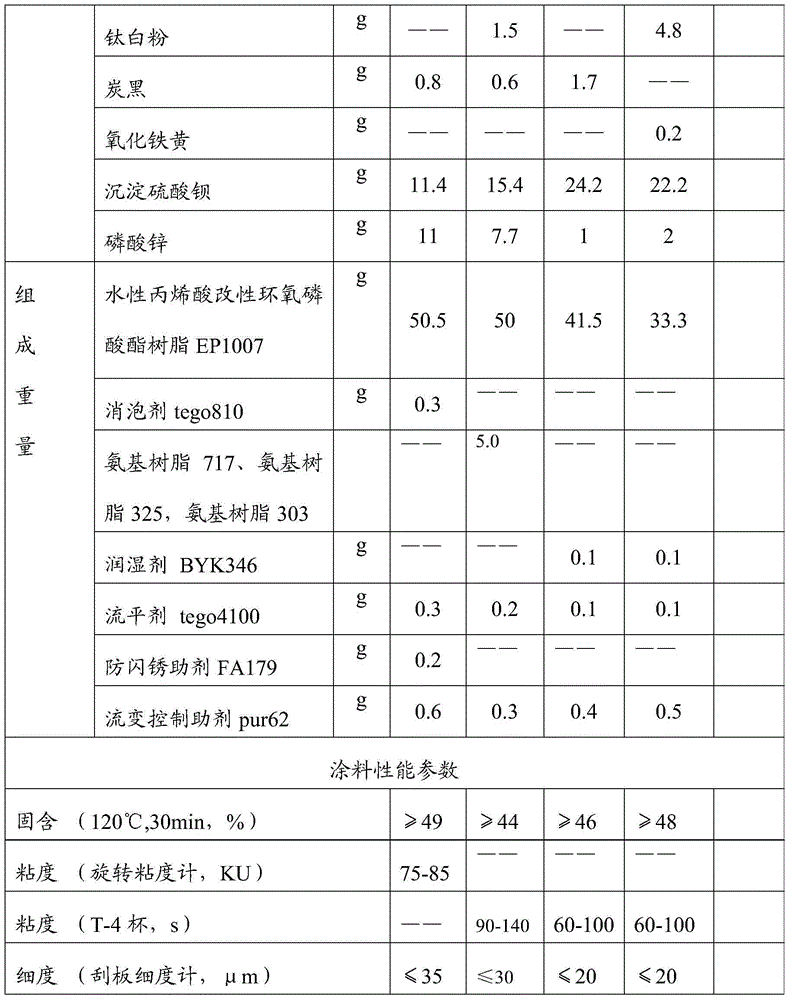

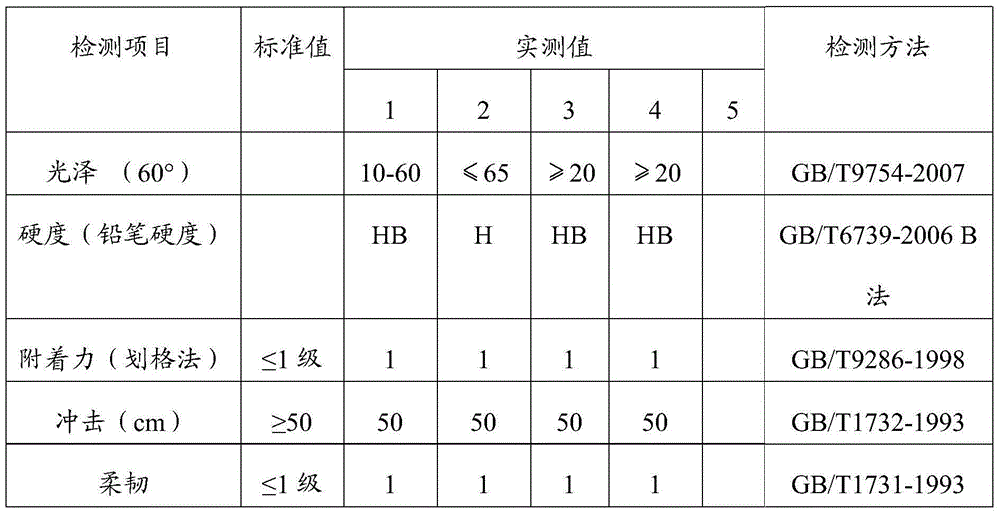

Paint containing water-based acrylic modified epoxy phosphate resin and preparation method thereof

InactiveCN104877526AImprove stabilityHigh solidsSiccativesAnti-corrosive paintsEpoxyPhosphoric Acid Esters

The invention belongs to the field of painting, and particularly relates to acrylic acid modified epoxy phosphate resin and an aqueous dispersion thereof. In the formula, the acrylic acid modified epoxy phosphate resin is prepared from 40-45 parts of epoxy resin, 20-30 parts of a solvent, 0.4-0.5 part of phosphoric acid, 8-12 parts of acrylic acid (ester) monomer of which acrylic acid accounts for 1.4-2 parts, 0.5-0.8 part of an initiator, 3.2-5.2 parts of neutralizer and 80-100 parts of water. The resin is prepared by the following steps: modifying epoxy resin with phosphoric acid, and reacting with acrylic acid and ester monomers thereof; adding the neutralizer and deionized water, stirring and emulsifying to obtain the acrylic acid modified epoxy phosphate aqueous dispersion, wherein the acid value of the emulsion is 10-12mgKOH / g, and the solid content is 28-38 percent. The prepared main resin dispersion body is epoxy resin, has a phosphate structure, and has a good adhesive force for metal base materials, thus having good corrosion resistance; acrylic resin is modified, introduced with carboxyl and neutralized by the neutralizer to give aqueous dispersion to resin, so that the resin can be produced into water-borne painting, and the content of VOC is greatly reduced; and multiple hydroxyl radicals are arranged on the main chain of the epoxy resin, and can be crosslinked with amino resin, urea resin and phenolic resin to produce stoving varnish.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Sludge petroleum charred slurry and preparing process and application thereof

ActiveCN101054541AHigh reactivityImprove utilization efficiencyBiofuelsSolid fuelsHigh concentrationHydrogen

The invention discloses a sludge petroleum coke slurry and its producing method and application. Said sludge petroleum coke slurry contains 100-200 shares of petroleum coke by weight, 5-100 shares of moisture sludge by weight, 5-200 shares of water by weight, 0.01-2 shares of dispersant by weight, 0.01-2 shares of sludge modification reagent by weight. The produced high concentration sludge petroleum coke slurry can be a burning fuel or producing synthetic gas and hydrogen by gasification. It not only fully utilize the caloric caloricity in the sludge and gets over the problems that the present moisture sludge has a high heat treatment energy consumption and the offgas and dregs are harmful and poisonous and has a big industrialization prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com