High solid anticorrosive paint and preparation method thereof

An anti-corrosion pigment and high solid technology, applied in the field of aluminum alloy, can solve the problems of easy cracking, high hardness and high VOC content, and achieve the effect of improving flexibility, good flexibility and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

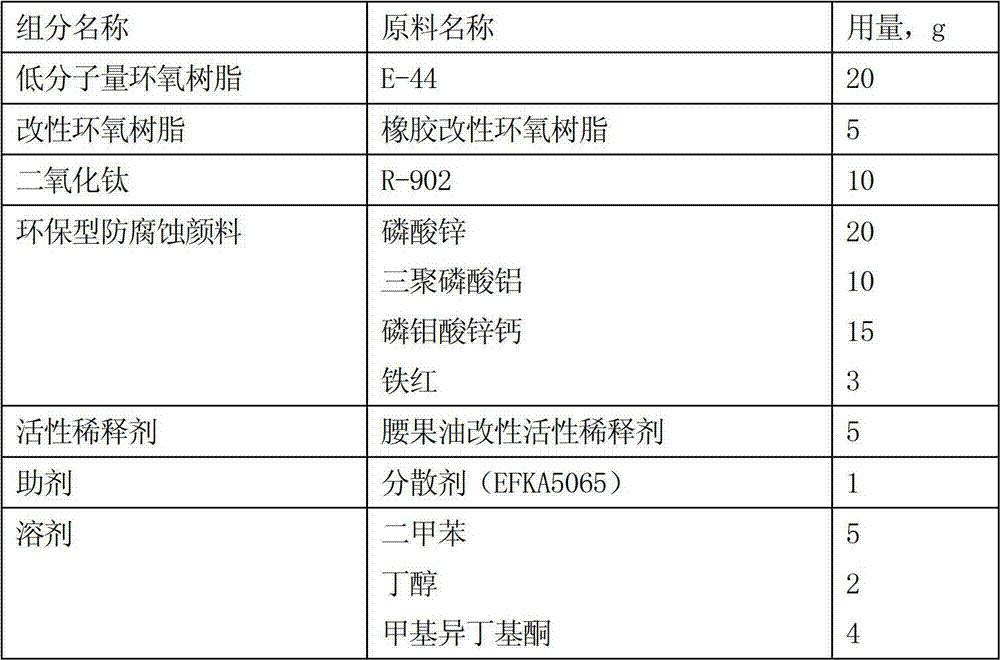

[0030] ①Preparation of component A1

[0031] First, prepare the raw materials of each component according to the formula in Table 1, then, add the prepared formula amount of low molecular weight epoxy resin, modified epoxy resin, reactive diluent, auxiliary agent and solvent into the mixing container, and stir for 15 minutes at a medium speed , then add the formula amount of titanium dioxide and environment-friendly anti-corrosion pigment, after stirring evenly, use a sand mill to grind to a fineness of <40 μm, stir evenly and pass through an 80-mesh filter screen to obtain component A, and pack it for later use;

[0032] Table 1

[0033]

[0034] Note: R902 is the brand name of DuPont’s titanium dioxide product; EFKA5065 is the brand name of Efka’s dispersant product, and it can also be replaced by the company’s EFKA5054, both of which belong to polymer carboxylate compounds.

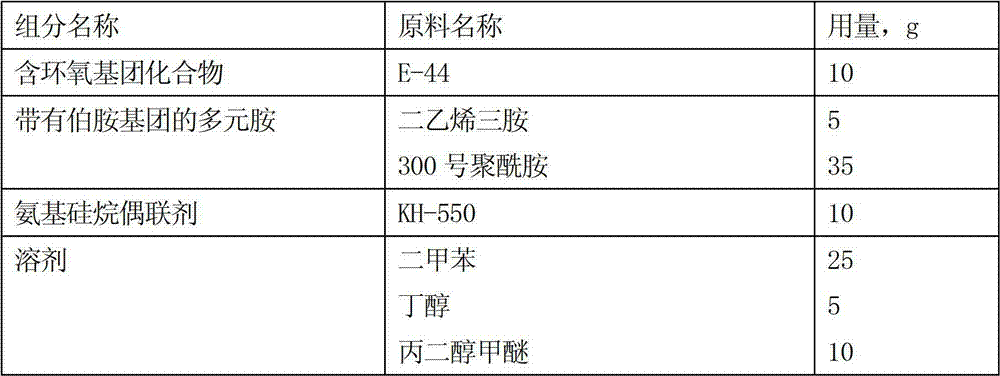

[0035] ②Preparation of component B1

[0036] First, prepare the raw materials of each component ...

Embodiment 2

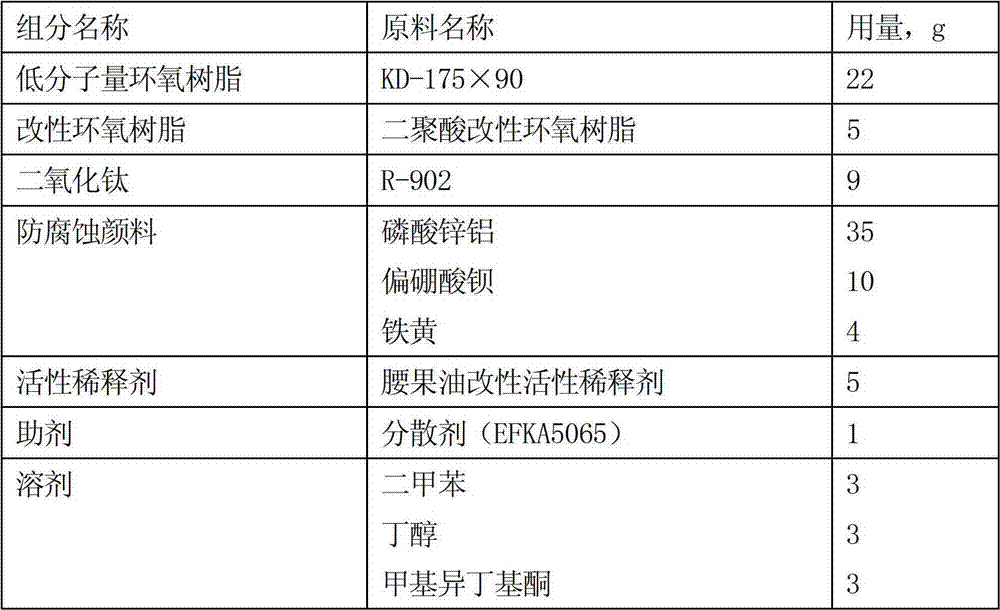

[0043] ①Preparation of component A2

[0044] First, prepare each component raw material according to the formula of Table 2, then, make component A2 by the method for Example 1;

[0045] table 3

[0046]

[0047] Note: KD-175×90 is the epoxy resin product brand of Guodu Chemical Company, R-902 is the product brand of DuPont’s titanium dioxide; EFKA5065 is the dispersant product brand of Efka Company, which can also be replaced by the company’s EFKA5054, both of which are It belongs to polymer carboxylate compounds.

[0048] ②Preparation of high solid content anti-corrosion coating

[0049] Before construction, weigh the component A2 prepared in step ① and the component B1 obtained in step ② in Example 1 according to the mass ratio of component A2 and component B1 as 4:1, and mix them evenly to obtain high solid content Anti-corrosion paint, its solid content is 80% (mass), the viscosity is 50 seconds (coating -4 cups, 25 ℃), and the construction period is 6 hours.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com